Page 1

PicoLog® 1000 Series

USB Data Loggers

Programmer's Guide

pl1000pg r7

Page 2

Page 3

Contents

1 Introduction ......................................................................................................................... 1

1 Overview ................................................................................................................................................. 1

2 Software license conditions .................................................................................................................. 2

3 Trademarks ............................................................................................................................................ 2

2 Getting started .................................................................................................................... 3

1 About the driver ...................................................................................................................................... 3

2 Installing the driver ................................................................................................................................. 3

3 Connecting the logger ............................................................................................................................ 3

4 USB ADC-11 compatibility mode ........................................................................................................... 3

3 Technical reference ............................................................................................................ 5

1 Capture modes ....................................................................................................................................... 5

2 Scaling .................................................................................................................................................... 5

4 Driver routines .................................................................................................................... 6

IPicoLog 1000 Series Programmer's Guide

1 Summary ................................................................................................................................................. 6

2 pl1000CloseUnit() - close the unit ......................................................................................................... 7

3 pl1000GetSingle() - get a single value from a specified channel ........................................................ 8

4 pl1000GetUnitInfo() - return information about the unit ...................................................................... 9

5 pl1000GetValues() - get a number of sample values after a run ...................................................... 10

6 pl1000MaxValue() - return the maximum ADC value ......................................................................... 11

7 pl1000OpenUnit() - open and enumerate the unit .............................................................................. 12

8 pl1000OpenUnitAsync() - open the unit without waiting for completion .......................................... 13

9 pl1000OpenUnitProgress() - report progress of pl1000OpenUnitAsync() ........................................ 14

10 pl1000PingUnit() - check that the unit is responding ...................................................................... 15

11 pl1000Ready() - indicate when pl1000Run() has captured data ..................................................... 16

12 pl1000Run() - tell the unit to start capturing data ............................................................................ 17

13 pl1000SetDo() - control the digital outputs on the unit ................................................................... 18

14 pl1000SetInterval() - set the sampling speed of the unit ................................................................ 19

15 pl1000SetPulseWidth() - configure the PWM output ....................................................................... 20

16 pl1000SetTrigger() - set the trigger on the unit ................................................................................ 21

17 pl1000Stop() - abort data collection ................................................................................................. 22

18 PICO_STATUS values ......................................................................................................................... 23

5 Glossary ............................................................................................................................ 25

Index ..................................................................................................................................... 27

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 4

Page 5

PicoLog 1000 Series Programmer's Guide 1

Version

Part No.

Resolution

Channels

PicoLog 1012

PP543

10 bits

12

PicoLog 1216

PP544

12 bits

16

1 Introduction

1.1 Overview

The PicoLog 1000 Series PC Data Loggers are medium-speed, multichannel

voltage-input devices for sampling analog data using a PC. This manual

explains how to use the Application Programming Interface to write your

own programs to control the unit. You should read it in conjunction with the

PicoLog 1000 Series User's Guide.

The following PicoLog 1000 Series Data Loggers are available:

These devices can also be used with the PicoLog data logging software and the PicoScope oscilloscope

software.

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 6

Introduction2

1.2 Software license conditions

The material contained in this release is licensed, not sold. Pico Technology Limited grants a license to the

person who installs this software, subject to the conditions listed below.

Access. The licensee agrees to allow access to this software only to persons who have been informed of

these conditions and agree to abide by them.

Usage. The software in this release is for use only with Pico products or with data collected using Pico

products.

Copyright. Pico Technology Ltd. claims the copyright of, and retains the rights to, all material (software,

documents, etc.) contained in this SDK except the example programs. You may copy and distribute the SDK

without restriction, as long as you do not remove any Pico Technology copyright statements. The example

programs in the SDK may be modified, copied and distributed for the purpose of developing programs to

collect data using Pico products.

Liability. Pico Technology and its agents shall not be liable for any loss, damage or injury, howsoever

caused, related to the use of Pico Technology equipment or software, unless excluded by statute.

Fitness for purpose. As no two applications are the same, Pico Technology cannot guarantee that its

equipment or software is suitable for a given application. It is your responsibility, therefore, to ensure that

the product is suitable for your application.

Mission-critical applications. This software is intended for use on a computer that may be running other

software products. For this reason, one of the conditions of the license is that it excludes use in missioncritical applications, for example life support systems.

Viruses. This software was continuously monitored for viruses during production, but you are responsible

for virus-checking the software once it is installed.

