Phoenix SPC10e Instruction Manual

Instruction & Maintenance Manual Sheet 1.21

INSTRUCTION MANUAL

For the

Phœnix

‘SPC10e’

Self Propelled

Metering

Chipping Spreader

Section 1.2

Drive Controls,

Engine & Transmission System

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.22

Blank

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.23

1.2.1 Operator’s Position -

Layout of Controls & Instruments

Always enter the Operator’s (Driver’s) position by climbing the

access steps to the front on either side. Normally enter the

machine from the LH side as the armrest and joystick obstructs

access for the RH side.

A second seat allows for an additional person to be carried.

However, there are no operating functions for this person. Any

person in this seat must not distract the operator.

HAZARD WARNING

DO NOT CARRY other persons, other than where the

seat is provided.

DO NOT ALLOW any person to climb onto or off the

machine whilst it is moving, including use of the

normal access steps.

AT NO TIME leave the operator’s position with the

machine still moving. ALWAYS place drive control to

neutral and apply the parking brakes.

ALWAYS ENTER & EXIT the operator’s position via the

access steps unless in an emergency you are unable

to do so.

Once seated in the main operator’s position, the controls

necessary to operate the machine are grouped around the seat.

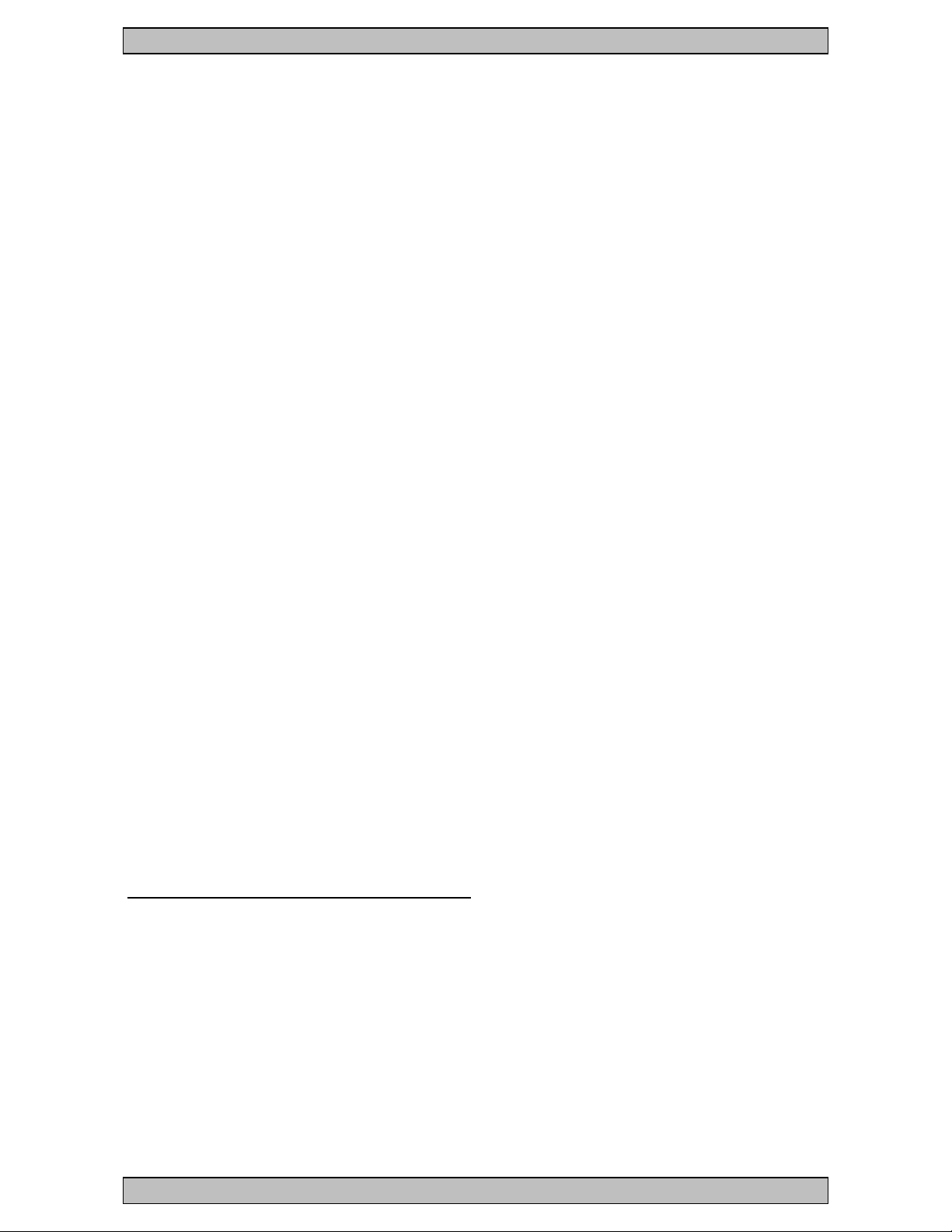

Seat and Front Steering Column

The operators seat is fitted with a self contained air suspension

to protect the operator from the immediate vibration of the

machine’s motion. The seat is adjustable for height,

forward/rearward position, back rake and posture.

