OV-10 BRONCO

OV-10 BRONCO

Technische Daten

- Spannweite = 1800 mm

- Länge = 1280mm

- Gewicht = ca. 6900g

2

- Flächeninhalt = 57.1dm

2

- Flächenbelastung = 119.1 g/dm

- Flächenprofil = Naca Airfoil

Empfohlener E-Antrieb

- Brushless Antriebsset BOOST 45

- LiPo Akku LEMONRC 4300-3S

Montageanleitung

Instruction Manual book

Specifications

- Wingspan = 1800 mm

- Length= 1280mm

- Weight = approx. 6900g

2

- Wing Area = 57.1dm

2

- Wing Loading = 119.1 g/dm

- Airfoil = Naca Airfoil

Power Set (recommended)

- Brushless Power Set BOOST 45

- LiPo Battery LEMONRC 4300-3S

Inhaltsverzeichnis / Table of Content

Cut off excess.

B

Apply epoxy glue.

Apply threadlocker

(screw cement).

C.A

Apply instant glue

(C.A glue, super glue).

Cut off shaded portion

carefully.

Assemble left and right

sides the same way.

Must be purchased

separately!

Ensure smooth, non-binding

movement when assembling.

Warning!

Set all scerws securely. If they come off during

flight you will lose control of your aircraft!

Pay close attention here.

Drill holes using the stated.

(in this case 1.5mm ).

1

.5mm

Take particular care here.

The number of times

the same way Assembly

(in this case twice).

2

Symbols used throughout this instruction manual, comprise:

Page 2

Instruction Manual Book OV-10 BRONCO

4 Symbols used throughout this instruction

manual, comprise: . . . . . . . . . . . . . . . . . . . . . . . . 2

4 Parts listing (not included). . . . . . . . . . . . . . . . 4

4 Tools & supplies needed. . . . . . . . . . . . . . . . . 4

4 Installing the ailerons and flaps. . . . . . . . . . . . 4

4 Installing the ailerons and flaps servos. . . . . . 4

4 Installing the control horns and linkages . . . . 6

4 Installing the engine mount. . . . . . . . . . . . . . . 8

4 Installing the fuel tank. . . . . . . . . . . . . . . . . . . 8

4 Installing the engine . . . . . . . . . . . . . . . . . . . . 9

4 Installing the throttle . . . . . . . . . . . . . . . . . . . 11

4 Installing the electric motor (ep version). . . . 12

4 Rudder installation . . . . . . . . . . . . . . . . . . . . 13

4 Installing horizontal stabilizer . . . . . . . . . . . . 14

4 Installing the wheel well . . . . . . . . . . . . . . . . 15

4 Installing main gear . . . . . . . . . . . . . . . . . . . 17

4 Electric gear retracts. . . . . . . . . . . . . . . . . . . 19

4 Installing the nose gear . . . . . . . . . . . . . . . . 20

4 Mounting the cowl. . . . . . . . . . . . . . . . . . . . . 24

4 Installing the spinner. . . . . . . . . . . . . . . . . . . 25

4 Plastic parts for fuselage . . . . . . . . . . . . . . . 28

4 Installing the receiver and battery. . . . . . . . . 28

4 Wing attachment, horizontal stabilizer . . . . . 29

4 Installing cockpit fuselage. . . . . . . . . . . . . . . 31

4 Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Lateral balance . . . . . . . . . . . . . . . . . . . . . . . 34

4 Pre-flight chec. . . . . . . . . . . . . . . . . . . . . . . . 34

4 Control throws . . . . . . . . . . . . . . . . . . . . . . . 34

4 For your radio installation basic connection for

airplane and adjustment of servos. . . . . . . . . . . 35

4 Main gear dimensional detail . . . . . . . . . . . . 36

Deutscher Modellflieger Verband e. V.

Rochusstraße 104-106

53123 Bonn

Telefon: +49 (0) 228 97 85 00

Telefax: +49 (0) 228 978 50 85

eMail: info@dmfv.aero

Internet: www.dmfv.aero

Deutscher Aero Club e.V.

