Page 1

Owner’s Manual

Assembly and Maintenance Instructions

THIS GAS APPLIANCE IS DESIGNED FOR OUTDOOR USE ONLY.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. Open Lid.

4. If odor continues, immediately

call your gas supplier or your

fire department.

FOR YOUR SAFETY

MH49347

Model: SDRIVDD - SDRIV4LDD - SDWELD

THESE INSTRUCTIONS SHOULD BE LEFT WITH

THE CUSTOMER. KEEP THESES INSTRUCTIONS

FOR FUTURE REFERENCE.

YOU MUST READ THIS OWNERS MANUAL BEFORE

OPERATING YOUR GAS GRILL.

1. Do not store or use gasoline or

other flammable vapors and liquids in the vicinity of this or any

other appliance.

2. An LP cylinder not connected

for use shall not be stored in

the vicinity of this or any other

appliance.

FOR YOUR SAFETY

Follow all leak-test procedures

carefully in this manual before using. Do this even if the grill was

dealer assembled. Do not try to

light this appliance without read-

ing the “Lighting” instructions in

this manual.

3/17

Page 2

Note To Customer:

We recommend that you “break in” your grill by cooking the first two or three times at medium or low

temperature settings. This allows the cast aluminum drip pan to “season/break in’.

Caution: We recommend after each use, you turn the control knobs to HIGH (with the lid closed)

and run the grill for approximately 10 minutes. This will allow the accumulated fats and greases to

cook off, and avoid a possible flare up on the next use. HINT: The fats and greases are cooked off

when no more smoke is flowing from the grill vents.

READ this book first!

SAVE this manual for future reference!

Safety

Your new gas grill is a safe, convenient appliance when assembled and used properly. However, as with all

gas-fired products, certain safeguards must be observed. Failure to follow these safeguards may result in

hazardous fire or an explosion causing serious bodily injury or property damage. If you have any questions concerning the assembly or operation of this appliance after reading these instructions thoroughly, consult your dealer, gas appliance serviceman, or your propane gas company.

CALIFORNIA PROPOSITION 65 WARNING: Chemicals known to the Sate of California to cause

cancer, and birth defects or other reproductive harm are created by the combustion of propane, charcoal,

wood products, or natural gas used with this grill, and in the preparation of grilled foods.

The SAFETY symbol identifies the most important safety messages in this manual. When you see

the SAFETY symbol, Be Alert to the possibility of personal injury and carefully read the messages that follow.

Installer: This instructions MUST be left with the consumer.

Consumer: Retain these instructions for future use.

SAFETY

For Your Safety

Never check for gas leaks with a lighted match or open flame.

-This grill is for outdoor use only.

-Never leave a lit grill unattended.

-Do not let children operate or play near your grill.

-This grill is for use with propane gas only.

-Always leave filled cylinders outdoors.

Plan The Location Carefully

This grill is for outdoor use only. The grill is not to be used in a building, garage or any other enclosed area.

Installation of this appliance must be in accordance with all applicable local codes and gas utility requirements. In the absence of local codes, installation must be in accordance with current National Fuel Gas Code,

Z223,I/NFPA54 (Latest Edition) or CAN/CGA-B149.1, Natural Gas Installation Code or Can/CGA-B149.2 Propane Installation Code.

This appliance is for outdoor installation only in a well ventilated space. This grill is not intended to

be installed in or on any recreational vehicle and/or boats.

2

Page 3

SAFETY

IMPORTANT!

Check for compliance to these safety rules before each use!

-Maintain a minimum clearance of 24 inches

(61 cm) from sides and back of the grill to

any combustible construction.

-Do not use this appliance under overhead

combustible surfaces.

-Always keep the area around the grill clear

from any combustible materials, gasoline,

and other flammable gas and liquids.

-Do not block air to the appliance.

-Do not block ventilation openings.

LP Gas Cylinder

The LP Gas Cylinder which you purchase separately for use with this grill must meet the following requirements and be equipped with a

listed Overfilling Protection Device.

All LP gas cylinders used with this appliance

must be approximately 12" (30.5 cm) in diameter and approximately 18" (45.7 cm) in height.

The maximum fuel capacity shall be 20 lbs.

(9.1 kg) of Propane (43.7 lbs. normal water capacity). The propane tank must be provided

with a shut-off valve terminating in a propane

gas tank valve outlet and be provided with an

overfilling protection device.

Please Note: Your Propane Tank accepts a

Type I, also known a “Quick Connect

Valve”

SAFETY

OPD—Overfilling Protection Device

As stated, the cylinder you purchase must be

equipped with an overfilling protection device.

This type of cylinder can be identified by its triangular shaped tank valve and handle (see

page 9 for diagram of tank valve and handle).

Be Certain if you exchange your cylinder, that

the cylinder you receive in exchange has this

new OPD safety device.

The cylinder must be arranged for vapor withdrawal and remain in the upright position. The

cylinders must include a collar to protect the

cylinder valve.

All LP gas cylinders used with this appliance

must be marked in accordance with the specifications for LP gas cylinders of the US Depart-

ment of Transportation (DOT), or the National

Standard of Canada CAN/CSA-B339 Cylinder, Spheres and Tubes For Transportation of

Dangerous Goods, and Commission as Applicable.

Use of LP Cylinder

Refer to the assembly instructions section

and the label on the LP cylinder for guidance on proper installation and disconnection of the LP cylinder.

SAFETY

Use of Cylinder Dust Cap

The cylinder dust cap provided with your tank

must be used whenever the cylinder tank is

not connected to the grill gas system. Install

the dust cap onto the tank valve. Always use

the tank dust cap and be sure the tank valve

is closed when storing or transporting the

tank.

NOTE:

-The tank valve must be closed even when

using the dust cap.

-Always transport, store and use the tank in

an upright position.

-DO NOT take or store the tank in a building,

garage or enclosed area.

-Always keep the tank valve closed when the

grill is not in use.

-When removing the dust cap, do so slowly

and only after checking to ensure that the

tank valve is still closed.

-Read and follow all safety rules in your in struction books and on cylinder tank.

SAFETY

Filling the LP Cylinder

Have the tank filled by a reputable propane

gas dealer. The air must be purged from the

tank by your propane gas dealer before the

first filling. Have your propane gas dealer

check the relief valve after filling to ensure

that it remains free to function, and check for

leaks.

SAFETY Storage

DO NOT store the LP cylinder in direct sunlight. When the grill is to be stored indoors,

the propane tank MUST be disconnected. The

propane tank must be stored outdoors in a

3

Page 4

well ventilated space, NOT in a building, garage, or any other enclosed area. It must be out

of reach of children. A dust cap MUST be used

whenever the tank is disconnected from the

grill. When grill is not in use, close propane tank

cylinder valve.

When the propane tank is connected, the grill

must be stored outdoors in a well ventilated

space, not in a building, garage or any other

enclosed area. Always close the propane tank

before disconnecting it from the grill or when

the grill is not in use.

If the grill is going to be stored for winter or for

an extended period of time, we suggest you follow these steps:

-The burner should be cleaned and coated

lightly with cooking oil to prevent from rusting.

-The venturi openings should be covered with

aluminum foil to prevent small insects from

entering the opening during storage and must

be removed before using.

-The grill should be covered if it is left outdoors.

Grill covers are available as an accessory.

-Follow the cleaning procedures.

Hose and Regulator

The pressure regulator and hose assembly supplied with the appliance must be used. This

pressure regulator is preset for an outlet pressure of 11 inches (27.9 cm) water column.

Therefore, this pressure regulator MUST be

used with your Phoenix Grill. Before each use

of the grill inspect the hose for wear, cracking

and examine for any cuts. If any these conditions exist, do not use, purchase a new hose

and regulator. If a replacement is needed, refer

to the parts list for the part number and contact

the dealer where your grill was purchased. Refer to “Connecting the Cylinder to the Grill”

for details of hooking up your regulator to the

LP gas cylinder. Make sure a leak test is performed every time you have your LP gas cylinder refilled, and visibly inspect for excessive

wear and damage on a regular basis. Always

follow the directions for the “Leak Test”.

Natural Gas

Your grill may be converted to natural gas by

replacing the LP Valve with the appropriate Natural Gas Valve. (Part #HHVLV32-SD). A conversion should only be made by an authorized

Phoenix Grill dealer or local gas utility in accordance with all applicable codes. CAUTION:

Any additions, changes, or conversions required in order for the appliance to satisfactorily

meet the application needs must be made by a

Phoenix dealer or local gas utility using factory

specified and approved parts. Always remember to shut gas off at gas connection when grill

is not in use.

SAFETY

Leak Test

Check for leaks before lighting the grill for the

first time, after storing the grill between seasons

and after refilling the propane cylinder.

Take your grill outdoors into a well ventilated area. Do not use or permit sources of ignition in the area during this test, this includes smoking. Use only a soap and water

solution to test for leaks.

Leak Test Check List

-Tank valve (all over) including area that

screws into the tank and the welds.

-Regulator fitting

-Hose connections

-Valves

Mandatory Leak Test

1. Have propane tank filled with propane gas

only by a reputable propane gas dealer.

2. Attach regulator fitting to tank valve.

3. Tighten regulator fitting securely.

4. Turn the control knobs to the right, clockwise.

This is the “OFF” position.

5. Make a solution of half liquid detergent and

half water.

6. Turn gas supply “ON” at the tank valve

(counter clockwise).

7. Brush soapy mixture on all connections listed

in the Leak Test Check List.

8. Observe each place for bubbles caused by

leaks.

9. Tighten any leaking connections, if possible.

If leak cannot be stopped, DO NOT USE

THE GRILL. Order new parts from an

authorized Phoenix dealer. Do not use the

grill until after the new parts are installed.