The front steering column and console is adjustable for angle so

that it can be moved towards the seat or towards the

windscreen. A locking screw on the LH side under the main

console slackens the column to allow adjustment.

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.24

A new operator should adjust the seat and column to their

individual comfort and to ensure that all controls are easily at

hand without, particularly ensuring the foot brake can be

reached in an emergency.

IMPORTANT

Ensure the column is locked and secure BEFORE

moving off.

DO NOT attempt to adjust the column with the

machine in motion.

The cab floor, either side of the centre is glazed with Perspex to

allow the centre spread feedroller to be visible. The Perspex

panels are hinged and a square key is provided to allow them to

be opened for cleaning.

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.25

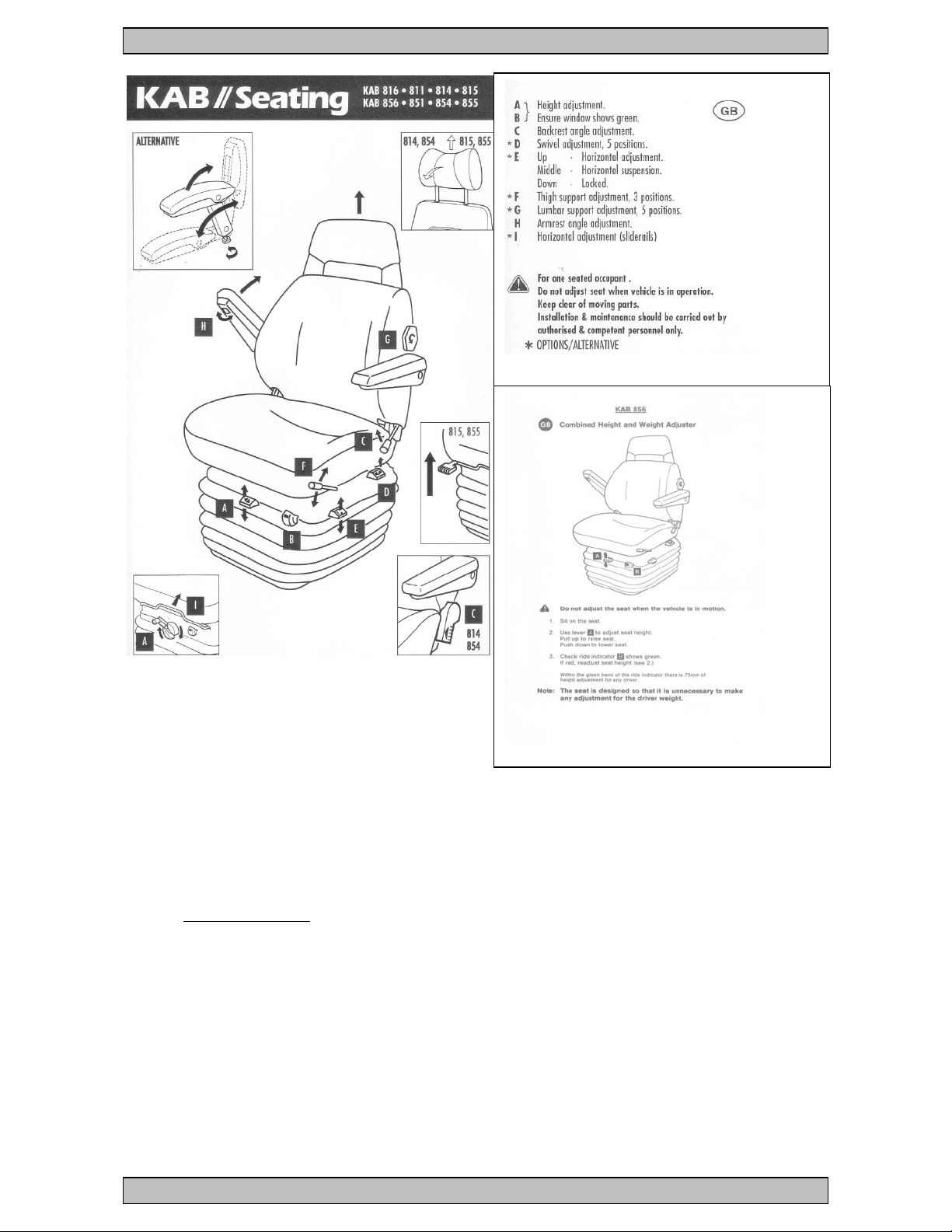

Visibility & Mirrors

Five mirrors are provided on the cab frame to give full side and

rear visibility. These should be set so that the full envelope of

the machine; over the rear receiving hopper; across to the

extension spreading hoppers & down the sides of the machine;

