Installation and User Guide

TM

10Spec

10 Degree Specular Reflectance

Accessory

The information in this publication is provided for reference only. All

information contained in this publication is believed to be correct and

complete. PIKE Technologies, Inc. shall not be liable for errors contained herein

nor for incidental or consequential damages in connection with the furnishing,

performance, or use of this material. All product specifications, as well as the

information contained in this publication, are subject to change without notice.

This publication may contain or reference information and products protected

by copyrights or patents and does not convey any license under the patent

rights of PIKE Technologies, Inc. nor the rights of others. PIKE Technologies, Inc.

does not assume any liability arising out of any infringements of patents or

other rights of third parties.

This document contains confidential or proprietary information of PIKE

Technologies, Inc. Neither this document nor the information herein is to be

reproduced, distributed, used or disclosed, either in whole or in part, except as

specifically authorized by PIKE Technologies, Inc.

PIKE Technologies, Inc. makes no warranty of any kind with regard to this

material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose.

Copyright 1991-2018 by PIKE Technologies, Inc., Madison, WI 53719. Printed in

the United States of America. All world rights reserved. No part of this

publication may be stored in a retrieval system, transmitted, or reproduced in

any way, including but not limited to, photocopy, photograph, magnetic or

other record, without the prior written permission of PIKE Technologies, Inc.

Address Comments to:

PIKE Technologies, Inc.

6125 Cottonwood Drive

Madison, WI 53719

Phone (608) 274-2721

Fax (608) 274-0103

E-mail info@piketech.com

Web Site www.piketech.com

Jan. 1, 2018

PN 350-010000-05

Introduction

1

Optical Diagram

1

Unpacking Your Accessory

2

Packing List

2

Installation

3

Accessory Installation

3

Accessory Alignment

3

Performance Verification

5

Using Your 10Spec Accessory

5

Reflectance Spectra and Applications

6

Free Standing Films

6

Effect of Dispersion

7

Kramers-Kronig Transform

8

Precautions

9

Maintenance Parts

9

Contents

PN 350-010000-05

Introduction

The 10Spec features a collimated beam that strikes the sample at a 10° angle of incidence. The size of

the collimated beam at the sample is approximately 12 mm. The accessory may be used to measure the

reflectivity of glass per ASTM Standard E1585-93 and other specular reflectance experiments. The

10Spec is well suited for specular reflectance measurements of polymers, reflectivity studies of polished

metals and transmission-reflectance work.

Figure 1: Optical diagram of 10Spec Accessory

PN 350-010000-05 Page | 1

10Spec Manual

10Spec Accessory

Sample Masks (3/8”, 5/8”, 2”)

PN 350-010000

PN 010-10XX

PN 010-3010

Quantity 1

Quantity 1

Quantity 1 Set

Gold Substrate Alignment Mirror

Hex Wrench Set

PN 300-0002

Quantity 1

Quantity 1

Unpacking Your Accessory

In order for you to quickly verify receipt of your accessory, we have included a packing list. Please

inspect the package carefully.

Packing List

PN 350-010000-05 Page | 2

Installation

The 10Spec accessory has been aligned and tested in the PIKE Technologies facility on the make of your

FTIR spectrometer to ensure that it performs to specifications. However, some variation in optical

alignment can occur from spectrometer to spectrometer. To allow for this difference, there are

alignment screws located within the 10Spec assembly for fine-tuning once the accessory is installed in

the spectrometer.

Accessory Installation

1. Set your FTIR spectrometer to collect data at 4 cm-1 spectral resolution (including the FTIR J-stop).

2. The 10Spec accessory fits into the sample compartment of the FTIR spectrometer. Your 10Spec is

provided with the appropriate sample compartment baseplate for the model FTIR instrument you

specified. Before inserting the accessory in the sample compartment, ensure that your

spectrometer is aligned. If the instrument is not aligned, maximize the interferogram signal (the IR

energy throughput) of your FTIR spectrometer. This should be performed by following the

manufacturer’s instructions.

3. Fasten the accessory directly into the FTIR sample compartment or onto the FTIR sample

compartment baseplate. In order to locate the accessory in the correct position, simply place the

entire accessory into the FTIR sample compartment with the 10Spec label facing the front and line

up the baseplate provided with the holes/pins in your model FTIR spectrometer.

4. Tighten the mounting screws to firmly position the accessory baseplate onto the FTIR sample

compartment baseplate.

Accessory Alignment

The 10Spec accessory may not require any alignment when installed - see page 5 for minimum energy

throughput values. However, should you choose to fine-tune the accessory, follow these steps:

1. Place the 10Spec into the sample compartment. Using the large mask (2 inch), place the gold mirror

over the mask opening (sample position).

2. Remove the front panel of the 10Spec by removing thumb screws.

3. Display the live interferogram of the FTIR spectrometer and adjust the output (detector) side tilt

mirror. The location of this mirror is shown in Figure 2 (page 4). Turn the individual screws clockwise

PN 350-010000-05 Page | 3

and check the energy signal. If it increases, continue until the maximum signal is obtained. If it

decreases, turn the screw counterclockwise to get the highest possible reading.