After installing new parts, perform complete

leak test.

10. Turn gas supply “OFF” at the tank valve.

4

Page 5

Phoenix Grill WARRANTY

LIMITED LIFETIME WARRANTY ON THE FOLLOWING:

(Against Rust Through)

Welded Stainless Steel Grill Top & Bottom

10-YEAR WARRANTY ON THE FOLLOWING:

(Against Rust Through)

• Riveted Stainless Steel Grill Top & Bottom • Stainless Steel Control Panel •

Stainless Steel Column & Base • Stainless Steel Burner • Stainless Steel Cooking

Grid • Stainless Steel Side Shelves • Cast Aluminum Drip Pan

1-YEAR WARRANTY ON THE FOLLOWING:

(Against Rust Through)

All other Components including; • Igniter System • Gas Valves • Knobs • Drain Valve

• Temperature Gauge • Grease Bucket • Hose & Regulator

• Wheels • Hood Handle

WHAT IS NOT COVERED:

Surface Corrosion and Discoloration • Transportation and shipping cost • Labor for replacement or repairs • Damage from accident, misuse, alteration, abuse, improper installation or

storage • Removal and reinstallation costs • Finishes on surface that are damaged by improper installation, improper storage, accident, misuse, abuse or alteration • Inoperable due

to improper installation or storage • The costs of a service call to diagnose a problem • All

warranties are non-transferable and apply only to the original purchaser • Warranties are

null and void if grills are put into commercial or community use. This warranty does not imply or assume any responsibility for consequential damages that might result from use, misuse, or improper installation of this cooking appliance. This warranty does not cover claims,

which do not involve defective workmanship or materials, bill of sale, cancelled check, or

payment record should be kept to verify purchase date and establish warranty period.

MODEL IDENTFICATION

Your Phoenix Grill is identified by a model number and a serial number located on the left side of the control panel. Always

use both the model and serial numbers when contacting ProFire Grills about your grill. For future reference, take the time

now to record the model and serial numbers below:

MODEL NUMBER: ______________SERIAL NUMBER: ________________DATE PURCHASED:__________________

How to contact us: phone: 1-888-781-4657, fax: 1-800-781-3965, E-mail: info@profiregrills.com or write: Customer

Service, ProFire Grills 5565 North 124th Street, Butler, WI 53007.

5

Page 6

GETTING TO KNOW YOUR PHOENIX GAS GRILL

Vents on

Back of Lid

Side Shelf

Grill

Fire Pit

Control Panel

Column

Base

Locking Casters

Heat Indicator

Grill Lid

Sta-Kool

Swivel Handle

Match

Hole

Electronic

Igniter

Left and Right Burner

Controls

Drip Pan Drain

Valve

Grease/Water

Collector Bucket

Dual Burner and

Gas Collector Box

INSIDE VIEW

Stainless Steel

Cooking Grid

Vents On

Rear Of Lid

Back View of

Column

Cast Aluminum

Drip Pan

Tank

Locking Bar

On Propane

Model

12 Ft. Hose with

Quick Disconnect

Included with

Natural Gas Model

6

Page 7

Phoenix Grill Assembly Instructions

Carton contains the following components for assembly:

Please check to be sure that all parts are included before proceeding.

Contact your dealer or the factory if any parts are missing.

Hardware/Fasteners

Grill and Cart Components

Grill Lid 1

Grill Bottom with Pre-Assembled Burner, Gas

Collector Box and Igniter Wire

Hinge Pins and Clips 2 Each

Column 3 (Front, 2 Sides)

Tank Locking Bar (See Pre-Pack Below)

(Propane Model)

12 Ft. Hose with Quick Disconnect

(Natural Gas Model)

Base 1

Locking Casters 4

Control Panel with Pre-Assembled Valve,

Hose, Regulator and Igniter

Burner Control Knobs 2

Electronic Igniter 1

Temperature Gauge 1

Shelf Brackets, Shelves

(See Pre-Pack Below)

Stainless Steel Handle, Handle End Caps

(See Pre-Pack Below)

1

1 Pre-Pack

1

1

1 Pre-Pack

1 Pre-Pack

HARDWARE QUAN. USE

1/4-20 x 1/2” Hex Head Bolt 12 Column to Base

KEP Nut 12 Column to Base

1/4-20 x 1/2” Hex Head Bolt 8 Heat Shield to Column

KEP Nut 8 Heat Shield to Column

1/4-20 x 1/2” Hex Heat Bolt 6 Grill Bottom to Column

KEP Nut 6 Grill Bottom to Column

KEP Nut 2 2 Threaded Studs on

1/4– 20 x 1/2” Hex Head Bolt 2 Control Panel to Column

KEP Nut 2 Control Panel To Column

Hinge Pin 2 Lid to Grill Bottom

Hinge Clip 2 Lid to Grill Bottom

1/4-20 x 1/2” Hex Head Bolt 16 Casters to Base

Fastener Totals

Hex Bolts 1/4-20x1/2 ........................................................................52

Kep Nuts............................................................................................42

Hex Bolts 1/4-20x3/4...........................................................................4

Pan Head 10-24 x 1/2”……………………………………………………8

Nylon Lock #10…………………………………………………………….8

Lock Washer #10…………………………………………………………..8

Cast Aluminum Drip Pan 1

Stainless Steel Cooking Grid 1

Drip Pan Drain Valve 1

Collector Bucket 1

Heat Indicator 1

Tank Locking Bar- Nylon Spacer, 2 -3/4” Hex Bolt, Flat Washers (4) and Kep

Nuts (2)

Handle– Handle End Caps (2), Graphite Gasket (2), Hex Bolts (2), Flat Wash-

ers (4) and Kep Nuts (2)

Shelf Assembly– Shelf Brackets (4), Shelves (2), Hex Head Bolts (8), #10

Lock Washer (8), 10/24” x 1/2” Pan Head (8), Nylon Lock Nuts

(8),and Kep Nuts (8)

