Instruction Manual

Specification:

Wingspan: 133 cm (52.3 inches)

Length : 104 cm (40.9 inches)

Weight : 1830gr

Engine : 25 - 32 two stroke

Radio : 4 channel - 4 servo

HIGH WING

1

AIR FRAME ASSEMBLIES

(2) Wing halves with ailerons

(1) Fuselage with motor mount

(1) Horizontal stabilizer

with elevator halves

(1) Vertical stabilizer with rudder

MAIN GEAR ASSEMBLY

(2) Main gear

(2) 50mm diameter wheels

(4) Wheel collars

(4) 3mm x 6mm set screws

(2) Nylon strap

(4)

3mm x 12mm sheet metal screw

NOSE GEAR

(1) Nose gear

(1) Steering arm

(1) 50mm diameter wheel

(2) Wheel collars

(2) 3mm x 6mm set screws

(1) Metal connector

(1) 4mm x 4mm machine screw

(1) 1,3mm x 500mm wire

(1) 3,5mm x 350mm nylon pushrod

ELEVATOR CONTROL SYSTEM

(1) Nylon clevis

(1) Silicone tube

(1) Nylon snap keeper

(1) Nylon control horn w/plate

(2)

2mm x 12mm sheet metal screw

RUDDER CONTROL SYSTEM

(1) Nylon clevis

(1) Silicone tube

(1) Nylon snap keeper

(1) Nylon control horn w/plate

(2) 2mm x 12mm sheet metal screw

AILERON CONTROL SYSTEM

(2) 2mm x 180mm threaded wires

(2) Nylon clevis

(2) Silicone tube

(2) Nylon snap keeper

(2) Nylon thread connector

(1) Plywood

(2) 8mm x 9mm x 45mm light wood

KIT CONTENTS: We have organized the parts as they come out of the box for better

identification during assembly. We recommend that you regroup the parts in the same

manner. This will ensure you have all of parts required before you begin assembly.

KIT CONTENTS

SUGGESTION:

To avoid scratching your new

airplane, do not unwrap the pieces

until they are needed for assembly.

Cover your workbench with an old

towel or brown paper, both to

protect the aircraft and to protect

the table. Keep a couple of jars or

bowls handy to hold the small parts

after you open the bag.

NOTE:

Please trial fit all the parts. Make

sure you have the correct parts and

that they fit and are aligned

properly before gluing! This will

assure proper assembly. The

SONIC ARF is hand made from

natural materials, every plane is

unique and minor adjustments may

have to be made. However, you

should find the fit superior and

assembly simple.

The painted and plastic parts used

in this kit are fuel proof. However,

they are not tolerant of many harsh

chemicals including the following:

paint thinner, C/A glue accelerator,

C/A glue debonder and acetone. Do

not let these chemicals come in

contact with the colors on the

covering and the plastic parts.

SAFETY PRECAUTION:

• This is not a toy

• Be sure that no other flyers are

using your radio frequency.

• Do not smoke near fuel

• Store fuel in a cool, dry place,

away from children and pets.

• Wear safety glasses.

• The glow plug clip must be

securely attached to the glow

plug.

• Do not flip the propeller with your

fingers.

• Keep loose clothing and wires

away from the propeller.

• Do not start the engine if people

are near. Do not stand in line with

the side of the propeller.

• Make engine adjustments from

behind the propeller only. Do not

reach around the spinning

propeller.

MOTOR MOUNT ASSEMBLY

(4) 3mm x 25mm machine screws

(4) 4mm x 25mm wood screws

THROTTLE CONTROL SYSTEM

(1) 1,3mm x 500mm wire

(1) 3,5mm x 350mm nylon

pushrod housing

(1) Metal connector

(1) 4mm x 4mm machine screw

FUEL TANK

(1) Nylon fuel tank

(1) Metal clunk

(1) Silicone tube / 80mm

(1) Pre - assembled stopper w / 2 tube

(1) 165mm x 250mm foam rubber

MISCELLANEOUS ITEMS

(1) Plywood dihedral brace

(2) 15mm x 15mm x 8mm blok of wood

(2) 15mm wood triangle stock

(1) 25mm x 600mm trim tape

(2) 115mm wood dowels

(12) Ruber bands

(1) Set of two pushrods

(2) Plywood

ADDITIONAL ITEMS REQUIRED

• 25 - 32 two stroke engine

• 4 channel radio with 4 servo

• Glow plug to suit engine

• Propeller to suit engine

• Protective foam rubber

• Silicone fuel line

• Stick on weight for balance

• Spinner: 2" (52mm)

TOOLS AND SUPPLIES NEEDED

• Medium thick C/A glue.

