Systematic ventilation.

COMFORT

VENTILATION

EN13141-7:2010

EU Regulation

1253/2014

ErP

20 18

OPERATING AND

INSTALLATION INSTRUCTIONS

SYSTEM VENTECH LG 500

The specified energy ecienc y

is applicable when controlled to

local re quirements and is valid

up to the spe cified maximum air

flow volume.

Contents

1 Introduction ............................................................................................................................................. 4

2 General .................................................................................................................................................... 4

2.1 Use in compliance with the intended use .................................................................................................. 5

2.1.1

Intended use

............................................................................................................................................................ 5

2.1.2

Stipulations for operation with fireplaces

................................................................................................................. 6

2.1.3

Stipulations in connection with extractor hoods

........................................................................................................ 6

2.2 Liability .................................................................................................................................................... 6

2.3 Warranty .................................................................................................................................................. 6

3 Safety ...................................................................................................................................................... 7

3.1 Symbols used ........................................................................................................................................... 7

3.2 Safety regulations .................................................................................................................................... 8

3.2.1

General

.................................................................................................................................................................... 8

3.2.2

Setting up the unit

.................................................................................................................................................... 8

3.2.3

Electrical connection work

....................................................................................................................................... 9

3.2.4

Operation of the system

........................................................................................................................................... 9

4 Functioning of the ventilation system .................................................................................................. 10

4.1 System description ................................................................................................................................. 10

4.2 Possibilities of system expansions for frost protection ........................................................................... 11

4.2.1

Earth heat exchanger (factory settings)

.................................................................................................................. 11

4.2.2

Brine geothermal energy with optional cooling function (factory setting)

................................................................ 12

4.2.3

PTC low temperature preheater battery factory setting

.......................................................................................... 13

4.2.4

Anti-frost protection by shutting down the supply air fan

........................................................................................ 13

4.3 System expansion for the purpose of external auxiliary heating ............................................................. 14

4.3.1

With external warm water heater battery (factory setting)

...................................................................................... 14

4.3.2

Needs-based system operation - CO2 control

.......................................................................................................... 14

4.4 Ventilation unit ....................................................................................................................................... 15

4.4.1

Description

............................................................................................................................................................ 15

4.4.2

Advantages and features

........................................................................................................................................ 15

4.4.3

Layout of the unit

................................................................................................................................................... 16

4.4.4

Versions

................................................................................................................................................................. 18

4.4.5

Dimensions

............................................................................................................................................................ 18

4.5 Safety devices ........................................................................................................................................ 19

5 Technical specifications ....................................................................................................................... 19

5.1 Unit specifications .................................................................................................................................. 19

5.2 Characteristic external pressure increase - air volume flow with volume flow constant function ........... 20

5.3 Characteristic external pressure increase - air volume flow without volume flow constant function ...... 20

5.4 Acoustic specifications ........................................................................................................................... 21

6 Operator control unit ............................................................................................................................ 21

6.1 General information ............................................................................................................................... 21

6.2 Control unit "

KOMFORT-G

" ...................................................................................................................... 21

6.2.1

Buttons on the control unit "KOMFORT-G"

............................................................................................................... 22

6.2.2

Representation on the display

................................................................................................................................ 22

6.2.3

Special menu 1 – Operating hour counter (only for specialist installers)

................................................................. 24

6.2.4

Special menu 2 - Language settings, basic ventilation, volume flows and fan speed IV

............................................ 24

7 Power unit ............................................................................................................................................. 25

7.1 Configuration and diagnosis via the PC software (only for specialist installers) ...................................... 25

7.1.1

Connecting the power section to a PC

..................................................................................................................... 25

7.1.2

Software overview

................................................................................................................................................. 26

8 Messages/Faults .................................................................................................................................. 26

8.1 Operating messages on control unit "

KOMFORT-G

" ................................................................................. 26

8.1.1

Deletion of the filter message after a requested filter change

................................................................................. 26

8.1.2

Deletion of the filter message after a premature filter change

................................................................................ 26

8.2 Malfunction messages on control unit "

KOMFORT-G

" .............................................................................. 27

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 2

9 Scope of delivery, transport, storage and disposal ............................................................................ 28

9.1 Scope of supply ..................................................................................................................................... 28

9.2 Transport and Packaging ....................................................................................................................... 28

9.3 Storage .................................................................................................................................................. 28

9.4 Waste disposal ...................................................................................................................................... 28

10 Installation ........................................................................................................................................... 29

10.1 Prerequisites for installation of the unit ................................................................................................. 29

10.2 Device installation ................................................................................................................................. 30

10.2.1

Setting up the ventilation unit - free-standing installation

....................................................................................... 30

10.2.2

Wall mounting

........................................................................................................................................................ 30

10.2.3

Production of the condensate water connection

..................................................................................................... 30

10.2.4

Connection of air lines and components

................................................................................................................. 31

10.3 Electrical connection.............................................................................................................................. 31

10.3.1

Cable leadthroughs

................................................................................................................................................ 32

10.3.2

Connection between the operator control unit and power unit

................................................................................ 32

10.3.3

Installation of the operator control unit

.................................................................................................................. 32

10.3.4

Circuit diagram

...................................................................................................................................................... 33

10.3.5

Mains connection and replacement of the unit’s internal fuse

................................................................................. 36

10.3.6

Connecting a water re-heater battery

..................................................................................................................... 37

10.4 Initial startup ......................................................................................................................................... 37

11 Servicing and cleaning ......................................................................................................................... 38

11.1 Safety directions .................................................................................................................................... 38

11.2 Customer service ................................................................................................................................... 38

11.3 Service instructions for the user ............................................................................................................ 38

11.3.1

Air filters

............................................................................................................................................................... 38

11.4 Service instructions for the specialized installing company ................................................................... 39

11.4.1

Heat exchanger with bypass flap

............................................................................................................................ 39

11.4.2

Fans

...................................................................................................................................................................... 39

11.4.3

Electrical PTC preheater battery (optional)

............................................................................................................. 40

11.4.4

Unit’s housing - internal cleaning

........................................................................................................................... 40

11.4.5

Condensate drainage

............................................................................................................................................. 40

11.4.6

Service table

.......................................................................................................................................................... 41

12 Spare parts and accessories ............................................................................................................... 42

12.1 Control elements ................................................................................................................................... 42

12.2 System components .............................................................................................................................. 42

12.3 Air filters ............................................................................................................................................... 42

13

Subject to change ................................................................................................................................. 42

