Pichler 08LG250A-R, 08LG250A-L-V, 08LG250A-R-V, 08LG250A-L, 08LG250A Operating And Installation Instructions

...

Systematic ventilation.

optional

COMFORT

VENTILATION

The specified energy eciency

is applicable when controlled to

local requirements and is valid

up to the specified maximum air

flow volume.

EU-Regulation

1253/2014

2016

1254/2014

ENERGIA · ʫʻʫˀʧʰ˔ · ȵɁȵɆȳȵȻȰ · ENERGIJA · ENERGY · ENERGIE ͽEZ'/

LG 250

A

43

dB

250 m³/h

+

A+

A

B

C

D

E

F

G

ErP

2018

OPERATING AND

INSTALLATION INSTRUCTIONS

SYSTEM VENTECH LG 250 A

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 2

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

GENERAL 3

1. Introduction 3

2. General 3

3. Authorised intended utilisation 4

4. Safety 6

USER 10

5. Customer service 10

6. Ventilation unit assembly guide for users 10

7. Control units for the user 10

8. Fault & notice messages 18

9. Filter maintenance for users 19

QUALIFIED PERSONNEL 22

Assembly /Installation 22

10. Scope of supply, transport, storage and disposal 22

11. Technical data 23

12. Functionality of the ventilation system 29

13. Operating units 34

14. Assembly 37

15. Electrical connection 41

16. Maintenance and cleaning 46

Commissioning - Service 51

17. Troubleshooting 51

18. Installation/Operation of service software

and firmware updates 52

19. Spare parts and accessories 52

20. Subject to change 52

21. Product data sheets 53

22. EG-Konformitätserklärung (EC Declaration of Conformity) 55

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 3

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

This chapter contains general information

on the LG 250 A System VENTECH compact

ventilation unit with "MINI" or "TOUCH"

control units.

READ THIS MANUAL

CAREFULLY THROUGH

BEFORE

COMMISSIONING!

This Manual contains notes and

information on safe operation and proper

installation of the System VENTECH

LG 250 A compact ventilation unit and

on its use and servicing. Refer to this

Manual during servicing to ensure proper

execution of the tasks. Keep this operating

manual in a safe place and readily

available at all times.

Troubleshooting and tasks on the compact

ventilation unit may only be performed

by an installation company (a specialist

company). These units are subject

to ongoing improvement and further

development. Your unit may therefore

vary slightly from the description in this

manual.

Changes reserved:

This manual has been compiled with

the utmost care. This does not, however,

imply any rights. We constantly strive

to improve and optimise our products

technically and we reserve the right

to modify our apparatus or technical

data fully or in part and without prior

notification.

The latest version of our "General Terms

and Conditions of Trade" is applicable.

1. Introduction

Dear Customer, thank you for purchasing

a LG 250 A System VENTECH compact

ventilation unit.

The LG 250 A System VENTECH

compact ventilation unit employs stateof-the-art technology. It is characterised

by cost eectiveness, ease of use and

reliability.

To operate your compact ventilation unit

safely, properly and economically, please

read this manual carefully and follow the

instructions provided.

Use the ventilation unit only when in

perfect condition and for its designated

use, be aware of safety and any hazards

and cognisant of all the notes and

information contained in this Manual.

Please always keep the model and serial

number (see nameplate on unit) to hand

in case of queries or when ordering spare

parts.

Please contact us if you have any

further questions or if you lose your

documentation.

2. General

J. Pichler Gesellschaft m.b.H.

9021 KLAGENFURT

Karlweg 5, Postfach 32

T +43 (0)463 32769

Gerätetype:

08LG250ALV

Baujahr:

03.2017

Seriennummer:

E170300156

Gewicht:

65 kg

Auftragsnummer:

3700031E

Volumenstrom:

max. 250 m³/h

Abmessung BxHxT:

675x850x595 mm

Spannung/Frequenz:

230V / 50 Hz

Leistungsaufnahme:

max. 1550 W

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 4

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The LG 250 A System VENTECH compact

ventilation unit is suitable for installation

in air-conditioning systems for controlled

mechanical ventilation and deaeration

of spaces and dwellings with purposes

similar, for example, to seminar rooms

and small oces at an adjustable air flow

volume of up to 250 m³/h.

Installation of a mechanical, controlled

domestic ventilation system provides

supply air and exhaust air ventilation for

the entire living area. Controlled air supply

with purified and filtered outdoor air is

provided in supply air areas. Odours and

damp ambient extract air are conducted

away in the extract air area.

The purpose of controlled mechanical

ventilation and deaeration of domestic

areas is to improve air quality, reduce

heating energy demand through use of a

highly ecient heat recovery system, and

to influence indoor air humidity.

The field of application and intended use

of the unit are restricted to use in air

conditioning systems for the extraction

of used air and the supply of fresh,

temperature-controlled outdoor air at

maximum temperatures between

-15°C and +35°C. In addition, the air

supply must be free from aggressive

vapours and substances which are

conducive to wear.

Any other use shall be deemed contrary

to designated use. The manufacturer shall

accept no responsibility for damages

or consequential damages arising from

improper use. Designated use also

includes adherence to our prescribed

operating and installation manual.

This unit is available to the general

public and is intended for installation in

residential or industrial buildings. The

unit is used for mechanical aeration

and ventilation of ambient air and, when

combined with a heater coil, is also used

to reheat air.

This unit is not intended for use by

persons, including children, with limited

physical, sensory or mental capacities

or lacking experience and/or knowledge,

unless under supervision or instruction of

a person responsible for their safety.

The unit is not suitable for outdoor

installation and may be installed in

suitable and temperature-controlled

interior areas only. The ventilation unit is

not suitable for drying new buildings.

The LG 250 A System VENTECH compact

ventilation unit is not a ready-to-use

product. It must not be put into operation

until it has been properly installed and

connected to the ventilation system. Only

qualified and instructed personnel may

work on and with the unit.

Personnel transporting,

installing or working on the unit

must have read and understood

the operating instructions, in particular

Section 4: "Safety". The end user must also

be instructed on potential hazards.

3. Designated use

INTENDED USE

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 5

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Local requirements in terms of standards,

laws and directives, must be taken into

account .

The central air conditioners with heat

recovery should not be installed in

comparably sized rooms, apartments

or facilities with room air dependent

heating apparatus unless:

• safety systems are in place to prevent

simultaneous operation of room air

dependent heating apparatus and units

extracting air, or

• special safety systems will monitor

waste gas extraction of a heating

apparatus dependent on room air.

Heating apparatus running on liquid or

gaseous fuels and drawing in room air,

or air conditioning systems, must switch

o should a safety system trigger. The

air conditioning system must switch o

should the safety system trigger in case

of solid fuel heating apparatus drawing

in room air.

Central air conditioning equipment for

controlled ventilation and extraction of air

in an apartment or similar facility shall

not be installed if the facility has room air

dependent heating apparatus connected

to waste gas units with multiple infeeds.

For normal operation of central air

conditioning systems, it must be possible

to close any ducts for combustion air

or waste gas systems from heating

apparatus dependent on room air. Shuto systems for waste gas from solid

fuel heating apparatus must be manual.

The position of the operating lever must

indicate the status of the shut-o device.

This is deemed complied with if a shut-o

system is used to block soot (soot shuto).

Fire protection requirements

The regional regulatory provisions,

especially the fire protection regulations

for air conditioning of buildings,

as amended, must be taken into

consideration when installing the air

conditioning system in accordance with

the instructions for fire protection.

Due to their heavy burden and irregular

operation, extract air from any kitchen

extractor hoods that may be present

must not be integrated into the dwelling's

air-conditioning system. Extract air from

such extractor hoods must be conducted

separately to the roof by means of an

exhaust air pipe. The supply air must be

provided separately (e.g. by means of

ventilation windows).

Where an extractor hood is operated with

no separate supply of air, the air volumes

in the home will no longer be balanced,

and it will no longer be possible to ensure

the proper function of the home ventilation system (odour extraction, etc.).

Another option is to operate the extractor

hood in recirculation mode.

