Page 1

TRL calibration for SMT devices

using the PicoVNA 108

AR548-1

© Pico Technology 2021

1/12

Nils Nazoa

1. Introduction

The TRL (Thru-Reflect-Line) calibration technique (1) was originally developed as a way of

enhancing calibration accuracy in coaxial lines. The improvement is based on the fact that

the impedance reference is a coaxial air line, which can be manufactured very accurately

to provide a precise known impedance. The other calibration Standards required are a

zero-length through (very simple to implement) and a pair of high-reflection mismatches.

The latter do not need to be known accurately but need to provide the same value of

reflection.

The air line reference is required to provide a phase shift of significantly greater than 0º

and significantly less than 180º. This gives rise to the key difficulty with TRL. At lower

frequencies (i.e. longer wavelengths) it is not possible to obtain air lines that are long

enough to provide sufficient phase shift. In addition, the characteristic impedance of the

line becomes appreciably complex and frequency-dependent, due to skin depth effects.

In general, these problems start to become significant below approximately 1 GHz so the

easiest solution is to restrict the TRL technique to frequencies above 2 GHz, say.

TRL calibration lends itself well to characterizing surface mount devices. The air line is

replaced with a microstrip line whose characteristic impedance can be controlled and also

reasonably well measured at microwave frequencies. The Reflect Standards can be either

open circuits or short circuits, both easily implemented in surface mount technology.

2. TRL on a printed circuit board

As mentioned already, the TRL technique is well suited for implementing on a surface