14

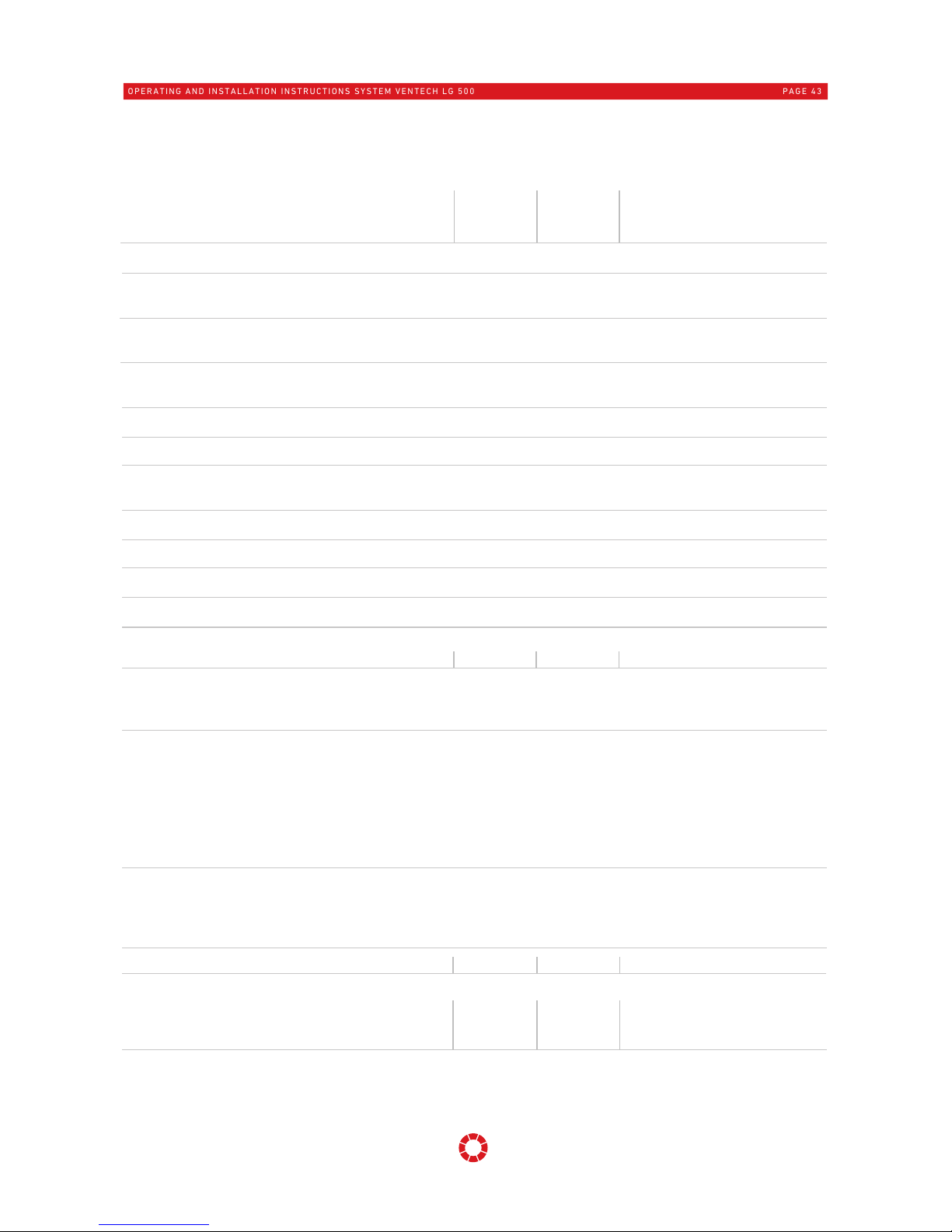

Product fiche......................................................................................................................................... 43

15 EG-Konformitätserklärung (EC Declaration of Conformity) ............................................................... 44

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 3

1 Introduction

Dear customer, thank you for your decision to purchase the compact ventilation unit LG 500 System

VENTECH.

The compact ventilation unit LG 500 System VENTECH is a state-of-the-art device. Its convincing features

are its high degree of economy, operator friendliness and operational safety.

To operate your compact ventilation unit safely, properly, and economically, please carefully read and comply

with these operating instructions.

Use the ventilation unit only in perfect condition, in compliance with the intended use, in a manner that is

safety and

danger conscious and in compliance with all information provided in these instructions. If you have

any queries or spare parts orders, please have the device type and serial number (see type plate on the

device) at hand.

Please contact us if you have any further queries or you have lost the documentation:

2 General

This chapter contains general information on the compact ventilation unit LG 500 System VENTECH with

control unit type "

KOMFORT-G

".

READ THESE INSTRUCTIONS CAREFULLY BEFORE INITIAL STARTUP OF THE UNIT!

These instructions contain advice and information about the safe operation, installation, service and

maintenance of the compact ventilation unit LG 500 System VENTECH. It also serves as a reference for service

work so that this can be performed in a responsible manner. Please keep these operating instructions in a

safe place where they are always accessible. Any troubleshooting or work on the compact ventilation unit

must only be performed by an installation company (specialists). We are continuously improving and

developing our products. Your device may therefore differ slightly from the one referred to in these

instructions.

Subject to change without notice:

These instructions have been drawn up with the greatest care. However, no rights may be derived from them.

We constantly make every effort to make technical improvements to and optimizations of our products and

reserve the right to partially or wholly modify the units or technical specifications without prior notice.

For the compact ventilation unit LG 500 System VENTECH, our "General Terms and Conditions" in the

applicable version apply.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 4

The compact ventilation unit LG 500 System VENTECH, together with all the

optional system components cited in this description, has been subjected by TÜVAUSTRIA Services GmbH, Testing, Inspection and Certification Centre/Vienna to

a safety test and inspection in accordance with the relevant product requirements,

standards and directives. The mark approval certificate No. 0010-PS/PZW-EX0067-2010 of 8 March 2011 and test reports No. 2010-PS/PZW-EX-0067 and No.

M/EMV-10/220 confirm that the requirements of the relevant test points with the

optional system accessories are met, on the condition that the requirements of

these operating instructions are observed and adhered to

.

2.1 Use in compliance with the intended use

2.1.1 Intended use

The compact ventilation unit LG 500 System VENTECH is intended for installation into air treatments systems

with an adjustable air volume flow of 550 m³/h for the controlled mechanical ventilation of living areas and

rooms with similar purpose, such as seminar rooms and small offices.

The entire living area is pro

vided with supply air and exhaust air ventilation by installing a mechanical,

controlled ventilation system for apartments. In this process there is a controlled air supply with conditioned

and filtered outdoor air in the supply air zones. Odours and humid indoor air are taken out of the extract air

zone.

The purpose of the controlled mechanical ventilation of living areas is to improve air quality and to reduce

heating requirements through the use of a highly efficient heat recovery system as well as influencing indoor

air humidity.

The application range and intended use of the device is limited to use in indoor air treatment systems for

exhausting consumed air and supplying fresh, temperate outdoor air at a maximum conveying temperature of

-15 °C to +35 Ԩ. In addition, the conveyed air must be free of aggressive vapours and wear-indu

cing

mat

erials. Any other application shall be deemed to be diverting from the intended use. The manufacturer

shall assume no further liability for any damages or consequential damages resulting from non-intended use.

Intended use also includes observing our prescribed operating and installation instructions. This unit, which is

accessible for the general public, is intended for installation in residential or commercial buildings. The device

is used for mechanical ventilation of indoor air and also for air reheating in conjunction with a heater battery.

This device is not intended to be used by people (including children) with limited physical, sensory, or mental

capabilities or with a lack of suitable experience and/or knowledge, unless supervised by a person who is

responsible for their safety or from whom they receive instructions on how to use the device.

The unit is not suitable for installation in the open air and must be installed in suitable and temperaturecontrolled indoor rooms. The ventilation unit is not suitable for drying out new-build properties. When the

device is shut down, ensure that no air circulation can occur through the device.

The compact ventilation unit LG 500 System VENTECH is not a ready-to-use product. It must not be put into

operation until it has been properly installed and connected in the indoor air treatment system. Only qualified,

assigned personnel may work on and with the device.

Any individual who transports, sets up or works on the device must have read and understood these

operating instructions, particularly Chapter 3 "Safety Instructions". In addition, the end user has to

be informed of any dangers that might occur.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 5

2.1.2 Stipulations for operation with fireplaces

Safety instructions and standards must be observed when using the device simultaneously with fireplaces

consuming indoor air. In the case of indoor air dep

endent fireplaces the combustion air supply for the

fireplace has to be provided separately.

Proper operation of ventilation systems based on the central “Compact ventilation unit LG 500 System

VENTECH” ventilation system requires that existing combustion air or waste gas ducts are isolated from

heating systems dependent on room air.

The ventilation unit LG 500 System VENTECH may only be installed in rooms, apartments and user units of a

comparable size in which indoor air dependent fireplaces are installed, if the simultaneous operation of

indoor air dependent fireplaces for liquid or gaseous fuels and of the apartment’s ventilation system is

prevented or the exhaust gas conveyance of the indoor air dependent fireplace is monitored by special safety

devices.

If the negative pressure in the room where the fireplace is installed is 4 Pa greater than the external pressure,

it must be ensured that the extract air system switches off automatically and reliably. In such cases, the input

"E3 fireplace mode" provided for this purpose can be used. When the contact is closed, the ventilation unit is

switched off immediately and "fireplace mode" is displayed on the control panel. When the contact is opened,

the ventilation unit returns to its original state.

2.1.3 Stipulations in connection with extractor hoods

On account of the heavy load and irregular operation the extract air of any kitchen extractor hood present

must not be integrated into the apartment’s ventilation system. The extract air from such extractor hoods

should be removed separately out of the roof via an exhaust air line. The supply air is provided separately, e.g.

via the window ventilation.

If an extractor hood is being operated without separate introduction of the supply air, the air volume balance

in the apartment is no longer balanced and the proper functioning of the apartment’s ventilation system is not

ensured (odour entrainment etc.). One possibility is to operate the extractor hood with adequate air filtering in

recirculated air mode.

2.2 Liability

The compact ventilation unit LG 500 System VENTECH has been developed and manufactured for use in the

controlled mechanical ventilation of living areas and rooms with a similar purpose, such as seminar rooms

and small offices.

Any other use is considered to be an improper use and can lead to personal injury or damage to the compact

ventilation unit LG 500, for which the manufacturer cannot be held liable. In the event of the following the

manufacturer is liable for no damage whatsoever:

non-compliance with the safety, operating and servicing instructions listed in these operating a

nd

installation instructions

the installation of replacement parts that are not supplied by the manufacturer, whereby the

responsibility for the use of such replacement parts lies completely with the system installer/fitter.

normal wear

2.3 Warranty

The warranty begins with initial startup, at the latest, however, one month after delivery has taken place. The

warranty covers the pure replacement of materials only and does not include any claims for the

compensation of services. It applies only if there is proof of appropriately performed servicing in accordance

with our regulations and by a licensed company that specializes in installation work.