The LG 250 A System VENTECH compact

ventilation unit has been developed and

manufactured for controlled mechanical

ventilation and deaeration of spaces with

purposes similar, for example, to seminar

rooms and small oces.

Any other use shall be deemed improper

use and may result in personal injury or

damage to the LG 250 A System VENTECH

compact ventilation unit, for which the

manufacturer cannot be held liable.

The manufacturer accepts no responsibility

for any damages due to:

• Non-observance of the Safety,

Operating and Servicing notes in this

Operating and Installation Manual

• Fitting of replacement parts which

were not provided by the manufacturer,

in which case responsibility for the use

of such parts shall lie solely with the

equipment fitter/installer.

• Normal wear and tear

LIABILITY

STIPULATIONS FOR OPERATION WITH

FIREPLACES

STIPULATIONS FOR OPERATION WITH

EXTRACTOR HOODS

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 6

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The warranty period shall commence

after the unit is put into operation, but

no later than one month after delivery.

The warranty shall cover exclusively

the replacement of basic material and

exclude claims based on services.

The warranty shall be subject to proof

of services performed as per our

instructions and executed by a licensed

installer/specialised company.

Warranty claims are valid for a maximum

of 24 months following installation of the

LG 250 A

System VENTECH compact ventilation

unit but are limited to 30 months from the

date of manufacture.

Warranty claims shall be limited to

material and/or constructional defects

occurring during the warranty period.

In the event of a warranty claim, the LG

250 A compact ventilation unit must

not be dismantled without prior written

authorisation from the manufacturer. The

manufacturer's liability shall be limited

to spare parts installed by an installation

company approved by the manufacturer.

The warranty shall automatically lapse at

the end of the warranty period, following

improper operation such as operation

without a filter, if parts other than

original manufacturer-supplied parts are

installed, or if unauthorised changes or

modifications are made to the unit.

The warranty is voided automatically by

failure to comply with the information in

this installation and operating Manual.

WARRANTY

4. Safety

Read this Operating and Installation

Manual carefully and heed the notes on

Safety during installation, commissioning,

general work or maintenance on the

unit. Keep the Operating and Installation

Manual near the unit for its entire service

life.

Always heed the safety regulations,

warnings, instructions and remarks in

this Operating Manual. The specifications

given in this document must not be

altered. Non-observance of these safety

regulations, warnings, instructions and

remarks may lead to physical injury or

damage to the compact ventilation unit.

The conclusion of a service contract is

recommended to ensure that the unit

will be checked at regular intervals. Ask

your supplier about approved specialised

companies/installers in your area.

SYMBOLS USED IN THIS DOCUMENT The following Safety symbols highlight

passages containing warnings in respect

of danger and potential hazards. Please

familiarise yourself with these symbols.

Attention/Note!

Attention! Ignoring this warning

may lead to injury or threat to

life and limb and/or damage to

the unit.

Attention: hazardous electrical

voltage! Ignoring this warning

may result in injury or threat to

life and limb.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 7

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Installation, initial start-up,

maintenance and repairs must

only be carried out by

an authorised specialist company

(specialised heating company/installer).

Over and above this operating and

installation manual, local and national

regulations and standards shall also

apply to the operation of this unit without

limitation.

Take instruction from your installer on

the unit and on its control unit following

installation. The ventilation unit may only

be used subject to the "Designated use"

section.

All safety and danger notices attached to

the unit must be observed.

In the event of a malfunction, switch o

the unit immediately and secure against

accidental re-activation. Faults must be

remedied immediately.

After repairs and maintenance work,

qualified personnel must verify that the

unit is safe to operate.

Attachment or installation of additional

parts and components is not permitted.

Modifications and alterations to the

LG 250 A System VENTECH compact

ventilation unit are prohibited. Only

original spare parts may be used.

Modifications and alterations to the

ventilation unit are prohibited and absolve

the manufacturer from all warranties and

liability. Ensure that children do not play

with the unit.

SAFETY REGULATIONS

National and local regulations

must be observed during

installation and setup. The unit

may only be installed in compliance with

national installation regulations.

Installation shall be carried out in

accordance with the general local

building, safety and installation

regulations of the relevant community or

the water and electricity department and

other bodies.

The unit may only be installed in frost-free

and dry rooms. The room temperature at

the installation area must consistently

be between a min. of +5°C and a max. of

+40°C.

The unit is designed for upright or wall

installation and may only be set up on

a suitable, load-bearing floor. The unit

must not be exposed to vibration of any

kind. Suitable drainage of condensate

generated when operating the unit will

be required, including eective odour

blocking traps (siphon).

Water, heating and condensate

connections may only be installed by a

specialist. The unit must be installed and

executed appropriately so as to ensure

seal-tightness and eective condensate

drainage in order to exclude the possibility

of building damage. Eective condensate

drainage must be verified on-site prior to

initial start-up and after servicing the unit.

The maximum permissible load must be

observed when transporting the unit.

Components of the ventilation plant,

e.g. air ducts which may need to be

installed in unheated areas, must be

suitably insulated to prevent heat loss or

condensate formation (for temperatures

under dewpoint). Observe all locallyapplicable construction and fire protection

guidelines, regulations and standards. If

necessary, appropriate suitable measures

should be taken when installing the unit

e.g. installation of fire dampers in air

ducts, etc.

UNIT SET-UP

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 8

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The operation of the ventilation

unit is permitted only if all builtin parts provided e.g. silencers

etc., have been properly connected.

The system must be taken

out of operation immediately

in the event of any fault or

damage that may cause harm to persons

or property. Further use must be actively

prevented until the unit is fully repaired!

• Warning: hazardous electrical

voltage!

•

Disregarding the hazard may

result in death, injury or material damage.

•

Before carrying out any work on live

parts, the unit must always be disconnected completely from the power

supply (all poles) and secured against

being switched back on!

The earthed connector-system

to the mains supply enables allpole disconnection of the unit

from the power supply

Electrical connection work as well as

tasks involving electrical plant components may only be performed by authorised electrical engineers in accordance

with national and local regulations.

Before opening the unit and when carrying out work on the unit e.g. maintenance

work and repairs, the unit must be isolated from the mains (all poles disconnected)

and secured against being switched back

on for the duration of the work.

The LG 250 A System VENTECH compact

ventilation unit is designed for a 230 V/50

Hz power supply. The unit is not designed

for connection to a 400 V/50 Hz, threephase supply.

Electrical equipment and the unit's

warning and protective devices must be

inspected regularly to ensure that they

are in perfect working order. In the event

of faults in the electrical power supply

or identification of defects e.g. loose connections or burnt cables, the unit must be

switched o immediately.

Damaged or faulty power supply cables to

the unit must be repaired immediately to

avoid hazards.

The unit may not be operated until safe

operational conditions are restored.

Fault finding and immediate remediation

of electrical defects and malfunctions

shall be carried out by authorised electricians only. All protective measures must

be inspected (e.g. earth resistance etc.)

after completion of electrical work on the

unit.

For details, see Section 15: "Electrical

Connections"

Work practices that could

compromise the unit's

safety are prohibited!

To ensure safe operation, safety devices must not be removed or bypassed.

ELECTRICAL CONNECTION WORK

PLANT OPERATION

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 9

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

The ventilation unit must be switched

o and disconnected from the mains

supply immediately in the event of a fault

message or damage. Be aware of your

safety and of hazards when opening the

front covers or removing cover plates.

Work practices that aect the safety of

the unit are prohibited. The unit may only

be operated with connected air ducts and

installed system components such as

acoustic dampeners and with a minimum

duct length of 1000 mm so as to ensure

that fans or electrical components cannot

be touched.

The ventilation unit may be operated

only in accordance with the

project documentation. The project

documentation shall comply with the

Equipment and Product Safety Act and the

pertinent provisions of the EC Directives

and Standards.

Consider environmental impacts and

refrain from installing the ventilation

units in the vicinity of flammable liquids

or gases, in swimming pools or in areas

exposed to chemicals.

