Page 1

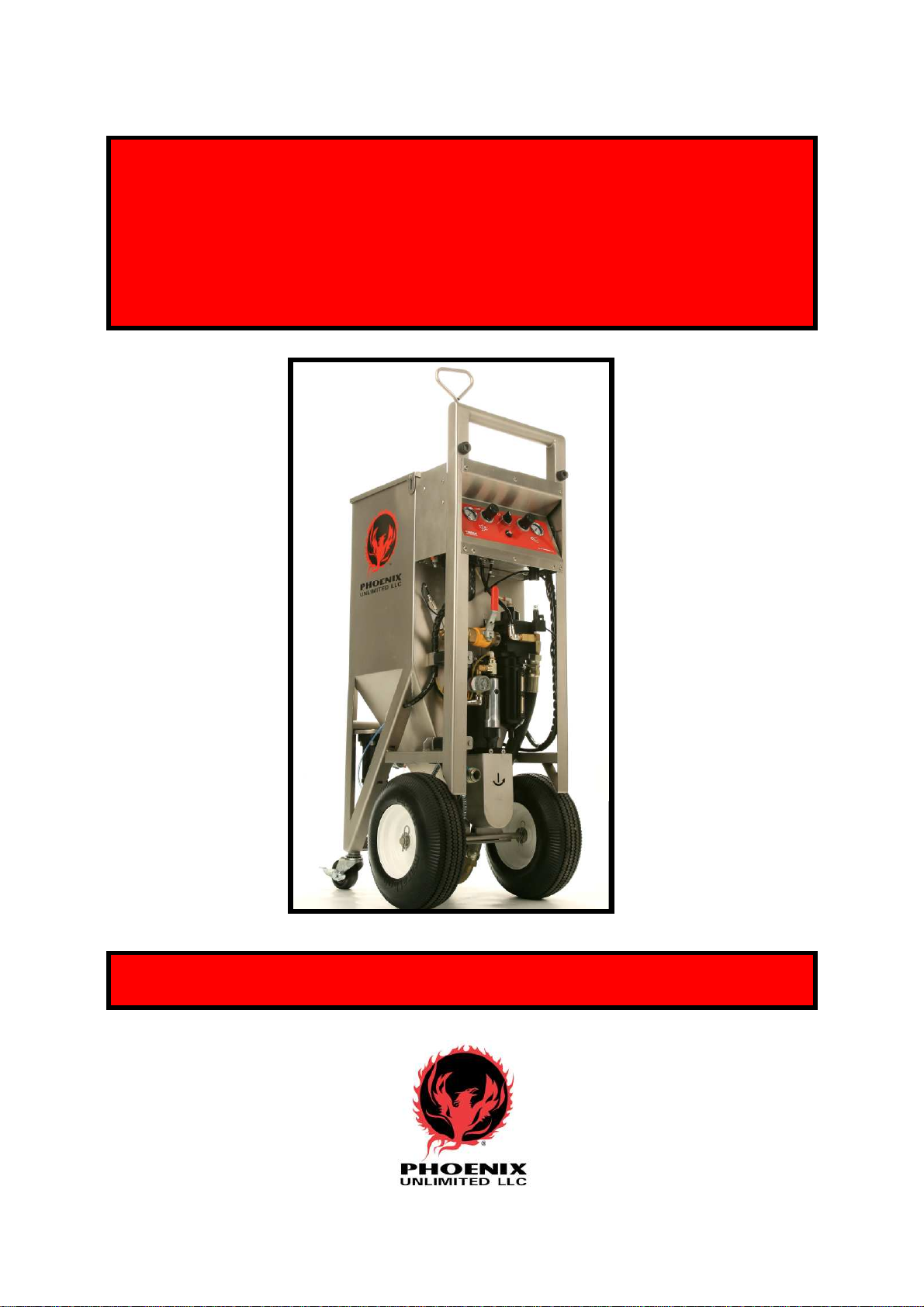

PHX

-

150

Dry Ice Cleaning System

U S E R ’ S G U I D E

30295-UG-040517

Page 2

****************************************************TTAABBLLEEOOFFCCOONNTTEENNTTSS*************************************************

SYSTEM I.D. …………………………………………………… Page 3

EQUIPMENT WARRANTY…………………………………… Page 4

INTRODUCTION ……………………………………………… Page 5

SAFETY PRECAUTIONS AND WARNINGS……….……… Page 6, 7

KEY COMPONENT I.D. ………..………………………..…… Page 8

CONTROL PANEL/WARNING LABEL ….………………… Page 9

OPERATION INSTRUCTIONS

Connecting the Air Supply ………………………..…………. Page 10

Connecting the Blast Gun …………………………...……….. Page 11

Loading Dry Ice ………………………………………………. Page 12

Setting the Panel Controls ……………………………..…….. Page 13, 14

Temporary Shutdown ………………………………….…….. Page 15

Overnight / Long Term Shutdown ……………………..……. Page 16

MAINTENANCE

Daily Preventive Maintenance ………….………………...….. Page 17

As Needed Maintenance

Emptying the Separator……………………………………. Page 18

Changing the Separator Filter Element………………...… Page 18

Changing the Inline Filter Element (Trigger Line) …...…. Page 18

Changing / Adding 10W Oil ……………………………..… Page 19

Checking / Adjusting the Drive Chain Tension…………... Page 19, 20

Periodic Maintenance

Replacing/Servicing Airlock Critical Components………... Page 21-24

*

Page 2

TROUBLESHOOTING CHART ……………………….…..… Page 26, 27

DRAWINGS / PARTS LISTS

Drawing Reference ……………………………………...…... Page 28

Control Panel Assembly ……………………………….……. Page 29

Control Shelf Assembly ……………………………….. .….. Page 30

Vibrator Assembly …………….……………………..……… Page 31

Air System Assembly …….……………………...……..….... Page 32

Filter/Regulator Assembly ….. …………………….………. Page 33

Auger Drive Assembly ………………………………….…… Page 34

Airlock Assembly ………………………………..……..……. Page 35

Auger Section……..……………………………………....…. Page 36

Gun Assembly …………………………………………..…. Page 37-38

Tube Diagram / Factory Settings…………..……………….. Page 39-43

RECOMMENDED SPARE PARTS …………………..…..…. Page 44

SPECIFICATIONS …………………………………….…..….. Page 45

**************************************************************************************************PPHHXX--115500*******************

*

Page 3

SYSTEM I.D.

This User’s Guide is printed for use with the following dry ice cleaning system:

Model: PHX-150

Part Number: 30295-001

Serial Number: 30292

Manufacturing Date: 04/17

U.S. Patent No. 6,346,035

It is recommended that the above information be kept in a safe place. Have it readily

available when utilizing the services of the manufacturer with regards to technical

support, service, parts, etc.