The warranty claim extends for a maximum period of 24 months after installation of the compact ventilation

unit LG 500 System VENTECH, however, up to a maximum of 30 months after the date of manufacture.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 6

Warranty claims can be asserted only for material and/or design defects that have occurred during the

warranty term. In the case of a warranty claim, the compact ventilation unit LG 500 System VENTECH may not

be removed without prior written approval of the manufacturer. The manufacturer accords a warranty on

spare parts only if they have been installed by an installer who is recognized by the manufacturer.

The warranty shall expire automatically at the end of the warranty period, or in the case of improper

operation, such as operating without filters, installation of parts not supplied by the manufacturer, or where

non-approved changes or modifications have been made to the system.

Failure to comply with these Operating and Installation Instructions will automatically void all warranties.

3 Safety

Read these operating

and installation instructions carefully and observe the safety instructions for

installation work, commissioning or for general work or maintenance performed on the device.

Retain these operating and installation instructions during the entire service life of the device and keep them

in an easily-accessible location for future reference.

The safety instructions, warnings, comments and directions described in these operating instructions must

always be observed.

The specifications stated in this document may not be modified.

Non-observance of these safety instructions, warnings, comments and directions can result in physical injury

or damage to the compact ventilation unit.

We recommend purchasing a maintenance contract to ensure that the device is inspected and maintained at

regular intervals. Your supplier can provide you with the addresses of approved specialists/installers in your

area.

3.1 Symbols used

The following safety symbols indicate text passages that warn against dangers and sources of danger. Please

familiarise yourself with these symbols!

Caution/Important information!

Caution! The non-observance of this warning can lead to injury or danger to life and limb and/or

damage to the unit.

Caution - dangerous electrical voltage! The non-observance of this warning can lead to injury or

danger to life and limb.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 7

3.2 Safety regulations

3.2.1 General

Installation, commissioning, maintenance, and repair must be performed by an authorised specialist

(heating specialist firm/installation specialist firm).

The local national regulations and standards apply without restriction beyond these operating installation

instructions in respect of operation of the device. Ensure that your system installer/fitter shows you how to

operate the device and the control unit after installation. Use of the ventilation unit may only take place in

accordance with the use set out in point 2.1 ‘Use in compliance with the intended use`.

All safety and danger notices attached to the device and described in these instructions must be observed. In

the event of any malfunctions, shut down the unit immediately and secure it suitably against being switched

back on. Any malfunction of the device must be rectified immediately. After servicing and maintenance work,

the operating safety of the device should be re-established by expert personnel.

The attachment or installation of additional parts and components is not permitted. Any modifications or

changes to the compact ventilation unit LG 500 System VENTECH are prohibited. Only original replacement

parts may be used. Modifications and adaptations to the ventilation unit are not permitted and release the

manufacturer from any warranty and liability. Make sure that children do not play with the unit.

3.2.2 Setting up the unit

The national and local regulations must be observed for installation and setup.

The unit must be installed only in compliance with the national installation regulations. Installation

shall be performed in accordance with the general, locally valid construction, safety and installation

regulations of the appropriate local authority or of the water and electricity company and other institutions.

The unit may be installed only in frost-free and dry rooms. The room temperature in the set-up room must

have a continuous temperature between a minimum of +5 Ԩ and a maximum of +40 Ԩ. The device is intended

for free-standing installation or wall mounting and may only be set up when there is suitable load-bearing

floor or wall construction. No vibrations must be allowed to affect the unit. A suitable water drain with

effective drain trap (siphon) must be provided for discharging condensate water accumulated during

operation of the device.

Installation work for the water, heating and condensate water connections may only be performed by a

professional. Proper installation is essential for ensuring the water-tightness and effectiveness of the

condensate discharge line and in order to prevent damage to the building. The condensate drainage has to be

checked for operability by means of an on-site inspection prior to initial startup and after any servicing work.

The permitted maximum expectable load has to be heeded for transportation of the unit. System components

of the ventilation system, such as air lines, that are installed in potentially unheated areas must be suitably

insulated to prevent heat loss or condensate water formation (where temperatures fall below the dew point).

The locally-applicable construction and fire prevention provisions, regulations and standards must be

adhered to. Appropriate suitable measures for erection of the unit, e.g. the installation of fire dampers in air

pipes etc., may have to be taken. Take into consideration the ambient influences and do not install the

ventilation unit in the vicinity of combustible liquids or gases, in swimming pools or in areas subject to the

influence of chemicals.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 8

3.2.3 Electrical connection work

Electrical connection work and work on the electrical parts of the system may be performed only by

authorized skilled electricians in compliance with national and local regulations.

Before opening the device and during all work on the device, such as maintenance work, repairs etc., the

device must be disconnected from power (power supply disconnected at all poles) and must be secured

against being switched on again for the duration of the work.

The compact ventilation unit LG 500 is designed for a voltage supply of 230 V/50 Hz/16 A. The device is not

designed for electrical connection to a three-phase supply network with 400 V/50 Hz! Refrain from any

manner of working that impairs the safety of the unit. For safe operation, safety devices may not be

disassembled or placed out of operation.

The electrical equipment and the warning and protection devices of the unit have to be regularly checked for

perfect operability. The device must be placed out of operation immediately if malfunctions occur in the

electrical supply or defects are detected, such as loose connections or melted cables.

If the mains power cable of the device is damaged or defective, it must be repaired immediately to prevent

risks. Only genuine fuses with the prescribed current strength and dimensions may be used. Operation of the

unit is prohibited until safe operation of the system has been re-created.

Only qualified electrical specialists may determine the cause of occurring defects and malfunctions and

immediately rectify them. After electrical work has been performed, the safety measures on the device must

be checked (e.g. earthing resistance etc.).

3.2.4 Operation of the system

Operation of the ventilation unit is only permitted if all required connections in conjunction with the

provided installed components, such as sound absorbers etc., have been properly established.

Upon the occurrence of any defects or damage that are able to injure people or damage property, the system

has to be put out of operation immediately. Further operation must be effectively prevented until the device is

completely repaired! Where fault messages or damage occur, the device must be immediately switched off

and disconnected from the mains.

When opening the front covers or removing cover plates, act in a safety-conscious manner and be aware of

the risks. Every working method that impairs safety is prohibited. Operation of the device is only permitted

with a connected air line or installed system components, such as sound absorbers, with a minimum line

length of 1000 mm to ensure that the fans or electrical components, for example, cannot be touched by hand.

The ventilation unit must be operated only in compliance with the project documents. These must comply with

the equipment and product safety act and with the relevant applicable stipulations of the EC directives and

standards.

Never operate the ventilation unit without installed air filters. The air filters must be checked regularly for

contamination and damag

e and cleaned or replaced if necessary. The air filters are to be replaced at least

every six months or when the "filter change" message appears on the control unit. Use only genuine spare

filters. If the system is not in operation in the summer, for hygienic reasons the air filters have to be replaced

before putting it back into operation.

In case of simultaneous use of the ventilation unit with fireplaces consuming indoor air, the applicable safety

instructions and standards must be observed. In the case of indoor air dependent fireplaces the combustion

air supply has to be provided separately. Advice on this is provided under

point

2.1.2 "Provisions for

operation with fireplaces".

Owing to their heavy loading and irregular operation, extractor hoods must not be integrat

ed into the extract

air or exhaust air circuit of the ventilation unit. Advice on this is provided under

point

2.1.3 "Provisions for

use with extractor hoods

" . Exhaust air extractor hoods must be operated via separate air lines, with

provision for a suitable fresh air supply, e.g. by opening windows, or via suitable air filters in recirculated air

mode.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 9

4 Functioning of the ventilation system

4.1 System description

In the case of mechanically controlled apartment ventilation the consumed, humid extract air from the wet

rooms of the apartment, e.g. bathroom, toilet and kitchen, is discharged and replaced by conditioned, fresh

and filtered outdoor air in the residential areas such as the lounge, bedrooms and other living areas.

High energy savi

ngs in the operation of the ventilation unit can be realised through needs-based system

operation, the use of a highly efficient heat exchanger for the recovery of heat from the extract air into the

supply air and the use of energy-efficient fans with the latest EC technology.

It should be particularly ensured that the highly efficient heat exchanger is protected against freezing via a

suitable, controlled frost-protection strategy and that an effective condensate water outlet, among other

measures, is in place. The more airtight the building shell and the more effectively a house is insulated, the

more effective this technology is.

