Page 1

Trans-O-Con@

Forged Branch

Connections

Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Trans-O-Con Features&Applications.. . . . . . . . . . 16

Trans-O-Con IndustryStandard Consolidation. . . . 17

Butt-Weld. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Threaded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Socket Reducing. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Elbow&LateralConnections.................. 19

Page 2

PHOENIX TRANS-O-CON@ transition pipe connections are used successfullyin

numerous types of product distribution installations. The structurally reinforced design of our

~ products insures a connection that is equal in strength to the originalpipe. Material costs and

installationtime can be greatly reduced by usingTRANS-a-CON connections in new

construction as well as for plant conversions and in maintenance operations.

Facilitiesnow usingour branch connections include:power generating stations, commercial

& industrial buildings,chemical & petrochemical plants and refineries.

STRENGTH RATINGS

TRANS-a-CONconnectionshavestrengthratingsequalto seamlesssteel pipe.

Theseratingsarebasedonthe ASMECodefor PressurePiping,B31,the ASMEBoilerConstructionCode and

For example,an extra-strong TRANS-a-CON applied to extra-strong pipe pf the equivalent material provides 100%pipe

strength. A standard weightTRANS-a-CON provides 100%pipe strength when used on standard weight pipe.

TRANS-a-CON connections are manufactured according to the requirements of the ANSIstandard for Steel Butt Welding

Fittings(B16.9,latest modification);the ASMEstandard for Forged Fittings,SocketWelding andThreaded Fittings

(B16.11,latest modification),the ANSI standard for Pressure Piping(B31,latest modification),and MSSSP-97.

When TRANS-a-CON connections are installed as recommended, their bursting strength exceeds the computed bursting

strength of pipe or the designated weight or schedule number and material.

Certifications are provided upon request. 24-hour acces to specifications through electronic MTR'son our web site.

ANSI/ASME B36.1 O.

SPECIFICATIONS

Approval listings on file.

IDENTIFICATION AND MARKING

TRANS-a-CON connections are forged from carbon steel hot rolled bar to meet A-IOSmaterial specifications.

Everyconnection is individuallyinspected and stamped with header size, outlet size, material specification,

pressure rating, manufacturer's symbol and identification number.