The written material herein contains proprietary information intended for the sole use of

the original owner. It may not be duplicated or disclosed to other parties.

Inspected By: __________________________ Date: __________________________

©2017 Phoenix Unlimited LLC. All rights reserved.

Federal law provides severe civil and criminal penalties for the unauthorized

reproduction or distribution of copyrighted material.

**************************************************************************************************PPHHXX--115500*******************

*Page 3

Page 4

Phoenix Unlimited LLC Equipment Warranty

Phoenix Unlimited LLC (the Company) warrants that the Equipment it manufactures and

delivers hereunder will be free of defects in material and workmanship for a period of

twelvemonths or 2000 hours of operation from the date of shipment, whichever occurs first.

Upon written request, Phoenix Unlimited shall, at its option, correct any nonconformity by

suitable repair to such Equipment, or furnish a replacement part F.O.B. point of shipment,

provided the Purchaser has stored, installed, maintained and operated such Equipment in

accordance with good industry practices and has complied with specific recommendations

of the Company. The Company shall not be liable for any repairs, replacements, or

adjustments to the Equipment or any costs of labor performed by the Purchaser or others

without the Company's prior written approval. The effects of corrosion, erosion and normal

wear and tear, are specifically excluded from warranty.

Correction by the Company of nonconformities whether patent or latent, in the manner and

for the period of time provided above, shall constitute fulfillment of all liabilities of the

Company for such nonconformities, whether based on contract, warranty, negligence,

indemnity,or strict liability with respect to or arising out of such Equipment.

The Purchaser shall not operate Equipment which is considered to be defective without first

notifying the Company in writing of its intention to do so. Any such use of Equipment will

be at the Purchaser's sole risk and liability and will void warranty coverage.

Page 4

Accessories or equipment furnished by the Company, but manufactured by others, shall

carry whatever warranty the manufacturers have conveyed to the Company and which can

be passedon to the Purchaser.

The Companymakes no otherwarrantyor representation of any kindwhatsoever,

expressed or implied,except that of title,and all implied warrantiesof merchantability

and fitness for a particular purposeare herebydisclaimed.

**************************************************************************************************PPHHXX--115500*******************

*

Page 5

INTRODUCTION

Congratulations on choosing the new PHX-150 dry ice cleaning system for your

industrial cleaning needs. Its’ unique design and variable logic control make it the perfect

choice for a wide range of applications, and in any type of environment. Using rice-sized

dry ice pellets, this versatile blasting machine not only handles your tough cleaning jobs;

it cuts your overhead costs in the process. Smart design, powerful, and portability too…

an industrial piece of equipment that will last for many years to come!

You are now ready to learn how to use your new PHX-150.

Before you attempt to operate the equipment, we recommend that you take the time to

fully familiarize yourself with the contents of this User’s Guide. The information

contained in this guide can save invaluable time by helping you gain a clear

understanding of the installation, safety, operation, and maintenance procedures.

Note: Pay particular attention to the sections on “Safety Precautions and Warnings”,

outlined on the following two pages.

Once you are comfortable with the information provided, you will be ready to say

goodbye to old-fashioned methods of cleaning and begin using your new dry ice blaster.

With proper equipment care, you will soon see that the PHX-150 is one tool you cannot

be without.

If you have questions concerning the installation, operation, or information contained in

this User’s Guide, please contact ‘Phoenix Unlimited LLC’ at: (951) 278-2229.

Customer support and technical assistance is always available.

Enjoy!

*****************************************************************************************************************

*

PPHHXX--115500*******************

*Page 5

Page 6

SAFETY PRECAUTIONS AND WARNINGS

User’s Guide Information

Dry ice cleaning equipment should not be operated without proper training and the

consent of your direct supervisor or management. The information contained in the

User’s Guide will provide all the tools necessary for proper operation, safety,

maintenance, and troubleshooting of the equipment. Read and understand the contents of

this guide before using or servicing your machine.

Equipment Usage

Your new cleaning system was designed for use in an industrial environment. Proper safety precautions

should be practiced, observed, and monitored at all times. Be especially careful when blasting around

materials that can shatter. Dry ice blasting adapts to many types of applications, but the high velocity

pellets can cause damage to fragile items or substrates of low integrity. Remember NEVER to direct the

blast stream at yourself or others.

Asphyxiation Hazard

Sublimation of dry ice creates CO2gas. This gas is 40% heavier than air, and thus

displaces oxygen in low-lying areas and enclosed spaces. When blasting, always have

adequate ventilation in and around your workspace. Contaminated compressed air (or

nitrogen) used as a propellant may greatly increase respiratory risk. A “High CO2”

sensor/monitor with indicators is a worthwhile investment and can help prevent

accidental asphyxiation.

Noise

Blasting equipment generates a high velocity air flow from the nozzle. This air flow creates friction as it

passes through normal static air, resulting in high decibel noise levels. Though these levels can be

controlled somewhat by altering pressures and flow rates, ear protection is required in all blasting

situations. Additional noise factors include the object being cleaned, distance from the targeted material,

media quantity being used (ice rate), and acoustic surroundings. If you are unsure about blasting in an area

around you or fellow co-workers, consult with your safety director for advice and/or safety parameters

before beginning work.

Page 6

Emergency Stop Mechanisms

Your unit is equipped with an Arm/Disarm switch located in the center of the control panel. Under normal

use, this switch acts as a convenient way to quickly interrupt power to your PHX-150. However, the true

designated E-STOP is the full-flow valve (bright yellow with a red handle) located on the air system

manifold under the control panel. This valve must be closed before attempting maintenance work or

repairs. A 5/16” hole is provided in the handle to accommodate your company lockout procedures, if

applicable. Raise the locking tab to re-open the valve.

Protective Gear

Before beginning work, make sure you have the proper protective gear for the job. This

includes the basics: Ear plugs or muffs (or both), eye protection, gloves, long sleeves,

long pants, and safety shoes. Dependant upon specialized cleaning jobs, you may also

need other protective items such as: self-contained breathing apparatus, respirator,

grounding straps, skin protectors, jumpsuit, special clothing, or other equipment as

deemed necessary by your company’s safety regulations.

**************************************************************************************************PPHHXX--115500*******************

*

Page 7

Ergonomics

The training process for using your new PHX-150 is relatively easy, but there will still be a “learning

curve” where technique and experience is concerned. The operator should understand that high velocity air

exits the gun barrel. Upon triggering the gun, the operator will experience a small reactive thrust, which

increases or decreases depending on pressure settings and air flow. Operator fatigue may also be an issue,

relating to blasting angles, pressure settings, dwell times, work area, temperatures, physical conditioning,

and time on duty. Do not exceed allowable limits as set by company policy and safety personnel.

High Velocity Particles

High velocity particles exiting the gun may cause serious injury. Never aim the gun at

yourself or others. The ice is sometimes difficult to see in the blast stream. However,

never use your hand, foot, or any other body part to check pellet flow. Do not blast

delicate or fragile items or equipment parts (i.e. glass or plastic gauge faces). Damage

may occur.