Hermann-Blenk-Str. 28

38108 Braunschweig

Telefon: 0531 23540 - 0

Telefax: 0531 23540 - 11

eMail: info(at)daec.de

Adressen der deutschen Modellsport Dachverbände

EPOXY A

EPOXY B

Page 3

Instruction Manual Book OV-10 BRONCO

# C9110

Brushless Power Set BOOST

Motor + Regler / Motor + ESC

Sonderzubehör für OV-10 Bronco / Accessories for OV-10 Bronco

# C7211 + # C7212

Elektrisches Einziehfahrwerk

Electric Power Retract Kit

# C9481 / x2

LiPo Akku LEMONRC 4300-4S

LiPo Battery LEMONRC 4300-4S

# C5374 MASTER

Fernsteuerset 2.4Ghz

Radio Set 2.4Ghz

# C5638 Servo DS3012MG

(8 Stück erforderlich)

(8 pcs. required)

Nachstehendes Zubehör wurde von uns ausgiebig erprobt und wird für beste Flugeigenschaften

empfohlen. Weitere Informationen und Bestellmöglichkeit unter www.pichler-modellbau.de

These accessories have been extensively tested and are recommended for best flying performance.

For more information please visit www.pichler-modellbau.de

# C6566

MASTER Flight Control 2

Flugstabilisator

Flight Stabilizer

# C5754 / x2

PI-CON Propeller

# C4738

Akku Klettband

Battery Straps

# C6342 Flächenschutztaschen

Protective Wing bags

................. x 4

................. x 1

250mm ...... x 8

400mm .... x 10

1000mm ...... x 1

Servokabel Verlängerungen / Servo Extension Leads

# X3598-200

# C8125

# C9097

# C1393

# C2036

# C2415

# X3571

# X3581

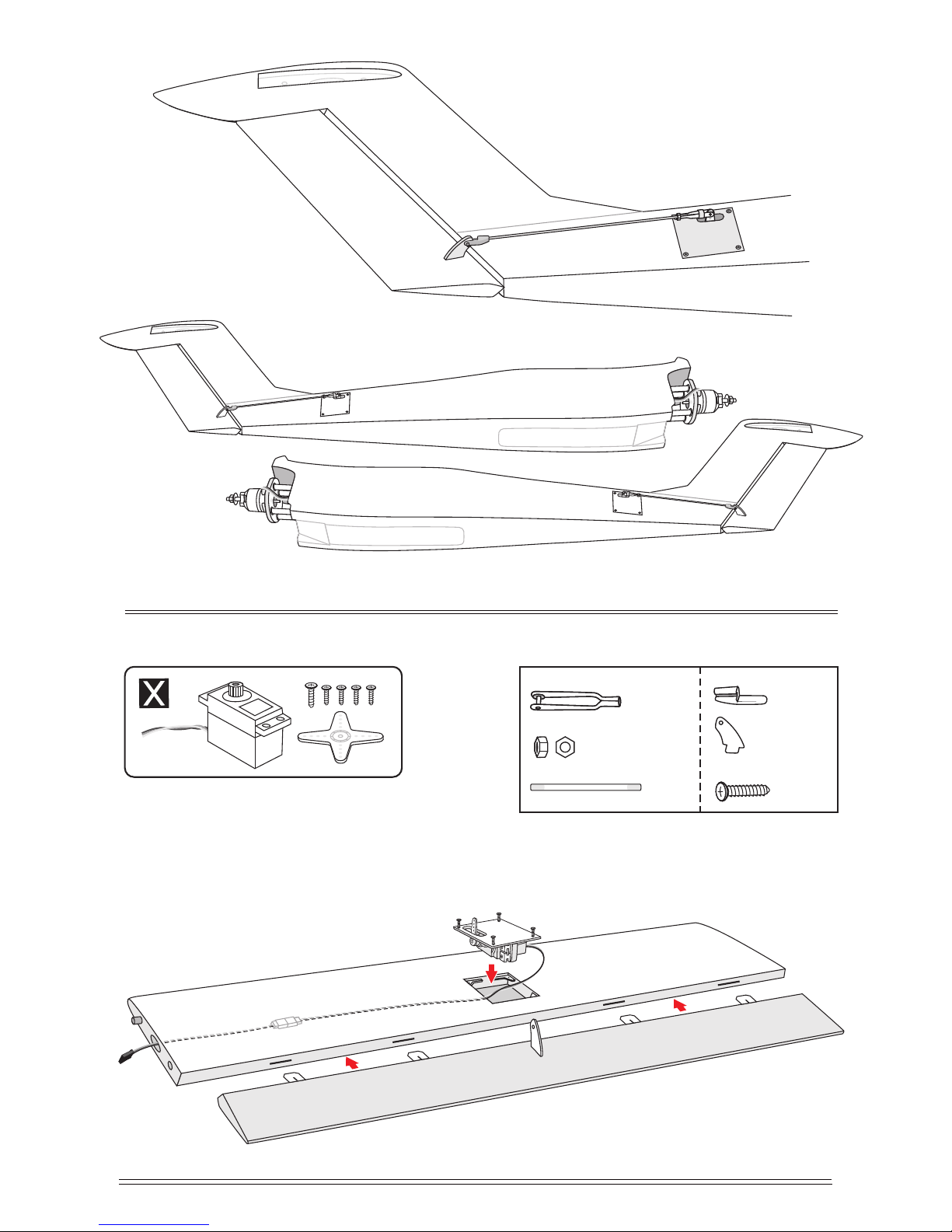

INSTALLING THE AILERONS AND FLAPS.

2) Apply drops of thin CA to the top and bottom of

each hinge. Do not use CA accelerator. After the CA

has fully hardened, test the hinges by pulling on the

aileron.

Temporary pin to

keep hinge centered.

1) Test fit the ailerons to the wing with the hinges. If

the hinges don’t remain centered, stick a pin through

the middle of the hinge to hold it in position.

Flap

Flap

Bottom view

Aileron

B

1

2

C.A

C.A

Secure nylon hinges with instant glue, being

careful not to glue the wing and aileron together.