Support. If you are dissatisfied with the performance of this software, please contact our technical support

staff, who will try to fix the problem within a reasonable time. If you are still dissatisfied, please return the

product and software to your supplier within 14 days of purchase for a full refund.

Upgrades. We provide upgrades, free of charge, from our web site at www.picotech.com. We reserve the

right to charge for updates or replacements sent out on physical media.

1.3 Trademarks

Pico Technology, PicoLog and PicoScope are trademarks of Pico Technology Limited, registered in the

United Kingdom and other countries.

PicoScope and Pico Technology are registered in the U.S. Patent and Trademark Office.

Windows is a registered trademark of Microsoft Corporation in the USA and other countries.

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 7

PicoLog 1000 Series Programmer's Guide 3

2 Getting started

2.1 About the driver

The PicoLog 1000 Series units are supplied with a kernel driver and a DLL containing routines that you can

call from your own programs. The drivers are supported by the following operating systems:

·

Windows 7

·

Windows 8

·

Windows 10

The PicoSDK containing the drivers is available in 32-bit and 64-bit versions from

www.picotech.com/downloads. The 32-bit driver will run on a 64-bit Windows system if you write a 32-bit

application and run it under WoW64.

The DLL can be used with any programming language or application that can interface with DLLs: for

example, C, Visual Basic for Applications (VBA) and LabVIEW. Example code is available in numerous

repositories under the "picotech" organisation on GitHub. Some of these examples are fairly simple, but the

C console mode example, pl1000con.c, demonstrates most of the facilities available in the driver.

The driver supports up to 64 USB units at one time.

2.2 Installing the driver

The driver is included in PicoSDK, which you can download from www.picotech.com/downloads.

Select PicoLog Data Loggers > PicoLog 1012 or PicoLog 1216 > Software > PicoSDK.

2.3 Connecting the logger

Before you connect your logger, please install the driver software.

To connect the data logger, plug the cable provided into any available USB port on your PC. The first time

you connect the unit, Windows may display a New Hardware Wizard. Follow any instructions in the Wizard

and wait for the driver to be installed. Later versions of Windows display an Installing new hardware

message and complete the process automatically. The unit is then ready for use.

2.4 USB ADC-11 compatibility mode

The PicoLog 1000 Series data loggers may be used as replacements for the USB ADC-11, an 11-channel

data logger previously available from Pico Technology. The 1000 Series units have all the functions of the

USB ADC-11 and some extra functions such as extra digital outputs, a PWM output and a sensor power

output.

The 1000 Series units are API-compatible with the USB ADC-11. This means that any programs that you

have already written do not need to be changed or recompiled - you simply need to update the

usbadc11.dll to the latest version supplied in PicoSDK. The 1000 Series unit will behave like a USB ADC-

11 and the extra outputs (pins 15 to 25) will be internally disconnected. You can continue to use the unit with

an old ADC-11 terminal board if you have one, or you can switch to the new Small Terminal Board (PP545).

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 8

Getting started4

If you wish to use the extra functions of the 1000 Series units, you must rewrite your application to use the

new PicoLog 1000 Series DLL (pl1000.dll), which is described in this manual and is available free of

charge from Pico Technology. Example code is available to help you make the transition.

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 9

PicoLog 1000 Series Programmer's Guide 5

3 Technical reference

3.1 Capture modes

Three modes are available for capturing data:

·

BM_SINGLE: collect a single block of data and exit

·

BM_WINDOW: collect a series of overlapping blocks of data

·

BM_STREAM: collect a continuous stream of data

BM_SINGLE is useful when you wish to collect data at high speed for a short period: for example, to collect

1000 readings in 50 milliseconds. The maximum capture size in this mode is 1 million samples.

BM_WINDOW is useful when collecting several blocks of data at low speeds - for example when collecting

10,000 samples over 10 seconds. Collecting a sequence of single blocks like this would take 10 seconds for

each block, so displayed data would not be updated frequently. Using windowing, it is possible to ask for a

new block more frequently, for example every second, and to receive a block containing 9 seconds of repeat

data and 1 second of new data. The block is effectively a 10-second window that advances one second per

cycle.

BM_STREAM is useful when you need to collect data continuously for long periods. In principle, it could be

used to collect data indefinitely. Every time pl1000GetValues() is called, it returns the new readings

since the last time it was called. The noOfValues argument passed to pl1000Run() must be sufficient to

ensure that the buffer does not overflow between successive calls to pl1000GetValues(). For example, if

you call pl1000GetValues() every second and you are collecting 500 samples per second, noOfValues

must be at least 500, or preferably 1000, to allow for delays in the operating system.