Fig 1 - Circuit diagram of system components

The circuit diagram illustrates the fundamental design of the domestic ventilation unit with the optional

additional system enhancements.

1 - Unit’s housing

2 - Supply air fan in EC execution

3 - Extract air fan in EC execution

4 - Outdoor air filter for fine dust F7

(optional as pollen filter in quality category F9)

5 -Extract air filter G4 for coarse dust

6 - Counterflow heat exchanger

7 - Bypass flap

8 - Frost pre-heating for counterflow - heat exchanger (optional)

9 - Condensate water tank with discharge and drain trap

(siphon) supplied by the customer

10 - Connection pieces for the ventilation unit

11 - Sound absorbers (optional) in the line system

12 - Switchable flap (optional)

13 - Re-heater battery design with warm water (optional)

with downstream supply air temperature sensor

14 - Earth heat exchanger (optional)

15 - Suction element with pre-filter G4

16 - Heater, cooling battery for brine EHE

(earth heat exchanger) (optional)

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 10

4.2 Possibilities of system expansions for frost protection

Particularly in the winter months, moderate to heavy frosts can pose a risk of freezing on the

exhaust air side of the heat exchanger depending on the extract air temperature and extract air

humidity. Where outdoor air temperatures fall to approximately -3 °C, the heat exchanger must be

protected by suitable measures against the formation of ice.

Various systems can be used for defrost monitoring of the heat exchanger. Possible strategies to counteract

freezing of the heat exchanger are described below:

4.2.1 Earth heat exchanger (factory settings)

Optimal frost protection in the presence of cold outdoor air temperatures can be realized by the integration of

an earth heat exchanger into the ventilation system. Additional components, such as a PTC pre-heater battery

integrated into the ventilation system, are then unnecessary.

In summer mode, the cooling effect of an earth heat exchanger is very limited and barely noticeable

for the user due to the low air exchange.

The following information has to be heeded for design of the earth heat exchanger:

Watertight pipes are laid underground at frost-free depth, in consideration of the cleanability of the

system

The design guidelines of the manufacturer have to be complied with

Provision should be made for condensate water discharge

When taking air lines through external walls, ensure an effective seal to prevent the entry of moisture

To avoid frost damage, a sufficient distance from other components such as water pipes, foundations

etc. has to be maintained when laying

In the event of polluted soil (e.g. radon incidence) the possibility of indirect preheating, e.g. a circuit

system with a frost protected heat transfer medium should be used by preference

Earth heat exchangers must be carefully planned and executed with respect to their energy efficiency and air

hygiene. The relevant directives and standards have to be complied with.

In particular, among other things, attention has to be paid to easy cleanability and a suitable filter concept.

EHE winter mode:

The earth heat exchanger is engaged via the switchable flap when the outdoor air temperature drops below

the parameterized EHE winter threshold value. In this case the outdoor air is drawn in via the earth heat

exchanger and preheated in the process. If the outdoor temperature (optional sensor AI9 required) falls below

the parameter EHE-winter 6 °C, the relay K8 switches on the earth heat exchanger (EHE).

EHE summer mode

In the summer the earth heat exchanger is engaged when the outdoor temperature rises above the

parameterized EHE summer threshold value. In this case the outdoor air that is drawn in is precooled via the

earth heat exchanger. If the outdoor temperature (optional sensor AI9 required) moves above the parameter

EHE-summer 20 Ԩ, the relay K8 switches on the earth heat exchanger (EHE).

An additional external outdoor temperature sensor (part. No.: 40LG040050) must be installed

outside. This sensor is connected to the input AI9 (outdoor temperature) which is automatically

recognised by the controls. The change-over valve (Fig 1 - Circuit diagram of system components

ref. 12) is then regulated by this temperature sensor.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 11

4.2.2 Brine geothermal energy with optional cooling function (factory setting)

In the winter, brine geothermal energy systems draw the energy from the ground via a brine pipeline; in th

e

summer, the system can also be utilised for cooling purposes. The heat or cold is transferred indirectly to the

supply air via an external air register integrated into the air line system.

Compared to other frost protection strategies such as electric preheater batteries or hot water preheater

batteries, brine earth heat systems have the advantage that they can make do with little energy when in

operation. The advantage in contrast to the air channel earth heat exchanger lies in hygienic aspects, the

simpler layout and good controllability.

In the event of polluted soil (e.g. radon incidence) it is preferential to use indirect preheating, e.g. a circuit

system with a frost protected heat transfer medium.

The design guidelines of the manufacturer have to be complied with. The brine heater battery should be

protected against contamination via an external air filter integrated into the air line system with a filter quality

category of at least G4. The basic system components are shown in the following diagram:

Fig 2 - Circuit diagram of brine geothermal energy with optional cooling function

Brine pump controlled automatically depending on outdoor temperature; optional sensor AI9 required.

Brine earth heat winter mode:

If the outdoor temperature (optional sensor AI9 required) falls below the parameter EHE-winter 6°C, the relay

K8 switches on the brine pump.

Brine earth heat summer mode:

If the outdoor temperature (optional sensor AI9 required) exceeds the parameter EHE-summer 20Ԩ, the relay

K8 switches on the brine pump.

An additional external outdoor temperature sensor (part. No.: 40LG040050) must be installed

outside. This sensor is connected to the input AI9 (outdoor temperature) which is automatically

recognised by the controls. The brine pump is then controlled via this temperature sensor.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 12

4.2.3 PTC low temperature preheater battery factory setting

The ventilation unit LG 500 System VENTECH can be optionally supplied with an integrated electric PTC

pre-heater battery. If the optional pre-heater battery is installed, the cold outdoor air is pre-heated via the

integrated electric PTC pre-heater battery if there is a risk of frost for the heat exchanger.

With this operating mode a balanced air volume flow is ensured between the supply air and extract

air for the defrosting time period!

Frost protection via integrated PTC pre-heater battery:

the temperature sensor AI4 (outdoor air temperature in the unit) is relevant for the de-icing

function.

the temperature sensor AI4 is positioned on the outdoor air inlet of the heat exchanger.

when the outdoor air inlet temperature is below -3 °C and the outlet temperatures at the exhaust air

sensor AI5 are below +5.5 °C, the PTC pre-heater battery is enabled and Stage I of the PTC preheater battery is switched on.

the air temperature at the sensor AI4 is constantly regulated between 0.5 °C and -2.5 °C.

to achieve this, up to 6 different heating stages are switched on and off automatically on the PTC

pre-heater battery, according to the outdoor air temperature, via the control system.

erroneous operation of the PTC pre-heater battery is monitored via the exhaust air sensor AI5

the pre-heater battery is only enabled when the air temperature at the exhaust air sensor AI5 falls

below +5.5 °C.

4.2.4 Anti-frost protection by shutting down the supply air fan

CAUTION: This operating mode is not suitable for frost protection in passive houses or

buildings with an air-tight design!

The compact ventilation unit LG 500 System VENTECH is equipped as standard with automatic frost-protection

for the heat exchanger by shutting down the supply air fan while the extract air volume flow remains constant.

These measures prevent the heat exchanger from freezing. If, however, this operating setting does not

achieve reliable de-icing, the system will be shut down for approx. 8 hours. The system will be switched on

again automatically.

To achieve reliable de-icing, a motorised shut-off valve should be integrated into the outdoor air line. This

valve will be controlled automatically via the controls and prevent the possible entry of outdoor air. This

function must be activated via the PC software (see 7.1).

In this operating mode an equalised air volume flow balance between the supply air and extract

air during the period of de-icing is not ensured!

Frost protection via extract air de-icing by shutting down the supply air fan:

the temperature sensor AI4 (outdoor air temperature in the device) is relevant for the de-icing

function

the temperature sensor AI4 is positioned on the outdoor air inlet of the heat exchanger

when inlet temperatures at the sensor AI4 are colder than -3 °C and outlet temperatures at the

exhaust air sensor AI5 are colder than +5.5 °C, the de-icing cycle is enabled

the de-icing process is only commenced when the temperature difference between the extract air

and supply air exceeds 6 °C.

once the de-icing shutdown period (15 min) is complete, the supply air fan is switched back on.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 13

---- Notification ----

frost protection switched off

4.3 System expansion for the purpose of external auxiliary heating

In order to be able to increase the air outlet temperature for the living area further after the heat exchanger,

additional external heating can be installed. This afterheating can be achieved via an external warm water

heater

battery integrated into the air line system.

4.3.1 With external warm water heater battery (factory setting)

The supply air temperature can be increased further via an external, optional water re-heater battery and 3-

point mixer control, which is installed in the supply air line downstream of the ventilation unit.