4. Next adjust the rotation output (detector) again while maximizing the energy shown on the live

interferogram. The rotation output mirror is accessed from the back of the accessory (Figure 3).

5. Adjust the input tilt mirror located on the inside of the accessory while maximizing the energy

shown on the live interferogram.

6. Next adjust the rotation output (detector) again while maximizing the energy shown on the live

interferogram. The rotation output mirror is accessed from the back of the accessory.

7. Repeat the entire procedure two to three times to fine-tune the accessory. This is an initial

alignment procedure which optimizes the 10Spec

to work with an individual optical bench. Once

completed, the alignment does not have to be repeated unless the accessory adjustments have

been moved or it has been placed in a different FTIR instrument. You are now ready to verify the

10Spec optical throughput performance.

Figure 2: Tilt Mirror Adjustment Figure 3: Rotation Mirror Adjustment

For right to left spectrometer beam path the output (detector) mirror is located on the left side of the

accessory and the input is located on the right. For left to right spectrometers beam path, the output

(detector) mirror is located on the right side of the accessory and the input is located on the left side.

PN 350-010000-05 Page | 4

Performance Verification

With the accessory removed from the sample compartment, collect a background spectrum. Place the

10Spec accessory in the sample compartment with the alignment mirror face down on the top surface

of the accessory. Collect a transmission spectrum using the same collection parameters as used to

collect the background spectrum.

The minimum transmission of the accessory should be at least 15% at 1000 cm

not meet this minimum value, contact PIKE Technologies. Please have ready the serial number of your

accessory (found on rear of accessory).

-1

. If your accessory does

Figure 4. Typical 10Spec energy throughput spectrum.

Using Your 10Spec Accessory

In order to collect a spectrum with your 10Spec accessory perform the following steps:

1. Place the alignment mirror face down on the top surface of the accessory.

2. Collect a background spectrum.

3. Remove the alignment mirror and place your sample face down on the top of the accessory.

4. Collect a sample spectrum.

PN 350-010000-05 Page | 5

10,000 (m)

Thickness (µ) =

Reflectance Spectra and Applications

Reflectance spectroscopy is useful for the measurement of films on metallic substrates, the thickness of

free standing transmitting films and for the characterization of samples which do not transmit IR

radiation and so cannot be measured by other techniques.