3.2 Scaling

The PicoLog 1000 Series devices produce values in the range 0 to maxValue, where maxValue is the value

returned by pl1000MaxValue(). To convert ADC readings to volts, multiply by 2.5 and divide by

maxValue.

For example, maxValue for the PicoLog 1216 is 4095. Therefore, an ADC reading of 132 from this device

from a represents 132 x 2.5 / 4095 = approx. 0.0806 volts.

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 10

Driver routines6

4 Driver routines

4.1 Summary

The driver routines in the PicoLog 1000 Series API are listed, with short descriptions, in the Table of

Contents at the start of this manual.

The driver allows you to do the following:

·

Identify and open the logger

·

Take a single reading from a particular channel

·

Collect a block of samples at fixed time intervals from one or more channels

·

Set up a trigger event for a particular channel

You can specify a sampling interval from 1 microsecond to 1 second. The shortest interval that the driver

will accept depends on the capture mode selected.

The normal calling sequence to collect a block of data is as follows:

Check that the driver version is correct

Open the driver

Set trigger mode (if required)

Set sampling mode (channels and time per sample)

While you want to take measurements,

Run

While not ready

Wait

End while

... Get a block of data ...

End While

Close the driver (this happens automatically when the application terminates)

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 11

PicoLog 1000 Series Programmer's Guide 7

4.2 pl1000CloseUnit() - close the unit

PICO_STATUS pl1000CloseUnit

(

int16_t handle

)

This function closes the unit.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

Returns:

PICO_OK

PICO_HANDLE_INVALID

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 12

Driver routines8

4.3 pl1000GetSingle() - get a single value from a specified channel

PICO_STATUS pl1000GetSingle

(

int16_t handle,

PL1000_INPUTS channel,

uint16_t * value

)

This function returns a single sample value from the specified input channel.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

channel, which channel to sample:

[PL1000_CHANNEL_1 to PL1000_CHANNEL_12] (PicoLog 1012)

[PL1000_CHANNEL_1 to PL1000_CHANNEL_16] (PicoLog 1216)

value, a location where the function will write the sample value

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NO_SAMPLES_AVAILABLE

PICO_DEVICE_SAMPLING

PICO_NULL_PARAMETER

PICO_INVALID_PARAMETER

PICO_DATA_NOT_AVAILABLE

PICO_INVALID_CALL

PICO_NOT_RESPONDING

PICO_MEMORY

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 13

PicoLog 1000 Series Programmer's Guide 9

4.4 pl1000GetUnitInfo() - return information about the unit

PICO_STATUS pl1000GetUnitInfo

(

int16_t handle,

int8_t * string,

int16_t stringLength,

int16_t * requiredSize,

PICO_INFO info

)

This function returns a string containing the specified item of information about the unit.

If you want to find out the length of the string before allocating a buffer for it, call the function with string

= NULL first.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

string, a location where the function writes the requested information, or NULL if you are only interested

in the value of requiredSize

stringLength, the maximum number of characters that the function should write to string

requiredSize, a location where the function writes the length of the information string before it was

truncated to stringLength. If the string was not truncated, requiredSize will be less than or equal to

stringLength.

info, the information that the driver should return. These values are specified in PicoStatus.h:

PICO_DRIVER_VERSION

PICO_USB_VERSION

PICO_HARDWARE_VERSION

PICO_VARIANT_INFO

PICO_BATCH_AND_SERIAL

PICO_CAL_DATE

PICO_KERNEL_DRIVER_VERSION

PICO_FIRMWARE_VERSION_1

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NULL_PARAMETER

PICO_INVALID_INFO

PICO_INFO_UNAVAILABLE

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 14

Driver routines10

4.5 pl1000GetValues() - get a number of sample values after a run

PICO_STATUS pl1000GetValues

(

int16_t handle,

uint16_t * values,

uint32_t * noOfValues,

uint16_t * overflow,

uint32_t * triggerIndex

)

This function is used to get values after calling pl1000Run().

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

values, an array of sample values returned by the function. The size of this buffer must be the number of

enabled channels multiplied by the number of samples to be collected.

noOfValues, on entry, the number of sample values per channel that the function should collect. On exit,

the number of samples per channel that were actually written to the buffer.

overflow, on exit, a bit field indicating which, if any, input channels overflowed the input range of the

device. A bit set to 1 indicates an overflow. The least significant bit corresponds to channel 1. May be NULL

if an overflow warning is not required.

triggerIndex, on exit, a number indicating when the trigger event occurred. The number is a zero-based

index to the values array, or 0xffffffff if the information is not available. On entry, the pointer may be

NULL if a trigger index is not required.

