Phoenix TS-332 Owner's Manual

PO Box 8680 • Madison, WI 53708

Owner’s Manual — Phoenix Solution LGR

Performance Amplifier

Installation, Operation & Service Instructions

Read and Save These Instructions

The new Phoenix Solution LGR Performance Amplifier widens

the effective operating range of LGR dehumidifiers, increases

grain depression, and improves water removal rates up to 100

percent.

The Solution is a specially designed intercooler that pre-cools

the incoming air stream to the LGR dehumidifier. This precooling is the same process that provides LGR dehumidifiers

with their leap in performance over conventional dehumidifiers.

The Solution is designed to take advantage of outside,

unaffected or air conditioned air to provide significant water

removal in drying conditions up to 140°F. Therma-Stor testing

has revealed an increase in water removal rates and faster

drying times using the Solution by utilizing cold outside air.

The Solution improves the grain depression of the dehumidified

air. This increases the vapor pressure differential (the key to

evaporation) up to 33% and accelerates the drying process.

This improves drying times in all classes of water damage but is

particularly beneficial in specialty drying applications, such as

hardwood floors.

Phoenix Solution

PN 4026600

The Phoenix Solution

LGR Performance Amplifier

• Widens the temperature range for LGR performance

up to 140°F.

• Increases water removal rates up to 100%.

• Increases grain depression up to 33% for faster

drying of more materials.

• Removes BTUs from the affected areas.

• Achieves optimal drying conditions in structures

with insufficient or without air conditioning.

• Drives the grains/lb. in the drying area from the mid

30’s to the low 20’s.

• Enhances the performance of heat based systems

when outside grains/lb. or indoor temperatures are

high by allowing dehumidification.

Specifications subject to change without notice.

TS-332

Revised 7/07

1

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

Table of Contents

Introduction ...............................................................1

1. Intended Application ..............................................2

2. Specifications ........................................................2

3. Set Up ..................................................................2

3.1 Transporting ...................................................2

3.2 Installation .....................................................2

3.3 Ducting ..........................................................3

3.4 Condensate Removal ......................................3

3.5 Electrical Requirements ...................................4

3.6 Control Switch ................................................4

4. Maintenance .........................................................4

5. Service .................................................................4

5.1 Technical Description ......................................4

5.2 Troubleshooting ..............................................4

5.3 Blower Replacement .......................................4

5.4 Thermostat & Switch Replacement ...................4

6. Options & Accessories ...........................................4

7. Wiring Diagram .....................................................5

8. Installation Diagram ..............................................6

9. Service Parts .................................................................... 7

10. Warranty ...............................................................9

1 Intended Application

The Solution is a specially designed intercooling head that

provides pre-cooling to the dehumidifier’s incoming air

stream. Just like the pre-cooling feature is the key to the

performance leap of LGR dehumidifiers, the Solution can

actually double the water removal rate of your LGR in some

conditions.

The enhanced efficiency achieved with the Solution

practically matches the 1.6 amps required to operate the

unit, resulting in a minimal overall power increase.

2 Specifications

Model: Phoenix Solution (P/N 4026600)

Electrical: 110-120 Vac, 1.6 Amps, grounded

Operating CFM & Temperature Range:

Primary air stream 300 CFM & 33°F min., 125°F max.

Secondary air stream 230 CFM & 15°F min., 125°F max.

Duct Connections: 4” x 10” rectangular exhaust

8” round intake

Size: 19” high x 19-1/2” wide x 19-1/2” deep

Weight: 40 lbs

Read the operation and maintenance instructions

carefully before using this unit. Proper adherence to

these instructions is essential to obtain maximum

benefit from your Phoenix Solution performance

amplifier.

• It is designed to be used INDOORS ONLY.

• If used in a wet area, plug it into a GROUND FAULT

INTERRUPTER.

• DO NOT use the Phoenix Solution as a bench or table.

• It must always be used in the upright position.

• The included bracket with engaging tabs must be

installed correctly on the dehumidifier that the

Phoenix Solution is attached to.

• The Phoenix Solution must be removed from the

dehumidifier for transport to and from the job site.

• Automatically operated device.

• Risk of electric shock.

• Can cause injury or death: disconnect all remote

electric power supplies before servicing.

3 Operation

3.1 Transporting

The Phoenix Solution is designed to be carried by the

recessed handles built into the front and rear of the unit.

Multiple Solutions may be stacked for transport on a

suitable cart. Transporting the Phoenix Solution as it is

attached to a dehumidifier is NOT RECOMMENDED.