Never operate the ventilation unit without

an air filter. Air filters must be checked

regularly for dirt and damage and

cleaned or replaced if necessary. The air

filters must be changed at least every

six months or when the "Change Filter"

message appears on the control unit. Use

original replacement filters only. If the

plant is not used in summer, the air filters

must, for hygienic reasons, be replaced

prior to restarting.

Comply with safety requirements and

standards when operating the ventilation

unit simultaneously with ambient airdependent fireplaces or extractor hoods.

When using fireplaces dependent on

ambient air, a combustion air supply must

be provided separately. See the provisions

on this topic under the section "Provisions

for operation with fireplaces".

Due to their heavy burden and irregular

operation, extractor hoods must under

no circumstances be integrated into

the exhaust or extract air circuits of the

ventilation unit. See the provisions on this

topic under the section "Provisions for

connection with extractor hoods". Exhaust

air extractor hoods must be operated

via separate air pipes with suitable air

replenishment e.g. by means of window

ventilation or in air recirculation mode.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 10

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The LG 250 A System VENTECH compact

ventilation unit is used for controlled,

mechanical ventilation and deaeration of

homes, large residential units and oces

and for similar purposes.

The scope of application normally extends

to living spaces between 80 m² and

approx. 200 m², with an adjustable air

flow of up to 250 m³/h.

The LG 250 A System VENTECH compact

ventilation unit comprises:

•

A compact, non-heat bridging and

thermally-insulated housing made from

galvanised steel sheeting, externally

powder-coated in RAL 9010

•

A high-eciency heat recovery system

with air/air-counterflow heat exchanger

made from recyclable plastic with an

eciency level of approx. 92 %

•

An automatic 100% bypass with energy-

saving DC radial fans with constant

airflow control,

•

Air filter, quality grade F7 or F9 in supply

air and G4 in extract air

•

Internally wired electronic control

system

•

A "MINI" or "TOUCH" OPERATING UNIT

(optional) , for standing or wall mounting

in spaces free from frost.

5. Customer service

Please contact the installer of your

ventilation and air conditioning system

or contact us directly for any questions

relating to the LG 250 A System VENTECH

compact ventilation unit supplied.

USER GUIDE

J. Pichler Gesellschaft m.b.H.

9021 KLAGENFURT

Karlweg 5, Postfach 32

T +43 (0)463 32769

6. Ventilation unit assembly guide for users

The following compact ventilation unit

functions can be configured with the

"MINI" control unit.

• Ventilation level of the ventilation unit

•

Switching between summer and winter

modes

• Display of filter change messages

•

Display of possible fault

messages with the LEDs provided for

this purpose.

•

Air flow volume for levels I to III can be

adjusted in certain areas using a combination of buttons.

•

In addition, the unit can be switched to

Standby mode or Basic Ventilation mode.

"MINI" CONTROL UNIT

7. Control units for the user

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 11

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

4 buttons

The ventilation unit is operated by means

of 4 buttons.

Summer/Winter mode:

The two buttons on the left-hand side

are used to switch between summer and

winter mode.

Summer / bypass modes support cooling

of the living area. The bypass circumvents

the heat exchanger and the cold outdoor

air is blown directly or via a ground collector into the living area.

The outdoor air is always conveyed via the

heat exchanger in winter operation.

Modifying the ventilation levels:

The two buttons on the right-hand side

change the unit’s ventilation level. Pressing the [+] button increases the ventilation

level until level III is reached which corresponds to boost ventilation. After 1 hour

operating time in the highest ventilation

level, normal ventilation mode is automatically reset to Level 2. The boost ventilation may, alternatively, also be stopped

manually after one hour. Pressing the [-]

button reduces the ventilation level.

Basic Ventilation operating mode:

If the ventilation level is less than I, the

unit switches to Standby mode or to Basic

Ventilation operating mode. A minimum

volume flow of 30 m³/h is configured.

7 LEDs:

The ventilation unit's various statuses are

signalled via a total of 7 LEDs. Three LEDs

display the current ventilation level.

If the unit is in

"Basic Ventilation" mode, this can be seen

from the gentling flashing of ventilation

level I.

On the left-hand side, the LEDs for summer and/or winter modes are arranged

beside the corresponding buttons.

Filter change required:

The potential need to change the filter is

signalled by the LED on the bottom left.

For details on filter replacement, see

Section 9

Fault messages

The LED for fault messages can be seen

on the lower right-hand side. Please con-

tact your installer!

For details on fault messages, see

Section 8

BUTTONS AND LEDS

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 12

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

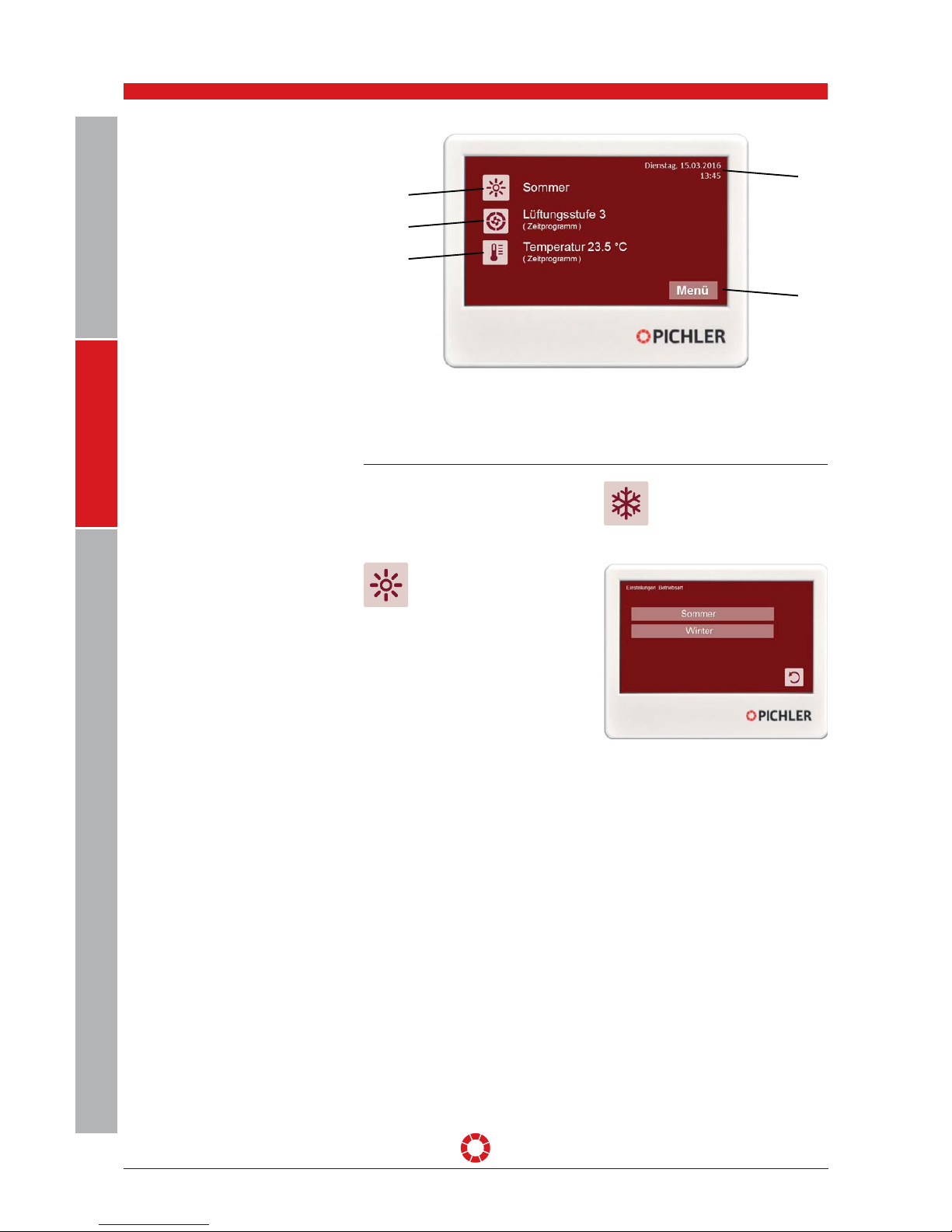

“TOUCH” CONTROL UNIT

1 Current operating mode

2 Ventilation level

3 Temperature (ambient air, supply air, extract air)

4 Menu

5 Date and time

1

2

3

5

4

OPERATING MODE The active operating mode is displayed by

various buttons. The operating mode can

be changed by pressing the buttons. The

following operating modes are available:

Summer:

Summer or bypass mode supports cooling of the living area.