• 30 minute epoxy

• 6 minute epoxy

• Hand or electric drill

• Assorted drill bits

• Modeling knife

• Straight edge ruler

• Pliers large and small

• Wire cutters

• Masking tape

• Thread lock

• Paper towels

• Rubbing alcohol

2

• Draw a center line on the wing joiner.

• Glue wing joiner in wing halves with 30 minute

epoxy. Put epoxy on wing joiner and in wing

joiner pocket. Wipe off excess epoxy with a

paper towel and alcohol.

• Hold wing halves together with tape while

epoxy cures.

• Cover wing joint with self adhesive trim strip.

• Glue 2 pieces of plywood onto the wing

with CA glue.

Center line

Tape

Joiner

4

Tape

WING ASSEMBLY

5

Ply wood

3

• Locate aileron servo mouting tray. Trim covering

from bottom of wing for aileron servo and tray. 6

minute epoxy the tray in place centered over the

aileron servo opening using the supplied spacer

blocks (trim to fit as needed).

• Install aileron servo using hardware supplied

with radio gear.

• Install the threaded connectors onto the aileron

torque rods.

• Thread one nylon clevis at least 6mm onto one of

the 2mm x 180mm threaded wires. Install a

silicone tube on the clevis. Attach the clevis to the

hole in the threaded connector. Locate one nylon

servo arm and using a wire cutter remove all but

two of the arms. Using a 2mm drill bit, enlarge the

third hole out from the cnter to accommodate the

aileron pushrod wire. Plug the aileron servo into

receiver and ceter the servo. Install the servo arm

onto the servo. The servo arm should be

perpendicular to the servo. Center the aileron and

hold it place using a masking tape.

With the aileron and aileron servo centered, carefully place a mark on the aileron pushrod wire where it crosses the

hole in the servo arm. Using pliers, carefully make a 90 degree bend down at the mark made. Cut off the excess wire,

leaving about 4mm beyond the bend. Insert the 90 degree bend down through the hole in the servo arm. Install one

nylon snap keeper over the wire to secure it to the arm. Install the servo arm retaining and remove the masking tape

from the aileron. Repeat for the second aileron linkage.

Thread connector

20mm

Silicone tube

Snap

keeper

Clevis

Servo tray

Tape

Snap keeper

Clevis

Thread connector

Aileron pushrod

4

• Center the wing. Cut the covering from the slots

in the fuselage for the horizontal stab and vertical

fin. Put horizontal stab on fuselage and center like

the wing, also level the stab to match up with the

wing. Mark the horizontal stab where it will glue

to the fuselage.

• Glue stab on with 30 minute epoxy and recheck

alignment.

• Trim the covering from the stab where it will glue

onto the fuselage. Cut only through the covering,

do not cut into the balsa.

• Cut the covering from the holes for the wing

dowels in the fuselage. Glue the dowels in place

with C.A

• Rubber band wing onto fuselage with suppied

rubber bands. See photo.

horizontal - vertical installation

BB

BB

AA

AA

Remove the covering

Dowel

5

• Put vertical fin in fuselage slot, mark where

covering needs to be trimmed. Carefully trim

covering. Line up vertical fin and epoxy in place

keeping the vertical fin perpendicular to the stab.

• Cut the covering the slot in the landing gear mount.

• Put landing gear wires in fuselage bottom and secure

using screws and nylon straps.

main gear installation

Nylon step

Landing gear

Screw

• Fit the nose leg steering arm onto the "Z" bend on

the steering pushrod. Now slide the steering arm

into the middle of the pre-fitted nylon nose gear

bearing. Hold the nose gear steering arm in place

then slide the nose wire into the nylon mount,

passing through the steering arm. Note that the

ground flat section of the leg should face forward.

Now tighten the nose gear steering arm retaining

screw onto the nose leg. This will ensure that the

nose leg cannot turn in the steering arm.

• Put wheels on the gear and secure using the

wheel collars.

Nose gear

Steering arm

Wire

pushrod

Remove the

covering

Glue epoxy

Collar

6

• Assemble the fuel tank.

Collar

• Install nose wheel using supplied wheel collars.