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NO_SAMPLES_AVAILABLE

PICO_DEVICE_SAMPLING

PICO_NULL_PARAMETER

PICO_INVALID_PARAMETER

PICO_TOO_MANY_SAMPLES

PICO_DATA_NOT_AVAILABLE

PICO_INVALID_CALL

PICO_NOT_RESPONDING

PICO_MEMORY

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 15

PicoLog 1000 Series Programmer's Guide 11

4.6 pl1000MaxValue() - return the maximum ADC value

PICO_STATUS pl1000MaxValue

(

int16_t handle,

uint16_t * maxValue

)

This function returns the maximum ADC value that the device will return. This value may be different on

different models in the PicoLog 1000 Series.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

maxValue, a location where the function will write the maximum ADC value

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NULL_PARAMETER

PICO_INVALID_PARAMETER

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 16

Driver routines12

4.7 pl1000OpenUnit() - open and enumerate the unit

PICO_STATUS pl1000OpenUnit

(

int16_t * handle

)

This function opens and enumerates the unit.

Arguments:

handle, the function will write a value here that uniquely identifies the data logger that was opened. Use

this as the handle parameter when calling any other PicoLog 1000 Series API function.

Returns:

PICO_OK

PICO_OS_NOT_SUPPORTED

PICO_OPEN_OPERATION_IN_PROGRESS

PICO_EEPROM_CORRUPT

PICO_KERNEL_DRIVER_TOO_OLD

PICO_FW_FAIL

PICO_MAX_UNITS_OPENED

PICO_NOT_FOUND

PICO_NOT_RESPONDING

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 17

PicoLog 1000 Series Programmer's Guide 13

4.8 pl1000OpenUnitAsync() - open the unit without waiting for completion

PICO_STATUS pl1000OpenUnitAsync

(

int16_t * status

)

This function opens a PicoLog 1000 Series data logger without waiting for the operation to finish. You can

find out when it has finished by periodically calling pl1000OpenUnitProgress() until that function

returns a non-zero value and a valid data logger handle.

The driver can support up to 64 data loggers.

Arguments:

status, a location where the function writes a status flag:

0: if there is already an open operation in progress

1: if the open operation is initiated

Returns:

PICO_OK

PICO_OPEN_OPERATION_IN_PROGRESS

PICO_OPERATION_FAILED

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 18

Driver routines14

4.9 pl1000OpenUnitProgress() - report progress of pl1000OpenUnitAsync()

PICO_STATUS pl1000OpenUnitProgress

(

int16_t * handle,

int16_t * progress,

int16_t * complete

)

This function checks on the progress of pl1000OpenUnitAsync().

Arguments:

handle, a pointer to where the function should store the device identifier of the opened data logger, if the

operation was successful. Use this as the handle parameter when calling any other PicoLog 1000 Series

API function.

0: if no unit is found or the unit fails to open

<>0: handle of unit (valid only if function returns PICO_OK)

progress, a location where the function writes an estimate of the progress towards opening the data

logger. The value is between 0 and 100.

complete, a location where the function will write a non-zero value if the operation has completed

Returns:

PICO_OK

PICO_NULL_PARAMETER

PICO_OPERATION_FAILED

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 19

PicoLog 1000 Series Programmer's Guide 15

4.10 pl1000PingUnit() - check that the unit is responding

PICO_STATUS pl1000PingUnit

(

int16_t handle

)

This function can be used to check that the already opened device is still connected to the USB port and

communication is successful.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_DRIVE_FUNCTION

PICO_BUSY

PICO_NOT_RESPONDING

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 20

Driver routines16

4.11 pl1000Ready() - indicate when pl1000Run() has captured data

PICO_STATUS pl1000Ready

(

int16_t handle,

int16_t * ready

)

This function indicates when pl1000Run() has captured the requested number of samples.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

ready, TRUE if ready, FALSE otherwise

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NOT_RESPONDING

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 21

PicoLog 1000 Series Programmer's Guide 17

4.12 pl1000Run() - tell the unit to start capturing data

PICO_STATUS pl1000Run

(

int16_t handle,

uint32_t no_of_values,

BLOCK_METHOD method

)

This function tells the unit to start capturing data.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

no_of_values, the total number of samples to be collected per channel

method, which method to use to collect the data, from the following list:

BM_SINGLE

BM_WINDOW

BM_STREAM

See Capture modes for details.