The bypass circumvents the

heat exchanger and the cold outdoor air

is blown directly or via a ground collector

into the living area.

Winter:

The outdoor air is always conveyed via the heat exchanger in

winter operation.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 13

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

VENTILATION LEVEL The active ventilation level is displayed by

various buttons. The ventilation level can

be changed by pressing the buttons. The

following selection options are available:

Time program:

The system runs at the ventilation level

that is currently programmed. The time

program can be programmed in the

"Menu" under "Settings".

O*:

The machine is switched o.

Basic ventilation*:

The unit runs with

basic ventilation

Ventilation level 1:

The unit runs at ventilation

level 1

Ventilation level 2:

The unit runs at ventilation

level 2

Ventilation level 3:

The unit runs at ventilation

level 3

The two buttons on the right-hand side

change the unit’s ventilation level. Pressing the [+] button increases the ventilation

level until level III is reached which corresponds to boost ventilation. After 1 hour

operating time in the highest ventilation

level, normal ventilation mode is automatically reset to Level 2. The boost ventilation may, alternatively, also be stopped

manually after one hour. Pressing the [-]

button reduces the ventilation level.

*Depending on the configuration of the

plant!

Basic ventilation activated: The user cannot switch o the unit.

Basic ventilation deactivated: The user can

switch o the unit.

Basic ventilation can only be activated and

deactivated by service engineers!

In principle: “Ventilate

as much as necessary”

Adjustment of air volume requires

relevant expertise and is performed by a

specialist during initial start-up.

If ventilation is too low, poor ambient air

quality or mould formation may result in

living areas.

If ventilation is too high, ambient air may

become too dry - particularly in the colder

months.

Superior air volume control

There are various configurations and

operating modes that result in the unit

being operated with air volumes other

than those defined.

These include:

• CO

2

concentration-based control

• Humidity concentration-based control

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 14

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

TEMPERATURE

The Main menu is opened by pressing

the Menu button. Information on the

ventilation unit is displayed here, and

various settings can be made and actions

performed.

The user is returned to the

Start menu by pressing the

Home button.

•

Set the required temperature in stand-

ard mode

•

Activate/deactivate the time program

•

Ambient air, extract air or supply air is

controlled, depending on the control

setting configured by the specialist

MAIN MENU

Current operating values, operating hours,

messages and firmware versions can be

retrieved under the “Information” menu

item.

Current operating values

Time meter

Fault signal

INFORMATION

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 15

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Current errors and error and filter logs

can be displayed here.

Current error

Error log

Filter log

Firmware

Firmware versions for control and display

are displayed here, as well as ventilation

unit model and ventilator model.

Air volume

Volume flow can be adjusted for each

individual ventilation level here (min. and

max. volume flows are preset).

Three times can be specified for each

day using the time program. These times

determine the time at which a particular

ventilation level is activated.

SETTINGS

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 16

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

Temperature

Temperatures for standard mode and

setback mode can be configured here. In

addition, three times can be specified for

room temperature each day. These times

determine the time at which a particular

ventilation level is activated.

Air filter changed

If the air filter has been changed, the filter

service time can be reset here so that a

filter warning no longer appears on the

display.

Date & time

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 17

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Language

The user can switch between Deutsch,

English, Français, Nederlands, Ceský,

Slovenskí and Italiano.

The following errors can be reset under

"Actions":

Standard for LG 250 A - no function:

Reset controlled

GL (Basic Ventilation)/OFF

Reset error Z04/Z05

The + and – options are displayed by

pressing the “No” button. The error is

reset by selecting "Yes" and confirming

with "OK".

Error Z04/Z05

One of the two fans is blocked or has no

power supply, no control voltage signal or

no tachometer feedback. Perform reset

only after remedying the error!

ACTIONS

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 18

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

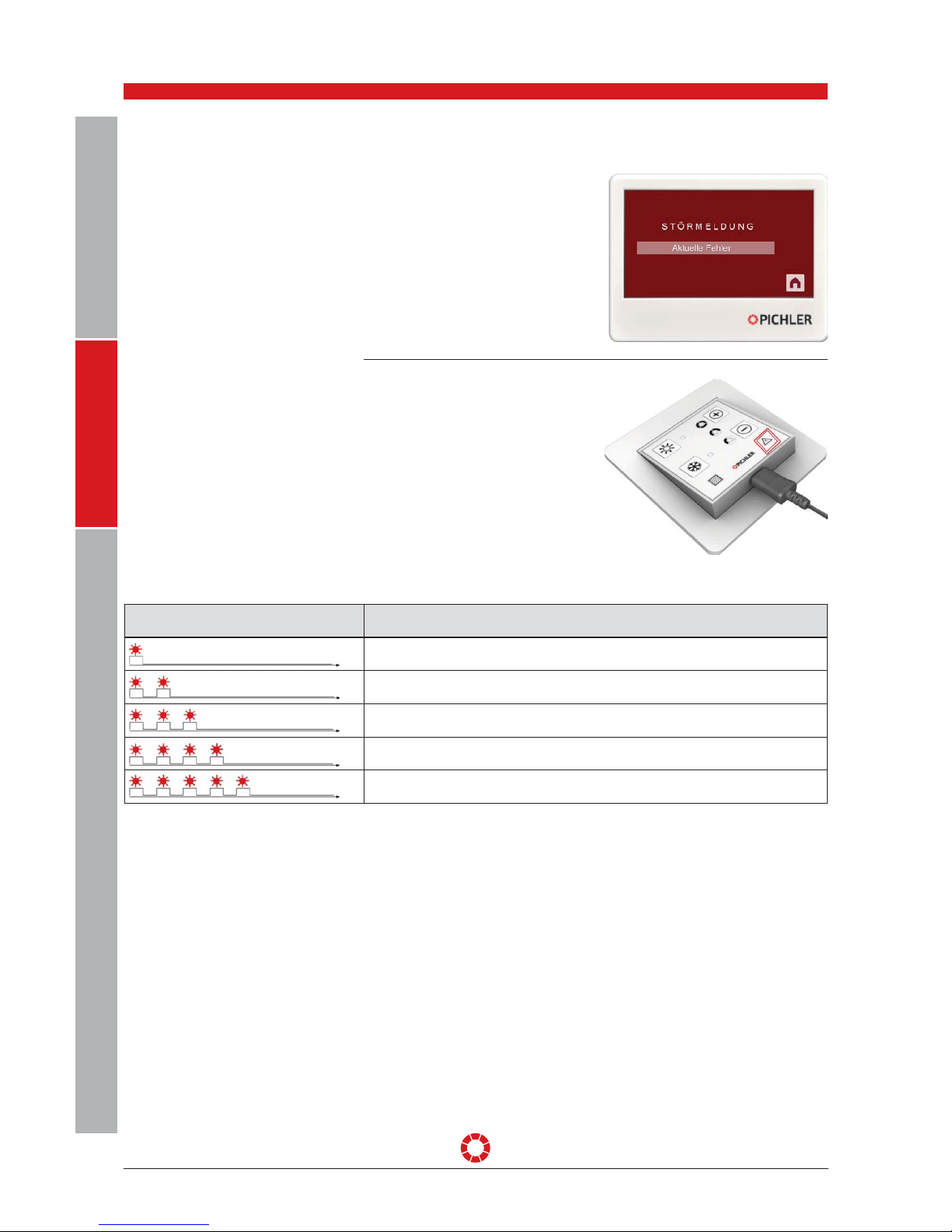

“TOUCH” CONTROL UNIT

8. Fault & notice messages

Error signal Reason for error

Supply air fan out of service

The error LED flashes once, followed by a long pause

Extract air fan out of service

The error LED flashes briefly twice in succession, followed by a long pause

Temperature sensor error

The error LED flashes briefly three times in succession, followed by a long pause

General fault

The error LED flashes briefly four times in succession, followed by a long pause

Communication between power section and control unit interrupted

The error LED flashes briefly five times in succession, followed by a long pause

The ventilation unit's fault status is indicated on the operating unit by the flashing

pattern of the fault LED.

