PICOTEST®

M3500A

6.5 Digit Digital Multimeter

Service Manual

Printed date: 01/2009

2

Table of Contents

1 GENERAL INFORMATION ......................................................................................... 4

1.1 WARRANTY INFORMATION.................................................................................. 4

1.2 LIMITATION OF WARRANTY ................................................................................ 5

1.3 PRECAUTION OF OPERATION.............................................................................. 5

1.4 MAINTENANCE OF M3500A .............................................................................. 6

1.5 SAFETY INFORMATION ........................................................................................ 6

1.6 SYMBOLS AND TERMS......................................................................................... 7

2 GENERAL MAINTENANCE ......................................................................................... 8

2.1 SETTING LINE VOLTAGE AND REPLACING FUSE............................................... 8

2.1.1 Voltage Selector................................................................................... 8

2.1.2 Transformer......................................................................................... 11

2.1.3 Power Line Fuse................................................................................. 13

2.2 CURRENT INPUT FUSE REPLACEMENT (3.15A ON THE FRONT & REAR PANELS)

15

2.2.1 Current Input Fuse Replacement (7A on the rear Panel)....... 18

2.3 PASS/FAIL OUTPUT FROM USB CONNECTOR ................................................ 21

2.4 MCUS & DSP FIRMWARE UPGRADE .............................................................. 22

3 TROUBLESHOOTING ................................................................................................. 26

3.1 INTRODUCTION ................................................................................................. 26

3.2 SYSTEM FUNCTION BLOCKS............................................................................. 28

3.3 PANEL MODULE ................................................................................................. 29

3.4 MAIN BOARD MODULE ..................................................................................... 30

3.4.1 Power Supply Circuitry.................................................................... 31

3.4.2 Analog Front-end Circuitry............................................................. 32

3.4.3 ADC & MCU .......................................................................................... 33

3.4.4 Main Control Circuitry...................................................................... 34

3.5 SELF-TEST ......................................................................................................... 35

4 DISASSEMBLY & RE-ASSEMBLY......................................................................... 39

4.1 INTRODUCTION ................................................................................................. 39

4.2 CASE COVER REMOVAL .................................................................................... 39

4.3 MAIN BOARD REMOVAL.................................................................................... 42

4.4 FRONT PANEL DISASSEMBLY ........................................................................... 48

4.5 ASSEMBLY DRAWINGS...................................................................................... 51

4.5.1 Front Panel Assembly....................................................................... 52

4.5.2 Chassis and Transformer Assembly............................................ 53

4.5.3 Main Board Assembly....................................................................... 54

4.5.4 Chassis Assembly .............................................................................. 56

4.5.5 GPIB Assembly ................................................................................... 58

5 REPLACEABLE PARTS ............................................................................................... 61

5.1 INTRODUCTION ................................................................................................. 61

5.2 PARTS LIST........................................................................................................ 61

5.3 LAYOUT DRAWINGS .......................................................................................... 82

6 SIMPL E CALIBRATION PROCEDURES...................................................................... 85

6.1 THE CALIBRATION SECURITY CODE ................................................................ 85

6.2 THE ZERO ADJUSTMENT................................................................................... 85

6.3 THE GAIN ADJUSTMENT FOR DCV, ACV, DCI, 4W & FREQ ....................................... 86

6.4 CALIBRATION COUNT .............................................................................................. 88

6.5 CALIBRATION DATE................................................................................................. 88

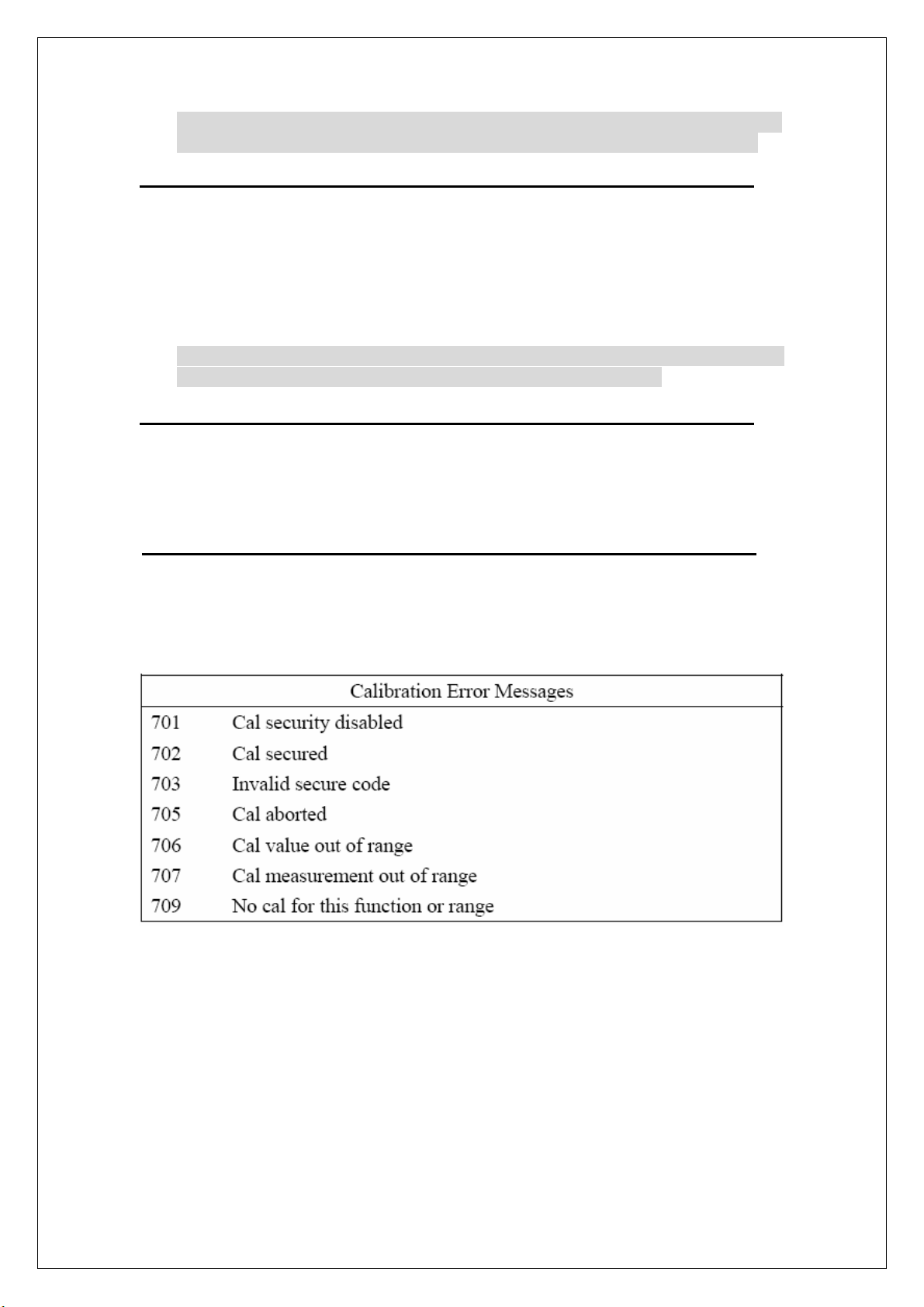

6.6 THE CALIBRATION ERROR MESSAGES ............................................................ 88

APPENDIX ................................................................................................................................89

A. SPECIFICATION LIST......................................................................................... 89

B. GENERAL SPECIFICATIONS .............................................................................. 92

C. POWER-ON AND RESET STATE ....................................................................... 93

3

4

1 General Information

1.1 Warranty Information

z Warranty: PICOTEST CORP. guarantees that this product meets its

published specifications at the time of shipment from the factory. Under

proper installation it should work as expected.

z Warranty Period: This equipment is warranted against defects in

material and manufacturing for a period of one year from the date of

shipment. During the warranty period, PICOTEST is responsible for

necessary repairs as long as the product can be proved to be defective.

For warranty service or repair this product must be returned to a service

facility designated by PICOTEST. Please contact your local service

representative.

z Excluded Items: This warranty does not include consumptive parts

such as fuses, buttons and relays. Neither does this warranty cover

defects caused by improper installation, improper or insufficient

maintenance, unauthorized modification, and improper operation,

ignorance of environmental specifications or improper software or

interfacing.

z Remarks:

1. No other warranty is expressed or implied, except for the above

mentioned.

2. The remedies provided herein are the buyer’s sole and exclusive

remedies. PICOTEST shall not be liable for any direct, indirect,

special, incidental or consequential damages.

5

1.2 Limitation of Warranty

z Our warranties do not cover any damage resulting from unauthorized

modification or misuse.

z Unless mentioned elsewhere in this document, our warranty does not

apply to fuses, probes, and problems arising from normal wear or user’s

failure to follow instructions.

z Our warranties do not apply on any direct, incidental, special, or

consequential damages.

z The above warranties are exclusive and no other warranty is

expressed or implied. PICOTEST disclaims any implied warranties of

MERCHANTABILITY, SATISFACTORY QUALITY, and FITNESS for any

particular reasons.

1.3 Precaution of Operation

z Please carefully read the manual before operating this device.

z This manual is for reference only. Please consult your local service

representative for further assistance.

z The contents of this manual may be amended by the manufacturer

without notice.

z Never dismantle the equipment by any unauthorized personnel, or

equipment may be damaged.

z The equipment has been strictly tested for quality before delivery from

our factory. However, this equipment must not be used in dangerous

situations or damage may result.

z This product should be placed in a safe area in case of unpredictable

personnel use.

z The rear protective conduct terminal needs to be connected to the actual

earth ground or electric shock may occur.

z The patent and related documents for the equipment belong to

PICOTEST CORP. and they aren’t allowed to be used by others without

permission.