Pre-Packaged Part and Fasteners

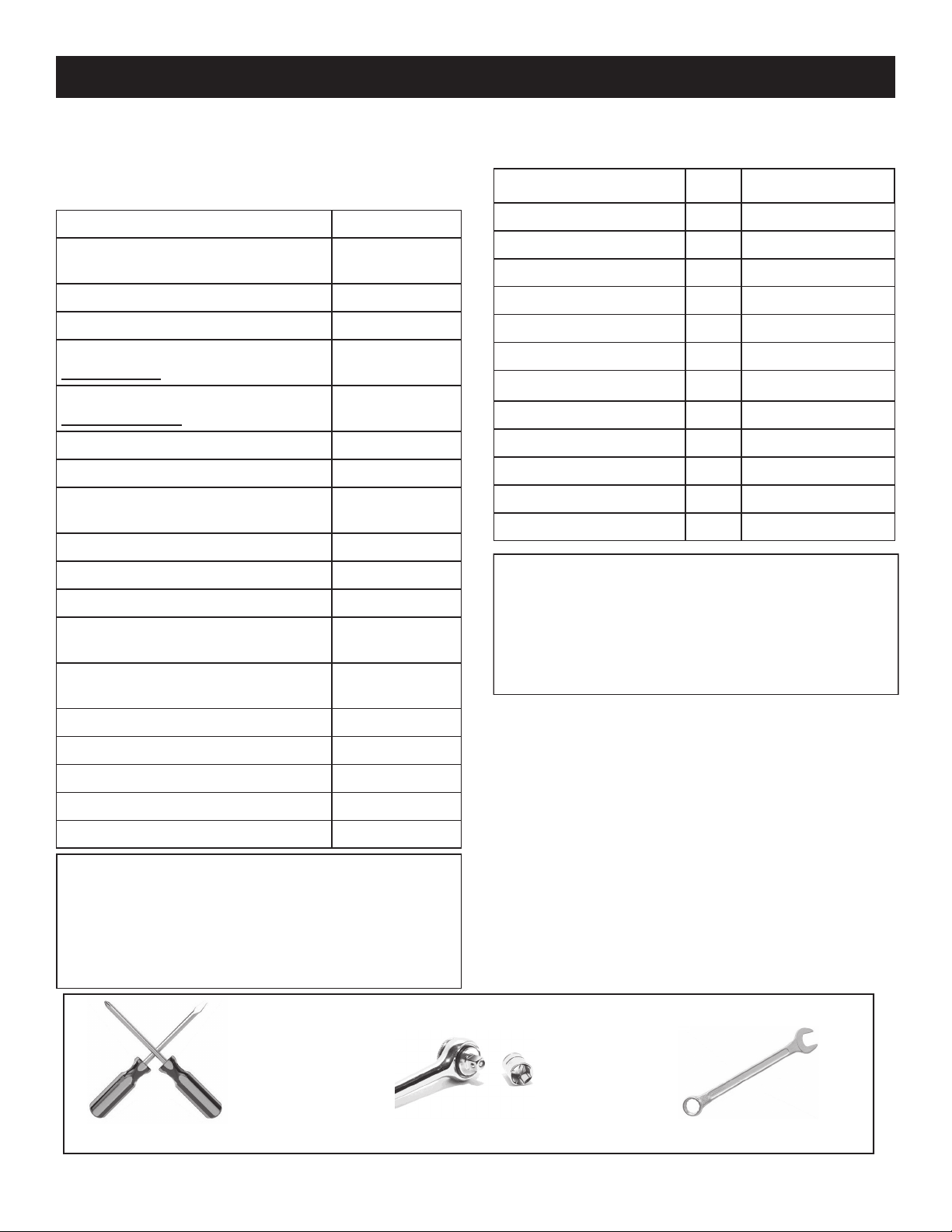

TOOLS NEEDED FOR ASSEMBLY

Phillips and Straight Screw Driver

7/16 Socket or Nut Driver

7/16 Wrench

7

Page 8

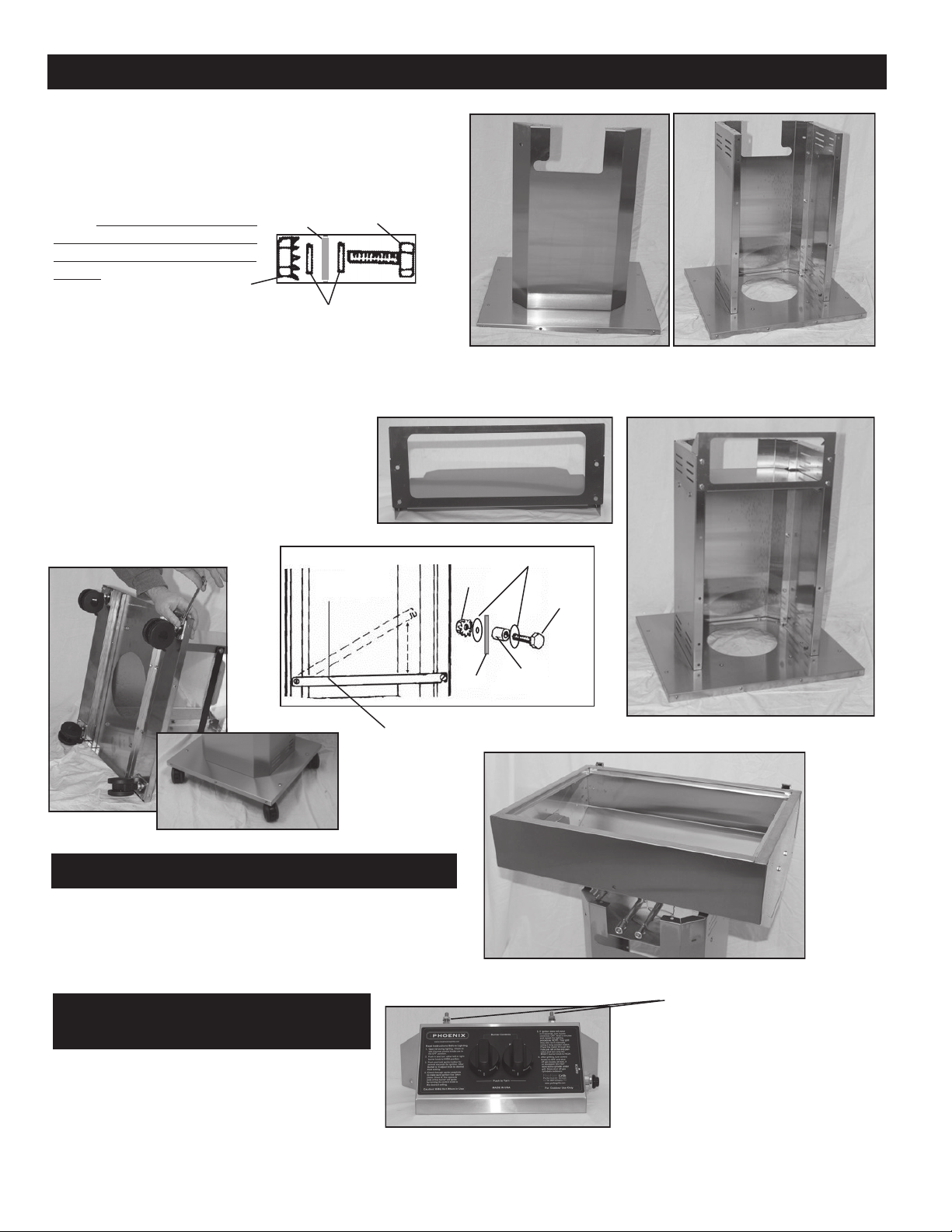

Step 1: Mounting Column to Base.

A. Attach the front (center) section of the column to the base using

2, 1/4-20 x 1/2” hex head bolts, 4 flat washers and 2 Kep nuts.

(Fig. A)

B. Attach the two (2) sides of the column to the base using 4, 1/4-20

x 1/2” hex head bolts, 8 flat washers and 4 Kep nuts. (Fig. B)

NOTE: Washers should be placed

Grill

after the hex head and before the

Kep nuts. Follow through-out assembly.

C. Attach sides of col umn sections

Kep Nut

Flat Washers

using 6 1/4-20 x 1/2” hex

head bolts, 12 flat washers and 6 Kep nuts.

D. Insert heat shield into top of column using 8 1/4-20

X 1/2” hex head bolts, 16 flat washers and 8 Kep

nuts. (Fig. D)

E. Lay base on its side and bolt caster into place with

Bolts at all 4 corners of base.

(Fig. E)

F. Attach the tank lock bar across the back of the col

umn. Use the 3/4” Hex bolt, 4 Flat Washers, Nylon

Spacer and the Kep nut on each side to fasten the

bar in place. (Fig. E-1)

Hex Headl

Fig. E-1

Heat Shield

Kep Nut

Flat Washer

Hex Bolt

Fig. A

Fig. B

Tank Locking Bar

Fig. E

Fig. E

Propane Model

Step 2: Mounting Grill Fire Pit to Column.

A. Set the grill pit onto the top of the column and align the 6 pit

mounting holes to the matching holes in the column lip.. Install

the 6 hex bolts, 12 washers and 6 Kep nuts. Tighten securely.

(Fig. F)

Step 3: Attaching Control Panel

to Grill Pit.

NOTE: The control panel has two (2) threaded studs

with a spacer nut that mounts to the fire pit allowing

airflow between the pit and control panel. Also, the

control panel comes with factory preassembled gas

regulator, hose and igniter. (Fig. G)

Fig. G

Grill

8

Nylon Spacer

Fig. D

Fig. F

Threaded Studs

Page 9

CONTINUE

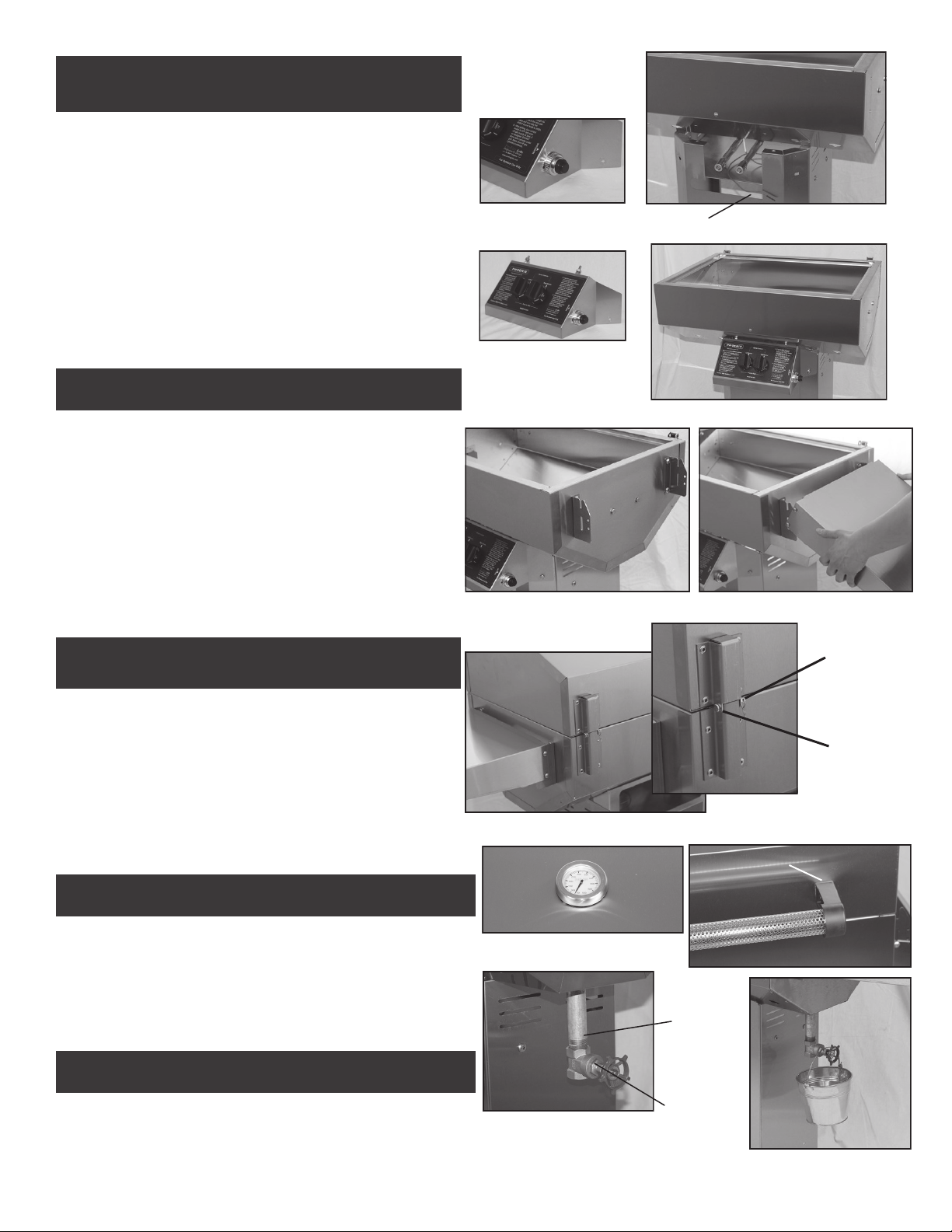

Step 3: Attaching Control Panel to Grill Pit.

