Phoenix R250 Owner's Manual

4201 Lien Rd. • Madison, WI 53704

Owner’s Manual — Phoenix R250 LGR Dehumidifier

Installation, Operation & Service Instructions

Read and Save These Instructions

The Phoenix R250 has been redesigned from the inside out

The Phoenix R250 LGR Dehumidifier

• Coated Coils – For longer life, protection against

corrosion in the harshest environments, and protection

against the loss of the heat transfer properties of the

coil.

• Capacity - The Phoenix R250 removes 135 pints per

day at AHAM, (80°F/60%RH).

• Energy Efciency - Draws only 8.3 amps and removes

6.0 pints/kWh.

• 310 CFM - Faster drying and superior static pressure

for ducting.

• Hi-Temp Operation - up to 110°F

• Heavy-Duty Condensate Pump.

• Compact Design - 20”x20”x33.5”.

• Telescoping Handle - A heavy-duty retractable handle

for ease of transport and reduces space for storage

and stacking.

• Recessed 12” Wheels - Allows greater maneuverability

on the job site and efcient storage. Rolls over

obstacles with ease.

• Pleated Media Air Filter - A 12”x12”x1” MERV-11 lter

is standard.

• Stacking/Nesting - Reduces space for ease of stacking

and storage.

• Patented ByPass™ Technology - Increased

performance over a wide temperature range.

to be a rugged, high-performance dehumidier. Phoenix is

leading the industry by introducing epoxy coated coils. This

new feature will extend the life of the coil, provide protection in

corrosive environments, and maintain the coil’s heat transfer

ability over the life of the coil.

We kept the outstanding handle used on the R200 along with

patented ByPass™ Technology, increased airow, multiple

ducting options, and a pleated media lter. And, with some

amazing Phoenix Engineering, the R250 removes the most

water of the Phoenix rotomolds at 135 pints per day (AHAM)

while drawing only 8.3 amps of electricity, making it one of the

smallest, lightest XL category LGRs on the market.

Patented

BYPASS

www.youtube.com/user/usephoenix

Phoenix R250

Part No. 4034460

Patent 7,246,503

D570,988

8,069,681

Specifications subject to change without notice.

1

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

TS-889

08/15

Table of Contents

Introduction ............................................................................ 1

1. Safety Certications ....................................................... 2

2. Specications .................................................................2

3. Operation ........................................................................2

3.1 Transporting ..............................................................2

3.2 Location ..................................................................... 3

3.3 Electrical Requirements ...........................................3

3.4 Condensate Removal ...............................................3

3.5 Ducting ...................................................................... 3

3.6 Defrost Cycle .............................................................3

3.7 Power Button ............................................................3

3.8 Purge Button .............................................................3

3.9 Hour Meter ................................................................ 3

3.10 Hours Button ..........................................................3

3.11 Defrost Light ........................................................... 4

3.12 Bypass Control .......................................................4

4. Maintenance ................................................................... 4

4.1 Air Filter .....................................................................4

4.2 Storage ......................................................................4

5. Service ............................................................................. 4

5.1 Technical Description ............................................... 4

5.2 Troubleshooting ........................................................ 5

5.3 Air Mover ................................................................... 6

5.4 Thermistor .................................................................6

5.5 Condensate Pump .................................................... 6

5.6 Float Safety Switch ................................................... 6

6. Options & Accessories ................................................... 7

7. Wiring Diagram ..............................................................7

8. Service Parts ................................................................... 8

9. Warranty .......................................................................... 9

Read the operation and maintenance instructions

carefully before using this unit. Proper adherence to these

instructions is essential to obtain maximum benet from

your Phoenix R250 dehumidier.

• It is designed to be used INDOORS ONLY.

• If used in a wet area, plug it into a GROUND FAULT

INTERRUPTER.

• DO NOT use the Phoenix R250 as a bench or table.

• It must always be used in the upright position.

1 Safety Certifications

The Phoenix R250 conforms to unied standard UL 60335-

2-40.

2 Specifications

Part No. 4034460

Power 8.3 amps, 120 VAC, Grounded

Water 135 pints/day @ AHAM (80°F, 60%)

Removal

Blower 310 CFM without external ducting

Refrigerant 2 lb, 0 oz. R-410A

Charge

Operating

Range

Filters:

Duct Inlet – 12” Flex-Duct

Options

Warranty Five years;

1st year 100% of Parts and Labor

2nd-5th year 100% of sealed refrigeration

system parts.

