A product of a PHYTEC Technology Holding company

phyBOARD®-Regor AM335x

Application Guide

Document No.: L-823e_2

SBC Prod. No.: PB-01802-xxx

CB PCB No.: 1447.3

SOM PCB No.: 1358.4

Edition: June 2018

phyBOARD-Regor AM335x [PB-01802-xxx]

EUROPE

NORTH AMERICA

FRANCE

Address:

PHYTEC Messtechnik GmbH

GERMANY

PHYTEC America LLC

USA

PHYTEC France

FRANCE

+49 6131 9221-32

sales@phytec.de

+1 800 278-9913

sales@phytec.com

+33 2 43 29 22 33

info@phytec.fr

Technical Support:

+49 6131 9221-31

support@phytec.de

+1 206 780-9047

support@phytec.com

support@phytec.fr

Fax:

+49 6131 9221-33

+1 206 780-9135

+33 2 43 29 22 34

http://www.phytec.de

http://www.phytec.eu

INDIA

CHINA

Address:

PHYTEC Embedded Pvt. Ltd.

INDIA

PHYTEC Information Technology (Shenzhen) Co. Ltd.

+91-80-4086 7046/49

sales@phytec.in

+86-755-6180-2110

sales@phytec.cn

Technical Support:

+91-80-4086 7047/50

support@phytec.in

support@phytec.cn

Fax:

Copyrighted products are not explicitly indicated in this manual. The absence of the trademark (, or ®)

and copyright (©) symbols does not imply that a product is not protected. Additionally, registered patents

and trademarks are similarly not expressly indicated in this manual.

The information in this document has been carefully checked and is considered to be entirely reliable.

However, PHYTEC Messtechnik GmbH assumes no responsibility for any inaccuracies. PHYTEC Messtechnik

GmbH neither gives any guarantee nor accepts any liability whatsoever for consequential damages

resulting from the use of this manual or its associated product. PHYTEC Messtechnik GmbH reserves the

right to alter the information contained herein without prior notification and accepts no responsibility for

any damages that might result.

Additionally, PHYTEC Messtechnik GmbH offers no guarantee nor accepts any liability for damages arising

from the improper usage or improper installation of the hardware or software. PHYTEC Messtechnik GmbH

further reserves the right to alter the layout and/or design of the hardware without prior notification and

accepts no liability for doing so.

Copyright 2018 PHYTEC Messtechnik GmbH, D-55129 Mainz.

Rights - including those of translation, reprint, broadcast, photomechanical or similar reproduction and

storage or processing in computer systems, in whole or in part - are reserved. No reproduction may occur

without the express written consent from PHYTEC Messtechnik GmbH.

Sales:

Web Site:

Sales:

Robert-Koch-Str. 39

D-55129 Mainz

No. 1688, 25th A Cross

th

27

Main, 2nd Sector, Opp. PEP School V2,

HRS Layout,

Bangalore 560102

203 Parfitt Way SW

Bainbridge Island, WA 98110

http://www.phytec.com http://www.phytec.fr

2106A, Block A, Tianxia Jinniu Square,

Taoyuan Road, Nanshan District,

518026 Shenzhen

CHINA

17, place Saint-Etienne

F-72140 Sillé-le-Guillaume

Web Site: http://www.phytec.in http://www.phytec.cn

2ndEdition June 2018

PHYTEC Messtechnik GmbH 2018 L-823e_2

Contents

List of Figures ................................................................................................... ii

List of Tables ................................................................................................... iii

Conventions, Abbreviations and Acronyms ............................................................. iv

Preface ......................................................................................................... vii

1 Introduction .............................................................................................. 1

1.1 Hardware Overview ........................................................................................ 1

1.1.1 Features of the phyBOARD-Regor AM335x ............................................... 1

1.1.2 Block Diagram ................................................................................... 2

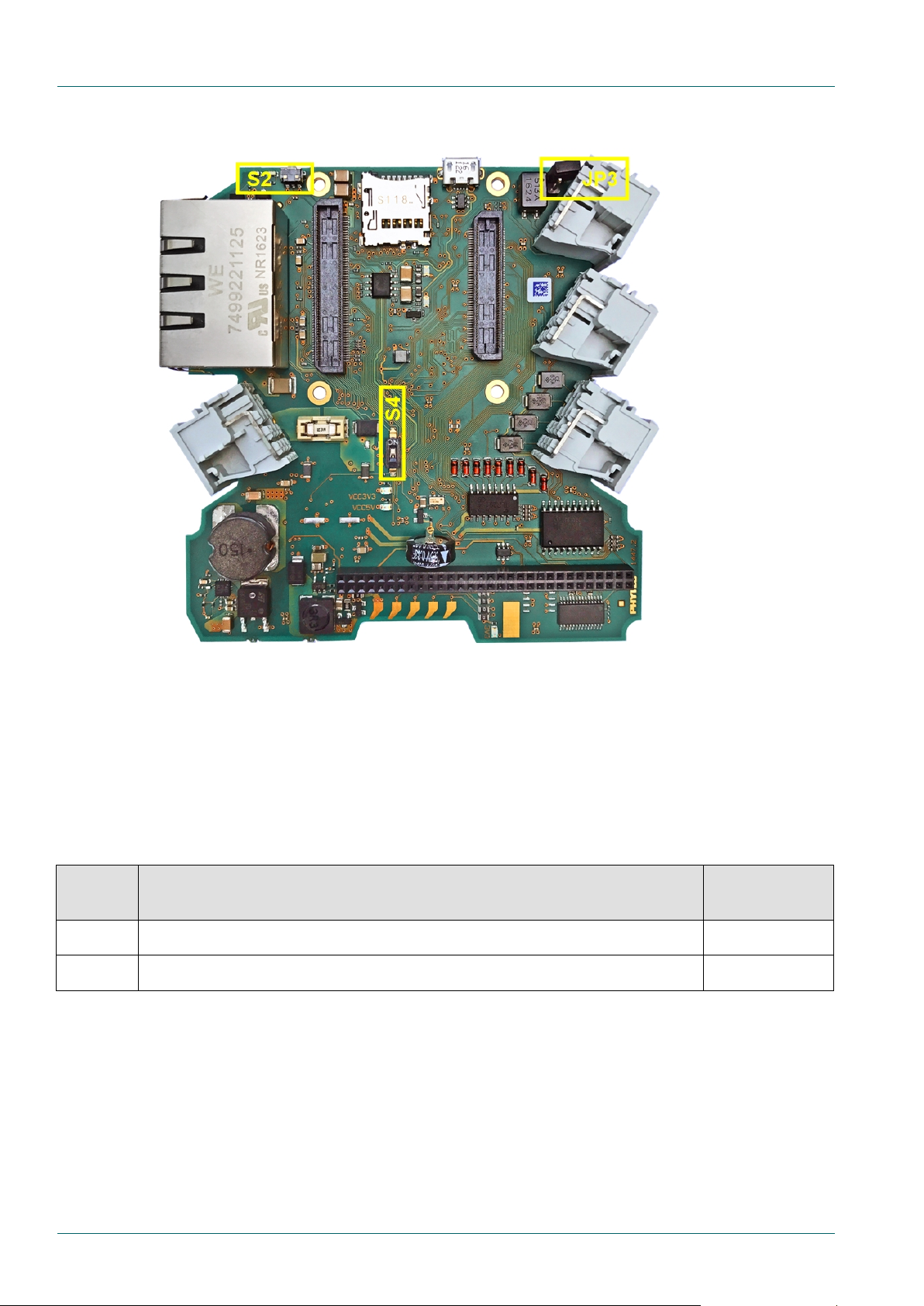

1.1.3 View of the phyBOARD-Regor AM335x .................................................... 3

2 Accessing the phyBOARD-Regor Features .......................................................... 4

2.1 Overview of the phyBOARD-Regor Peripherals ..................................................... 4

2.1.1 Connectors and Pin Header .................................................................. 4

2.1.2 LEDs ................................................................................................ 6

2.1.3 Switches .......................................................................................... 8

2.1.4 Jumpers ........................................................................................... 9

2.2 Functional Components on the phyBOARD-Regor SBC .......................................... 10

2.2.1 Power Supply ................................................................................... 10

2.2.1.1 Power Connector (X1) ........................................................... 10

2.2.1.2 Power LEDs D62, D63, and D68 ............................................... 11

2.2.1.3 Status LEDs D66 and D67 ....................................................... 12

2.2.1.4 Backup Supply ..................................................................... 12

2.2.2 UART Connectivity (X3, X5, X6, X7) ....................................................... 13

2.2.2.1 RS-232 Connectivity (X5)....................................................... 14

2.2.2.2 RS-485 Connectivity (X3)....................................................... 15

2.2.3 CAN Connectivity (X3, JP3) ................................................................. 16

2.2.4 Ethernet Connectivity (X9) ................................................................. 17

2.2.4.1 MAC Address ....................................................................... 17

2.2.5 USB Connectivity (X4, X6) ................................................................... 18

2.2.6 Secure Digital Memory Card/ MultiMedia Card (X11) ................................. 19

2.2.7 Digital GPIOs 1-4 (X2) ........................................................................ 20

2.2.8 Card Edge Connector (X7) ................................................................... 22

2.2.9 Boot Mode (S4) ................................................................................ 23

2.2.10 System Reset Button (S2) ................................................................... 23

2.2.11 RTC ................................................................................................ 24

3 System Level Customizing ........................................................................... 25

3.1 Expansion Connector (X6) ............................................................................. 25

3.1.1 I2C Connectivity ................................................................................ 27

4 Technical Specifications ............................................................................. 28

4.1 Product Power Rating ................................................................................... 29

4.2 Product Temperature Grades .......................................................................... 29

5 Revision History ....................................................................................... 31

Index ............................................................................................................ 32