A. Thread on the push button to the igniter stem. (Fig. H)

B. Attach the igniter probe wire (preassembled at factory to the gas

collector box) to the electronic spark generator. (Fig. I)

C. Attach the control panel to the front of pit by pushing the two

threaded studs thru the holes in the bottom of the pit, making

sure the venture tubes fit over the valve orifices and secure with

2, flat washers and 2, 1/4” Kep nuts. (Fig. J-1)

D. Attach the bottom of the control panel to column using 2 1/4-20 x

1/2” hex head bolts , 4 flat washers and 2 Kep nuts. Press the 2

gas control knobs onto the valve stems. (Fig. J-2)

Step 4: Attaching Side Shelves

Fig. H

Fig. J-1

Igniter Wire

Fig. I

A. Remove white film from side shelves and grill.

B. Attach brackets to grill using bolts and kep nuts to each side of

your grill as shown in (Fig. K-1) Use 2 bolts and kep nuts per

bracket.

C. Place the left bottom shelf post into the left bottom bracket slot as

shown in (Fig. K-2). Gently spread the shelf apart to insert the

right bottom shelf post into the right bottom bracket slot. Secure

bottom posts with Nylock Nut—making sure nuts are snug but do

not restrict the movement of folding and unfolding of the shelf.

Note: Top posts on shelf do not use nuts.

Step 5: Lid Assembly to Fire Pit

A. Position the top and bottom hinges together and

complete assembly using the two (2) hinge pins and hinge

clips. (Fig. L)

B. With the lid open attach the handle to the lid using two 1/4-20 x 3/4” hex

bolts, flat washers, graphite gaskets, and Kep nuts. The gaskets are

positioned between the handle end caps and grill lid. (Fig. M)

C. Install the thermometer through the hole in the center of the lid.

And snug thermometer with thumb bolt. Do Not Over Tighten.

Fig. K-1

Fig. J-2

Fig. K-2

Hinge Clip

Hinge Pin

Fig. L

Graphite Gasket

Step 6: Install Drip Pan and Drain Valve

A. With the lid open, insert drip pan into place using the lift tabs on

each end. Line up the drain pipe with the hole in the pit bottom and

make sure the drain pipe extends out the bottom of the pit. Install

the brass valve onto the drain pipe, hand tighten only. (Fig. O)

(You may need to remove the valve occasionally for cleaning.

Hang the drain bucket on the brass valve and open valve. (Fig. P)

Step 7: Install Cooking Grid

A. Place the cooking grid into the grill.

Fig. N

Fig. M

Drain Pipe

Fig. O

9

Brass Valve

Fig. P

Page 10

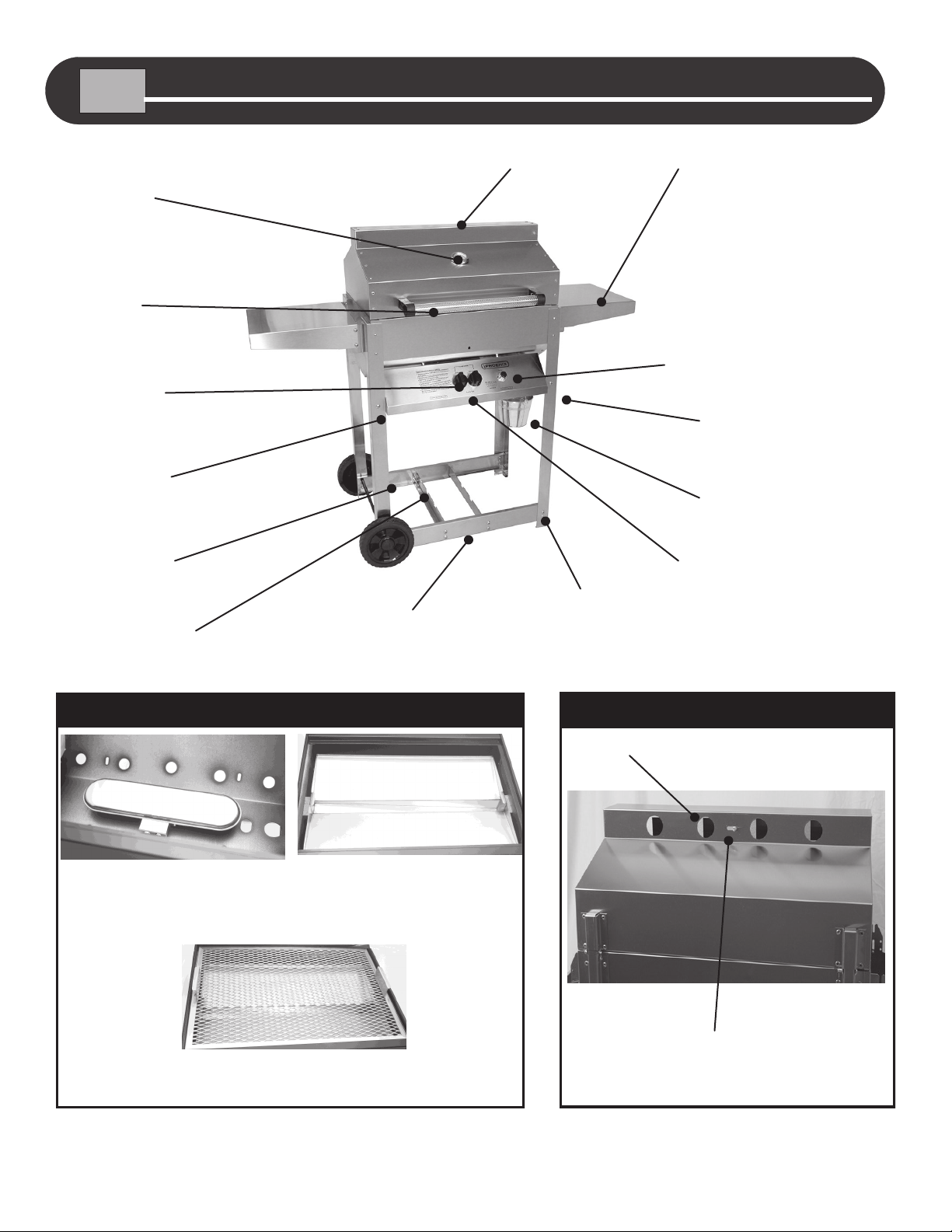

GETTING TO KNOW YOUR

SDRIV4LDD

PHOENIX GAS GRILL

Heat Indicator

Sta-Kool

Stainless

Steel

Handle

Right & Left

Burner Controls

LP Hose Ring

Holder

Short Legs

LP Tank Holder

Lower Shelf

Bolts To Each

Leg

Grill Lid

Stainless Steel

Drop Down

Side Shelf

Electronic

Igniter

Drip Pan Drain

Valve

Grease Collector

Bucket

Gas Valve In Back

Of Control Panel

Long Legs

Dual Burner and

Gas Collector Box

INSIDE VIEW

Cooking Grid

REAR VIEW

Vents

Drip Pan

Vent Slide

Page 11

PEEL ALL LASER TAPE BEFORE ASSEMBLING

SDRIV4LDD Cart Assembly

Tools Required For Assembly:

7/16” Wrench, 7/16” Socket Wrench with Extension, 3/8”

Wrench.

CAUTION: Edges of some of the grill parts may be sharp,

use care when assembling grill.

CAUTION: While handling the grill head be very careful not

to damage the Venturi Tubes or the Ceramic Ignitor Insulator

which protrudes from below the grill.

CART HARDWARE

Carton contains the following components for the cart mounting:

Please check to be sure that all parts are included before proceeding. Contact your dealer or the factory if any parts are missing.