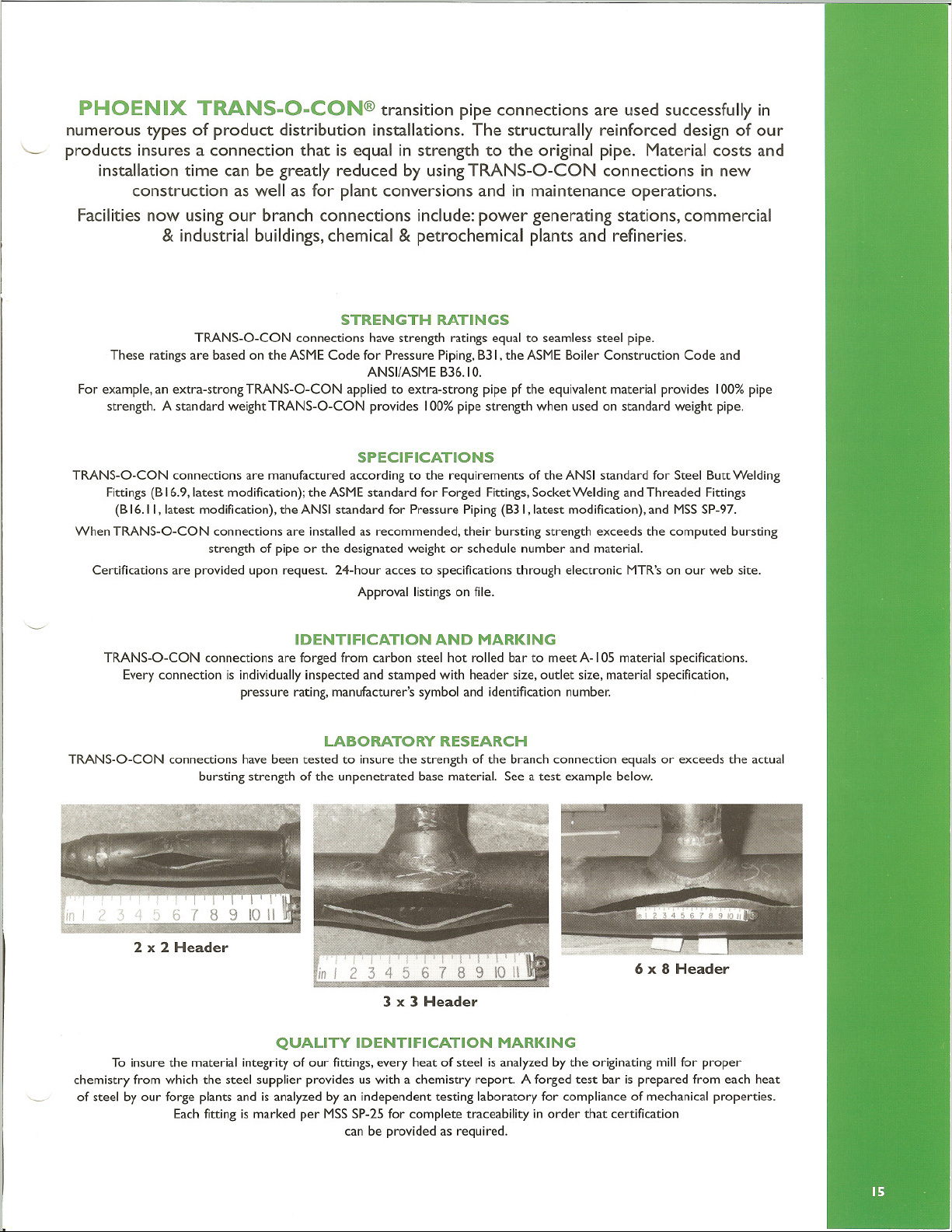

LABORATORY RESEARCH

TRANS-a-CONconnectionshavebeentested to insurethe strengthof the branchconnectionequalsor exceedsthe actual

burstingstrengthofthe unpenetratedbasematerial.See a test examplebelow.

2 x 2 Header

in j

3 x 3 Header

QUALITY IDENTIFICATION MARKING

To insure the material integrity of our fittings,every heat of steel is analyzed by the originating millfor proper

chemistry from which the steel supplier provides us with a chemistry report. A forged test bar is prepared from each heat

' ' of steelbyour forgeplantsandisanalyzedbyanindependenttestinglaboratoryforcomplianceof mechanicalproperties.

Eachfittingis marked per MSSSP-25 for complete traceability in order that certification

can be provided as required.

Page 3

...

. .

......................................................................................................................

+

ASME SA10S1 A3S0-LF21 MSS SP-97 1 POWER PIPINGASMEB31.1

LIQUIDTRANSPORTATION.ASME B31.41 ASTM A10S1 NACEMR017S

Phoenix Trans-a-Con@Conventional Butt-Weld Size Range

BUTT-WELD (STD & X STRONG) OUTLET SIZE-INCHES

REFININGASMEB31.31GASTRANSMISSIONASMEB31.8

ASME B16.91 ASME B16.111 ASME B1.20.1

5" 6" 8" 10" 12" 14"

14- 12"

36- 24" 24 - 20" 36" 36" 36" 36"

10

20 -16 18 -16 24" 24"

8

5 8 8

14 -12 14 - 12 20" 20" 20" 24" 24"

6 10 10 18" 18" 18" 20"

6 14"

TRANS-O-CON @ design provides

100% pipe strength and unrestricted fluid flow

TRANS-a-CON connections maintain the

strength of the run pipe and optimize

flow characteristics of the entire system.

The cutawaydrawing shows exactly

how this isaccomplished.

Additional TRANS-O-CON

Advantages:

.TAPERED TRANSITION

FROM BRANCH TO HEADER

AND HEAVY JUNCTURE

MINIMIZES STRESS

CONCENTRATIONS.

·Low Initial Cost

· Fast,EasyInstallation

· No Cutting, Shapingor Beveling

· Easyto Align

· Strength and quality Properties

Found Only in a Forged Product

.WIDE FOOTING IMPROVES

MECHANICAL STRENGTH TO

WITHSTAND VIBRATIONAL STRESSES.

16" 16"

14" 14" 16"

12" 12"

10"

J

~

16" 18"

30" 30"

24"

18" 18"

16"

.SHORT HEIGHT

PERMITS ACCESS TO

INSIDE SURFACE

TO INSPECT FOR

FULL-PENETRATION

WELD.