• Put the fuel tank in the fuselage using foam rubber

to cushion the tank, and route the fuel lines out

the hole in the firewall.

. Insert the Z - bend of the throttle pushrod into the

throttle arm of the engine. See the "high throttle"

photo on page 9.

. Istall the engine of your choice using the Philip

head screws. Make sure the engine is pointing

straight ahead or pointing a little to the right, i. e.

with right thrust. Mark the locations of the screws

and drill mounting holes with a drill bit that is

slightly smaller than the screw threads. Test to get

the right size drill bit before drilling holes in the

engine mount.

fuel tank installation

engine installation

To muffler

To carburator

Down thrust 2

0

To muffler

To carburator

80mm

2.5mm

Right thrust 2

0

7

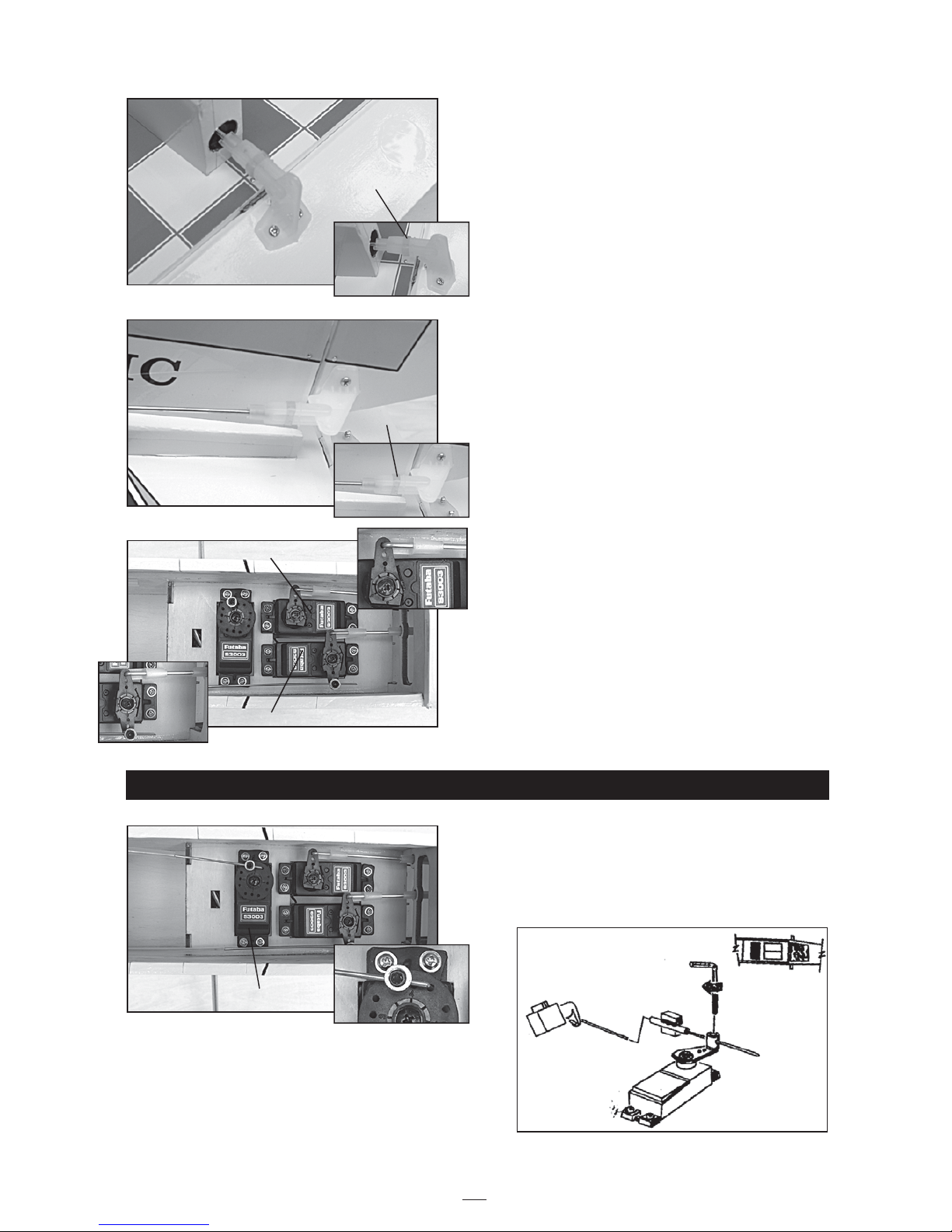

• Install the rubber grommets and brass eyelets into

the elevator, rudder and throttle servos. Test fit

the servos into the servo tray.