Long Legs 2

Short Legs 2

Lower Frame Brackets 2

Lower Tank Brackets 2

8" Rubber Wheels 2

Axle 22 1/2" 1

Axle Hitch Pins 2

LP Tank Fastener 1

1/4—20 Wing Nut 1

Complete View of Cart Assembly

1/4-20 x 1/2” Carriage 1

Hub Caps 2

Hose Retaining Ring 1

1/4-20x1/2” Truss Head 18

1/4-20x3/4” Hex Head 10

1/4-20 Kep Nut 28

10-24x1/2" Pn..Hd. 11

10-x24 Kep Nut 11

10-24 Nylon Lock Nut 8

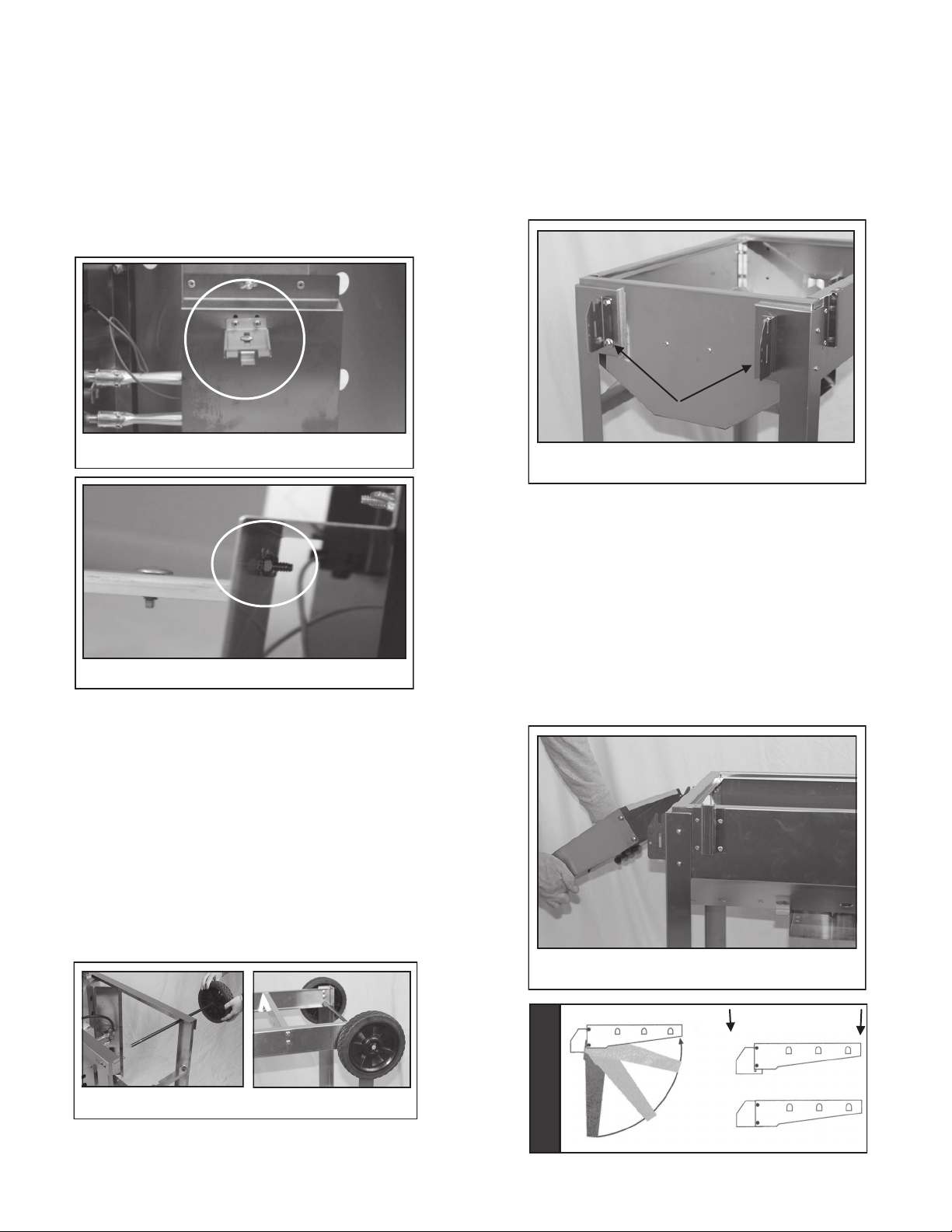

Step 1: Leg Assembly (Fig 2)

1. Tip the grill head bottom on end as shown in Fig. 2

(TIP: work on protected area such as carpet, tarp or one

of the boxes to protect grill finish.)

2. Attach the two long legs to the right end of the grill’s bot-

tom pit. Use two 10-24 x 1/2” Pan Head Bolts for each

leg. Insert bolts from outside of grill pit and fasten with 10

–24 kep nuts.

3. Flip the grill over and attach the 2 short legs to the left

side of the grill pit bottom. Use two 10-24 x 1/2” Pan

Head Bolts for each leg. Insert bolts from outside of grill

pit and fasten with 10-24 kep nuts. Note: When attach-

ing front legs make sure the control panel tab is

tucked behind the front legs as shown in (Fig. 3) The

valve stems must be seated properly in the venturi

tubes as shown in (Fig. 4) before tightening.

4. Flip grill upside down and attach the lower shelf brackets

to the front and back of the grill with four 1/4-20x1/2” Hex

Head Bolts for each bracket as shown in (Fig. 5).

5. Next attach the lower tank brackets from front to back to

the lower frame brackets as shown in (Fig. 6)Note: An-

gled edges face out.

6. Tighten all fasteners with wrench before moving on to

next steps.

FINGER TIGHTEN ALL BOLTS UNTIL

LOWER BRACKETS ARE ATTACHED.

Fig. 2

Hose Ring

Short Legs

FIG. 1

Lower

Cart Frame Bolts to

Each Leg

Long Legs

Fig. 3

Fig. 5

Fig. 4

Fig. 6

Page 12

Step 2: Installing LP Tank Fastener

1. Located on the underside of grill pit, mount the

LP tank fastener to the underside of the heat

shield with 2 10-24 Pan Head Blots as shown in

(Fig. 7).

2. Secure the LP tank fastener from the inside of

the heat shield with two 10-24 Kep nuts as

shown in (Fig. 8) and tighten with wrench.

Fig. 7

Fig. 8

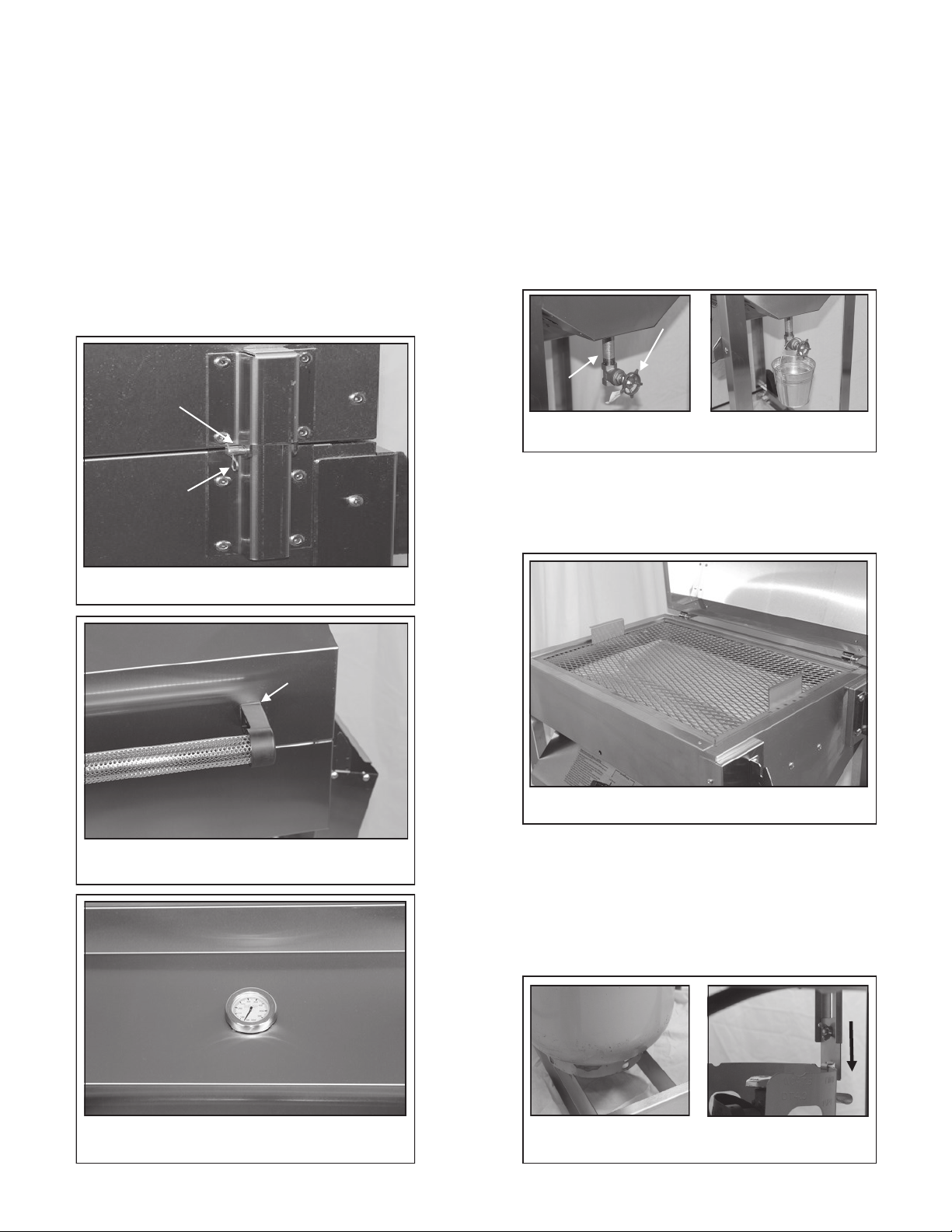

Step 4: Installing the Drop Down Shelves

Mounting Bracket to Grill

1. Attach brackets to grill using bolts and kep nuts

to each side of your grill as shown in (Fig. 10)

Use 2 bolts and kep nuts per bracket.

Shelf Brackets

Fig. 10

Mounting Shelf to Bracket

2. Place the left bottom shelf post into the left bottom bracket slot as shown in (Fig. 11). Gently

spread the shelf apart to insert the right bottom

shelf post into the right bottom bracket slot. Secure bottom posts with Nylock Nut—making

sure nuts are snug but do not restrict the movement of folding and unfolding of the shelf.

Note: Top posts on shelf do not use nuts.

Step 3: Axle and Wheel Assembly

1. Install (1) axle hitch pin into the small end hole of

the axel. Slide (1) wheel onto the axle, hubcap

side out.

2. Slide open axle end through the short leg holes

and install remaining wheel, washer and hitch

pin. Install hubcaps after the cart bolts are completely tightened.

3. Stand grill upright to seat legs and tighten all

bolts and nuts making legs and frame rigid.

Note: Recheck all fasteners for tightness.

Fig. 9

Fig. 11

LOCK INTO PLACE

OPENING SHELF

Page 13

Step 5: Lid Assembly to Fire Pit

1. Position the top and bottom hinges together and

complete assembly using the 2 hinge pins and

hinge clips (Fig. 12).

2. With the lid open attach the handle to the lid

using two 1/4-20 x 3/4” hex bolts, flatwashers,

graphite gaskets and kep nuts. The gaskets are

positioned between the handle end caps and

grill lid. (Fig. 13)

3. Install the thermometer through the hole in the

center of the lid and snug the thermometer with

thumb bolt. (Fig. 14) Do Not Over Tighten.