can be viewed, particularly any person moving around the

machine.

When correctly adjusted, using all five mirrors together, it is

possible to see a person continuously as they move around the

machine remaining close to the side and back; i.e. within

300mm

[1 ft]. However the area immediately behind the rear receiving

hopper can be partly obscured and may require the rear hopper

sides to be in the lowered position.

HAZARD WARNING

With the rear folding sides in their raised position,

the area immediately behind the machine may not be

fully visible. When reversing, either lower the folding

sides to give make this area fully visible or move the

machine one metre forward to check the reversing

area is clear before starting the reverse manoeuvre.

Always ensure when carrying out reversing

manoeuvres that the area to the rear and immediately

to the sides into which the machine is moving is clear

of any persons or obstruction. STOP IMMEDIATELY if

your visibility is restricted into this area.

Convex mirrors distort perspective - people and

objects may be closer than they appear in the

mirrors.

IMPORTANT

The mirrors must all be present and adjusted, as

stated below before using the machine.

There are FIVE rear view mirrors fitted to the machine that must

be adjusted as follows –

Rear view inside cab gives a view over the operator’s

shoulder. Adjust so that both sides of the rear receiving

hopper are visible when lowered. The view should also

allow the inside of the raised body of the supply truck to be

seen when being towed.

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.26

Top side mirrors (LH & RH), located at top of mirror arms,

give a rear view along the side of the machine so that the

area immediately behind the front hopper and back is

visible. Adjust so the top of the rear tyre is visible in the

centre inside of the mirror. This gives a view into the top of

the front spreading hopper of the machine on the inside of

the mirror and a view into and over the rear receiving

hopper folding side on the top inside of the mirror.

Bottom side mirrors (LH & RH), located at bottom of the

mirror arms, give a side view immediately outward of the

front spread hopper and back along the side, including the

extension spreading hopper when out. Adjust so the area

immediately to the side of the machine (side of front

spreading hopper) is visible. Approximately 3 metres

further to the side of the machine and rearward to the

centre of the machine should be visible.

A further sixth mirror is located at the level of the

operator’s platform, front LHS or RHS, attached to its own

arm. It is placed to view the centre spreading feedroller. It

can be adjusted to see about 2/3rds of the feedroller and

the aggregate falling to the road surface. It can be placed

on either side of the cab as desired. This mirror is not

required for safe manoeuvring of the machine. It is however

of the same type as the side mirrors and may be used to

replace them should the need arise.

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.27

Reverse Warning Bleeper

The reverse warning bleeper will sound at a high pitch to attract

the attention of anybody close to the machine. When reverse is

selected it will sound to alert anybody to the side or behind the

machine that it is immediately about to manoeuvre backwards.

The volume emitted by the bleeper will increase as background

noise increases.

IMPORTANT

DO NOT obstruct the reverse warning bleeper, as this

may effect the sound level emitted.

Daily, before starting to use the machine the reverse

warning bleeper MUST be tested to ensure its

operation.

There is no manual OFF switch provided and the

reverse warning bleeper must always sound when

reversing.

Hazard Warning

DO NOT use or continue to use the machine unless the

reverse warning bleeper is working.

DO NOT rely on the reverse bleeper sounding to ensure

that people move clear of the machine. Always check and

continue to look all around the machine with the visibility

aids supplied.

DO NOT allow the machine to roll back without selecting

reverse gear, as the bleeper will not sound.