Please contact your installer.

“MINI” CONTROL UNIT

*See pages 17/18 for detailed descriptions

Please contact your installer.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 19

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

These instructions relate exclusively to regular inspection,

maintenance and replacement

of air filters by the user.

Check the condition of the air

filters regularly

Filter change interval

Filters must be replaced imme-

diately if very dirty. Otherwise,

they should be replaced at least

twice a year, depending on outdoor air

pollution levels.

Only original replacement filters of the

specified quality class may be used.

9. Filter maintenance for the user

1 Exhaust air filter, coarse dust filter class G4

2 supply air filter, fine dust filter class F7,

optionally F9 as a pollen filter

MAINTENANCE INSTRUCTIONS

(AIR FILTER)

1

2

When the filter service time has elapsed

(factory setting: 2,900 hours), the control

unit signals the need for a filter change

through the LED provided for this purpose,

which lights yellow continuously.

FILTER MESSAGE ON THE "MINI” CONTROL UNIT

The control unit reminds the

user of filter maintenance at

regular intervals (filter service

time: 2900 hours)!

FILTER MESSAGE ON THE "TOUCH" CONTROL UNIT

1

2

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 20

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

When replacing the air filters,

avoid soiling the unit and its

components. Dirty air filters

must be immediately and suitably disposed of.

It is advisable to package the air filters in

an airtight container immediately after

removal to avoid contamination of the

ventilation system and the unit.

Before carrying out any work

on live parts, the unit must

always be disconnected com-

pletely from the power supply

(all poles) and secured against being

switched back on!

1. Filter message on control unit

2. Undo the wing nuts on the housing

cover.

3. Open the front doors.

4.Before drawing the air filters out from

the unit, release the filter stentering rails.

Only then may the air filters be easily

lifted out and replaced.

5. Extract the filter.

ATTENTION: Never operate the

ventilation unit without using air

filters!

6. Insert the new filter. Please note: Only

original replacement filters of the specified quality class may be used.

Note the installation position

(direction of ventilation) of the

filter!

7. When inserting the new filter, ensure

that it is installed correctly, and close the

filter stentering rails.

8. Close the housing cover and secure it

with the wing nuts. When replacing the

cover, ensure that it is completely closed

and that there is sucient seal-tightness

between the front cover and the unit

housing.

Where can I order filters?

Use only original replacement filters of

the filter quality class specified.

FILTER CHANGING

J. Pichler Gesellschaft m.b.H.

9021 KLAGENFURT

Karlweg 5, Postfach 32

T

+43 (0)463 32769

filter@pichlerluft.at

Designation Item no.:

Supply air filter quality grade F7 standard

40LG050060

Extract air filter quality grade G4 standard

40LG050050

Supply air filter quality grade F9 standard

40LG050070

1 Filter stentering rails

2 Air filter

1

2

2

1

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 21

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Filter change required:

Reset the filter counter after changing the

filter.

Press the [+] button and the [-] button at

the same time for 5 seconds in order to do

this. The filter message disappears after

entering this combination.

Premature filter changing:

If the air filters are replaced prematurely,

the filter counter must be reset without a

pending filter message.

Press the [+] button and the [-] button at

the same time for 5 seconds in order to

do this..

CLEARING FILTER MESSAGES

Reset the filter signal on the control unit

after every filter change! The filtering time

can also be reset later in the settings.

If the air filter has been changed, the filter

service time can be reset here so that a

filter warning no longer appears on the

display.

“TOUCH” control unit

“MINI” control unit

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 22

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

10. Scope of supply, transport, storage and disposal

The scope of supply includes:

• The ventilation unit with the "MINI"

control unit, optional: "TOUCH"

• The operating and installation manual

• The wall mounting bracket

On delivery of the unit, check that the

type and serial number on the nameplate

correspond with the information on

the order and delivery documents,

that the equipment (including optional

accessories) is complete, and that all

parts have been delivered in perfect

condition.

Note: Any transport damage

and/or missing parts must be

reported immediately in writing

to the forwarder or supplier.

SCOPE OF SUPPLY

The LG 250 A System VENTECH ventilation

unit range is supplied with transport

packaging. The safety markings on the

packaging must be observed.

The LG 250 A System VENTECH compact

ventilation unit must be handled with care

in order to prevent possible damage due

to forceful impact during transportation.

• Unit dimensions

( W x H x D): 672 x 870 x 610 mm

• Weight: approx. 65 kg with no optional

accessories

Ensure that the unit is not damaged from

being toppled or overturned. Avoid knocks

and blows during transportation.

Applicable safety and accident

regulations must be complied with during

transportation. If transported manually,

ensure that necessary human lifting and

carrying forces are reasonable.

TRANSPORT AND PACKAGING

The unit must be stored in its packaging

in suitable dry, dust-free rooms and

protected from frost. Avoid storing for

more than one year.

STORAGE

Care must be taken to ensure that the

packing material and protective packaging

are disposed of in an environmentally

friendly manner.

The packaging materials must be

disposed of in accordance with local

regulations; wooden pallets or cartons

must be recycled, for instance.

Units that are no longer

in working order must be

dismantled by a specialised

company and properly disposed of via

suitable collection centres in accordance

with the Waste Electrical and Electronic

Equipment Ordinance (WEEE), which

provides for the implementation of

community law, Directive 202/95/EC

(RoHS) and Directive 2002/96/EC (WEEE

Directive).

DISPOSAL

GUIDE FOR SPECIALIST PERSONNEL

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 23

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Ventilation unit

Dimensions:

(W x H x D) 672 x 870 x 610 mm

Thermally-insulated housing in single

formwork design, made from galvanised

steel sheeting, coated in RAL 9010 – white

Air line connector:

4 x ø 160 mm

Condensate connector:

ø 15 mm on underside

Electrical connection:

230 V/50 Hz/16 A

Protection class:

IP 20

Permissible unit ambient temperature:

+5°C to +40°C

Permissible external air temperature:

-15°C to +35°C

Weight with no accessories:

approx. 65 kg

"MINI" and "TOUCH" operating unit

Dimensions "MINI" (W x H x D):

80 x 80 x 19 mm

Dimensions "TOUCH" (W x H x D):

110 x 84 x 25 mm

Connector cable to output component:

Cable J-Y(ST)Y 2 x 2 x 0.8, shielded,

max. length < 100 m

Air filter

External air/supply air filter:

Compact filter quality class F7,

Optional quality class F9

Exhaust air filter:

Compact filter quality class G4

Fans (default setting)

Air flow rate setting range:

80 to 250 m³/h, adjustable in 5 m³/h steps

Power eciency in accordance with PHI:

0.30 W/m³/h

Stand-by mode input:

1.9 W

Heat exchanger

Counterflow heat exchanger made from

plastic

Heat provision level in accordance with

PHI: 88%

Comfort criterion in accordance with PHI:

T

ZUL

= +18.2°C at T

AUL

= -10°C

Housing thickness (in accordance with PHI)

external tightness < 0.6%

within pressure range between 50 Pa and

300 Pa

internal tightness < 1.0%

based on average air volume flow

11. Technical data

UNIT DATA

Ventilation

stages

Stage I Stage II Stage III

Air volume

flow

[m³/h]

80 160 250

Power consumption at

external 50

Pa/100 Pa

[W]

24/33 37/50 70/91

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 24

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The characteristic curves shown are valid

for the unit version with Class F7 supply

air and G4 extract air air filters, as well as

the version with no PTC preheater coil.

The rated overall output comprises the

power consumption of the two supply

and extract air fans as well as the power

consumption of the control system.