The set value for the temperature and recording of the room temperature is set via the "

KOMFORT-G

" control

unit, which has the room temperature sensor integrated into it. The temperature set value for the room

temperature can be set within a range of +10 °C to +35 °C. In the "Service menu" under Control, you can

select between room temperature control and supply air temperature control (see point 6.2.5).

The mixer works in a clocked control mode with PID control circuit. The control parameters are factory set for

a mixer with a runtime of 120 seconds and can be adjusted via the PC software (see point 7.1).

This operating mode requires an additional external temperature sensor type KTY8110, length 5 m

(part. No.: 40LG040370) to be installed downstream of the re-heater battery in the air line. The

sensor is connected to the input AI6 (temperature sensor RHB (re-heater battery)) and recognised

automatically by the the controls. The supply air temperature is then controlled via this sensor.

If a warm water heater battery is connected, the re-heater battery can be protected against risk of frost for

additional security via the potential-free input "E2". If this potential-free contact is closed via an external

temperature sensor, which must be set to a trigger temperature of +5 °C, the ventilation unit will emit a "Frost

shutdown" fault message.

This customer-supplied sensor is positioned immediately in front of the

external heater battery in the air line system. In this "frost protection"

fault state, the mixer will be 100 % open and the circulation pump

activated. The fans are switched off until the frost danger message drops away again.

The same frost protection strategy is also applied with a temperature of below +5 °C at the integrated supply

air sensor AI3 or at the external supply air sensor RHB.

4.3.2 Needs-based system operation - CO

2

control

The air volume flow can be controlled via optional accessories with surfacemounted housing, the "CO2 sensor module“, the "humidity sensor module“,

the "CO2 and humidity sensor module“. Needs-based operation via the CO2

and/or humidity control sensor module only functions in automatic

mode and must be activated via the PC software.

A maximum of 10 sensors can be connected, with the highest value for

each fan speed is used. The measured CO

2

– and/or humidityconcentration is used to regulate the fan speed in accordance with the

table. The assignment of the fan speeds, the ppm and humidity values can

be changed via the PC software.

When using humidity sensors the priority can be selected on air quality

(factory setting) or humidity control (regulation to set humidity) on the

control panel.

14 : 30 Di 04.08.09

automatic mode

fan step II

ventilation 24° C

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 14

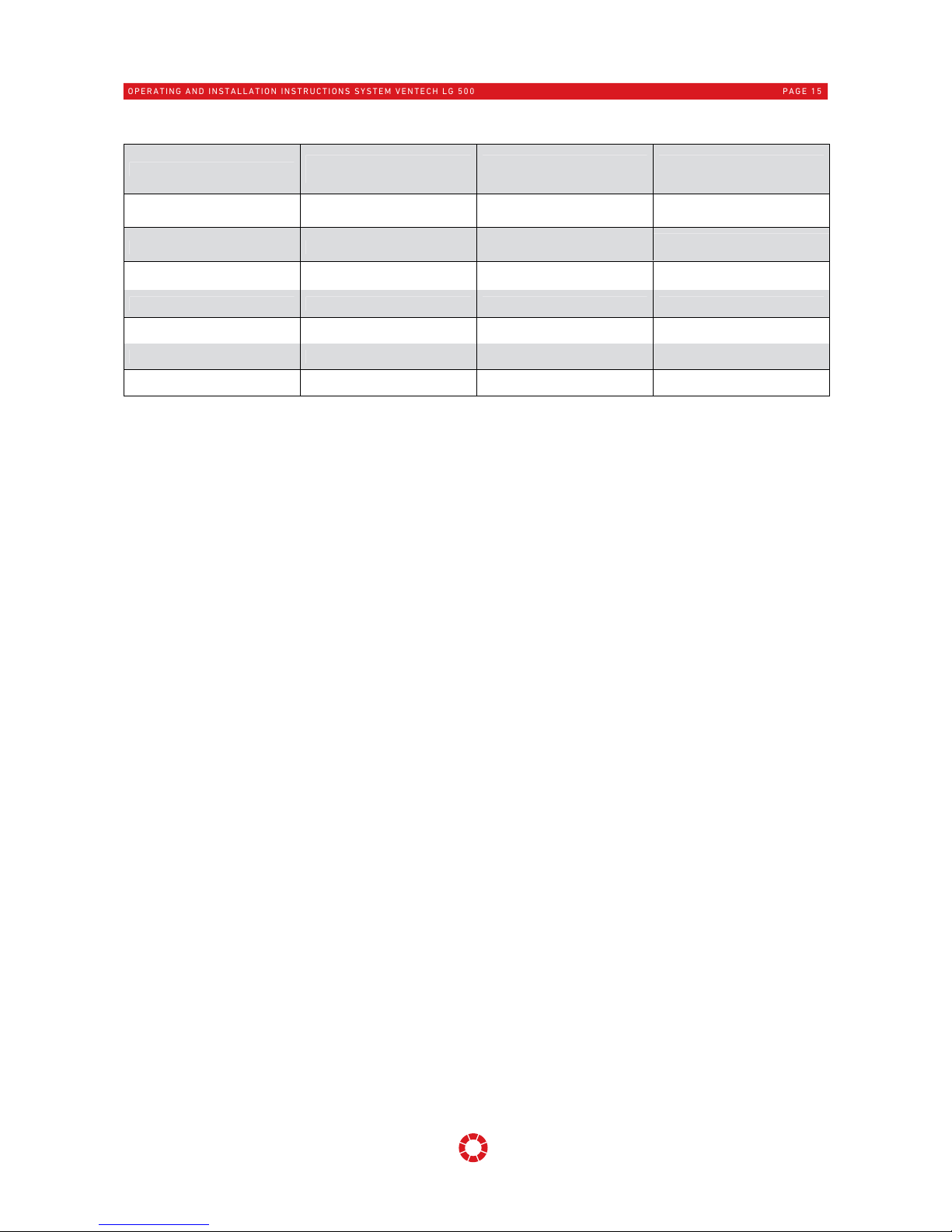

Example:

Sensors adjustment

CO2-Sensor

0 - 2000

Humidity Sensor

0 - 100

CO2- and Humidity Sensor

Fan speed CO2 in ppm Relative humidity in %

0 < 400 < 25

1 401 - 600 26 - 35

2 601 - 900 36 - 50

3 901 - 1500 51 - 65

on request

4 > 1500 > 65

4.4 Ventilation unit

4.4.1 Description

The compact ventilation unit LG 500 System VENTECH is used for the controlled mechanical ventilation of

houses, larger residential units, offices, surgeries and similar applications. The range of use extends

fundamentally to residential areas of 150 m² up to approx. 400 m², with an

adjustable air volume flow up to 550 m³/h.

The compact ventilation unit LG 500 System VENTECH, consists of a compact,

heat bridge-free and heat-insulated housing made from zinc-plated steel plate,

powder-coated exterior in RAL 9010, a highly efficient heat recovery system

with air/air counterflow heat exchanger made from recyclable plastic with an

efficiency level of approximately 92 %, an automatic 100 % bypass with energysaving radial fans in direct-current technology and EC technology with optional

constant flow volume regulation, air filters in quality category F7 in the supply

air and G4 in the extract air with integrated, wired, control electronics and an

optional "KOMFORT-G" remote control panel, for free-standing or wall mounting

in frost-free rooms.

4.4.2 Advantages and features

• With PHI passive house certificate and CH energy cluster declarati

on

• Ventilation unit with highly

efficient energy recovery

• Supply air an

d extr

act air fans with energy-saving EC motors

• 4-stage fan operation without constant volume flow function

• Optional with constant pressure control or electronic volume flow control for

constant air volume flow, adjustable up to 550 m³/h.

• Even with changes in the system pressure is the programmed air volume flow

maintained, for example, if the filter is dirty.

• Needs-based air volume control via CO2 sensor

• User-friendly "

KOMFORT-G

" control unit with integrated room temperature sensor

• Integrated 100 % bypass for bypassing the heat exchanger in summer mode

• Selectable, automatically operating frost protection switch for the heat exchanger,

optionally available with a PTC low temperature preheater battery

• Filter monitoring integrated, upon attainment of the time interval message ‘Filter

change’ appears on the display.