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_USER_CALLBACK

PICO_INVALID_CHANNEL

PICO_TOO_MANY_SAMPLES

PICO_INVALID_TIMEBASE

PICO_NOT_RESPONDING

PICO_CONFIG_FAIL

PICO_INVALID_PARAMETER

PICO_NOT_RESPONDING

PICO_TRIGGER_ERROR

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 22

Driver routines18

4.13 pl1000SetDo() - control the digital outputs on the unit

PICO_STATUS pl1000SetDo

(

int16_t handle,

int16_t do_value,

int16_t doNo

)

This function controls the digital outputs DO0 to DO3 on the unit.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

do_value, whether to switch the output on or off:

1 - turns the digital output on

0 - turns the digital output off

doNo, which output to switch:

[PL1000_DO_CHANNEL_0 to PL1000_DO_CHANNEL_3]

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_NOT_RESPONDING

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 23

PicoLog 1000 Series Programmer's Guide 19

4.14 pl1000SetInterval() - set the sampling speed of the unit

PICO_STATUS pl1000SetInterval

(

int16_t handle,

uint32_t * us_for_block,

uint32_t ideal_no_of_samples,

int16_t * channels,

int16_t no_of_channels

)

This function sets the sampling rate of the unit.

Call this function with us_for_block set to the number of microseconds in which you wish to capture the

entire requested data set. The function will return the actual number of microseconds the operation will

take. You can then calculate the sampling interval i as follows:

in BM_SINGLE mode*:

i = 1 µs x us_for_block / (ideal_no_of_samples x no_of_channels)

in other modes:

i = 10 µs x us_for_block / (ideal_no_of_samples x no_of_channels)

* BM_SINGLE mode can achieve sampling intervals down to 1 µs when ideal_no_of_samples x

no_of_channels is no more than 8192. Under all other conditions, the fastest possible sampling interval

is 10 µs per channel and ideal_no_of_samples x no_of_channels may be anything up to 1000000.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

us_for_block, on entry: the target total time in which to collect (ideal_no_of_samples *

no_of_channels) samples, in microseconds; on exit: the time the driver will actually take to achieve this.

ideal_no_of_samples, the number of samples that you want to collect per channel. This number is

used only for timing calculations.

channels, an array of numbers identifying the channels from which you wish to capture:

[PL1000_CHANNEL_1 to PL1000_CHANNEL_12] (PicoLog 1012)

[PL1000_CHANNEL_1 to PL1000_CHANNEL_16] (PicoLog 1216)

Sampling of multiple channels is sequential.

no_of_channels, the number of channels in the channels array

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_INVALID_CHANNEL

PICO_INVALID_TIMEBASE

PICO_NOT_RESPONDING

PICO_CONFIG_FAIL

PICO_INVALID_PARAMETER

PICO_NOT_RESPONDING

PICO_TRIGGER_ERROR

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 24

Driver routines20

4.15 pl1000SetPulseWidth() - configure the PWM output

PICO_STATUS pl1000SetPulseWidth

(

int16_t handle,

uint16_t period,

uint8_t cycle

)

This function sets the pulse width of the PWM (pulse-width modulated) output.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

period, the required period of the PWM waveform in microseconds, from 100 to 1800

cycle, the required duty cycle as a percentage from 0 to 100

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_SIG_GEN_PARAM

PICO_NOT_RESPONDING

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 25

PicoLog 1000 Series Programmer's Guide 21

4.16 pl1000SetTrigger() - set the trigger on the unit

PICO_STATUS pl1000SetTrigger

(

int16_t handle,

uint16_t enabled,

uint16_t auto_trigger,

uint16_t auto_ms,

uint16_t channel,

uint16_t dir,

uint16_t threshold,

uint16_t hysteresis,

float delay

)

This function sets up the trigger, which controls when the unit starts capturing data.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

enabled, whether to enable or disable the trigger:

0: disable the trigger

1: enable the trigger

auto_trigger, whether to rearm the trigger automatically after each trigger event:

0: do not auto-trigger

1: auto-trigger

auto_ms, time in milliseconds after which the unit will auto-trigger if the trigger condition is not met

channel, which channel to trigger on:

[PL1000_CHANNEL_1 to PL1000_CHANNEL_12] (PicoLog 1012)

[PL1000_CHANNEL_1 to PL1000_CHANNEL_16] (PicoLog 1216)

dir, which edge to trigger on:

0: rising edge

1: falling edge

threshold, trigger threshold (the level at which the trigger will activate) in ADC counts

hysteresis, trigger hysteresis in ADC counts. This is the difference between the upper and lower

thresholds. The signal must then pass through both thresholds in the same direction in order to activate the

trigger, so that there are fewer unwanted trigger events caused by noise. The minimum value allowed is 1.

delay, delay between the trigger event and the start of the block as a percentage of the block size. 0%

means that the trigger event is the first data value in the block, and -50% means that the trigger event is in

the middle of the block.