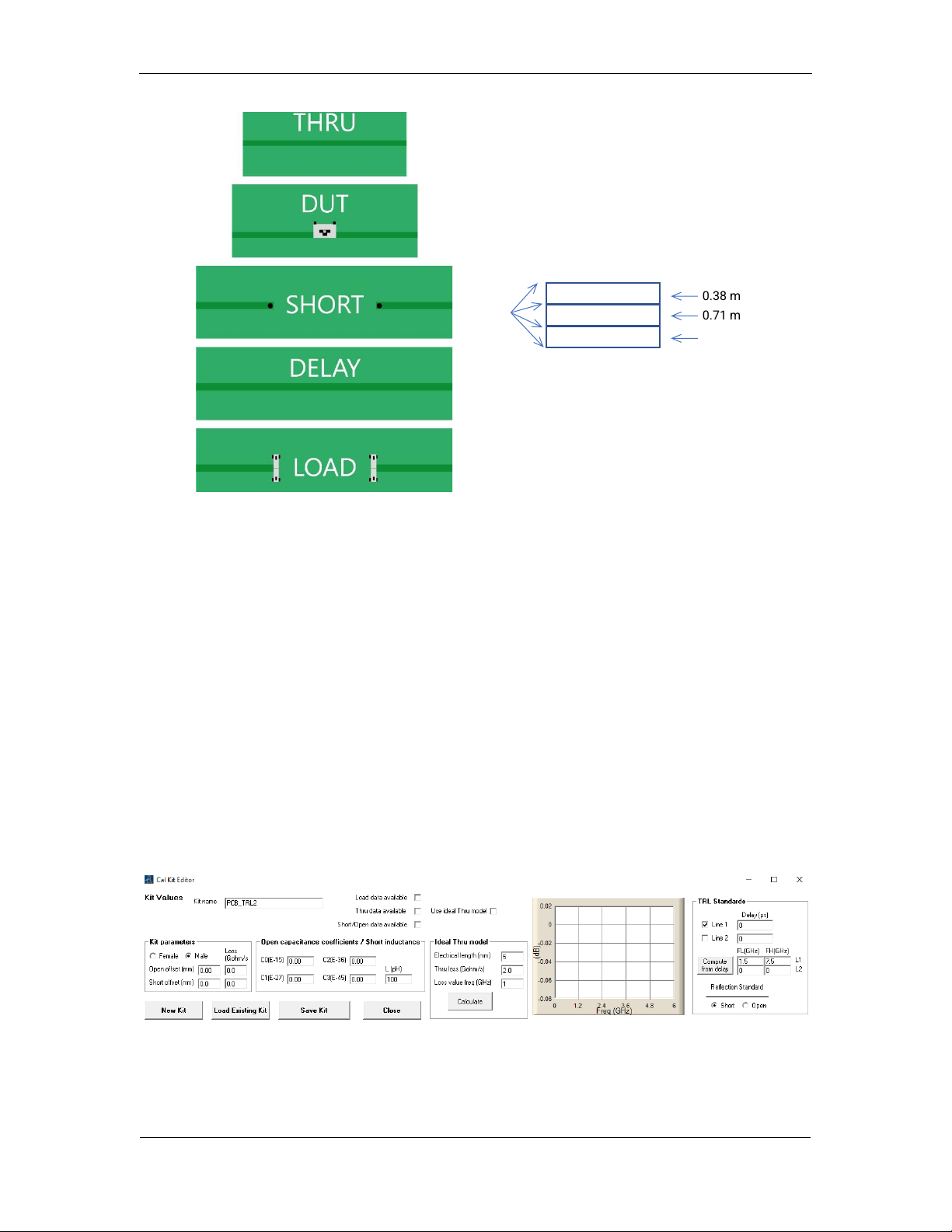

mount printed circuit board. The Standards are easy to define and implement. Fig. 1

shows the various components required, laid out on PCB. There are four 2-port circuit

blocks.

• Through line

• Reflect Standards (Shorts)

• Reference line (Delay)

• DUT (device under test)

Connections to each of the circuit blocks is by means of edge connectors. These must all

be identical and with complete soldering underneath to provide the best grounding. The

microstrip length, L, is not significant. It is chosen to be a convenient length to handle and

populate the board with the edge connectors. The short circuits are simply via-holes to

the ground plane.

Page 2

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

2/12

As an aid to clarity, Fig.1 includes the equivalent connections for TRL using coaxial

components. It is instructive to note where the measurement plane(s) is for each of the

Standard measurements illustrated in Fig. 1. Note particularly that the ‘Through’ is zero

length and equivalent to the coaxial ‘insertable’ Through connection which is zero length

and zero loss. For all calibration and DUT measurement steps, the measurement plane of

each of the instrument’s ports is on the PCB and, for this technique to work well, it is

critically important that all L/2 sections illustrated in Fig. 1 are made identical and that the

L/2 sections lengths are precisely half the length L of the Through.

Reference line length

It is generally recommended that the line length, L, is selected to provide no less than

20º and no more than 160º of phase shift with respect to the thru length over the band of

operation. In practice, best results are achieved by restricting the range to around 30º to

150º.

The required reference line length can be calculated as follows.

∆𝐿=

∅

360

(

𝑐

𝑓√ε

eff

)

∅ = phase shift in degrees

f = frequency

c = speed of light

ε

eff

= effective dielectric constant

Further, as mentioned already, it is sensible to avoid lower microwave frequencies in order

to avoid skin depth effects. So, keeping to 1.5 or 2 GHz and above may be a good idea.

Page 3

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

3/12

Figure 1: PCB circuit blocks for TRL calibration and measurement

For example, assuming a nominal 50 Ω line with resulting effective dielectric constant of

3.35, to achieve 30º phase shift at, say, 1.5 GHz, we find that:

∆L = 9.1 mm

This reference line length of 9.1 mm would in turn provide 150º of phase shift at 7.5 GHz.

So, the useable bandwidth for this line, as a TRL line standard, is 1.5 GHz to 7.5 GHz.

Test PCB

A test board made to illustrate the operation of the TRL technique with the PicoVNA is

shown below in Fig. 2. This includes an additional DUT and a pair of matched loads.

These loads are used by the software to perform a TRM (Thru-Reflect-Match) calibration

at frequencies below the lowest frequency of the TRL calibration (set by the length of the

TRL reference line).

Zero length

Thru

Reflect

Length = L

L/2

L/2

Delay

∆L

DUT

L/2

L/2

Measurement

plane

Measurement

plane

Shorts

Shorts

Line

L/2

L/2

Delay line

DUT

DUT

(Measurement)

Basic TRL Calibration steps

(TRM Load step not shown)

TRL on PCB

Equivalent TRL setup using coaxial components

Note: The absolute value of L is not important.

However, all L/2 sections shown must be

identical and be exactly half the value of L.

Page 4

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

4/12

Figure 2: Test board for TRL calibration and measurement

Lower frequencies

The PicoVNA 108 automatically switches to TRM at frequencies below those supported

by the TRL reference line. The TRM technique relies on matched loads to set the reference

impedance. This approach works well since good matched loads can easily be

implemented at lower microwave frequencies (< 2 GHz). The frequency range of the TRL

reference line is set in the calibration kit definition and is described in the following

section.

TRL calibration kit

In order to perform a TRL calibration with the PicoVNA 108, a calibration kit file needs to

be created. This can be done very easily using the calibration kit editor (Tools > Calibration

kit > Cal Kit Editor).

Figure 3: Use the calibration kit editor to create the TRL cal kit file

0.38 mm dielectric

0.71 mm dielectric

0.38 mm dielectric

Example FR4 layer build-up

εr =4.6

Copper

layers

50 Ω microstrip line width = 0.67 mm

Page 5

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

5/12

TRL calibration kit – entering the reference line information

In our test board (Fig.2) there is only one reference line (‘Delay’) so we check just the box

next to ‘Line 1’ to indicate that the cal kit has only one reference line. The Line 2 box is left

unchecked as shown in Fig. 3.

Now, we can either enter the electrical delay in ps and click the button ‘Compute from

delay’ to set the frequency range of the line, or preferably, enter directly the frequency

range we wish to assign to the reference line. The low frequency is entered into the box

labelled ‘FL’ and the high frequency into the box ‘FH’. Both values are in GHz.

TRL calibration kit – entering the Reflect Standard information

The next step is to select whether the Reflect Standard is going to be a short or an open

circuit. Click on the appropriate radio button as required. Note that it is only necessary to

know approximately the value of the reflection coefficient of the Reflect Standard. So, in

the case of our test PCB, we will use short circuits implemented with vias to ground. For

this, we can enter 100 pH as an approximate value of the inductance into the box labelled

‘L (pH)’.

Finally, we enter the desired Kit name in the top left box and click on ‘Save Kit’ to save the

file to disk.

3. Performing the TRL/TRM calibration and measured results

Performing the TRL/TRM Calibration is simple. The first step is to load the TRL calibration

kit file created for the test PCB. This is done using the calibration kit form (Tools >

Calibration kit) which is shown below.

The cal kit files for the test PCB are loaded for both port 1 and port 2 by clicking on the

‘Load P1 kit’ and ‘Load P2 kit’ in turn. Thereafter, click on ‘Apply’ and close the form.

Page 6

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

6/12

Figure 4: Load the TRL calibration kit files for ports 1 and 2

Once the calibration kit files have been loaded, the sweep plan can be set (if needed)

and the calibration completed using the Calibration Form. See Fig. 5.

Once the Measurement is set to ‘Insertable DUT (TRL/TRM)’ proceed to connect to each

of the PCB calibration Standards (see Fig. 6) and then click on the corresponding button

on the Calibration form. So, for example, after connecting to the Short circuits, click on the

Reflect button on the form to measure these Standards.

Once all the Standards have been measured, click on the ‘Apply Cal’ button to complete

the calibration. The Calibration form will close and the DUT can then be connected and

measured.

Page 7

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

7/12

Figure 5: The calibration form is used to set the sweep plan and carry out the calibration

Figure 6: Connect to each Standard in turn to complete the calibration

Select TRL

Connect and click on

each Standard to

complete the calibration

Page 8

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

8/12

Example measurement results

DUT 1: Mini-Circuits BFCN-2700+ bandpass filter

The first DUT on the test PCB is a LTCC (Low Temperature Co-fired Ceramic) bandpass

filter manufactured by Mini-Circuits. This device has a nominal pass band 200 MHz wide

centred on 2.7 GHz.

Figure 7a shows the measured value of S21 compared to the data published by the

manufacturer. It can be seen that the measurement taken using the PicoVNA 108 is in

good agreement with the manufacturer’s data. It is not known how the manufacturer data

was taken but it does show some apparent measurement anomalies above 4 GHz. It is

interesting to see that the measurements from the PicoVNA 108 show somewhat lower

loss and deeper sidelobe responses.