Moving Parts

Though the moving parts inside your PHX-150 are minimal, they are critical components and serious injury

may occur if safety parameters are not adhered to. Your machine incorporates an auger that turns, feeding

dry ice pellets into the delivery system. A safety sensor is activated to immediately stop the auger from

turning anytime the pellet screen is removed. Do not attempt to override this sensor. The auger drive motor

and chain are shielded by a protective guard and should never be operated without the guard in place. Do

not attempt to operate the airlock assembly while detached from unit. Always follow shut-down procedures

before attempting any periodic maintenance or repairs.

Burn Hazard

Dry ice is extremely cold, -109°F (-78°C). Do not allow skin to directly contact dry ice or

the outside of the PHX-150 hopper while it is loaded with dry ice. Doing so may cause

severe deep tissue burns. Always wear heavy-duty insulated gloves and long sleeved

clothing for protection when handling dry ice or cold equipment during use.

Static Discharge

The gun of the PHX-150 is grounded through the blast hose to the frame, then through

the special conductive front wheels; therefore any significant amount of static discharge

is uncommon. Still, the possibility exists that minor static discharges can occur pending

weather conditions, the travel of high velocity ice particles, etc. If static discharge is

experienced, wear the grounding wrist strap supplied with your unit. Also, you may wish

to add an additional wire from the machine to a good earth ground, AND ground the item

that you are blasting.

Caution: Static discharge may ignite flammables. Be aware of your surroundings!

Lower Limit Blast Pressure

The PHX-150 utilizes an additional regulator that maintains the blast pressure at 45 psi, even though it is

turned all the way down. When conducting function tests while the unit is energized, take the necessary

precautions to insure that the blast gun is secured and pointed in a safe direction.

Logic Control Stored Air Hazard

The control circuitry of this machine may trap air in and between associated components. Vent unit before

any maintenance or service is performed to prevent accidental release of trapped air.

Lock Out/Tag Out Precaution

Do not perform any type of service to this equipment until all lock out/tag out procedures have been

followed according to your company’s safety regulation guidelines. As mentioned previously (page 6),

a lock out hole (5/16”) is provided in the E-Stop valve handle if required.

**************************************************************************************************PPHHXX--115500*******************

*Page 7

Page 8

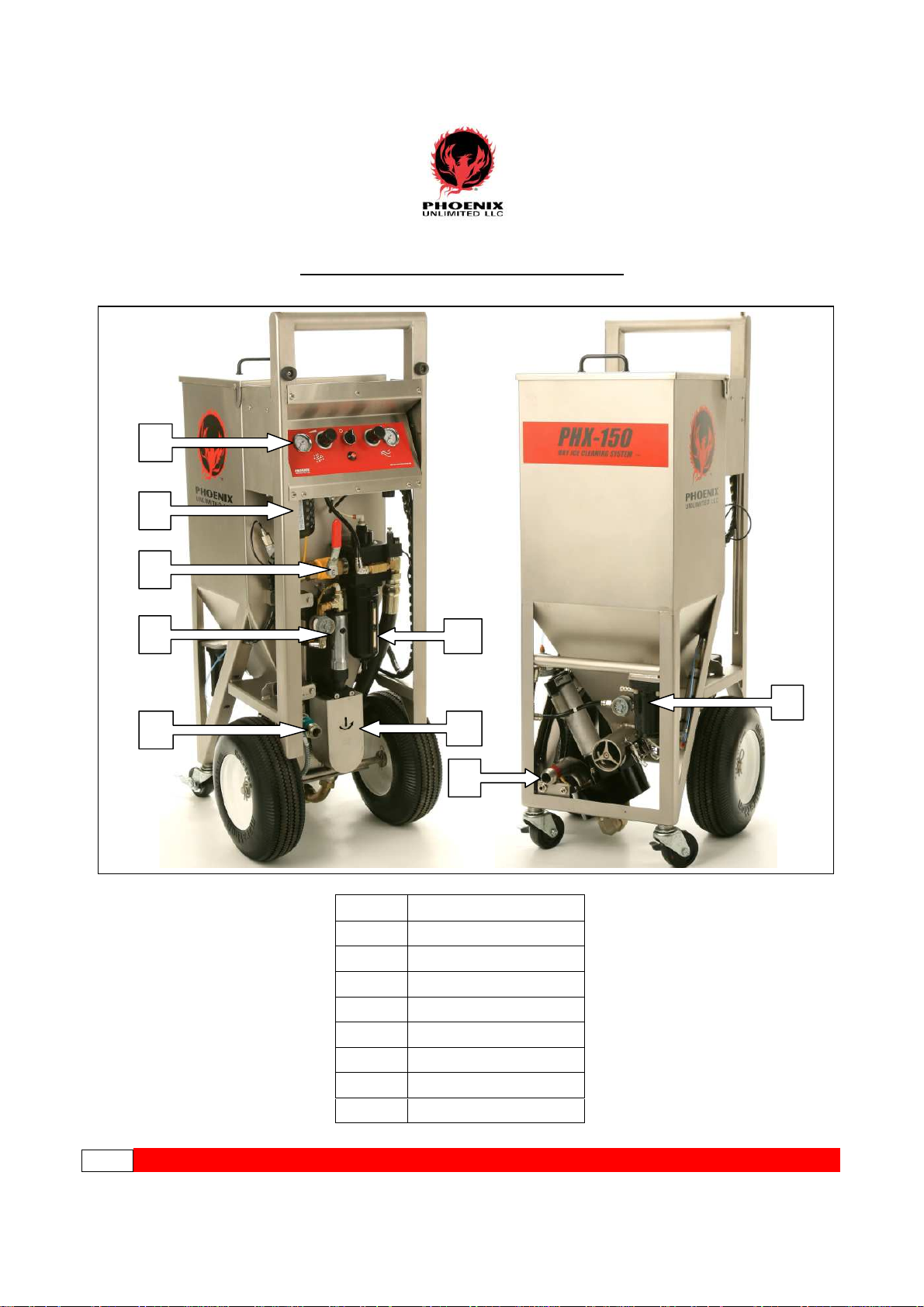

KEY COMPONENT IDENTIFICATION

1

2

3

5

4

9

6

7

8

1

Control Panel

2

Lubricator

3

E-Stop Valve

4

Separator/Regulator

5

Ratchet Motor

6

Auger Drive/Chain Guard

7

Air Supply Inlet

8

Airlock Assembly

9

Vibrator Assembly

Page 8

**************************************************************************************************PPHHXX--115500*******************