Returns:

PICO_OK

PICO_INVALID_HANDLE

PICO_USER_CALLBACK

PICO_TRIGGER_ERROR

PICO_MEMORY_FAIL

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 26

Driver routines22

4.17 pl1000Stop() - abort data collection

PICO_STATUS pl1000Stop

(

int16_t handle

)

This function aborts data collection. It is the normal method of terminating BM_WINDOW and BM_STREAM

data collection. You can also call it to terminate a BM_SINGLE data collection early, but this will invalidate

any data that has been captured.

Arguments:

handle, device identifier returned by pl1000OpenUnit() or pl1000OpenUnitProgress()

Returns:

PICO_OK

PICO_INVALID_HANDLE

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 27

PicoLog 1000 Series Programmer's Guide 23

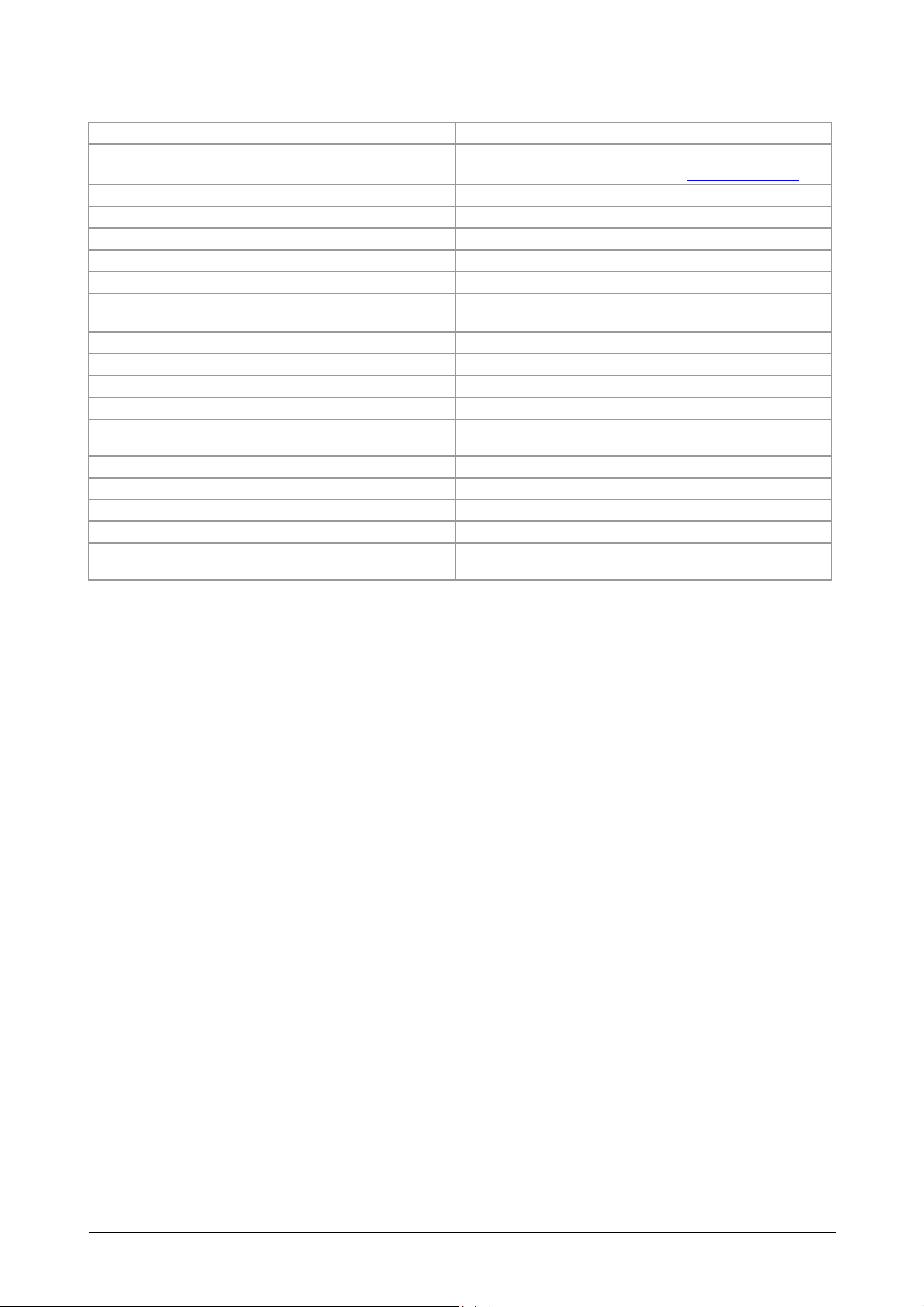

Code

(hex)