Align the center line of main wing with aileron.

1

2

Warning!

Make certain the hinges are

adequately secured with glue. if they come loose in

flight accidents may result.

1. Install the rubber grommets and brass eyelets

onto the aileron servos.

2. Using a modeling knife, remove the covering

from over the pre-cut servo arm exit hole on the

aileron servo tray / hatch. This hole will allow the

servo arm to pass through when installing the aileron

pushrods.

3. Place the servo into the servo tray. Center the

servo within the tray and drill 1.5mm pilot holes

INSTALLING THE AILERONS AND FLAPS SERVOS.

through the block of wood for each of the four

mounting screws provided with the servo.

4. Using the thread as a guide and using masking

tape, tape the servo lead to the end of the thread:

carefully pull the thread out. When you have pulled

the servo lead out, remove the masking tape and the

servo lead from the thread.

5. Place the servo into the servo tray/ hatch into the

servo box on the bottom of the wing and drill 1.5mm

pilot holes through the tray and servo box for each of

the four mounting screws. Secure the servo tray in

place using the mounting screws provided.

6. Repeat step # 2 - # 5 to install the second aileron

servo in the opposite wing half.

Page 4

Instruction Manual Book OV-10 BRONCO

For Flap servo.

For Aileron servo.

2 x 10mm Screw

- - - - 16

Warning!

Tie the string.

Pull out servo cord with string.

1

2

2x10mm

1

2

For Aileron.

o

60

Flap

o

90

Aileron

approx.16mm

2mm

4

Aileron and

flap servos.

4

2x10mm Screw

2

For Flap.

For Aileron.

1.5mm

2 mm

2

For Flap.

For Aileron.

Screw

1.5mm

1.5mm

Page 5

Instruction Manual Book OV-10 BRONCO

INSTALLING THE CONTROL HORNS AND LINKAGES.

100mm Push rod

- - 4

M2

- - - 4

- - - - - - - 4

Horn

- - - - - - 4

- - - - - - 4

Flaslink

2mm Nut

1) Working with the aileron linkage for now, thread

one nylon clevis at least 14 turns onto one of the

2mm x 180mm threaded wires.