• Mount the servos to the tray using the mounting

screws provided with your radio system.

servo installation

elevator - rudder linkage

Throttle servo

Rudder servo

Elevator servo

• Remove the covering from the hole as shown.

• The elevator control horn should be mounted on

the bottom of the elevator at the leading edge,

IN LINE WITH THE ELEVATOR PUSHROD.

• Cut the covering from the exit slot for the rudder

pushrod on the top of the fuselage, on the left side

of the vertical fin.

• The rudder control horn should be mounted on

the left of the rudder at the leading edge,

IN LINE WITH THE RUDDER PUSHROD.

Hole

Screw

Control horn

Screw

Control horn

8

throttle linkage

• Install the elevator pushrod in fuselage. Thread a

nylon clevis at least 6mm onto the pushrod. Route

it to the elevator, attach clevis to horn and secure

using small piece of silicone tubing.

Silicone tube

• Install the rudder pushrod in fuselage. Thread a

nylon clevis at least 6 mm onto the pushrod. Route

it to rudder, attach clevis to horn and secure using

small piece of silicone tubing.

• Trim and attach the pushrod to the servos using

fast loc connectors.

• Install a metal connector onto the rudder servo

arm and connect the nose wheel steering

pushrod to it.

• Attach throttle pushrod to throttle servo arm using

a metal connector. Use two wood blocks to hold

the pushrod securely.