36"

20"

...................................................................................................................................

...................................................................................................................................

TRANS-O-CON @ Applications

Use TRANS-O-CON connectors instead of

·WeldingTees · Reinforced Branches · Non-Reinforced Branches

TRANS-a-CON transition pipe connections can be used in all of these applications to advantage.

Not only is the cost lower,but consider the TRANS-a-CON benefits shown below.

Why TRANS-O-CON connections

are better than welding tees:

·Quicker Fabrication time

·Pipe can be run before branch

connections are attached

·Gradual transition from header to branch

improves stress distribution

·Lower material costs

Why TRANS-O-CON connections

are better than Reinforced and

Non-Reinforced Miter Branches:

·Quicker installation

·Provides perfectly contoured internal joint

·Requires no shaping

·Requires less cutting and welding

·Eliminatesmetal-to-metallapped

surfaces and sharp corners

·Reduces overall cost of installation

TRANs-a-coN WELDING TEE

TRANs-a-coN MITERBRANCH

Page 4

...

Phoenix Trans.O.Con@ ASME SA105 I A 350-LF21 MSS SP-97 I POWER PIPING ASME831.1

Indust

Standard Consolidation LIQUIDTRANSPORTATIONASME 831.41 ASTM A1051 NACEMR0175

ry

REFINING ASME 831.31 GAS TRANSMISSION ASME 831.8

. .

+

Straight Bore Branch Connections ASME 816.91 ASME816.111 ASME 81.20.1

BUTT-WELD (STD)

I/)

1/4"

w

36-318" 36 -3/4" 36 -11/4" 36 -21/2" 36 -2" 36 -8" 36 -4" 36 -8" 36 -12" 36 -16" 36 -22" 42 -36"

N

1/4" 1/2

3/a" 1/2" 3/4"

_ 3/8" I -1/2" 2 -3/4" 31/2" -11/4"

OUTLET SIZE. INCHES

I" 11/4" 11/2" 2" 21/2" ]" 4" 6"

6 -21/2" 31/2" -2" 6-31/2" 10- 5" 14- 8" 20 - 12" 34 - 26"

- I" 2 - 11/2" 11/2" 3 -21/2" 4 -3" 6 -5" 10-8" 24 -20"

I/)

Z

:I

BUTT-WELD (EXTRA STRONG)

II:

1/4"

36-114" 36-1/2" 36 - I" 36 - 2" 36 - 2" 36- 6" 36- 4" 36- 8" 36 - 12" 36- 16" 36 - 22" 42 - 36"

w

a.

3/a" 1/2" 3/4" I"

3/8" 3/4"- 1/2" 11/2"_3/4"

3"- 11/4" 5 - 21/2" 31/2"- 2" 6 - 31/2" 10- 5" 14- 8"

I" 2 - 11/4" 11/2"

11/4"

OUTLET SIZE. INCHES

11/4"

11/2" 2" 21/2" ]" 4" 6"

-

a.

SOCKET-WELD (3000#)

I/)

1/4"

w

36 -318" 36 -3/4"

N

1/4" 1/2_3/8" 1/2"

-

I/)

Z

:I OUTLET SIZE

SOCKET-WELD (6000#)

II:

1/4" 3/a"

36 -1/4"

w

a.

-

a.

THREADED (3000#)

I/)

1/4" 3/8" 1/2" 3/4" 11/4" 11/2"

w

36 - 112" 36 -11/4" 36 -314"

N

3/8 -1/4"

I/)

Z

THREADED (6000#)

:I

II:

1/4" 3/8"

-112" 36 - 11/4"

36

w

3/8- 1/4"

a.

-

3/8"

36 -3/8" 36 -3/4" 36- 11/4" 36- 3" 36- 5"

1/2"

36 -3/4"

1/2" 3/4" I" 11/4"

1/2" I- 3/4"

3/4" I" 11/4" 11/2"

36 - 11/2" 36 -3" 36 -4" 36 -6" 36 -8"

11/4_314" 21/2-11/4" 31/2-2"

I"

21/2 - 11/4" 4- 11/2" 5- 3" 6 - 4" 18-6" 26- 12" 14- 10"

I" 11/4"

I"

-11/2" 36 -3" 36 -4" 36 -6" 36 -8" 36 -10" 36 -16" 36 -22"

36

I -3/8" 1/2"

1/2"

36 -314" 36- 11/2" 36 - 3" 36 - 10" 36- 6" 36 - 8"

I - 3/8" 1/2"

11/4

_ 314" 21/2-11/4"

I"

3/4" I"

21/2- I" 21/2-11/4"

-I" 31/2 -2" 21/2-2"

3/4"

11/4

a.