Dimensions

Width 20” 21”

Height 33.5” 35.25”

Depth 20” 21”

Weight 109 lbs 125 lbs

Patent - 7,246,503

D570,988

8,069,681

33°F to 110°F

12” x 12” x 1” Pleated Media MERV-11

Outlet – 10” Lay-Flat

Unit Shipping

3 Operation

Place dehumidier inside structure,

place condensate hose into a drain, or a

large water tight container, and turn on.

To decrease drying times, make sure all

windows and doors are closed to the outside

and seal off the affected wet areas from

unaffected areas.

Optimum performance will be observed

between the temperatures of 70°F and

95°F.

3.1 Transporting

The Phoenix R250 must always be upright when transported

by vehicle. It may be tipped on to its handle and back for

loading and moving by hand.

If the unit is transported on its side, let it sit upright at least

30 minutes before use.

Figure 1: Stacked

Phoenix R250

2

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

3.2 Location

Note the following precautions when locating the Phoenix

R250:

• It is designed to be used INDOORS ONLY.

• If used in a wet area, plug it into a GROUND FAULT

INTERRUPTER.

• DO NOT use the Phoenix R250 as a bench or table.

• It must always be used in the upright position.

3.3 Electrical Requirements

The Phoenix R250 plugs into a common grounded outlet on

a 15 amp circuit. It draws 8.3 amps at 80°F, 60% RH. If used

in a wet area, a ground fault interrupter (GFI) is required. If

an extension cord is required, it must have a minimum of

14 gauge conductors if 25 feet long or less and 12 gauge

conductors if greater than 25 feet long.

3.4 Condensate Removal

The Phoenix R250 is equipped with an internal condensate

pump to remove the water that is condensed during

dehumidication. This pump allows the condensate to be

pumped 20 feet above the unit with the attached hose. If the

condensate must be pumped more than 20 feet above the

unit, a relay pump must be added. The condensate pump

automatically purges for 20 seconds every eight minutes. Use

the PURGE button to empty reservoir. If the condensate level

rises in the reservoir to a critical level a back-up oat switch

will activate the pump-out for up to 1 minute. If the water in

the reservoir fails to be evacuated, the safety switch will turn

off the compressor.

3.5 Ducting

A wire duct collar is supplied to allow 10” lay-at duct to be

attached to the Phoenix R250 outlet. Lay-at plastic ducting

is available (see accessories in section 6). Attach ducting to

the wire duct collar by inserting the plastic duct end through

the collar center and rolling the duct end outward to overlap

the outside of the collar. The duct and collar may then be

quickly attached to the Phoenix R250 by snapping the collar

over the four plastic exhaust tabs.

If the R250 is located in the unaffected area, the intake can

be ducted with 12” ex duct (see accessories in section 6).

Attach the ex duct to the top cover by hooking the spiral

wire under the four tabs. Tape the duct to the top cover for a

complete seal.

Figure 2: Phoenix R250 with lay-at duct.

state control and the defrost light. The control cycles the

compressor “off” and “on” by the thermistor temperature

measurement. The air mover will continue to run, causing air

to ow through the evaporator coil and melt the ice when the

compressor is off. When the air temperature and/or humidity

increases, the evaporator temperature will rise and the

thermistor will end the defrost cycle at the defrost set point.

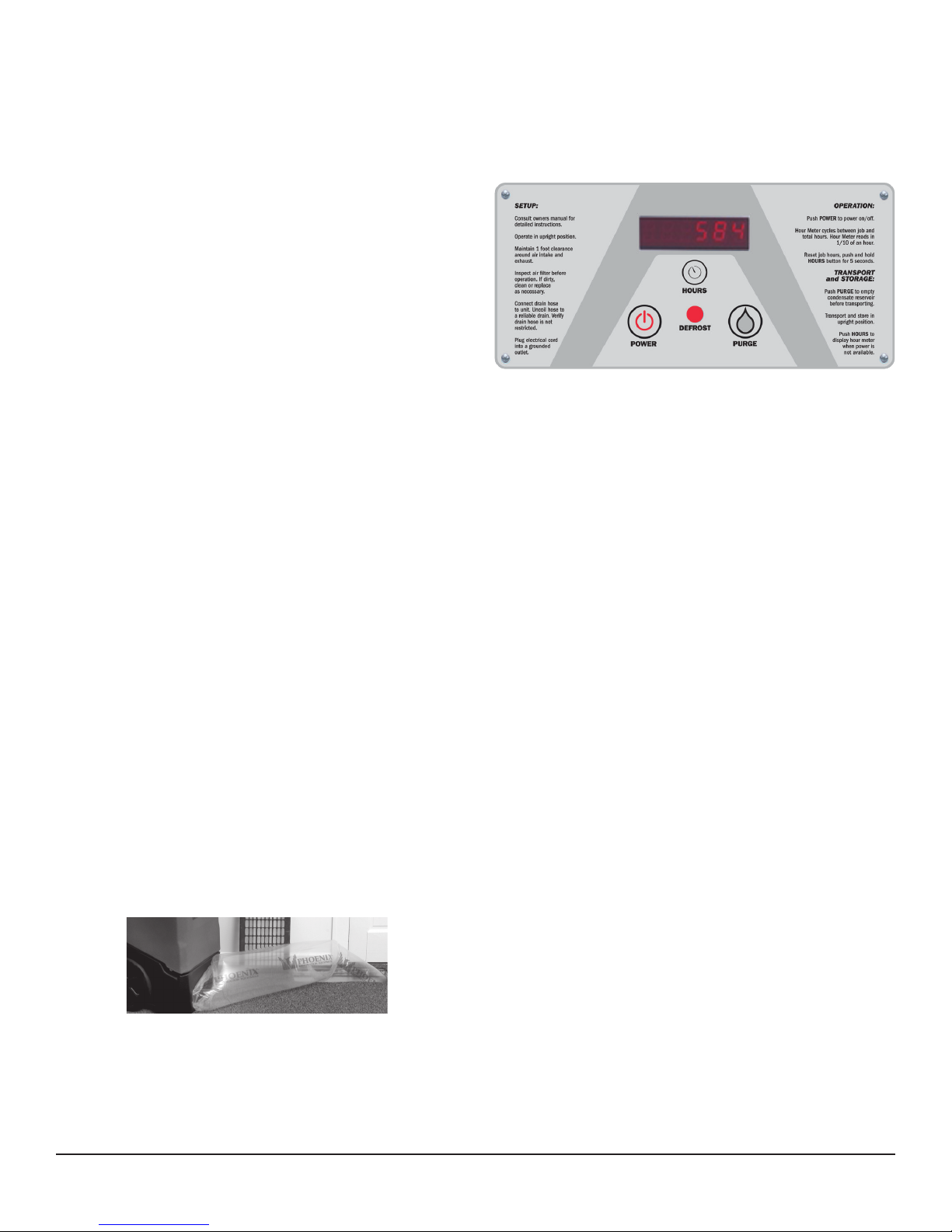

Figure 3: Phoenix R250 control board.

3.7 POWER Button

Press the POWER button to turn the dehumidier “on” or

“off”. When starting the dehumidier the display will show

the accumulated hours. Press the POWER button again to

turn the dehumidier off. The display will also power off.

3.8 PURGE Button

During normal operation the pump automatically cycles

every eight minutes. Press the PURGE button to remove

condensate manually from the reservoir. There are three

ways to manually remove water from the reservoir:

1. Press the PURGE button once and the pump will run for

20 seconds

2. Press and hold the PURGE button and the pump will run

for up to 30 seconds

3. Press the PURGE button while the dehumidier is

plugged in but powered off and the pump will run for 30

seconds.

Always manually purge the water reservoir before transport

or storage. Turn off the power and allow the plugged in

dehumidier to rest 15 minutes before the nal purge.

3.9 Hour Meter

The digital hour meter displays the amount of time the

dehumidier has been turned on to the tenth of an hour. The

hour meter continuously cycles between total machine hours

and job hours every 3 seconds. Hours are stored in memory

even when the unit is unplugged. The previous totals will be

displayed next time the unit is powered on.

3.6 Defrost Cycle

If the low side refrigerant temperature drops below the

defrost set point, due to excessive frost formation on

the evaporator coil, the thermistor activates the solid-

3.10 HOURS Button

Pressing the HOURS button displays the hour meter when the

unit is turned off but plugged into power. To reset job hours,

press and hold the HOURS button for 5 seconds when the

unit is operating.

3

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Loading...

Loading...