Photon Focus MV0 CMOSIS Series, MV0-D2048x1088-C01-160-G2, MV0-D2048-C01-160-G2 User Manual

Photonfocus

MV0 CMOSIS Camera Series

CMOS camera series with GigE Interface

MV0-D2048x1088-C01-160-G2

MV0-D2048-C01-160-G2

MAN078 12/2018 V1.1

All information provided in this manual is believed to be accurate and reliable. No

responsibility is assumed by Photonfocus AG for its use. Photonfocus AG reserves the right to

make changes to this information without notice.

Reproduction of this manual in whole or in part, by any means, is prohibited without prior

permission having been obtained from Photonfocus AG.

2 of 111 MAN078 12/2018 V1.1

Contents

1 Preface 7

1.1 IMPORTANT NOTICE! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 About Photonfocus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Sales Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6 Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Introduction 11

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Camera Naming Convention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Camera list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Product Specification 13

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Feature Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.3 Spectral Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 RGB Bayer Pattern Filter (color models) . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4 Image Acquisition 21

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.1 Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.2 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1.3 Image Acquisition, Frame and Exposure Control Parameters . . . . . . . . . . 22

4.1.4 Image Acquisition, Frame and Exposure Trigger . . . . . . . . . . . . . . . . . 23

4.1.5 Image Acquisition, Frame and Exposure Status . . . . . . . . . . . . . . . . . . 23

4.2 Acquisition Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.1 Acquisition Start and Stop Commands, Acquisition Mode and Acquisition

Frame Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.2 Acquisition Frame Rate and Acquisition Frame Rate Enable . . . . . . . . . . 24

4.2.3 Acquisition Start Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.4 Acquisition End Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.5 Acquisition Control Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3 Frame Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 Frame Start Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.2 Frame Burst Start Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.3 Frame Burst End Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3.4 Frame Control Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 Exposure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MAN078 12/2018 V1.1 3 of 111

CONTENTS

4.4.1 Exposure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.2 Exposure Start Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.3 Exposure End Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4.4 Exposure Control Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 Overlapped Image Acquisition Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.6 Acquisition-, Frame- and Exposure-Trigger Configuration . . . . . . . . . . . . . . . . 34

4.6.1 Trigger Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.6.2 Trigger Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.3 Trigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.4 Trigger Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.6.5 Trigger Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.6.6 Trigger Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.7 Software Signal Pulse and User Output . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5 Counter & Timer 39

5.1 Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.1 Counter Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.2 Counter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.3 Counter Active, -Start and -End Signal . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.4 Counter Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1.5 Counter Event Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.1.6 Counter Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.1.7 Counter Reset Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.1 Timer Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.2 Timer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.3 Timer Active, -Start and -End Signal . . . . . . . . . . . . . . . . . . . . . . . . 45

5.2.4 Timer Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.2.5 Timer Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 I/O Control 47

6.1 Input Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Output Signal Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7 Action Control 49

7.1 Action Command Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 Action Control Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Image Format Control 51

8.1 Region of Interest (ROI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Frame Rate 53

9.1 Exposure time is dominant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.2 Image size is dominant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.3 Maximum Frame Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10 High Dynamic Range Mode (HDR) 55

10.1 Multiple Slope Mode (High Dynamic Range) . . . . . . . . . . . . . . . . . . . . . . . 55

4 of 111 MAN078 12/2018 V1.1

CONTENTS

11 Image Data Processing 57

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.2 Column FPN Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.2.1 Enable / Disable the Column FPN Correction . . . . . . . . . . . . . . . . . . . 59

11.2.2 Calibration of the Column FPN Correction . . . . . . . . . . . . . . . . . . . . . 59

11.2.3 Storing the calibration in permanent memory . . . . . . . . . . . . . . . . . . 60

11.3 Gain and Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.4 Grey Level Transformation (LUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

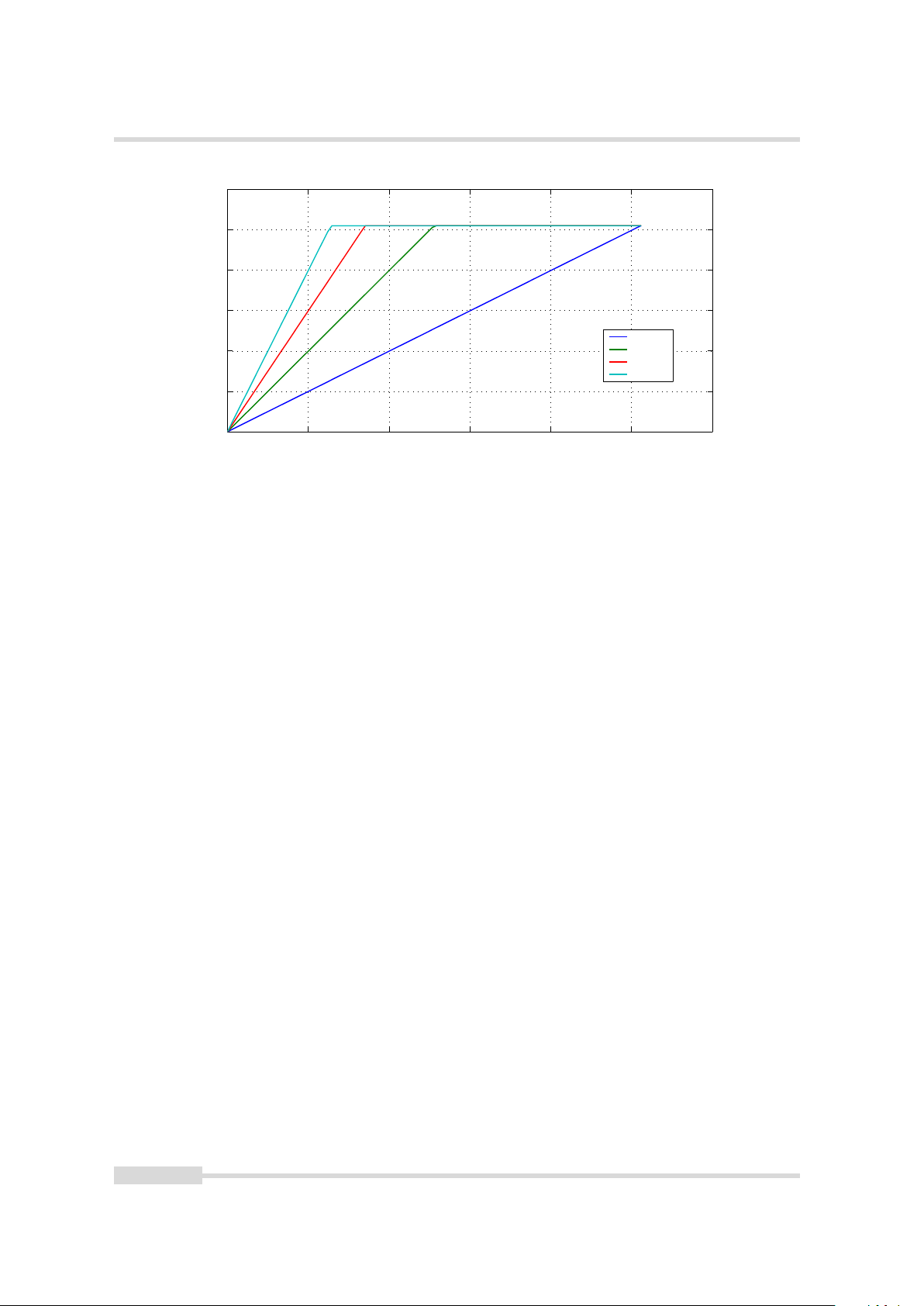

11.4.1 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11.4.2 Gamma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11.4.3 User-defined Look-up Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.4.4 Region LUT and LUT Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.5 Crosshairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

11.6 Status Line and Image Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.6.1 Image Average Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