OUTLET SIZE -INCHES

5- 3" 6-4" 8-6" 14- 8" 20- 12"

11/2 - 11/4"

OUTLET SIZE. INCHES

31/2- 2" 5 - 3"

11/2- 11/4" 21/2- 2"

OUTLET SIZE

11/4" 11/2"

8 - 4"

11/2-11/4"

21/2 -2"

11/2"

11/2" 2"

36- 6" 36- 8" 36- 20" 36- 28" 36- 16"

21/2-2" 31/2 -21/2"

11/2" 2" 3 -21/2" 5 -4" 5"

11/2"

-INCHES

5- 3"

11/2" 2" 5 -4" 4" 6"

2"

3 - 21/2" 4 - 3" 6- 5" 10- 8" 24 - 20"

2"

2" 21/2" ]" 4"

31/2 -21/2"

2"

21/2" 4 -31/2"

3" 4" 14- 12"

21/2" 4 - 31/2"

3" 4" 14-12"

- 10" 36 - 16" 36 -22"

36

5 -4" 6 -5" 10-8"

31/2 -3" 4 -31/2" 6 -5"

21/2" 3" 4"

-INCHES

21/2"

5 -31/2" 10-6" 8 -6"

2" 21/2"

6- 4"

8 - 6" 14- 8" 20 - 12"

31/2- 21/2" 5 -4" 6- 5" 10- 8"

2"

2" 21/2" ]" 4"

31/2 -3" 4 -31/2" 6 -5"

21/2" 3" 4"

36- 28" 36 - 14"

6- 4" 26 - 12" 12-8" 18-12"

-21/2" 10-6" 6 -5" 10-8"

31/2

31/2 -3" 31/2" 5"

21/2" 3" 4"

]" 4"

31/2 -3"

]" 4"

6 -5" 18 -16"

10"

8"

6"

20- 12" 34- 26"

6- 5" 18- 16"

10"

8"

6"

FLATSI

available

I/a" thro.

6" pipe

outlet.

Tradition

line of ru

pipe size

available

on inquir

Size on

Size are

4"

conventi.

funneled

inlet desi

36- 20"

ES

gh

al

n

y.

nal

gn.

1/16"(~~hAP

MAXIM ~

1 <-. 36"RUNPIPE

SKIRT GAP

HOW CONDENSED SIZE WORKS:

Eachforged outlet size listed on the chart is designed to

fit a range of pipe run sizes.

For example: The 1/2"fitting marked 36-3/4" will fit each pipe

run size from 3/4" to 36". There will be a maximum 1/16"gap as

illustrated in diagrams. This gapis negligible when welding and

has no adverse effect on the integrity of the connection.

MINIMIZE WARHOUSE INVENTORY

CROTCH GAP

3/4" - 36" RUN PIPE

Page 5

...

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

+

STANDARD

1/4" .652 .364 .625 .302

3/a" .750 .493 .750 .423

1/2" .750 .622 .750 .546

3/4" .875 .824 .875

I" 1.063 1.049 1.063 .957 .50

11/4"

11/2" 1.313 1.610 1.313 1.500

2" 1.500 2.067 1.500 1.939 1.29 1.35

21/2" 1.625 2.469 1.625 2.323 1.75 1.82

3" I.750 3.068 1.750 2.900 2.63 2.75

4" 3.000 4.026 2.000 3.826 4.30 4.45

5" 2.125 5.047 2.125 4.813 9.59 6.39

6"

8"

10" 3.06 10.02 3.69 9.750 27.22 36.19

12" 3.38 12.00 4.06 11.750 34.00 67.00

14" 3.50 13.25 3.94 13.000 56.00 72.25

16" 3.69 15.25 4.18 15.000 76.00 102.10

18" 3.81 17.25 4.38 17.000 97.00 129.75

20" 4.00 19.25 4.69 19.000 120.00 166.00

24" 4.56 23.25 5.50 23.000 194.61 262.00

1.250 1.380 1.250 1.278

2.375 6.065 2.375 5.761 12.00 17.60

2.750 7.981 3.875 7.625 23.00 34.80

TRANS-O-CON@Butt-Weld Reducing Sizes

EXTRASTRONG I

.08 .10

.09

.35 .40

.742

.40

.70 .80

.75 .85

MSS SP-97

.15

.45

.60

STRAIGHT

THRU

BORE

.....................................................................................................................................