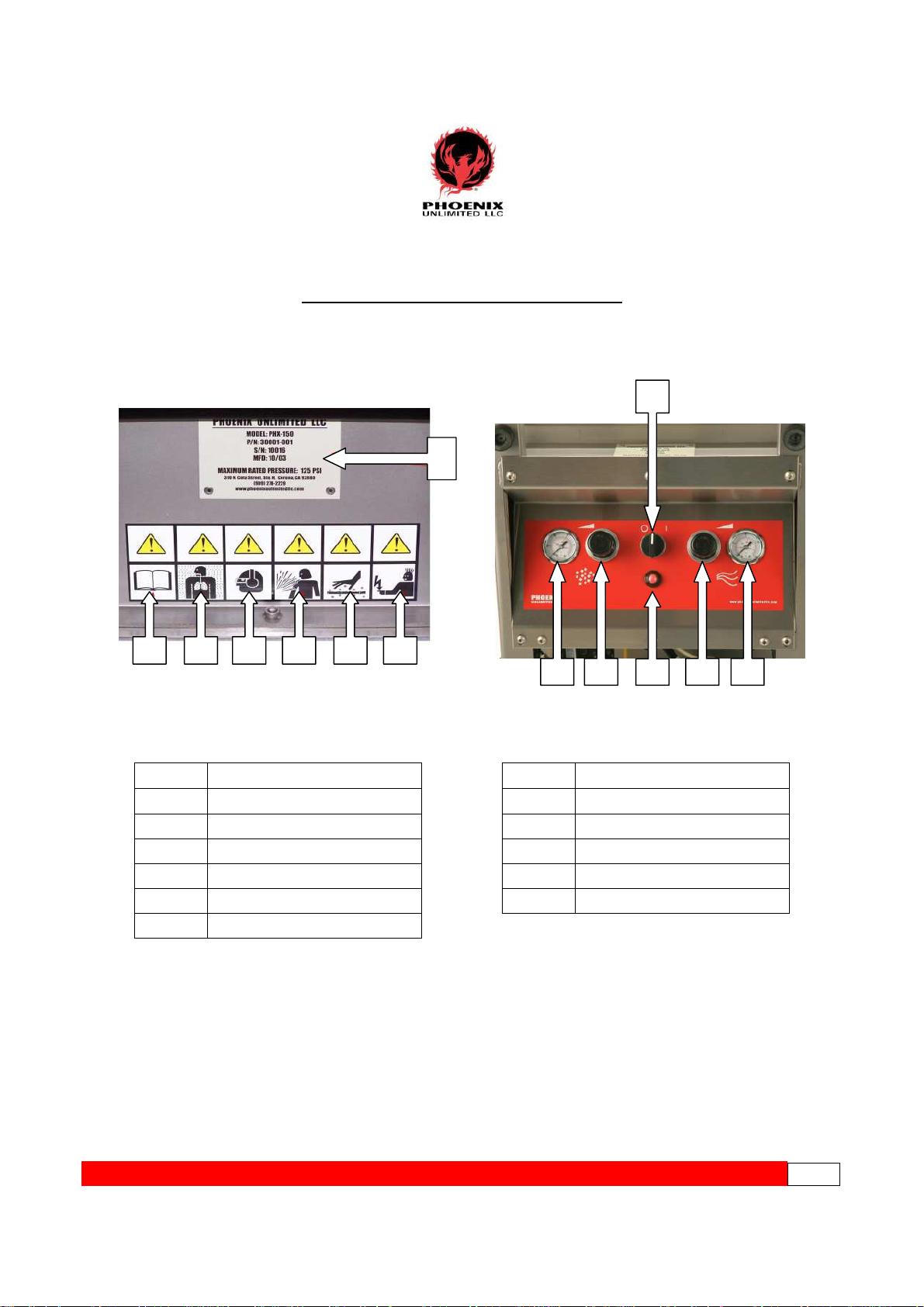

*

Page 9

CONTROL PANEL/WARNING LABEL

Hig

h Velocity Particles

Pressure Indicator

7

1 2 3 4 5 6

3

1 2 5 6

4

1

Read User's Guide Information

2

Asphyxiation Hazard

3

Wear Proper Protective Gear

4

5

Burn Hazard

6

Static Discharge

7

Equipment I.D. Tag

1

Ice Rate Gauge

2

Ice Rate Regulator

3

Arm/Disarm Switch

4

5

Blast Air Regulator

6

Blast Air Gauge

**************************************************************************************************PPHHXX--115500*******************

*Page 9

Page 10

OPERATING INSTRUCTIONS

This User’s Guide is the best tool available during the initialization of your new PHX150 Dry Ice Cleaning System. It contains all the information necessary for the proper

installation, safety, operation, maintenance and troubleshooting right at your fingertips.

Familiarize yourself with its’ contents before operating this equipment.