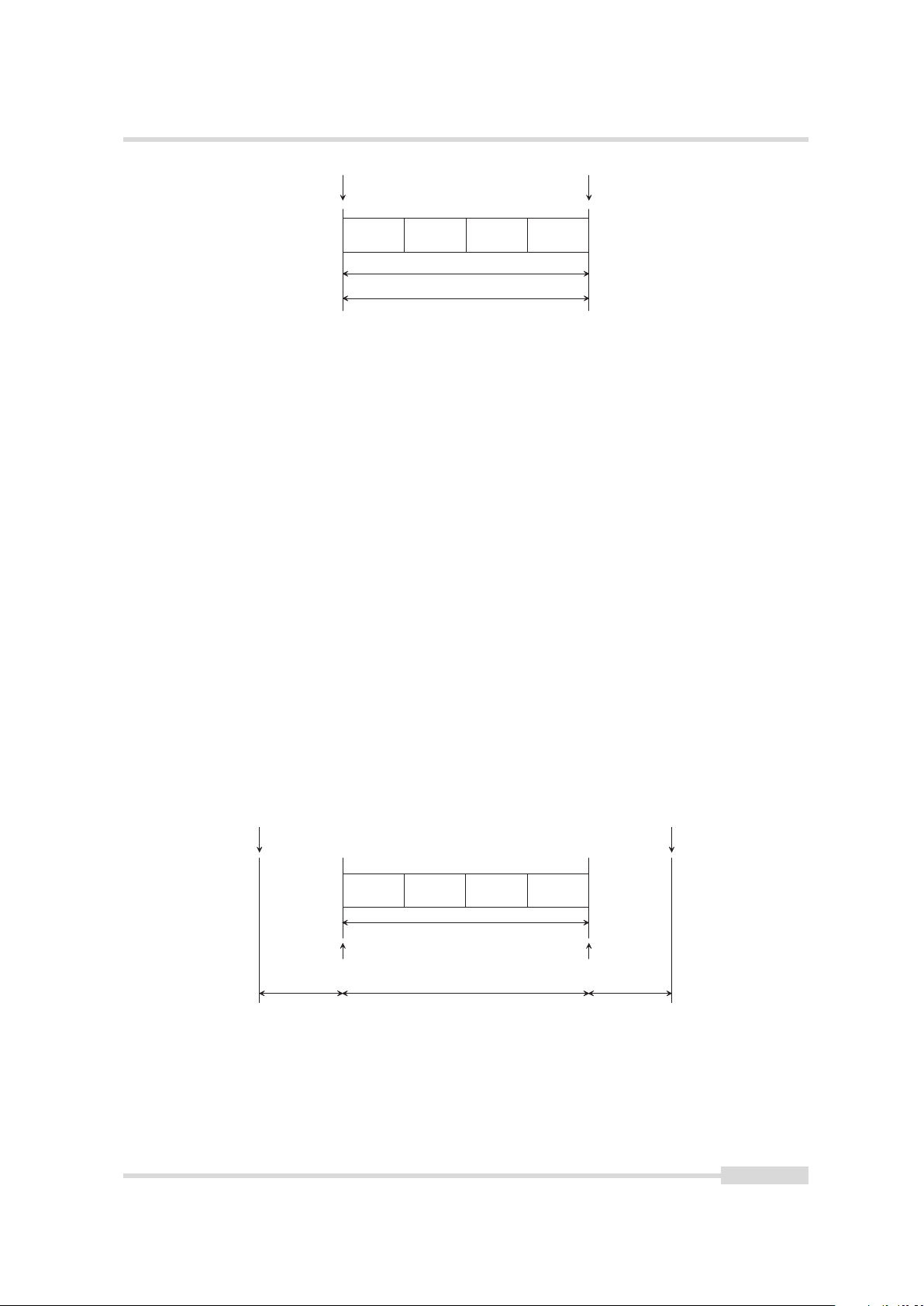

11.6.2 Status Line Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.6.3 Camera Type Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.7 Test Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.7.1 Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.7.2 LFSR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11.7.3 Troubleshooting using the LFSR . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12 Precautions 75

12.1 IMPORTANT NOTICE! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

13 Hardware Interface 79

13.1 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.2 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.3 GigE Camera Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.4 Power Over Ethernet (PoE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.5 Status Indicator (GigE cameras) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

13.6 I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.6.2 Single-ended Line Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.6.3 Single-ended Line Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.6.4 Master / Slave Camera Connection . . . . . . . . . . . . . . . . . . . . . . . . . 84

14 Mechanical Considerations 85

14.1 Mechanical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.1.1 Cameras with GigE Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.2 Optical Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14.2.1 Cleaning the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

15 Troubleshooting 89

15.1 No images can be acquired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15.1.1 No acquisition due to no triggers . . . . . . . . . . . . . . . . . . . . . . . . . . 89

16 Standards Compliance 91

16.1 Directives and General Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

16.2 Country-specific Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

16.2.1 For customers in the USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

16.2.2 For customers in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

16.2.3 Pour utilisateurs au Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

MAN078 12/2018 V1.1 5 of 111

CONTENTS

16.3 Life support applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

17 Warranty 93

17.1 Warranty Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

17.2 Warranty Claim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

17.3 Breach of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

18 Support and Repair 95

18.1 Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

18.2 Repair and obtaining an RMA Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

18.3 Temporal Abandoning and Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

19 References 97

A Pinouts 99

A.1 I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

A.2 GigE Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

B Camera Timing 101

B.1 Timed Exposure Mode Camera Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

C Use Cases 103

C.1 Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

C.1.1 Camera runs in "free-running" mode . . . . . . . . . . . . . . . . . . . . . . . 103

C.1.2 Camera runs in "constant frame rate" mode . . . . . . . . . . . . . . . . . . . 103

C.1.3 Camera runs in triggered mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

C.1.4 Camera runs in burst triggered mode . . . . . . . . . . . . . . . . . . . . . . . 104

C.1.5 Triggered controlled exposure mode . . . . . . . . . . . . . . . . . . . . . . . . 105

C.2 Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

C.2.1 Strobe Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

C.3 Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C.3.1 Counter Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C.3.2 Image Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C.3.3 Real Time Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

C.3.4 Missed Trigger Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

C.4 Look-Up Table (LUT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C.4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C.4.2 Full ROI LUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C.4.3 Region LUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C.4.4 User defined LUT settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

C.4.5 Predefined LUT settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

D Document Revision History 111

6 of 111 MAN078 12/2018 V1.1

Preface

1.1 IMPORTANT NOTICE!

READ THE INSTRUCTIONS FOR USE BEFORE

OPERATING THE CAMERA

1

STORE THE INSTRUCTIONS FOR USE FOR

FURTHER READING

Photonfocus AG

Bahnhofplatz 10

CH-8853 Lachen SZ

Switzerland

www.photonfocus.com

info@photonfocus.com

+41 – 55 451 00 00

MAN078 12/2018 V1.1 7 of 111

1 Preface

1.2 About Photonfocus

The Swiss company Photonfocus is one of the leading specialists in the development of CMOS

image sensors and corresponding industrial cameras for machine vision.

Photonfocus is dedicated to making the latest generation of CMOS technology commercially

available. Active Pixel Sensor (APS) and global shutter technologies enable high speed and

high dynamic range (120 dB) applications, while avoiding disadvantages like image lag,

blooming and smear.

Photonfocus’ product range is complemented by custom design solutions in the area of camera

electronics and CMOS image sensors.

Photonfocus is ISO 9001 certified. All products are produced with the latest techniques in order

to ensure the highest degree of quality.

1.3 Contact

Photonfocus AG, Bahnhofplatz 10, CH-8853 Lachen SZ, Switzerland

Sales Phone: +41 55 451 00 00 Email: sales@photonfocus.com

Support Phone: +41 55 451 00 00 Email: support@photonfocus.com

Table 1.1: Photonfocus Contact

1.4 Sales Offices

Photonfocus products are available through an extensive international distribution network

and through our key account managers. Contact us via email at sales@photonfocus.com.

1.5 Further information

Photonfocus reserves the right to make changes to its products and documentation without notice. Photonfocus products are neither intended nor certified for

use in life support systems or in other critical systems. The use of Photonfocus

products in such applications is prohibited.

Photonfocus and LinLog®are registered trademarks of Photonfocus AG.

CameraLink®and GigE Vision®are a registered mark of the Automated Imaging Association. Product and company names mentioned herein are trademarks

or trade names of their respective companies.

Reproduction of this manual in whole or in part, by any means, is prohibited

without prior permission having been obtained from Photonfocus AG.

Photonfocus can not be held responsible for any technical or typographical errors.

8 of 111 MAN078 12/2018 V1.1

1.6 Legend

In this documentation the reader’s attention is drawn to the following icons:

Important note, additional information

Important instructions

General warning, possible component damage hazard

Warning, electric shock hazard

Warning, fire hazard

1.6 Legend

MAN078 12/2018 V1.1 9 of 111

1 Preface

10 of 111 MAN078 12/2018 V1.1

2

M V 0 - D 2 0 4 8 x 1 0 8 8 C - C 0 1 - 1 6 0 - G 2

P r e f i x 1

P r e f i x 2

S e n s o r w i d t h & h e i g h t

( o p t i o n a l )

S e n s o r t y p e

C a m e r a

s p e e d

I n t e r f a c e t y p e

S e n s o r

M a n u f a c t u r e r

S e n s o r

F a m i l y

Introduction

2.1 Introduction

This manual describes standard Photonfocus MV0 CMOSIS series cameras that have a Gigbit

Ethernet (GigE) interface. The cameras contain CMV2000 and CMV4000 from CMOSIS.

2.2 Camera Naming Convention

The naming convention of the MV0 CMOSIS camera series is summarized in Fig. 2.1.

Figure 2.1: Camera naming convention

Prefix1 Camera platform and usage prefix. The following prefix are available for this camera

series: MV0 with form factor 30x30.

Prefix2 Camera family specifier. The following specifiers are used in this manual: "D": digital

standard area scan cameras.

Sensor width Width of image sensor of the camera.

Sensor type Sensor types specification: "I": NIR enhanced sensors, "C": color cameras.

Cameras without sensor type specifier have a standard monochrome sensor.