CHARACTERISTIC CURVE - EXTERNAL

PRESSURE INCREASE – AIR VOLUME

FLOW RATE

ACOUSTIC DATA Level I = 80 m³/h / Level II = 160 m³/h/

Level III = 250 m³/h at external pressure

increase of 100 Pa

Note: Tolerances ± 2 dB for acoustic data

Measuring

point

Housing

radiation

Outdoor air

connection

Supply air

connection

Exhaust air

connection

Extract air

connection

Level I II III I II III I II III I II III I II III

63 Hz

Lw in dB

55 57 57 64 65 65 79 80 81 76 73 75 66 69 67

125 Hz 50 53 55 55 59 61 67 71 73 69 69 71 52 57 60

250 Hz 41 45 50 51 57 60 63 70 73 62 65 70 49 55 59

500 Hz 35 38 42 39 44 46 55 61 66 55 55 60 34 42 45

1000 Hz 32 36 40 30 33 37 55 62 66 54 56 59 24 31 36

2000 Hz 22 27 34 19 24 29 46 56 61 46 48 53 21 31 36

4000 Hz 15 17 25 12 17 22 39 49 55 39 42 48 17 28 33

8000 Hz 18 18 18 11 12 15 35 46 52 35 37 44 12 17 23

Total

LWA in dB(A)

39 42 46 45 49 52 60 67 70 59 61 65 43 48 51

The LG 250 A System VENTECH compact

ventilation unit is used for controlled,

mechanical ventilation and deaeration of

homes, large residential units and oces

and for similar purposes.

The scope of application normally extends

to living spaces between

80 m² and approx. 200 m², with an

adjustable air flow of up to

250 m³/h.

The LG 250 A System VENTECH compact

ventilation unit, comprising a compact,

non-heat bridging and thermally-insulated

housing made from galvanised steel

sheeting, externally powder-coated in

RAL 9010, a high-eciency heat recovery

system with air/air-counterflow heat

exchanger made from recyclable plastic

with an eciency level of approx. 92%,

automatic 100% bypass, with energysaving DC radial fans with constant

flow regulation, Class F7 in outdoor air

and Class G4 extract air air filters, an

internally wired electronic control system

and a “MINI” control unit (optional).

"TOUCH" for floor or wall mounting in

frost-free spaces.

VENTILATION UNIT

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 25

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

• LG 250 A compact ventilation unit with

PHI passive house certification

• Ventilation unit with high-eciency heat

recovery

• Supply air and extract air fan with

energy-saving EC motors

• Electronic volume flow control for

constant air volume flow, adjustable up

to approx. 250 m³/h. The set air volume

flow is maintained even in the event of

a change in system pressure, e.g. in the

event of filter contamination

• With simple "MINI" ventilation unit with

adjustable Basic Ventilation mode.

• Optional comfortable "TOUCH" operating

unit with integrated room temperature

sensor

• Integrated 100% bypass for bypassing

the heat exchanger in Summer mode

• Selectable automatic frost protection

switch for heat exchanger, optionally

available with PTC low-temperature

preheater coil

• Integrated filter monitoring, "Filter

replacement" message on operating unit

once time interval has elapsed

• Filter replacement possible without

tools

• Optional reheating for additional

increase in room temperature

1 "MINI" type operating unit

2 "TOUCH" type operating unit (optional)

3 Output component

4 Connector cable, J-Y(ST)Y2x2x0.8

5 Outdoor air filter, quality class F7

(optional pollen filter, quality class F9)

6 Exhaust air filter, quality class G4 (optional M5)

7 Counterflow heat exchanger

(optional enthalpy heat exchanger)

8 Condensate drain

9 Frost protection heater with PTC low temperature

preheater coil (optional)

10 Bypass flap with electrothermal

servo motor

11 Supply air fan

12 Extract air fan

13 Front cover with handwheel bolt

14 Air line connection

15 Cable inlets, 4x M16 / 1 x M12

ADVANTAGES AND FEATURES

DEVICE CONFIGURATION

3

5

6

7

8

9

10

12

11

13

14

15

1

2

12

5

9

7

8

10

14

15

13

6

3

11

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 26

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

1. "MINI" control unit

The “MINI“ control unit, installed in the

living area, is used to easily control the

ventilation unit. Its ease of operation

enables the manual setting of ventilation

levels, switching between summer and

winter modes, the setting of base volume

flows, etc. The mode and current faults

are also displayed.

2. "TOUCH" operating unit (optional)

The “TOUCH“ control unit is easy to use

and provides an overview via a TFT touch

display. It should be installed at a central

location in residential buildings so that

users have access to control and an

overview of messages at all times. The

integrated temperature sensor records

the current ambient temperature and

ensures that supply air is regulated

correctly.

3. Output component

The output component installed in the

ventilation unit is used by the installer or

service technician to set the individual

operating parameters, based on the

respective on-site application. The

settings can be made either using the

operating unit or via a PC interface and

communications software.

4. Connecting cable J-Y(ST)Y2x2x0.8

A screened cable Y(ST) YYx2x0.28 is

required to establish a connection and for

communication between the control unit

and control board. Cable length must not

exceed 100 m.

5. Outdoor air filter, quality class F7

(optional pollen filter, quality class F9)

The outdoor air filter filters dust and dirt

from the outdoor air.

6. Exhaust air filter quality class G4

(optional M5)

Coarse contaminations are filtered out of

the extract air via the extract air filter.

7. Counterflow heat exchanger

The ecient heat exchanger extracts the

energy content from the extract air and

transfers this to supply air.

Optional enthalpy heat exchanger

available.

8. Condensate drain

Condensate generated during the

operation of the heat exchanger is

directed into the condensate tray. The

connected condensate drain, which

passes through an eective odour trap

(siphon), drains the generated condensate.

9. Frost protection heating with PTC low

temperature preheater coil (optional)

Used to prevent the condensate from

freezing in the heat exchanger at very

low exterior temperatures. The optional

electric PTC low temperature preheater

coil preheats the outdoor air based on the

outdoor and exhaust air temperatures.

When an optional water battery

or brine battery is used to

provide frost protection for the

heat exchanger, this must be

provided with appropriate frost protection.

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 27

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

The LG 250 A System VENTECH compact

ventilation unit is available in several

dierent versions:

• Right or left, depending on position of

supply air connection.

• Version with or without electrical PTC

preheater coil integrated into the ventilation unit.

10. Bypass flap with electrothermal servo

motor

Used in Summer mode to transfer the

air flow to the heat exchanger when the

outdoor air temperature is lower than the

room temperature.

11. Supply air fan

Ensures the air volume flow for supply

air, directs processed outdoor air into the

living area.

12. Extract air fan

Ensures the air volume flow for extract

air, directs used air from the house into

the open air.

13. Front cover with handwheel bolt

The front cover is easy to open for

maintenance on the unit.

When replacing the cover, ensure that

it is completely closed and that there is

sucient seal-tightness between the front

cover and the unit housing.

14. Air pipe connections

Serve as a connection to the air pipe

system. Correct connection to supply air,

extract air, outdoor air and exhaust air

must be ensured during assembly.

15. Cable guides

The ventilation unit is normally supplied

complete with electrical wiring. The cable

guides are used to create the electrical

connections to connect the operating unit

with optional system accessories such as

temperature sensors, etc.

Version

Left-hand version Right-hand version

Item no. without integrated

preheater coil

08LG250A-L 08LG250A-R

Item no. with integrated

preheater coil

08LG250A-L-V 08LG250A-R-V

With optional enthalpy heat

exchanger for moisture

recovery

08LG250A + 08EWTLG250 08LG250A + 08EWTLG250

For stand or

wall mounting

1

2

3

4

MODEL TYPES

1 Supply air

2 Extract air

3 Outdoor air

4 Exhaust air

3

1

4

2

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 28

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

47 282 14

3

1

81

76

1

5484

67

2

1

0

2

1 Supply air ø 160 mm

2 Extract air ø 160 mm

3 Outdoor air ø 160 mm

4 Exhaust air ø 160 mm

5 Counterflow heat exchanger

6 Extract air fan

7 Supply air fan

8 Control system

9 Bypass flap

10 Exhaust air filter G4

11 Outdoor air filter F7

12 Condensate tray

13 Cable inlet 4 x M16 / 1 x M12

14 PTC electric preheater coil (optional)

15 Height-adjustable feet

16 Condensate outlets

Structural diagram (stand or wall mounting, left-hand version)

Structural diagram (stand or wall mounting, right-hand version)

484

544

672

332

92

778

610

633

4

3

1

2

13

215

276 181

13 0

272

19 1

143 282 247

9

10

7

6

8

15

12

5

14

11

16

870

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 29

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

To ensure safe operation of the system,

safety devices and covers must not be

rendered inoperative; nor may measures

be taken to bypass or dismantle them.