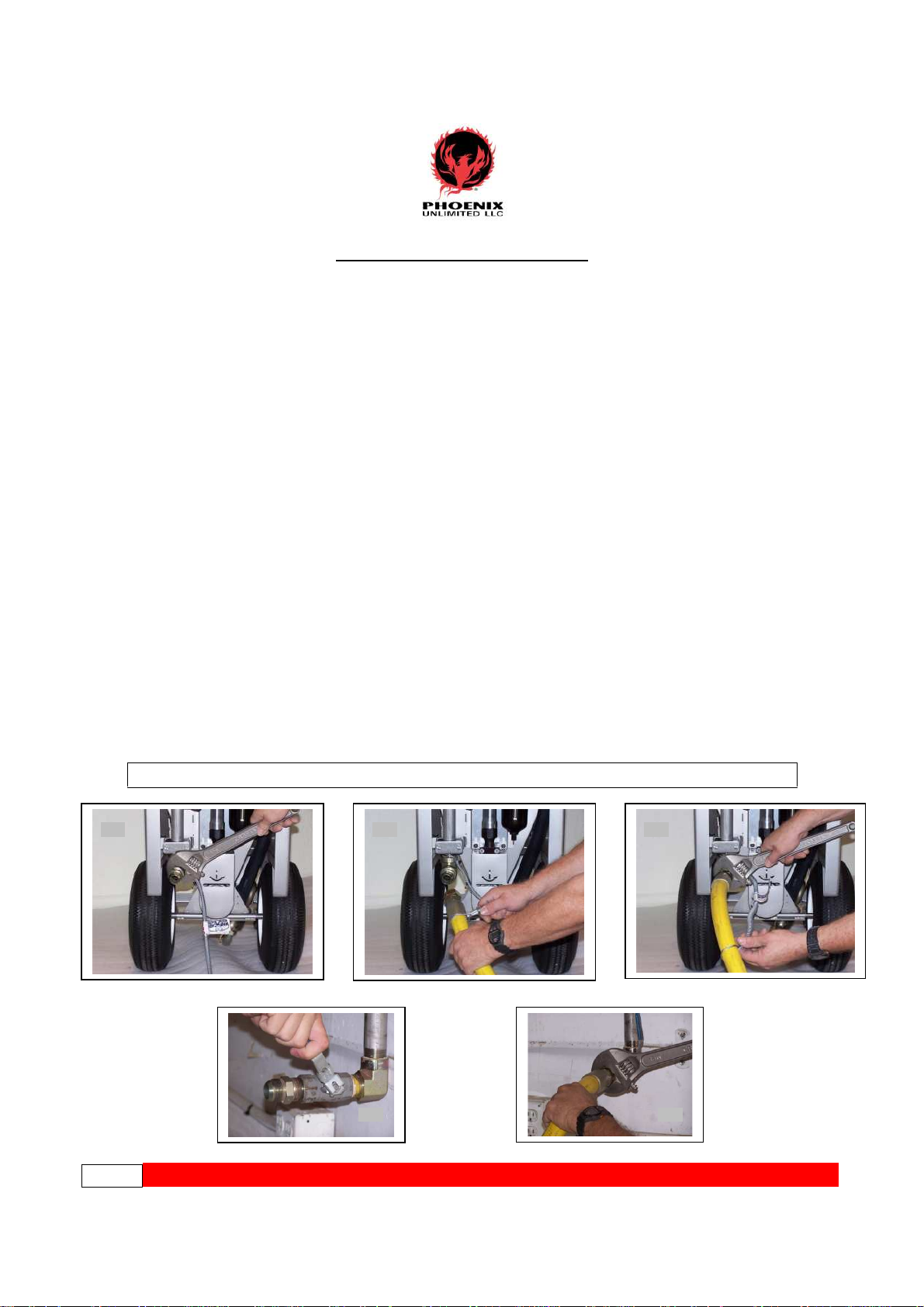

CONNECTING THE AIR SUPPLY

Since the PHX-150 is an “all pneumatic” design, it is critical that only clean, dry air be

supplied to the unit. Air containing excess amounts of moisture, oil, rust, or other

contaminants may clog filters and damage the logic control and internal components. A

good desiccant or refrigerant dryer should be installed between your compressor and the

PHX-150. The dew point should not exceed +40°F/+4.4°C. Good air quality will save

you time for repairs and increase the life of the unit.

1. Install a 1” JIC/NPT male fitting into the supply inlet of the PHX-150. Be careful

with other types of common connectors as they often have gaskets or other restrictive

material, which prevent full air flow. This can drastically reduce your unit

performance level. (pic 1)

2. Install the whip check over the end of the 1” air supply hose. (pic 2)

3. Connect air supply hose to the JIC fitting and extend the whip check as far down the

hose as possible. (pic 3)

4. Wearing hearing protection, blow down the air source at the drop to remove any

accumulated moisture. This helps to insure equipment performance. (pic 4)

5. Connect the air supply hose to the air source. (pic 5)

Caution! Maximum air pressure supplied to the PHX-150 should never exceed 125 psi!

Pic 1 Pic 2 Pic 3

Pic 4 Pic 5

Page 10

**************************************************************************************************PPHHXX--115500*****************

*

Page 11

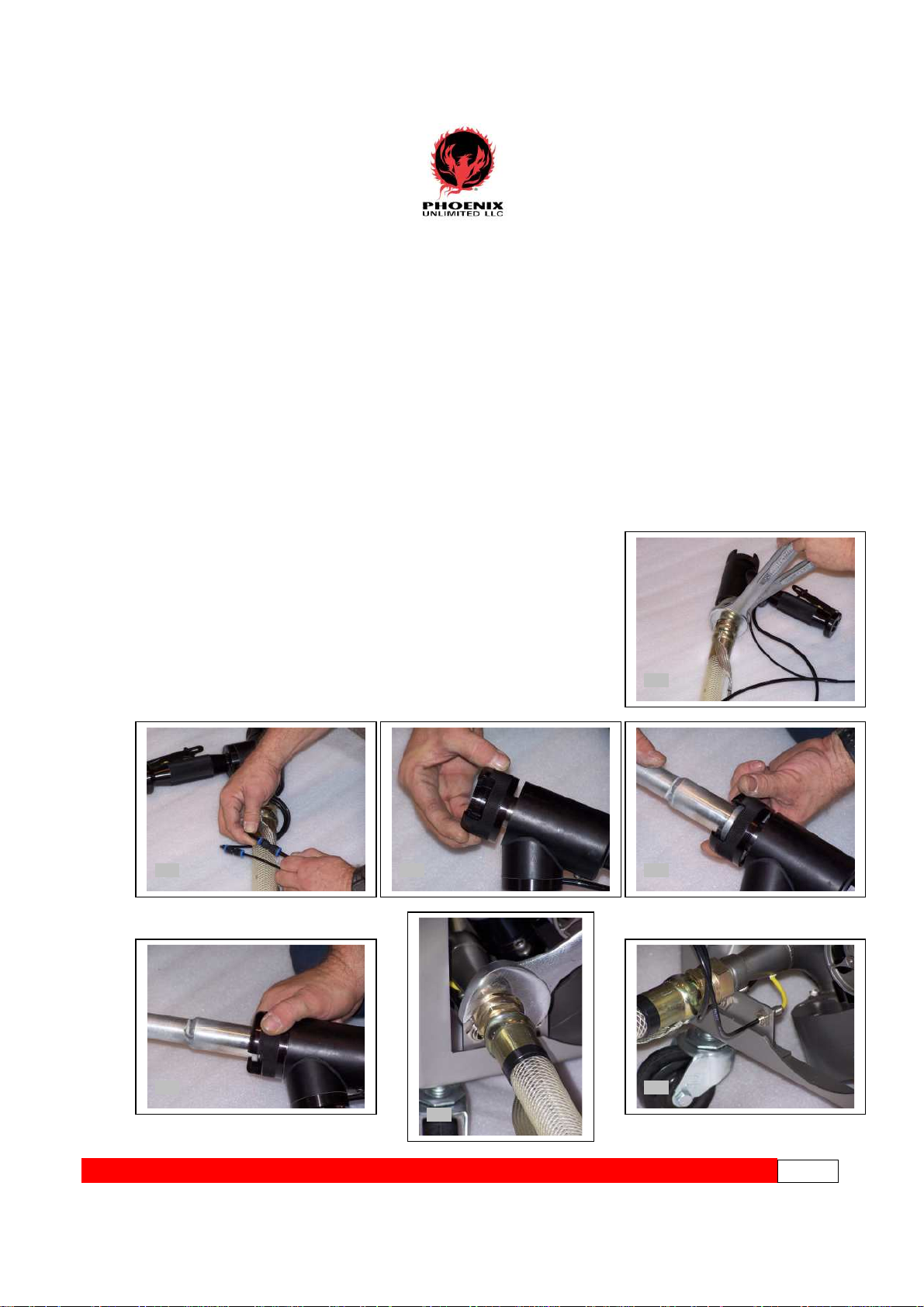

CONNECTING THE BLAST GUN

1. Use 1¼” and 1½” wrenches to connect the gun to the end of the blast hose with the

shorter length trigger lines. Do not over-tighten. (pic 1)

2. Connect the respective trigger lines (different sizes) to the gun, pushing firmly into the

quick-connect fittings. (pic 2)

3. Install the nozzle by a) twisting threaded retainer to completely ‘open’ position;

b) place nozzle into end of blast gun; c) tighten retainer to secure the nozzle. Improper

seating of the nozzle in the gun may result in air leakage. (pics 3, 4, 5)

4. Using the 1½” wrench, connect the remaining end of the blast hose to the front of the

PHX-150. (pic 6)

5. Connect the two trigger lines to the unit, pushing firmly until seated. Failure to attach

trigger lines will result in the non-functioning of the unit. (pic 7)

6. If necessary, ground the item you are blasting.

Pic 1

Pic 2 Pic 3 Pic 4

Pic 5

Pic 6

Pic 7

**************************************************************************************************PPHHXX--115500*****************

*Page 11

Page 12

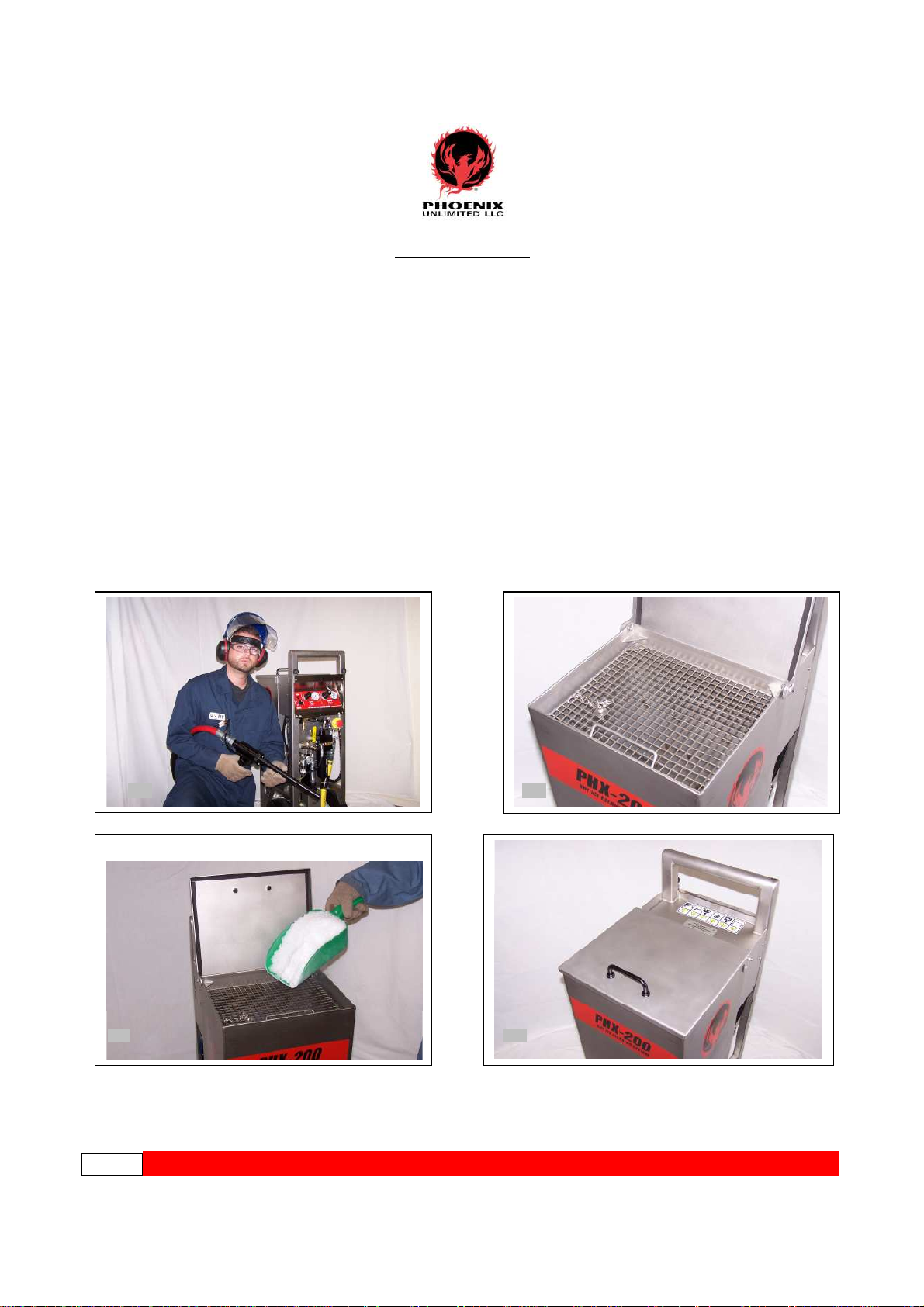

LOADING DRY ICE

1. Before you begin loading dry ice, it is important that you have the protective gear

previously mentioned in the “Safety Precautions and Warnings” section (page 6).

This includes basic items such as earplugs or muffs (or both), eye protection, face

shield, heavy-duty gloves, long sleeves, long pants, and safety shoes. (pic 1)

2. Lift hinged metal lid to expose hopper. BE AWARE OF AND KEEP CLEAR OF

PINCH POINTS (pic 2)

3. Use a sturdy scoop or similar device to load dry ice pellets into the hopper. (pic 3)

Be careful not to inhale concentrated CO2gas during the loading process, as it will

temporarily rob you of oxygen. If overexposed, get fresh air immediately. Signs

of overexposure include dizziness, cold sweats, headaches, nausea, and heavy

breathing.

4. Close the lid on the hopper. This will prevent airborne contaminants from

inadvertently falling through the pellet screen to the ice and ultimately ending up

on the surface you are cleaning or damaging internal airlock parts. (pic 4)

Pic 1 Pic 2

Page 12

**************************************************************************************************PPHHXX--115500*****************