Sensor Manufacturer Sensor manufacturer. "C": CMOSIS

Sensor Family Sensor family of the prior indicated manufacturer. "01": CMV2000/4000 series

Camera speed The camera speed is usually the product of the camera interface clock in MHz

and the number of parallel interface channels (taps).

Interface type Interface type specification: "CL": CameraLink®, "G2": Gigabit Ethernet

(GigEVision), "U3": USB3 (USB3 Vision).

2.3 Camera list

A list of all cameras covered in this manual is shown in Table 2.1.

MAN078 12/2018 V1.1 11 of 111

2 Introduction

Name Resolution Frame Rate Notes

MV0-D2048x1088-C01-160-G2 2048 x 1088 50 fps

1)

Gigabit Ethernet 2 MP

monochrome standard camera.

MV0-D2048-C01-160-G2 2048 x 2048 26 fps

1)

Gigabit Ethernet 4 MP

monochrome standard camera.

Table 2.1: Camera models covered by this manual (Footnotes:1)frame rate at at full resolution)

12 of 111 MAN078 12/2018 V1.1

3

Product Specification

3.1 Introduction

The Photonfocus MV0 CMOSIS GigE camera series is built around the CMOS image sensors

CMV2000 and CMV4000 from CMOSIS. They provide a resolution of 2048 x 1088 (CMV2000)

and 2048 x 2048 (CMV4000) pixels. The camera series is optimized for low light conditions and

there are standard monochrome, NIR enhanced monochrome (I) and colour (C) models. The

cameras are aimed at standard applications in industrial image processing where high

sensitivity and high frame rates are required.

The principal advantages are:

• Resolution of 2048x1088 (CMV2000) and 2048x2048 (CMV4000) pixels

• Optimized for low light conditions

• Spectral range: monochrome standard: 350 - 900 nm, NIR enhanced 350 - 970 nm

• Global shutter

• Micro lenses

• Color cameras: Bayer pattern filter and cut off filter @ 660nm

• Gigabit Ethernet interface, GigE Vision and GenICam compliant

• Power Over Ethernet (PoE).

• Frame rates at maximal resolution 50 fps (CMV2000) and 26 fps (CMV4000)

• I/O capabilities: 1 isolated input and 1 isolated output

• 2 look-up tables (12-to-8 bit) on user-defined image region (Region-LUT)

• Crosshairs overlay on the image

• Image information and camera settings inside the image (status line)

• Software provided for setting and storage of camera parameters

• The rugged housing at a compact size of 30 x 30 x 53 mm3makes the Photonfocus MV0

CMOSIS GigE camera series the perfect solution for applications in which space is at a

premium.

The general specification and features of the camera are listed in the following sections.

MAN078 12/2018 V1.1 13 of 111

3 Product Specification

Figure 3.1: Photonfocus MV0 CMOSIS GigE camera series

14 of 111 MAN078 12/2018 V1.1

3.2 Feature Overview

3.2 Feature Overview

The general specification and features of the camera are listed in the following sections. The

detailed description of the camera features is given in the following chapters.

Characteristics Photonfocus MV0 CMOSIS GigE Camera Series

Interface Gigabit Ethernet (PoE), GigE Vision and GenICam compliant

Camera Control GigE Vision Suite

Trigger Modes Software Trigger / External isolated trigger input

• Greyscale / colour resolution 10 bit / 8 bit

• Region of Interest (ROI)

• 2 look-up tables (12-to-8 bit) on user-defined image region

Features

(Region-LUT)

• Test pattern (LFSR and grey level ramp)

• Image information and camera settings inside the image (status line)

• Crosshairs overlay on the image

• 1 isolated trigger input and 1 isolated output

Table 3.1: Feature overview

3.3 Technical Specification

MAN078 12/2018 V1.1 15 of 111

3 Product Specification

2 MPix Cameras 4 MPix Cameras

Sensor Manufacturer CMOSIS

Sensor Type CMV2000 CMV4000

Technology CMOS active pixel

Scanning system progressive scan

Optical format / diagonal 2/3” (12.75 mm diagonal) 1" (15.92 mm diagonal)

Resolution 2048x1088 pixels 2048x1088 pixels

Pixel size 5.5 µm x 5.5 µm

Active optical area 11.26 mm x 5.98 mm 11.26mm x 11.26 mm

Full well capacity 11 ke

Readout noise 13 e

−

−

Spectral range standard sensor < 350 to 900 nm (to 10 % of peak responsivity)

Spectral range of (I) models < 350 to 970 nm (to 10 % of peak responsivity)

Spectral range of colour models 390 to 670 nm (to 10 % of peak responsivity)

Sensitivity (with micro lenses) 5.56 V / lux.s (with micro lenses @ 550 nm)

Optical fill factor 42 % (without micro lenses)

Dark current 125 e−/s @ 25°C

Dynamic range 58.5 dB

Micro lenses Yes

Colour format (C) cameras RGB Bayer Raw Data Pattern

Characteristic curve Linear, Piecewise linear (multiple slope)

Shutter mode global shutter

Sensor bit depth 10 bit

Maximal frame rate

1)

50 fps 26 fps

Camera pixel formats 10 / 8 bit

Digital gain 0.1 to 15.99 (Fine Gain)

Exposure time range 10 µs ... 419 ms

Table 3.2: General specification of the Photonfocus MV0 CMOSIS GigE camera series (Footnotes:1)at full

resolution)

16 of 111 MAN078 12/2018 V1.1

3.3 Technical Specification

Photonfocus MV0 CMOSIS GigE Camera Series

Operating temperature / moisture 0°C ... 50°C / 20 ... 80 % (camera needs to be connected

to heat sink)

Storage temperature / moisture -25°C ... 60°C / 20 ... 95 %

Trigger signal input range +5 .. +20 V DC

Maximal power consumption < 4.2 W

Lens mount C-Mount

I/O Inputs 1x Opto-isolated

I/O Outputs 1x Opto-isolated

Dimensions 30 x 30 x 54.1 mm

3

Mass 75 g

Connector I/O Binder M5 x 0.5, 4 pole, series 707

Connector Interface (Power) X-coded M12

Conformity CE / RoHS / WEEE

IP Code IP40

Table 3.3: Physical characteristics and operating ranges

3.3.1 Absolute Maximum Ratings

Parameter Value

Camera Control Input Signal Voltage Single Ended 0 V ... +24 V

Camera Control Output Signal Voltage Single Ended 0 V ... +24 V

Camera Control Output Signal Output Current Single Ended 0.1 A

Camera Control Output Signal Output Power Single Ended 0.15 W

ESD Contact Discharge Camera Control Signals 4 kV

ESD Air Discharge Camera Control Signals 8 kV

Fast Transients/Bursts Data and Camera Control Signals 2 kV

Surge immunity Data and Camera Control Signals 1 kV

Maximum Installation Altitude 2000m above sea level

Table 3.4: Absolute Maximum Ratings

3.3.2 Electrical Characteristics

Parameter Value

Camera Control Input Single Ended +5 V ... +20 V

Table 3.5: Electrical Characteristics

MAN078 12/2018 V1.1 17 of 111

3 Product Specification

0%

10%

20%

30%

40%

50%

60%

70%

400 500 600 700 800 900 1000

Wavelength [nm]

Monochrome

NIR

3.3.3 Spectral Response

Fig. 3.2 shows the quantum efficiency curve of the monochrome CMV2000/4000 sensors from

CMOSIS measured in the wavelength range from 400 nm to 1000 nm.

Figure 3.2: Quantum efficiency (QE) [%] of the CMV2000/4000 monochrome and near infrared image

sensors (with micro lenses)

Fig. 3.3 shows the quantum efficiency curve of the color CMV2000/4000 sensors from CMOSIS

used in the Photonfocus MV0 CMOSIS GigE color cameras.

18 of 111 MAN078 12/2018 V1.1

3.3 Technical Specification

0%

10%

20%

30%

40%

50%

60%

70%

400 500 600 700 800 900 1000

Wavelength [nm]

Red Bayer

Green Bayer

Blue Bayer

Figure 3.3: Quantum efficiency (QE) [%] of the CMV2000/4000 CMOS color image sensors (with micro

lenses)

MAN078 12/2018 V1.1 19 of 111

3 Product Specification

G B

0

C o l u m n

R o w

1 2 3

G B

G GR R

G B G B

G GR R

0

1

2

3

The color cameras are equipped with a IR cut-off filter to avoid false colors arising when an

infra-red component is present in the illumination. Fig. 3.4 shows the transmssion curve of the

cut-off filter.

Figure 3.4: Transmission curve of the cut-off filter in the Photonfocus MV0 Pyhton GigE cameras

3.4 RGB Bayer Pattern Filter (color models)

Fig. 3.5 shows the bayer filter arrangement on the pixel matrix which is often denoted as

"Green - Blue" pattern.

The fixed bayer pattern arrangement has to be considered when the ROI configuration is changed or the MROI feature is used (see Chapter 8). It depends on

the line number in which a ROI starts. A ROI can start at an even or an odd line

number.