PHYTEC Messtechnik GmbH 2018 L-823e_2 i

phyBOARD-Regor AM335x [PB-01802-xxx]

List of Figures

Figure 1: Block Diagram of the phyBOARD-Regor AM335x ................................................ 2

Figure 2: View of the phyBOARD-Regor AM335x with phyCORE-AM335x ............................... 3

Figure 3: phyBOARD-Regor AM335x connectors ............................................................. 3

Figure 4: phyBOARD-Regor AM335x LEDs locations ......................................................... 6

Figure 5: phyBOARD-Regor AM335x Switch Locations ...................................................... 8

Figure 6: Power Supply Connector X1 ......................................................................... 10

Figure 7: LEDs D66 and D67 with Switch S2 ................................................................. 12

Figure 9: RS-485 Interface Connector X3 .................................................................... 15

Figure 10: Components supporting the CAN Interface ..................................................... 16

Figure 11: Ethernet Interfaces at Connector X9 .............................................................. 17

Figure 12: USB Interface Connector X4 ........................................................................ 18

Figure 13: MMC/SD Card Interface at Connector X11 ....................................................... 19

Figure 14: Digital GPIOs at Connector X2 ...................................................................... 20

Figure 15: Card Edge Connector X7 .............................................................................. 22

Figure 16: Boot Switch S4 ......................................................................................... 23

Figure 17: System Reset Button S2 .............................................................................. 23

Figure 18: Expansion Connector X6 ............................................................................. 25

ii PHYTEC Messtechnik GmbH 2018 L-823e_2

Contents

List of Tables

Table 1: Abbreviations and Acronyms used in this Manual ................................................v

Table 2: phyBOARD-Regor Connectors and Pin Headers .................................................. 4

Table 3: phyBOARD-Regor LEDs Descriptions ................................................................ 6

Table 3: phyBOARD-Regor LEDs Descritption (continued) ............................................... 7

Table 4: phyBOARD-Regor Switches Description ............................................................ 8

Table 5: phyBOARD-Regor Jumper Description ............................................................. 9

Table 6: Pin Assignment of the 5 position Phoenix Contact MINI COMBICON Base Strip X1 .... 11

Table 7: Connectors and Signal Levels of the UART Interfaces ......................................... 13

Table 8: Pin Assignment of the RS-232 Interface at Connector X5 .................................... 14

Table 9: Pin Assignment of the RS-485 Interface at Connector X3 .................................... 15

Table 10: Pin Assignment of CAN Connector X3 .............................................................. 16

Table 11: Digital input switching levels for GPIO 1-4....................................................... 20

Table 13: Pin Assignment of CardEdge Connector X7....................................................... 22

Table 14: Boot Switch Configuration for S4................................................................... 23

Table 15: Pin Assignment of PHYTEC Expansion Connector X6 ........................................... 25

Table 16: I2C Addresses in Use ................................................................................... 27

Table 17: Power ratings of the phyBOARD-Regor ........................................................... 29

Table 18: Product Temperature Grades ........................................................................ 30

PHYTEC Messtechnik GmbH 2018 L-823e_2 iii

phyBOARD-Regor AM335x [PB-01802-xxx]

Conventions, Abbreviations and Acronyms

This hardware manual describes the PB-01802-xxx Single Board Computer (SBC), hereby

referred to as phyBOARD-Regor AM335x. The manual specifies the

phyBOARD-Regor AM335x's design and function. Precise specifications for the Texas

Instruments AM335x microcontrollers can be found in the Texas Instrument’s

Sheet and Technical Reference Manual

.

Conventions

The conventions used in this manual are as follows:

Signals that are preceded by an "n", "/", or “#”character (e.g.: nRD, /RD, or #RD), or

that have a dash on top of the signal name (e.g.: RD) are designated as active low

signals. That is, their active state is when they are driven low, or are driving low.

A "0" indicates a logic zero or low-level signal, while a "1" represents a logic one or

high-level signal.

2

The hex-numbers given for addresses of I

C devices always represent the 7 MSB of the

address byte. The correct value of the LSB, which depends on the desired command

(read (1), or write (0)), must be added to get the complete address byte. E.g. the given

address in this manual 0x41 => the complete address byte = 0x83 to read from the

device and 0x82 to write to the device.

Tables which describe jumper settings show the default position in bold, blue text.

Text in

blue italic

indicates a hyperlink within, or external to the document. Click these

links to quickly jump to the applicable URL, part, chapter, table, or figure.

AM335x Data

iv PHYTEC Messtechnik GmbH 2018 L-823e_2

Conventions, Abbreviations and Acronyms

A/V

Audio/Video

BSP

Board Support Package (Software delivered with the Development Kit

the module and Development Tools)

CB

Carrier Board; used in reference to the phyBOARD-Regor Development

Kit Carrier Board

DFF

D flip-flop

DSC

Direct Solder Connect

EMB

External memory bus

EMI

Electromagnetic Interference

GPI

General purpose input

GPIO

General purpose input and output

GPO

General purpose output

IRAM

Internal RAM; the internal static RAM on the Texas Instruments AM335x microcontroller

J

Solder jumper; these types of jumpers require solder equipment to remove and place

JP

Solderless jumper; these types of jumpers can be removed and placed by hand with no special tools

NC

Not Connected

NM

Not Mounted

NS

Not Specified

PCB

Printed circuit board

PDI

PHYTEC Display Interface; defined to connect PHYTEC display adapter boards or custom adapters

PEB

PHYTEC Expansion Board

PMIC

Power management IC

PoE

Power over Ethernet

PoP

Package on Package

POR

Power-on reset

RTC

Real-time clock

SBC

Single Board Computer; used in reference to the PBA-CD-02

/phyBOARD-Regor AM335x

SMT

Surface mount technology

SOM

System on Module; used in reference to the PCL-051

/phyCORE-AM335x module

Abbreviations and Acronyms

Many acronyms and abbreviations are used throughout this manual. Use

Table 1

to

navigate unfamiliar terms used in this document.

Abbreviation Definition

including an operating system (Windows, or Linux) pre-installed on

Table 1: Abbreviations and Acronyms used in this Manual

PHYTEC Messtechnik GmbH 2018 L-823e_2 v

phyBOARD-Regor AM335x [PB-01802-xxx]

Abbreviation

Definition

Sx

User button Sx (e.g. S1, S2) refers to the available user buttons or DIP switches on the CB

Sx_y

Switch y of DIP switch Sx; refers to the DIP switch on the carrier board

VSTBY

SOM standby voltage input

, it is possible to

Table 1: Abbreviations and Acronyms used in this Manual (continued)

At this icon you might leave the path of this Application Guide.

This is a warning. It helps you to avoid annoying problems.

You can find useful supplementary information about the topic.

The BSP delivered with the phyBOARD-Regor AM335x usually includes

drivers and/or software for controlling all components such as interfaces,

memory, etc. Therefore, programming close to hardware and register

level is not necessary in most cases. For this reason, this manual contains

no detailed description of the controller’s registers. Please refer to the

AM335x Technical Reference Manual

if such information is needed to

connect customer designed applications

Beginning with BSP version AM335x-PD14.1-rc1

configure the BSP in regards to the hardware configuration. This allows

the user to easily adapt the BSP if an expansion board is attached,

removed or exchanged.

vi PHYTEC Messtechnik GmbH 2018 L-823e_2

Preface

Preface

As a member of PHYTEC's new phyBOARD® product family, the phyBOARD-Regor AM335x is

one of a series of PHYTEC System on Modules (SBCs) that offer off-the-shelf solutions for a

huge variety of industrial applications. The new phyBOARD

series of extremely compact embedded control engines featuring various processing

performance classes. All phyBOARDs are rated for industry, cost optimized, and offer longterm availability. The phyBOARD-Regor AM335x is one of currently six industrial-grade

carrier boards which are suitable for series production and that have been realized in

accordance with PHYTEC's new SBCplus concept. It is an excellent example of this concept.

For easy implementation into industrial control system racks, the

phyBOARD-Regor AM335x comes in a housing with integrated DIN-Rail sockets.

Furthermore, the board is equipped with connectors allowing for interconnection to

commonly used industrial interfaces.

SBCplus Concept

The SBCplus concept was developed to meet many slight differences in customer requirements with little development effort and thus greatly reduce the time-to-market.

The core of the SBCplus concept is the SBC design library (a kind of construction set) that

consists of a great number of function blocks (so-called "building blocks") which are

constantly refined. The recombination of these function blocks allows PHYTEC to develop a

customer specific SBC within a short time. Thus, PHYTEC is able to deliver production-ready

custom Single Board Computers within a few weeks at very low costs.

The already developed SBCs, such as the phyBOARD-Regor, each represent an intersection

of different customer wishes. Because of this, all necessary interfaces are already available

on the standard versions. This allows the user to integrate the phyBOARD in a large number

of applications without modification. For any necessary detail adjustments, extension

connectors are available to enable adding a wide variety of functions.

Customized Expandability from PHYTEC

Common interface signals route to standard connector interfaces on the carrier board such

as Ethernet, CAN, RS-232, and audio. Due to the easily modifiable phyBOARD design

approach (see "

SBCplus concept

"), these plug-and-play interfaces can be readily adapted

into customer-specific variants according to end system requirements.