The system must be taken out of

operation immediately in the event of any

fault or damage to the ventilation unit that

may cause harm to persons or property.

Further use must be actively prevented

until the unit is fully repaired!

The unit may only be restarted by a

specialist installer.

Overheating protection: A

thermo-bimetal switch

is built into the optional,

integrated frost protection heater or the

optional reheater coil to protect against

overheating. If a temperature of +50°C

is reached, power supply to the electric

battery is interrupted and the anti-freeze

heating is switched o.

SAFETY DEVICES

With mechanically-controlled residential

ventilation, used, damp extract air is

conducted away from wet domestic areas,

e.g. bathroom, toilet and kitchen, and

is replaced with fresh, processed and

filtered outdoor air in lounge areas e.g. in

living rooms and bedrooms.

Significant energy savings are achieved

when the system is operated continuously

thanks to highly ecient heat exchangers

for heat recovery from extract air and use

of energy-ecient fans with the latest

DC technology for air flow control. This

technology is particularly eective in

air-tight building shells and with active

thermal insulation. An eciency factor of

up to 92% heat recovery provides highly

ecient energy savings.

It must in particular be ensured that the

heat exchanger is protected against frost

by means of an appropriately adjusted

frost protection strategy, and that eective

condensate drainage is ensured.

12. Functionality of the ventilation system

SYSTEM DESCRIPTION

PTC-Niedertemperaturregister mit

Schutzabdeckung

Thermo-Biemetallschalter

optionales PTC-Niedertemperatuur-

Heizregister-Einheit für Frostschutz

PTC low temperature coil with protective

cover

Thermo-bimetal switch

Optional PTC low temperature

heater coil unit for frost protection

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 30

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

The basic design of a domestic ventilation system is

illustrated in the pictorial schematic with optional

additional system enhancements.

1 Unit housing

2 Supply air fan with EC technology

3 Extract air fan with EC technology

4 Outdoor air filter for fine dust F7

(optional quality class F9 pollen filter)

5 Extract air filter G4 for coarse dust

6 Counterflow heat exchanger

7 Bypass flap for Summer mode

8 Frost preheating heat exchanger (optional)

9 Condensate tray with onsite drainage and

eective odour trap (siphon)

10 Pipe connection

11 Silencer (optional)

12 Switching flap (optional)

13 Reheater coil - electrical or

with water (optional)

14 Geothermal exchanger EWT (optional)

15 Suction element with pre-filter G4 for EWT

16 Sole-geothermal exchanger (optional)

Outdoor air

Air supply

Outgoing air

Exhaust air

+/-

Outdoor air

+

+

Bypass

EWT

5

4

8

2

3

1

6

7

9

14

15

12

12

16

13

11

10

15

There is a risk of the heat

exchanger freezing on the

exhaust air side, particularly

during winter months with moderate to

severe frost, depending on the extract air

temperature and air humidity. Appropriate

measures must be taken to protect the

heat exchanger against ice formation at

low outdoor air temperatures of under

approx. -4°C.

Various systems are available to monitor

defrosting of the heat exchanger. Possible

strategies to protect against freezing are

outlined below.

SYSTEM ENHANCEMENT OPTIONS FOR

FROST PROTECTION

Optimal frost protection can be achieved

with cold outdoor air temperatures by

integrating a geothermal heat exchanger

into the ventilation system. Additional

components, such as a PTC pre-heater

coil integrated in the ventilation unit, are

not necessary.

In summer mode, the

geothermal heat exchanger's

cooling performance is

determined by the low rate of

air exchange, is very limited and is barely

perceptible to the user.

The following information must be

observed for execution of a geothermal

heat exchanger:

• The heat exchanger is laid in the ground

with waterproof pipes at a frost-free

depth with due consideration of the

system's cleanability options.

• The manufacturer's guidelines for

implementation must be observed.

• Condensate drainage must be provided.

• If the air pipe is routed through an

external wall, eective sealing against

moisture ingress must be ensured.

Geothermal exchanger EWT

(factory setting)

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 31

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Brine geothermal energy with optional

cooling function (factory setting)

Basic system components are illustrated in the

“Brine Geothermal Energy with Optional Cooling

Function” pictorial schematic.

• Sucient distance from other parts, e.g.

water pipes, foundations, etc. must be

maintained during positioning in order to

prevent frost damage.

• Indirect pre-heating possibilities via a

circulatory system with frost-protected

heat carrier, for instance, should

preferably be used in ground containing

hazardous substances (e.g. radon

contamination).

Geothermal exchangers must be carefully

planned and implemented taking into

account their energy eciency and air

hygiene. The relevant guidelines and

standards must be observed. In particular,

amongst other things, ease of cleaning

and a suitable filter concept must be

ensured.

Support of a geothermal heat exchanger

with a changeover flap must be

specifically activated in the ventilation

unit. This is performed using PC software.

Geothermal heat exchanger winter mode

The geothermal heat exchanger is

connected via the changeover flap

when the outdoor air temperature falls

below the geothermal heat exchanger's

parametered winter threshold value. In

this instance, the outdoor air is aspirated

into the geothermal exchanger and hence

preheated. If the outdoor temperature

(optional T5 sensor required) falls below

the geothermal heat exchanger's winter

parameter, the K1 relay switches on the

geothermal heat exchanger.

Geothermal heat exchanger summer mode

In summer, the geothermal heat

exchanger is connected when the outdoor

temperature exceeds the geothermal

heat exchanger’s parametered summer

threshold value. In this case, the outdoor

air is drawn in via the geothermal heat

exchanger and is thus pre-cooled. If the

outdoor temperature (optional T5 sensor

required) exceeds the geothermal heat

exchanger's summer parameter, the K1

relay switches on the geothermal heat

exchanger.

Ventilation unit with

heat recovery

Outdoor air

Outgoing air Air supply

Exhaust air

Brine

register

Brine pipe in

soil environment

Control system

power unit

Voltage

supply

Temperature

sensor AUL

Pump (on / off)

Safety module

(pressure equalisation, overpressure valve,

ventilator, manometer, shut-off valve,

filling and drainage valve)

Preliminary outdoor

air filter G4

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 32

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

Brine geothermal systems extract energy

from the earth in winter via a brine

pipe. The system may also be used for

cooling in summer. The heat or cold is

transferred indirectly into the supply air

via an external air register in the air duct

system.

In contrast to other frost protection

strategies such as an electric preheating

batteries, the advantage of geothermal

brine systems is their low operating

power. Their advantages compared to

the air duct geothermal heat exchanger

comprise hygienic aspects, simple laying

and good controllability. Indirect preheating via a circulatory system with

frost-protected heat carrier, for instance,

should preferably be used in ground

containing hazardous substances (e.g.

radon contamination).

The manufacturer's guidelines for

implementation must be observed. The

brine heater battery must be protected

against contamination by an air filter

integrated into the air pipe system that

has a filter quality class of at least G4.

The brine pump is activated automatically,

depending on the outdoor air temperature.

Support for a brine geothermal heating

system must be activated in the

ventilation unit. PC software is used for

this purpose. Further information on

PC software is available from certified

partners upon request.

Brine geothermal heat - winter mode

If the outdoor air temperature (optional

T5 sensor required) falls below the

geothermal heat exchanger's winter

parameter, the K1 relay switches on the

brine pump.