Silicone tube

Throttle servo

Rudder servo

Elevator servo

9

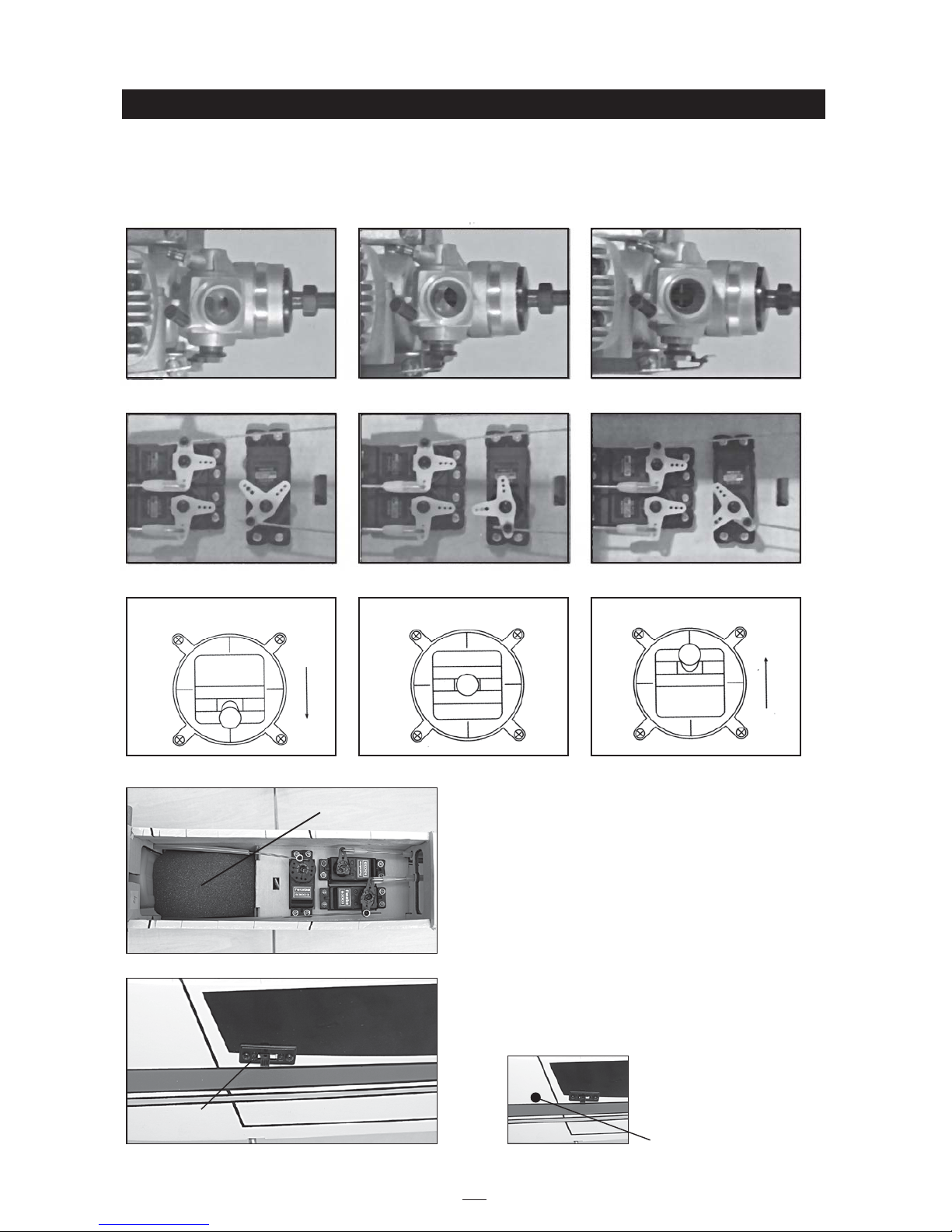

This is a very important stage in the completion of

the model. The throttle must open and close fully without the linkage binding at either end of its travel.

Work by setting the "mid throttle" position first,

followed by the low and high. Once the linkage

has been properly set-up it can be adjusted

mechanically or by using the Travel Adjust, or

ATV/EPA feature on most modern transmitters.

Note: The final adjustment of the low throttle point

can only be carried out with the engine running.

setting up the throttle

• Wrap battery and receiver in protective

foam padding.

• Install the switch.

Low throttle Mid throttle High throttle

Low throttle stick position Mid throttle stick position High throttle stick position

Antenna exit

Switch

Receiver - battery

10

BALANCING

1. It is critical that your airplane be balanced correctly.

Improper balance will cause your plane to lose

control and crash.

Place receiver and battery in radio compartment and

adjust their position to make the plane blance on the

center of gravity (70mm from leading edge of wing).

Make sure the center of gravity is located where it is

indicated before flying. If additional tail or nose

weigh is needed, securely attach it at the nose or tail

as needed.

2. Wrap battery and receiver in protective foam

padding. Route the receiver antenna out of the

fuselage and to the rear of the airplane. Secure to

the vertical fin or one side of the horizontal stab with

a pin and small rubber band.

CONTROL THROWS

1.

We highly recommed setting up a plane using the

control throws listed. Adjust pushrod positions on

control arms or horns to provide control surface

throws as illustrated. Center all control surfaces.

2. The control throws should be measured at the

widest point of each surface!

FLIGHT PREPARATION

PRE FLIGHT CHECK

1. Completely charge your transmitter and receiver

batteries before your first day of flying.

2. Check every bolt and every glue joint in your

plane to ensure that everything is tight and well

bonded.

3. Double check the balance of the airplane

4. Check the control surface

5. Check the receiver antenna . It should be fully

extended and not coiled up inside the fuselage.

6. Properly balance the propeller.

7. Use at leat 5 rubber bands per side to hold the

wing onto the fuselage.

We wish you many enjoyable flights with

your plane and once again thank you for

your choosing a Phoenix Model's product.

Ailerons : 5mm up 5mm down

Elevator : 8mm up 8mm down

Rudder : 13mm right 13mm left

65 - 70mm

Elevator Control

Aileron Control

5mm

5mm

Rudder Control

13mm

13mm

8mm

8mm

Metric Conversions

Inches x 25.4 = mm (conversion factor)