Hinge Pin

Hinge Clip

Fig. 12

Graphite Gasket

Fig. 13

Fig. 12

Step 6: Install Drip Pan and Drain Valve

1. With the lid open, insert drip pan into place using

the lift tabs on each end. Line up the drain pipe

with the hole in the bottom of the pit.

2. Once drain pipe is in place resting in the bottom of

the pit thread the brass valve onto the drain pipe

hand tightened only. Note: You may need to

remove the valve occasionally for cleaning.

(Fig. 15)

3. Hang the drain bucket on the brass valve and

open valve. (Fig. 16)

Drain Pipe

Brass Valve

Fig. 15 Fig. 16

Step 7: Installing Cooking Grid

1. Place the mesh stainless steel cooking grid into

the grill as shown in (Fig. 17).

Fig. 17

Step 8: Installing & Locking LP Tank Into Place

1. Place LP tank into slots in support shelf on the

bottom of grill cart as shown in (Fig. 18).

2. Slide the LP tank lock down as shown in (Fig. 19)

and tighten wing nut to lock in place.

Fig. 18 Fig. 19

Page 14

Gas and LP Tank Connections

CONNECTING THE LP CYLINDER (Fig. R)

Install the gas cylinder in the back of your grill, with the open side of the

tank valve collar pointing towards the square hole in the tank enclosure.

Ensure that all hoses, fittings and regulators are properly protected from

heat and accidental damage. Hoses can be burned or chaffed if routed

improperly. (See Hose and Regulator, page 3). Be sure all burner con-

trol valves on the grill are turned “OFF”. To connect hose and regulator

to cylinder turn coupling nut clockwise as shown in diagram below (Fig.

R). (To remove the quick connect coupling nut, turn counter clockwise).

Your Phoenix Grill comes with a Type I connector, also known as a

“Quick Connect Valve” connection. It has a large plastic (coupling nut”

that screws onto the propane tank gas outlet. Note: Your Phoenix

Grill does not come with a propane tank. Therefore, be sure the

tank you purchase has this type of hook-up. Also, the cylinder you

use must be equipped with a listed overfilling protection device.

This can be identified by the triangular hand wheel. (See diagram

below and page 2 of these instructions).

Hand Wheel

Regulator

Tank

Coupling

Nut

Dust Cap

Fig. R

REMOVAL OF THE LP CYLINDER

1. Close the LP tank valve.

2. Unscrew the QCC-1 plastic nut BY HAND COUNTERCLOCKWISE (to the left).

3. Raise the tank locking bar

4. Lift cylinder off.

WARNING: If you exchange your LP cylinder, make

sure you get a similar tank in return.

Your exchanged LP cylinder must be equipped with a

QCC-1 or type-1 valve and an OPD (Overflowing

Prevention Device). Other LP cylinders may not be

compatible with your grill connection.

LP-GAS CYLINDER FILLING & HANDLING (Continued)

Air must be removed from a new LP cylinder before the initial

filling. Your LP dealer is equipped to do this.

The cylinder supply system must be arranged for vapor with-

drawal

Always keep and store cylinders in an upright, secure position.

Use this grill outdoors in a well-ventilated area. Do not use in a

garage, building, or any other enclosed area.

Storage of an outdoor cooking gas appliance indoors is permis-

sible only the cylinder is disconnected and removed from the

outdoor cooking gas appliance.

If the outdoor cooking appliance is not in use, the gas must be

turned off at the supply cylinder.

Cylinders must be stored outdoors out of reach of children and

must not be stored in a building, garage or any other enclosed

area.

LP GAS CYLINDERS SAFE HANDLING TIPS

Liquid propane (LP) gas is a petroleum product as are gasoline

and natural gas. LP gas is a gas at regular temperatures and

pressures. Under moderate pressure, inside a cylinder, LP gas

is a liquid. As the pressure is released, the liquid readily vaporizes and becomes gas.

LP gas has an odor similar to natural gas. Be aware of this

odor.

LP gas is heavier than air. Leaking gas collects in low areas

and prevents dispersion.

To fill, take the LP cylinder to your local authorized LP dealer,

or look up “gas-propane” in the yellow pages to find authorized

dealers.

A new LP cylinder must be purged before the first filling. Your

LP dealer is equipped to do this.

An LP cylinder must be transported, installed and stored in an

upright position.

LP cylinders should not be handled roughly.

Never store or transport an LP cylinder where the temperatures

can reach 125 degrees. Never leave an LP cylinder in a car on

a hot day.

Always close the LP cylinder valve before disconnecting the

tank or any other gas fitting.

Always close the LP Cylinder valve after using grill.

Do not use a damaged LP cylinder. Dented, rusty or a dam-

aged LP cylinder valve may be hazardous and should be replaced with a new one immediately.

LP-GAS CYLINDER FILLING & HANDLING

A qualified attendant, who fills the cylinder by weight, should

fill your LP cylinder at an authorized LP gas dealer. Improper filling is dangerous.

When transporting the LP cylinder be sure the plastic dust

cover is in place over the valve. This keeps the valve

threads free of dirt.

Do not handle the cylinder roughly.

Do not apply heat directly to the cylinder.

● Never fill the LP cylinder beyond 80% full.

● Do not store a spare LP gas cylinder under or near the

grill.

If this information is not followed exactly, a fire causing

death or serious injury may occur.

10

Page 15

Leak Testing and Lighting Your Grill

Leak Testing

LEAK TEST ALL GAS CONNECTIONS BEFORE USING YOUR GRILL.

DO NOT SMOKE WHILE LEAK TESTING.

DO NOT LEAK TEST WITH A MATCH OR OPEN

FLAME.

DO NOT USE A GRILL THAT IS LEAKING GAS.

YOU SHOULD TEST FOR GAS LEAKS EVERY TIME

YOU DISCONNECT AND RECONNECT A GAS FIT-

TING.

PERFORM A LEAK TEST EVEN IF YOUR GRILL WAS

DEALER OR STORE ASSEMBLED.

DO NOT IGNITE BURNERS WHEN LEAK TESTING.

LEAK TESTING

1. For LP models, leak test with a full propane cylinder.

2. For systems other than self-contained LP cylinders:

A. The grill and its individual shut-off valve must be discon-

nected from the gas supply piping systems during any

pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

B. The grill must be isolated from the gas supply piping

system by closing its own manual shut off valve during

any pressure testing of the gas supply piping system at

pressures equal to or less than 1/2 psi (3.5 kPa).

1. Grill burner control valves should be turned off and the gas

turned on at source.

2. Apply soap solution to all gas connections.

To make soap solution, mix together equal amounts of

liquid detergent and water.

3. Soap bubbles will appear if there is a leak.

4. Tighten the connection to make proper seal. And recheck for

soap bubbles.

If you cannot stop a gas leak by tightening, turn gas

supply off. Take leaking joint apart, clean it, reconnect and test again. If leak persists, contact the dealer or gas utility.

A gas system MUST be tested yearly, or whenever

the LP cylinder or any other gas system part is replaced.

Lighting Your Grill

ALWAYS OPEN GRILL BEFORE LIGHTING THE BURNER.

DO NOT LEAN OVER AN OPEN GRILL. KEEP YOUR

HEAD AND BODY AT LEAST ONE FOOT AWAY WHEN

LIGHTING THE GRILL.

IF BURNER DOES NOT LIGHT, IMMEDIATELY TURN

BURNER CONTROL KNOBS TO OFF. WAIT FIVE

MINUTES TO LET GAS CLEAR BEFORE YOU TRY

LIGHTING AGAIN.

LIGHTING

1. Open Lid. Examine the interior to be sure it appears normal.

2. Turn burner control knobs to OFF position.

3. Turn gas ON at LP tank or supply. Wait 5 seconds for regulator to set itself.

4. Turn either burner control knob to HIGH and rotate the ignitor knob CLOCKWISE several times. One half of the burner

should light. Turn the other burner control knob to HIGH and

the other half of the burner will light automatically.

5. The burner flame should be a hard blue cone with a minimum amount of yellow flame, although some yellow dust

flicks may occur.

BURNER

FLAME

GOOD FLAME BAD FLAME

6. Close the grill lid and pre-heat the grill for five to ten minutes

before cooking.

WARNING: If burner fails to light, turn control knobs OFF

and wait five minutes for gas to clear and try lighting procedure again.

To light burner manually: With the grill lid opened, open valve

at propane tank or natural gas supply. Turn the right burner

control to “HIGH” and insert lit match or lighter into match hole

located in the lower section of the fire pit and to the right of the

control panel.

To Extinguish your grill: Turn each burner control knob to

OFF position. Turn gas supply OFF at the source.

YELLOW

BLUE

YELLOW

BLUE

11

Page 16

Maintenance

Annual Maintenance

After a period of nonuse or to keep your grill in top

operating condition, you should perform the following maintenance procedures to keep the grill ready for instant use and for

your safety.

Do not obstruct the flow of combustion and ventilation air.

Clean inside the grill head. Remove the burner/venturi as-

sembly and cover the valve orifices with a piece of aluminum

foil to keep out dirt. Brush inside bottom and sides with a stiff

wire brush to remove built-up grease and debris. Be careful

not to damage the Ignitor or Collector Box.

Test the Ignitor for a good spark. (See Rotary Spark Ignitor

System in the General Maintenance section.)

The stainless steel burner may be brushed lightly with a stiff

laundry brush. Any clogged flame holes may be opened using a thin wire. Use the supplied venturi cleaning brush or a

bottle brush, pipe cleaner to clean out the venturis. (See

Flashback in General Maintenance.)