Figure 3.5: Bayer Pattern Arrangement

20 of 111 MAN078 12/2018 V1.1

4

C o u n t e r / T i m e rI / O C o n t r o l

A c q u i s i t i o n

C o n t r o l

F r a m e

C o n t r o l

E x p o s u r e

C o n t r o l

S o f t w a r e S i g n a l

P u l s e

&

U s e r O u t p u t

L i n e I n

L E D

L i n e O u t

A c t i o n

S i g n a l R o u t i n g

Image Acquisition

This chapter gives detailed information about the controlling of the image acquisition. It

shows how the camera can be triggered or run in free-running mode, and how the frame rate

can be configured.

The structure offers a lot of flexibility in the configuration. It follows the GenICam naming convention. Typical camera configurations are included in the chapter "Use Cases" in the Appendix C.

4.1 Overview

The overview shows the major camera elements which are involved in the image acquisition.

The section starts with a description of the vocabulary and terms, which are used to explain the

acquisition related features.

4.1.1 Vocabulary

An acquisition is composed of one or many frames. A frame is a single acquired image which

consists of an exposure time and an image read out. A burst of frame is defined as a capture of

a group of one or many frames within an acquisition. An acquisition can be grouped in N

single frames or N burst of frames.

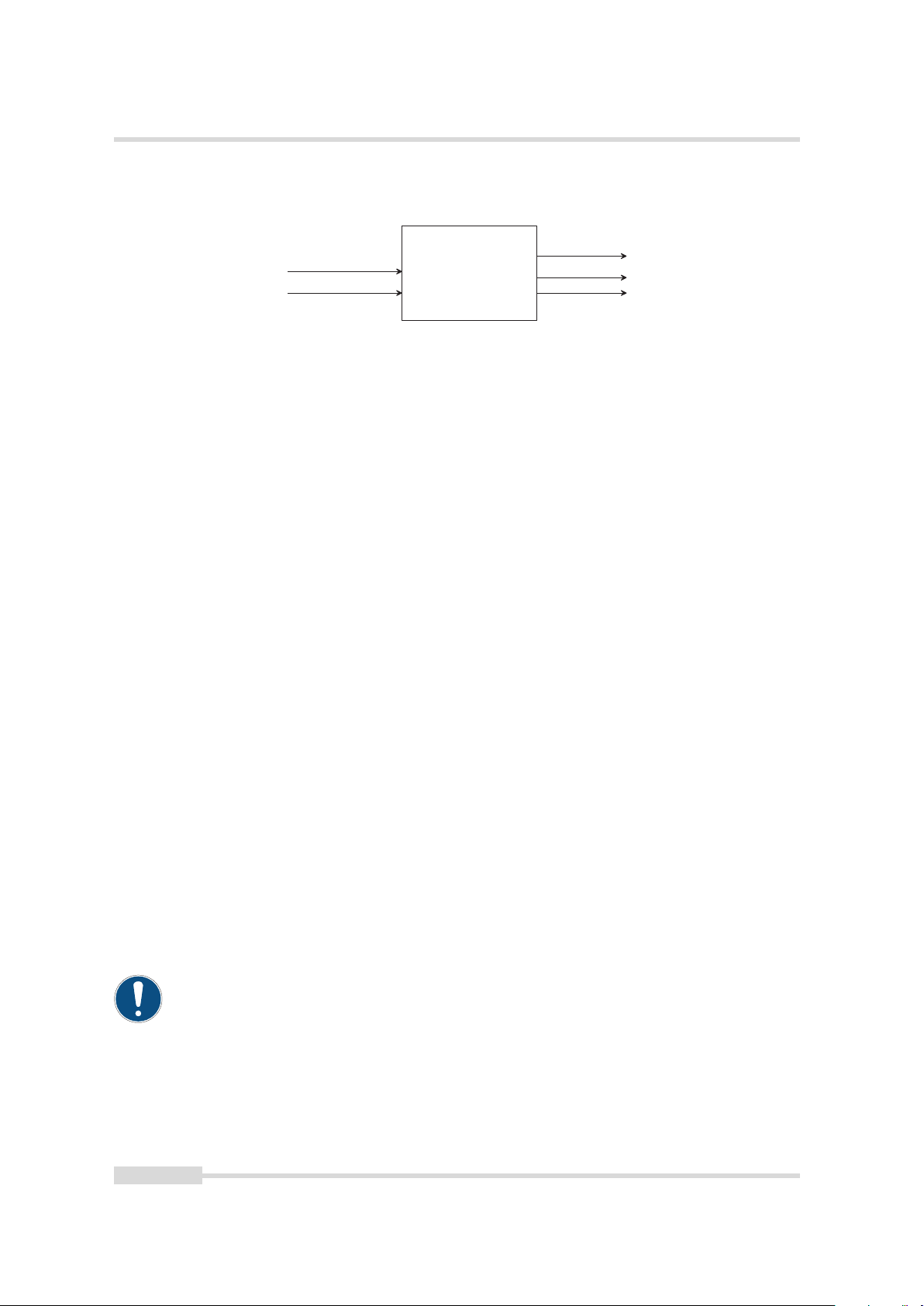

4.1.2 Structure

The image acquisition is controlled by the three sub-blocks acquisition control, frame control

and exposure control. Furthermore the camera contains controller blocks which take care of

the I/O signals, the counters, the timers, the action signals, the software signals and the user

outputs. All of these elements can be connected through an interconnect, which allows

controlling the image acquisition by these elements.

Figure 4.1: Structure

MAN078 12/2018 V1.1 21 of 111

4 Image Acquisition

Acquisition Control The acquisition control block takes care of the acquisition function. The

camera can only capture frames, when the acquisition has been started and is active (see

Section 4.2 for more information).

Frame Control The frame control block takes care of the capturing of one or many frames and

burst of frames (see Section 4.3 for more information).

Exposure Control The exposure control block takes care of the exposure time of a frame (see

Section 4.4 for more information).

Counter The camera has four independent counters. They count events from a selectable

source (see Section 5.1 for more information about counter configuration and usage).

Timer The camera has four independent timers. A timer delay and duration are configurable

and the timers are triggered by a selectable source (see Section 5.2 for more information

about timer configuration and usage).

Action There are four actions, which can be used to trigger functions in the GigE camera, such

like aquisition and frame capture or counter and timer. Action commands can be

generated by the host application and are transmitted via GigE interface to the camera

with low latency and low jitter.

I/O Control The I/O control unit manages physical camera inputs and outputs and LED. A

switch matrix within this block allows connecting internal status signals to the output

lines or LED. Status signals can come from the acquisition, frame or exposure control

block, also from timer or counter, or even input lines can be routed to an output. The

input lines can be used to control the acquisition, frame and/or exposure, also to start a

timer or count events with a counter (see Chapter 6 for more information).

Software Signal Pulse and User Output The camera has user outputs, which can be set to 1 or

0 by software access, and a software signal pulse generator block (see Section 4.7). These

user outputs and signal pulses can be used to control camera functions by software

access, such like acquisition and frame capture or counter and timer.

Signal Routing All these elements are connected to each other by the signal routing block. The

following sections show which signals are available and how they can be used in the

others blocks.

4.1.3 Image Acquisition, Frame and Exposure Control Parameters

Mainly the following commands/settings are involved in order to control and configure the

camera acquisition and frame capturing:

• Acquisition Start and Stop Command

• Acquisition Mode (Single Frame, Multi Frame, Continuous Frame)

• Acquisition Frame Count

• Acquisition Frame Burst Count

• Acquisition Frame Rate

• Exposure Mode (Timed, Trigger Controlled)

• Exposure Time

This list shows only an overview of available parameters. The function and usage of them are

explained in the following chapters.

22 of 111 MAN078 12/2018 V1.1

4.1 Overview

4.1.4 Image Acquisition, Frame and Exposure Trigger

The camera can run in "free-running" mode, which means that it captures images

automatically in full frame rate once the acquisition has been started. However the acquisition

and image capturing can be controlled by triggers. For this purposes, there are seven triggers

available:

• Acquisition Start Trigger

• Acquisition End Trigger

• Frame Start Trigger

• Frame Burst Start Trigger

• Frame Burst End Trigger

• Exposure Start Trigger

• Exposure End Trigger

The source of these trigger can be set for every trigger individually; it can come from an

external line, an internally generated pulse from the counters, the timers, the action signals or

from a pulse generated by a software command. Each of these triggers can be switched on or

off individually. The camera generates the triggers pulses internally, which are switched off.

The following sections (Acquisition, Frame & Exposure Control) show the usage of these

triggers.

Each trigger has its own source signal processing path. Section 4.6 gives more information

about the configuration.

4.1.5 Image Acquisition, Frame and Exposure Status

The following list shows the acquisition, frame and exposure related status signals:

• Acquisition Trigger Wait

• Acquisition Active

• Frame Trigger Wait

• Frame Active

• Exposure Active

These status signals are used within the camera to control the camera timing. The current state

of these signals can be read out by software. Furthermore it can be connected to an output

line or LED through the I/O control block (see Chapter 6), which allows tracking the status from

an external device. The timing of these signals are explained in the following sections.