®

product family consists of a

PHYTEC Messtechnik GmbH 2018 L-823e_2 vii

phyBOARD-Regor AM335x [PB-01802-xxx]

OEM Implementation

Implementation of an OEM-able SBC subassembly as the "core" of an embedded design

allows for increased focus on hardware peripherals and firmware without expending

resources to "re-invent" microcontroller circuitry. Furthermore, much of the value of the

®

phyBOARD

SBC lies in its layout and test.

Software Support

Production-ready Board Support Packages (BSPs) and Design Services for our hardware will further reduce development time and risk, while at the same time allowing for increased focus on the product expertise.

viii PHYTEC Messtechnik GmbH 2018 L-823e_2

Preface

Ordering Information

Ordering numbers:

phyBOARD-Regor AM335x Development Kit: KPB-01802-xxx

phyBOARD-Regor AM335x SBC:

PB-01802-xxx

Product Specific Information and Technical Support

In order to receive product specific information on all future changes and updates, we recommend registering at:

http://www.phytec.de/de/support/registrierung.html or http://www.phytec.eu/europe/support/registration.html

For technical support and additional information concerning your product, please visit the

phyBOARD-Regor section of our web site which provides product specific information,

such as errata sheets, application notes, FAQs, etc.

http://www.phytec.de/produkt/single-board-computer/phyboard-regor/

Other Products and Development Support

Aside of the new phyBOARD® family, PHYTEC supports a variety of 8-/16- and 32-bit controllers in two ways:

(1) as the basis for Rapid Development Kits which serve as a reference and evaluation

platform

(2) as insert-ready, fully functional OEM modules, which can be embedded directly into

the user’s peripheral hardware design.

Take advantage of PHYTEC products to shorten time-to-market, reduce development costs,

and avoid substantial design issues and risks. With this new innovative full system

solution, new ideas can be brought to market in the most timely and cost-efficient manner.

For more information go to:

http://www.phytec.de/de/leistungen/entwicklungsunterstuetzung.html or www.phytec.eu/europe/oem-integration/evaluation-start-up.html

PHYTEC Messtechnik GmbH 2018 L-823e_2 ix

phyBOARD-Regor AM335x [PB-01802-xxx]

unpacked, handled or operated in

trained personnel (such as electricians, technicians and engineers)

not be operated without protection circuitry if connections to the

Declaration of Electro Magnetic Conformity of the PHYTEC

phyBOARD-Regor AM335x

PHYTEC Single Board Computers (henceforth products) are designed for

installation in electrical appliances, as part of custom applications, or as dedicated

Evaluation Boards (i.e. for use as a test and prototype platform for hardware/software

development) in laboratory environments.

PHYTEC products lacking protective enclosures are subject to damage by

ESD and, therefore, must be

environments in which sufficient precautionary measures have been take

in respect to ESD dangers. It is also necessary that only appropriately

handle and/or operate these products. Moreover, PHYTEC products should

product’s pin header rows are longer then 3m.

PHYTEC products fulfill the norms of the European Union’s Directive for Electro Magnetic

Conformity only in accordance with the descriptions and rules of usage indicated in this

hardware manual (particularly in respect to the pin header row connectors, power

connector and serial interface to a host-PC).

Implementation of PHYTEC products into target devices, as well as user modifications and

extensions of PHYTEC products, is subject to renewed establishment of conformity to, and

certification of, Electro Magnetic Directives. Users should ensure conformance following

any modifications to the products as well as implementation of the products into target

systems.

x PHYTEC Messtechnik GmbH 2018 L-823e_2

Preface

Product Change Management and information in this manual on parts populated on the SOM / SBC

With the purchace of a PHYTEC SOM / SBC, you will, in addition to our HW and SW offerings, receive free obsolescence maintenance service for the HW we provide.

Our PCM (Product Change Management) Team of developers, is continuously processing all incoming PCN's (Product Change Notifications) from vendors and distributors concerning parts which are used in our products.

Possible impacts to the functionality of our products, due to changes of functionality or obsolesce of a certain part, are constantly being evaluated in order to take the right measures in purchasing or within our HW/SW design.

Our general philosophy here is: We never discontinue a product as long as there is demand for it.

Therefore, we have established a set of methods to fulfill our philosophy:

Avoidance strategies

• Avoid changes by evaluating longevity of parts during design in phase.

• Ensure availability of equivalent second source parts.

• Stay in close contact with part vendors to be aware of roadmap strategies.

Change management (in the rare event of an obsolete and non replaceable part)

• Ensure long term availability by stocking parts through last time buy management

according to product forecasts.

• Offer long term frame contract to customers.

Change management (in case of functional changes)

• Avoid impacts on product functionality by choosing equivalent replacement parts.

• Avoid impacts on product functionality by compensating changes through HW redesign

or backward compatible SW maintenance.

• Provide early change notifications concerning functional relevant changes of our

products.

Therefore, we refrain from providing detailed part specific information within this manual, which can be subject to continuous changes, due to part maintenance for our products.

In order to receive reliable, up to date, and detailed information concerning parts used for our product, please contact our support team through the contact information given within this manual.

PHYTEC Messtechnik GmbH 2018 L-823e_2 xi

phyBOARD-Regor AM335x [PB-01802-xxx]

xii PHYTEC Messtechnik GmbH 2018 L-823e_2

Introduction

1 Introduction

1.1 Hardware Overview

The phyBOARD-Regor for phyCORE-AM335x is a low-cost, feature-rich software

development platform supporting the Texas Instruments AM335x microcontroller.

Moreover, due to the numerous standard interfaces, the phyBOARD-Regor AM335x can

serve a foundation for many applications. At the core of the phyBOARD-Regor is the

PCM-051/phyCORE-AM335x System On Module (SOM), containing the processor, DRAM,

NAND Flash, power regulation, supervision, transceivers, and other core functions required

to support the AM335x processor. Surrounding the SOM is the PBA-C-08/phyBOARD-Regor

carrier board, adding power input, buttons, connectors, signal breakout, and Ethernet

connectivity amongst other things.

1.1.1 Features of the phyBOARD-Regor AM335x

The phyBOARD-Regor AM335x supports the following features :

• Developed in accordance with PHYTEC's new SBCplus concept (

Preface

)

• PHYTEC’s phyCORE-AM335x SOM

• Phoenix Contact ME Max 3U1 standard dimensions

• Boot from SD card or NAND Flash

• Max. 1 GHz core clock frequency

• Single supply voltage of 24 V ±10 % via 1×5 position Phoenix Contact MINI COMBICON

connector 3.5 mm) or via Card Edge connector

• Two RJ45 jacks for 10/100 Mbps Ethernet

• Two USB OTG interfaces available (one at USB Micro-AB connector and one at the

expansion connector)

• One Secure Digital / Multi Media Memory Card interface brought out to a Micro-SD

connector

• 2 x RS-232 transceivers supporting UART0 and UART2 with data rates of up to 1 Mbps at

1×5 position Phoenix Contact MINI COMBICON connector 3.5 mm

• RS-485 transceiver supporting UART1 with data rates of up to 1 Mbps at 1×5 position

Phoenix Contact MINI COMBICON connector 3.5 mm

• CAN interface at 1×5 position Phoenix Contact MINI COMBICON connector 3.5 mm

• Reset-Button

• RTC with memory backup capacitor (Gold Capacitor, lasts approx. 7 days)

• Expansion connector with different interfaces

• Card Edge connector to incorporate a DIN rail bus connection

PHYTEC Messtechnik GmbH 2018 L-823e_2 1

phyBOARD-Regor AM335x [PB-01802-xxx]

1.1.2 Block Diagram

Figure 1: Block Diagram of the phyBOARD-Regor AM335x

2 PHYTEC Messtechnik GmbH 2018 L-823e_2

Introduction

1.1.3 View of the phyBOARD-Regor AM335x

Figure 2: View of the phyBOARD-Regor AM335x with phyCORE-AM335x

Figure 3: phyBOARD-Regor AM335x connectors

PHYTEC Messtechnik GmbH 2018 L-823e_2 3

phyBOARD-Regor AM335x [PB-01802-xxx]

Reference

Power supply 12 V – 24 V (1×5 positions Phoenix Contact MINI COMBICON connector 3.5 mm pitch)

4 x digital input/output (1×5 positions Phoenix Contact

CAN / RS-485 connector (UART1) (1×5 positions Phoenix Contact MINI COMBICON connector 3.5 mm pitch)

2.2.2

2.2.3

X4

USB On-The-Go connector (USB Micro-AB)

2.2.5

RS-232 (UART0 and UART2) (1×5 positions Phoenix

Contact MINI COMBICON connector 3.5 mm pitch)

X6

Expansion connector (2×30 socket connector 2 mm pitch)

3.1

Card Edge connector to incorporate DIN rail bus

interface (CAN0)

Ethernet 0/1 connector (dual RJ45 with speed and link LED)

X11

Secure Digital / Multi Media Card (Micro-slot)

2.2.6

phyCORE-Connector (1x50 pin and 1x60 pin Samtec

connector)

2 Accessing the phyBOARD-Regor Features

PHYTEC phyBOARD-Regor is fully equipped with all mechanical and electrical components

necessary for a speedy and secure start-up.

2.1 Overview of the phyBOARD-Regor Peripherals

The phyBOARD-Regor is depicted in

equipped with the components listed in

description of each peripheral, refer to the appropriate chapter listed in the applicable

table.

2.1.1 Connectors and Pin Header

Table 2

the location of each connector for easy identification.