• Simple filter change without tools

• Optional reheater battery for additional raising of the room temperature

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 15

0 - 2000 / 0 - 100

on request

on request

on request

on request

CO2 in ppm /

Relative humidity in %

1

2

2

Measuring sensor

4.4.3 Layout of the unit

1. Operator control unit type ‘

KOMFORT-G

’

2. Power unit

3. Connecting lead Y(ST)Y2x2x0.64

4. Outdoor air filter of quality class F7

5. Extract air filter of quality class G4

6. Counterflow heat exchanger

7. Condensate tank with discharge fitting

8. Frost protection heating with a PTC low temperature

preheater battery (optional)

9. Bypass valve with actuator

10. Outdoor air and supply air fan

11. Exhaust air and extract air fan

12. Pressure sensor for volume flow constant function (optional)

13. Exhaust-air-side sound absorber insert (optional)

14. Front cover with a knurled screw fastener

15. Air line connection

16. Cable leadthroughs

1. Operator control unit type ‘

KOMFORT-G

’

The "

KOMFORT-G

" control unit fitted directly in the living area is used to make settings for the ventilation unit.

The current operational statuses and system values, e.g. operating mode, fan speed, temperatures, etc., are

shown on the four-digit display. Operation (green), faults and filter change (flashing red) are displayed by way

of signal lamps. Automatic or manual mode can be selected. In automatic mode the system operates fully

automatically in accordance with programmable time programs, while in manual mode the fan speed, for

example, can be increased individually (air blast ventilation). The "

KOMFORT-G

" control unit can also be used

to make individual operating parameter settings during servicing work.

2. Power unit

The individual operating parameters are set by the skilled installer or service technician, matched to the

relevant application on site, via the power unit installed in the ventilation unit. The settings can be made either

via the "

KOMFORT-G

" control unit or via the PC interface and communication software.

3. Connecting lead Y(ST)Y2x2x0.64 (not included in the scope of supply)

A screened cable Y(ST)Y2x2x0.64 is required for communication between the operator control unit and the

power unit. The connecting cable is not included in the scope of supply. The cable length must not be longer

than 100 m. The plug connection to the power unit and to the operator control unit is by means of an IDE

connector.

4. Outdoor air filter of quality class F7

(

optional pollen filter of quality class F9)

The outdoor air filter removes dust and contamination from the outdoor air.

2

6

5

4

7

8

12

14

9

10

11

15

16 13

1

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 16

5. Extract air filter of quality class G4 (optional F5)

Coarse contamination is filtered out of the extract air via the extract air filter.

6. Counterflow heat exchanger

The highly-efficient heat exchanger removes the energy content from the extract air and transfers this into

the supply air.

7. Condensate tank with discharge fitting

Any condensate incurred in the heat exchanger during operation is collected via the condensate trough. The

condensate incurred is discharged via the connected condensate drainage system, which is routed via an

effective odour trap.

8. Frost protection heating with a PTC low temperature preheater battery (optional)

In very cold outdoor air temperatures, protects against freezing of condensate in the heat exchanger. The

outdoor air is pre-heated, depending on the outdoor air temperature, via the optional electrical PTC lowtemperature pre-heater battery.

If a water battery or brine battery is used for frost protection the heat exchanger, the battery has to

be protected in a suitable way against freezing when there is frost.

9. Bypass valve with actuator

In summer mode, enables the bypassing of the air flow to the heat exchanger, provided that the outdoor air

temperature is lower than the room temperature.

10. Outdoor air and supply air fan

Ensures the air volume flow for the supply air; provides the living spaces with conditioned outdoor air.

11. Exhaust air and extract air fan

Ensures the air volume flow for the extract air; conveys the consumed air externally out of the apartment.

12. Pressure sensor for volume flow constant function (optional)

Measured value sensor and pressure sensors for the optional definable volume flow constant function of the

fans.

13. Exhaust-air-side sound absorber insert (optional)

For noise reduction in the vicinity of the exhaust air fan.

14. Front cover with a knurled screw fastener

The front cover can be easily opened for maintenance work to the device, e.g. filter exchange. When closing it,

make sure of complete fastening and sufficient seal tightness between the front cover and the unit’s housing.

15. Air line connection

Is for the purpose of connection to the air line system. When installing, ensure correct connection to the

supply, extract, outdoor air and exhaust air lines.

16. Cable leadthroughs

Fundamentally the ventilation unit is supplied electrically ready wired. The cable leadthroughs are used for

making the electrical connection, for connecting the operator control unit and the optional system

accessories, for example, temperature sensors etc.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 17

4.4.4 Versions

The compact ventilation unit LG 500 System VENTECH is available in several different versions:

right-hand or left-hand, depending on the location of the supply air connecting piece,

with or without electrical PTC pre-heater battery integrated into the ventilation unit for frost

protection of the heat exchanger

the device may also be optionally equipped with the following additional functions:

pressure sensor technology for volume flow or pressure constant function

exhaust-air-side sound absorber insert

needs-based ventilation operation via CO

2

sensor

Version Right-hand version Left-hand version

Part no. wit

hout

integrated PTC preheater battery

08LG500-R 08LG500-L

Item no. with an

integrated PTC

preheater battery

08LG500-RV 08LG500-LV

For standing or

wall-mounted

installation

4.4.5 Dimensions

Illustration with optional PTC low-temperature pre-heater battery, sound absorption unit for exhaust air side

and pressure sensor for extract air and supply air.

1 Supply air dia. 200 mm

2 Extract air dia. 200 mm

3 Outdoor air dia. 200 mm

4 Exhaust air dia. 200 mm

5 Counterflow heat

exchanger

6 Extract air fan

7 Supply air fan

8 Control unit

9 Extract air filter G4

10 Outdoor air filter F7

11 Condensate trough

12 Condensate connector ø 15 mm

13 Cable entry 6 x M16

14 PTC electrical preheater battery (optional)

15 Sound absorber insert for EHA

16 Height-adjustable feet

17 Supply air pressure sensor (optional)

18 Extract air pressure sensor (optional)

Illustration: LG 500-RV (right-hand version)

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 18

Page 19 of 44

4.5 Safety devices

For the purpose of ensuring safe operation of the system the safety devices and covers must not be put out of

service, bypassed or dismantled by any measures.

The system must be shut down immediately if faults or malfunctions occur in the ventilation system that could

pose a risk to persons or property.

Further operation must be effectively prevented until a complete repair has been made! Repair may only be

performed by a skilled installer.

Overheating protection. A thermo bi-metal switch is built in to

protect the optionally-integrated frost protection heater battery

from overheating. When a temperature of +50 °C is reached, this

element interrupts the power supply to the PTC electric heater battery.

5 Technical specifications

5.1 Unit specifications

Ventilation unit

Dimensions (w x h x d) 915 x 855 x 655 mm

Housing of single-shell construction made of galvanized sheet

steel, coated in RAL 9010 – white Insulation 25 mm / 30 mm

Air line connection 4 x dia. 200 mm

Condensate connection dia. 15 mm at bottom

Voltage / frequency / current 230 V / 50 Hz / 16 A

Degree of protection IP 20

Permitted ambient temperature for unit 5 °C to +40 °C

permissible air temperatures -15 °C to +35 °C

Weight without accessories 75 kg

Operator control unit „

KOMFORT-G

"

Dimensions (w x h x d) 150 x 82 x 20 mm

Connecting cable to the power unit Cable Y(ST)Y2x2x0.64, screened, max. length < 100 m

Air filters

Outdoor air/supply air filter Pocket filters quality category F7, optional quality category F9

Extract air filter Pocket filters quality category G4

Fans (factory setting)

Fan speed Speed I Speed II Speed III Speed IV

Air volume flow [m³/h] 200 300 400 500

Output in [W] with external 50/100 Pa 50/65 80/100 130/155 210/235

Air volume flow setting range 150 to 550 m³/h, settable

in increments of 5 m³/h.

Flow efficiency in accordance with PHI 0.33 W/m³/h

Power consumption in standby mode 2.9 W

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 19

Heat exchanger

Counterflow heat exchanger made of plastic

Degree of heat provision in accordance with

PHI 82 %

Comfort criterion in accordance with PHI T SAir= +16.5 Ԩ where T FAir= -10 °C

Degree of recovery in accordance with EN 308

(where extract air is 21 °C / 40 % RH)

Housing seal-tightness (according to PHI where nominal air volume flow is 366 m³/h)

external seal-tightness at 100 Pa < 0,6 %

external seal-tightness at 100 Pa < 0,5 %

5.2 Characteristic external pressure increase - air volume flow with volume flow constant

function

5.3 Characteristic external pressure increase - air volume flow without volume flow

constant function

The characteristics illustrated are applicable for the device

design with pressure sensor technology for volume flow

constant regulation, supply air filter quality category F7,

extract air filter quality category G4 and the design with PTC

pre-heater battery in bypass mode. The SFP values shown

take into account power consumption for both fans for supply

air and extract air as well as the power consumption of the

control unit.