Figure 7a: Bandpass filter (BFCN-2700+) S21 measurement

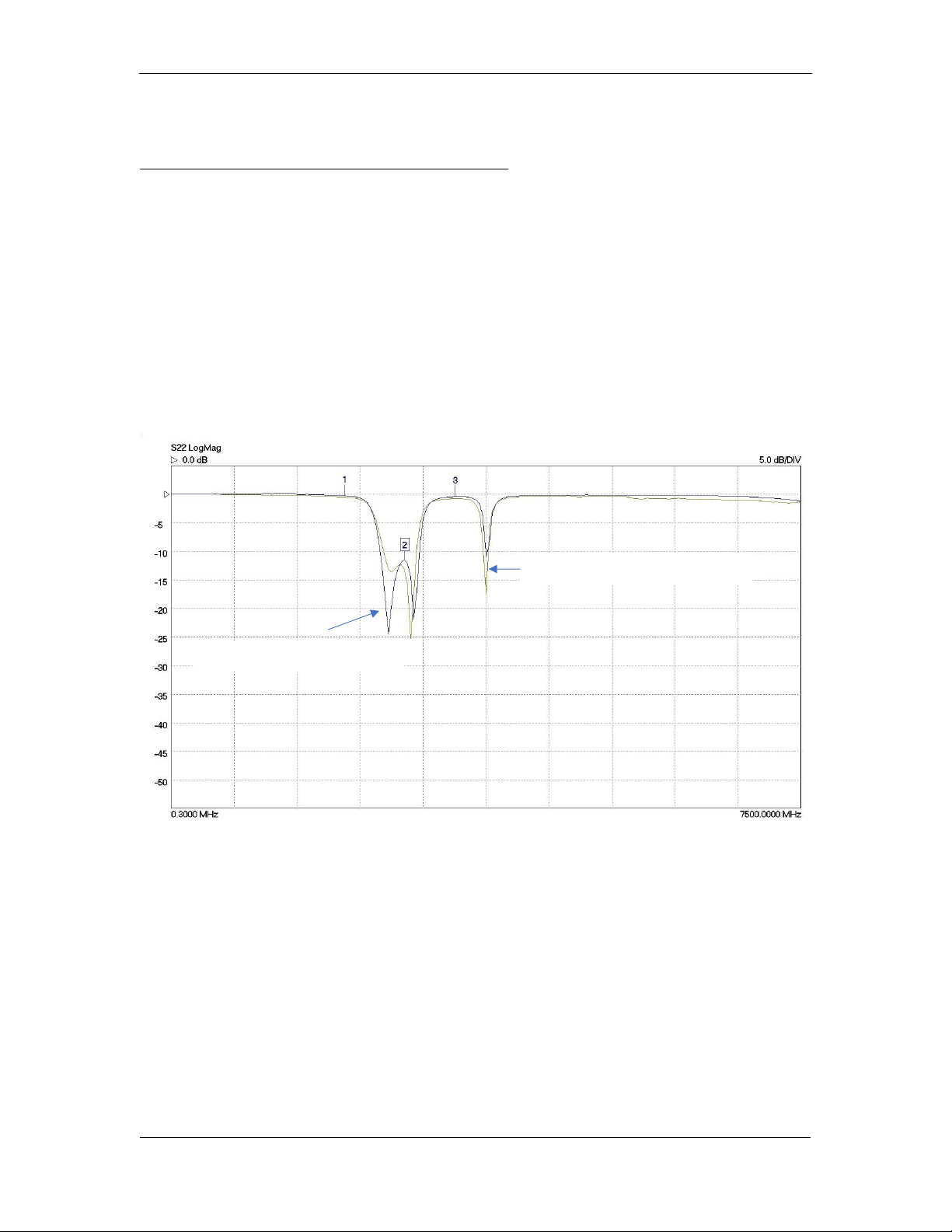

Figure 7b shows the measured value of S22 compared to the data published by the

manufacturer. As before there is general good agreement, including the presence of an

out-of-band resonance at about 3.8 GHz.