6

1.4 Maintenance of M3500A

z Although M3500A multimeter is very durable and weather resistant, care

should be taken not to expose it to severe impact or pressure.

z Keep M3500A far from water and damp environment.

z Calibration should be taken every year. Please contact with your local

service representative for more information.

z If the incorrect display or abnormal beeps occurred you should stop using

the equipment at once.

z Do not use the Meter around explosive gas or inflammable vapor.

z Wipe the surface of M3500A multimeter with a piece of dry and clean

cloth.

1.5 Safety Information

Warning! Please read through the following safety information before

using the product.

To avoid possible electric shock or personal injury, please read and follow

these guidelines carefully:

z Follow the guidelines in this manual and DO NOT use the Meter if the case

is damaged. Check the Meter case and terminals, and make sure all the

devices are in the proper positions.

z Do not apply excessive voltage to the Multimeter. Apply voltage within

the rated range only.

z Use caution when measuring voltages above 30 V RMS, 42 V peak, or 60

V DC. These voltages pose an electric shock hazard.

z When using the probes, always keep your fingers behind the finger

guards.

z Always connect the common test leads (black) before connecting the live

test leads (red), and disconnect the live test leads (red) before

disconnecting the common test leads (black). This will reduce the chance

of an electric shock.

7

z Disconnect circuit power and discharge all high-voltage capacitors before

testing resistance, continuity, diodes or capacitance.

z If you need to open the Meter case or replace any parts, read the

instruction in this manual first. Do not perform these actions unless you

are qualified to do so.

z When replacing fuses, use only the same type and same rating as

specified.

z Do not try to operate the Meter if it is damaged. Disconnect the power

from the equipment and consult the local service representative. Return

the product to PICOTEST service department if necessary.

1.6 Symbols and Terms

This symbol indicates hazards that may cause damages to the

instrument or even result in personal injury.

This symbol indicates high voltage may be present. Use extra caution

before taking any action.

This symbol indicates the frame or chassis terminal presented need

to be connected to the actual earth ground.

This symbol indicates “Protective Conductor Terminal”.

This symbol indicates earth (ground) terminal.

This symbol indicates this product complies with the essential

requirements or the applicable European laws or directives with

respect to safety, health, environment and consumer protections.

8

2 General Maintenance

2.1 Setting Line Voltage and Replacing Fuse

Before turning on the multimeter, you should check the Line voltage setting

and the power-line fuse. If the line voltage setting is not properly, correct it.

If the power–line fuse is not good, replace a new one in the same type. The

following sections will show you how to do.

Warning! Before changing the line voltage setting or replacing the

power line fuse, make sure the multimeter is disconnected from the AC

power and remove all the test leads connected to it. An incorrect voltage

setting may cause severe damage to your instrument.

2.1.1 Voltage Selector

Normally, the line voltage is selected for your country properly when the

multimeter is shipped from the factory. Refer to your local power utility

voltage to see if the setting is correct. Follow the steps below to select a

properly line voltage for your instrument if the setting is not fit your

requirement.

NOTE: In some areas, the power utility voltage is 240V or 120V; in others,

it is 220 V or 100 V. The equipments are set properly according to users’

requirements when they are shipped from the factory. For more information,

please refer to section 2.1.2.

[Step 1]

Verify current line voltage setting from the window. If it is incorrect, you

must change it to a properly value. The position of the window is shown in

Figure 2-1.

[Step2]

Turn off the power and disconnect the line cord from your multimeter as

shown in Figure 2-1. Also, you should remove all the leads connected to it.

Window

Figure 2-1

[Step 3]

Open the cap and remove the voltage setting selector from the right middle

seam as shown in Figure 2-2. (You might need a flat-blade screwdriver to

do so.)

Figure 2-2

9

[Step 4]

Turn the voltage selector over, the value you want to set must in the right

side.

Figure 2-3

[Step 5]

Insert the voltage setting selector back into the socket and close the cap as

shown in Figure 2-4. Check the setting from the window again.

Figure 2-4

NOTE: Before re-connecting the power line cord to your multimeter, make

sure that power switch is in the “POWER OFF” state.

10

2.1.2 Transformer

Usually you can change the line voltage setting by voltage selector as the

shown in section 2.1.1. If the voltages shown in the selector do not fit your

requirement, you may change the transformer connections to change the

line voltage setting selections. The voltages can be set for M3500A are 100,

120, 220, 240 Vac.

Warning! Do not perform this action unless you are qualified to do so.

For more information, please contact your local service representative.

[Step 1]

Turn off the power and disconnect the line cord from your multimeter as

shown in Figure 2-5. Also, you should remove all the leads connected to it.

Figure 2-5

[Step 2]

Remove the handle and then the metal cover. Please refer to section 4.2 for

more detail.

Warning! Do not open the case unless disconnecting the AC line cord

and all test leads. Do not perform this action unless you are qualified to do

so.

11

[Step 3]

There are four wires in different colors on the transformer. Two of them

connect to the power entry according to the regular line voltage selections

for your country as shown in Figure 2-8.

Power Entry

Transformer

Figure 2-8

[Step 4]

Please refer to the Table 2-1 to connect the wires for your need.

Figure 2-9

Power Line Voltage Wire color

100 Vac Brown

120 Vac Red

220 Vac Orange

240 Vac Yellow

Table 2-1

12

[Step 5]

Recover the case of the multimeter and then follow the steps in section

2.1.1 to set the desired line voltage.

NOTE: After transformer wiring modification, you should change the sticker

on voltage setting selector also. PICOTEST will provide the stickers for free.

Please contract your local service representative for the stickers for your

requirement.

2.1.3 Power Line Fuse

A power-line fuse located next to the AC receptacle (in the line voltage

selector) protects the power line input of the instrument. Verify that the

power-line fuse is good and replace a new one if it is damaged. The

multimeter is shipped from the factory with a fuse 0.25 A / 250 V, slow-blow,

5

× 20 mm (Picotest part number: 024-001-000004, the reference number:

FS102) installed. This is the correct fuse type for all line voltage settings.

Please follow the steps below to change the fuse.

[Step 1]

Turn off the multimeter and disconnect the line cord as shown in Figure 2-9.

Also, you should remove all the test leads that connected to your

instrument.

Figure 2-9

13

[Step 2]

Open the cap and remove the voltage setting selector from the right middle

seam as shown in Figure 2-10. (You might need a flat-blade screwdriver to

do so.)

Figure 2-10

Warning! For continued protection against fire or instrument damage,

only replace fuse with the same type and rating. If the instrument

repeatedly blows fuses, locate and correct the cause of the trouble before

replacing the fuse.

[Step 3]

Remove the broken fuse from the selector and replace a new one as shown

in Figure 2-11. You must replace the fuse with the same type or same

rating.

Figure 2-11

14

[Step 4]

Insert the voltage setting selector back into the socket and close the cap as

shown in Figure 2-12.

Figure 2-12

Warning! Before re-connecting the power line cord to your multimeter,

make sure that power switch is in the “POWER OFF” state. Verify if the line

voltage setting is correct before you turn on your instrument.

2.2 Current Input Fuse Replacement (3.15A on

the Front & Rear Panels)

There are two fuses located in the front and rear current input terminals to

protect your multimeter against damage of strong current pulse. The front

current input fuses used in M3500A is the type 3.15A, 250 V, 5

fast acting, HBC and Ceramic Tube with high breaking character (Picotest

part number: 024-001-000008, the reference number: FS101). If you need

to replace them, please follow the steps shown below.

Warning! For continued protection against fire or instrument damage,

only replace fuse with the same type and rating. If the instrument

repeatedly blows fuses, locate and correct the cause of the trouble before

15

× 20 mm,

replacing the fuse.

[Step 1]

Turn off the multimeter and disconnect the power line cord as shown in

Figure 2-13. Also, you should remove all the test leads that connected to

your instrument.

Figure 2-13

[Step 2]

Push the current input terminal and turn it right as shown in Figure 2-14 .

Figure 2-14

16

[Step 3]

Pull out the terminal (fuse holder) gently and you will find the current input

fuse as shown in Figure 2-15.

Current input Fuse

Figure 2-15

[Step 4]

Remove the broken fuse and replace a new one with the same type or same

rating as shown in Figure 2-16.

Fuse

Current Fuse Holder

Figure 2-16

17

[Step 5]

Insert the fuse holder back and turn it left as shown in Figure 2-17. Make

sure the fuse holder is properly seated and secured.

Figure 2-17

Warning! Before re-connecting the power line cord to your multimeter,

make sure that power switch is in the “POWER OFF” state.

NOTE: The rear current input fuse can be replaced by the same method as

the front one.

2.2.1 Current Input Fuse Replacement (7A on the

rear Panel)

The current input Fuse provides an additional level of current protection

(The diagram in the below Figure 2-18 would get you know the function

more clearly). It used in M3500A is the type 7A, 5 x 20 mm, fast acting and

Ceramic Tube (Picotest part number: 024-001-000006, the reference

number: FS103). To replace the fuse, you have to release a holder by a

flat-blade screwdriver as shown in the following.