Figure 3

lists all available connectors on the phyBOARD-Regor

Designator

X1

X2

X3

highlights the location of each peripheral for easy identification.

Description See Section

MINI COMBICON connector 3.5 mm pitch)

Figure 2

. It features many different interfaces and is

Table 2

and

Table 3

. Figure 3

. For a more detailed

highlights

2.2.1.1

2.2.7

X5

X7

X9

X64

Table 2: phyBOARD-Regor Connectors and Pin Headers

4 PHYTEC Messtechnik GmbH 2018 L-823e_2

connectivity with RS-485 interface (UART1) or CAN

2.2.2

2.2.8

2.2.4

4

Accessing the phyBOARD-Regor Features

Ensure that all module connections do not exceed their expressed

peripherals.

maximum voltage or current. Maximum signal input values are indicated in

the corresponding controller User's Manual/Data Sheets. As damage from

improper connections can vary according to use and application, it is the

user‘s responsibility to take appropriate safety measures to ensure that the

module connections are protected from overloading through connected

PHYTEC Messtechnik GmbH 2018 L-823e_2 5

phyBOARD-Regor AM335x [PB-01802-xxx]

See

Section

Indicates presence of VBUS for the USB OTG interface at expansion connector X6

Indicates presence of VBUS for the USB OTG interface at USB Micro-AB connector X4

D62

green

5 V voltage generation of the phyBOARD-Regor

3.3 V voltage of the phyBOARD-Regor (approved and

enabled by supply voltage supervisor IC)

2.1.2 LEDs

Figure 4: phyBOARD-Regor AM335x LEDs locations

he phyBOARD-Regor is populated with seven LEDs to indicate the status of the USB VBUS

T

voltages, the power supply voltages, and the RUN/STOP and ERROR status which are visible

through 2 holes in the housing.

Figure 4

LED Color Description

D7 green

D8 green

D63 green

shows the location of the LEDs. Their functions are listed in

Table 3

.

3.1

2.2.5

2.2.1.2

Table 3: phyBOARD-Regor LEDs Descriptions

6 PHYTEC Messtechnik GmbH 2018 L-823e_2

LED Color Description

See

Section

3.3 V voltage on the output of the LDO (has to be

supply the phyBOARD-Regor)

Accessing the phyBOARD-Regor Features

D68 green

approved and enabled by supply voltage supervisor IC to

D66 green RUN/STOP status LED

D67 red ERROR status LED

Table 3: phyBOARD-Regor LEDs Descritption (continued)

2.2.1.2

2.2.1.3

PHYTEC Messtechnik GmbH 2018 L-823e_2 7

phyBOARD-Regor AM335x [PB-01802-xxx]

See

Section

S2

Reset Button

2.2.10

S4

Boot Switch

2.2.9

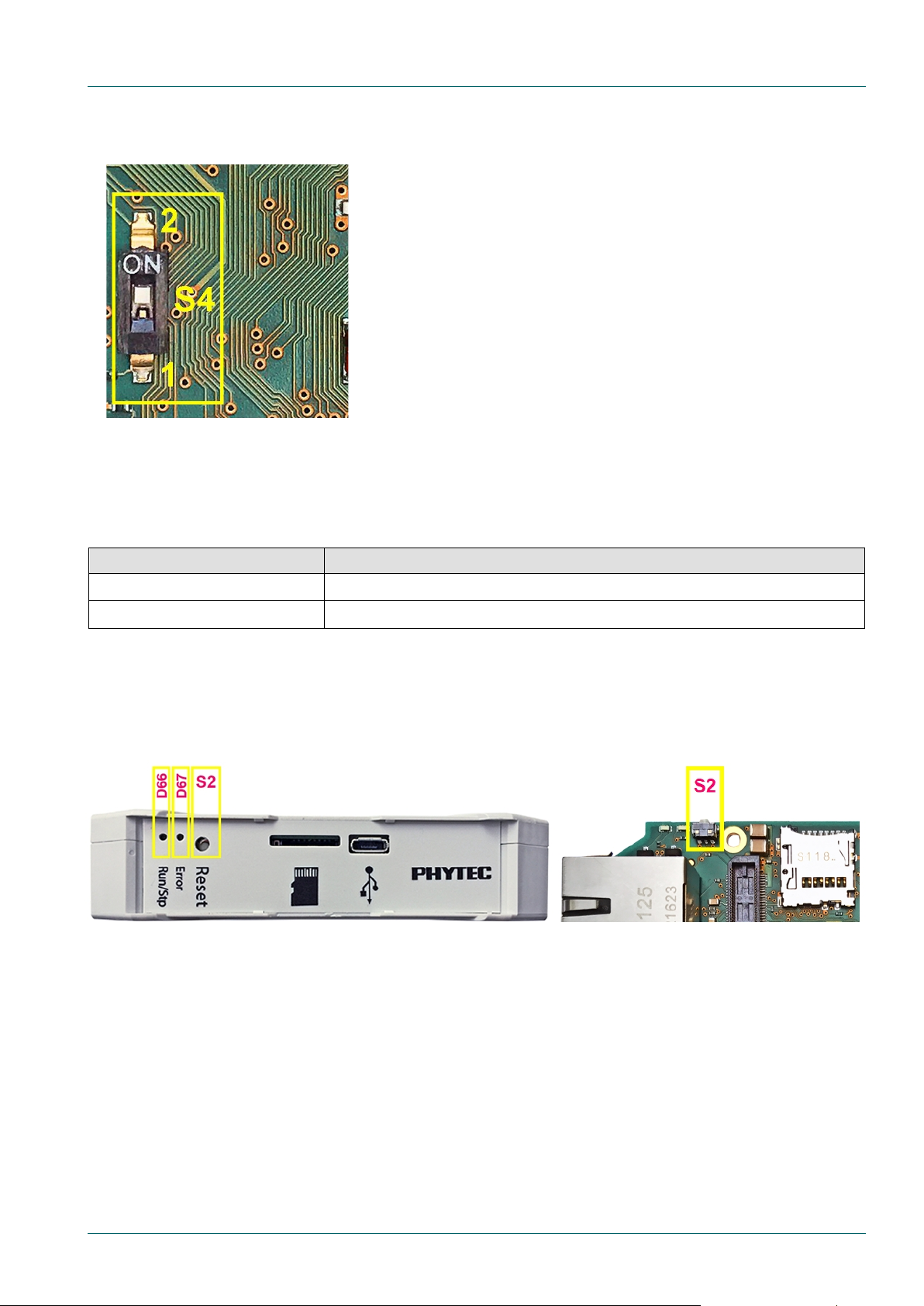

2.1.3 Switches

Figure 5: phyBOARD-Regor AM335x Switch Locations

The phyBOARD-Regor is populated with two switches, one to reset the phyBOARD-Regor

and another to configure the boot sequence.

Figure 5

Switch Description

Table 4: phyBOARD-Regor Switches Description

shows the location of the switches. Their functions are listed in

Table 4

.

8 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

Due to the small footprint of the solder jumpers (J), PHYTEC does not

team if you need jumper

configurations different from the default configuration.

See

Section

JP3

CAN termination (removable)

2.2.3

J5

Connect RS485-A or CANL signal at pin 5 of connector X7 (fixed)

2.2.8

J6

Connect RS485-B or CANH signal at pin 4 of connector X7 (fixed)

2.2.8

2.1.4 Jumpers

The phyBOARD-Regor comes with one removable jumper (JP) and two solder jumpers (J).

The removable jumper JP3 allows for optional termination of the CAN-interface by the user.

With jumpers J5 and J6, the interface at the Card Edge Connector X7 can be chosen to be a

RS485 (UART1) or a CAN (CAN0) interface.

y default, JP3 is set to terminate the CAN interface. J5 and J6 are set to connect the

B

RS485 interface to the card edge connector X7.

recommend manual jumper modifications. This might also render the

warranty invalid. Because of this, only the removable jumper is described

in this section. Contact the PHYTEC sales

Figure 5

shows the location of the removable jumper JP3. The fixed jumpers J5 and J6 are

placed on the bottom of the PCB. The function of the jumpers on the phyBOARD-Regor are

described in

Table 5

. More detailed information can be found in the appropriate section.

Jumper Description

Table 5: phyBOARD-Regor Jumper Description

Detailed descriptions of the assembled connectors, jumpers and switches can be found in the following sections.

PHYTEC Messtechnik GmbH 2018 L-823e_2 9

phyBOARD-Regor AM335x [PB-01802-xxx]

(F1) is used to protect the

2.2 Functional Components on the phyBOARD-Regor SBC

This section describes the functional components of the phyBOARD-Regor. Each subsection

details a particular connector/interface and associated jumpers for configuring that

interface.

2.2.1 Power Supply

Do not change modules or jumper settings while the phyBOARD-Regor is supplied with power!