1/64" = .4 mm 3/16" = 4.8 mm 1" = 25.4 mm 21" = 533.4 mm

1/32" = .8 mm 1/4" = 6.4 mm 2" = 50.8 mm 24" = 609.6 mm

1/16" = 1.6 mm 3/8" = 9.5 mm 3" = 76.2 mm 30" = 762.0

mm

3/32" = 2.4 mm 1/2" = 12.7 mm 6" = 152.4 mm 36" = 914.4 mm

1/8" = 3.2 mm 5/8" = 15.9 mm 12" = 304.8 mm

5/32" = 4.0 mm 3/4" = 19.0 mm 18" = 457.2 mm

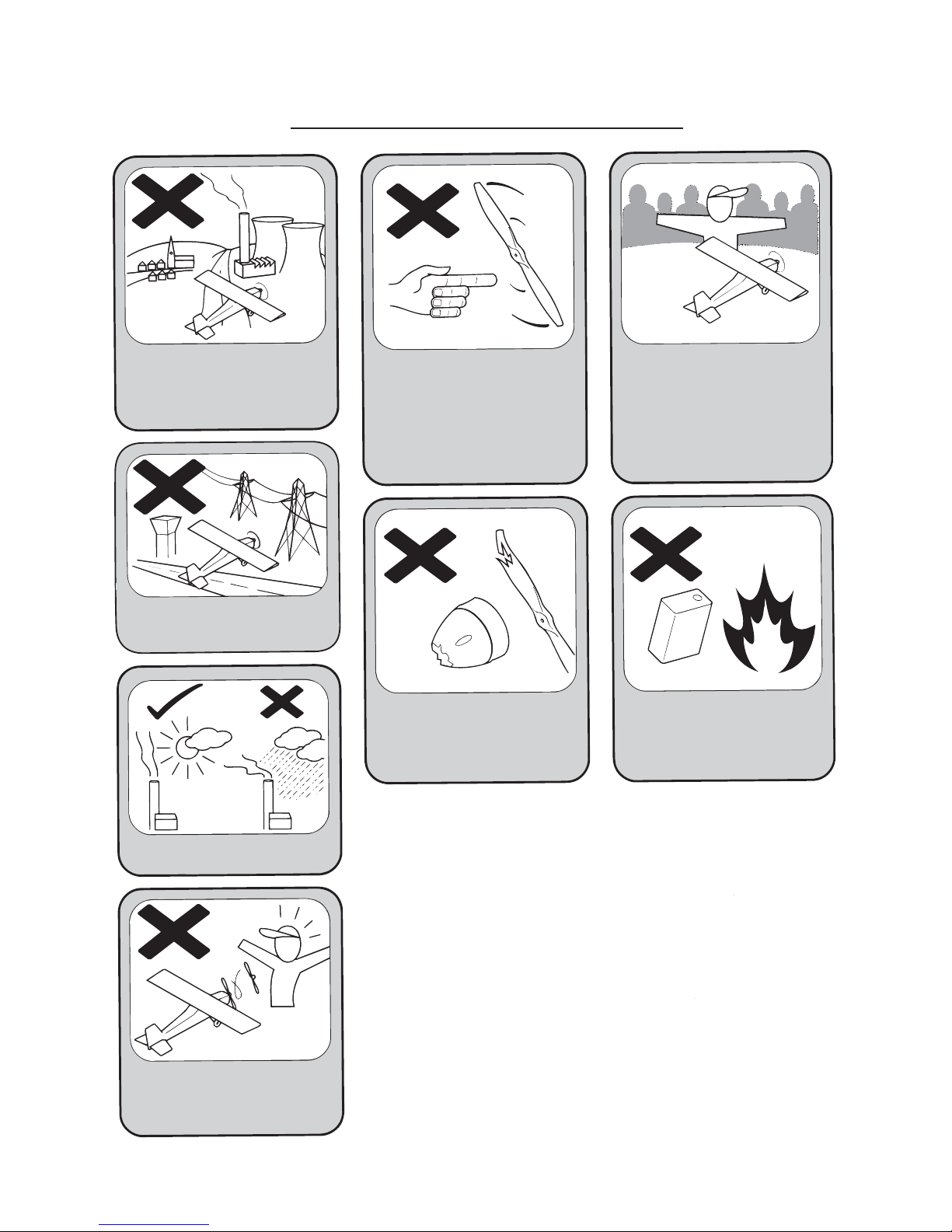

I/C FLIGHT WARNINGS

Always operate in open areas, away

from factories, hospitals, schools,

buildings and houses etc. NEVER fly

your aircraft close to people or built

up areas.

THE PROPELLER IS DANGEROUS

Keep fingers, clothing (ties, shirt

sleeves, scarves) or any other loose

objects that could be caught or drawn

in, away from the propeller. Take care

at ALL times.

Keep all onlookers (especially small

children and animals) well back from

the area of operation. This is a flying

aircraft, which will cause serious

injury in case of impact with a person

or animal.

NEVER fly near power lines, aerials

or other dangerous areas including

airports, motorways etc.

NEVER use damaged or deformed

propellers or spinners.

DO NOT dispose of empty fuel

containers on a fire, this can lead to

an explosion.

NEVER fly in wet conditions or on

windy or stormy days.

ALWAYS adjust the engine from

behind the propeller, and do not allow

any part of your body to be in line

with the propeller.

Made in Vietnam

Loading...

Loading...