Enum

Description

00

PICO_OK

The Data Logger is functioning correctly

01

PICO_MAX_UNITS_OPENED

An attempt has been made to open more than 64 units

02

PICO_MEMORY_FAIL

Not enough memory could be allocated on the host

machine

03

PICO_NOT_FOUND

No PicoLog 1000 device could be found

04

PICO_FW_FAIL

Unable to download firmware

05

PICO_OPEN_OPERATION_IN_PROGRESS

A request to open a device is in progress

06

PICO_OPERATION_FAILED

The operation was unsuccessful

07

PICO_NOT_RESPONDING

The device is not responding to commands from the PC

08

PICO_CONFIG_FAIL

The configuration information in the device has become

corrupt or is missing

09

PICO_KERNEL_DRIVER_TOO_OLD

The picopp.sys file is too old to be used with the device

driver

0A

PICO_EEPROM_CORRUPT

The EEPROM has become corrupt, so the device will use a

default setting

0B

PICO_OS_NOT_SUPPORTED

The operating system on the PC is not supported by this

driver

0C

PICO_INVALID_HANDLE

There is no device with the handle value passed

0D

PICO_INVALID_PARAMETER

A parameter value is not valid

0E

PICO_INVALID_TIMEBASE

The timebase is not supported or is invalid

0F

PICO_INVALID_VOLTAGE_RANGE

The voltage range is not supported or is invalid

10

PICO_INVALID_CHANNEL

The channel number is not valid on this device or no

channels have been set

11

PICO_INVALID_TRIGGER_CHANNEL

The channel set for a trigger is not available on this device

12

PICO_INVALID_CONDITION_CHANNEL

The channel set for a condition is not available on this

device

13

PICO_NO_SIGNAL_GENERATOR

The device does not have a signal generator

14

PICO_STREAMING_FAILED

Streaming has failed to start or has stopped without user

request

15

PICO_BLOCK_MODE_FAILED

Block failed to start - a parameter may have been set

wrongly

16

PICO_NULL_PARAMETER

A parameter that was required is NULL

18

PICO_DATA_NOT_AVAILABLE

No data is available from a run block call

19

PICO_STRING_BUFFER_TOO_SMALL

The buffer passed for the information was too small

1A

PICO_ETS_NOT_SUPPORTED

ETS is not supported on this device

1B

PICO_AUTO_TRIGGER_TIME_TOO_SHORT

The auto trigger time is less than the time it will take to

collect the data

1C

PICO_BUFFER_STALL

The collection of data has stalled as unread data would be

overwritten

1D

PICO_TOO_MANY_SAMPLES

The number of samples requested is more than available in

the current memory segment

1E

PICO_TOO_MANY_SEGMENTS

Not possible to create number of segments requested

1F

PICO_PULSE_WIDTH_QUALIFIER

A null pointer has been passed in the trigger function or one

of the parameters is out of range

20

PICO_DELAY

One or more of the hold-off parameters are out of range

21

PICO_SOURCE_DETAILS

One or more of the source details are incorrect

4.18 PICO_STATUS values

Every function in the PicoLog 1000 Series API returns an error code from the following list of PICO_STATUS

values defined in PicoStatus.h:

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 28

Driver routines24

22

PICO_CONDITIONS

One or more of the conditions are incorrect

24

PICO_DEVICE_SAMPLING

An attempt is being made to get stored data while

streaming. Stop streaming by calling pl1000Stop().

25

PICO_NO_SAMPLES_AVAILABLE

...because a run has not been completed

26

PICO_SEGMENT_OUT_OF_RANGE

The memory index is out of range

27

PICO_BUSY

Data cannot be returned yet

28

PICO_STARTINDEX_INVALID

The start time to get stored data is out of range

29

PICO_INVALID_INFO

The information number requested is not a valid number

2A

PICO_INFO_UNAVAILABLE

The handle is invalid so no information is available about

the device. Only PICO_DRIVER_VERSION is available.