2) Attach the clevis to the outer hole in the control

horn. Install a silicone tube on the clevis.

3) Locate one nylon servo arm, and using wire

cutters, remove all but one of the arms. Using a

2mm drill bit, enlarge the third hole out from the

center of the arm to accommodate the aileron

pushrod wire.

4) Plug the aileron servo into the receiver and

center the servo. Install the servo arm onto the

servo. The servo arm should be perpendicular to

the servo and point toward the middle of the wing.

5) Center the aileron and hold it in place using a

couple of pieces of masking tape.

6) With the aileron and aileron servo centered,

carefully place a mark on the aileron pushrod wire

where it crosses the hole in the servo arm.

7) Using pliers, carefully make a 90 degree bend

down at the mark made. Cut off the excess wire,

leaving about 6mm beyond the bend.

8) Insert the 90 degree bend down through the

hole in the servo arm. Install one nylon snap

keeper over the wire to secure it to the arm. Install

the servo arm retaining screw and remove the

masking tape from the aileron.

9) Repeat step # 4 - # 8 to install the second

aileron linkage. After both linkages are completed,

connect both of the aileron servo leads using a Yharness you have purchased separately.

Bottom view

Bottom view

B

Horn

4

Page 6

Instruction Manual Book OV-10 BRONCO

Flaslink

Push rod

4

2

Mark the spot to attach

o

Bend 90

1

2

Cut

Silicone tube

5mm

Bottom view

Silicone Tube

M2

2mm Nut

Servo arm

Push rod

6mm

1

Page 7

Instruction Manual Book OV-10 BRONCO

There are two options:

1. Engine mount.

2. Electric motor

INSTALLING THE ENGINE MOUNT

OPTION 1: ENGINE INSTALLATION

Installing the engine mount, fuel tank

To carburetor

fuel inlet

(see front view of fuel tank). Insert and tighten the screw.

Be sure to equip

air vent pipe.

Tubing for

re-fuelling

Not included.

Tygon tubing (Gas). And

silicone tubing (Methanol).

5mm

INSTALLING THE FUEL TANK.

1) The stopper has been pre-assembled at the

factory.

2) Using a modeling knife, cut one length of silicon

fuel line (the length of silicon fuel line is calculated by

how the weighted clunk should rest about 8mm away

from the rear of the tank and move freely inside the

tank). Connect one end of the line to the weighted

clunk and the other end to the nylon pick up tube in

the stopper.

3) Carefully bend the second nylon tube up at a 45

degree angle (using a cigarette lighter). This tube will

be the vent tube to the muffler.

4) Carefully bend the third nylon tube down at a 45

degree angle (using a cigarette lighter). This tube

will be vent tube to the fueling valve.

When the stopper assembly is installed in the

tank, the top of the vent tube should rest just below

the top surface of the tank. It should not touch the top

of the tank.

5) Test fit the stopper assembly into the tank. It may

be necessary to remove some of the flashing around

the tank opening using a modeling knife. If flashing is

present, make sure none of it falls into the tank.

6) When satisfied with the alignment of the stopper

assembly tighten the 3mm x 20mm machine screw

until the rubber stopper expands and seals the tank

opening. Do not over tighten the assembly as this

could cause the tank to split.

7) Using a modeling knife, cut 3 lengths of fuel line.

Connect 2 lines to the 2 vent tubes and 1 line to the

fuel pickup tube in the stopper.

8) Fe ed thr ee li nes t hro ugh t he fue l ta nk

compartment and through the pre-drilled hole in the

firewall. Pull the lines out from behind the engine,

while guiding the fuel tank into place. Push the fuel

tank as far forward as possible, the front of the tank

should just about touch the back of the firewall.

Blow through one of the lines to ensure the fuel lines

have not become kinked inside the fuel tank

compartment. Air should flow through easily.

Do not secure the tank into place permanently

until after balancing the airplane. You may need to

remove the tank to mount the battery in the fuel tank

compartment.