Clean the Control Panel, Side Shelf Supports, Lid Handle

Spacers, Lower Cart Frame, Posts with a mild detergent

soap and warm water solution. For the column use a mild

detergent soap and water, Windex is also great to clean the

column and grill lid facing. Do Not Use cleaning agents

such as bleach, powdered cleansers, steel wool pads or

caustic solutions like oven cleaners because they will

damage the surfaces.

Occasional white oxidation on the exterior of your grill head

and lid may be washed off with mild soap and warm water.

Severe weathering of the grill head and lid can be remedied

by lightly sanding or rubbing with steel wool. Then it can be

recoated with a high quality heat resistant paint similar to

MHP’s BF-1 Paint, available in spray cans from your dealer.

Inspect the hose and gas fittings. Remember to leak check

every time you disconnect and reconnect a gas fitting.

Keep the ventilation openings of the LP cylinder enclosure

free and clear from debris.

General Maintenance

Flashback

In some areas of the country, spiders and other insects build

nests, lay eggs and spin webs in the grill’s venturi tube or valve

orifice. This obstructs the full flow of gas to the burner. Some

gas backs up resulting in a “Flashback” - a fire in the venturi

behind the control panel which could cause serious bodily injury

or damage to your grill.

Orifice

To remove spider webs and/or other obstructions, you must

clean out the venturis. This should be done routinely if the

grill has sat idle for extended periods. Also, if you live in an

area where spiders are plentiful, you should clean the venturis often, especially in the fall when there is an increase

in egg sack production.

To clean, be sure the grill is cold. Open lid and remove the

cooking grids, the briquettes and the briquette grate.

1. Remove the burner clip holding the burner in place.

2. Lift burner and venturi assembly out. With supplied cleaning brush, a pipe cleaner or a flexible wire, clean out the

venturi tube.

3. Remove hex head orifice with a 3/8" wrench. Clean Orifice

hole and inner part of the valve with a toothpick. Be careful

not to enlarge the orifice hole.

4. Check orifice receptacle in valve body.

When finished cleaning reassemble the complete unit.

Unscrew and

Clean Orifice

Air Shutter

Spider Webs

Inside Venturi

Lift Out

Warning: Check the hose before each use of the grill for nicks,

cracking, abrasions or cuts. If the hose is found to be damaged

in any way, do not use the grill. Replace using only MHP authorized replacement hose.

Clean Out

Venturi Tube

Venturi Brush

12

Page 17

Maintenance

General Maintenance

Rotary Spark Ignitor System

If you experience an occasional “No-spark-No light” condition here’s a check list to troubleshoot the problem.

1. Inspection. WITH GAS OFF, position a mirror in front of the

collector box and rotate the ignitor knob several times. Observe

the condition of the spark. (Low light conditions are the best for

seeing the spark.)

Mirror

Collector Box

B. Check spark. Pull the connector wire from the collector box

(see “X” Fig. S). Bring wire to bottom or top of control panel,

hold about 1/8" away and operate the ignitor. Check for spark.

If there is no spark replace the Rotary Ignitor. If there is a

spark the Rotary Ignitor is OK, but the Collector Box/Electrode

assembly should be replaced (the ceramic insulator could be

cracked).

B. Hold Connector

1/8” From Panel

Bottom.

Rotate Ignitor

Knob

C. Check Knob, confirm quality of the electrical ground at the

Rotary Ignitor. Remove the knob, loosen and retighten the

mounting screws.

A. If there’s a good spark, but the grill

won’t light, gas may not be flowing to the

burner and into the collector box. The gas

orifice or the venturi tube may be blocked.

To clean, follow “Flashback” instructions.

B. If a weak spark arcs down around the

ceramic insulator, the insulator should be

cleaned. The insulator has a coating of

grease or it is wet. Use an old tooth brush

to break up the conductive electric path.

2. If there is no spark in the

collector box.

A. Check the wire connections

at the ignitor and electrode

Mechanism

WD

40

Lubricate

Ignitor

under the grill. Lubricating

(use WD-40 or equivalent)

the star wheel and tension

spring of the ignitor will help

connection contacts and im-

Connector

prove operation.

A. GOOD SPARK

B. WEAK SPARK

Check Connection

Fig. S

“X”

Electrode Replacement or

Adjustment

The electrode inside the

collector box is pre-set for

optimum spark. The tip is

1/8" from inside surface of

the collector box.

Check the gap of the new

part before installing. Loosening and tighten the two

jam nuts will move the electrode tip, set at 1/8".

1/8”

Gap

Collector

Box

Electrode

Ceramic

Insulator

Ignitor

Wire

13

Page 18

Cooking Tips

Cooking Tips For Your

New Phoenix Grill

Your new Phoenix eliminates flare-ups because the cooking

surface is shielded from direct flame contact by a drip pan. For

best results we recommend that all preheating, grilling,

smoking, baking and steaming be performed with the lid

closed!

WARNING: ALWAYS LIGHT YOUR GRILL WITH THE

LID OPEN.

GETTING STARTED

Before you use your grill for the first time be sure to read and

thoroughly understand all grill safety, lighting, locating, operating and maintenance procedures found in this book.

We recommend you “break-in” your grill by cooking the

first 2 or 3 times at medium or low temperature settings.

This allows the drip pan to “season/break-in”. Please note:

as long as the grease can flow into the grease bucket it is

not necessary to clean the drip pan after each use. Clean

as needed or approximately every 10 uses.

After each use, we recommend you turn the control knobs

to “HIGH” (with the lid closed) and run the grill for approxi-

mately 10 minutes. This will allow the accumulated fats and

greases to cook off, and avoid a possible flare up on the

next use. HINT: The fats and greases are cooked off when

no more smoke is flowing from grill vents.

We recommend cleaning the cooking surface (cooking grid)

before each use and before you light the grill. Simply run a wire

brush front to back and side to side across the diamond shaped

cooking surface. This can be performed with the cooking grid in

place or you can remove the cooking grid for cleaning.

The drip pan valve should be kept open while your grill is

in use. This allows the grease that drips from your food to con-

tinuously drain into the grease catch bucket. If you are cooking

a small quantity of food or food with very little fat, you may not

notice any grease collecting in the grease bucket. However, if

you notice grease accumulating in the drip pan but is not running into the grease bucket, then either your drain valve is not

open or the drip pan pipe is clogged. Don’t attempt to clear the

clog while the grill is hot! Wait until the grill has cooled, remove

the cooking grid and run a stick down the drain pipe until the

clog is cleared.

The only time the drip pan drain valve should be closed during

grill use, is when you are steaming or smoking with liquid

smoke. See below for steaming and smoking instructions.

The following grilling steaming, smoking and baking tips are

provided as helpful guidelines. With experience you will find the

cooking times and temperature control settings that best suit

your taste. Please refer to page 15 for suggested cooking

times.

GRILLING

Pre-heat your grill with both controls on “HIGH” for 15 minutes.

If you are cooking hamburgers or steaks we recommend that

you leave the temperature controls on the “HIGH” setting. Re-

member, for best results, cook all your foods with the lid closed.

If you are cooking chicken, turkey, roasts, hot dogs or sausages

we recommend that after preheating your grill on “HIGH”, turn

both controls on the “MEDIUM” settings (half way between the

high and low setting). To keep food warm, or to further slow the

cooking process, you may try running only one side of the grill

and warming or cooking on the opposite side. Or you may try

cracking the lid (with a wood spacer) to let out heat.

BAKING

Pre-heat with both controls on “HIGH” for 10 minutes. Then set

your controls to the following setting that most closely matches

the temperature you want to achieve.

(Hint: the lid thermometer will help to more accurately set you

control).

Low Setting 350° Degrees to 400° Degrees

Middle Setting 400° Degrees to 450° Degrees

High Setting 450° Degrees to 500° Degrees

SMOKING

Caution: Before you proceed, make sure that your grill is on a

solid level surface. Check to see that your drip pan is relatively

clean. Smoking or steaming with a dirty drip pan can affect the

taste of your food. To clean your drip pan, simply unscrew the

drain valve and lift out the drip pan. Never attempt to clean the

drip pan while the grill is hot or if the grill is in use. A putty knife

or scraper works well for cleaning out the drip pan.

WOOD CHIP OR CHUNK SMOKING

Place the desired amount of wood in a wood chip container.

You can fabricate your own container(s) by folding heavy gauge

aluminum foil into an open square or purchase a MHP stainless

steel smoker box (part #SDSSST) from your Local Dealer.

Place one or more containers directly on top of the drip pan

located under the cooking grid. Do not place the container in

the middle of the drip pan. For best results place the container

halfway between the center and the edge of the drip pan. Heat

the grill on “HIGH” for 30 minutes, or until you detect smoke,

before you place your food on the grill. Cook to desired taste.

14

Page 19

Cooking Tips

LIQUID SMOKE GRILLING

Make sure your drip pan is relatively clean, see page 14 for drip

pan removal cleaning. Close the drip pan drain valve and fill the

drip pan with water (be sure not to overfill your drip pan). Add

several ounces of liquid smoke. Experience will dictate how

much liquid smoke is required to suit your taste. Heat the grill

with both controls on “HIGH” for 20 to 25 minutes. Keep controls on the “HIGH” settings and cook to desired taste. Add

more water and liquid smoke if you are cooking for an extended

period of time. Do not attempt to move your grill with water in

the drip pan, and wait until your grill has cooled before draining

out any remaining water.

STEAMING

CAUTION: Before you proceed, make sure that your grill is on a

solid surface. Check to see that your drip pan is relatively clean,

see “smoking” instructions for drip pan removal and cleaning.