MAN078 12/2018 V1.1 23 of 111

4 Image Acquisition

A c q u i s i t i o n C o n t r o l

A c q u i s i t i o n S t a r t T r i g g e r

A c q u i s i t i o n E n d T r i g g e r

A c q u i s i t i o n T r i g g e r W a i t

A c q u i s i t i o n S t a r t

A c q u i s i t i o n E n d

A c q u i s i t i o n T r i g g e r

A c q u i s i t i o n S t a r t ( )

A c q u i s i t i o n E n d ( )

A c q u i s i t i o n A c t i v e

4.2 Acquisition Control

Figure 4.2: Acquisition Control Block

4.2.1 Acquisition Start and Stop Commands, Acquisition Mode and Acquisition Frame Count

The camera can only capture frames when the acquisition is started. The acquisition start

command, which is executed by the software, starts the acquisition and prepares the camera to

acquire frames. The acquisition is stopped, when the acquisition stop command is executed or depending on the acquisition mode parameter - a certain number of frames is captured.

Following acquisition mode parameters are available:

Acquisition Mode = Single Frame When the acquisition is started, the camera stops the

acquisition automatically as soon as one frame has been captured. To capture another

frame, the acquisition start command needs to be performed again.

Acquisition Mode = Multi Frame When the acquisition is started the camera stops the

acquisition automatically after a certain number of frames, which are defined by

acquisition frame count parameter, or when the acquisition stop command is executed.

Acquisition Mode = Continuous Frame When the acquisition is started the camera captures

images continuously until the acquisition stop command is executed.

4.2.2 Acquisition Frame Rate and Acquisition Frame Rate Enable

With frame start trigger mode=off (see Section 4.3.1) and frame burst start trigger mode=off

(see Section 4.3.2), and when exposure mode is set to "timed" (see Section 4.4.1), the camera

generates frame start triggers internally according to the acquisition frame rate enable and

acquisition frame rate configuration:

Acquisition Frame Rate Enable = off The camera runs in the "free-running" mode. It means

frame start triggers are generated internally as soon as the camera is ready to start a new

image capture. The frame rate is defined by the exposure time and the ROI settings (see

Chapter 9).

Acquisition Frame Rate Enable = on The camera generates frame start triggers internally

according to the acquisition frame rate configuration. See Chapter 9 for more

information about the range of supported frame rates.

Fig. 4.3 shows the procedure of a capture of N frames. The modes of acquisition start trigger,

frame start trigger and frame burst start trigger is set to off and the exposure mode is timed.

Once an acquisition start command has been executed, the camera starts capturing frames

until the acquisition stop command is received.

24 of 111 MAN078 12/2018 V1.1

4.2 Acquisition Control

F r a m e 1 F r a m e 2 . . . . F r a m e N

A c q u i s i t i o n S t a r t ( )

A c q u i s i t i o n A c t i v e

F r a m e A c t i v e

A c q u i s i t i o n S t o p ( )

A c q u i s i t i o n S t a r t T r i g g e r M o d e = O f f

A c q u i s i t i o n E n d T r i g g e r M o d e = O f f

F r a m e S t a r t T r i g g e r M o d e = O f f

F r a m e B u r s t S t a r t T r i g g e r M o d e = O f f

E x p o s u r e M o d e = T i m e d

A c q u i s i t i o n A c t i v e

A c q u i s i t i o n S t a r t

T r i g g e r 1

A c q u i s i t i o n E n d

T r i g g e r 1

A c q u s i t i o n

T r i g g e r

W a i t

A c q u i s i t i o n S t o p ( )

A c q u s i t i o n

T r i g g e r

W a i t

A c q u i s i t i o n S t a r t ( )

F r a m e 1 F r a m e 2 . . . . F r a m e N

F r a m e A c t i v e

A c q u i s i t i o n S t a r t T r i g g e r M o d e = O n

A c q u i s i t i o n E n d T r i g g e r M o d e = O n

F r a m e S t a r t T r i g g e r M o d e = O f f

F r a m e B u r s t S t a r t T r i g g e r M o d e = O f f

E x p o s u r e M o d e = T i m e d

Figure 4.3: Free-running Image Capture, when Acquisition Start and End Trigger Mode is Off

4.2.3 Acquisition Start Trigger

The acquisition start trigger can be used to control the acquisition start procedure. The main

property of this trigger is the trigger mode. It can be set to on or off:

Acquisition Start Trigger Mode = on As soon as the acquisition is started by executing of the

acquisition start command, the camera goes into the state "Acquisition Trigger Wait". In

this state, the camera can’t start capturing images; it waits for an acquisition start trigger.

As soon as the trigger has been received, the camera goes then into the state

"Acquisition Active" and is ready to capture frames.

Acquisition Start Trigger Mode = off As soon as the acquisition is started by executing of the

acquisition start command, the camera goes immediately into state "Acquisition Active"

and is ready to capture frames.

Fig. 4.4 shows an example when the trigger mode of the acquisition start trigger is on. The

acquisition status goes to acquisition trigger wait once an acquisition start command has been

executed. As soon as an acquisition start trigger has been arrived, the acquisition status goes to

acquisition active.

Figure 4.4: Free-running Image Capture, when Acquisition Start and End Trigger Mode is On

MAN078 12/2018 V1.1 25 of 111

4 Image Acquisition

4.2.4 Acquisition End Trigger

The acquisition end trigger can be used to control the acquisition end procedure. The main

property of this trigger is the trigger mode. It can be set to on or off:

Acquisition End Trigger Mode = on When the acquisition status is "Acquisition Active", it goes

to "Acquisition Trigger Wait" as soon as an acquisition end trigger has been received. The

camera stops capturing images and waits until an acquisition start trigger has been issued

again.

Acquisition End Trigger Mode = off The acquisition end triggers are ignored and the

acquisition status remains active until an acquisition stop command has been executed or

the certain amount of frames has been captured, depending on the acquisition mode

parameter (see Section 4.2.1)

4.2.5 Acquisition Control Output Signals

The acquisition control block has the following output signals:

Acquisition Trigger Wait An asserted acquisition trigger wait indicates, that the acquisition

control is waiting for an acquisition start trigger (see Section 4.2.3).

Acquisition Active Acquisition active is a status signal, which is asserted, when the acquisition

has been started and deasserted, when the acquisition is stopped.

Acquisition Start The acquisition start is an event, which is generated, when the acquisition is

started.

Acquisition End The acquisition end is an event, which is generated, when the acquisition is

stopped.

Acquisition Trigger The acquisition trigger is an event, which is generated, when the

acquisition is started by the acquisition start trigger (see Section 4.2.3).

Acquisition trigger wait and acquisition active status signal are routed to the I/O control block

and can there be selected for output on the physical output line or on one of the available leds

(see Chapter 6). Acquisition start, acquisition end and acquisition trigger event can be used to

trigger or to control other function in the camera, like counter or timer.

26 of 111 MAN078 12/2018 V1.1

4.3 Frame Control

F r a m e C o n t r o l

F r a m e S t a r t T r i g g e r

F r a m e B u r s t S t a r t T r i g g e r

F r a m e T r i g g e r W a i t

F r a m e S t a r t

F r a m e E n d

F r a m e B u r s t E n d T r i g g e r

F r a m e T r i g g e r

F r a m e A c t i v e

F r a m e B u r s t S t a r t

F r a m e B u r s t E n d

4.3 Frame Control

Figure 4.5: Frame Control Block

As soon as the acquisition is active the camera is ready to capture frames, which is controlled by

the frame control block. The behaviour depends on the frame start trigger, frame burst start

trigger and frame burst end trigger configuration.

4.3.1 Frame Start Trigger

The frame start trigger can be used to start a single frame capture. The main property of this

trigger is the trigger mode. It can be set to on or off:

Frame Start Trigger Mode = on As soon as a frame start trigger has been received, a capture of

one frame will be started and the frame status goes to "Frame Active". Once one frame

has been processed, that camera status goes to "Frame Trigger Wait" again. The camera

is ready to process frame start triggers, when the acquisition is active, showed by the

"Acquisition Active" status, and when the "Frame Trigger Wait" status is asserted.

Frame Start Trigger Mode = off The frame start triggers are ignored.

The camera runs in free-running mode when the mode of both triggers, the

frame start trigger and frame burst start trigger, is set to off and the exposure

mode is set to "Timed" (see Section 4.4.1 for more information about the exposure mode).

Fig. 4.6 shows the procedure of a single frame capture started with a frame start trigger. The

acquisition start trigger mode is off, so the camera waits for a frame start trigger once the

acquisition command has been executed. Every receiving frame start trigger starts a capture of

one single frame.

4.3.2 Frame Burst Start Trigger

The frame burst start trigger can be used to start a burst of frame capture. The main property

of this trigger is the trigger mode. It can be set to on or off:

Frame Burst Start Trigger Mode = on As soon as a frame burst start trigger has been received,

a capture of a burst of frames has been started and the frame status goes to "Frame

Active". The number of frames is defined by the "Acquisition Burst Frame Count" value.