Manufacturers’ published data

LA19-13-04B Measurement

PicoVNA measurement

Manufacturer’s published data

Page 9

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

9/12

Figure 7b: Bandpass filter (BFCN-2700+) S22 measurement

Reference line impedance correction

It is very likely that using low-cost FR4 boards for this kind of evaluation leads to an error

in the characteristic impedance of the TRL reference line. This can be measured using the

TDR facility in the PicoVNA 108. The result, in terms of the line’s linear reflection

coefficient, is shown below in Fig. 8. Marker 2 indicates a value of Z0 of 52.2 Ω.

Figure 8: Reference line Z0 can be determined from the reflection coefficient, measured

using TDR

Manufacturer’s published data

LA19-13-04B measurement

Page 10

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

10/12

In order to be able to carry out a TDR measurement of the reference line, it is important to

bear in mind the available time resolution (or effective rise time) of the VNA TDR

measurement. This is equivalent to the inverse of the frequency span (stop frequency

minus the start frequency) used. By selecting the widest available span, we end up with a

time resolution value of around 118 ps. Therefore, it is sensible to ensure that the overall

length of the reference line, plus the interconnecting lines to the edge connectors,

amounts to at least 2.5 x 118 ps. This will allow an unambiguous TDR impedance

measurement to be made as shown in Fig. 8.

Once the impedance of the reference line has been determined as described, the value

can be entered in the Enhancement Set Up form as shown in Fig. 9. Once the value is

entered and the box next to the corresponding line is checked, all TRL measurements will

be corrected using impedance conversion back to the system impedance, typically 50 Ω.

Note that the correction will only be applied over the frequency range applicable to the line

selected.