Close the drip pan drain valve and fill the drip pan with water )

be sure not to overfill). Heat the grill with both controls on

“HIGH” for 20 to 25 minutes. Keep controls on the “HIGH” set-

ting and cook to desired taste. Steaming is good for foods as

oysters, clams, lobsters, and shrimp, etc. Do not attempt to

move your grill with water in the drip pan, and wait until your

grill has cooled before draining out any remaining water.

The following quality MHP accessories are designed to make

your smoking experience more convenient and enjoyable. See

these products and a complete list of accessories for your new

Phoenix grill on pages 18 and 19.

Stainless Steel

Smoker Box

COOKING TIMES

A Quick Reference

Control Setting

Chicken 3 lb. Whole

Chicken

Chicken Legs or

45-60 Minutes LOW

Thighs

Pork Chops 1 Inch Thick 15 Minutes Each

Italian Sausage 40 Minutes MEDIUM

Pork Sausage Patty 8 Minutes Each Side MEDIUM

Pork Ribs 60 Minutes MEDIUM

Prime Rib 2 1/2 Hours (Use

Vegetables All 30 Minutes LOW

Biscuits Canned 7 Minutes Each Side LOW

90 Minutes LOW

MEDIUM

Side

MEDIUM

Meat Thermometer)

15

Page 20

TROUBLE SHOOTING GUIDE

If you are having difficulty with your grill, follow this guide to solve some common problems.

Problem #1: BURNER(S) WILL NOT LIGHT OR THE GRILL

DOES NOT GET HOT ENOUGH.

PROBABLE CAUSE SOLUTION

A. Propane Cylinder Almost Empty. Have Propane Cylinder Filled.

B. Propane Cylinder Valve Not On. Turn Valve On. Turn Counter-Clockwise to Open.

C. Kink In The Gas Hose. Reposition The Propane Cylinder To Straighten The Hose.

D. Burner Holes Clogged. Clean With Small Wire or Round Toothpick and Sire Brush the Entire

Burner. See “Care and Maintenance” Section For Further Instructions.

E. Venturi Blocked. Clean Venturis. Refer to “Venturi Cleaning” Section

F. Venturis Not Sealed. Refer to “Prior to Use” Section

G. Orifices In Valve Outlet Plugged. Clean Orifices (small hole in valve outlet).

H. Regulator And/Or Valve Defective. Take Complete Hose, Valve and Regulator Assembly to a Servicing LP

Gas Dealer for Inspection.

I. Ignitor Not Working. Check For Proper Electrode Gap. Make Sure All Wires Are Connected

and None Broken. Check Ceramic for Cracks.

Problem #2: FLASHBACK (fire in venture or control panel area).

IF FLASHBACK SHOULD OCCUR, SHUT CONTROLS OFF THEN TURN VALVE OFF

AT PROPANE CYLINDER.

PROBABLE CAUSE SOLUTION

A. Venturi Blocked Clean Venturis. Refer To “Venturi Cleaning” Section.

B. Venturis Not Sealed. Refer To “Prior To Use” Section.

C. Valve Out Of Alignment. Adjust Valve So The Valve Outlets Are Pointing Straight Into

The Venturis.

D. Burner Holes Clogged. Clean With Small Wire or Round Toothpick and Wire Brush

the Entire Burner. See “Care and Maintenance” Section

For More Information.

E. Windy Day Shield Grill From The Wind.

16

Page 21

Parts Information

QUANTITY PART NO. DESCRIPTION

1 SDBASE Grill Base (SDWELDD & SDRIVDD)

4 KKWL3 Locking Casters (SDWELDD & SDRIVDD)

1 PFCFT Column Front (SDWELDD & SDRIVDD)

2 PFCSD Column Sides (SDWELDD & SDRIVDD)

1 SDHOOD Hood (Lid) (SDWELDD)

1 SDRVHOOD Riveted Hood (Lid) (SDRIVDD & SDRIV4LDD)

1 GGSH Stainless Steel Handle

2 GGSHC Handle End Caps

2 GGSHG Handle Graphite Gaskets

1 GGTG4 Temperature Gauge

1 SDPIT Fire Pit (SDWELDD)

1 SDRVPIT Riveted Fire Pit (SDRIVDD & SDRIV4LDD)

2 PFHH Hood (Lid) Hinge

2 PFPH Fire Pit Hinge

2 SDHP Lid Hinge Pins

1 SDCV-430 Vent Control

2 PFDPBKT Drip Pan Bracket

1 SDFABCP Control Panel (SDWELDD & SDRIVDD)

1 SDRIVCONT Control Panel (SDRIV4LDD)

2 SDPF80-5 Control Knobs

1 SDCPLBL-P Control Panel Label (SDWELDD & SDRIVDD)

2 PFSB-A Right Side Shelf Brackets

2 PFSB-B Left Side Shelf Brackets

2 SDSSDD Stainless Steel Side Shelves

1 SDSUP Column Support (SDWELDD & SDRIVDD)

1 OBS-SD Stainless Steel Burner

2 SDV34 Venturi Tubes

2 GGLPP1 Burner Hitch Pins

1 IG5 Gas Collector Box

1 GGEIB Electronic Ignitor

1 GGEIBPB Ignitor Push Button

1 HHVLV28SD Propane Gas Grill Valve (For Propane Models)

1 HR6B Propane Gas Hose and Regulator (For Propane Models)

1 HHVLV32SD Natural Gas Grill Valve (For Natural Gas Models)

1 ASCPL1 12’ Quick Disconnect Hose (For Natural Gas Models)

1 SDSSDT-A Cast Aluminum Drip Pan

1 SDDV Drip Pan Drain Valve

1 SDGB Grease Collector Bucket

1 VTC Venturi Tube Cleaning Brush

2 GGWL 8” Wheel (SDRIV4LDD)

2 GGAWP Axle Wheel Pin (SDRIV4LDD)

2 GGHC Hub Cap (SDRIV4LDD)

17

Page 22

UPGRADES AND ACCESSORIES

FOR ADDED

VERSATILITY, CONVENIENCE AND OUTDOOR

COOKING ENJOYMENT.

Infrared Burner

#PFMGSEAR

State-of-art cooking system gives you time saving grilling at

high temperature in seconds. The overall intense heat seals in

meat juices for better flavor. Stainless Steel construction and mounts

easily to the side of you grill. Our patented reversible cooking grid included. Electronic ignition for fast starts. Removable drip pan for easy

clean-up. 22,000 BTU’s and is available in Natural or Propane Gas.

Heavy Aluminum Griddle

#SDAG

Heavy-duty griddle perfect for

breakfast French toast, eggs, bacon,

etc. 16" L x 12" W

Fish Spatula

#FS1

Stainless steel fish spatula with

genunie rosewood handle.

18-1/2" L x 10" wide spatula

Stainless Steel Smoker Box

#SSST

Stainless steel smoker box with cover. For

use with all grills. Insert moistened wood

chips for your favorite smoke

flavor. 8-3/4" L x 3-1/2" W x 1-1/2" D

Super Flipper

#SF1

Stainless steel super flipper. The

ultimate spatula tool, specially

curved for perfect flips every time.

18" overall length.

18

Anodized Aluminum Grid

#SDGRIDS

Reversible rust-free anodized cooking

grid that heats up faster and spreads

heat more evenly. Wide-ribbed side for

steaks, chops, etc. and flat side for cook-

ing delicate foods. 161/2" x 8"

Wire Cleaning Brush

#WB3B

Brass bristle brush with scrapper, wood handle and leather

tong for hanging.

18" overall length.

Page 23

Secondary Cooking

Surface/Warming Rack

#SDSCS

More than a typical warming rack.

This elevated surface cooks at

lower temperatures for added

flexibility. 24” W x 8” D x 4 1/4” H

Roast Holder

#RR3

Holds roasts, ham, fowl so heat

circulates evenly around meat

for thorough balanced cooking.

Made of nickel-plated steel.

15-1/4" L x 10-1/2" W

Rib/Potato Rack

#RR2

Chrome plated accommodates 6

racks of ribs and 6 poatatoes.

12" L x 7-1/4" W

Ceramic Pizza Stone

#PZT13

For an evenly cooked pizza and a

crispy crust. The stone sumulates

the hearth of a pizza oven. For

cean-up, just wipe it off. 13” round

Stainless Steel Scraper

#SDDPS

Unique rust-free designed drip

pan scraper for Phoenix and

Hollard Grills. Hanging hole for

easy storage.

Skewer Set

#SR7B

6-piece chrome plated skewers

designed so food does not

rotate.

19-1/2" long.

Mid-Length Cover

#GGCVPREM

Premium quality polyester lined

vinyl with E-Z on/off Velcro tabs.

Fits Scottsdale Grill with two (2)

side shelf.

60" left to right, 20" front to back

and 24" top to bottom.

19

Stainless Steel Cleaner

#SCC

Specially formulated for MHP

stainless steel grills.

8 oz. bottle.

Full-Length Cover

#CV4PREM

Premium quality polyester lined vinyl

with E-Z on/off Velcro tabs. Fits

Scottsdale Grill with two (2) side

shelf.

60" left to right, 20" front to back and

42" top to bottom.

Page 24

Professional Quality Products For Your Backyard

5565 North 124th Street • Butler, Wisconsin 53007

Phone: 262.781.4657 • 888.761.4657

Fax: 262.781.3965 • 888.781.3965

Email: info@profiregrills.com

Produced by ProFire Grills

A Division of Modern Home Products Corp.

©2012 Modern Home Products Corp. MHP configuration, SearMagic, ProFire Grills are registered trademarks of Modern Home Products Corp.

Because of constant product improvement, ProFire Grills reserves the right to change specification without notice. 3/17

Web Site: www.newphoenixgrills.com

Loading...

Loading...