The camera goes to "Frame Trigger Wait" again, when the configured number of burst

frames has been captured. The camera is ready to process a frame burst start trigger,

when the acquisition is active, showed by the "Acquisition Active" status, and when the

"Frame Trigger Wait" status is asserted. The frame rate of a burst sequence is configured

MAN078 12/2018 V1.1 27 of 111

4 Image Acquisition

F r a m e 1 . . . . F r a m e N

A c q u i s i t i o n A c t i v e

F r a m e S t a r t

T r i g g e r 1

F r a m e S t a r t

T r i g g e r 2

F r a m e S t a r t

T r i g g e r N

F r a m e

A c t i v e

F r a m e

A c t i v e

F r a m e

T r i g g e r

W a i t

F r a m e

A c t i v e

F r a m e

T r i g g e r

W a i t

F r a m e

T r i g g e r

W a i t

F r a m e

T r i g g e r

W a i t

A c q u i s i t i o n S t o p ( )A c q u i s i t i o n S t a r t ( )

A c q u i s i t i o n S t a r t T r i g g e r M o d e = O f f

A c q u i s i t i o n E n d T r i g g e r M o d e = O f f

F r a m e S t a r t T r i g g e r M o d e = O n

F r a m e B u r s t S t a r t T r i g g e r M o d e = O f f

E x p o s u r e M o d e = T i m e d

Figure 4.6: Triggered Image Acquisition of single Frames

by the acquisition frame rate value and the acquisition frame rate enable configuration

(see Section 4.2.2 for more information)

Frame Burst Start Trigger Mode = off The frame burst start triggers are ignored. No capturing

of burst of frames is started.

It is possible to set both, the mode of frame start trigger and frame burst start

trigger, to on. In this case, the camera starts a single frame or a burst of frame

capture, depending which trigger arrives first.

Fig. 4.7 shows the procedure of a burst of frames and a single frame capture. The Acquisition

start and end trigger mode is on. So the camera waits for an acquisition trigger once the

acquisition command has been executed. During this period any frame burst start or frame

start triggers are ignored. As soon as an acquisition start trigger has been received, the camera

waits for frame triggers. It can be a frame start trigger or a frame burst start trigger.

Depending which trigger - frame start or frame burst start - arrives first, the camera starts a

single frame or burst of frame acquisition.

4.3.3 Frame Burst End Trigger

The frame burst end trigger can be used to abort a current running burst capturing cycle. The

main property of this trigger is the trigger mode. It can be set to on or off:

Frame Burst End Trigger Mode = on The frame burst end trigger is processed only, when burst

acquisition cycle is active. Once this trigger has been received, it waits, until the current

frame has been processed and then aborts the burst cycle. The camera status goes to

"Frame Trigger Wait" again.

Frame Burst End Trigger Mode = off The frame burst end triggers are ignored.

The value "Acquisition Burst Frame Count" is ignored when the mode of the

frame burst end trigger is set to on. It means, when a burst capture has been

started, the camera captures frames until a frame burst end trigger arrives.

28 of 111 MAN078 12/2018 V1.1

F r a m e 1 . . . . F r a m e N

A c q u i s i t i o n A c t i v e

A c q u i s i t i o n S t a r t

T r i g g e r 1

A c q u i s i t i o n E n d

T r i g g e r 1

F r a m e

T r i g g e r

W a i t

F r a m e

T r i g g e r

W a i t

A c q u s i t i o n

T r i g g e r

W a i t

A c q u i s i t i o n S t o p ( )

A c q u s i t i o n

T r i g g e r

W a i t

A c q u i s i t i o n S t a r t ( )

F r a m e B u r s t S t a r t

T r i g g e r 1

F r a m e B u r s t E n d

T r i g g e r 1

( o p t i o n a l )

F r a m e

A c t i v e

F r a m e S t a r t

T r i g g e r 1

F r a m e

A c t i v e

F r a m e

T r i g g e r

W a i t

F r a m e 1

A c q u i s i t i o n S t a r t T r i g g e r M o d e = O n

A c q u i s i t i o n E n d T r i g g e r M o d e = O n

F r a m e S t a r t T r i g g e r M o d e = O n

F r a m e B u r s t S t a r t T r i g g e r M o d e = O n

E x p o s u r e M o d e = T i m e d

Figure 4.7: Triggered Acquisition of a Burst of Frame and of a single Frame

4.3.4 Frame Control Output Signals

The frame control block has the following output signals:

4.3 Frame Control

Frame Trigger Wait An asserted frame trigger wait indicates, that the frame control is waiting

for a frame start trigger (see Section 4.3.1), frame burst start trigger (see Section 4.3.2) or

an exposure start trigger (see Section 4.4.2).

Frame Active An asserted frame active signal indicates, that one or more frames are being

captured.

Frame Start The frame start is an event, which is generated, when a new frame starts.

Frame End The frame end is an event, which is generated, when a frame is finished.

Frame Burst Start The frame burst start is an event, which is generated, when a new burst of

frame starts.

Frame Burst End The frame burst end is an event, which is generated, when a burst of frame is

finished.

Frame Trigger The frame trigger is an event, which is generated, when a frame is started by a

frame start trigger (see Section 4.3.1), by a frame burst start trigger (see Section 4.3.2) or

by an exposure start trigger (see Section 4.4.2).

Frame trigger wait and frame active status signal are routed to the I/O control block and can

there be selected for output on the physical output line or on one of the available leds. Frame

start, frame end and frame trigger event can be used to trigger or to control other function in

the camera, like counter and timer.

MAN078 12/2018 V1.1 29 of 111

4 Image Acquisition

E x p o s u r e C o n t r o l

E x p o s u r e S t a r t T r i g g e r

E x p o s u r e E n d T r i g g e r

E x p o s u r e A c t i v e

E x p o s u r e S t a r t

E x p o s u r e E n d

4.4 Exposure Control

Figure 4.8: Exposure Control Block

A frame consists of an exposure cycle and an image read out. The exposure control block takes

care of the exposure cycle. The camera has two modes of exposure time operations, which are

defined by the exposure mode settings:

• Timed Exposure

• Trigger Controlled Exposure

4.4.1 Exposure Mode

The exposure mode configuration defines, if the exposure time is controlled by the exposure

time registers or by the triggers. Following configurations are available:

Timed Exposure The exposure time is defined by the exposure time register. The value will

determine the exposure time for each frame.

Trigger Controlled Exposure The exposure time is controller by exposure start and exposure

end triggers (see Section 4.4.2 and Section 4.4.3 for more information).

4.4.2 Exposure Start Trigger

The exposure start trigger is used to start an exposure.

Exposure Start Trigger Mode = on As soon as a exposure start trigger has been received, the

camera starts with the exposure cycle, which is showed by the "Exposure Active" status.

The exposure remains until an exposure end trigger has been received (see Section 4.4.3).

The camera is ready to process exposure start triggers, when the acquisition is active,

showed by the "Acquisition Active" status, and when the "Frame Trigger Wait" status is

asserted.

Exposure Start Trigger Mode = off The exposure start triggers are ignored.

The exposure start trigger is only available, when the exposure mode is set to

"trigger controlled". The camera sets the trigger modes of this trigger automatically to on, when the exposure mode is set to "trigger controlled" and vice versa

to off when the exposure mode is set to "timed".

4.4.3 Exposure End Trigger

The exposure end trigger is used to terminate an active exposure cycle.

30 of 111 MAN078 12/2018 V1.1

4.4 Exposure Control

A c q u i s i t i o n A c t i v e

F r a m e A c t i v e F r a m e T r i g g e r

W a i t

F r a m e T r i g g e r

W a i t

F r a m e T r i g g e r

W a i t

A c q u i s i t i o n S t a r t ( ) A c q u i s i t i o n S t o p ( )

E x p o s u r e 1 R e a d O u t 1

F r a m e 1

E x p o s u r e S t a r t

T r i g g e r 1

E x p o s u r e E n d

T r i g g e r 1

F r a m e A c t i v e

E x p o s u r e 2 R e a d O u t 2

F r a m e 2

E x p o s u r e S t a r t

T r i g g e r 2

E x p o s u r e E n d

T r i g g e r 2

E x p o s u r e

A c t i v e

E x p o s u r e

A c t i v e

A c q u i s i t i o n S t a r t T r i g g e r M o d e = O f f

A c q u i s i t i o n E n d T r i g g e r M o d e = O f f

F r a m e S t a r t T r i g g e r M o d e = O f f

F r a m e B u r s t S t a r t T r i g g e r M o d e = O f f

E x p o s u r e M o d e = T r i g g e r C o n t r o l l e d

Exposure End Trigger Mode = on An activated exposure cycle will be terminated and the

image read out will be started, as soon as an exposure end trigger has been received. The

"Exposure Active" status goes to inactive. Exposure end triggers are only processed, when

an exposure start trigger has started a trigger controlled exposure cycle previously.