2B

PICO_INVALID_SAMPLE_INTERVAL

The sample interval selected for streaming is out of range

2C

PICO_TRIGGER_ERROR

Not used

2D

PICO_MEMORY

Driver cannot allocate memory

36

PICO_DELAY_NULL

NULL pointer passed as delay parameter

37

PICO_INVALID_BUFFER

The buffers for overview data have not been set while

streaming

3A

PICO_CANCELLED

A block collection has been canceled

3B

PICO_SEGMENT_NOT_USED

The segment index is not currently being used

3F

PICO_NOT_USED

The function is not available

41

PICO_INVALID_STATE

Device is in an invalid state

43

PICO_DRIVE_FUNCTION

You called a driver function while another driver function

was still being processed

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 29

PicoLog 1000 Series Programmer's Guide 25

5 Glossary

ADC. Analog to Digital Converter. An ADC samples analog signals and converts them to digital data for

storage and processing. It is an essential component of a data logger.

DLL. Dynamic Link Library. A file containing a collection of Windows functions designed to perform a

specific class of operations. A DLL is supplied with the PicoLog Data Loggers to enable you to control the

devices from your own programs.

Driver. A small program that acts as an interface, generally between a hardware component and a computer

program. The PicoLog Data Loggers require a USB driver that runs in the Windows kernel, and a second

driver in the form of a DLL that communicates with your application.

Maximum sampling rate. A figure indicating the maximum number of samples the ADC is capable of

acquiring per second. Maximum sample rates are usually given in S/s (samples per second). The higher the

sampling rate of the ADC, the more accurately it can represent the high-frequency details in a signal.

Streaming. An operating mode in which the ADC samples data and returns it to the computer in an unbroken

stream.

USB. Universal Serial Bus. This is a standard port that enables you to connect external devices to PCs. A fullspeed USB 2.0 port operates at up to 480 megabits per second. The PicoLog 1000 Series is also compatible

with any USB port from USB 1.1 upwards.

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 30

Page 31

PicoLog 1000 Series Programmer's Guide 27

Index

6

64-bit Windows 3

A

ADC value, maximum 11

ADC-11 compatibility 3

Asynchronous operation 5

B

BM_SINGLE mode 5

BM_STREAM mode 5

BM_WINDOW mode 5

C

Capture modes

BM_SINGLE 5

BM_STREAM 5

BM_WINDOW 5

Closing a unit 7

Connecting to the PC 3

D

Data, reading 8, 10

Digital outputs, setting 18

DLLs 3

Driver routines

pl1000CloseUnit 7

pl1000GetSingle 8

pl1000GetUnitInfo 9

pl1000GetValues 10

pl1000MaxValue 11

pl1000OpenUnit 12

pl1000OpenUnitAsync 13

pl1000OpenUnitProgress 14

pl1000Ready 16

pl1000Run 17

pl1000SetDo 18

pl1000SetInterval 19

pl1000SetPulseWidth 20

pl1000SetTrigger 21

pl1000Stop 22

summary 6

G

Glossary 25

I

Information on unit, obtaining 9

Installation 3

L

Legal information 2

M

Maximum ADC value 11

N

New Hardware Wizard 3

O

Opening a unit 12, 13, 14, 16

Overview 1

P

PicoLog 1000 Series SDK 3

Programming 3

Pulse width, setting 20

PWM output, setting up 20

R

Running a unit 17

S

Sampling interval, setting 19

Scaling 5

SDK 3

Software license conditions 2

Stopping a unit 22

Streaming 5

T

Trademarks 2

Trigger, setting 21

U

Unit information, obtaining 9

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved. pl1000pg r7

Page 32

USB ADC-11 compatibility 3

W

WoW64 3

Index28

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.pl1000pg r7

Page 33

US regional office:UK headquarters:

Asia-Pacific regional office:

Pico Technology

James House

Colmworth Business Park

St. Neots

Cambridgeshire

PE19 8YP

United Kingdom

Tel: +44 (0) 1480 396 395

Fax: +44 (0) 1480 396 296

sales@picotech.com

support@picotech.com

pl1000pg r7 2018-03-01

Copyright © 2013–2018 Pico Technology Ltd. All rights reserved.

Pico Technology

320 N Glenwood Blvd

Tyler

Texas 75702

United States

Tel: +1 800 591 2796

Fax: +1 620 272 0981

www.picotech.com

Pico Technology

Room 2252, 22/F, Centro

568 Hengfeng Road

Zhabei District

Shanghai 200070

PR China

Tel: +86 21 2226-5152

pico.china@picotech.com

Loading...

Loading...