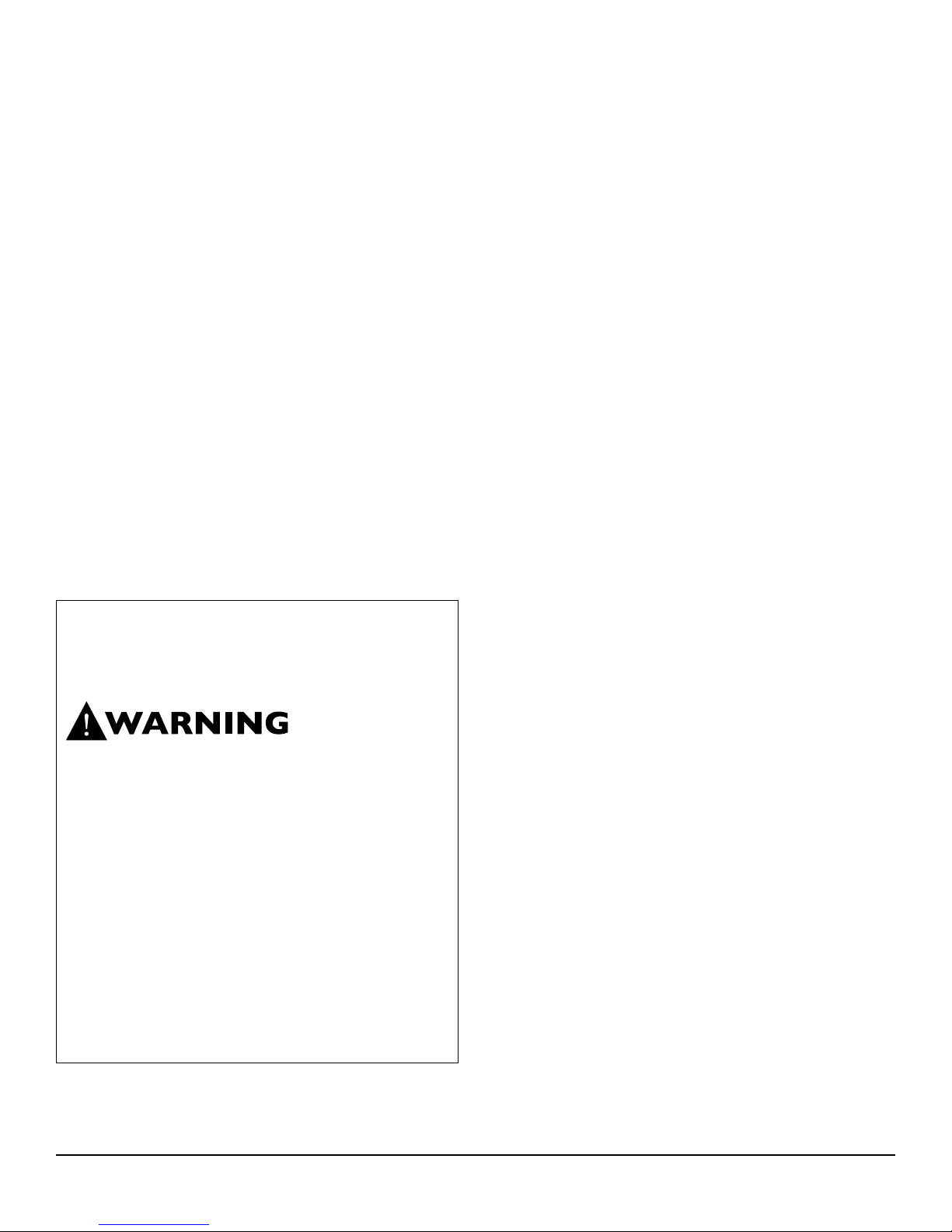

3.2 Installation

The top of the Phoenix Solution is designed to accept the

filter and top cover from the Phoenix 200 MAX or Phoenix

200 HT that it is mounted on. The Phoenix Solution is

designed to engage the spring clips found on the Phoenix

200 MAX and 200 HT dehumidifiers. An additional bracket

with engaging tabs (1 included) must be installed on the

dehumidifier to secure the front of the Phoenix Solution

chassis.

2

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

Figure 1: Bracket installed in Phoenix HT using existing fasteners.

Note tabs bent down between plastic heat exchanger panels. 200

MAX installation is similar

Figure 2: The front of the Solution has four slots to engage the

tabs on the dehumidifier bracket. The top two slots are for use

when installing on a Phoenix 200 HT and the bottom two are for

use on a Phoenix 200 MAX.

Figure 3: Solution slides forwards and engages clips on side of

dehumidifier.

3.3 Ducting

A detachable rectangular duct ring is supplied to allow 10”

round lay-flat duct to be attached to the Phoenix Solution

outlet. Lay-flat plastic ducting is available. See accessories

table section 6. To attach ducting to a ring, put the plastic

duct end through the ring center and roll the duct end

outward so that it overlaps the outside of the ring. The

duct and ring may then be quickly attached to the Phoenix

Solution by snapping the ring over the three screws at the

blower outlet.

3.4 Condensate Removal

In applications where the temperature of the secondary

air stream is significantly below the dew point of the

primary air stream, condensation may occur inside the

Solution’s heat exchanger. A drip pan underneath the heat

exchanger, along with the mounting bracket secured in

the dehumidifier, direct condensate into the dehumidifier’s

drain pan for removal.

3

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

Loading...

Loading...