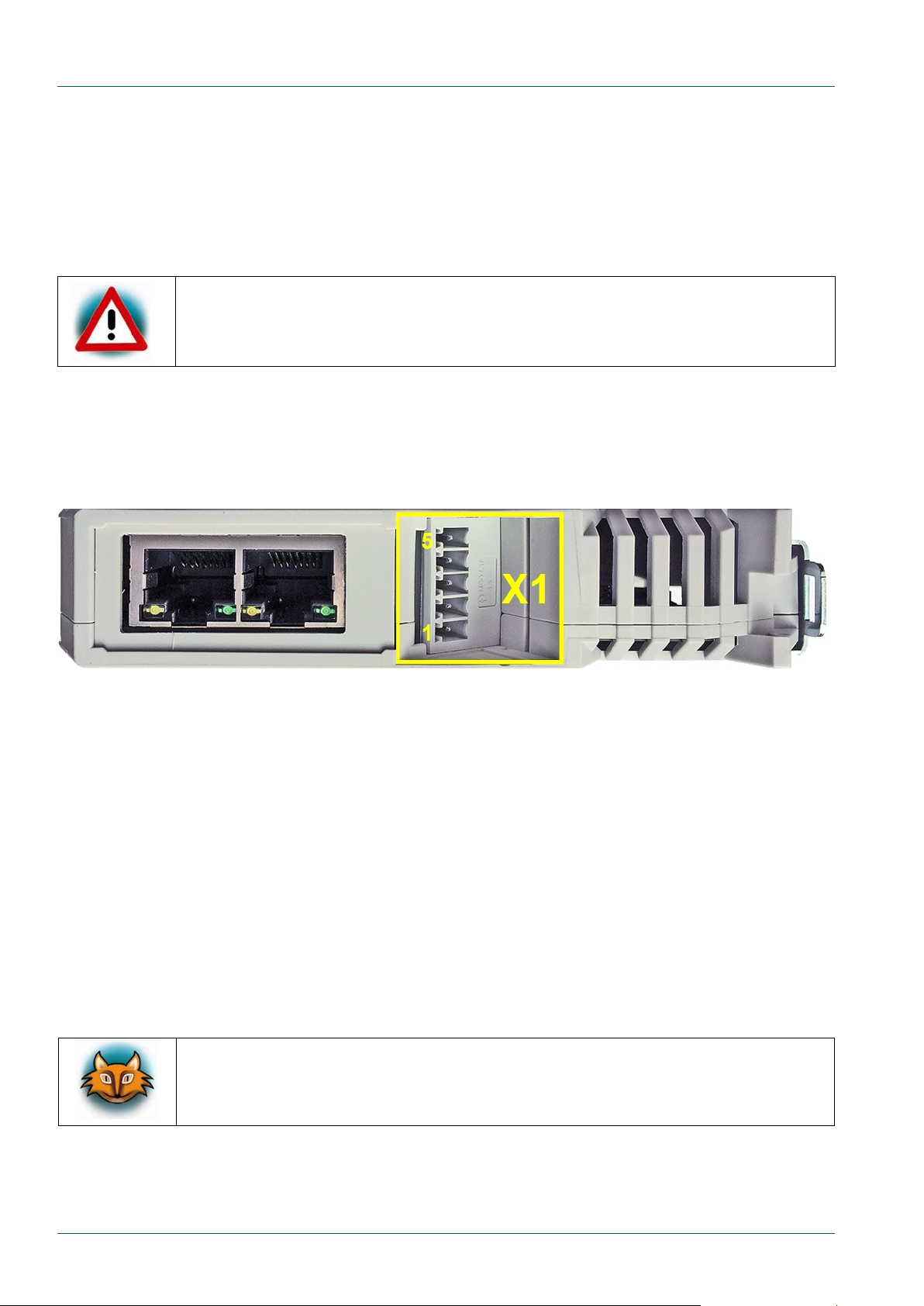

2.2.1.1 Power Connector (X1)

Figure 6: Power Supply Connector X1

The phyBOARD-Regor is equipped with a 5-pole Phoenix Contact MINI COMBICON base strip

3.5 mm connector (X1) suitable for a single 24 V ±10 % supply voltage.

The required current load capacity depends on the specific configuration of the phyCORE

mounted on the phyBOARD-Regor, the particular interfaces enabled while executing

software, as well as whether an optional expansion board is connected to the carrier

board.

The permissible input voltage is +24 V DC ±10 % at the 5-pole Phoenix Contact MINI

COMBICON base strip X1 or, alternatively, at the CARD Edge connector X7 (

section 2.2.8

). A

24 V adapter with a minimum supply of 1A is recommended to supply the board.

A 3A socketed SMD Littelfuse 452

phyBOARD-Regor against over-current.

10 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

1

X_VIN

+24 V DC ±10 % power supply

2

GND

Ground

3 - NC 4 -

NC 5 -

NC

Figure 6

and

Table 6

show the pin assignment of the connector X1.

Pin Signal Description

Table 6: Pin Assignment of the 5 position Phoenix Contact MINI COMBICON Base Strip X1

2.2.1.2 Power LEDs D62, D63, and D68

The LEDs D62,D63, and D68 indicate the presence of the 3.3 V (D63, D68) and 5 V (D62) supply voltage generated from the input voltage.

he presence of the 3.3 V voltage generated by the LDO is indicated by D68. This voltage is

T

verified by a voltage supervisor IC and is interconnected to the phyBOARD-Regor to supply

its components. The presence of the approved 3.3 V phyBOARD-Regor supply voltage is

indicated by D63.

Figure 4

shows the locations of the three LEDs.

PHYTEC Messtechnik GmbH 2018 L-823e_2 11

phyBOARD-Regor AM335x [PB-01802-xxx]

2.2.1.3 Status LEDs D66 and D67

Figure 7: LEDs D66 and D67 with Switch S2

he status-LEDs D66 and D67 are located next to the reset button and are visible at the

T

front of the housing.

D D66 indicates the RUN/STOP status of the phyBOARD-Regor. This LED is green and can

LE

be used to show if the module is currently running.

T

he ERROR-LED D67 is red and can be used to indicate if there is an error with the module.

Figure 4

2.2.1.4 Backup Supply

The phyBOARD-Regor is equipped with a Gold Capacitor (C339 placed next to connector X6)

which is intended to back up the external RTC (

source is also connected to the backup voltage pin VBAT (A2) of the phyCORE-AM335x and

supplies the module's RTC and some critical registers of the Power Management IC when

the primary system power, X_VIN, is removed. The backup supply lasts approximately 7

days.

and

Figure 7

show the location of the two LEDs.

section 2.2.11

) on the SBC. This voltage

12 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

Signal

level

See

Section

X5 (1×5 positions Phoenix Contact MINI COMBICON

connector 3.5 mm pitch)

X5 (1×5 positions Phoenix Contact MINI COMBICON

UART3

X6 (2×30 socket connector 2 mm pitch)

TTL

3.1

2.2.2 UART Connectivity (X3, X5, X6, X7)

The AM335x SOM supports up to 6 so called UART units. The phyBOARD-Regor provides the

interfaces of UART0 to UART3 on various connectors at different signal levels.

an overview of the UART signals' availability, locations and signal levels.

or a more detailed description of each serial interface, refer to the appropriate chapter

F

listed in the table.

UART Connector

Table 7

gives

UART0 (standard console)

UART1

UART2

Table 7: Connectors and Signal Levels of the UART Interfaces

connector 3.5 mm pitch)

X6 (2×30 socket connector 2 mm pitch) TTL

X3 (1×5 positions Phoenix Contact MINI COMBICON

X7 (Card Edge connector) RS-485

connector 3.5 mm pitch)

X6 (2×30 socket connector 2 mm pitch) TTL

RS-232

RS-485

RS-232

2.2.2.1

3.1

2.2.2.2

2.2.8

2.2.2.1

3.1

PHYTEC Messtechnik GmbH 2018 L-823e_2 13

phyBOARD-Regor AM335x [PB-01802-xxx]

UART0 serial receive signal RS-232 level (receive signal from

peripheral device at phyBOARD-Regor)

UART0 serial transmit signal RS-232 level (send signal to

peripheral device from phyBOARD-Regor)

3

GND

Ground

UART2 serial receive signal RS-232 level (receive signal from

peripheral device at phyBOARD-Regor)

UART2 serial transmit signal RS-232 level (send signal to

2.2.2.1 RS-232 Connectivity (X5)

Figure 8: RS-232 Interface Connector X5

Two RS-232 transceivers on the phyBOARD-Regor convert the TTL level signals of UART0

(the standard console) and UART2 from the phyCORE-AM335x to RS-232 level signals. The

RS-232 level signals are available at the Phoenix Contact MINI COMBICON connector X5

(5 positions, 3.5 mm pitch).

Connector X5 is located on the right side of the board (

view of the X5 connector.

Table 8

shows the pin assignment of X5. The pin-description in

Figure 2). Figure 8

shows a detailed

the table is given from the perspective of the phyBOARD-Regor.

The UART0 interface serves as the standard console output of the phyCORE-AM335x module

on the phyBOARD-Regor. The initial setting of the UART0 interface is specified to a baudrate of 115200 baud with 8N1 configuration (8 data bits, no parity bit, 1 stop bit).

Pin Signal Description

1 UART0_RXD_RS232

2 UART0_TXD_RS232

4 UART2_RXD_RS232

5 UART2_TXD_RS232

Table 8: Pin Assignment of the RS-232 Interface at Connector X5

peripheral device from phyBOARD-Regor)

14 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

1

X_UART1_RS485_A

UART1 serial A signal RS-485 level

2

X_UART1_RS485_B

UART1 serial B signal RS-485 level

3

GND

Ground

4

X_CANH

CAN High signal CAN1

5

X_CANL

CAN Low signal CAN1

2.2.2.2 RS-485 Connectivity (X3)

Figure 9: RS-485 Interface Connector X3

n RS-485 transceiver on the phyBOARD-Regor converts the TTL level signals of UART1

A

from the phyCORE-AM335x to RS-485 level signals. The RS-485 level signals are available

at the Phoenix Contact MINI COMBICON connector X3 (5 positions, 3.5 mm pitch).

onnector X3 is located on the right side of the board (

C

view of the X3 connector.