The characteristics illustrated are applicable for the device

design with supply air filter quality category F7, extract air

filter quality category G4 and the design with PTC pre-heater

battery in bypass mode.

The SFP values shown take into account power consumption

for both fans for supply air and extract air as well as the power

consumption of the control unit.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 20

5.4 Acoustic specifications

Speed I = 200 m³/h / Speed II = 300 m³/h / Speed III = 400 m³/h / Speed IV = 500 m³/h

with external pressure increase of 100 Pa and integrated sound absorption splitter on the exhaust air side

Remark: Tolerances ± 2 dB for acoustic data

Measuring

point

Housing emission Outdoor air Supply air Exhaust air Extract air

Fan speed I II III IV I II III IV I II III IV I II III IV I II III IV

63 Hz

L

w

in dB

45 47 49 52 65 67 69 71 59 65 72 79 64 66 68 70 62 64 66 68

125 Hz 44 44 44 44 60 60 60 60 55 58 61 64 60 61 62 63 56 57 57 57

250 Hz 44 47 49 51 60 61 62 63 49 52 55 58 60 62 63 65 57 58 59 60

500 Hz 35 37 40 42 45 50 55 59 37 43 48 54 43 50 57 64 44 49 54 59

1000 Hz 31 32 33 34 31 35 39 44 25 31 37 43 31 36 41 47 30 35 39 44

2000 Hz 26 29 31 34 27 32 37 42 18 25 31 38 32 37 43 48 27 32 36 41

4000 Hz 24 28 31 34 21 26 32 37 14 20 26 32 30 35 40 46 16 21 26 32

8000 Hz 19 21 22 24 13 17 21 25 11 13 16 18 17 23 30 36 11 13 14 16

Total

LWA in dB(A)

39 41 44 45 53 55 57 59 44 48 53 57 53 55 60 63 50 51 55 58

6 Operator control unit

6.1 General information

The settings made on the ventilation unit are performed via an operator control unit. Control and operation of

the ventilation unit is performed via the "

KOMFORT-G"

control unit with an integrated room sensor for surface

mounting. The function buttons on the control panel make performing settings simple. All important operating

data are displayed. The signal lamps visualize the operating messages and fault messages.

The control unit is normally installed in the living area and should be suitably positioned. Thermal

source areas, radiators, direct sunlight etc. have to be avoided on account of their temperature

influence!

6.2 Control unit "

KOMFORT-G

"

The

KOMFORT-G

control unit impresses with its simple manipulation of all functions of the ventilation unit. All

status and fault messages in a text display are shown in plain text.

An integrated real-time clock enables automatic mode for clock-controlled adaptation of the fan speed and of

the temperature setpoint of the unit.

A battery is inset on the rear side of the operator control unit (type CR 2430 3V). If the supply voltage fails, the

system time is maintained by this. When the battery is empty the clock must be reset after any loss of power

to the ventilation unit - see Point 6.2.2.3 of these instructions.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 21

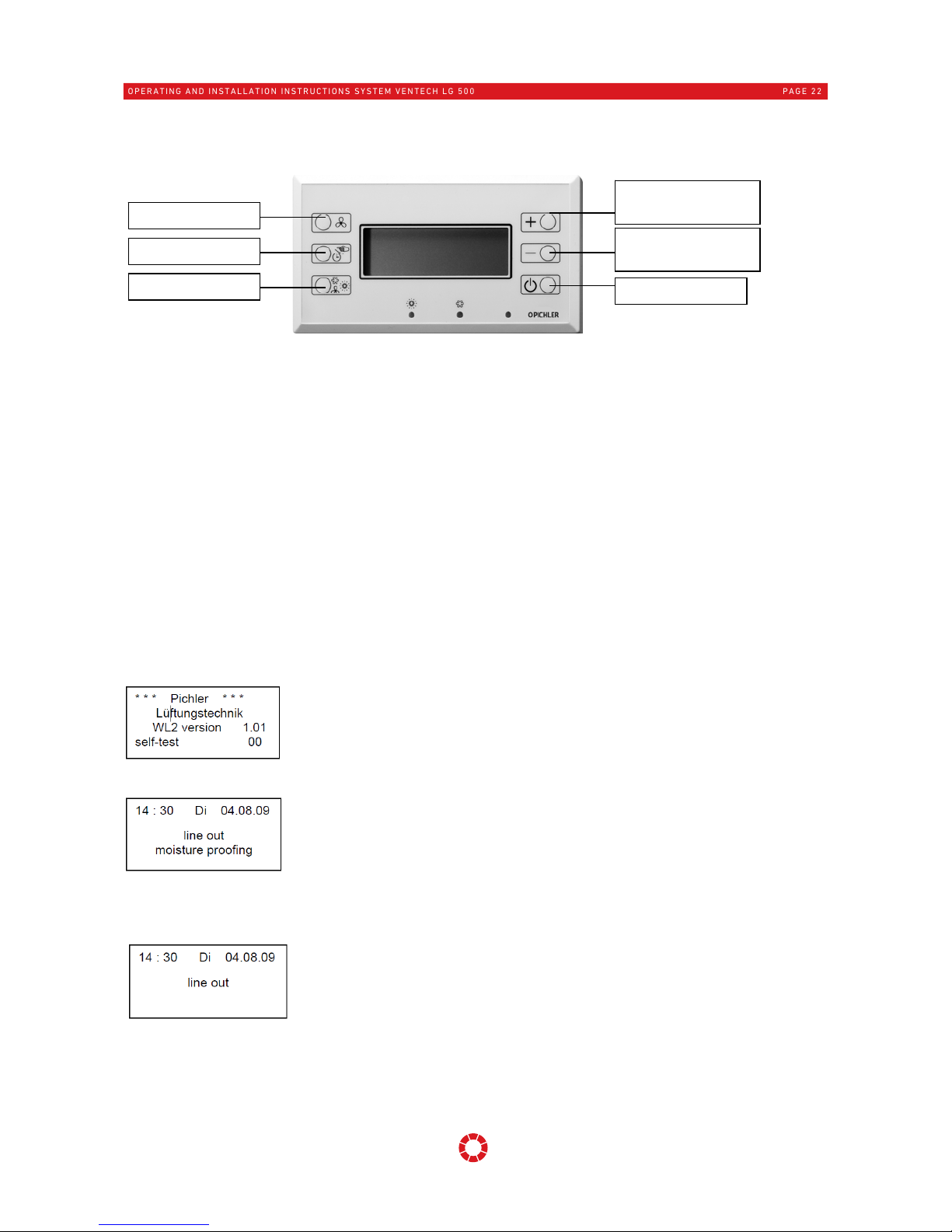

6.2.1 Buttons on the control unit "

KOMFORT-G

"

The "

KOMFORT-G

" control unit has 6 buttons.

The button at the bottom right switches the ventilation unit on or over to standby mode.

The two other buttons on the right-hand side are used to increase or decrease the temperature set value.

These buttons are also used in the configuration menu for setting other parameters.

The desired fan speed is set by means of the button at the top left. Pushing this button increases the fan

speed. If fan speed IV is exceeded, the setting returns to fan speed I.

The automatic button is located on the left-hand side in the centre. In automatic mode the fan speed and any

temperature reduction is determined with the aid of a timer. In manual mode, only the fan speed set by the

user is set, with no consideration of the time programme.

The lower left button switches between summer and winter operation.

6.2.2 Representation on the display

The operator control unit has a four-line display and three light emitting diodes for display purposes. The

display indicates the current status and any messages in clear text. The right-hand LED indicates whether the

system is in operation. When the device is in fault-free operation, this indicator lights green. If there is a fault,

the indicator flashes red. The two remaining LEDs indicate cooling or heating mode.

6.2.2.1 Starting the unit

Upon first voltage supply the operator control unit performs a self-test. This takes

10 seconds at the maximum and is shown on the display. The status last pending is

re-created when a restart take place after a voltage failure.

6.2.2.2 Switching the device on/off

The "

KOMFORT-G

" control unit has an On/Off button that switches the device into

standby mode when required.

In standby mode, depending on the configuration, the ventilation unit is either

completely deactivated or the fan speed is reduced to basic ventilation. When the

On/Off button is pressed the unit is switched back on and returns to its original status.

6.2.2.3 Setting the date and time

To set the time on the "

KOMFORT-G"

control unit, the device must be switched into

standby mode. In switched off condition the time can be edited by pressing the

automatic/manual button.

The present time display will then begin to flash. To change the displayed value,

the [+] and [-] buttons have to be pressed. Pressing the Automatic/Manual button

again will confirm the figure.