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.28

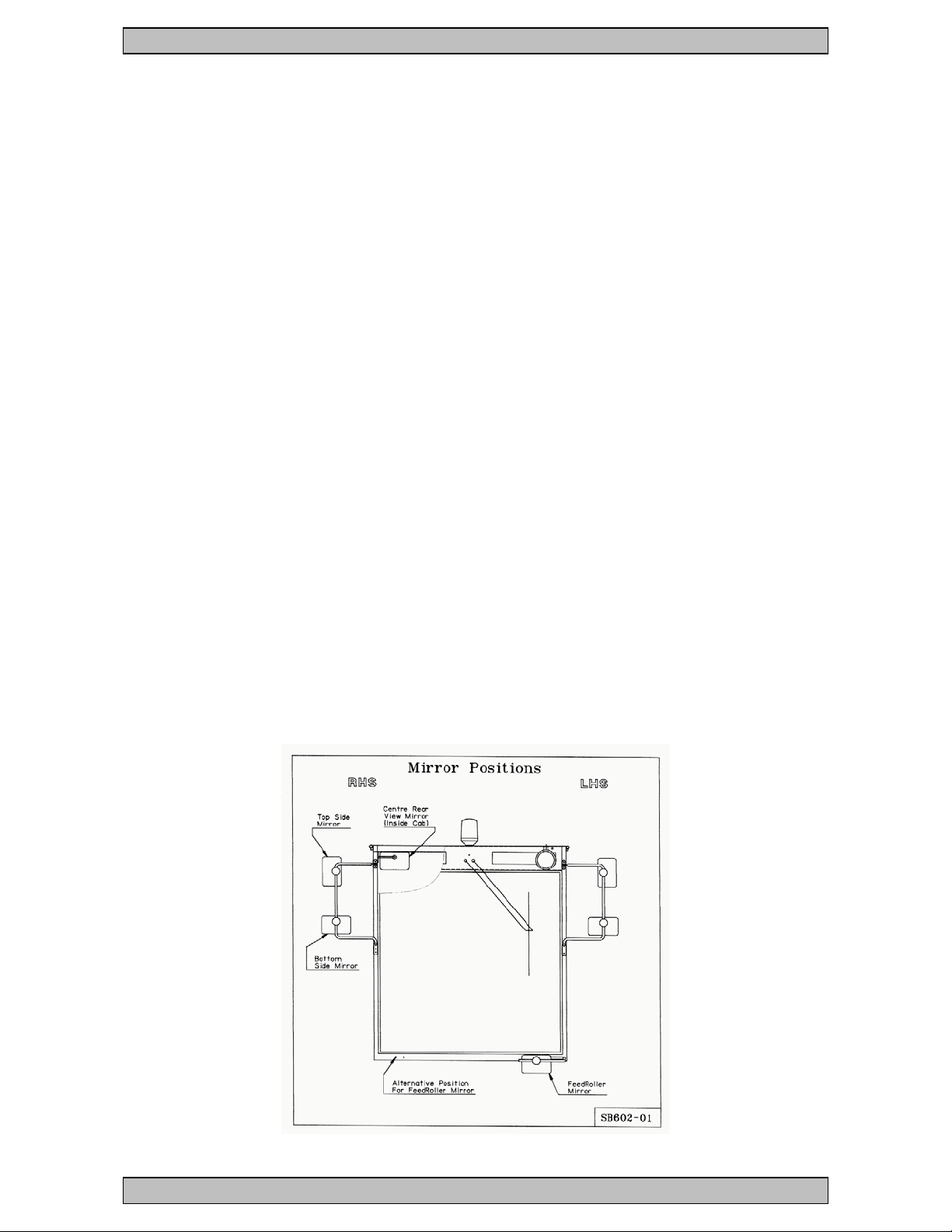

Controls Layout – Front Console

H

H

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Instruction & Maintenance Manual Sheet 1.29

Control & Gauge Types and Locations

The following engine and transmission controls are provided for

the operator of the ‘SPC10e’. They are located in either the –

Front steering column and console, immediately to

front

Stack on steering wheel column

Side arm console (part of seat arm rest)

Foot controls in floor under the front console

Right (RH) console adjacent to right armrest

Overhead console above the windscreen

Location

Ignition switch (key switch) front console

Engine throttle control switch - PERKINS front console

Engine throttle control switch - JCB RH console

Parking Brake RH console

Brake foot pedal (service brake) floor

Steering control (wheel) front console

Joystick with additional switches side arm console

Speed control switch (Low/High) front console

Ground Speed Adjuster RH console

Ground Speed ON/OFF switch RH console

Indicator/headlamp dip/horn stalk stalk

Headlamp/sidelamp switch front console

Headlight dip/mainbeam control stalk

Horn warning switch stalk

Hazard beacon switch. front console

Fog light (rear) switch front console

Windscreen wiper switch overhead console

Windscreen washer switch. overhead console

Working lights – Cab roof overhead console

MidRange Speed switch front console

See Fig. SE902-10,

SE902-05B (PERKINS) &

SE902-26D (JCB)

Phoenix ‘SPC10e’ Self Propelled Metering Chipping Spreader 03/12

Loading...

Loading...