9) Secure the fuel tank.

Silicone tube

Foam ring

Fuel tank

Page 8

Instruction Manual Book OV-10 BRONCO

Fuel tank

Fuel tank

Zip tie

INSTALLING THE ENGINE.

* Locate the long piece of wire used for the throttle

pushrod. One end of the wire has been pre-bend in to

a "Z" bend at the factory. This "Z" bend should be

inserted into the throttle arm of the engine when the

engine is fitted onto the engine mount. Fit the engine

to the engine mount using the screws provided.

3mm Flat washer

- - - - - - - 8

4mm Spring Washer

- - - - - - - 8

3x25mm Cap Screw

- - - - - 8

3 - - 8mm Nut

Engine

mount

500mm Pushrod wire

- - - 2

4x25mm Cap Screw

- - - - - 8

4mm asherFlat w

- - - - - - - 8

Page 9

Instruction Manual Book OV-10 BRONCO

Pushrod wire

Secure

4mm Spring

4mm asherFlat w

4x25mm Secure

125mm

2

3x25mm

3mm asherFlat w

3mm Nut

Page 10

Instruction Manual Book OV-10 BRONCO

2

Screw

o

90

approx.16mm

2mm

Linkage stopper

4x4mm

2x10mm

2mm

Pushrod wire

Adjust the throttle input

(transmitter throttle stick),

throttle trim movement and the

carburattor opening to the

suitable position and screw in

the 4x4mm set screw.

INSTALLING THE THROTTLE

2) Plug the throttle servo into the receiver and turn

on the radio system. Check to ensure that the

throttle servo output shaft is moving in the correct

direction. When the throttle stick is moved forward

from idle to full throttle, the throttle barrel should

also open and close using this motion. If not,

reverse the direction of the servo, using the

transmitter.

3) Slide the adjustable metal connector / servo

arm assembly over the plain end of the pushrod

wire. Position the throttle stick and the throttle trim

at their lowest positions.

4) Manually push the carburator barrel fully

closed. Angle the arm back about 45 degree from

center and attach the servo arm onto the servo.

With the carburator barrel fully closed, tighte the

set screw in the adjustable metal connector.

5) Remove the excess throttle pushrod wire using

wire cutters and install the servo arm retaining

screw.

Connector - - - - 2

1) Install one adjustable metal connector through

the third hole out from the center of one servo arm,

enlarge the hole in the servo arm using a 2mm drill

bit to accommodate the servo connector. Remove

the excess material from the arm.

After installing the adjustable metal connector

apply a small drop of thin C/A to the bottom nut.

This will prevent the connector from loosening

during flight.

Throttle Servo

2

Throttle servo

Fuel tank

Page 11

Instruction Manual Book OV-10 BRONCO

OPTION 2: INSTALLING THE ELECTRIC MOTOR (EP VERSION)

- - - - - 8

10x40mm Aluminum

Mount Nut

- - - - - 8

4mm Washer

- - - - - 8

4mm Spring Washer

- - - - - 8

4mm Washer

- - - - - 8

- - 8

4x60mm Cap Screw

3x15mm Cap Screw

- - - - - 8

3mm Spring Washer

- - - - - 8

3x15mm

3mm Spring

4x60mm

4mm Spring

4mm Washer

4mm Washer

10x40mm

Page 12

Instruction Manual Book OV-10 BRONCO

RUDDER INSTALLATION

1) Hinges and servo for Rudder are glued the

same way as the aileron before (see page 6, 7).

2) Control horn and linkages for Rudder are

installed the same way as the aileron before

(see page 8, 9).

300mm Push rod

- - 2

M2

- - - 2

- - - - - - - 2

2mm Nut

Horn

- - - - 2

- - - - 2

Flaslink

2 x 10mm Screw

- - 8

Rudder pushrod

Rudder servo

Horn

Page 13

Instruction Manual Book OV-10 BRONCO

INSTALLING HORIZONTAL STABILIZER

1) Hinges and servo for Elevator are glued the

same way as the aileron before (see page 6, 7).