Exposure End Trigger Mode = off The exposure end triggers are ignored.

The exposure end trigger is only available, when the exposure mode is set to

"trigger controlled". The camera sets the trigger modes of this trigger automatically to on, when the exposure mode is set to "trigger controlled" and vice versa

to off when the exposure mode is set to "timed".

Fig. 4.9 shows procedure of a trigger controlled exposure mode. The Acquisition start trigger

mode is off. The camera goes directly into status "Frame Trigger Wait" once the acquisition

status has been executed. An exposure of a new frame is started as soon as an exposure start

trigger has been received. The exposure ends with an exposure end trigger.

Figure 4.9: Trigger Controlled Exposure Mode

4.4.4 Exposure Control Output Signals

The frame control block has the following output signals:

Exposure Active An asserted exposure active signal indicates, that an exposure time of a

current frame is active.

Exposure Start The exposure start is an event, which is generated, when a new exposure time

has been started.

Exposure End The exposure end is an event, which is generated, when a currently running

exposure time is finished.

Exposure active status signal is routed to the I/O control block and can there be selected for

output on the physical output line or on one of the available leds. Exposure start and exposure

end event can be used to trigger or to control other function in the camera, like acquisition,

frame and exposure control or counter and timer.

MAN078 12/2018 V1.1 31 of 111

4 Image Acquisition

E x p o s u r e 1 R e a d O u t 1

F r a m e 1

E x p o s u r e 2 R e a d O u t 2

F r a m e 2

E x p o s u r e N R e a d O u t N

F r a m e N

A c q u i s i t i o n A c t i v e

A c q u i s i t i o n S t a r t

T r i g g e r 1

A c q u i s i t i o n E n d

T r i g g e r 1

F r a m e S t a r t

T r i g g e r 1

F r a m e S t a r t

T r i g g e r 2

F r a m e S t a r t

T r i g g e r N

F r a m e

T r i g g e r

W a i t

F r a m e

T r i g g e r

W a i t

F r a m e

T r i g g e r

W a i t

A c q u s i t i o n

T r i g g e r

W a i t

A c q u s i t i o n

T r i g g e r

W a i t

A c q u i s i t i o n S t a r t ( ) A c q u i s i t i o n S t o p ( )

F r a m e A c t i v e

F r a m e

T r i g g e r

W a i t

4.5 Overlapped Image Acquisition Timing

The camera is able to perform an overlapped image acquisition. It means, a new exposure can

be started during the image readout of the previous image. Fig. 4.10 shows an image

acquisition procedure when images are captured in overlapped mode. The status "Frame

Active" remains active during the acquisition of the three frames since there is no gap between

two frames. The "Frame Trigger Wait" is asserted during the frame read out in order to

indicate, that a new exposure can be started.

All examples in the previous sections show a non overlapping frame timing. A new frame is

always started after the previous image read out has been finished. All these examples work

also in the overlap mode. It doesn’t show the overlap mode in order to simplify the diagrams.

The overlapped image acquisition is not available, when the triggered controlled

exposure mode is configured.

Figure 4.10: Overlapped Image acquisition Timing

There is a restriction of the overlapped image acquisition: The exposure time of the current

frame must not end prior to the end of the read out of the previous frame. Two different

timing situation needs to be distinguished:

Exposure Time > Read Out Time An new exposure cycle can be started as soon as the read out

Exposure Time < Read Out Time The start of a new exposure has to be delayed by a certain

The camera adjusts the timing automatically, and ensures that it complies with this restriction.

of the previous frame has been started (See Fig. 4.11).

amount of time in order to ensure, that the exposure doesn’t end prior to the image read

out end of the previous frame (See Fig. 4.12).

Frame start or frame burst start triggers which arrive too early and which violates the

overlapping restriction, will be ignored by the camera and indicated by a missed trigger event,

32 of 111 MAN078 12/2018 V1.1

4.5 Overlapped Image Acquisition Timing

E x p o s u r e 1 R e a d O u t 1

F r a m e 1

E x p o s u r e 2 R e a d O u t 2

F r a m e 2

E x p o s u r e 1 R e a d O u t 1

F r a m e 1

E x p o s u r e 2 R e a d O u t 2

F r a m e 2

which can be counted by a counter (see Section 5.1.5 for more information how to count

missed triggers). Fig. 4.11 and Fig. 4.12 shows both timing situations, when the exposure time

longer than the read out time and when the exposure time is shorter than the read out time.

Figure 4.11: Overlapped Image acquisition when exposure time > read out time

Figure 4.12: Overlapped Image acquisition when exposure time < read out time

MAN078 12/2018 V1.1 33 of 111

4 Image Acquisition

E x p o s u r e E n d T r i g g e r

E x p o s u r e S t a r t T r i g g e r

F r a m e B u r s t E n d T r i g g e r

F r a m e B u r s t S t a r t T r i g g e r

F r a m e S t a r t T r i g g e r

A c q u i s i t i o n E n d T r i g g e r

D e l a yD i v i d e r

M o d e

O n

O f f

A c t i v a t i o n

R i s i n g E d g e

F a l l i n g E d g e

B o t h E d g e s

S o u r c e

. . .

S o f t w a r e

A c q u i s i t i o n S t a r t T r i g g e r

4.6 Acquisition-, Frame- and Exposure-Trigger Configuration

The acquisition-, frame- and exposure timing can be controlled by 7 triggers:

• Acquisition Start Trigger

• Acquisition End Trigger

• Frame Start Trigger

• Frame Burst Start Trigger

• Frame Burst End Trigger

• Exposure Start Trigger

• Exposure End Trigger

Fig. 4.13 shows the signal path which is available for every of the 7 triggers. It contains:

• Trigger Source Selection

• Trigger Software

• Trigger Mode

• Trigger Activation

• Trigger Divider

• Trigger Delay

Figure 4.13: Trigger Path

4.6.1 Trigger Source Selection

The user can select the source which is used to generate the corresponding trigger. The source

can come from an external line input, internal pulse generated by a counter or timer or a

pulse, which is generated by software. The following list shows the signal sources, which are

available:

Line In A trigger is generated by a line input signal. The activation configuration defines, if the

Software A trigger is generated by the locally trigger software command register (see Section

34 of 111 MAN078 12/2018 V1.1

rising edge, the falling edge or both edges are taken into account (see Section 4.6.4).

4.6.2 for more information).

4.6 Acquisition-, Frame- and Exposure-Trigger Configuration

Software Signal Pulse A trigger is generated by the software signal pulse, which comes from a

common software signal pulse register (see Section 4.7 for more information).

Counter Start A trigger signal is generated by the counter start event (see Section 5.1.3 for

more information about the counter start event).

Counter End A trigger signal is generated by the counter end event (see Section 5.1.3 for more

information about the counter end event).

Timer Start A trigger signal is generated by the timer start event (see Section 5.2.3 for more

information about the timer start event).

Timer End A trigger signal is generated by the timer end event (see Section 5.2.3 for more

information about the timer end event).

Action A trigger signal is generated by the action control block (see Chapter 7 for more

information about the action control).

4.6.2 Trigger Software

The trigger software is a software command register, which is available in the signal path of

each trigger. Accessing to this register generates an internal trigger, which will be processed in

the signal path.

Trigger source must be set to software in order that a trigger software command

will be processed.

4.6.3 Trigger Mode

The trigger mode defines, if the trigger is active. Following settings are available:

• On

• Off

4.6.4 Trigger Activation

The trigger activation defines, which edge of the selected trigger is processed in the trigger

signal path. Following configuration is available:

• Rising Edge

• Falling Edge

• Both Edges

The trigger activation configuration is only available, when the trigger source is

set to Line In.

MAN078 12/2018 V1.1 35 of 111

4 Image Acquisition

4.6.5 Trigger Divider

The trigger divider specifies a division factor of the incoming trigger pulses. A division factor of

1 processes every incoming trigger. A division factor of 2 processes every second trigger and so

on.

4.6.6 Trigger Delay

The trigger delay lets the user specify a delay, that will be applied between the reception of a

trigger event and when the trigger becomes active.

36 of 111 MAN078 12/2018 V1.1

4.7 Software Signal Pulse and User Output

4.7 Software Signal Pulse and User Output

The software signal pulse block contains eight general purpose registers which allow

generating internal pulse signals by software access. These pulse signals are internally

connected to following functions, where it can be used to start a procedure:

• Acquisition Start Trigger

• Acquisition End Trigger

• Frame Start Trigger

• Frame Burst Start Trigger

• Frame Burst End Trigger

• Exposure Start Trigger

• Exposure End Trigger

• Counter Trigger

• Counter Event

• Counter Reset

• Timer Trigger

The user output block is an eight bit status register. The bits can be set to 0 or 1 by software.

The bits are available in the following firmware blocks/functions:

• Counter Trigger

• Counter Reset

• LED S0, S1 and S2

• Line Out

MAN078 12/2018 V1.1 37 of 111

4 Image Acquisition

38 of 111 MAN078 12/2018 V1.1

Counter & Timer

C o u n t e r

S o u r c e

. . .