18

Figure 2-18

[Step 1]

Turn off the multimeter and disconnect the power line cord as shown in

Figure 2-19. Also, you should remove all the test leads that connected to

your instrument.

Figure 2-19

[Step 2]

Please use a flat-blade screwdriver with a suitable pushing strength to turn

it left for releasing the holder.

19

Figure2-20

[Step 3]

Pull out the terminal (fuse holder) gently and you will find the current input

fuse as shown in Figure 2-21.

[Step 4]

Remove the broken fuse and replace a new one with the same type or same

rating as shown in Figure 2-22.

Figure 2-21

Current input Fuse

20

±

Fuse

Current Fuse Holder

Figure 2-22

[Step 5]

Insert the fuse holder back and turn it right as shown in Figure 2-23. Make

sure the fuse holder is properly seated and secured.

Figure 2-23

2.3 Pass/Fail Output From USB Connector

The USB connector on the rear panel of M3500A is a series “B” connector.

When the USB interface is disabled (IEEE-488 interface is selected), the

internal pass and fail TTL output signals (limit testing) will be connected to

the USB connector.

The pass and fail signals are low true and indicate the Math Pass/Fail Limit

Test result for the next reading to be output to the GPIB interface. The

signals are active low for approximately 2ms (

taken. Figure 2-24 shows the USB connector (series “B”).

100 μsec) for each reading

21

Figure 2-24

Contact

Number

1 VBUS Red Floating

2 D- White Limit Test Pass

3 D+ Green Limit Test Fail

4 GND Black GND

If you disable the USB interface, the Pass/Fail output function will enable

automatically. Please follow the procedure below to enable/disable this

function.

Procedure: MENU

Or you can do this by the other way:

Signal Name

Table 2-2

→

INTERFACE→USB→ENABLE/DISABLE

Typical Wiring

Description

Assignment

Procedure: CONFIG+SHIFT+RATIO

Warning! You can’t use the USB interface if you want to enable the

Pass/Fail signal output. You must use the GPIB interface for remote control.

Please disconnect the USB cable from you multimeter. The signal from the

USB cable may make the Pass/Fail signal output abnormal.

→

OUTPUT→ENALBLE/DISABLE

2.4 MCUs & DSP Firmware Upgrade

M3500A has three microprocessors, DSP processor, Panel processor, and

Front-end processor, for various internal systems. PICOTEST allows users to

22

3

upgrade their multimeter by update firmware of these microprocessors.

Firmware updating will support more stability or functions for your

multimeter. To upgrade your M3500A, please follow the steps below.

[Step 1]

Link to PICOTEST homepage: http://www.picotest.com.tw/

by your browser.

Click the banner “Support” and login to enter the support page. If you are

visit the site first time, please register for more service. Download the latest

firmware file for your instrument.

[Step 2]

Unzip the downloaded file, you will find the files as shown in Figure 2-25.

Please read the document include in the downloaded zip file for detail.

Figure 2-25

NOTE: You can select the firmware file for the MCU that you want to

upgrade only. Please refer to Table 2-3 to choose the firmware file you need.

The code “x” at last of the file name indicates the version. For more

information, please contract your local service representative.

Microprocessor File name

DSP DATA_X1_xxx.bin

Panel Processor DATA_X3_x.bin

Front-end Processor DATA_X4_x.bin

Table 2-3

2

4

[Step 3]

Connect your M3500A to PC via USB cable. Execute DmmUpdate.exe, and

a window as Figure 2-26a will show. Click the “Update” button and choose

the firmware file that you want to update, for example DATA_X1_10A.bin,

as shown in Figure 2-26b and open it.

Figure 2-26a

[Step 4]

Figure 2-26b

Restart your multimeter when the window as Figure 2-27 shows up. Please

ignore the “ERR” annunciator on the panel if it is lit after you restart your

instrument. It will disappear after you complete whole installation.

2

5

Figure 2-27

[Step 5]

Click “Update” bottom again after you restart your multimeter for installing

the other firmware, or click “Exit” to exit the program and complete whole

installation.

[Step 6]

To confirm the updating is successful, follow the procedure below to check

the system version.

Procedure: MENU

→

SYSTEM→SYSTEM VER.

The system version will show in the format of “xx.xx-xx-xx”. The first code

“xx.xx” is the firmware version of the DSP (Digital Signal Processor); the

second code “xx” is for the panel microprocessor and the last one indicates

the front-end MCU’s firmware version. If the result is incorrect, update it

again.

Also, you can check the firmware version of DSP by pressing

“DISPLAY-NEXT/PREV” button. The DSP’s firmware version will show on the

lower-raw display panel by the form “DSP VER.: xx.xx”. It will be the same

as the version shown in the MENU.

NOTE: If you have any trouble when you upgrading the firmware, please

contact your local service representative.

2

6

3 Troubleshooting

3.1 Introduction

The information provide in this section will assist you in troubleshooting the

M3500A. This section is arranged as follows:

z Introduction – Introduce what is provided in this section includes some

considerations that should be noted before making any repairs to the

M3500A.

z System function block – Provides brief descriptions about the principles

of operation in M3500A.

z Front panel module – Provides the procedure to test the functionality of

the front panel module.

z Main board module – Provides the test procedures and brief operation

theories of the main board module, includes power supply circuitry,

analog front-end circuitry, DSP & MCU, and main control circuitry.

z Self-Test – Explain to the self-test procedures built in M3500A.

Warning! Some procedures in this section may expose you to

hazardous voltage or damage your instrument. Do not perform these

procedures unless you are qualified to do so.

Be sure to read the following considerations before making any repairs to

the M3500A.

z Repairs will require various degrees of disassembly. Please refer to the

section 4 of this manual for detail disassembly instructions of M3500A.

It is recommended performing self-test procedure prior to any

disassembly.

z Do not make repairs to the PC-board unless you are equipped and/or

qualified to do so. Without proper equipment and training, you could

damage a surface mount PC-board before repair. It is recommended

2

7

that sending your unit back to the factory for repairs or only replace the

PC-board if you are not equipped or qualified.

z There are many CMOS devices installed in M3500A. CMOS devices are

static sensitive and can be destroyed by electrostatic discharge during

handling. Handle these devices with following precautions to avoid

damaging them:

1. Transport and handle ICs only in containers designed to prevent

static charge.

2. Disassemble instruments only in a static-free area.

3. Ground yourself with a suitable wrist strap.

4. Handle the devices only at a properly grounded work station.

5. Minimize handling and do not touch the pins during handling the

devices.

6. Remove all plastic, styrofoam, vinyl, paper and other materials that

may generate static from your work station.

7. Only use grounded tip solder irons and anti-static type solder

suckers.

z If a circuit board is removed during repair or a component is replaced,

the M3500A must be recalibrated for accuracy.

2

8

3.2 System Function Blocks

Figure 3-1 shows the main system function blocks of M3500A multimeter.

Front /

Front

Terminal

Rear

Terminal

Front/Rear Selector

Rear

Switch

Analog

Front-End

Circuit

Main Board Module

ADC

&

MCU

Linear

Regulator

B

Power Supply

Linear

Regulator

A

AC-IN

Main

Control

Circuit

Panel

Module

System Function Blocks of M3500A

Figure 3-1

As shown in Figure 3-1, the system consists of Front/Rear Selector, Main

Board Module, and Panel Module. In this section, the discussion of the

front/rear selector is provided. The detail of the panel module is provided in

section 3.3, and the main board module is discussed in section 3.4.

The front/rear selector is used to select either the front terminals or the rear

terminals. The front terminals and the rear terminals have the same

functions and users can choose one of them for their convenience. Both front

and rear terminal have a fused current input terminal (Input-I) to protect

against potential catastrophic damage caused by accidental input

connection. The current input fuses used in M3500A is the type 3.15A, 250

V, 5

× 20 mm, fast acting, ceramic tube with a high breaking character

(Picotest part number: 024-001-000008, the reference number: FS101).

For more detail about current input fuses, please refer to section 2.2.

2

9

3.3 Panel Module

The panel module consists of VFD control, keypad scanning, and beeper

control. Figure 3-2 shows the block diagram of the panel module of

M3500A.

Beeper

VFD

(Vacuum Fluorescent Display)

Keypad

50Hz/60Hz

Detect

Circuit

Data Lines

Scan Lines

Panel

MCU

To

Main board

Module

Panel Module

Figure 3-2

Panel MCU U3 controls the functions of panel module. Communication

between the panel module and the main board module is accomplished

through a 4-wire bidirectional serial interface. The panel MCU sends a key

scanning signal sequentially to the keypad via scan lines to detect the status

of keys. In a similar manner, the key data are sent back sequentially through

data lines.

If any key is pressed, a key down parameter will be sent to panel MCU. Panel

MCU U3 interprets the key down data and sends the data to the main

controller on the main board module. Main controller U1601 will operate

according to the received data, and then return the result to U3. According

to the result from U1601, U3 sends control signals to the VFD (vacuum

fluorescent display) for correct display and to beeper to generate a beep.

Filament voltage for the VFD is derived from the power supply transformer.

A 50Hz/60Hz detecting circuit consists of comparator U4 detects the

2

0

frequency of supply voltage AC2 from the transformer and then informs

main controller to set PLC (Power Line Cycle) parameters. Panel MCU will

response automatically according to the detecting result to make the VFD

operating properly.

3.4 Main Board Module

The main board module of M3500A consists of power supply circuit, analog

front-end circuit, ADC and MCU, and main control circuit. The block diagram

is shown in Figure 3-3.

Analog

Front-End

Circuit

ADC

&

MCU

Linear

Regulator

B

Power Supply Circuit

Linear

Regulator

A

AC-IN

Main

Control

Circuit

To

Panel

Module

Main Board Module

Figure 3-3

As shown in Figure 3-3, input signals routed through analog front-end

circuit and then convert to digital signal by the ADC. Digital signals are sent

to main control circuit via opto-couplers. The calculated data will send to

panel module and display the result on VFD. The powers needed in these

circuits are supplied by the power supply circuit.

The discussion about power supply circuit is provided in section 3.4.1; the

circuitry theories of the analog front-end circuit and ADC & front-end

processor are shown in section 3.4.2 and 3.4.3 respectively, and section

3.4.4 provides the discussion about the main control circuit of M3500A.

3

3.4.1 Power Supply Circuitry

→

In this section, a basic circuit theory that can help you to troubleshoot the

power supply circuit of M3500A is provided. The power supply circuit

transforms the AC line voltage to required voltage (AC or DC) for various

internal circuits. The block diagram of power supply circuit is shown in

Figure 3-4.

240V

220V

120V

100V

Regulator

Circuit

Regulator

Circuit

Regulator

Circuit

Regulator

Circuit

37V

AC1

AC2

5VD

3.3VD

+18VA

-18VA

5VA

3.3VA

For VFD driver Supply Voltage

⇒ For VFD Filament Voltage

→ For Panel MCU and Peripherals

→ For Main Board DSP and Peripherals

⇒ For Analog Front-End Circuit

→

For Relay Power Supply Voltage

→

For Slope ADC Digital Circuit

Power Supply Circuit

Figure 3-4

As shown in Figure 3-4, AC power is applied through the line voltage

selector to power transformer. There are four selections of line voltage (240,

220, 120, and 100 Vac) can be applied to M3500A. You must choose a

correct line voltage for your multimeter according to your local power utility

voltage or damage may occur.

The power transformer has a total five secondary windings to produce AC

and DC voltages for M3500A. AC voltage is used to provide the VFD filament

voltage, and each DC supply uses a regulator circuit for various purposes.

Please refer to Figure 3-4 to check the purpose of each supplied voltage.

31

2

3.4.2 Analog Front-end Circuitry

A

The purpose of the analog front-end circuit is to converter the input signals

from the front or rear terminal to ADC (analog-to-digital converter) input.

The block diagram of the analog front-end circuit of M3500A is shown in

Figure 3-5.

Front

Terminal

Rear

Terminal

Front /

Rear

Switch

Input-HI

Input-LO

Sense-LO

Sense-HI

AMP

Protection

Circuit

DCV

Divider

Buffer

Current

Shunts

ACV

DCV & OHMS

OHMS Current

Source

RMS to DC

Converter

Function

Switching

nalog Front-End Circuit

Buffer

Voltage

Reference

PGA

To A/D

Converter

Figure 3-5

The purpose of the function switching circuit is to connect the input terminal

to the various functions. All measurement signals are changed to a DC

voltage and then sent to the function switching circuit. The amplifier in the

function switching circuit converts the voltage to a properly value according

to the function which is selected and then send it to the A-to-D converter

through the PGA circuit.

The PGA circuit switches the various signals for measurement. In addition to

the input signal, it also switches among reference and zero signals at various

phases of the measurement cycle.

DC input signals from Input-HI terminal are routed via a protection circuit to

the function switching circuit. If an overload condition occurs, the protection

circuit will disconnect the analog input signal from the rest of the analog

circuit. For the 100 VDC and 1000 VDC ranges, the protection circuit is open

and input DC voltage is through a DCV divider R204 to the function switching

3

3

circuit.

Ω

A

Tx Rx

The ACI or DCI input signal is applied to the current shunt circuit from the

Input-I terminal and a relay is used to select shunts. For 10mA DC and

100mA DC ranges, a 5.1

other DCI and all ACI ranges, a 0.1

Ω resistance is shunted across the input. For the

shunt is used. Since the shunt

resistance is known, a voltage proportional to the input current is generated

and measured by the function switching circuit.

Resistance measurements are made by applying a known current through

an unknown resistance. The current from OHMS current source makes a

voltage drop across the unknown resistance. The resulting voltage drop is

then routed through the protection circuit and measured by the function

switching circuit. For 4-wire ohms measurements, Sense-HI and Sense-LO

are connected to the function switching circuit, too.

AC input voltage from the Input-HI terminal is sent to a RMS to DC converter

via protection circuit. RMS to DC converter changes the input AC voltage to

a DC voltage and then sends it to the function switching circuit. All voltage

ranging is performed in the converter circuit so that the input of the function

switching circuit is nominally 2 VDC for a full scale AC input.

3.4.3 ADC & MCU

Figure 3-6 shows the block diagram of the A-to-D convert circuit of

M3500A.

Voltage

Reference

To

Analog

Front-End

Circuit

A/D

Converter

ADC

&

Analog

Circuits

Control

Unit

Figure 3-6

To

Main

Control

Circuit

DC & MCU

3

4

The analog-to-digital converter (ADC) is used to change dc voltage into

digital information. The digital signals are then sent to the main controller on

the main board module through opto-couplers to calculate readings. The

voltage reference circuit is used to provide precision voltage reference for

the multimeter.

A microprocessor (front-end processor), U2001, controls the functions of

ADC and the analog front-end circuit to make sure the analog-to-digital

conversions are performed properly. The output data of the ADC circuit are

then sent to the main controller on the main board module through the Tx

lines via opto-couplers.

When the multimeter is triggered, an analog-to-digital conversion is

performed. The ADC starts by clearing the integrator slope count in the

front-end MCU, and the slope count is latched at the end of the integration

period. The slope count provides the most significant bits of the input

voltage conversion.

3.4.4 Main Control Circuitry

The main control circuit controls operations of the entire instrument. Figure

3-7 shows the block diagram of the main control circuit.

To

Panel

Module

USB

COMM

VM COMP

&

EXT TRG

To

Analog

Circuit

XTAL

Main Controller

RAM

Flash

Memory

Main Control Circuit

Figure 3-7

3

5

All measurement control and bus command interpretation is performed in

the main controller (DSP) U1601, and the panel processor U3 and front-end

processor U2001 operate as slaves to the DSP. The main controller (DSP) is

a 16-bit fixed-point Digital Signal Processor. It has parallel and serial ports

to control various circuits, such as USB and COMM interface.

A conventional address/data bus is used to transfer data between the DSP

and the external RAM U1701 and flash memory. The flash memory is used to

store the firmware for M3500A operation and calibration data, and the

external RAM provides temporary operating storage.

The clock frequency of the DSP is controlled by an oscillating circuit consists

of a 10 MHz crystal.

3.5 Self-test

Self-test procedures are built in M3500A for checking that the logic and

measurement hardware are functioning properly. Every time when the

multimeter is powered on, a set of test procedures is performed to make

sure the basic function of the multimeter works properly. If any error occurs

during self-test procedures, it indicates that parts of the multimeter are not

operating properly and need to be serviced.

Warning! Erroneous self-test failures may occur if the setting of

power line voltage is incorrect. Errors may also occur because of signals

present on the input terminal (front and rear) during self-test procedure.

Long test leads can act as an antenna causing pick-up of ac signals.

Or users may execute a complete self-test by front panel operation. This test

procedure provides more tests for the hardware of M3500A than the

power-on tests. Please follow the procedure below to perform the complete

self-test.

Procedure: MENU

→

SYSTEM→SELF TEST

3

6

After self-test procedure, the result, PASS or FAIL, will be shown. If the

±

±

±

result is FAIL, the “ERR” annunciator on the display panel will be lit, and

error codes will be stored. You can check the error codes by the following

procedure.

Procedure: MENU

The descriptions of self-test procedures are listed below including test

number, purpose, test setup, and failure criteria.

601 Front panel does not respond The main CPU U1601 attempts to

establish serial communications with the front panel processor U3.

Communication must function in both directions for this test to pass.

602 RAM read/write failed This test writes and reads a 55h and AAh

checker board pattern to each address of ram U1701. Any incorrect read

back will cause a test failure. This error is only readable from the remote

interface.

603 Front-End MCU does not respond The main CPU U1601 attempts to

establish serial communications with the front-end processor U2001.

Communication must function in both directions for this test to pass.

→

SYSTEM→ERROR

604 A/D noisy test failed This test configures to the 10V dc range with the

internal 0V. A 20ms ADC measurement is performed and the result is

checked against a limit of 0V

605 N2 calibration parameter failed This error message indicates that

N2 calibration parameter is out of range.

606 N3 calibration parameter failed This error message indicates that

N3 calibration parameter is out of range.

607 Buffer1 offset out of range This procedure is to test the offset of

buffer U507. The result is checked against a limit of 0

608 Buffer2 offset out of range This procedure is to test the offset of

buffer U508. The result is checked against a limit of 0

20uV

0.1mV

0.1mV

3

7

609 DC gain x1 failed This procedure is to test the tolerance of DC gain×1

±

±

±

μ

±

±

μ

±

amplifier. The limit of gain tolerance is

610 DC gain x10 failed This procedure is to test the tolerance of DC

gain

×10 amplifier. The limit of gain tolerance is

611 DC gain x100 failed This procedure is to test the tolerance of DC

gain

×100 amplifier. The limit of gain tolerance is

612 Ohms 500 nA source failed This test configures to the 10V dc range

with the internal 10M 100:1 divider R204 connected across the input. The

500nA ohms current source is connected to produce a nominal 5V signal. A

20ms ADC measurement is performed and the result is checked against a

limit of 5V

613 Ohms 5 uA source failed This test configures to the 1000V dc range

with the internal 10M 100:1 divider R204 connected across the input. The

5

A ohms current source is connected. The compliance limit of the current

± 1V.

0.005.

0.05.

0.5.

source is measured. A 20ms ADC measurement is performed and the result

is checked against a limit of 0.12V

614 DC 1000V zero failed This test configures to the 1000V dc range with

no input applied. A 20ms ADC measurement is performed and the result is

checked against a limit of 0V

615 Ohms 10 uA source failed This test configures to the 1000V dc range

with the internal 10M 100:1 divider R204 connected across the input. The

10

A ohms current source is connected. The compliance limit of the current

source is measured. A 20ms ADC measurement is performed and the result

is checked against a limit of 0.12V

616 DC current sense failed This test configures to the 3A dc range. A

20ms ADC measurement is performed and the result is checked against a

limit of 0A

functional. The test limit is set wide because K303 does not open the current

± 5A. This test confirms that the dc current sense path is

5 mV.

0.01V.

0.01V.

input during self-test. This test should catch a dc current sense failure

without causing false failures when current inputs are applied during

self-test.

3

8

617 Ohms 100 uA source failed This test configures to the 1000V dc

μ

±

±

range with the internal 10M 100:1 divider R204 connected across the input.

The 100

current source is measured. A 20ms ADC measurement is performed and

A ohms current source is connected. The compliance limit of the

the result is checked against a limit of 0.12V

618 DC high voltage attenuator failed This test configures to the 1000 V

dc range. The 500nA ohms current source is connected to produce a nominal

5V signal. A 20ms ADC measurement is performed and the result is checked

against a limit of 5V

619 Ohms 1 mA source failed his test configures to the 1000V dc range

with the internal 10M 100:1 divider R204 connected across the input. The

1mA ohms current source is connected. The compliance limit of the current

source is measured. A 20ms ADC measurement is performed and the result

is checked against a limit of 0.12V

620 AC rms zero failed This test configures for the 100mV ac range with

the ac input grounded. The internal residual noise of the ac section is

measured and checked against a limit of -10mV to 70mV at the output of the

rms-to-dc converter.

± 1V.

0.01V.

0.01V.

621 AC rms full scale failed This test configures for the 100mV ac range.

The 1mA ohms current source is switched on to charge the ac input capacitor

C614. This produces a pulse on the output of the rms-to-dc converter which

is sampled 100ms after the current is applied. A 20ms A/D measurement is

performed and checked against a limit of 2V to 13V into the ADC.

624 Unable to sense line frequency The supplied voltage AC2 is routed

through a comparator U4 to generate a logic input signal. This test checks

that the logic input from U4 to panel MCU U3 is toggling. If no logic input is

detected, the instrument will assume 50Hz line operation for all future

measurements.

3

9

4 Disassembly & Re-assembly

4.1 Introduction

This section explains how to disassemble and reassemble the M3500A

multimeter. This section provides the procedure to assist in case cover

removal, main board removal, and front panel disassembly. Also, there are

mechanical drawings in this section to assist in the disassembly and

re-assembly of the M3500A.

Warning! Do not disassemble the M3500A multimeter unless you are

qualified to do so.

4.2 Case Cover Removal

If you need to remove the case cover when you are troubleshooting your

multimeter or you want to replace a component, this section will show you

how to do.

Warning! Do not remove the case cover before you disconnect the

line cord and all the test leads connecting to the multimeter, or electric

shock may occur.

NOTE: When you want to re-install the case cover, please reverse the steps

shown below. Make sure all the parts are properly seated and secured.

3

0

[Step 1]

Turn the handle up to 90° with the multimeter, and pull it out as shown in

Figure 4-1.

Figure 4-1

[Step 2]

Pull the front mounting ear out as shown in Figure 4-2.

Figure 4-2

NOTE: When re-installing the front mounting ear, make sure the ear is in

the correct direction.

4

[Step 3]

Remove the six fastening screws securing the rear bezel on the chassis as

Figure 4-3 shown. Pull the bezel and the rear mounting ear out together.

Figure 4-3

[Step 4]

Remove one screw that secures the metal cover on the chassis. The screw is

on the bottom as shown in Figure 4-4.

Figure 4-4

41

2

[Step 5]

Slide the metal cover out of the chassis as shown in Figure 4-5 and

complete the cover removal.

Figure 4-5

4.3 Main Board Removal

Follow the steps below to remove the main board. Of course, you must

complete the metal cover removal first.

[Step 1]

Remove the scanner card and GPIB card. If there are no scanner card and

GPIB card installed in your instrument, please skip this step.

z Remove two fasteners of GPIB card and two captive screws that secure

the scanner card on the rear panel as shown in Figure 4-6. Pull out the

scanner card gently.

4

3

Figure 4-6

z Loose the screw that secures the GPIB card on the plastic cylinder, and

remove the GPIB card carefully.

Figure 4-7

z Disconnect the cable from GPIB card to the connector J1605 on the

main board.

4

4

[Step 2]

Remove the rear panel module.

z Disconnect the three connectors from the transformer to power entry as

shown in Figure 4-8.

Figure 4-8

Warning! Make sure the connection is correct when you re-connect

the connectors between the transformer and power entry. An incorrect

connection will make the power supplied to the multimeter improperly and

cause damage to your instrument. For more information about the power

transformer, please refer to section 2.1.2.

z To remove the power switch rod from power entry, turn the multimeter

to the bottom. Place the edge of a flat-blade screwdriver in the notch on

the pushrod, and twist the driver gently while pulling the rod from the

shaft as shown in Figure 4-9.

4

5

Figure 4-9

z Remove the six screws as shown in Figure 4-10.

Grounding cord

fastening screw

Grounding cord

fastening screw

Figure 4-10

Warning! Two grounding cords that connect between the rear panel

and the left and right chassis are fastened by the screws pointed by blue

arrows in Figure 4-10. Make sure the connections are correct when you

re-install the rear panel.

4

6

z Remove the fastener of the rear terminal set as shown in Figure 4-11,

and pull the rear panel out from the chassis. Remove the fastener of the

front terminal set by the same way.

Terminal set fastener

Figure 4-11

[Step 3]

Remove the transformer.

z Loose the tow fastening screws as shown in Figure 4-12.

Figure 4-12

z Unplug the three cables to the connectors J2201, J2202, and J2203, and

then remove the transformer.

4

7

[Step 4]

To remove the front/rear switch rod, place the edge of a flat-blade

screwdriver in the notch on the pushrod, and twist the driver gently while

pulling the rod from the shaft as shown in Figure 4-13.

Figure 4-13

[Step 5]

Unplug the ribbon cable from the display panel to the connector J1604, and

then remove the screw that secure the main board on the chassis as shown

in Figure4-14.

Figure 4-14

4

8

[Step 6]

Pull the main board gently to make the fixed points leaving their positions.

Raise the board a little bit and then pull it out carefully as Figure 4-15.

Fixed point

Fixed point

Figure 4-15

NOTE: When you want to re-install the main board, please reverse the steps

shown above. Make sure all the parts are properly seated and secured.

4.4 Front Panel Disassembly

Follow the steps below to remove the front panel. This procedure assumes

that you removed the metal cover and main board already.

[Step 1]

Unscrew the input terminal heat conducting header and remove it as shown

in Figure 4-16.

4

9

Heat conducting header

Figure 4-16

[Step 2]

Remove the fasteners of the right/left chassis as shown in Figure 4-17, and

then remove the chassis.

Figure 4-17

4

0

[Step 3]

Remove the two fastening screws that secure the front panel PCB board as

Figure 4-18. Slide the front panel board to the right carefully to leave the

fixed points, and then remove the front panel board

Fix Points

Fix Points

Figure 4-18

[Step 4]

Now you can remove the conductive keypad module easily as shown in

Figure4-19.

Figure 4-19

5

NOTE: When you want to re-install the front panel, please reverse the steps

shown above. Make sure all the parts are properly seated and secured.

4.5 Assembly Drawings

The mechanical drawings provided in this section will help you to

disassemble and re-assemble the M3500A multimeter quickly. Section

4.5.1 shows the front panel assembly, section 4.5.2 shows the chassis and

transformer assembly, section 4.5.3 is the main board assembly, and

section 4.5.4 provides the chassis assembly drawings.

51

4.5.1 Front Panel Assembly

52

4.5.2 Chassis and Transformer Assembly

53

4

4.5.3 Main Board Assembly

5

5

5

6

4.5.4 Chassis Assembly

5

7

5

8

4.5.5 GPIB Assembly

Before assembling the GPIB, operators have to disassemble the M3500A’s case cover. For more information about case cover

removal, please refer to the Section 4.2 Case Cover Removal. Then the GPIB assembly in the following just can proceed.

[Step 1]

Remove the screws by available tools.

[Step 2]

Remove the screws on the other side by available tools.

5

[Step 3]

Remove the GPIB OPTION cover.

[Step 5]

Adjust the card to a proper position.

[Step 4]

Connect the GPIB cord to the socket of the main board.

[Step 6]

Fasten the card with a screw by a screwdriver.

59

[Step 7]

Fasten the terminal by hand’s assistance.

[Step 9]

Fasten the terminal by tool’s assistance.

[Step 8]

Do it again on the other side.

[Step 10]

Do it again on the other side. And finished!

60

5 Replaceable Parts

5.1 Introduction

This section contains replacement parts information and components layout

drawings for the M3500A. Section 5.2 shows the parts lists for the main

board and panel board of M3500A, and the components layout drawings of

the main board PCB and panel PCB are shown in section 5.3. Table 5-1 lists

the components of M3500A main board, and the components used in panel

board of M3500A are listed in Table 5-2. Figure 5-1 and Figure 5-2 show

the components layout of main board of M3500A. Figure 5-1 shows the top

layer, and Figure 5-2 is bottom layer. The panel board components layouts

are shown in Figure 5-3 and Figure 5-4. Figure 5-3 shows the top layer,

and Figure 5-4 shows the bottom layer.

5.2 Parts List

Parts list of M3500A main board

Picotest Part NO. Description Part Reference

056-001-000001 220pF-1206 NPO,200V,5% C101

056-001-000001 220pF-1206 NPO,200V,5% C103

056-001-000001 220pF-1206 NPO,200V,5% C511

056-001-000003 100nF-0603 X7R,50V,10% C1003

056-001-000003 100nF-0603 X7R,50V,10% C1004

056-001-000003 100nF-0603 X7R,50V,10% C1005

056-001-000003 100nF-0603 X7R,50V,10% C1006

056-001-000003 100nF-0603 X7R,50V,10% C1101

056-001-000003 100nF-0603 X7R,50V,10% C1102

056-001-000003 100nF-0603 X7R,50V,10% C1103

056-001-000003 100nF-0603 X7R,50V,10% C1104

056-001-000003 100nF-0603 X7R,50V,10% C1201

056-001-000003 100nF-0603 X7R,50V,10% C1202

056-001-000003 100nF-0603 X7R,50V,10% C1204

056-001-000003 100nF-0603 X7R,50V,10% C1205

056-001-000003 100nF-0603 X7R,50V,10% C1207

056-001-000003 100nF-0603 X7R,50V,10% C1208

056-001-000003 100nF-0603 X7R,50V,10% C1210

056-001-000003 100nF-0603 X7R,50V,10% C1211

61

056-001-000003 100nF-0603 X7R,50V,10% C1301

056-001-000003 100nF-0603 X7R,50V,10% C1302

056-001-000003 100nF-0603 X7R,50V,10% C1303

056-001-000003 100nF-0603 X7R,50V,10% C1304

056-001-000003 100nF-0603 X7R,50V,10% C1305

056-001-000003 100nF-0603 X7R,50V,10% C1306

056-001-000003 100nF-0603 X7R,50V,10% C1307

056-001-000003 100nF-0603 X7R,50V,10% C1308

056-001-000003 100nF-0603 X7R,50V,10% C1313

056-001-000003 100nF-0603 X7R,50V,10% C1401

056-001-000003 100nF-0603 X7R,50V,10% C1402

056-001-000003 100nF-0603 X7R,50V,10% C1403

056-001-000003 100nF-0603 X7R,50V,10% C1501

056-001-000003 100nF-0603 X7R,50V,10% C1502

056-001-000003 100nF-0603 X7R,50V,10% C1504

056-001-000003 100nF-0603 X7R,50V,10% C1506

056-001-000003 100nF-0603 X7R,50V,10% C1508

056-001-000003 100nF-0603 X7R,50V,10% C1510

056-001-000003 100nF-0603 X7R,50V,10% C1515

056-001-000003 100nF-0603 X7R,50V,10% C1601

056-001-000003 100nF-0603 X7R,50V,10% C1607

056-001-000003 100nF-0603 X7R,50V,10% C1608

056-001-000003 100nF-0603 X7R,50V,10% C1609

056-001-000003 100nF-0603 X7R,50V,10% C1610

056-001-000003 100nF-0603 X7R,50V,10% C1611

056-001-000003 100nF-0603 X7R,50V,10% C1612

056-001-000003 100nF-0603 X7R,50V,10% C1613

056-001-000003 100nF-0603 X7R,50V,10% C1614

056-001-000003 100nF-0603 X7R,50V,10% C1615

056-001-000003 100nF-0603 X7R,50V,10% C1616

056-001-000003 100nF-0603 X7R,50V,10% C1617

056-001-000003 100nF-0603 X7R,50V,10% C1618

056-001-000003 100nF-0603 X7R,50V,10% C1622

056-001-000003 100nF-0603 X7R,50V,10% C1701

056-001-000003 100nF-0603 X7R,50V,10% C1702

056-001-000003 100nF-0603 X7R,50V,10% C1703

056-001-000003 100nF-0603 X7R,50V,10% C1801

056-001-000003 100nF-0603 X7R,50V,10% C1802

056-001-000003 100nF-0603 X7R,50V,10% C1803

056-001-000003 100nF-0603 X7R,50V,10% C1902

62

056-001-000003 100nF-0603 X7R,50V,10% C1905

056-001-000003 100nF-0603 X7R,50V,10% C2001

056-001-000003 100nF-0603 X7R,50V,10% C201

056-001-000003 100nF-0603 X7R,50V,10% C202

056-001-000003 100nF-0603 X7R,50V,10% C2101

056-001-000003 100nF-0603 X7R,50V,10% C2207

056-001-000003 100nF-0603 X7R,50V,10% C2208

056-001-000003 100nF-0603 X7R,50V,10% C2219

056-001-000003 100nF-0603 X7R,50V,10% C2220

056-001-000003 100nF-0603 X7R,50V,10% C2226

056-001-000003 100nF-0603 X7R,50V,10% C2229

056-001-000003 100nF-0603 X7R,50V,10% C2230

056-001-000003 100nF-0603 X7R,50V,10% C2231

056-001-000003 100nF-0603 X7R,50V,10% C2232

056-001-000003 100nF-0603 X7R,50V,10% C2233

056-001-000003 100nF-0603 X7R,50V,10% C2252

056-001-000003 100nF-0603 X7R,50V,10% C2253

056-001-000003 100nF-0603 X7R,50V,10% C301

056-001-000003 100nF-0603 X7R,50V,10% C303

056-001-000003 100nF-0603 X7R,50V,10% C402

056-001-000003 100nF-0603 X7R,50V,10% C403

056-001-000003 100nF-0603 X7R,50V,10% C404

056-001-000003 100nF-0603 X7R,50V,10% C405

056-001-000003 100nF-0603 X7R,50V,10% C501

056-001-000003 100nF-0603 X7R,50V,10% C502

056-001-000003 100nF-0603 X7R,50V,10% C503

056-001-000003 100nF-0603 X7R,50V,10% C504

056-001-000003 100nF-0603 X7R,50V,10% C505

056-001-000003 100nF-0603 X7R,50V,10% C506

056-001-000003 100nF-0603 X7R,50V,10% C507

056-001-000003 100nF-0603 X7R,50V,10% C508

056-001-000003 100nF-0603 X7R,50V,10% C509

056-001-000003 100nF-0603 X7R,50V,10% C510

056-001-000003 100nF-0603 X7R,50V,10% C513

056-001-000003 100nF-0603 X7R,50V,10% C515

056-001-000003 100nF-0603 X7R,50V,10% C516

056-001-000003 100nF-0603 X7R,50V,10% C517

056-001-000003 100nF-0603 X7R,50V,10% C518

056-001-000003 100nF-0603 X7R,50V,10% C519

056-001-000003 100nF-0603 X7R,50V,10% C602

63

056-001-000003 100nF-0603 X7R,50V,10% C603

056-001-000003 100nF-0603 X7R,50V,10% C604

056-001-000003 100nF-0603 X7R,50V,10% C605

056-001-000003 100nF-0603 X7R,50V,10% C606

056-001-000003 100nF-0603 X7R,50V,10% C607

056-001-000003 100nF-0603 X7R,50V,10% C608

056-001-000003 100nF-0603 X7R,50V,10% C609

056-001-000003 100nF-0603 X7R,50V,10% C610

056-001-000003 100nF-0603 X7R,50V,10% C611

056-001-000003 100nF-0603 X7R,50V,10% C620

056-001-000003 100nF-0603 X7R,50V,10% C621

056-001-000003 100nF-0603 X7R,50V,10% C622

056-001-000003 100nF-0603 X7R,50V,10% C623

056-001-000003 100nF-0603 X7R,50V,10% C803

056-001-000003 100nF-0603 X7R,50V,10% C805

056-001-000003 100nF-0603 X7R,50V,10% C808

056-001-000003 100nF-0603 X7R,50V,10% C810

056-001-000003 100nF-0603 X7R,50V,10% C901

056-001-000003 100nF-0603 X7R,50V,10% C902

056-001-000003 100nF-0603 X7R,50V,10% C906

056-001-000003 100nF-0603 X7R,50V,10% C907

056-001-000004 1nF-0805 X7R,200V,10% C302

056-001-000005 220pF-0603 NPO,5%,50V C401

056-001-000006 47pF-0603 NPO,5%,50V C1311

056-001-000006 47pF-0603 NPO,5%,50V C512

056-001-000006 47pF-0603 NPO,5%,50V C806

056-001-000006 47pF-0603 NPO,5%,50V C807

056-001-000007 470pF-0603 NPO,50v,5% C1621

056-001-000007 470pF-0603 NPO,50v,5% C1706

056-001-000007 470pF-0603 NPO,50v,5% C1904

056-001-000009 680pF-0603 NPO,50V,1% C613

056-001-00000B 10nF-0603 X7R,50V,10% C1007

056-001-00000B 10nF-0603 X7R,50V,10% C1008

056-001-00000B 10nF-0603 X7R,50V,10% C1514

056-001-00000B 10nF-0603 X7R,50V,10% C2002

056-001-00000B 10nF-0603 X7R,50V,10% C804

056-001-00000B 10nF-0603 X7R,50V,10% C812

056-001-00000D 3.3nF-0603 X7R,50V,10% C1903

056-001-00000D 3.3nF-0603 X7R,50V,10% C617

056-001-00000E 68pF-0603 NPO,50V,5% C2250

64

056-001-00000F 1.8nF-0603 X7R,50V,10% C624

056-001-00000H 100pF-0603 NPO,50V,5% C1310

056-001-00000H 100pF-0603 NPO,50V,5% C1623

056-001-00000H 100pF-0603 NPO,50V,5% C1624

056-001-00000H 100pF-0603 NPO,50V,5% C1625

056-001-00000H 100pF-0603 NPO,50V,5% C1626

056-001-00000H 100pF-0603 NPO,50V,5% C1627

056-001-00000H 100pF-0603 NPO,50V,5% C1628

056-001-00000H 100pF-0603 NPO,50V,5% C1629

056-001-00000H 100pF-0603 NPO,50V,5% C1630

056-001-00000H 100pF-0603 NPO,50V,5% C1631

056-001-00000H 100pF-0603 NPO,50V,5% C1632

056-001-00000H 100pF-0603 NPO,50V,5% C1633

056-001-00000H 100pF-0603 NPO,50V,5% C1634

056-001-00000H 100pF-0603 NPO,50V,5% C1635

056-001-00000H 100pF-0603 NPO,50V,5% C1636

056-001-00000H 100pF-0603 NPO,50V,5% C1637

056-001-00000H 100pF-0603 NPO,50V,5% C1638

056-001-00000H 100pF-0603 NPO,50V,5% C1639

056-001-00000H 100pF-0603 NPO,50V,5% C1640

056-001-00000H 100pF-0603 NPO,50V,5% C1641

056-001-00000H 100pF-0603 NPO,50V,5% C1642

056-001-00000H 100pF-0603 NPO,50V,5% C1643

056-001-00000H 100pF-0603 NPO,50V,5% C1644

056-001-00000H 100pF-0603 NPO,50V,5% C1906

056-001-00000H 100pF-0603 NPO,50V,5% C1907

056-001-00000H 100pF-0603 NPO,50V,5% C1908

056-001-00000H 100pF-0603 NPO,50V,5% C1909

056-001-00000H 100pF-0603 NPO,50V,5% C2104

056-001-00000H 100pF-0603 NPO,50V,5% C2105

056-001-00000H 100pF-0603 NPO,50V,5% C2244

056-001-00000H 100pF-0603 NPO,50V,5% C2245

056-001-00000H 100pF-0603 NPO,50V,5% C2246

056-001-00000H 100pF-0603 NPO,50V,5% C2247

056-001-00000H 100pF-0603 NPO,50V,5% C2248

056-001-00000H 100pF-0603 NPO,50V,5% C903

056-001-00000H 100pF-0603 NPO,50V,5% C904

056-001-00000H 100pF-0603 NPO,50V,5% C905

056-001-00000I 2.2uF-0805 Y5V,16V,Z% C1212

056-001-00000j 2.2nF-0603 X7R,50V,10% C1312

65

056-001-00000K 10pF-0603 NPO,50V,5% C1503

056-001-00000K 10pF-0603 NPO,50V,5% C1505

056-001-00000K 10pF-0603 NPO,50V,5% C1507

056-001-00000K 10pF-0603 NPO,50V,5% C1509

056-001-00000K 10pF-0603 NPO,50V,5% C1511

056-001-00000K 10pF-0603 NPO,50V,5% C638

056-001-00000M 33pF-0603 NPO,50V,5% C1105

056-001-00000M 33pF-0603 NPO,50V,5% C1619

056-001-00000M 33pF-0603 NPO,50V,5% C1620

056-001-00000M 33pF-0603 NPO,50V,5% C627

056-001-00000N 10uF-0805 X5R,10V,10% C1512

056-001-00000N 10uF-0805 X5R,10V,10% C1513

056-001-00000N 10uF-0805 X5R,10V,10% C1704

056-001-00000N 10uF-0805 X5R,10V,10% C1705

056-001-00000O 4.7nF-0603 X7R,50V,10% C1901

056-001-00000P 56pF-0603 NPO,50V,5% C2102

056-001-00000P 56pF-0603 NPO,50V,5% C2103

056-001-00000q 100nF-0805 X7R,50V,10% C2201

056-001-00000q 100nF-0805 X7R,50V,10% C2209

056-001-00000q 100nF-0805 X7R,50V,10% C2237

056-001-00000S 33nF-0603 X7R,16V,10% C1009

056-001-00000S 33nF-0603 X7R,16V,10% C1011

056-001-00000U 10nF-1812 X7R,1kV,10% C2238

056-001-00000U 10nF-1812 X7R,1kV,10% C2239

056-001-00000U 10nF-1812 X7R,1kV,10% C2240

056-001-00000U 10nF-1812 X7R,1kV,10% C2241

056-001-00000U 10nF-1812 X7R,1kV,10% C2242

056-001-00000U 10nF-1812 X7R,1kV,10% C2243

056-001-00000W 3.9pF-0603 NPO,50V,tolerance:0.1P C625

056-001-00000X 4.7pF-0603 NPO,50V,tolerance:0.1P C612

056-001-00000X 4.7pF-0603 NPO,50V,tolerance:0.1P C616

056-001-00000Z 68pF-0603 NPO,50V,1% C619

056-001-000010 220pF-0603 NPO,50V,1% C629

056-001-000011 470pF-0603 NPO,50V,1% C601

056-001-000012 24pF-0603 NPO,50V,1% C628

056-001-000013 68nF-0603 X7R,25V,10% C1010

056-001-000014 1uF-0805 Y5V,50V,Z% C2236

056-001-000016 1uF-0603 25V/X5R/10% C1203

056-001-000016 1uF-0603 25V/X5R/10% C1206

056-001-000016 1uF-0603 25V/X5R/10% C1209

66

056-001-000016 1uF-0603 25V/X5R/10% C1309

056-001-000016 1uF-0603 25V/X5R/10% C801

056-001-000016 1uF-0603 25V/X5R/10% C802

056-003-000001 1.8pF-1206 1000V C615

056-019-000001 TF811 U701

056-019-000002 TF812 U403

056-032-000002 10uF 10V,A-CASE C2204

056-032-000002 10uF 10V,A-CASE C2225

056-032-000002 10uF 10V,A-CASE C2228

056-032-000002 10uF 10V,A-CASE C2234

057-001-000001 GSNL453232-102K L301

057-001-000001 GSNL453232-102K L302

057-001-000004 BLM31PG391SN1L 1206 L2201

057-001-000004 BLM31PG391SN1L 1206 L2202

057-001-000004 BLM31PG391SN1L 1206 L2203

057-001-000004 BLM31PG391SN1L 1206 L2204

057-001-000005 GSNL453232-220K L303

057-003-000001 985BH-1007 L2101

057-009-000001 BLM18AG102SN1D 0603 L1301

057-009-000001 BLM18AG102SN1D 0603 L801

057-009-000001 BLM18AG102SN1D 0603 L802

057-009-000002 BLM18BD601SN1D 0603 L1201

057-009-000002 BLM18BD601SN1D 0603 L1202

057-009-000002 BLM18BD601SN1D 0603 L1203

057-009-000002 BLM18BD601SN1D 0603 L1204

057-009-000002 BLM18BD601SN1D 0603 L1205

057-009-000002 BLM18BD601SN1D 0603 L1206

057-009-000002 BLM18BD601SN1D 0603 L1207

057-009-000002 BLM18BD601SN1D 0603 L1208

057-009-000002 BLM18BD601SN1D 0603 L1401

057-009-000002 BLM18BD601SN1D 0603 L1402

057-009-000002 BLM18BD601SN1D 0603 L1403

057-009-000002 BLM18BD601SN1D 0603 L2104

057-009-000003 BLM21BD601SN1D 0805 L1901

057-009-000003 BLM21BD601SN1D 0805 L1902

057-009-000003 BLM21BD601SN1D 0805 L2102

057-009-000003 BLM21BD601SN1D 0805 L2103

057-018-000001 PESD5V0S1BA D1904

057-018-000001 PESD5V0S1BA D1905

057-018-000001 PESD5V0S1BA D2103

67

057-018-000001 PESD5V0S1BA D2104

057-018-000001 PESD5V0S1BA D2105

057-018-000001 PESD5V0S1BA D2214

057-018-000001 PESD5V0S1BA D2215

060-002-000001 24K-2512 tolerance:1%,1W R101

060-002-000001 24K-2512 tolerance:1%,1W R102

060-002-000001 24K-2512 tolerance:1%,1W R103

060-002-000001 24K-2512 tolerance:1%,1W R104

060-002-000001 24K-2512 tolerance:1%,1W R105

060-002-000001 24K-2512 tolerance:1%,1W R106

060-002-000001 24K-2512 tolerance:1%,1W R107

060-002-000001 24K-2512 tolerance:1%,1W R110

060-002-000001 24K-2512 tolerance:1%,1W R111

060-002-000001 24K-2512 tolerance:1%,1W R112

060-002-000001 24K-2512 tolerance:1%,1W R113

060-002-000001 24K-2512 tolerance:1%,1W R114

060-002-000001 24K-2512 tolerance:1%,1W R115

060-002-000001 24K-2512 tolerance:1%,1W R116

060-002-000002 1M-1206 tolerance:1%,1/4W R108

060-002-000002 1M-1206 tolerance:1%,1/4W R109

060-002-000003 10K-0603 tolerance:1%,1/10W R1106

060-002-000003 10K-0603 tolerance:1%,1/10W R119

060-002-000003 10K-0603 tolerance:1%,1/10W R1306

060-002-000003 10K-0603 tolerance:1%,1/10W R1614

060-002-000003 10K-0603 tolerance:1%,1/10W R1615

060-002-000003 10K-0603 tolerance:1%,1/10W R1616

060-002-000003 10K-0603 tolerance:1%,1/10W R1617

060-002-000003 10K-0603 tolerance:1%,1/10W R1618

060-002-000003 10K-0603 tolerance:1%,1/10W R1620

060-002-000003 10K-0603 tolerance:1%,1/10W R1901

060-002-000003 10K-0603 tolerance:1%,1/10W R2107

060-002-000003 10K-0603 tolerance:1%,1/10W R2108

060-002-000003 10K-0603 tolerance:1%,1/10W R2204

060-002-000003 10K-0603 tolerance:1%,1/10W R2218

060-002-000003 10K-0603 tolerance:1%,1/10W R515

060-002-000003 10K-0603 tolerance:1%,1/10W R516

060-002-000003 10K-0603 tolerance:1%,1/10W R901

060-002-000003 10K-0603 tolerance:1%,1/10W R908

060-002-000005 470R-1206 tolerance:1%,1/4W R120

060-002-000005 470R-1206 tolerance:1%,1/4W R121

68

060-002-000006 1K-0603 tolerance:1%,1/10W R1502

060-002-000006 1K-0603 tolerance:1%,1/10W R1503

060-002-000006 1K-0603 tolerance:1%,1/10W R1504

060-002-000006 1K-0603 tolerance:1%,1/10W R1505

060-002-000006 1K-0603 tolerance:1%,1/10W R1506

060-002-000006 1K-0603 tolerance:1%,1/10W R1619

060-002-000006 1K-0603 tolerance:1%,1/10W R1905

060-002-000006 1K-0603 tolerance:1%,1/10W R201

060-002-000006 1K-0603 tolerance:1%,1/10W R2011

060-002-000006 1K-0603 tolerance:1%,1/10W R2216

060-002-000006 1K-0603 tolerance:1%,1/10W R305

060-002-000006 1K-0603 tolerance:1%,1/10W R306

060-002-000006 1K-0603 tolerance:1%,1/10W R308

060-002-000006 1K-0603 tolerance:1%,1/10W R309

060-002-000006 1K-0603 tolerance:1%,1/10W R310

060-002-000006 1K-0603 tolerance:1%,1/10W R320

060-002-000006 1K-0603 tolerance:1%,1/10W R507

060-002-000006 1K-0603 tolerance:1%,1/10W R509

060-002-000006 1K-0603 tolerance:1%,1/10W R531

060-002-000006 1K-0603 tolerance:1%,1/10W R804

060-002-000006 1K-0603 tolerance:1%,1/10W R818

060-002-000006 1K-0603 tolerance:1%,1/10W R903

060-002-000007 100K-0603 tolerance:1%,1/10W R2009

060-002-000007 100K-0603 tolerance:1%,1/10W R203

060-002-000007 100K-0603 tolerance:1%,1/10W R205

060-002-000007 100K-0603 tolerance:1%,1/10W R2213

060-002-000007 100K-0603 tolerance:1%,1/10W R501

060-002-000007 100K-0603 tolerance:1%,1/10W R504

060-002-000007 100K-0603 tolerance:1%,1/10W R505

060-002-000007 100K-0603 tolerance:1%,1/10W R506

060-002-000007 100K-0603 tolerance:1%,1/10W R511

060-002-000007 100K-0603 tolerance:1%,1/10W R514

060-002-000007 100K-0603 tolerance:1%,1/10W R517

060-002-000009 3.24K-1206 tolerance:1%,1/4W R311

060-002-000009 3.24K-1206 tolerance:1%,1/4W R312

060-002-00000A 200K-2010 tolerance:1%,2W R313

060-002-00000A 200K-2010 tolerance:1%,2W R314

060-002-00000A 200K-2010 tolerance:1%,2W R315

060-002-00000A 200K-2010 tolerance:1%,2W R316

060-002-00000D 10K-0603(01%) TCR:25ppm R1312

69

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1203

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1204

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1205

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1303

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1601

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1604

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1606

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1607

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1608

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1609

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1611

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1612

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1621

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1622

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1623

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1702

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1703

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1704

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1705

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1706

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1707

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1708

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1709

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1710

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R1711

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R2101

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R2104

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R2105

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R2106

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R319

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R326

060-002-00000G 4.75K-0603 tolerance:1%,1/10W R406

060-002-00000H 3.32K-0603 tolerance:1%,1/10W R503

060-002-00000L 100R-0603 tolerance:1%,1/10W R1201

060-002-00000L 100R-0603 tolerance:1%,1/10W R1202

060-002-00000L 100R-0603 tolerance:1%,1/10W R1307

060-002-00000L 100R-0603 tolerance:1%,1/10W R1401

060-002-00000L 100R-0603 tolerance:1%,1/10W R1602

060-002-00000L 100R-0603 tolerance:1%,1/10W R2201

060-002-00000L 100R-0603 tolerance:1%,1/10W R525

70

060-002-00000L 100R-0603 tolerance:1%,1/10W R530

060-002-00000L 100R-0603 tolerance:1%,1/10W R902

060-002-00000L 100R-0603 tolerance:1%,1/10W R905

060-002-00000M 4.87K-0603 tolerance:1%,1/10W R1107

060-002-00000M 4.87K-0603 tolerance:1%,1/10W R518

060-002-00000M 4.87K-0603 tolerance:1%,1/10W R519

060-002-00000O 75K-0603 tolerance:1%,1/10W R1003

060-002-00000O 75K-0603 tolerance:1%,1/10W R604

060-002-00000P 21.5K-0603 tolerance:1%,1/10W R1001

060-002-00000P 21.5K-0603 tolerance:1%,1/10W R1904

060-002-00000P 21.5K-0603 tolerance:1%,1/10W R607

060-002-00000Q 215R-0603 tolerance:1%,1/10W R608

060-002-00000Q 215R-0603 tolerance:1%,1/10W R613

060-002-00000S 1.78K-0603 tolerance:1%,1/10W R612

060-002-00000S 1.78K-0603 tolerance:1%,1/10W R614

060-002-00000U 15K-0603 tolerance:1%,1/10W R1101

060-002-00000U 15K-0603 tolerance:1%,1/10W R616

060-002-00000V 80.6K-0603 tolerance:1%,1/10W R621

060-002-00000W 240K-0603 tolerance:1%,1/10W R618

060-002-00000X 68.1K-0603 tolerance:1%,1/10W R619

060-002-00000Y 56.2K-0603 tolerance:1%,1/10W R620

060-002-00000Z 422R-0603 tolerance:1%,1/10W R801

060-002-00000Z 422R-0603 tolerance:1%,1/10W R815

060-002-000010 4.99K-0603 tolerance:1%,1/10W R1008

060-002-000010 4.99K-0603 tolerance:1%,1/10W R802

060-002-000010 4.99K-0603 tolerance:1%,1/10W R813

060-002-000011 3.57K-0603 tolerance:1%,1/10W R803

060-002-000011 3.57K-0603 tolerance:1%,1/10W R817

060-002-00001A 392R-0603 tolerance:1%,1/10W R906

060-002-00001B 3.83K-0603 tolerance:1%,1/10W R1002

060-002-00001D 200R-0603 tolerance:1%,1/10W R2005

060-002-00001D 200R-0603 tolerance:1%,1/10W R2006

060-002-00001F 49.9K-0603 tolerance:1%,1/10W R1310

060-002-00001F 49.9K-0603 tolerance:1%,1/10W R2211

060-002-00001G 34K-0603 tolerance:1%,1/10W R1302

060-002-00001H 2.21K-0603 tolerance:1%,1/10W R1103

060-002-00001H 2.21K-0603 tolerance:1%,1/10W R1304

060-002-00001H 2.21K-0603 tolerance:1%,1/10W R1305

060-002-00001J 221R-0603 tolerance:1%,1/10W R1309

060-002-00001J 221R-0603 tolerance:1%,1/10W R1903

71

060-002-00001L 47.5K-0603 tolerance:1%,1/10W R2001

060-002-00001L 47.5K-0603 tolerance:1%,1/10W R2002

060-002-00001M 100R-1206 tolerance:1%,1/4W R1902

060-002-00001M 100R-1206 tolerance:1%,1/4W R2109

060-002-00001M 100R-1206 tolerance:1%,1/4W R2110

060-002-00001O 1K-1206 tolerance:1%,1/4W R1906

060-002-00001P 22.1K-0603 tolerance:1%,1/10W R2003

060-002-00001P 22.1K-0603 tolerance:1%,1/10W R2004