Free Standing Films

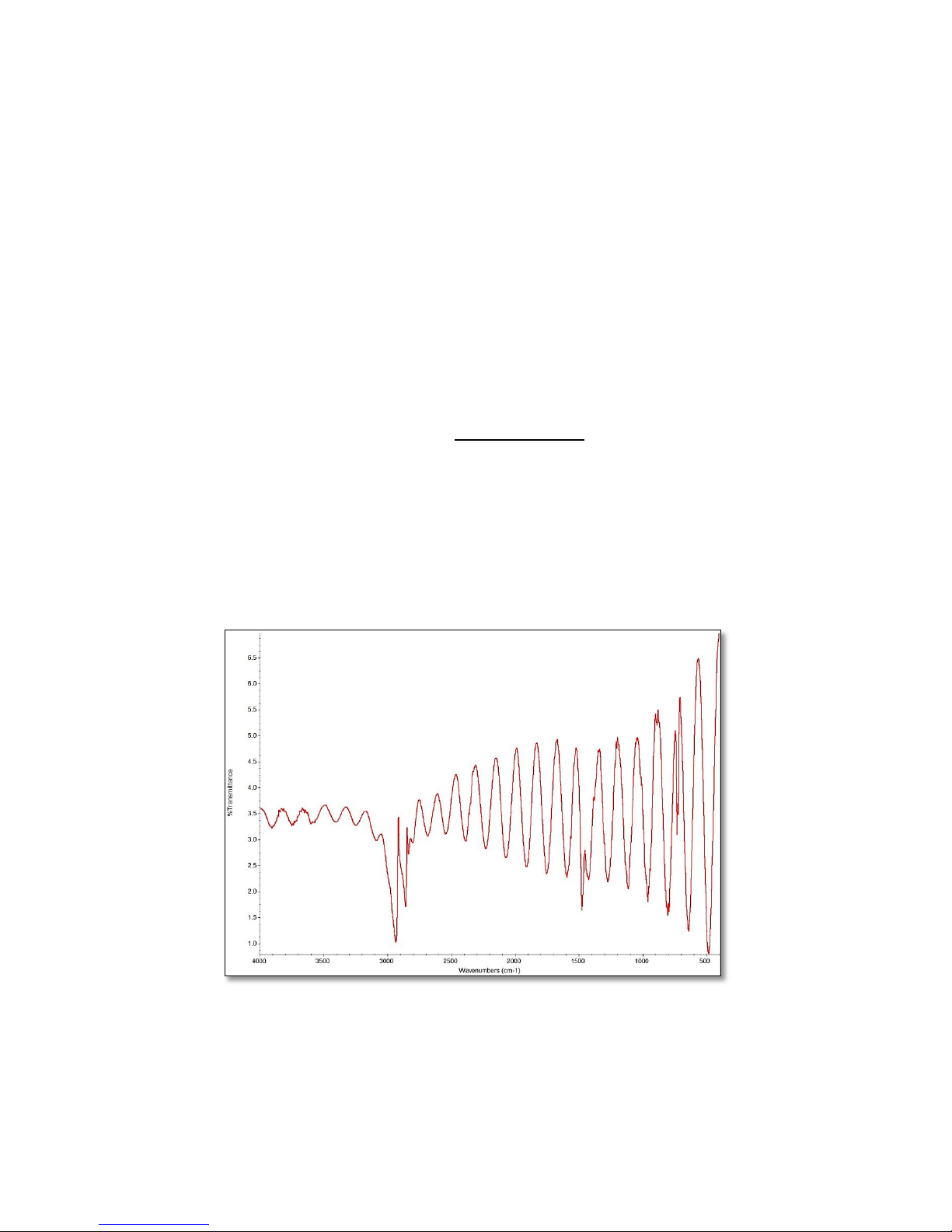

Free standing films exhibit a fringe pattern in the collected spectrum due to constructive and destructive

interference caused by reflection from both sides of the thin film. Measurement of the period of the

fringes will give the thickness of the film as long as the refractive index is known. For an angle of

incidence and a refractive index n, the equation governing this measurement is:

Δ · 2 · (n2-sin2 θ)

where m is the number of fringes counted, Δ is the wavelength difference between the first and last

fringe (cm

-1

), and θ is the angle of incidence. This interference fringe effect can create problems when

measuring thin film samples. The interference fringes can hide spectral features and cause quantitation

problems since the fringe position and spacing is sensitive to the thickness of the sample. Note the low

level of the spectrum, since only a small percentage of the infrared energy is reflected from the sample.

1/2

Figure 5: Reflectance fringe pattern of polyethylene film

PN 350-010000-05 Page | 6

The spectrum below is a reflection-absorption spectrum of the plastic film. The sample is placed on the

Refractive Index n1

Sample,

(n1 – n2)

2

(n1 + n2)2

Figure 6: R-A spectrum of polyethylene film

accessory and a mirror is placed on top of the sample. The spectrum shows no sign of interference

fringes. The band shapes are correct and have twice the absorption of the transmission case, consistent

with the double passage of the infrared beam through the sample. The technique of using a mirror

behind the sample works well as long as the sample is smooth, flat and non-scattering.

Effect of Dispersion

The spectra of many samples are distorted by anomalous dispersion in the sample. The reflectivity of

a sample is dependent upon the refractive index of the sample and is governed by the Fresnel

equations. For light hitting a sample at normal incidence, the reflection at the sample is given by the

following equation:

For example, the amount of reflection at the first glass surface is equal to R= (0.5/2.5)

passing through a pane of glass, which has a refractive index of about 1.5.

R=

Refractive Index n2

2

= 4% for light

PN 350-010000-05 Page | 7

Absorption Absorption Wavelength

Band Band

In the vicinity of an absorption band the refractive index varies considerably, an effect known as

anomalous dispersion. So a reflection spectrum is formed because the refractive index changes around

an absorption band.

Refractive Index

Figure 7: Spectrum exhibiting anomalous dispersion

Kramers-Kronig Transform

In order to produce a spectrum that is corrected for this anomalous dispersion, a correction known as a

Kramers-Kronig transformation may be performed on the spectrum. This transformation attempts to

produce a spectrum that does not contain any derivative peak shapes. The raw data and the result of a

Kramers-Kronig transform are shown below.

Figure 8: Reflectance spectrum of Poly (Methyl Methacrylate)

PN 350-010000-05 Page | 8

Figure 9: KKT absorption spectrum of Poly (Methyl Methacrylate)

The above curve is generated using the double FFT algorithm. Note that Kramers-Kronig transforms are

approximations and the resulting spectra should be used with caution when attempting quantitation.

The transform should only be performed on spectra that show derivative peaks. If a Kramers-Kronig

transform is performed on a spectrum with non-derivative peaks, the results may be erroneous.

Precautions

In order to provide the maximum transmission in the infrared, with the minimum spectral interferences,

the mirrors used in this device are uncoated (bare) aluminum on a glass substrate. Since the coatings are

soft, care must be taken to avoid damage. Normally, these mirrors will not need cleaning, since they are

contained within the housing of the accessory. If they do need cleaning, they may be gently wiped with

a lint-free, abrasive-free cloth, such as lens tissue, or with a camel hair brush. Under no circumstances

must the mirrors be rubbed with paper products such as “Kleenex” since this will produce scratching of

the mirror coating.

Maintenance Parts

The following parts may be ordered separately:

Description Part Number

10Spec Alignment Mirror 300-0002

10Spec Sample Mask Set 010-3010

PN 350-010000-05 Page | 9

6125 Cottonwood Drive · Madison, WI 53719-5120 · (608) 274-2721 (TEL) · (608) 274-0103 (FAX)

info@piketech.com · www.piketech.com

Loading...

Loading...