.....................................................................................................................................

TRANS-O-CON@Threaded Reducing Sizes

MSS SP-97

.

.

I/a" .750 .328 .875

1/4" .750 .437 .875 .10

3/a" .813 .562 1.000 .16

1/2" 1.000

3/4" 1.063 .906 1.438 1.438 .906

I"

11/4" 1.359 1.469 2.188 1.469 .90 1.50

11f2" 1.375 1.719 2.436 1.688 1.719 3.000 1.40 1.90

2" 1.531 2.188 2.938 2.063 2.188 3.625 1.80 5.00

21/2" 1.813 2.528 3.438 3.00

3" 2.000 3.203 4.125 4.35

4" 2.250 4.203 5.125 7.10

1.313 1.141 1.813 1.563 1.141 2.250 .70 1.20

NOTE: NPTThreads

to 81.20.1.

IItH-.

6000# ul

.703 1.250 1.250 .703 1.563

1.813

,"J;j;{.>.«.~::H

IiI.I'J~I.J,.'"

11111"1__.1"111-'

.10

.25 .40

.38 .70

~ NEW FORGING

TECHNOLOGY ~

i:SOO::'4.i:j674.p~~~~~.I~~.~i~..:... i:ssii.7.44:ij26L~~i;i.~~~...

Page 6

. .

...

TRANS.O.CON@Socket Reducing Sizes

MSS SP-97

.

I/a" .750 .364 .10

1/4" .750 .364 .10

3/a" .813 0493 .16

1/2" 1.000

3/4" 1.063

I" 1.313 1.049 1.563 .8153 .70 1.10

J1/4" 1.359 1.380 1.625 1.160 .90 1.50

11/2" 1.375 1.610 1.668 1.338 1040 1.80

2"

21/2" 1.563 20469 2.75

3" 1.750 3.068 3.80

4" 1.875 4.026 7.25

1/16" NOTE: Socket minimum depth per ANSI B 16.11.

1111I-.

.622 1.250 0464 .25

.824 10438 .612

1.531 2.067 2.063 1.687 1.80 4.70

+

6000#

'11I'.;__.11111I-.

AS

.38 .70

.....................................................................................................................................

.....................................................................................................................................

TRANS.O.CON@Elbow. Lateral Connections

3000# for 90° long radius pipe elbows ButtWeld / Socket / Threaded

SIZES SIZE WEIGHT

(INCHES) (INCHES) C

ELBOW

36 -3/4" 1/2"* 1.500

36 - I" 3/4"* 1.813

36- 2" I" * 2.250 2.188

36- 2" 11/2" 3.125

36- 3" 2" 4.188

45° LATERAL

THREADED

LATERAL

CONNECTION

I OUTLET .-wl[)]IIMIE::INS:1I[O.]NS:1...n..

1/2"*

12-3 12 - 6 12 -6 12 -6 12 -10 12 - 10

21/2

-11/4 5 -3 5 -3 5 -3

3/4"* 11/4" 11/2"1"* 2"

21/2- 2 21/2- 2 21/2- 2 5-4 5-4

*Available in 6000#

SOCKET

LATERAL

CONNECTION

E

1.594 .50

1.875 .70

2.625 2.65

3.185 5.25

APPROX.

POUNDS

1.15

8-6 8-6

THREADED

FULL

PENETRATION

WELD

SOCKET

FULL

PENETRATION

WELD

NOTE: Butt-Welding end dimensions to ANSI B16.9 and ANSI B 16.25.

.Ui:800-44.:j.74'p;.;;;YI~';';j~.U:..i:...:7.;':,'ii6.':;';;~i';;';;.. u. U 00 0000 ... . U U U. 00 U. U U. U U. U U U 00 00.00 0000.001

Loading...

Loading...