2) Control horn and linkages for Elevator are

installed the same way as the aileron before

(see page 8, 9).

100mm Push rod

- - 1

M2

- - - 1

- - - - - - - 1

2mm Nut

Horn

- - 1

- - - 1

Flaslink

2x10mm Screw

- - - 4

2x10mm

Page 14

Instruction Manual Book OV-10 BRONCO

INSTALLING THE WHEEL WELL

Fuselage Bottom Side

2

C.A

2

* Using a modeling knife, carefully

re mo ve the fi lm covering from the

f gear tray. Make sure that you do uselage

not remove any wood.

W

HE

EL W

EL

L

5mm

5mm

Cut the plastic

Cut the plastic

Page 15

Instruction Manual Book OV-10 BRONCO

Fuselage Bottom Side

C.A

45mm Aluminium

- - - - 2

B

45mm Aluminium

Page 16

Instruction Manual Book OV-10 BRONCO

INSTALLING MAIN GEAR.

Main gear

Nose gear

5x30mm

5mm Washer

4x4mm

ELECTRIC NOT INCLUDED.

3x6mm Button Screw

- - - - - - - - 1

5x30mm Cap Screw

- - - - - - 3

3x15mm Screw

- - - - 12

5mm Washer

- - - - - - - - 3

350mm Cable

- - 2

- - - - 2

M3

- - - - - - - 4

- - - - - 2

- - - - - - 2

3mm Nut

Cab link

ONLY INCLUDING OLEO STRUTS.

Nose gear

Main gear

3x6mm

Spring

65mm Wheels.

5.1mm hold

75mm Wheels.

5.1mm hold

5x40mm Pin

5x50mm

Landing gear mount.

Page 17

Instruction Manual Book OV-10 BRONCO

# C7211 + # C7212

Elektrisches Einziehfahrwerk

Electric Power Retract Kit

Wir empfehlen den Einbau unseres Elektrischen Einziehfahrwerks

das Sie unter der Bestellnummer C7211 und C7212 bestellen können

unter www.shop.pichler.de

We recommend installing our electric retract gear which have the

order number C7211 and C7212 from our webstore at

www.shop.pichler.de

C.A

3x15mm

Fuselage Bottom Side

2

.5mm

Screw

Screw the gear in position

2

THERE ARE TWO OPTIONS:

OPTION 1: MAIN GEAR STRUTS

Screw

Page 18

Instruction Manual Book OV-10 BRONCO

OPTION 2: ELECTRIC GEAR RETRACTS

Screw

2

.5mm

Screw the gear in position

Screw

Page 19

Instruction Manual Book OV-10 BRONCO

INSTALLING THE NOSE GEAR

OPTION 1: NOSE GEAR STRUT

Screw

Cable rod

Crimp

1

2

3

4

5

Page 20

Instruction Manual Book OV-10 BRONCO

3x6mm

Spring

Screw

1

2

3

4

5

OPTION 2: ELECTRIC GEAR RETRACTS

2

.5mm

3x15mm

Screw

Screw the gear in position

Page 21

Instruction Manual Book OV-10 BRONCO

2

.5mm

3x15mm

Screw the gear in position

Screw

Screw

3x6 mm Screw

Cable rod

Crimp

Screw the gear in position

Page 22

Instruction Manual Book OV-10 BRONCO

Servo nose gear

approx.16mm

2mm

Servo nose gear

o

90

1

2

3

4

5

Cab link

3mm

M3

Page 23

Instruction Manual Book OV-10 BRONCO

3 x 12mm Screw

- - - - 12

MOUNTING THE COWL

1) Remove the muffler and needle valve assembly

from the engine. Slide the fiberglass cowl over the

engine.

2) Measure and mark the locations to be cut out

for engine head clearance, needle valve, muffler.

Remove the cowl and make these cutouts using a

rotary tool with a cutting disc and a rotary sanding

drum attachment.

3) Slide the cowl back into place. Align the front of

the cowl with the crankshaft of the engine. The

front of the cowl should be positioned so the

crankshaft is in the middle of the precut opening.

Hold the cowl firmly in place using several pieces

of masking tape.