A c t i v a t i o n

R i s i n g E d g e

F a l l i n g E d g e

B o t h E d g e s

S o u r c e

. . .

A c t i v a t i o n

R i s i n g E d g e

F a l l i n g E d g e

B o t h E d g e s

S o u r c e

. . .

A c t i v a t i o n

R i s i n g E d g e

F a l l i n g E d g e

B o t h E d g e s

C o u n t e r

T r i g g e r

C o u n t e r

E v e n t

C o u n t e r

R e s e t

T i m e S t a m p

T i c k

C o u n t e r D u r a t i o n

C o u n t e r S t a r t V a l u e

C o u n t e r V a l u e

C o u n t e r S t a t u s

C o u n t e r R e s e t ( )

C o u n t e r V a l u e A t R e s e t

C o u n t e r A c t i v e

C o u n t e r S t a r t

C o u n t e r E n d

5.1 Counter

5

Figure 5.1: Counter Structure

Four general purpose counters are available (Counter0 . . . Counter3) which are used for

counting events. Each counter can be individually configured by software and controlled by

counter trigger, counter event and counter reset signals. This section describes the

configuration and the function of the counters.

Fig. 5.1 shows the structure of one counter. Along with the counter function itself it contains a

counter trigger source, a counter event source and a counter reset source selection and

activation block. Furthermore there is a counter active status signal, which is available in the

I/O control block (see Chapter 6). And the counter generates counter start and counter end

events, which can be used to trigger other blocks, like counter, timer, acquisition, frame or

exposure control.

5.1.1 Counter Usage

In a basic usage, at least a counter event source needs to be selected (see Section 5.1.5 for more

information about the counter event source selection). Once an event source has been

selected, the counter needs to be reset in order to start the counter. When started it counts

from a defined start value, which is configurable by the CounterStartValue property, and ends

counting events after a certain number of events, which is configurable by the

CounterDuration property.

MAN078 12/2018 V1.1 39 of 111

5 Counter & Timer

If additionally a trigger source is selected, the counter is waiting for a trigger. It ignores

counter events until a valid trigger event has been received. A valid trigger signal on the

selected trigger source starts the counter, which means, that it counts the predefined number

of events from the start value according to the counter start value and duration configuration.

The current counter value is readable by the property CounterValue.

5.1.2 Counter Status

The counter has different states, which depends on the configuration and usage. The current

state can be read out by the register CounterStatus. The following list shows the available

states:

Counter Idle Counter is idle, and doesn’t count any events.

Counter Trigger Wait As soon as a counter trigger source is selected (counter trigger source 6=

OFF), the counter goes into the counter trigger wait state and waits for a trigger signal

on the selected source. In this state, the counter does not count any events.

Counter Active Counter is active and is ready to count every event. The counter can be

temporarely stopped by setting the counter event source to OFF .

Counter Completed Counter has stopped as it reached its programmed duration.

Counter Overflow Counter has reached its counter limit, which is 2^32-1, and an additional

counter event signal has been received. Once the counter is in the state overflow, it has

to be reset by software or by counter reset signal in order to recover it from this state.

5.1.3 Counter Active, -Start and -End Signal

Each counter has the following output signals:

Counter Active An asserted counter active signal indicates, that the counter is active and is

counting events. The counter active signal is internally routed to the I/O control block and

can there be selected for output on the physical output line or on one of the available

leds.

Counter Start The counter start is an event, which is generated, when the counter goes into

the counter active state or is restarted during counter active period.

Counter End The counter end is an event, which is generated, when the counter arrives its

configured end condition; and changes to the state counter completed.

The counter start and end event can be used to trigger or to control other function in the

camera, like acquisition, frame and exposure control or counter and timer. It can also be used

to cascade counters in order to get a bigger counting range.

5.1.4 Counter Reset

There are two ways how to reset a counter: Either by a software reset command or by a

hardware reset source signal. The reset behaviour depends on the current counter event and

trigger source configuration:

Counter Trigger Source = Off and Counter Event Source = Off The state of the counter

changes to "idle".

Counter Trigger Source = Off and Counter Event Source 6= Off The state of the counter

changes to "active".

40 of 111 MAN078 12/2018 V1.1

5.1 Counter

Counter Trigger Source 6= Off The state of the counter changes to "trigger wait".

The counter reset source can be set to the counter end signal of the same

counter. This allows to restart the counter automatically as soon as it arrives

its end condition.

The current counter value at the time, when the reset is performed, is stored to the

CounterValueAtReset property, which can be read out by software.

5.1.5 Counter Event Source

The counter event source selects the signal event, which will be the used to increment the

counter. The following signal sources are available:

Off Counter is idle or has been stopped temporarely and doesn’t count any events.

Acquisition Trigger Counts the number of acquisition triggers.

Acquisition Start Counts the number of acquisition start events.

Acquisition End Counts the number of acquisition end events.

FrameTrigger Counts the number of frame triggers.

Frame Start Counts the number of frame start events.

Frame End Counts the number of frame end events.

Frame Burst Start Counts the number of frame burst start events.

Frame Burst End Counts the number of frame burst end events.

Exposure Start Counts the number of exposure start events.

Exposure End Counts the number of exposure end events.

Counter 0 ... 3 Start Counts the number of the chosen counter start events.

Counter 0 ... 3 End Counts the number of the chosen counter end events.

Timer 0 ... 3 Start Counts the number of the chosen timer start events.

Timer 0 ... 3 End Counts the number of the chosen timer end events.

Action 0 ... 3 Counts the number of the chosen action signal events.

Software Signal Pulse 0 ... 7 Counts the number of the chosen software signal pulse events

(see Section 4.7).

Line Input Counts the number of transitions on the line input according to the signal input

activation configuration.

MissedAcqStartTrigger Count the number of missed acquisition start triggers. A missed

acquisition start trigger event is generated, when a acquisition start trigger cannot be

processed.

MissedFrameStartTrigger Count the number of missed frame start triggers. A missed frame

start trigger event is generated, when a frame start trigger cannot be processed.

MAN078 12/2018 V1.1 41 of 111

5 Counter & Timer

MissedFrameBurstStartTrigger Count the number of missed frame burst start triggers. A

missed frame burst start trigger event is generated, when a frame burst start trigger

cannot be processed.

MissedExposureStartTrigger Count the number of missed exposure start triggers. A missed

exposure start trigger event is generated, when an exposure start trigger cannot be

processed.

Missed Trigger Counts the number of any generated missed triggers. The missed trigger is the

logical OR connection of MissedAcqStartTrigger, MissedFrameStartTrigger,

MissedFrameBurstStartTrigger and MissedExposureStartTrigger.

Time Stamp Tick Counts the number of time stamp ticks. A time stamp tick generator is

available for every counter. It generates events with a rate, which can be configured. For

instances if the rate is set to 1 us and the counter event source is set to count time stamp

ticks, the counter increments every 1 us.

Line input source has additionally an activation configuration, which needs to be set

accordingly. Following configuration values are available:

Rising Edge Counter counts rising edges on the selected line input.

Falling Edge Counter counts falling edges on the selected line input

Both Edges Counter counts both edges on the selected line input

Activation configuration has only effect when line input is selected as a counter

event source, otherwise this configuration is ignored.

The counter can be temporarely switched off, if the counter event source is set

to off. It continue counting events as soon as counter event source has been

selected again.

5.1.6 Counter Trigger Source

The counter trigger source selects the signal which will be used to start the counter. The

following signals sources are available:

Off Disables the counter trigger.

Acquisition Trigger Starts with the reception of the acquisition trigger event.

Acquisition Start Starts with the reception of the acquisition start event.

Acquisition End Starts with the reception of the acquisition end event.

FrameTrigger Starts with the reception of the frame trigger event.

Frame Start Starts with the reception of the frame start event.

Frame End Starts with the reception of the frame end event.

Frame Burst Start Starts with the reception of the frame burst start event.

Frame Burst End Starts with the reception of the frame burst end event.

42 of 111 MAN078 12/2018 V1.1

5.1 Counter

Exposure Start Starts with the reception of the exposure start event.

Exposure End Starts with the reception of the exposure end event.

User Output 0 ... 7 Starts and counts events as long as the selected user output bit is asserted.

When the counter is started, it ignores counter events as long as the corresponding user

output bit is deasserted (see Section 4.7).

Counter 0 ... 3 Start Starts with the reception of the chosen counter start event.

Counter 0 ... 3 End Starts with the reception of the chosen counter end event.

Timer 0 ... 3 Start Starts with the reception of the chosen timer start event.

Timer 0 ... 3 End Starts with the reception of the chosen timer end event.

Action 0 ... 3 Starts with the receiption of the chosen action signal event.

Software Signal Pulse 0 ... 7 Starts with the reception of chosen software signal pulse event

(see Section 4.7).

Line Input Starts when the specified counter trigger activation condition is met on the chosen

line.

Line input source has additionally an activation configuration, which needs to be set

accordingly. Following configuration values are available: