Page 1

Phoenix

™

Rocket Launched

R/C Aerobatic

Glider

Assembly and Operation

Manual

CONSUMER AEROSPACE

© 1991 AeroTech Inc.

Page 2

Warning!

Read This Carefully!

The radio controlled model that you will build from this kit and the AeroTech motors and propel-

lants that you will use are not toys!

This model is not intended to be flown by inexperienced pilots.

If incorrectly built, mishandled or misused, they are capable of bodily harm and property damage. Therefore,

it is your responsibility to correctly build this kit, to install all components carefully and accurately, and to

test and fly this product in accordance with all safety standards prescribed by the Academy of Model Aeronautics Safety Code. We strongly suggest that you join the AMA and become fully and properly insured before

using these products. If you require technical, construction or flying assistance, contact your local hobby

shop or the AMA to locate experienced instructors.

AeroTech certifies that it has exercised reasonable care in the design and manufacture of its products. As we

cannot control the storage and use of our products, once sold we cannot assume any responsibility for product storage, transportation or usage. AeroTech shall not be held responsible for any personal injury or property damage resulting from the handling, storage or use of our product. The buyer assumes all risks and liabilities therefrom and accepts and uses AeroTech products on these conditions.

No warranty either expressed or implied is made regarding AeroTech products, except for replacement or

repair, at AeroTech ’s option, of those products which are proven to be defective in manufacture within one

year from the date of original purchase. For repair or replacement under this warranty, please contact

AeroTech. Proof of purchase will be required. Note: Your state may provide additional rights not covered by

this warranty.

AeroTech, Inc. Academy of Model Aeronautics

1955 S. Palm St. 1810 Samuel Morse Dr.

Suite #15 Reston, VA 22090

Las Vegas, NV 89104 (703) 435-0750

(702) 641-2301

(800) 752-8018

Table of Contents

Introduction................................................................................................1

About Phoenix ...........................................................................................2

Before You Begin Construction.....................................................................3

Wing Construction......................................................................................6

Tail Construction.......................................................................................16

Fuselage Construction...............................................................................17

Final Assembly.........................................................................................21

Launcher Assembly...................................................................................27

Finishing..................................................................................................31

Flying Phoenix .........................................................................................31

Appendix A: Safety..................................................................................36

Appendix B: About Rocket Motors.............................................................38

Appendix C: Parts Layout .........................................................................40

Appendix D: Parts List ..............................................................................41

Appendix E: Launcher Base.......................................................................42

Appendix F: Suppliers ..............................................................................43

Phoenix, AeroTech, Reloadable Motor System, RMS, Mantis, Interlock, White Lightning, BlackJack, BP4d and Easy Reference are trademarks of Aerotech Inc. All other trademarks are property of their respective owners.

Page 3

Phoenix

Page 1

Introduction

C

ONGRATULATIONS! You are now embarking

on a new and exciting era in model aviation,

high performance rocket gliders! Phoenix is the

first of a new generation of rocket gliders from

AeroTech and it will provide you with many

exciting and satisfying flights. Thank you for

choosing Phoenix!

Phoenix is the culmination of many years of

flight and design experience with model airplanes, model rockets and with rocket gliders.

Designed for the intermediate to advanced

level pilot who wants high performance, both

in the launch and in the glide phases of flight,

Phoenix is a revolutionary design. You’ll have a

new class of model, exciting and different,

unlike anything you currently have in your

model airplane hangar.

What do we mean when we describe Phoenix

as revolutionary ? By using extensive computer

aided design, from the custom airfoils to the

overall configuration, Phoenix uses the latest

breakthroughs in aerodynamics to achieve

these unique design goals:

• smooth, precise handling on launch

• low drag for outstanding launch performance

• ability to withstand the high speed and

acceleration of launch

• high L/D and large speed range during

glide for easy thermalling

• fully aerobatic during glide

• light weight and ease of construction

• maximum efficiency through an integrat-

ed rocket design

You’ll be able to experience all of these objectives for yourself as you build and fly Phoenix.

We’ve carefully laid out the plans, detailed the

instructions and chosen the wood and other

components so that your Phoenix can be as

good as ours and you can have as much fun as

we have had.

If you are an intermediate level pilot, you’ll be

able to immediately enjoy the high performance characteristics of Phoenix. By intermediate level, we mean someone who has previously built and successfully flown aileron

equipped aerobatic RC models. While Phoenix

is not difficult to fly for a pilot who has already

flown several other planes, it is not for the

novice or beginner pilots.

P

HOENIX does not require that you have pre-

vious experience with model rockets. You

just have to remember to follow some common

sense safety rules. Just like it is a good idea to

keep your hand out of a spinning prop, Phoenix

should be launched only from its launcher, and

only with a remote electrical ignition system.

Please read the flying and safety sections in

this manual for further details..

We ask that you follow the instructions as written, because after many prototypes and much

experimentation, we’ve learned what tools,

techniques and components work best. While

Phoenix is easy to build because of the work

we’ve put into it, the design is integrated, so

that every detail contributes to the overall performance and changing one part of the design

will impact the performance in other areas.

For maximum performance and safety, you

must:

• Build Phoenix as described

• Install a fully working, tested and legal

radio system

• Follow the AMA safety code, and the

Rocket Glider safety code, as described

in this manual

• Always use the recommended rocket

motor reloads from AeroTech

• Test fly the Phoenix as described in this

manual, and lastly

• Have a great time flying Phoenix!

We know that you’ll enjoy your Phoenix Rocket

Glider and you will have many exciting flights.

We look forward to hearing from you: your

comments, suggestions and experiences.

Included in this kit is a product registration

and evaluation card. We’d appreciate you completing it so we may do a better job in future

rocket glider kits. We always look forward to

your comments.

Thanks again for choosing Phoenix!

Page 4

Phoenix

Page 2

About Phoenix

Integrated Rocket Motor

P

HOENIX has a carefully integrated rocket

motor for both good performance and good

behavior on boost. For example, the placement

of the rocket thrust line is critical for a stable

boost. With Phoenix’s high thrust to weight

ratio (5:1 for Phoenix versus 1.5 to 1 for a hot

power plane), Phoenix’s motor thrust line had

to pass through the CG or the model would try

to loop violently on launch. Phoenix’s motor is

located as close as possible to the model’s CG

to reduce the amount

of CG movement as

fuel is burned. Finally,

the motor mount

angle on Phoenix was

carefully tested with

over 100 flights to

minimize drag while

providing easy access

to the motor for

reloading.

Computer Designed

Airfoil

P

HOENIX uses a custom computer designed

airfoil, the BP4d™, for maximum boost and

glide performance. To achieve the best overall

results, the main design goal for the airfoil was

a significant reduction in drag. The BP4d

design did this, and is a significant improvement over sections such as the S3021, a common RC sailplane airfoil. When compared with

the S3021, the BP4d has 33% lower drag at

launch speeds and 5 to 15% lower drag during

typical gliding flight, with only a slight

decrease in maximum lift. As a result , Phoenix

has a very wide speed range in glide, and

retains a good glide ratio at high cruising

speeds. Also, the Phoenix airfoil is slightly

thicker, for better strength and for adequate

room for aileron servos. With its substantially

thicker aft section, the ailerons are thicker,

reducing the possibility of flutter at high flight

speeds.

Two Aileron Servos

P

HOENIX has an aileron servo installed in

each wing panel for several important reasons. First, by locating the servos away from

the center section of the wing, where the flight

loads are the greatest, less structural reinforcement is required to maintain the designed

strength of the overall wing. The wing is

stronger and actually lighter by having two servos outboard in the wing instead of one in the

center surrounded by extensive reinforcements! Second, by moving the servos into the

wings, closer to the ailerons, the result is stiffer

linkages which are much less prone to flutter at

high speeds, such as during launch. Finally, a

dedicated servo for each aileron gives more

accurate control for

precise roll authority,

as expected by experienced pattern flyers. While this is not

essential for a sport

plane such as

Phoenix, once we

started using the two

ailerons and enjoyed

the roll response, we

couldn’t give it up.

Offset Vertical Tail

O

NE unique feature of Phoenix is its offset

vertical tail. If you haven't already noticed,

the tail is not on the centerline of the fuselage,

it is offset to one side! This is intentional

because it provides several distinct advantages

for Phoenix. First, it allows for the pushrods to

the elevator and rudder to be perfectly

straight, for better stiffness and minimum

weight. Second, the linkages and horns are

shielded from the hot rocket exhaust, so they

won't be damaged. Third, the larger fuselage

cross section gives a stiffer tailboom for consistent and precise rudder and elevator

response. Even though the back of the fuselage

is larger than normal, the linkages are hidden,

so the drag is less than or equal to the total

drag of a conventional design. Finally, this

design is stronger because the tail is glued

directly to the side of the boom.

Although the plans show the vertical tail

mounted on the left side of the boom, you can

put it on the right side if you wish. You might

avoid having to reverse a servo, if you have a

radio without servo reversing switches.

Page 5

Phoenix

Page 3

Before You Begin Construction

P

HOENIX has several critical construction

requirements. First, it must be strong

enough to withstand high speed launches and

aerobatic maneuvers. Second, the wing must

be built precisely as designed, with an accurate

airfoil, to give good overall performance. Most

importantly, the model must be light to obtain

good launch performance. Strong, accurate but

light - are your construction goals!

Why is weight so critical for Phoenix? Each

additional ounce of weight will result in

approximately a 10% decrease in still air

glide times! Most of this reduction comes from

lower launch altitudes. In designing Phoenix,

we have taken lightweight building issues to

heart and have selected components and techniques to make it easier for you to be successful. As you sort the wood in your Phoenix kit

notice how the critical pieces (such as for the

tail) are light weight balsa wood, carefully

specified and selected for optimal strength to

weight ratios. At first you may have wondered

about some of these pieces - they are "fuzzy" or

have "threads" on the edges. These are characteristics of lightweight, premium balsa wood selected especially for Phoenix.

All of our Phoenix prototypes weighted

between 23 to 24 ounces without the rocket

motor. This is readily achievable with the components in this kit if you take reasonable care

in building. So build it strong but light!

Vacuum Bagged Wings

T

HE best way to make strong, accurate and

light wings on a model this size is to use

medium weight balsa wood skins epoxied to

foam cores, with fiberglass reinforcements

where required. A vacuum bag is used to hold

the skins firmly in contact with the core while

the epoxy cures.

If you are not familiar with the vacuum bagging

process, it really is quite simple. First we apply

the epoxy resin and fiberglass resin to the

balsa skins. The skins are positioned on the

cores, and the assembly is placed in an airtight

plastic bag. A vacuum pump with a regulator,

or else a low power pump designed for vacuum

bagging model foam wings, is connected to the

plastic bag. A low pressure setting ( 3 psi or

approximately 6 inches of mercury) is used.

This pressure is maintained until the epoxy has

cured. That's all there is to it!

You may now be wondering if this is sufficient

If you never read the instructions:

Phoenix is a new and exciting category in model aviation, and you have probably

never built and flown anything quite like it before. We really want you to be suc-

cessful with your Phoenix, so:

Please:

• Build strong, light and true!

• Read the flying instructions!

• Follow the safety code!

• Read the flying instructions!

• Enjoy your Phoenix!

Page 6

Phoenix

Page 4

Before You Begin Construction

pressure to guarantee a good, lightweight and

strong bond. If we pump all of the air out of the

bag, the surrounding atmosphere will apply a

pressure of about 15 pounds per square inch at

sea level. This will actually crush the

lightweight foam cores used on Phoenix. So we

need to pull only a partial vacuum in the bag. A

pressure of 3 psi may not seem like a lot of

pressure, but it is equivalent to putting a one

foot thick steel plate on top of the wing cores!

More than enough to guarantee a strong bond,

but not so much as to crush the cores!

You may not have tried making vacuum bagged

wings before, but the resulting wings are much

stronger and lighter than with any other

method. Once you try it, we doubt you will

ever go back to the old methods again. Ready

to use, low cost, vacuum bagging kits are available from several suppliers (See Appendix F).

While you can improvise most of a bagging system, the commercial units use professional

materials that are much easier to use, less likely to have an air leak, and not much more

expensive. You might also want to get together

with some of your flying buddies to share the

cost of a system. Just remember that you only

need a vacuum of about 3 psi for the Phoenix

wings.

If you really do not want to vacuum bag the

wings, the next best alternative is to hold the

skins in place with weights while the epoxy

cures. To equal the pressure of the vacuum

bag, you need about 500 pounds on each wing

half. The big problem is that it is almost impossible to get that much weight stacked up on

that little wing! One hundred pounds per side

is a good, practical weight to aim for. You

should plan on using a bit more epoxy to get a

good bond since you won't have as much pressure as the vacuum bag. We have used such

weights as milk cartons filled with water, magazines, stereo speakers and scrap metal. It really

depends on what you have available. It isn’t

worthwhile to buy weights, since you could get

a vacuum bag system for about the same price.

Airfoil accuracy

B

UILDING the wing airfoil accurately is

always going to require careful craftsmanship. We have found that the effort is really

worthwhile to obtain the best possible performance from the model. On one of the prototype models, we were in a hurry and got sloppy on the airfoil shape. The resulting

performance loss was very noticeable, possibly over 25%! We have tried to make building

an accurate wing as easy as possible.

No wing shape is going to be perfect, but some

errors are less critical than others. The most

important thing is that the airfoil be a smooth

shape with no wrinkles or bumps. It is actually

very difficult to make the wing chord match

the plans. A small error in thickness at the

trailing edge will make a big error in the chord.

Fortunately, this is not critical. Just make sure

that both wing halves are the same. A small difference in trailing edge thickness is not important. The leading edge requires very careful

shaping, so we have included precision die cut

templates to make the job easier.

Adhesives

E

VERYONE has their own preferences about

which glue to use for which job. Throughout the instructions, we make suggestions

based on the glues we prefer for a given job,

based on our experience with the Phoenix prototypes.

For applying the wing skins, there really isn’t

any choice but a good epoxy resin. We have

used the PIC, Z-poxy and Bob Smith finishing

resins with good results. These resins have a

low viscosity and are easy to spread in a thin

layer, but all have a “pot life” of only 10 to 20

minutes. Once the epoxy is spread into a thin

layer, the cure time is greatly extended. If you

pour some resin on each of the skins as soon

as it is mixed, spread it around a bit, and then

go back to do the final spreading, you should

have plenty of time.

We routinely will skin a pair of Phoenix wing

Page 7

Phoenix

Page 5

Before You Begin Construction

panels with one batch of 9 minute pot life

epoxy. If you have never done vacuum bagging

before, you might want to either do one wing

panel at a time or use a slower setting resin.

Resins such as EZ-Lam, West System and SafeT-Poxy are all low viscosity with a 30 to 60

minute pot life. Do not try to apply the skins

with a standard epoxy glue because it will be

difficult to keep the weight down. We use about

one fluid ounce of resin total to bond all four

wing skins to the cores.

For the remainder of the construction, we use 5

and 30 minute epoxies, thin and thick CA as

well as aliphatic resin glues. The instructions

will mention any areas where a specific glue is

required. For most of the construction, use

either aliphatic resin glue (Titebond, PIC Rigid

White Glue etc.) or CA. The CA glues have the

obvious advantage of a fast cure time, but we

find the aliphatics easier to sand, not all that

much slower to use and non-toxic. Do not use

standard CA glue near the foam cores! Take

your pick. In any case, be sure to use a good

quality, fresh glue to build your Phoenix.

Radio System

T

O get good performance, you should use a

moderately light weight radio system in

Phoenix. For the aileron servos, only micro servos will fit in the wing. We have used Futaba S133’s in the prototypes with good results.

Avoid servos with less than 20 inch-ounces of

torque. We have also used S-133’s for the elevator and rudder, although there is room for a

slightly larger servo. Extra room for a standard

servo can be made by deleting the rudder

servo and only using a servo for the elevator.

This does not greatly impact the maneuverability of Phoenix, but using properly coordinated

rudder and aileron controls does make a significant improvement in thermalling performance.

Therefore, we do recommend a servo for both

rudder and elevator.

For the remainder of the radio gear, we have

used either a standard receiver and a 150 mAh

battery or a small receiver and a 275 mAh battery. Both combinations weigh about the same.

The prototypes would balance properly with

either of these radio options, without any additional nose weight. If your Phoenix comes out

nose heavy, try not to add weight to the tail,

but put in a lighter radio and enjoy the extra

performance.

Finishing

P

HOENIX is not the airplane to try out your

latest 57 coat, hand-rubbed super finish!

Remember that each extra ounce is going to

cost you 10% in performance! All of the prototypes were covered with iron-on film coverings.

We have found that the different coverings

have different characteristics. A high temperature covering, such as MonoKote™ or Ultracote™ should be used on the bottom of the tail

since it is close to the rocket exhaust. Lower

temperature coverings can become loose or

bubble due to the high heat in this area.

Regardless of the covering used on the wings,

make sure that there aren't any wrinkles or

bubbles, because they cause an increase in

boost drag. Be especially careful to avoid wrinkles near the leading edge.

Finally, applying striping tape to the wing can

also hurt the performance. If you really have to

put on the striping, try flying your model first.

If you notice a loss of performance when you

put the tape on, then you have to decide if you

want the performance or the looks.

Since Phoenix can be launched to high altitudes, good visibility is important. We have

found that very dark colors are best for the

bottom of the wing. We also put a fluorescent

yellow stripe on the bottom for contrast. The

upper surface can be any colors you want, but

should be different from the bottom of the airplane.

Page 8

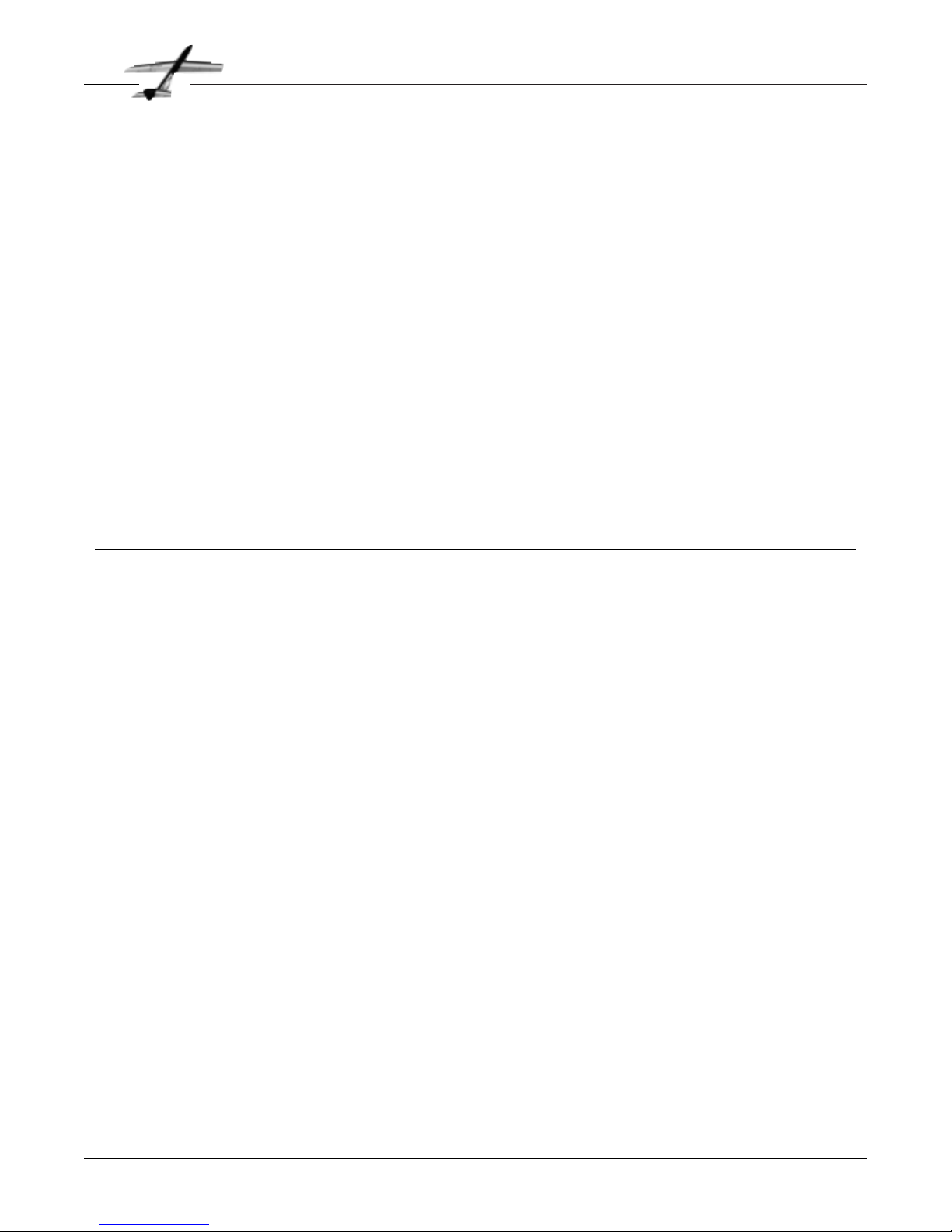

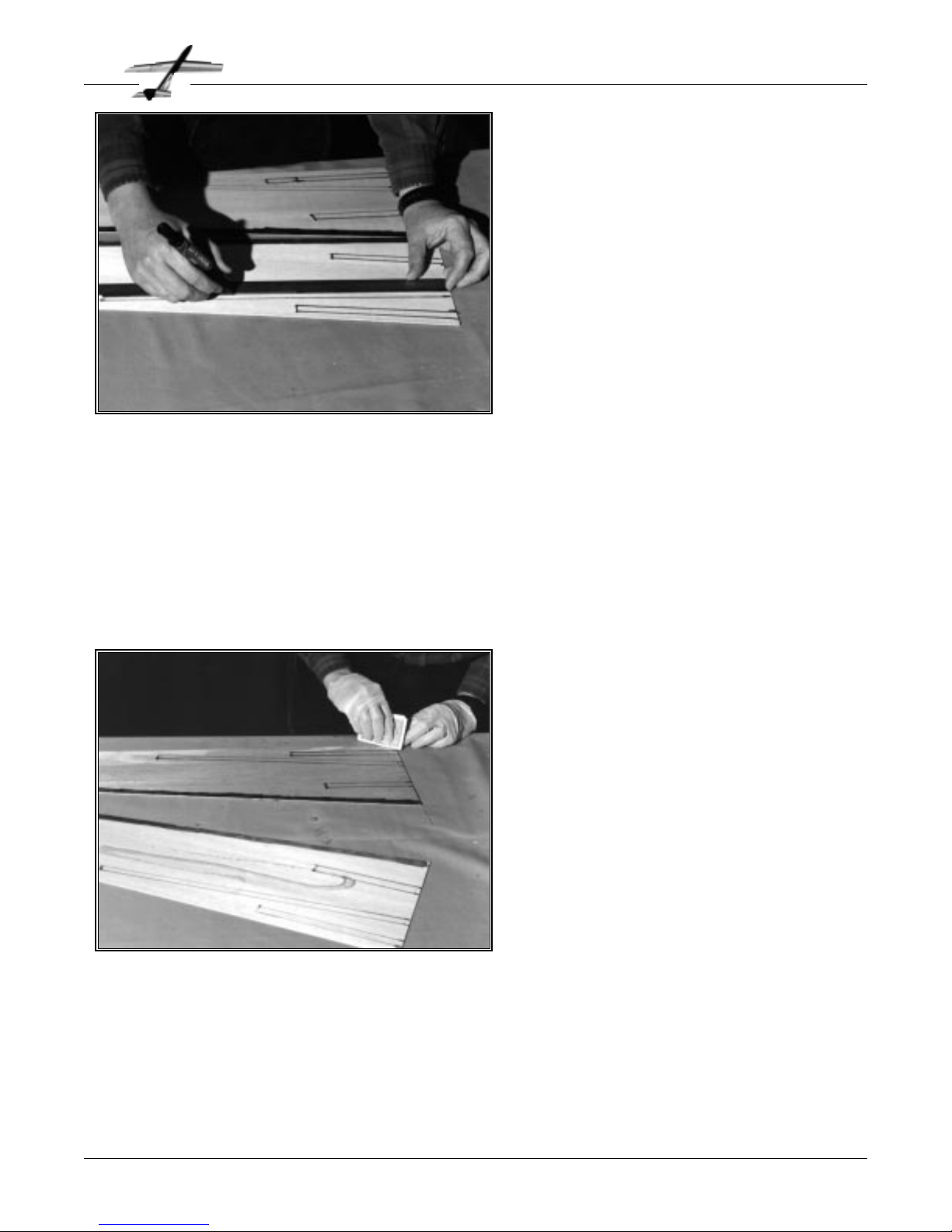

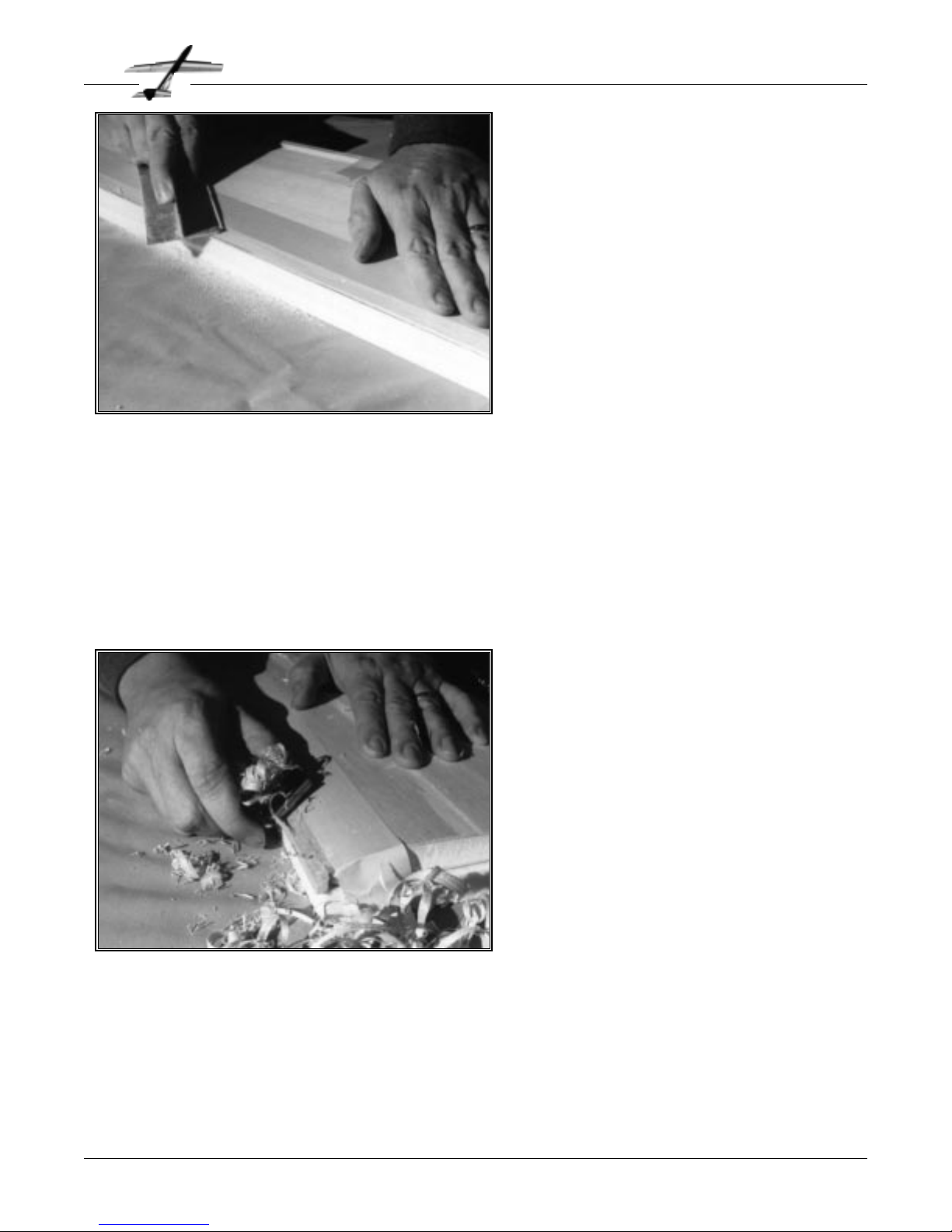

W

E use one of two different ways of splic-

ing wing skins. The CA method is a bit

quicker, but the aliphatic glue method generally needs less sanding later, so use the one

you prefer.

To use a thin CA glue, lay a piece of wax

paper on your workbench. Then lay 2 sheets

of wood down, hold the seam closed with

one hand, and apply the thin CA. Use the

minimum possible amount of glue, as it is difficult to sand off the excess later.

To use an aliphatic resin glue, lay the sheets

flat on the bench and apply a strip of masking tape along the length of the seam. Make

sure that there is no gap between the sheets.

When you have all of the sheets taped together, turn them

over and apply glue in the seams as shown. Lay the sheets flat

on the bench and wipe off the excess glue with a damp paper

towel. A few strips of masking tape will help hold the seam

closed while the glue dries. If you have a good gap-free fit

between the skins, try thinning the glue about 20% with water

and applying it with a small paint brush. This will make it easier to sand.

B

EGIN construction with the wing. We pre-

fer to build both wings at the same time,

however, you can build them individually if

you wish.

Locate the 10 pieces of

1

⁄16" x 3" x 24" balsa

for the wing skins. Trim the edges using a

straightedge and a sharp knife blade. Make

sure that you hold the knife so the cut edges

are vertical. We find it best to make several

light cuts. Also, be careful how you hold the

straightedge so you don’t trim your fingers!

The skin splicing layout is shown on the

plans. Note that you need to splice together

two sets of 5 sheets each. Check the sheets

to verify that they fit together with no gaps. If

there is a minor problem with the fit, clean it up with a sanding block. The other option is to re-trim that edge.

Select the stiffest C-grain sheets for use on the trailing edges

of the wing. Use the more flexible A-grain wood for the leading

edges.

Trim edges of skins

Don't trim your fingers

Check that the sheets fit

Phoenix

Page 6

Wing Construction

Trim wing skins

Glue skins together

Don’t use too much glue

Glue wing skins

❏

❏

❏

❏

❏

Page 9

T

HE foam cutting process leaves some

very fine “threads” on the surface of the

core. In most cases, they can be removed by

rubbing the cores with your fingers. In some

cases, you might need to very lightly sand

the core with a fresh piece of 400 grit sandpaper. Be careful not to change the shape of

the core or gouge the wing. You do not need

to remove any of the foam itself, just the

threads. It is a good idea to support the wing

in its foam “cradle” anytime you are working

on it.

You may want to remove the threads from

the surface of the foam cradles so they don’t

accidentally end up in some glue joint later.

Next, using a sharp knife, trim off the ragged trailing edge of

the core. The trailing edge should be about

1

⁄32" thick when

you are done.

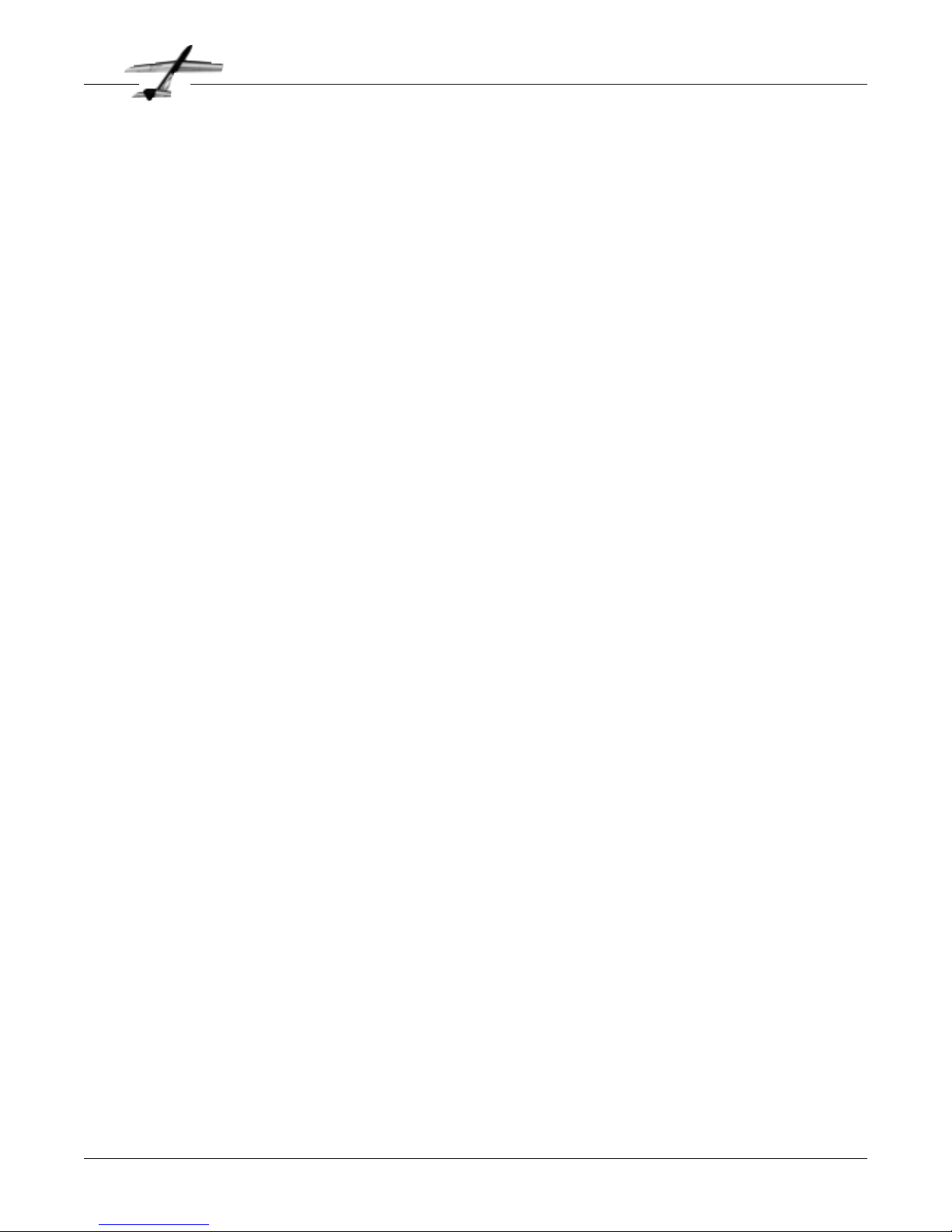

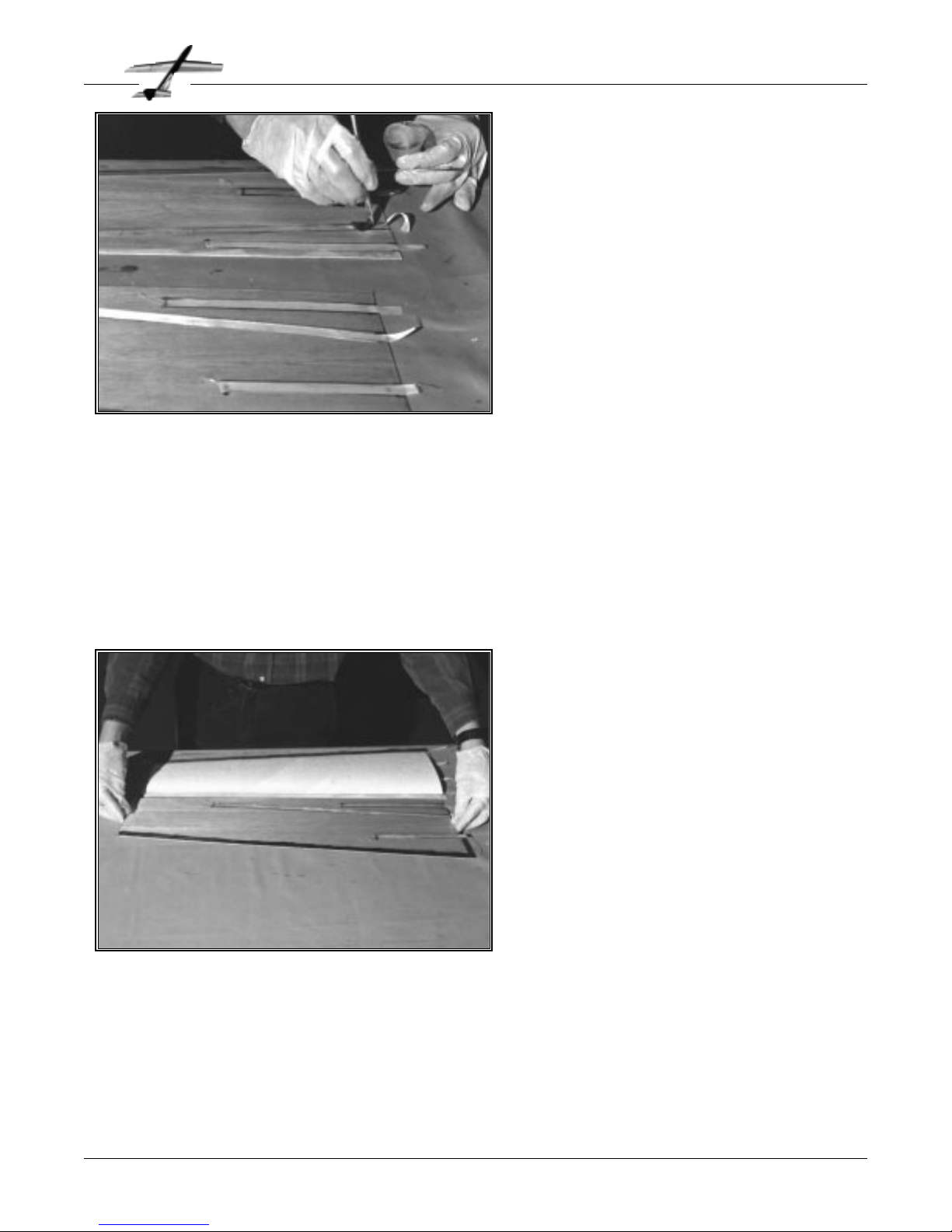

W

HEN the glue is dry, examine the wing

skins. Generally, you will find that one

side is smoother and more even than the

other. This will be the outside of the skin.

Mark the inside with a felt tip pen so you

won’t get it mixed up later. Use a good flat

sanding block (we prefer the aluminum “T”

bar as shown) and 120 grit sandpaper to

remove any excess glue. Finish sand with 320

grit. For best results, clean off all of the balsa

dust with a brush attachment on a vacuum

cleaner. We also wipe the skins with a

painters tack rag.

When the skins are smooth, trim them to

shape as shown on the plans. The dimen-

sions shown are slightly oversize to allow for trimming later.

Mark the skins “upper right”, “lower left” etc. on the inside of

the skins

Mark the inside of the skins

Sand off excess glue

Sand smooth

Clean off balsa dust

Trim to size

Phoenix

Page 7

Wing Construction

Sand wing skins

Remove “threads”

Trim trailing edge

Clean up foam cores

❏

❏

❏

❏

❏

❏

❏

Page 10

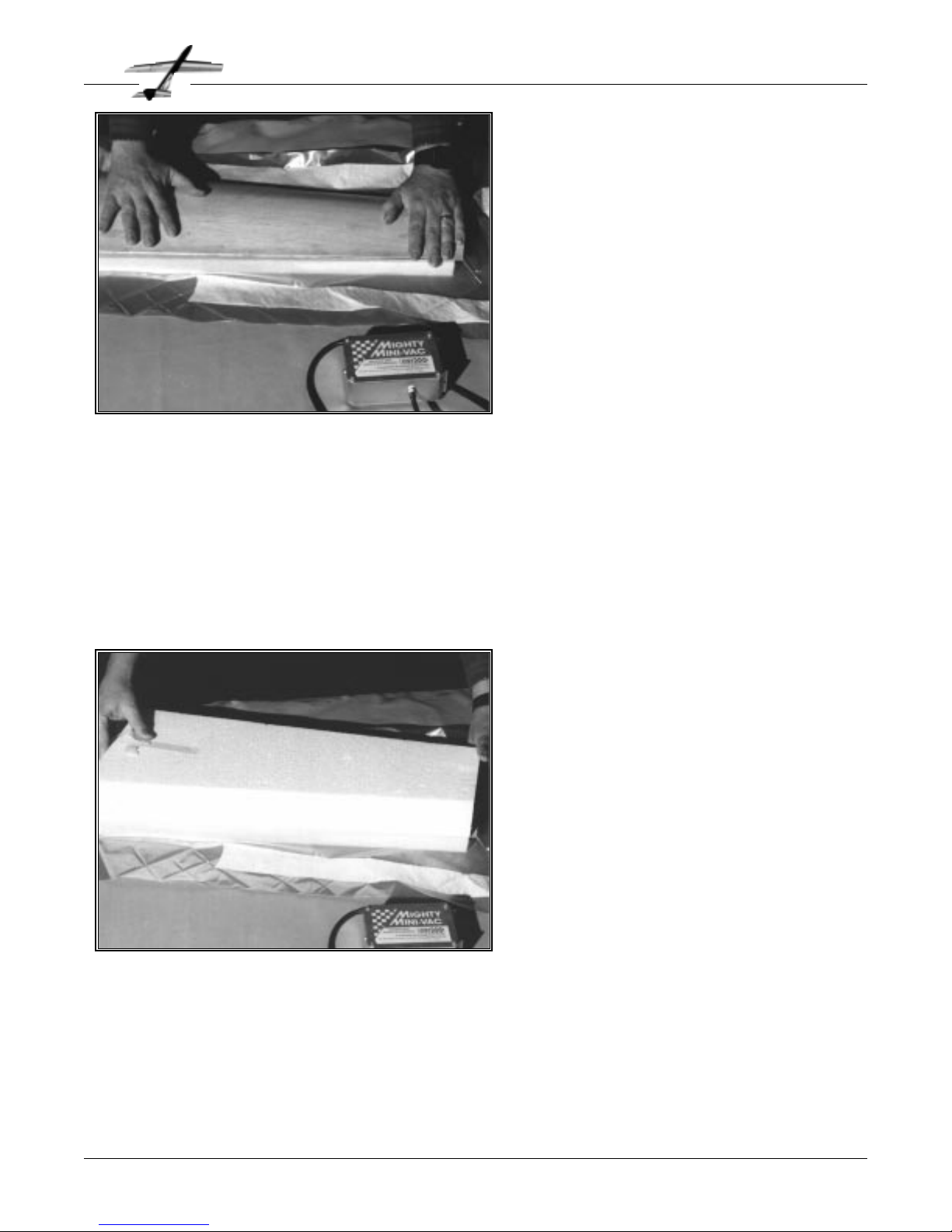

T

HERE are several types of epoxy suitable

for applying skins. To keep the weight

down, we need to use the minimum amount

of epoxy possible. This is easiest with the

low viscosity finishing resins. Most resins of

this type tend to have working times under

30 minutes. If you are familiar with vacuum

bagging, then this is not a problem. If this is

your first time, then you might want to

obtain a “laminating epoxy” with an hour or

more of working time. These are available

from most of the vacuum pump suppliers. Do

not dilute the epoxy with any type of solvent.

Mix the epoxy according to the directions.

We use about 1 ounce to do an entire set of

wings. If you are using weights instead of a vacuum bag, you

might want to use about 1

1

⁄2ounces of epoxy. If you are using

a fast setting resin, it helps to pour most of it out on the skins

as soon as it is mixed. This will extend the working time.

Now spread the epoxy on the skins using a couple of old playing cards as a squeegee. You should have some resin left for

the next step. Remember, the skin to foam glue joint does not

have to be any stronger than the foam core itself!

U

SING a felt tip pen, layout the position of

the

1

⁄2" fiberglass reinforcing tape on the

inside of the wing skins. The location of the

tape is shown on the plans. The exact position is not too critical.

Cut the glass tape to the lengths marked on

the wing skins. Leave a half inch extra at the

wing root. Be careful when cutting the tape

since it will unravel very easily. Remember

that you only need 2 pieces of tape for the

trailing edge(left and right), while there are 4

pieces of each length (upper and lower, left

and right) for the other two lengths

It is a good idea to color the aft

3

⁄4" of each

wing skin trailing edge with a dark color

marker as shown in the photo. This will make it easier to find

the trailing edge center line when you are sanding it later.

If you are using a vacuum bag, now is the time to get it ready.

If you are skinning both wing halves at the same time, make

the bag at least 5 feet long. Re-read the manufacturers instructions one more time. Otherwise, make sure that you have at

least 100 pounds of weights, and practice stacking them on an

area the size of the wing cradles. Once you mix the epoxy, it

will be too late…

Mark location of glass tape

Color trailing edge of skins

Cut glass tape to length

Prepare vacuum bag

Phoenix

Page 8

Wing Construction

Prepare fiberglass tape

Mix the epoxy carefully

Spread epoxy on skins

Wear gloves

Don’t use too much glue

Apply epoxy to wing skins

❏

❏

❏

❏

❏

❏

❏

❏

Page 11

P

LACE a foam core on the lower skin. The

trailing edge of the foam should be about

1

⁄16" ahead of the front edge of the trailing

edge tape as shown on the plans. Lay the

upper skin in place so that both the upper

and lower skins trailing edges are aligned.

Apply several pieces of masking tape to keep

the skins and core aligned.

P

OSITION the fiberglass tape on the skins

in the wet resin. Make sure that you apply

the trailing edge tape to the lower left skin

and to the lower right skin. The aft edge of

the trailing edge tape should be even with

the edge of the skin. Again, be careful to

avoid unravelling the ends of the tape. If you

used the right amount of epoxy on the skins,

the tape should soak up enough turn partially clear about a minute after you lay it in

place. If the tape turns completely clear, you

used too much resin and your wing will be

heavier than it needs to be. If it does not

change color at all, then you did not use

enough resin on the skins. You can go back

and add some more resin or try to squeegee some more off,

as required.

Finally, use the remaining resin and a disposable brush to

fully wet out the tape. The tape will turn clear when it is properly wetted out. Use the minimum amount of resin to make

the tape turn clear..

Now it is time to put the wings together.

Lay the tape in place

Saturate with resin

Phoenix

Page 9

Wing Construction

Apply fiberglass tape

Position core on lower skin

Lay upper skin on core

Align trailing edges

Tape together

Assemble wing

❏

❏

❏

❏

❏

❏

Page 12

I

F you are using weights, place the core and

skins in the cradle and set the upper cradle

in place. Make sure everything is aligned

properly, and use masking tape to hold the

stack together. (A good place to check it is at

the leading edge.) Carefully set weights on

top, until you have at least 50 pounds, and

preferably over 100 pounds. Remember, the

vacuum bag is equivalent to about 500

pounds per wing panel.

Be careful, since many workbenches will

bend noticeably with this kind of weight on

them, resulting in a warped wing. The best

place to do the wing assembly is on a flat

concrete floor(check it first!). If you have to

set up the wing on a workbench or wood floor, we suggest

that you get a couple of flat 2" x 10" boards at least 30" long to

set everything on. This will help keep the wing straight.

Regardless of the technique you use to hold everything

together, wait until the epoxy is fully cured before proceeding.

We prefer to wait about 50% longer than the epoxy manufacturer suggests, just to be safe. Remember, epoxy can take a

very long time to cure at low temperatures.

N

OW, apply pressure to the wing to hold

everything together while the epoxy

cures. If you are using a vacuum bag, insert

the wings and finish sealing the bag. Set the

entire bag assembly on the appropriate foam

cradles, and align the wings in the cradles.

Start the pump. As the air is removed, hold

the wings flat in the cradle as shown to avoid

warps.

If you have a vacuum gauge and regulator, set

the system for about 3 psi (6 inches of mercury). Pumps like the one in the photo are

preset for this value. Make sure that the wing

is still straight. If not, shut off the pump,

bleed some air into the bag, straighten it out

and try again.

If your pump does not use a “bleed valve” to control the vacu-

um, you should shut off the pump and check for air leaks.

Watch the bag carefully, if it “relaxes” noticeably within a few

minutes, you have a leak. Check all of the seams and plumbing until you fix the problem. Sometimes you can even hear

the leak. With some experience, you will be able to judge the

pressure pretty accurately by the look and feel of the bag.

Put wing in vacuum bag

Seal the bag

Pump out the air

Make sure wing is straight

Check for leaks

Phoenix

Page 10

Wing Construction

Vacuum bag the wing

Stack weights on wing

Make sure it is straight

Wait until epoxy cures

Allow wing to cure

❏

❏

❏

❏

❏

❏

❏

❏

Page 13

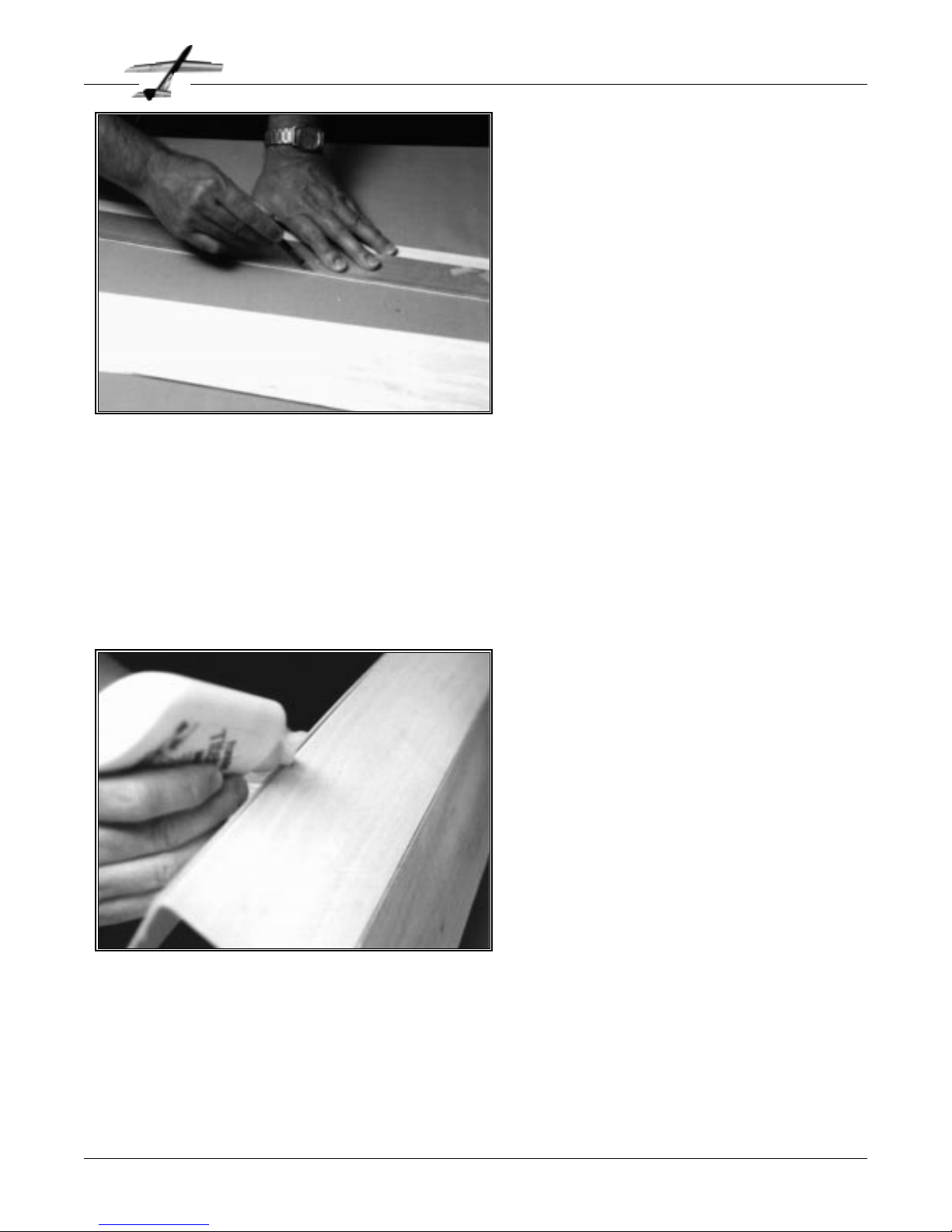

S

ET THE WING panel in its cradle. Using a

straightedge and a sharp knife, trim the

leading edge on the lines you marked in the

last step. Try to keep the cut vertical. Clean

up the cut with a sanding block if required.

Glue the

3

⁄16" x 3⁄8" x 24" balsa leading edge

strip in place. We prefer to use aliphatic glue

for this step. Apply the glue to the wood and

spread it into a thin layer. Hold the balsa in

place with masking tape while the glue dries.

If you want to use CA glue, make sure it is

one of the styrofoam compatible types. Do

not use epoxy, since it is very difficult to

sand cleanly.

N

OW THAT you have this nice straight,

strong piece of balsa and foam, we need

to turn it into a wing.

First, trim the balsa skins flush with the root

and tip ends of the foam cores. This does not

have to be a particularly neat job, since we

will be trimming them again later. The

approximate trim lines are shown on the

plans.

Set the wing on the appropriate wing end airfoil section drawing, and mark the location of

the leading edge trim line on both the root

and the tip of the wing. You will probably

have to move the wing around a bit to get the

best match possible with the drawing. You

want to match up the shapes over as much of the airfoil as

possible. The fit will probably not be perfect, but do the best

you can. Repeat this process until both ends of each panel are

marked. It is a good idea to check the two panels against each

other to make sure they match.

Trim balsa flush with foam

Mark LE trim line

Match wing panels

Phoenix

Page 11

Wing Construction

Mark LE trim line

Trim wing panel

Glue on leading edge

Attach leading edge

❏

❏

❏

❏

❏

Page 14

T

HE LEADING edge is probably the most

critical part of the Phoenix wing shape.

The leading edge shape was designed to give

the best balance of low drag on launch and

good glide performance. This is the place to

put in that extra bit of effort to get things

really right.

Start out by protecting the wing with masking tape, the same as you did for the trailing

edge. Use a razor plane and sanding block to

Rough out the leading edge. At this stage,

you just want get the shape close, without

taking off too much. Again, resting the wing

in its cradle will help.

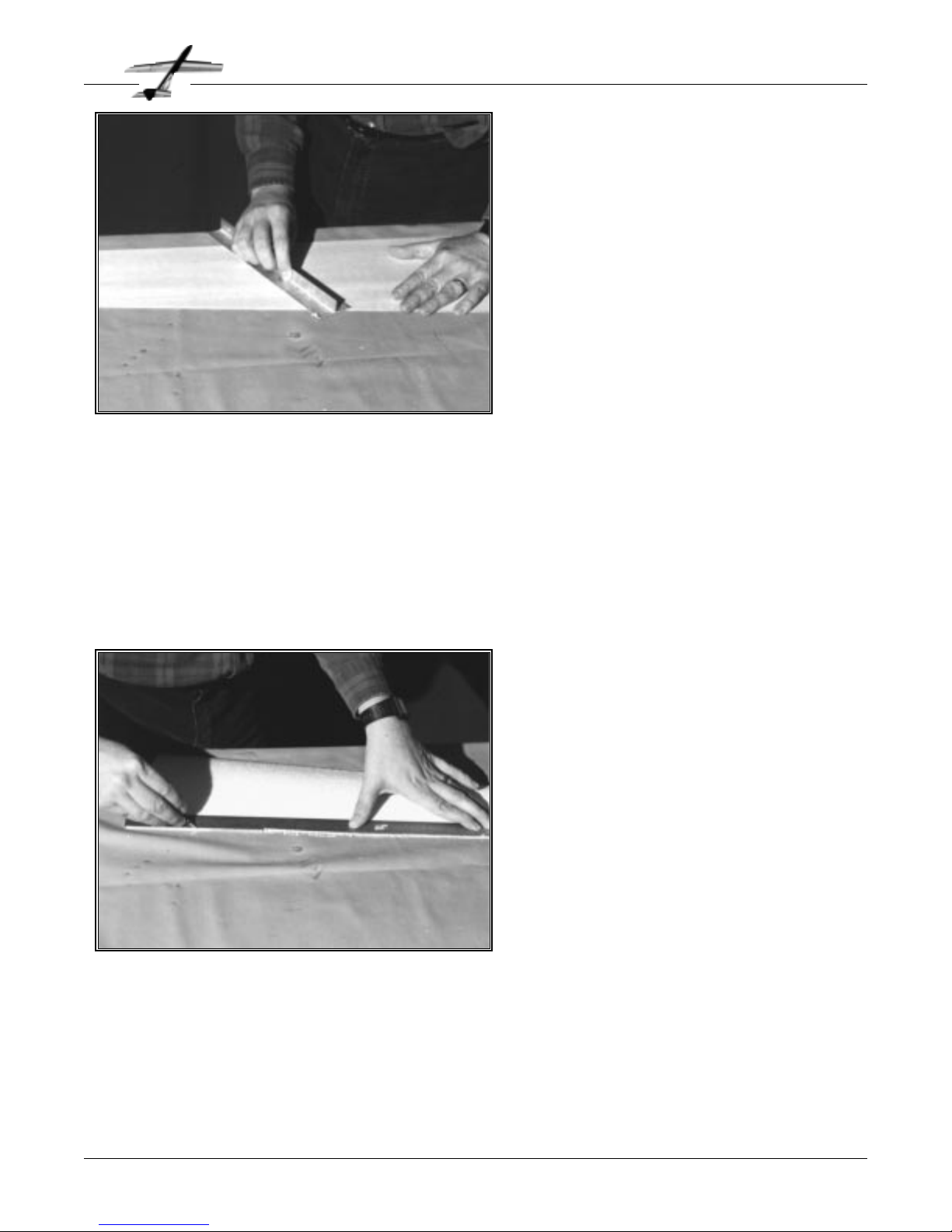

N

OW SHAPE the leading and trailing edges.

This has to be done without modifying

the contour anywhere else. The best way is

to protect the remainder of the wing with

masking tape while you are working. See the

trailing edge sketches on the plans

On the trailing edge, you need to remove the

excess balsa until you get to the fiberglass

tape. Lay a piece of masking tape on the wing

with its aft edge aligned with the aft edge of

the foam core. Add additional strips of tape

adjacent to the first one until you have at

least 2" covered. Using a straight sanding

block, sand the trailing edge to the shape on

the plans. Support the wing in its cradle

while sanding.

The black marks on the inside of the skin will help you judge

the progress of the sanding. We sand the edge until it is sharp,

and then trim it back slightly to blunt it. Yes, you can cut your

finger on one of these trailing edges!

It is hard to make the trailing edge the right shape while maintaining the proper wing chord. We prefer to get the airfoil

right, and then make the chords of the wing panels match. It

is not critical if the chord does not match the plans exactly.

Protect the wing with tape

Sand the TE to shape

Phoenix

Page 12

Wing Construction

Shape trailing edge

Protect wing with tape

Start shaping the LE

Carve leading edge

❏

❏

❏

❏

Page 15

M

ARK the aileron cutout and tip trim line

as shown on the plans. Use a fine mark-

ing pen.

Trim the tip of the wing to size with a fine

razor saw. Clean up the cut with a sanding

block and glue the tip block in place using

the same technique you used for the leading

edge.

Cut out the ailerons as shown. We make the

spanwise cut with a knife and straightedge,

similar to the way you trimmed the leading

edge. You might find it helpful to remove the

razor saw blade from its stiffening spine for

making the final chordwise cuts. Clean up the

cut with a sanding block.

O

NCE THE leading edge shape is close,

start checking things with the die cut

templates. The exact locations of the templates are shown on the plans; however, they

will still give you a good idea of the proper

shape for several inches each side of the

proper location. While it probably is not possible to get the shape exact using lightweight

balsa construction, you want to get it as

close as possible. Remove the masking tape

for the final shaping, and sand very carefully

with fine sandpaper to avoid changing the

main wing airfoil.

The most important thing is to keep the

shape smooth. The lower surface is especial-

ly critical for launch performance.

If things get really messed up, it is best to cut off the entire

leading edge strip and start over.

Check LE with templates

Sand carefully

Check LE with template

Sand carefully

Repeat until finished

Phoenix

Page 13

Wing Construction

Shape airfoil

Layout cut lines

Trim wing tips

Glue on tip blocks

Cut out ailerons

Cut out ailerons and tip

❏

❏

❏

❏

❏

❏

❏

❏

❏

Page 16

C

UT 4 aileron servo mounts from the 1⁄4" x

3

⁄8" x 6" basswood strip. The lengths are

shown on the plans. Note that the aft mount

is shorter than the front mount.

Drill

1

⁄16" diameter holes in the mounts to

match your servos. The servo is attached to

the bottom of the mounts, as shown. Use the

special #2 Allen head sheet metal screws and

wrench from the hardware package to mount

the servos. Remember to reverse the eyelets

that came with your servo to allow for this

“upside-down” mounting.

Lay the servo and mounts on the bottom of

the wing, and mark the area for the cutout.

Cut out the skin with a knife. Use a knife or

Dremel tool to remove the foam. Be careful not to cut into the

upper wing skin.

Trim the top of the mounts until the servo is flush with the

lower wing surface. Epoxy the servo mounts in place. The

mounts should be glued to the upper skin and the edge of the

lower skin.

Remove the servo. The enclosed “ball end” Allen wrench

allows easy removal of the servo screws.

T

RIM the two 3⁄16" x 3⁄8" x 9" balsa strips to

fit in the aileron cutout as shown. Glue in

place. Glue one of the die cut W-1 pieces on

each end of the cutout as shown.

Cut about

1

⁄4" from the end of each aileron so

it will fit back in the opening. Trim the leading edge of the aileron to allow for the thickness of both the wing trailing edge strip and

the

3

⁄16" thick aileron leading edge strip. Glue

the aileron leading edge strip in place. The

aileron trailing edge should match up with

the wing trailing edge with both strips in

place when you are done.

Sand one end of the aileron smooth. Glue a

W-1 in place. Trim the other end to allow for

the thickness of the other W-1, plus about

1

⁄16" extra clearance

as shown on the plans. Glue the final W-1’s in place.

When the glue is dry, sand all of the framing pieces flush with

the wing skin. Remember to protect the wing surface with

masking tape while sanding.

Glue cutout framing in place

Trim ailerons to fit

Glue aileron LE in place

Glue W-1 parts in place

Sand flush with wing

Phoenix

Page 14

Wing Construction

Install aileron framing

Attach servo to mounts

Layout and cut hole

Epoxy mounts in place

Install aileron servos

❏

❏

❏

❏

❏

❏

❏

❏

Page 17

T

RIM the wing root to the sweep angle

shown on the plans. Clean up the cut, and

sand the dihedral angle. We prop each wing

tip up 1

3

⁄4" with the root at the edge of the

workbench and use the edge of the bench to

guide the sanding block. Take your time and

get the angle right. Mark the location of the

aileron cable tunnel on top of the wing as

shown.

Glue the wing halves together with 5 minute

epoxy. Wipe off any excess glue before it

cures. It is very important make the dihedral

angle as shown on the plans. An error in the

dihedral will change the vertical location of

the CG. The resulting offset between the

thrust line and the CG will cause Phoenix to loop as it leaves

the launcher. If you change the dihedral, you will have to

change the thrust line to compensate. This will take a lot of

trial and error before you get it right again!

Glass the joint top and bottom with the 6" wide cloth and

epoxy.

When the resin is cured, trim the cloth at the leading and

trailing edges.

C

UT a “tunnel” for the aileron cable. Find a

12" long piece of brass tubing of a diameter large enough to clear your servo connectors (but not more than

1

⁄2"). Sharpen one

end with a knife or file.

Very carefully, use the tubing to cut out the

foam as shown. We generally cut about an

inch or two, remove the tubing, push the

“plug”of foam out of the brass tube with a

balsa stick and then continue. You should be

able to feel the progress of the tubing with

your other hand right through the wood

skins. Do not let the tubing cut through the

skins. Try to aim the tubing at the servo

cutout. You might want to draw some refer-

ence lines to help guide the cut. Make sure the holes on each

panel line up at the root.

It might have been easier to cut the tunnel before skinning the

wings, however the pressure from the vacuum bag would

have crushed the wing!

Sharpen tube

Cut tunnel

Phoenix

Page 15

Wing Construction

Cut aileron lead tunnel

Trim the wing roots

Sand the dihedral angle

Glue the wings together

Get the dihedral right!

Glass the wing center

Join wing halves

❏

❏

❏

❏

❏

❏

❏

Page 18

C

UT the vertical and horizontal stabilizer

parts from the

3

⁄16" x 3" balsa sheets using

a sharp knife or razor blade. Use the die cut

templates as guides. Note the grain direction

on all parts, especially the S-3’s. Square up

the edges of the parts with a sanding block.

We feel that cutting these parts out using a

template is easier than cleaning up die cut

parts. ( Light balsa die cuts very poorly.)

Glue the parts together as shown on the

plans. Use either a thick CA or an aliphatic

resin glue. Both types are relatively easy to

sand when cured. Be careful when gluing the

end grain edges, since they will tend to soak

up some glue. It is best to apply the glue,

wait a few moments for it to soak in, apply some more glue

and then assemble the parts.

Sand both surfaces smooth. The leading and trailing edges

should be shaped as shown on the plans. Note that the trailing edge is about

3

⁄32" thick. This provides better control

response as well as keeping the control surfaces stronger. Do

not round off the corners on the trailing edge! Cut the hinge

slots the same as you did on the ailerons. Shape the “V” on

the rudder and elevator leading edges.

C

UT the hinge slots. We like to start the

slot with a knife, and then enlarge it with

an X-acto #26 saw blade. Sand the aileron

leading edge to the “V” shape shown on the

plans after the slots are cut. We cover the

ailerons before gluing in the hinges.

The enclosed hinges are the best we have

used. Roughen the surface with 80 grit sandpaper. Flex the hinges 180° a few times for

“break-in”. Coat the hinge with 30 minute

epoxy and force some epoxy into the hinge

slot. Insert the hinge into the slot. Wipe off

any excess glue. Pinning the hinges is not

required. We glue the hinges into the control

surface, let the glue cure and then attach the

control surface to the wing.

Trim the servo arm to the shortest length that will allow full

movement without the clevis interfering with the servo arm

hub. Cut a slot in the upper surface of the wing to clear the

linkage. Mount the aileron horn, and adjust everything for the

correct throw and centering.

In case you are wondering, the aileron horn is on top to keep

it from dragging on the ground during landing and damaging

the servo gears.

Hinge ailerons

Cut slot to clear linkage

Install control horns

Make and adjust linkage

Phoenix

Page 16

Wing and Tail Construction

Install aileron linkages

Cut out parts

Clean up edges

Glue parts together

Sand and shape

Cut hinge slots

Assemble tail surfaces

❏

❏

❏

❏

❏

❏

❏

❏

❏

Page 19

T

HE tailboom is too small in cross section

to be built with internal bulkheads, so

you have to use a square or triangle on the

outside to check the alignment as you build.

Since the parts are long and narrow, you also

have to check that everything is straight.

Remove the two F-2 parts and the F-3 bulkhead from the die cut sheets. Be careful not

to break the thin legs on the bulkhead. Use a

knife to help separate the part from the sheet

if required.

Pin one F-2 onto the board. Check it with a

straightedge, and use pins to hold it straight

during assembly. This part will be the bottom

of the tailboom. Trim back of F-2 until it is

the length shown on the plans. Glue the side assemblies in

place on top of F-2. Make sure the sides are vertical. Slip the F3 bulkhead over the front and adjust the sides for a snug fit as

shown. Do not glue the bulkhead in place.

T

HERE are 8 pieces of 3⁄16" square by 30"

balsa in the kit. Pick out the two straightest and stiffest ones and save them for use as

pushrods.

Remove the F-5 pod sides from the die cut

plywood sheet. Typically, the surface finish

on one side of the plywood is better than on

the other. Make sure to use the good side of

each part on the outside of the model. Pin

the F-5’s to the board with the good side

down. Make sure you build both a right side

and a left side. Select the softest

3

⁄16" square

stringer. Cut and glue it to the bottom edge of

each F-5 as shown on the plans. Use the nose

block to determine the location of the front

of the stringer.

Remove the F-1 tailboom sides from the die cut sheets. Pin

the two F-1’s to a building board as shown. It might be necessary to bend the parts slightly to keep the edges straight as

you pin them down. Glue the stringers in place. Note the position, trim angle and length of the extra stringers near the

front.

Clean up the edges after the glue dries.

Sort stringers

Pin sides on workbench

Make a right and a left

Check for straightness

Glue on stringers

Phoenix

Page 17

Fuselage Construction

Frame tailboom sides

Pin bottom on board

Check for straightness

Glue sides in place

Check spacing at front

Check that sides are vertical

Glue sides on tail boom

❏

❏

❏

❏

❏

❏

❏

❏

❏

❏

Page 20

M

ARK and drill the 3⁄16" hole for the wing

dowel and the larger hole for the aileron

servo leads in bulkhead F-3 as shown on the

plans. (Yes, they do not show in the photo,

but it is easier to drill the holes now!) A

“bradpoint” type wood drill (available from a

good hardware store) will cut a much cleaner

hole than a normal twist drill.

Glue F-3 on the front of the tailboom as

shown. It should be perpendicular to the

workbench.

Use the pod sides to locate and mark the

position of bulkhead F-4. Note the position of

the parts on the plans. F-4 should be centered on the boom side to side. the back of F-

4 should be flush with the back of the pod sides. It should

canted forward at the bottom to match the back edge of the

pod. Glue in place with CA. You can make small adjustments

to the angle by flexing F-4 when you glue the pod sides in

place.

T

HE other F-2 is the top of the tailboom.

Trim the front and back to the length

shown on the plans. Glue it in place. Check

the entire boom one more time to make sure

everything is straight and square before the

glue dries.

Trim top to length

Glue in place

Check for straightness

Check that boom is square

Phoenix

Page 18

Fuselage Construction

Assemble tailboom

Drill holes in F-3

Glue F-3 in place

Locate position of F-4

Glue F-4 in place

Attach bulkheads to boom

❏

❏

❏

❏

❏

❏

❏

❏

Page 21

B

EVEL the top aft edge of the pod sides as

shown on the plans. Check the fit on the

boom as shown in the photo. When the sides

fit properly over the boom, glue in place. We

use either aliphatic glue or thick CA. Check

carefully to make sure the pod is straight in

relation to the boom. If you build over the

plans, check the position of the pod sides

over the drawing using a square.

This interlocking construction of the pod and

boom provides a very strong fuselage.

G

LUE the pod sides to the pre-cut hard

balsa nose block. Note that the nose

block is flush with the top and front of the

pod sides. Assemble everything together

upside down on a flat surface as shown.

Thick CA or aliphatic glue both work well.

When the glue is dry, trim and sand the bottom of the nose block flush with the bottom

of the pod sides.

Glue sides to nose block

Align nose block with sides

Trim block flush with sides

Phoenix

Page 19

Fuselage Construction

Attach pod sides to nose

Bevel aft upper edge of pod

Check fit to boom

Glue in place

Check for straightness

Glue pod to boom

❏

❏

❏

❏

❏

❏

❏

Page 22

U

SING a flat sanding block, sand the edges

of the tailboom sides and stringers flush

with the top of the pod sides. Do not sand F-

2. Carve out the bottom of the aft canopy

block to clear the pushrods.

The aft block is cut slightly oversize, and

must be trimmed to length. Place the forward

and middle canopy blocks in place as shown

on the plans. Test fit the aft block, and trim

as required.

Glue the aft canopy block in place. Make sure

to get a good bond to both the tailboom

sides and the pod sides.

W

HEN the glue is dry, determine where to

install the F-6 bulkhead. Its position is

set by the size of the rudder and elevator servos you are using. Remember to allow for the

servo mount rails. Cut the hole for the servo

leads in F-6. Glue F-6 in place.

Install the

1

⁄4" x 3⁄8" servo mounting rails. The

rails should be positioned so the servo arms

are at the height shown on the plans. Do not

drill the servo mounting holes at this time.

Sand the bottom edges of the pod smooth.

Glue F-7 and F-8 in place to the pod sides,

nose block and bulkheads. These parts are

cut slightly oversize to allow for trimming

later.

Cut servo lead hole in F-6

Glue F-6 in place

Glue servo mounts

Glue pod bottom in place

Phoenix

Page 20

Fuselage Construction

Finish pod assembly

Test fit and trim canopy

Hollow for pushrods

Glue aft block in place

Attach aft canopy block

❏

❏

❏

❏

❏

❏

❏

Page 23

M

ARK the position of the wing bolt hole

on the bottom of the wing. The hole

needs to be approximately centered on the F9 wing mounts. We prefer to make the hole

along the side of the dihedral joint instead of

on the exact center, to avoid drilling through

the epoxy.

Align the wing on the fuselage carefully.

Check the alignment by measuring from each

wingtip to the centerline at the aft end of the

tailboom. The dimensions on the right and

left sides should be identical.

Drill the hole through the wing and the F-9’s

using a number 29 drill. The hole should be

approximately perpendicular to the F-9 parts.

If you do not have a #29 drill, use a

1

⁄8" drill, and enlarge the

hole slightly with a knife or file.

G

LUE the the two F-9 aft wing mounts

together, using epoxy or thick CA glue.

When cured, glue them into the fuselage as

shown on the plans. Note that they are about

1

⁄16" above the top of the wing. Use epoxy, and

apply a fillet along the entire joint.

Place the wing in position on the fuselage

and mark the location of the wing dowel on

the leading edge. Drill a

3

⁄16" hole through the

leading edge. This is somewhat tricky, since

the drill will tend to wander off center

because of the epoxy in the dihedral joint,

but do the best you can. Trim the dowel to

length, and radius the front end with sandpaper. Chucking the dowel in an electric drill

and spinning it while sanding the radius works very well.

Insert the dowel in the wing and position the wing on the

fuselage. If necessary, use a file to enlarge the dowel hole in

the wing until the wing fits properly in its saddle.

Remove the dowel and fill the hole with an epoxy and

microballoon mixture. Insert the dowel and wipe off any

excess epoxy. Place the wing on the fuselage, align carefully

and allow the epoxy to cure.

Install F-9’s

Drill wing for dowel

Glue dowel in place

Check alignment

Phoenix

Page 21

Final Assembly

Install wing mounts

Mark hole position on wing

Align wing on fuselage

Drill hole through wing

Drill for wing mount bolt

❏

❏

❏

❏

❏

❏

❏

Page 24

T

HE motor alignment on Phoenix is very

critical. To install the motor mount accu-

rately, you need to build a jig.

Remove the J-1 and two J-2 parts from the die

cut plywood sheet and clean up the edges.

Slide the 1

1

⁄8" outside diameter liner tube

over J-1. Slide the J-2’s into place as shown.

The front end of the liner tube should be

flush with the front ends of the plywood

parts. When all the parts are properly

aligned, glue the liner tube, J-1 and the J-2’s

in place with CA.

The motor casing should be slid over the

liner tube as far as it will go. Apply masking

tape to the casing until it is a snug but not

tight fit in the 1

3

⁄16" motor mount tube. Slide the motor mount

tube over the casing until it is flush with the front of the casing.

R

EMOVE the wing. Enlarge the hole in the

F-9’s with a

11

⁄64" drill.

Installing the 6-32 blind nut is a bit tricky

since there is not a lot of room in the back of

the pod. Set the fuselage on the bench upside

down. Set the blind nut on top of the tailboom and slide it aft until it is under the

hole. Insert a 6-32 screw through the hole

and thread it a few turns into the blind nut.

Now pull the blind nut into place with the

screw. Once the nut is started into the hole,

you can tighten the screw to pull it fully into

place.

Remove the screw and apply some thin CA

around the nut so it doesn’t fall out.

Enlarge hole in F-9’s

Install blind nut

Phoenix

Page 22

Final Assembly

Install aft wing mount

Assemble jig parts

Fit casing to mount tube

Assemble motor mount jig

❏

❏

❏

❏

Page 25

T

RIM the edges of the F-10 spacers until

the motor mount tube will fit in place as

shown. The top of the motor mount tube

should just touch the bottom of the tailboom. The spacers should be within

1

⁄16" of

the motor mount tube, but not touch it. This

allows the motor alignment to be set entirely

by the jig.

Apply epoxy to the spacers and set the

motor mount tube and jig in place. Check

that the jig is sitting flat on the tailboom and

is aligned with the centerline. You can tack

glue the jig to the boom with CA if you want.

Wipe off any excess epoxy, and allow to cure.

Remove the motor casing and jig.

C

AREFULLY layout and draw a centerline

on the bottom of the tailboom.

Remove the two F-10 motor spacers from the

3

⁄32" die cut balsa sheets. Bevel the aft ends

until they will fit together as shown, and glue

in place.

A thin, trailing edge is important on the spacers where they meet. Excessive turbulence in

the airflow in this area will tend to pull the

hot motor exhaust up towards the tailboom.

Draw centerline on boom

Bevel aft end of F-10’s

Glue in place

Phoenix

Page 23

Final Assembly

Attach motor pylon

Trim F-10’s to fit tube

Glue motor mount in place

Check alignment !

Install motor mount

❏

❏

❏

❏

❏

❏

Page 26

R

EMOVE the F-11, F-12 and F-13 filler

blocks from the die cut balsa sheets. Glue

in place as shown.

We prefer to glue these parts in place with a

small amount of thick CA near the center of

each part. Next, carve and sand the pieces to

final shape. Be especially careful with the

motor mount and lower tailboom area. A

smooth, clean shape here helps to keep the

motor exhaust away from the tailboom. Since

there is no glue near the edges of the parts, it

is easy to blend them into the body shape.

Finally, flow thin CA around the edges of the

parts to firmly attach them.

Tack glue the middle canopy block in place,

then glue the forward canopy firmly in place.

Carve and sand the entire fuselage to shape as shown on the

plans. Cut the middle canopy block loose.

T

HE upper surface wing skins need to be

trimmed away to clear the motor mount

tube. Place the wing in position on the fuselage, and approximately mark the area to be

removed. Begin trimming with a knife. The

final shaping can be done with the motor casing wrapped in sandpaper as shown. Work

carefully, and keep checking the fit of the

wing to the motor tube and body. When you

are finished, the wing should again fit properly in its saddle on the fuselage.