Table 9

shows the pin assignment of X3.

Figure 2

).

Figure 9

shows a detailed

n case jumpers J5 and J6 (

I

section 2.1.4

) are set to the respective positions, the RS-485

level signals are also available at the card edge connector X7 (

Pin Signal Description

Table 9: Pin Assignment of the RS-485 Interface at Connector X3

section 2.2.8

).

PHYTEC Messtechnik GmbH 2018 L-823e_2 15

phyBOARD-Regor AM335x [PB-01802-xxx]

1

X_UART1_RS485_A

UART1 serial A signal RS-485 level

2

X_UART1_RS485_B

UART1 serial B signal RS-485 level

3

GND

Ground

4

X_CANH

CAN High signal line

5

X_CANL

CAN Low signal line

2.2.3 CAN Connectivity (X3, JP3)

Figure 10: Components supporting the CAN Interface

The Controller Area Network (CAN) bus offers a low-bandwidth, prioritized message

fieldbus for serial communication between microcontrollers. It efficiently supports

distributed real time control with a high level of security. The DCAN module of the AM335x

implements the CAN protocol according to the CAN 2.0B protocol specification and

supports bit rates up to 1 Mbit/s. The CAN interface of the phyBOARD-Regor AM335x is

connected to the CAN-controller DCAN1 of the AM335x SOM.

T

he CAN interface of the phyBOARD-Regor AM335x is accessible at the Phoenix Contact

MINI COMBICON connector X3 (5 positions, 3.5 mm pitch as shown in

jumpers J5 and J6 (

signals are also available at the card edge connector X7 (

(

section 2.1.4

lines if needed.

Table 10

Pin Signal Description

Table 10: Pin Assignment of CAN Connector X3

) can be installed to add a 120 Ohm termination resistor across the CAN data

shows the signal mapping of the CAN signals at connector X3.

section 2.1.4

) are set to the respective positions, the CAN interface

section 2.2.8

Figure 10

). In case

). Jumper JP3

epending on the muxing options, a second CAN interface (DCAN0 of the

D

phyCORE-AM335x) is available on expansion port X6 (

be used instead of UART0 (RX and TX) or MMC2 (DAT1 and DAT2).

16 PHYTEC Messtechnik GmbH 2018 L-823e_2

section 3.1

). DCAN0 (TX and RX) can

Accessing the phyBOARD-Regor Features

2.2.4 Ethernet Connectivity (X9)

Figure 11: Ethernet Interfaces at Connector X9

The Ethernet interfaces of the phyBOARD-Regor are accessible at dual RJ45 connectors X9A (Ethernet 0) and X9B (Ethernet 1).

Both Ethernet interfaces are configured as 10/100Base-T networks. The LEDs for LINK

(green) and SPEED (yellow) indication are integrated in the connector. Both Ethernet

transceivers support HP Auto-MDIX, eliminating the need for a direct connect LAN or a

cross-over path cable. They detect the TX and RX pins of the connected device and

automatically configure the PHY TX and RX pins accordingly.

2.2.4.1 MAC Address

In a computer network such as a local area network (LAN), the MAC (Media Access Control)

address is a unique computer hardware number. For a connection to the Internet, a table is

used to convert the assigned IP number to the hardware’s MAC address.

In order to guarantee that the MAC address is unique, all addresses are managed in a central location. The MAC address of the phyBOARD-Regor is saved on the CPU (AM335x).

PHYTEC Messtechnik GmbH 2018 L-823e_2 17

phyBOARD-Regor AM335x [PB-01802-xxx]

Due to the small footprint of the resistors, PHYTEC does not recommend

from the default configuration.

2.2.5 USB Connectivity (X4, X6)

Figure 12: USB Interface Connector X4

he phyBOARD-Regor provides two USB OTG interfaces.

T

SB0 is accessible at connector X4 (USB Micro-AB) located at the top of the

U

phyBOARD-Regor (

3.1

). Both interfaces are configured as USB OTG and are compliant with USB revision 2.0.

USB OTG devices are capable of initiating a session, controlling the connection, and

exchanging host and peripheral roles between each other.

Figure 2

), whereas USB1 is available at expansion connector X6 (

section

wo resistors configure the OTG operating mode. By default, the USB0_ ID pin is left

T

floating, thereby configuring the OTG interface at X4 as slave. USB1_ID is connected to

GND, and configures the OTG interface at expansion connector X6 as host. Typically,

configuring a connecting device as host or slave is done automatically via a USB OTG cable.

However, given the limited number of OTG enabled devices in the embedded market, these

resistors are provided to either simulate an OTG cable, or force the OTG interface into host

mode when OTG operation is not required.

LED D8 displays the status of USB0_VBUS at connector X4 and LED D7 displays the status of

USB1_VBUS at expansion connector X6.

manual jumper modifications. This might also render the warranty invalid.

Contact the PHYTEC sales team if you need USB configurations different

Figure 4

shows the location of the two LEDs.

18 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

2.2.6 Secure Digital Memory Card/ MultiMedia Card (X11)

Figure 13: MMC/SD Card Interface at Connector X11

The phyBOARD-Regor provides a standard microSDHC card slot at X11 for connection to

MMC/SD interface cards. It allows for an easy and convenient connection to peripheral

devices like SD and MMC cards. Power to the SD interface is supplied by inserting the

appropriate card into the MMC/SD connector which features card detection, a lock

mechanism and a smooth extraction function by Push-in/ Push-out of card.

Ensure that the device is not unplugged while it is still mounted. This may result in data loss!

DIP switch S4 allows the device to toggle between booting from NAND or SD card. In order

to boot from an SD card, S4 must be switched ON (refer to

section 2.1.3

for further

information).

PHYTEC Messtechnik GmbH 2018 L-823e_2 19

phyBOARD-Regor AM335x [PB-01802-xxx]

Please consider that the GPIOs do not have a separate current-driver on

Signal Level

Voltage

H-Level

>11 V

L-Level

<5 V

2.2.7 Digital GPIOs 1-4 (X2)

Figure 14: Digital GPIOs at Connector X2

The phyBOARD-Regor provides four digital IOs that are designed for processing DC-signals

with up to 24 V DC. The digital output voltage depends on the input voltage of the board.

Input and output signals are routed to the CPU (AM335x) through two discrete

optocouplers for galvanic isolation. Thus, it is possible to write and read the status of every

single GPIO of the phyBOARD-Regor simultaneously.

board. In case the GPIOs are used as outputs, the current is self-limited by

the output-optocoupler and should not exceed 750mA for each GPIO

channel. These outputs are low-side outputs.

When the GPIOs on the phyBOARD-Regor are used as digital inputs, they are configured active high with the following switching voltages:

Table 11: Digital input switching levels for GPIO 1-4

20 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

Digital Input/Output

Digital Input/Output (connects to GPIO0_26 (IN) and GPIO1_14 (OUT) of the AM335x)

Digital Input/Output (connects to GPIO0_23 (IN) and GPIO1_13 (OUT) of the AM335x)

Digital Input/Output (connects to GPIO0_22 (IN) and GPIO1_12 (OUT) of the AM335x)

5

GND

Ground

Table 12

shows the pin assignment of connector X2.

Pin Signal Description

1 DIGIO1

(connects to GPIO0_27 (IN) and GPIO1_15 (OUT) of the AM335x)

2 DIGIO2

3 DIGIO3

4 DIGIO4

Table 12: Pin Assignment of GPIO Connector X2

PHYTEC Messtechnik GmbH 2018 L-823e_2 21

phyBOARD-Regor AM335x [PB-01802-xxx]

Alternative Power supply for the phyBOARD-Regor +24 V DC ±10 %

2

GND

Ground

3

VCC3V3

Power supply for external 3.3 V logic (max. 500 mA)