4) While holding the cowl firmly in position, drill

four 1,6mm pilot holes through both the cowl and

the side edges of the firewall.

5) Using a 3mm drill bit, enlarge the four holes in

the cowling.

Enlarging the holes through the cowl will

prevent the fiberglass from splitting when the

mounting screws are installed.

6) Slide the cowl back over the engine and secure

it in place using four screws.

7) Install the muffler. Connect the fuel and pressure

lines to the carburator, muffler and fuel filler valve.

Tighten the screws completely.

3x12mm Screw

2

mm

15mm

Page 24

Instruction Manual Book OV-10 BRONCO

2

6 x 45mm

- - - 2

2

C.A

2

6 x 45mm

Antenna

Antenna

Page 25

Instruction Manual Book OV-10 BRONCO

Warning!

* Install the spinner back-plate, propeller and spinner

cone. The spinner cone is held in place using two screws.

The propeller should not touch any part of the

The propeller should not touch any part of the spinner

cone. If it dose, use a sharp modeling knife and carefully

trim away the spinner cone where the propeller comes in

contact with it.

INSTALLING THE SPINNER.

2

2

3x15mm- - 4

- - - - 2

- - - - 2

2

mm

3x12mm

Screw

2

2

mm

3x12mm

Screw

3mm

Page 26

Instruction Manual Book OV-10 BRONCO

2

3x15mmScrew

Page 27

Instruction Manual Book OV-10 BRONCO

3 x 10mm Screw

- - - - 12

PLASTIC PARTS FOR FUSELAGE.

INSTALLING THE RECEIVER AND BATTERY.

INSTALLING THE SWITCH

1) The switch should be mounted on the fuselage

side, opposite the muffler, close enough to the

receiver so the lead will reach. Use the face plate

of the switch cut out and locate the mounting

holes.

2) Cut out the switch hole using a modeling knife.

Use a 2mm drill bit and drill out the two mounting

holes through the fuselage side.

3) Secure the switch in place using the two

machine screws provided with the radio system.

1) Plug the servo leads and the switch lead into

the receiver. You may want to plug an aileron

extension into the receiver to make plugging in the

aileron servo lead easier when you are installing

the wing. Plug the battery pack lead into the

switch.

2) Wrap the receiver and battery pack in the

protective foam to protect them from vibration. Use

a rubber band or masking tape to hold the foam in

place.

Do not permanently secure the receiver and

battery until after balancing the model.

3x10mm Screw

25mm

Page 28

Instruction Manual Book OV-10 BRONCO

544mm

Aluminium tube.

19mm

384mm

WING ATTACHMENT, HORIZONTAL STABILIZER .

Fuselage top side

Switch

ON

OFF

Fuselage top side

Switch

Battery

for Receiver

Zip tie

Zip tie

Battery

for Motor

Receiver

Page 29

Instruction Manual Book OV-10 BRONCO

4 x 20mm

- - - 2

Screw in position.horizontal stabilizer

4x20mm

4x20mm

Fuselage top side

4x20mm

Screw

4x20mm

Screw

Attach the wings to the joiner tube and

secure the wing panels to the fuselage.

4x15mm

4x15mm

Page 30

Instruction Manual Book OV-10 BRONCO

INSTALLING COCKPIT FUSELAGE

Position the canopy so the rear frame on the

canopy is aligned with the rear edge of the

cockpit opening. Use canopy glue to secure the

canopy to the canopy hatch. Use low-tack tape

to hold the canopy in position until the glue fully

cures. Wrap the tape completely around the

canopy hatch.

Fuselage top side

Screw

Screw

1

Main wing must be inserted and attached completely.

1

Page 31

Instruction Manual Book OV-10 BRONCO

B

Open/Close

Page 32

Instruction Manual Book OV-10 BRONCO

Adhesive tape.

Open/Close

BALANCING

1) It is critical that your airplane be balanced

correctly. Improper balance will cause your plane to

lose control and crash.