Pic 4Pic3

*

Page 13

SETTING THE PANEL CONTROLS

Applying Air to the Unit

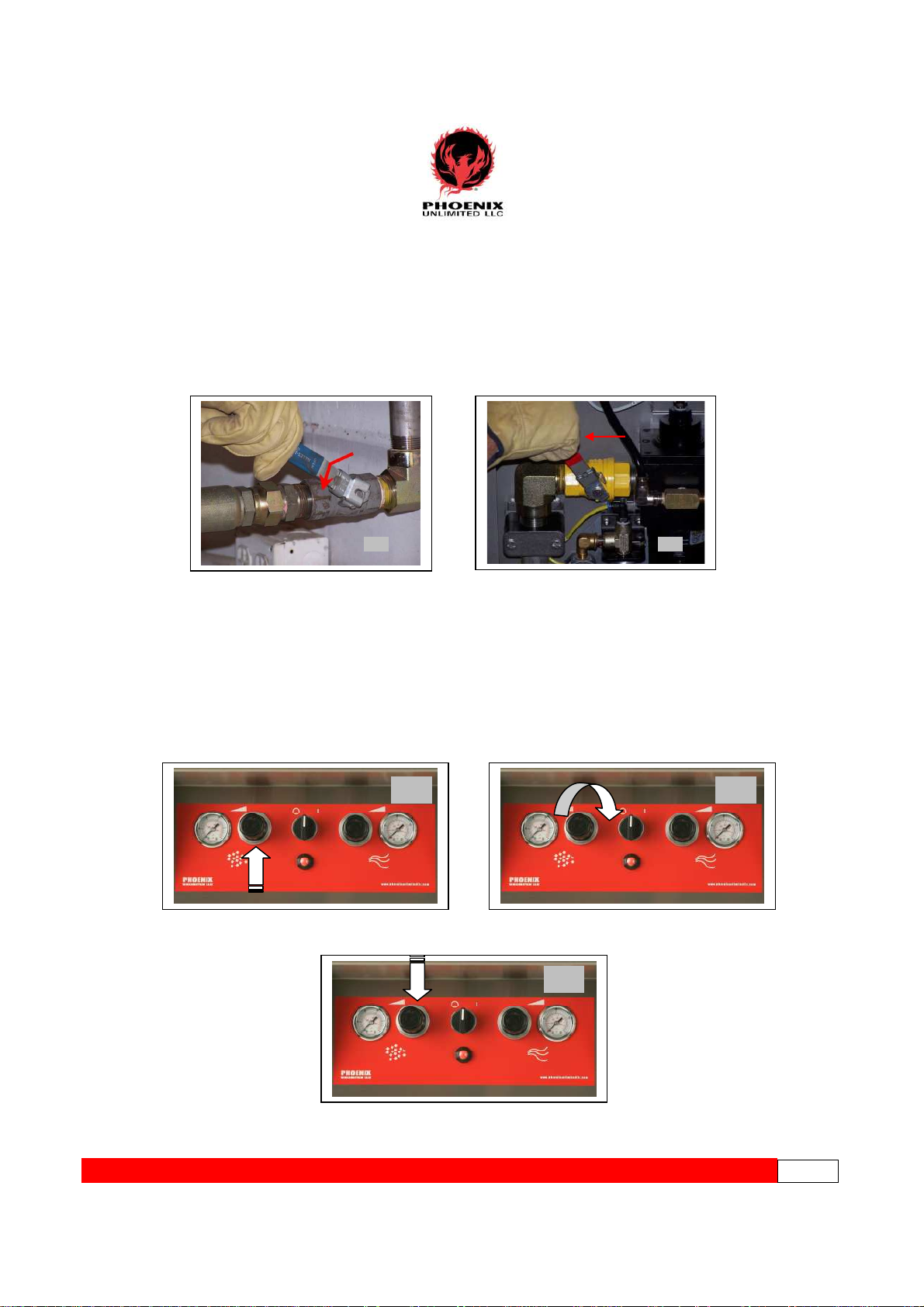

1. Slowly open the main air supply valve (source). (pic1)

2. With the gun pointed in a safe direction, slowly open the E-Stop valve on the

PHX-150. (pic 2)

Pic 2Pic 1

Setting the Panel Controls

1. Pull the ‘Ice Rate’ knob outwards to unlock it. (pic 1)

2. Turn the control clockwise until the gauge reaches the desired pressure. If unsure, start

at about 25 psi, then adjust the rate up or down as necessary for your particular blasting

application. (pic 2) Note: Trigger on gun must be pulled in order for gauge to read!

3. Push the knob in to lock the ice rate. (pic 3)

Pic 2Pic 1

Pic 3

**************************************************************************************************PPHHXX--115500*****************

*Page 13

Page 14

SETTING THE PANEL CONTROLS (cont.)

4. Next set the blast pressure. Pull the ‘blast pressure’ knob outwards to unlock it. (pic 4)

5. Turn the knob clockwise until desired pressure is reached. The PHX-150 has a blast

pressure range from 45 psi to 125 psi. Satisfactory results are generally achieved in the

80-100 psi range for most applications. If you are unsure or concerned about damage to

the item being blasted, start at a lower blast pressure and increase it gradually until the

optimum performance level is achieved. (pic 5)

6. Push the knob in to lock the blast rate. (pic 6)

Note: The PHX-150 utilizes an additional regulator that maintains the blast pressure at

45 psi, even if the control panel knob is turned all the way down. This prevents “freezeups” in the airlock assembly, which will occur if ice continually feeds without

sufficient pressure to propel it to the gun.

7. Turn the Arm/Disarm switch clockwise to arm the PHX-150. The indicator will turn

green, and the momentary switch will return to the center position. (pic 7)

8. Point the gun at the target or in a safe direction. Push upwards on the safety catch to

release and pull the trigger to initialize blasting. (pic 8)

Pic 4 Pic 5 Pic 6

Pic 4 Pic 5 Pic 6

Pic 7 Pic 8

Pic 7

Page 14

**************************************************************************************************PPHHXX--115500*****************

*

Page 15

TEMPORARY SHUTDOWN

1. When blasting is complete, release the trigger and wait for airflow to stop. (There is a

short delay while residual ice is purged from the blast hose. Keep gun pointed at the

target until air stops flowing!) (pic 1)

2. Turn the Arm/Disarm switch counter-clockwise. The indicator will turn red, and the

momentary switch will return to the center position. (pic 2)

3. Close the air supply valve at the source. Important! Failure to disconnect the source

end of the air supply first may create potential “air entrapment” or “hose whip”

hazards! (pic 3)

4. Vent remaining air from the machine and supply hose by closing the

E-Stop valve approximately halfway. (pic 4)

5. After the air stops flowing, you may fully close the E-Stop valve. (pic 5)

6. If moving the unit to another location for blasting, disconnect the supply hose at the

source and wrap around the machine handle for quick transport. It is not necessary to

disconnect the hose from the unit unless storing overnight or long term. (pic 6)

Pic 1 Pic 3

Pic 4 Pic 5

Pic 2

**************************************************************************************************PPHHXX--115500*****************

Pic 6

*Page 15

Page 16

OVERNIGHT / LONG TERM SHUTDOWN

1. If you won’t be blasting again soon, release the trigger and wait for airflow to stop.

(There is a short delay while residual ice is purged from the blast hose. Keep gun pointed

at the target until air stops flowing!) (pic 1)

2. Turn the Arm/Disarm switch counter-clockwise. The indicator will turn red and the

momentary switch will return to the center position. (pic 2)

3. Remove any unused ice from the hopper with a scoop and return it to the storage

container.