Figure 9: TRL Measurement can be corrected using known Reference line Z0

Enter TRL Reference line Z0 value to

allow live correction of measurement

Page 11

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

11/12

Reference line impedance correction example

DUT2: Mini-Circuits 0805 6 dB chip attenuator

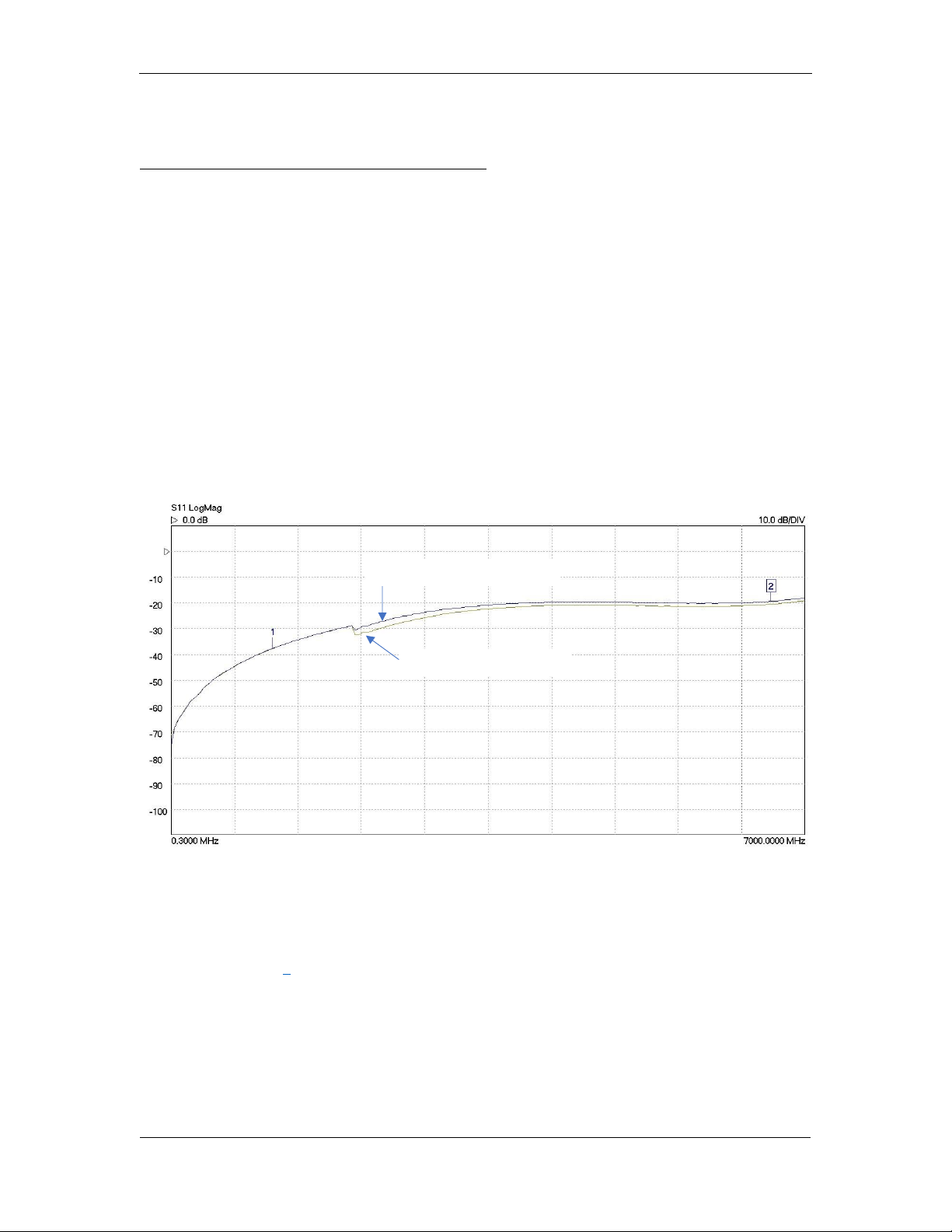

The second DUT on the test board (see Fig.2) is a 6 dB chip attenuator. It provides broadband performance from DC to beyond 7 GHz. Figs. 10a and 10b show the measured S11

and S21 of the attenuator.

The measured data show a step at 2 GHz. This is the frequency chosen where the

calibration switches between TRM and TRL. As a reminder, this frequency is set in the TRL

calibration kit file. In particular, it is the lowest frequency where the reference line is used

as a standard, which was chosen to be 2 GHz for this measurement.

The effect of applying the impedance correction is evident in Figs. 10a and 10b. In

particular, the reduction in the step size in S11 is clear to see. The residual error may be

likely to be associated with the imperfect 50 Ω loads used on the board for the TRM

calibration. Although a small error of around 1 dB it is nevertheless clearly evident.

Figure 10a: 0805 6 dB attenuator S11 measurement

It is worth commenting that reducing the transition frequency below 2 GHz to reduce the

error introduced by the 50 Ω loads in turn leads to other sources of errors, in particular

skin depth effects (2) that are likely to begin affecting the characteristic impedance

(making Z0 complex) of the microstrip reference line.

No impedance adjustment

52.2 Ω Impedance adjustment

Page 12

TRL calibration for SMT devices using the PicoVNA 108

AR548-1

© Pico Technology 2021

12/12

Figure 10b: 0805 6 dB attenuator S21 measurement

4. Conclusions

This application note has described how to use the TRL/TRM calibration technique

available on the PicoVNA 108 to characterize SMT components. In particular, it details

how a suitable test PCB can be designed and used to measure components over the

operating bandwidth of the VNA.

A way to reduce measurement errors arising from incorrect characteristic impedance of

the reference line has been described and details of two measurement examples have

been given.

Overall, the TRL/TRM feature on the PicoVNA 108 provides another useful option for

accurately characterizing SMT components on low-cost PCBs.

5. References

1. Engen, Glenn F. and Hoer, Cletus A. “Thru-Reflect-Line”: An Improved Technique for

Calibrating the Dual Six-Port Automatic Network Analyzer, IEEE Transactions Microwave

Theory and Techniques, Vol MTT-27, No.12, Dec 1979. New York, NY, USA : IEEE, 1979.

Electronic ISSN: 1557-9670.

2. Johnson, Howard W. and Graham, Martin. High-Speed Signal Propagation: Advanced

Black Magic. Hoboken, NJ, USA : Prentice Hall, 2005. ISBN 013084408X.

52.2 Ω Impedance adjustment

No impedance adjustment

Loading...

Loading...