Brine geothermal heat - summer mode

If the outdoor air temperature (optional T5

sensor required) exceeds the geothermal

heat exchanger's summer parameter, the

K1 relay switches on the brine pump.

The LG 250 A System VENTECH ventilation

unit can be supplied with a built-in (not

passive house-certified) or external

electrical PTC pre-heater coil as optional.

If an optional pre-heater coil is connected,

cold outdoor air is pre-heated via the

integrated electrical

PTC low temperature coil.

This operating mode provides

guaranteed balanced air flow

volume between supply air and

extract air during defrosting!

Frost protection thanks to stepless

preheater coil control:

•

At outdoor air aspiration temperature

below -4°C, the preheater coil is

activated.

•

The stepless control and adjustment

of the preheater coil maintains the

temperature upstream of the heat

exchanger at -1°C and hence prevents

the heat exchanger from freezing up.

•

If the outdoor air aspiration temperature

exceeds -3°C, the preheater coil

switches o again.

•

Where the ventilation unit with

integrated preheater coil is switched

o manually, the fans will continue to

run for approx. 3 minutes to cool the

preheater batteries.

PTC low temperature preheating

coil (factory setting)

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 33

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

ATTENTION: Not suitable for

frost protection in passive

houses!

An external, optional two-stage electric

heater coil which is inserted downstream

into the supply air duct of the ventilation

unit enables the supply air temperature to

be increased.

An external electric air heater

can be connected in 2 stages to

the output component.

Setting the temperature target value and

determining the room temperature are

achieved using the "TOUCH" operating

unit, which incorporates the room

temperature sensor.

The room target temperature can be set in

a range between +15°C and +35°C.

The heater battery can only be operated

using a constant supply air temperature

set to 21°C. This can be disabled by

switching to Summer mode.

This function is provided on the "MINI"

operating unit.

Reheating of the supply air temperature

(x

d

= target – actual) is adjusted

automatically based on the set room

target temperature.

In order to minimise switching frequency,

minimum pause times are set for the

switching stages. Once the switching point

is reached, switching stage 1 remains

active for at least 30 seconds; switching

stage 2 remains disabled for at least 60

seconds.

Where the electrical reheater battery is

enabled, the fans continue to run for 120

seconds when switching o.

ATTENTION: Contact load per

switching output K5 and K6

maximum 2 amperes!

ATTENTION: This operating

mode is not suitable for frost

protection in passive houses!

The LG 250 A System VENTECH compact

ventilation unit range is equipped with

automatic heat exchanger frost protection

as standard. Frost protection is provided

by a continuous reduction in the supply air

flow volume with simultaneous constant

extract air flow volume. This measures

prevents the condensate generated from

freezing in the heat exchanger.

This operating mode does not

guarantee balanced air flow

volume between supply air and

extract air during defrosting!

Frost protection thanks to extract air

defrosting

• The defrosting strategy is only enabled

starting from an outdoor air intake

temperature below -4°C

• Where the exhaust air temperature

undercuts the "Defrost-In" setting, the

defrost function is started and the

supply air fan is then switched o. After

the defrost period has elapsed, the

rotational speed on the supply air fan is

increased continuously

• The dierence in temperature between

extract air and supply air is also

monitored. The defrost process is

activated when the "Defrost Dierential"

parameter setting is exceeded

Frost protection through

reduction of supply air flow volume

In order to further increase the air outlet

temperature in the living area, an external

additional heater can be installed with

the ventilation unit (air heater). You can

choose between two-stage electric as well

as hot water heater batteries, which can

be integrated into the air ducting system.

Additional Heating mode is only available

in Winter mode!

SYSTEM EXPANSION FOR

ADDITIONAL INTERNAL HEATING

With external electric air heater

x

d

Action

> +0.5 K Switch to level 1

> +2.0 K Switch to level 2

> 0 K Switch to level 2

> -1.0 K Switch to level 1

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 34

Changes reserved

USER

GENERALSPECIALIST PERSONNEL

An external, optional water reheater

battery with 3-stage mixing motor which

is inserted downstream into the supply

air duct of the ventilation unit enables the

supply air temperature to be increased.

Setting the temperature target value and

determining the room temperature are

achieved using the "TOUCH" operating

unit, which incorporates the room

temperature sensor. The room target

temperature can be set in a range

between +15°C and +35°C.

This function is not provided on the "MINI"

operating unit.

The mixer runtime and mixer clock

sequence parameters are provided to

adjust the mixer on the control unit. The

mixer operates according to a clocked

control mode. The mixer is therefore only

adjusted in the set clock sequence.

Where the hot water heater battery is set

in the output component (factory setting),

input "E2" is used as a potential-free

contact. This contact is used to provide

frost protection for the reheater battery.

Where this potential-free contact is fitted

with an external temperature sensor

which is set to an actuation temperature

of +5°C, the ventilation unit switches to

frost protection and a fault is reported.

This sensor is positioned immediately in

front of the external heater battery in the

air ducting system. In this fault state, the

mixer is opened, and the circulation pump

is enabled. The fans are switched o until

the frost risk message is switched o.

In addition, the same frost protection

strategy is used where the temperature

on the integrated supply air sensor is

below +5 °C.

With external hot water heater battery

Basic functions for users, see User Information, Section 7.

Basic ventilation and volume flow can be

configured by pressing certain combinations of buttons on the "MINI" control unit.

Switch basic ventilation on/o

By pressing the "Summer" and "Winter"

buttons simultaneously for 3 seconds, the

user is taken to the Settings menu

The setting is configured with the [+]- and

[-] buttons.

If no buttons are pressed for 5 seconds,

the parametered value is stored and the

control unit returns to the main menu.

If the LED for ventilation level I flashes,

basic ventilation is switched on; if the LED

lights up continuously, ventilation level I

is active.

Setting air flow volume, ventilation level I

Users can access the menu for ventilation

level I by pressing the “Summer“ and

“Plus button“ buttons simultaneously for

3 seconds.

The volume flow is configured using

the [+]- and [-] buttons. If no buttons are

pressed for 5 seconds, the parametered

values are stored and the control unit

switches to the main menu.

"MINI" SPECIAL SETTINGS FOR SPECIALIST PERSONNEL

13. Operating units

OPERATING AND INSTALLATION INSTRUCTIONS SYSTEM VENTECH LG 250 A PAGE 35

USER

GENERALSPECIALIST PERSONNEL

Changes reserved

Configuration of ventilation level I begins

at 50 m³/h if no LED lights up. By respective flashing or lighting of the individual

LEDs, the volume flow increases by 10

m³/h up to a maximum of 90 m³/h or 190

m³/h.

Setting air flow volume, ventilation level I

Users can access the menu for ventilation

level II by pressing the “Winter“ and “[-]“

buttons simultaneously for 3 seconds.

Ventilation level II can be set between 80

m³/h (no LED is lit) and a maximum of 220

m³/h in 10 m³/h steps.

Setting air flow volume, ventilation level III

Users can access the menu for ventilation

level III by pressing the "Summer" and

"[-]" buttons simultaneously for 3 seconds.

Ventilation level III can be set between 110

and 250 m³/h.

By respective flashing or lighting of the

individual LEDs,

the volume flow increases by 10 m³/h.

If no LED is lighting, the lowest air flow

volume is set in ventilation level I, II or III.

Ventilation level

Air flow volume

LG 250 A

Basic ventilation 30–60 m³/h

I 50 –190 m³/h

II 80 – 220 m³/h

III 110 – 250 m³/h

"TOUCH” SPECIAL SETTINGS FOR SPECIALIST PERSONNEL

The Service menu is activated by pressing

the Menu button for an extended period

(min. 5 seconds) and entering the customer service password.

The Service menu is indicated with an "S"

in the top left edge of the screen.

The technician can change the unit's

parameters after activating the Service

menu.

Change temperature control type

The "Control" menu item is accessed

through the service menu in the home

screen under temperature. There is a

choice between "supply air", "extract air"

and "room" temperature control.

Current operating values

All of the unit's parameters can be

checked in the main menu -> "Information" -> "Current Operating Values".

For more information on error signals

and reasons for errors, see section 17

“Error Description“.