If you trim too much, the gap can be filled

with microballoons and epoxy. Cover the

motor tube with plastic wrap to protect it,

apply the filler to the wing cutout and bolt

the wing in place. After the epoxy has cured, remove the wing

and trim the filler flush with the wing skin.

Trim top of wing

Check the fit often

Phoenix

Page 24

Final Assembly

Trim wing to clear motor

Glue filler blocks

Glue canopy blocks

Carve and shape fuselage

Remove mid canopy block

Add blocks and shape

❏

❏

❏

❏

❏

❏

Page 27

T

HIS is a good time to cover the elevator,

rudder and the trailing edges of the horizontal and vertical tails. After all of the

model is assembled, do the remainder of the

covering.

Locate the position of the elevator horn as

shown on the plans. The edge of the horn

should be as close to the vertical stabilizer

as possible. Drill the

1

⁄16" holes for the mount-

ing screws. Insert the two #4 x

3

⁄8" sheet metal

screws though the top of the elevator, and

thread them directly into the nylon control

horn. Install the elevator and rudder hinges

using the same procedure as on the aileron

hinges.

The small size of the Phoenix tail boom makes it difficult to

use a normal clevis to connect to the horns. Instead we use a

Z bend. All adjustments are made with the clevis on the servo

end of the pushrod. To remove the pushrods, simply unscrew

the control horns, and slide the entire pushrod out the back

of the tailboom. The use of the #4 screws from the top of the

elevator allows us to remove the elevator horn more easily.

F

IND the two 3⁄16" square balsa pushrods

that you set aside earlier. Bend and cut

the two pieces of

1

⁄16" Z-bend wire as shown

on the plans. There is not a lot of room in the

back of the tailboom, so make the pushrods

carefully. Drill the

1

⁄16" hole through the

pushrods. Glue the wire to the pushrods with

CA. Wrap the ends of the pushrods with

thread as shown. Saturate the thread with

glue.

Trim the rudder and elevator horns to the

length shown on the plans.

Phoenix uses wood pushrods for several reasons. First, and most important, balsa

pushrods used in a model with a balsa fuse-

lage will have essentially no change in trim with changes in

humidity or temperature. Once you get the model trimmed

out, it will stay trimmed. This is a big advantage on a model

like Phoenix. Second, if you keep the pushrods straight, they

will be very rigid, so you will have precise control at all

speeds. The Phoenix tailboom and offset vertical tail were

designed so the pushrods could be perfectly straight. Finally,

the wood pushrods are very light.

Bend and cut the wire

Glue and bind to pushrods

Trim horns to length

Phoenix

Page 25

Final Assembly

Assemble pushrods

Cover the control surfaces

Attach horn to elevator

Hinge the control surfaces

Attach elevator horn

❏

❏

❏

❏

❏

❏

Page 28

S

ET the servos in place on the mounts.

Trim a pair of servo arms so that only one

arm remains. Attach a clevis to each servo

arm. Hook up the servos to the radio, and

center the trims. Install the servo arms and

clevises.

Hold the elevator and rudder at neutral position with tape. Trim the front of the balsa

pushrods off

1

⁄4" in back of the clevises.

Remove the elevator and rudder control

horns and slide the pushrods out the back of

the boom. Remove the clevises.

Thread the clevises onto the short 2-56

threaded rods. There should be about

1

⁄8" of

threads visible inside the clevis. Attach the

threaded rod to the bottom of the pushrods with CA. Leave

1

⁄4" between the back of the clevis and the end of the balsa as

shown. Wrap the joint with thread and saturate with glue.

Reinstall the pushrods and horns.

Check the control throws, and move the clevis on the servo

arm as required. Trim off any excess servo arm. Position the

servos so the arms are as close to the center as possible, and

install the servo mount screws that came with your servos.

M

OUNT the wing to the fuselage. Check

the roll axis alignment of stabilizer and

the wing. Sand the top of the boom until the

tail is level. Glue the tail in place. Make sure

the elevator hinge line is perpendicular to

the boom centerline.

The vertical tail is mounted flush with the

side of the tail boom, not on the centerline.

This allows us to have a very strong attachment of the tail. The aft end of the F-1 tailboom side will have to be trimmed as shown

on the plans. Note the

1

⁄16" clearance between

the elevator joiner and the V-3 tailpost. You

will have to trim away some of the lower

3

⁄16"

square stringer until the outer surface of the

tailpost is flush with the side of the tailboom.

Carefully draw a centerline on the top of the horizontal tail.

Glue the vertical tail in place. You should have a good bond to

the side of the boom, the lower stringer, and the horizontal

tail. Check that the tail is vertical and parallel to the centerline. Note that the tail is not parallel to the side of the boom!

Trim the bottom of the tailpost flush with the boom.

Install the rudder horn and pushrod as shown. Make sure the

pushrods do not bind.

Align horizontal tail

Glue horizontal tail

Align vertical tail

Glue vertical tail

Attach rudder linkage

Phoenix

Page 26

Final Assembly

Attach tail surfaces

Trim pushrods to length

Attach clevises

Check control throws

Mount servos

Install servos

❏

❏

❏

❏

❏

❏

❏

❏

❏

Page 29

B

EFORE you can continue, you will need to

obtain 4 pieces of

3

⁄8" diameter aluminum

rod about 36" long. Aluminum rod is available from most good hardware stores in

either 6 or 12 foot lengths. Take a piece of the

13

⁄32" diameter by 3" long brass tube with you

to the store to make certain that the aluminum rod is a smooth slip fit in the tubing.

Next, plug one end of each of the four

13

⁄32"

diameter brass tubes. Use a knife or file to

sharpen one end of a tube by removing material from the inside edge to form a sharp

bevel. Use this as a punch to cut four discs

from

1

⁄16" scrap balsa. Glue a disc into one

end of each piece of brass tube with CA. The

discs will keep the epoxy out of the tubes. Rough up the outside of the tubes with coarse sandpaper.

Lay the launcher sides on some waxed paper or plastic wrap.

Slide the aluminum rods into the brass tubes. Glue the tubes

into the slots in the L-2 parts with epoxy. Use enough epoxy

to fill the voids between the tubing and L-1. Some epoxy will

be squeezed out of the channel. It can be cleaned off later.

Check that the rods are parallel before the glue sets. Do not

glue the aluminum rods in place.

R

EMOVE all launcher parts from the die

cut plywood sheets. Be careful when

removing the eight L-2 parts, since the area

around the slots is fragile. It is a good idea to

use a knife to remove the parts from the

sheets.

Lay the two L-1 parts on the bench. Be sure

to orient them as shown so you make both a

left side and a right side. Laminate four L-2’s

onto each L-1. This can be done with either

epoxy or a thick CA glue. Make sure that the

slots line up and are oriented as shown.

While you are at it, laminate the four L-7

parts into 2 pairs of two layers each.

If you want, sand the edges of the lamina-

tions smooth. It doesn’t make any difference in how well the

launcher works, but it does look better.

Remove parts from sheets

Laminate parts

Make a left and a right

Sand edges

Phoenix

Page 27

Launcher Assembly

Laminate launcher sides

Obtain aluminum rod

Plug ends of tubing

Glue in place

Make sure rods are parallel

Install brass tubes

❏

❏

❏

❏

❏

❏

❏

❏

Page 30

M

ARK the location of the 3⁄8" hole on one

of the sides. The exact location is not

too critical, but, you need to make sure to

miss the brass tubes,and don’t get to close to

the edge of the part.

Tape or clamp the side assemblies together.

Drill a

3

⁄8" diameter hole through both sides

for the pivot dowel. Try to keep the hole perpendicular to the sides. A“bradpoint” type

wood drill makes a much cleaner hole than a

conventional drill.

G

LUE an L-3 on top of each L-2 stack. You

might want to sand the edge of each L-3

nearest the rods before you glue them since

it will be difficult to sand later.

Fill the slots in the L-2’s with epoxy. Microballoons can be used to thicken the epoxy to

keep it from running. Coat the inside of each

L-3 with epoxy and glue in place. Clamp the

stack together until the glue cures. Do not

glue the aluminium rods in place! Also note

that the grain on the L-3 parts is parallel to L1 grain.

This is also a good time to glue the L-4 parts

in place.

Trim off the excess epoxy after everything is fully cured, and

sand the edges of the stack.

Glue on L-3’s

Fill the slots with epoxy

Glue on L-4’s

Phoenix

Page 28

Launcher Assembly

Finish sides

Layout location of hole

Clamp sides together

Drill hole

Drill for pivot dowel

❏

❏

❏

❏

❏

❏

Page 31

S

LIDE an aluminum rod into the top tube of

each side. Using the

3

⁄8" dowel as a shim,

set up the launcher as shown.

Glue the second side in place. Make sure the

rods are parallel. Tape or pin the side in

place while the glue dries.

If you want, this is the time to give the

launcher a good final sanding. Also, sand the

laminated L-7 parts smooth, and radius all

the edges except the one that will be glued to

L-6.

Radius the ends of the

3

⁄8" dowel slightly. An

easy way to do this is to chuck the dowel in

an electric drill and sand the ends while it is

spinning. Insert the dowel in the holes, make sure it is centered side to side, and glue it in place.

B

EVEL the ends of part L-5 and the two L6’s as shown on the plans. Clean up the

other edges with sandpaper.

Glue L-5 and the two L-6 ‘s onto one of the

sides as shown. Check to see that everything

is square before the glue sets.

Bevel ends of L-5 and L-6

Glue in place

Phoenix

Page 29

Launcher Assembly

Attach bulkheads

Set up as shown

Glue the side in place

Keep rods parallel

Glue the dowel in place

Attach second side

❏

❏

❏

❏

❏

❏

Page 32

A

SSEMBLE the entire launcher and your

Phoenix. Set the Phoenix in the launcher,

and center it carefully. Glue the L-7 parts in

place on top of the launcher as shown on the

plans. Allow about a

1

⁄16" space between the

L-7’s and the tailboom. Make sure the radius

on the edges of the L-7’s is smooth so they

do not scratch the finish on the model. These

parts help guide Phoenix when launching in

gusty weather.

Remove the launcher from the Mantis base.

Give the entire launcher a good coat of finishing resin to seal the wood. If you want, you

can apply extra resin, sand and paint. Just

remember, you are building a rocket launch-

er, and it will get very dirty with use, so don’t go overboard!

At least you don’t have to worry about adding too much

weight!

Finally, glue the ceramic tiles in place with epoxy. Note the

scrap

3

⁄16" balsa shim under the lower tile. You might have to

remove a paper or cloth backing from the tiles before you

glue them in place.

I

F you are going to use a Mantis™ base for

the launcher, you need to drill holes for the

elevation screw. First, note the location of

the holes on the plans. Install the launcher

adapter into the Mantis launcher by flexing

the side supports apart and inserting the

3

⁄8"

dowel in the molded holes. Using the holes in

the Mantis as a guide, drill the 2 sets of

3

⁄16"

holes. Unless you have an extra long drill bit,

you will have to drill the hole in one side, flip

the launcher over and then drill in from the

other side. Insert a screw or dowel through

the first holes to keep the parts aligned while

you drill the hole on the other side.

The exact location of the holes is not critical,

as long as the screw will fit and it is not too sloppy. The locations shown on the plans give launch elevations of about 45°

and 60° respectively. The 60° setting is used for initial flights,