X_UART1_RS485_A

UART1 serial A signal RS-485 level

X_CANL

CAN Low signal line

X_UART1_RS485_B

UART1 serial B signal RS-485 level

X_CANH

CAN High signal line

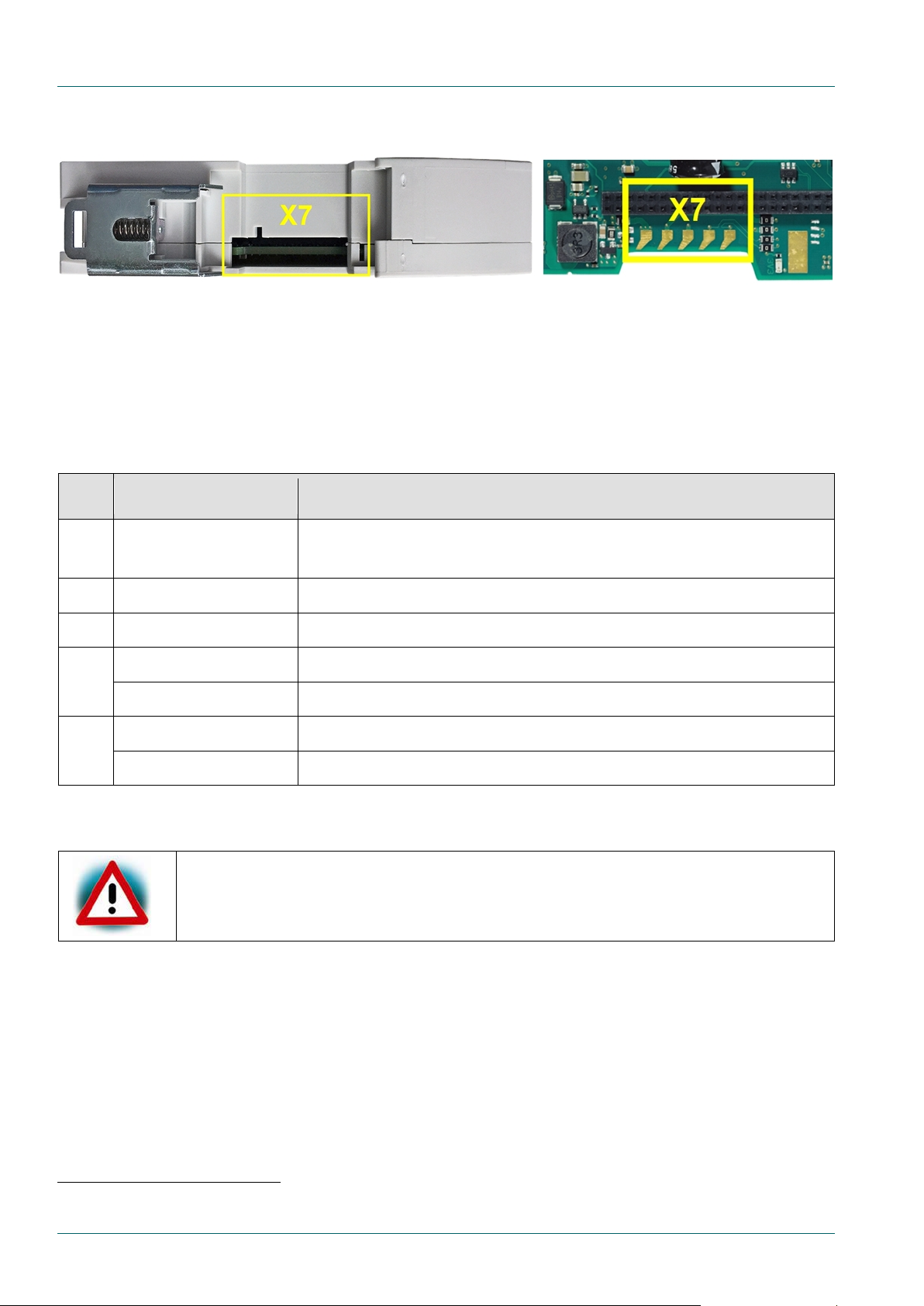

2.2.8 Card Edge Connector (X7)

Figure 15: Card Edge Connector X7

he Card Edge Connector at X7 is a PHYTEC development connector and allows other custom

T

expansion boards or DIN rail bus modules to be connected. The connector can be used as a

RS485 or CAN interface, depending on the position of jumpers J5 and J6 (

As there exists no standard, pay close attention to the pin assignment shown in

section 2.1.4

Table 13

).

.

Pin Signal Description

1 VIN

41

52

Table 13: Pin Assignment of CardEdge Connector X7

If the phyBOARD-Regor is supplied via the card edge connector, there is no protection against overcurrent through fuse F1.

1: The functionality of pin 4 of X7 depend on the jumper J6.

2: The functionality of pin 5 of X7 depend on the jumper J5.

22 PHYTEC Messtechnik GmbH 2018 L-823e_2

Accessing the phyBOARD-Regor Features

Boot Mode

Description

Boot mode 1 (S4 = OFF)

SYSBOOT[4:0] = 10011b → NAND, NANDI2C, MMC0, UART0

Boot mode 2 (S4 = ON)

SYSBOOT[4:0] = 10111b → MMC0, SPI0, UART0, USB

2.2.9 Boot Mode (S4)

Figure 16: Boot Switch S4

The pyhBOARD-Regor has two defined boot sequences which can be selected with DIP switch S4.

Table 14: Boot Switch Configuration for S4

2.2.10 System Reset Button (S2)

Figure 17: System Reset Button S2

The phyBOARD-Regor is equipped with a system reset button at S2. Pressing this button

will toggle the X_nRESET_IN pin (X64A11) of the phyCORE SOM low, causing the module to

reset. Additionally, the reset signal nRESET_OUT is generated on the module and will also

reset the peripherals on the carrier board.

PHYTEC Messtechnik GmbH 2018 L-823e_2 23

phyBOARD-Regor AM335x [PB-01802-xxx]

2.2.11 RTC

The phyBOARD-Regor features an external RTC (RV-4162-C7) as a replacement for the

normally mounted RTC on the phyCORE-AM335x module. It is used for real-time or timedriven applications.

lease note that if the RTC’s interrupt is needed, pin 37 (X_INTR1_GPIO0_20)

P

and pin 40 (X_INT_RTCn) at expansion connector X6 need to be shortcut (

he phyBOARD-Regor is equipped with a Gold Capacitor (C339 placed next to connector X6)

T

which is also intended to back up the external RTC (

section 2.2.1.4

).

section 3.1

).

24 PHYTEC Messtechnik GmbH 2018 L-823e_2

System Level Customizing

Pin #

Signal Name

Type

SL

Description

1

VCC3V3

OUT

3.3 V

3.3 V power supply

2

VCC5V

OUT

5.0 V

5 V power supply

3

VDIG1_1P8V

OUT

1.8 V

1.8 V power supply (max. 300 mA)

4

GND

- - Ground

5

X_SPI0_CS0

OUT

3.3 V

SPI 0 chip select 0

6

X_SPI0_MOSI

OUT

3.3 V

SPI 0 master output/slave input

7

X_SPI0_MISO

IN

3.3 V

SPI 0 master input/slave output

8

X_SPI0_CLK

OUT

3.3 V

SPI 0 clock output

9

GND

- - Ground

UART 0 receive data (standard debug interface)

11

X_I2C0_SDA

I/O

3.3 V

I2C0 Data

UART 0 transmit data (standard debug interface)

13

X_I2C0_SCL

I/O

3.3 V

I2C0 Clock

14

GND

- - Ground

3 System Level Customizing

3.1 Expansion Connector (X6)

Figure 18: Expansion Connector X6

Expansion connector X6 provides an easy way to add other functions and features to the

phyBOARD-Regor. Standard interfaces such as UART, SPI and I

2

C as well as different supply

voltages and some GPIOs are available at the expansion female connector.

The expansion connector is intended to add specific functions with custom expansion boards. This expansion board is developed together with the newest version of the carrier board.

The pinout of the expansion connector is shown in

Table 15

.

10 X_UART0_RXD IN 3.3 V

12 X_UART0_TXD OUT 3.3 V

Table 15: Pin Assignment of PHYTEC Expansion Connector X6

PHYTEC Messtechnik GmbH 2018 L-823e_2 25

phyBOARD-Regor AM335x [PB-01802-xxx]

Pin #

Signal Name

Type

SL

Description

15

X_JTAG_TMS

IN

3.3 V

JTAG Chain Test Mode Select signal

16

X_nJTAG_TRST

IN

3.3 V

JTAG Chain Test Reset (active low)

17

X_JTAG_TDI

IN

3.3 V

JTAG Chain Test Data Input

18

X_JTAG_TDO

OUT

3.3 V

JTAG Chain Test Data Output

19

GND

- - Ground

20

X_JTAG_TCK

IN

3.3 V

JTAG Chain Test Clock signal

21

USB_DP1

I/O

3.3 V

USB data plus USB1

22

USB_DM1

I/O

3.3 V

USB data minus USB1

23

nRESET_OUT

OUT

3.3 V

Reset (active low)

24

GND

- - Ground

25

X_MMC2_CMD

I/O

3.3 V

MMC command3

26

X_MMC2_DAT0

I/O

3.3 V

MMC data 03

27

X_MMC2_CLK

I/O

3.3 V

MMC clock3

28

X_MMC2_DAT1

I/O

3.3 V

MMC data 13

29

GND

- - Ground

30

X_MMC2_DAT2

I/O

3.3 V

MMC data 23

31

X_UART2_RX_GPIO3_9

I/O

3.3 V

UART 2 receive data; GPIO3_94

32

X_MMC2_DAT3

I/O

3.3 V

MMC data 33

33

X_UART2_TX_GPIO3_10

I/O

3.3 V

UART 2 transmit data; GPIO3_104

34

GND

- - Ground

35

X_UART3_RX_GPIO2_18

I/O

3.3 V

UART 3 receive data; GPIO2_184

36

X_UART3_TX_GPIO2_19

I/O

3.3 V

UART 3 transmit data; GPIO2_194

37

X_INTR1_GPIO0_20

I/O

3.3 V

Interrupt 1; GPIO0_20

38

X_GPIO0_7

I/O

3.3 V

GPIO0_7

39

X_AM335_EXT_WAKEUP

IN

3.3 V

External wakeup

40

X_INT_RTCn

OUT

3.3 V

Interrupt from the RTC (active low)

41

GND

- - Ground

42

X_GPIO3_7

I/O

3.3 V

GPIO3_7

43

nRESET_IN

IN

3.3 V

Push-button S2 reset (active low)

44

X_GPIO1_31

I/O

3.3 V

GPIO1_31

45

X_AM335_NMIn

IN

3.3 V

AM335x non-maskable interrupt

Table 15: Pin Assignment of PHYTEC Expansion Connector X6 (continued)

3: These pins are configured as GPIO pins. To use them as MMC/SD card interface, the pin muxing must be changed and

additional software development is required.

4: These pins are configured as GPIO pins. To use them as UART interface, the pin muxing must be changed and additional

software development is required.