THE CENTER OF GRAVITY IS LOCATED 85MM

BACK FROM THE LEADING EDGE OF THE

WI NG. AT THE FU SE LA GE. BALANCE A

PLANE UPSIDE DOWN WITH THE FUEL

TANK EMPTY.

2) Mount the wing to the fuselage. Using a couple of

pieces of masking tape, place them on the top side of

the wing 85mm back from the leading edge, at the

3) Turn the airplane upside down. Place your

fingers on the masking tape and carefully lift the

plane.

4) If the nose of the plane falls, the plane is nose

heavy. To correct this first move the battery pack

further back in the fuselage. If this is not possible or

does not correct it, stick small amounts of lead

weight on the fuselage under the horizontal

stabilizer. If the tail of the plane falls, the plane is tail

heavy. To correct this, move the battery and receiver

forward or if this is not possible, stick weight into the

firewall. When balanced correctly, the airplane

should sit level or slightly nose down when you lift it

up with your fingers.

CG

85 mm

Page 33

Instruction Manual Book OV-10 BRONCO

Schwerpunkt

LATERAL BALANCE

After you have balanced a plane on the C.G.

You should laterally balance it. Doing this will

help the airplane track straighter.

1) Turn the airplane upside down. Attach one

loop of heavy string to the engine crankshaft and

one to the tail wheel wire. With the wings level,

carefully lift the airplane by the string. This may

require two people to make it easier.

2) If one side of the wing fall, that side is heavier

than the opposite. Add small amounts of lead

weight to the bottom side of the lighter wing half's

wing tip. Follow this procedure until the wing stays

level when you lift the airplane.

1) We highly recommend setting up a plane using

the control throws listed.

2) The control throws should be measured at the

widest point of each control surface.

3) Check to be sure the control surfaces move in the

correct directions.

CONTROL THROWS

— Aileron: 12 m m up 12 mm down

— Elevator: 14 mm up 14 mm down

— Rudder: 25 mm right 25 mm left

— Flap: 20 mm down

Low rate:

PRE-FLIGHT CHECK

1) Completely charge your transmitter and

receiver batteries before your first day of flying.

2) Check every bolt and every glue joint in your

plane to ensure that everything is tight and well

bonded.

3) Double check the balance of the airplane.

4) Check the control surface.

5) Check the receiver antenna. It should be fully

extended and not coiled up inside the fuselage.

6) Properly balance the propeller.

20mm

Flap control

12mm

12mm

Aileron control

14mm

14mm

Elevator

25mm

25mm

Rudder control

Page 34

Instruction Manual Book OV-10 BRONCO

Ruderausschläge

Querruder

Höhenruder

Seitenruder

Landeklappen

Example of connection

FOR YOUR RADIO INSTALLATION

BASIC CONNECTION FOR AIRPLANE AND ADJUSTMENT OF SERVOS

Engine

Aileron

Rudder

Rudder

Elevator

Elevator Servo

Aileron

Throttle Servo

Throttle Servo

Aileron Servo

Aileron Servo

Electric retract

Electric retract

Electric retract

Flap Servo

Flap

Flap Servo

Flap

Cable rod

Rudder Servo

Rudder Servo

Nose gear servo

Receiver

Y-Harness

Battery (Receiver)

Switch

For more information, refer to radio system instruction manual.

Follow instruction manual of Engine and Battery.

Suggestion: Use a sharp

secewdriver to take the red

cable out from (only one ESC)

the BEC connector, and

then insulate it with a bit of

electrical tape for futher use.

Motor

Motor

ESC

B

A

TTE

RY

ESC

B

A

TTE

RY

Take the red line out

Receiver

Page 35

Instruction Manual Book OV-10 BRONCO

Rote Leitung stillegen

44mm

41mm

51mm

31mm

MAIN GEAR DIMENSIONAL DETAIL

MAIN GEAR STRUTS

NOSE GEAR STRUTS

5.1mm hold

152mm

40mm

75mm

5mm

5.1mm hold

122mm

50mm

65mm

5mm

41mm

21mm

25mm

LANDING GEAR MOUNT.

Page 36

Instruction Manual Book OV-10 BRONCO

Loading...

Loading...