Once the correct hour is set and confirmed, the cursor will shift to the minute display. Repeat this process to

set the date and time. Once all figures are set, press the Automatic/Manual button again and the cursor will

disappear. The input can be terminated at any time by pressing the On/Off button.

on/standby

reducing temperature

set point

increasing temperature

set point

ventilation/heating

automatic/manual

fan step

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 22

Temperatures

temperature set value 24 °C

room temperature 24 °C

outdoor temperature 14 °C

6.2.2.4 Automatic/Manual mode

The real-time clock integrated into the operator control unit enables automatic

mode. Optionally the fan speed can also be specified manually. Switch-over

between the two operating modes can be performed with the automatic/manual

button.

In automatic mode the fan speed is specified in accordance with a timer. In winter

mode, automatic mode also enables temperature reductions to be set for certain

times of day.

There is still manual mode as an alternative to automatic mode. In this mode, the

fan speed and the temperature set by the user are constantly maintained.

6.2.2.5 Summer mode/Winter mode

Switching between summer and winter mode in both manual and automatic mode enables change-over of the

earth heat exchanger (via the change-over value) and to control the brine pump.

In summer mode, the earth heat exchanger or brine pump will be activated when the outdoor temperature

(sensor AI9 required) reaches 20 °C (cooling function). In winter mode, the ground collector or brine pump will

be switched on when the outdoor temperature falls below 6 °C (outdoor air pre-heating).

In automatic mode, the device switches between summer and winter modes automatically with the time

changes in spring and autumn. In automatic mode no changeover from summer or winter mode is possible

manually. It is only possible to switch between these modes manually in manual mode. In addition, in

automatic mode, it is also possible to set separate switching times for summer and winter.

6.2.2.6 Bypass mode

Cooling mode:

If the outdoor air temperature is lower than the extract air temperature, and the extract air temperature is

2 °C (hysteresis) higher than the set temperature, the bypass valve bypasses the heat recovery to cool the

living area slightly (only a cooling effect!). The bypass valve function is only enabled when the outdoor air

temperature is a minimum of +14 °C.

Heating mode:

If the outdoor air temperature is higher than the extract air temperature, and the extract air temperature is

2°C lower than the set temperature, the bypass valve bypasses the heat recovery to blow the warm outdoor

air directly into the building and heat the living area.

6.2.2.7 Selecting the fan speed

In automatic mode, the current fan speed is selected via the set time

programme. However, there is the option to switch the ventilation unit to fan

speed IV. Fan speed IV is activated by pressing the fan speed button once. After

120 min (this time is adjustable), the control unit automatically switches back to

the fan speed preset by the time programme.

In manual mode the fan speed is prespecified only by hand. Pressing the fan speed key switches between fan

speed I, II, III and IV.

6.2.2.8 Setting the room temperature in conjunction with external auxiliary heating

Where ventilation units are installed in conjunction with additional external

heating, there is the facility to heat the supply air and, thus, regulate the

room temperature. The target temperature is adapted by pressing the

buttons [+] and [-] on the operator control unit’s operating display. When the

[+] or [-] button is pressed once, the current target temperature appears on

the display. The temperature set value can now be adjusted. The current room temperature and outdoor

temperature can also be viewed (outdoor temperature only with outside sensor AI9). If no buttons are pressed

for one minute, the new set value will be accepted and the control unit switches back to the display showing

the time.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 500

PAGE 23

Service Menü

>Supply air

Extract air

Boost ventilation

Service Menü

>Offset T-Room

Basic ventilation

Filter

Service Menü

>Language setting

Regulation

6.2.2.9 Week time/Day time program

The integrated time programme has the facility to set the fan speed automatically, depending on the current

time and day. In the winter program a lowering mode for the air temperature can be set additionally on units

with external auxiliary heating.

The time programme has the facility to divide each day into three time intervals, for

each of which an individual fan speed can be set. The timer also differentiates

between weekdays, so that, for example, a different switching program can be set

for the weekend than that during the week. In addition, the time programme can

also differentiate between summer and winter modes. To adjust the day and time

programme as required, a special button combination is used to switch into the input mode for the time

programme.

Manual mode should be enabled. Hold down the Automatic/Manual button and press the On/Standby button.

The control unit then switches into the input mode for the time programme.

In the time programme menu, the Summer/Winter mode button is used to switch

between the time programmes for summer and winter. The time programme can

be processed by pressing the Automatic/Manual button. The [+] and [-] buttons are

used to alter the selected value. Further pressing of the automatic/manual button

causes the cursor to jump to the next entry.

If the switching program has been completed for one day (the cursor is on the fan speed for a time period c)

and if the cursor is moved further with the automatic/manual button, the day time program just created is

copied to the following day. The [+] button has to be confirmed for this.

To not adopt the values for the following day, the automatic/manual button has to be pressed, which moves

the cursor back to selection of the weekday again.

The time programme menu will automatically disappear if no button is pressed for one minute. The menu can

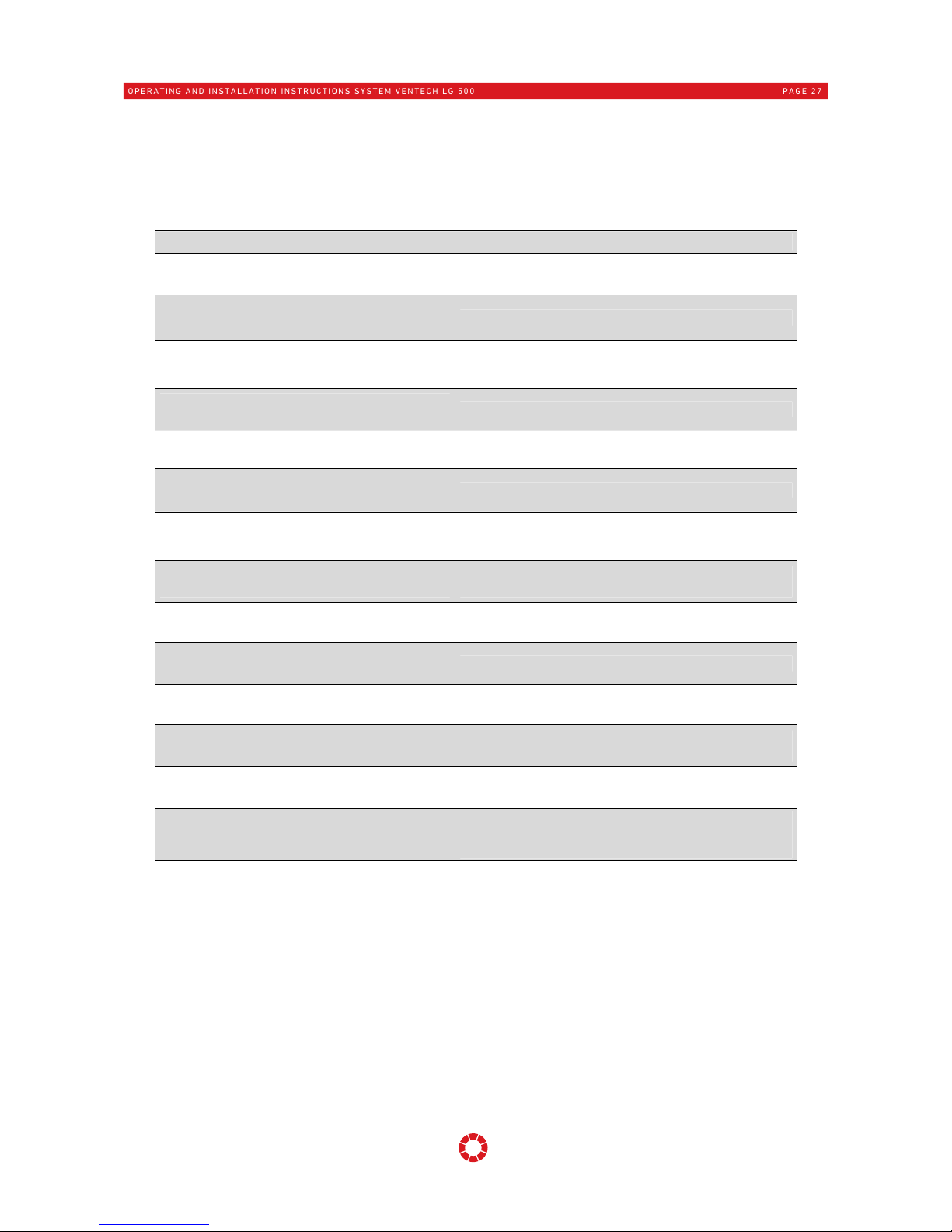

be quitted at any time by pressing the On/Standby button. The control unit will then return to the original