26 PHYTEC Messtechnik GmbH 2018 L-823e_2

System Level Customizing

Pin #

Signal Name

Type

SL

Description

46

GND

- - Ground

47

X_AIN4

IN

1.8 V

Analog input 4

48

X_AIN5

IN

1.8 V

Analog input 5

49

X_AIN6

IN

1.8 V

Analog input 6

50

X_AIN7

IN

1.8 V

Analog input 7

51

GND

- - Ground

52

X_GPIO_CKSYNC

I/O

3.3 V

GPIO Clock Synchronization

53

X_USB1_ID

IN

1.8 V

USB1 ID (connected to Ground)

54

USB1_VBUS

OUT

5.0 V

USB bus voltage USB1

55

X_USB1_CE

OUT

3.3 V

USB 1 charger enable

56

GND

- - Ground

57

NC - -

Not connected

Power On for Power Management IC for AM335x

59

GND

- - Ground

60

VCC5V_IN

IN

5.0 V

5 V input supply voltage

Board

Prod. No.

Device

Address used (7 MSB)

EEPROM

0x52

PMIC

0x2D, 0x12

phyBOARD-Regor

PBA-C-08

RTC

0x68

58 X_PB_POWER IN 5.0 V

Table 15: Pin Assignment of PHYTEC Expansion Connector X6 (continued)

If the SPI-NOR Flash on the phyCORE-AM335x is populated, the SPI signals

on the expansion port cannot be used.

3.1.1 I

2

C Connectivity

The I2C interface of the AM335x is available at pin 11 (X_I2C0_SDA) and pin 13

(X_I2C0_SCL) of the expansion connector X6 (

Table 15

).

To avoid any conflicts when connecting external I

addresses of the on-board I

2

C devices must be considered.

2

C devices to the phyBOARD-Regor, the

Table 16

lists the addresses

already in use. This table shows only the default address.

phyCORE-AM335x PCM-051

Table 16: I2C Addresses in Use

PHYTEC Messtechnik GmbH 2018 L-823e_2 27

phyBOARD-Regor AM335x [PB-01802-xxx]

Dimensions:

100 mm x 100 mm

Weight:

129 g

Storage temperature:

-40°C to +85°C

Operating temperature:

refer to

section 4.2

Humidity:

95% r.F. not condensed

Operating voltage:

VCC 24 V +/- 5%

Power consumption:

TBD

4 Technical Specifications

The module’s profile is max. 10 mm thick, with a maximum component height of 3.0 mm on the bottom (connector) of the PCB and approximately 5.0 mm on the top (microcontroller). The board itself is approximately 1.4 mm thick.

n order to design a custom housing for the phyBOARD-Regor, the CAD data of the board is

I

available on our FTP server at:

ftp://ftp.phytec.de/pub/Products/phyBOARD-REGOR-AM335x/

The CAD data of the housing can be found on the web page of Phoenix Contact at:

http://www.phoenixcontact.com/online/portal/us!uri=pxc-ocitemdetail:pid=2201546&library=usen&pcck=P-01-04-02-01&tab=1

Additional specifications:

These specifications describe the standard configuration of the phyBOARD-Regor as of the

printing of this manual.

Connectors on the phyBOARD-Regor:

X1: Manufacturer Phoenix Contact

MCO 1,5/ 5-G1L-3,5 KMGY - 2278380

X2, X3, X5: Manufacturer Phoenix Contact

MCO 1,5/ 5-G1R-3,5 KMGY - 2278351

Mating Connector

or X1, X2, X3, X5: Manufacturer Phoenix Contact

f

MC 1,5/ 5-ST-3,5 GY7035 - 1769087

hytec article number: GP354

P

Please refer to the corresponding data sheets and mechanical specifications provided by

Phoenix Contact® (

www.phoenixcontact.com

).

28 PHYTEC Messtechnik GmbH 2018 L-823e_2

Technical Specifications

Operating condition

Supply voltage

Current value

Power consumption

on bootloader prompt

+12 V

230 mA

2,76 W

on kernel prompt

+12 V

180 mA

2,16 W

stresstest

+24 V

218 mA

5,23 W

The right temperature grade of the board highly depends on the use case.

used for temperature compensation

4.1 Product Power Rating

The current ratings and power consumption of the phyBOARD-Regor are shown in

Table 17

.

The measurements are performed using the NAND Flash as the boot source. The ratings

given in the table can vary depending on different operating and load conditions.

Table 17: Power ratings of the phyBOARD-Regor

4.2 Product Temperature Grades

It is mandatory to determine if the use case suites the temperature range

of the chosen module (see below). If necessary, a heat spreader can be

The feasible operating temperature of the SOM greatly depends on the use case of your

software application. Modern high performance microcontrollers and other active parts

like the ones described within this manual are usually rated by qualifications based on

tolerable junction or case temperatures. Therefore, making a general statement about

minimum or maximum ambient temperature ratings for the described SOM is not possible.

However, the above mentioned parts are available in different temperature qualification

levels by the producers. PHYTEC offers SOMs in different configurations, making use of

those temperature qualifications. To indicate which level of temperature qualification is

used for active and passive parts of a SOM configuration, PHYTEC has categorized SOMs in

three temperature grades.

These grades describe a set of components which, in combination, add up to a useful set of product options with different temperature grades. This enables PHYTEC to make use of cost optimizations depending on the required temperature range.

In order to determine the right temperature grade and whether the minimum or maximum qualification levels are met within an application, the following conditions must be defined when considering the use case:

Table 18

describes these grades in detail.

PHYTEC Messtechnik GmbH 2018 L-823e_2 29

phyBOARD-Regor AM335x [PB-01802-xxx]

Product

Grade

Industrial -40 °C to +105 °C / Automotive -40 °C to+125 °C

Industrial

-40 °C to +95 °C

Industrial

-40 °C to +85 °C

Extended Commercial

-20 °C to +105 °C

Industrial

-40 °C to +95 °C

Industrial

-40 °C to +85 °C

Consumer 0 °C to +95 °C

Consumer 0 °C to +70 °C

• Determined processing load for the given software use case

• Maximum temperature ranges of components (see

Table 18

)

• Power consumption resulting from a base load and the calculating power required (in

consideration of peak loads as well as time periods for system cool down)

• Surrounding temperatures and existing airflow if the system is mounted into a housing

• Heat resistance of the heat dissipation paths within the system along with the

considered usage of a heat spreader or a heat sink to optimize heat dissipation

Controller Temp Range

Temp.

RAM (Case Temp) Others (Ambient)

(Junction Temp)

I

X

C Commercial 0 °C to +95 °C

Table 18: Product Temperature Grades

30 PHYTEC Messtechnik GmbH 2018 L-823e_2

Revision History

Date

Version #

Changes in this manual

30.08.2016

Manual

First edition.

)

with phyBOARD-Regor- Carrier Board (PCB 1447.1).

27.06.2018

Manual

Second edition.

Regor Carrier Board (PCB

1447.3).

5 Revision History

L-823e_1

L-823e_2

Describes the phyBOARD-Regor AM335x SOM (PCB 1358.3

Updated layout for the phyBOARD-

PHYTEC Messtechnik GmbH 2018 L-823e_2 31

phyBOARD-Regor AM335x [PB-01802-xxx]

Index

B

Backup supply ..................................... 12

Block Diagram ....................................... 2

Boot Modes ........................................ 23

C

CAN ................................................... 16

Card Edge Connector ............................ 22

Connectors ........................................... 4

D

Digital GPIO ........................................ 20

Dimensions ........................................ 28

E

EMC .................................................... x

Ethernet ............................................ 17

Expansion connector ............................ 25

F

Features............................................... 1

H

Humidity ............................................ 28

J

JP3 ................................................... 16

Jumpers ............................................... 9

L

LAN ................................................... 17

LEDs .................................................... 6

D62 .......................................... 11, 12

D63 .......................................... 11, 12

D68 ............................................... 11

D7 ................................................. 18

D8 ................................................. 18

LINK LED ............................................ 17

M

MAC Address ....................................... 17

O

Operating Temperature ......................... 28

Operating Voltage ................................ 28

P

Peripherals ........................................... 4

Pin Header ........................................... 4

Power Connector ................................. 10

Power Consumption ............................. 28

R

Reset................................................. 23

RS-232 .............................................. 13

RS-485 .............................................. 13

S

S2 ..................................................... 23

S4 ..................................................... 23

SD card .............................................. 19

SPEED LED .......................................... 17

Storage Temperature ............................ 28

Switches .............................................. 8

T

Technical Specifications ........................ 28

U

USB .................................................. 18

USB 2.0 ............................................. 18

W

Weight............................................... 28

X

X1 ..................................................... 10

X11 ................................................... 19

X2 ..................................................... 20

X3 ................................................ 13, 16

X4 ..................................................... 18

X5 ..................................................... 13

X6 ........................................... 13, 18, 25

X7 ................................................ 13, 22

X9 ..................................................... 17

32 PHYTEC Messtechnik GmbH 2018 L-823e_2

Suggestions for Improvement

Document: phyBOARD-Regor AM335x

Document number: L-823e_2, June 2018

How would you improve this manual?

Did you find any mistakes in this manual? page

Submitted by:

Customer number:

Name:

Company:

Address:

Return to: PHYTEC Messtechnik GmbH Postfach 100403 D-55135 Mainz, Germany Fax : +49 (6131) 9221-33

PHYTEC Messtechnik GmbH 2017 L-823e_2 33

phyBOARD-Regor AM335x [PB-01802-xxx]

Published by

PHYTEC Messtechnik GmbH 2018 Ordering No. L-823e_2

Printed in Germany

Loading...

Loading...