4. Turn the Arm/Disarm switch clockwise. Indicator will turn green. (pic 3)

5. Pull the trigger and expel remaining pellets through the gun. (pic 4)

6. Follow steps 2-6 on page 15 to complete the shutdown procedure, then store unit. (text

box)

Pic 1

Pic 3

FOLLOW STEPS

2-6 ON PAGE 15

TO COMPLETE

Pic 2

Pic 4

Page 16

**************************************************************************************************PPHHXX--115500*****************

*

Page 17

MAINTENANCE

CAUTION! Do not attempt to perform any maintenance or service on your PHX-150

unless safety guidelines and lock out/tag out procedures have been satisfactorily met!

DAILY PREVENTIVE MAINTENANCE

Before starting the machine each day/shift, a quick preventive maintenance inspection

should be performed to ensure that your unit operates problem-free now and in the future.

1. Check the separator sight glass for accumulated moisture or remove the canister to

inspect the filter for contamination. Clean canister if needed. (See page 18 for filter

replacement procedure). (pic 1)

2. Visually inspect lubricator to confirm fluid level is adequate. (pic 2)

3. Inspect hose assembly for cracks or leaks. Replace if necessary. (pic 3)

Pic 1 Pic 2 Pic 3

AS NEEDED MAINTENANCE

Separator / Auto-Drain Leak Check

The PHX-150 features an “auto-drain” in the separator to relieve excess moisture during

normal use. The float mechanism should be securely in place with no air leakage under

pressure. To check:

1. Slowly open the main air supply valve. (pic 1)

2. Slowly open the E-Stop valve of the PHX-150. (pic 2)

3. Check for air leakage under pressure. If air is present, you may need to clean the auto-

drain or replace. Tighten the drain nut securely after replacement. (pic 3)

Pic 1 Pic 2 Pic 3

************************************************************************************************PPHHXX115500*****************

*

PPaaggee117

7

Page 18

Changing the Separator Filter

To ensure that your dry ice cleaning system operates correctly and continues to provide

reliable performance levels, the separator needs to be inspected regularly. Poor filtering

leads to excessive moisture being passed into the control system, airlock, blast gun, and

ultimately to the targeted surface. A discolored filter element should be replaced. Follow

this simple procedure:

1. Press locking tab on separator canister and turn in either direction to disengage. (pic 1)

2. Lower the canister to expose filter element. (Empty any accumulated moisture in

canister before reinstalling). (pic 2)

3. Remove element retainer umbrella by turning counter-clockwise. (pic 3)

4. Remove old filter element, pulling straight down and away. (pic 4)

5. Install new element by reversing steps 1-4.

Pic 1

Pic 2 Pic 3 Pic 4

Changing the Inline Filter Element (Trigger Line)

If the unit is ready to blast (Arm/Disarm indicator is green), but does not start when the

trigger is pulled, it may indicate the need to change the trigger line inline filter element.

To perform this:

1. Locate the filter housing on inner leg of the PHX-150 near the trigger connectors. (pic1)

2. Disconnect the tubing from filter housing push fittings (both ends), then remove filter

housing from unit. (pic 2)

3. Using two ¾” wrenches, remove the cap from the filter housing to expose the sintered

bronze filter element. (pic 3)

4. Remove filter element. Important: Remember proper configuration of internal spring

in relation to the element. Improper installation will result in the non-operation of the

unit. (pic 4)

5. Install new filter element and housing by reversing steps 2-4.

Pic 1 Pic 2

Pic 3 Pic 4

Page 18

**************************************************************************************************PPHHXX--115500*****************

*

Page 19

Changing / Adding 10W Oil

1. Turn the lubricator retaining ring counter-clockwise by hand, then lower the

bowl/housing away from suction wick. (pic 1)

2. Add 10W tool oil (or equivalent) until level with fill line. (pic 2)

3. Be sure that the O-ring is properly seated in the top of the lubricator bowl. (pic 3)

4. Reinstall the bowl/housing into place. Hand tighten only. Do not over tighten. (pic 4)

Pic 1 Pic 2 Pic 3 Pic 4

Checking / Adjusting the Drive Chain Tension

1. Use a 5/32” hex key wrench to loosen two screws located at the top of the motor/chain

guard. Do not remove the screws. (pic 1)

2. Gently tilt the unit forward and remove third screw located at the bottom of the guard.

(pic 2)

3. Remove the chain guard to reveal drive chain. (pic 3)

4. Apply pressure to mid-span point. Movement should not be more than 3/32”. (pic 4)

5. If tension adjustment is necessary, loosen the two upper hex screws on the motor

mounting plate. (pic 5)

6. Locate the drive chain adjustment screw at the very top of the motor mounting plate.

(pic 6)

(continued)

Pic 1 Pic 2 Pic 3

Pic 4 Pic 5 Pic 6

**************************************************************************************************PPHHXX--115500*****************

*Page 19

Page 20

Checking / Adjusting the Drive Chain Tension (cont.)

7. Use a 7/16” box wrench to loosen the adjustment screw retaining nut by turning

counter-clockwise. (pic 7)

8. Hold the retaining nut in position and use a 3/16” hex key wrench to adjust the screw

(clockwise to increase tension, counter-clockwise to relieve) until proper tension is

achieved. (pic 8)

9. Tighten the retaining nut to lock the adjustment screw into place. (pic 9)

10. Tighten the two upper hex screws on the motor mounting plate. (pic 10)

11. Verify that the auger directional switch on motor ratchet is rotated fully clockwise.

(pic 11)

12. Install the motor/chain guard into position. (pic 12)

13. Tighten the three screws that secure the guard into place. (pic 13)

Pic 7 Pic 8 Pic 9

Page 20

Pic 10

Pic 11 Pic 12

VIBRATOR

The Vibrator Pad (30031-001) will wear over time allowing the piston to strike

the bare frame metal. The Pad can be replaced by removing the four mounting bolts.

The Vibrator can be service by removing it from the frame. Remove the two

screws that secure the end cap. Use caution not to tear the gasket and remove end cap.

Remove piston and clean any debris and rust from bore and piston using ATF fluid.

Reassemble piston and end cap. Piston should move freely. Reinstall unit to frame.

**********************************************************************************************PPHHXX--115500*****************

*

Page 21

PERIODIC MAINTENANCE

CAUTION! Do not attempt to perform any maintenance or service on your PHX-150

unless safety guidelines and lock out/tag out procedures have been satisfactorily met!

Replacing Airlock Critical Components

Diminished performance or a noticeable drop in blast pressure at the gun may indicate a

worn or damaged component in the airlock. Most airlock problems are typically caused

by a foreign object (airborne or otherwise) falling through the hopper pellet screen,

mixing with the dry ice pellets, and becoming lodged inside the airlock or doing damage

as it passes through to the blast hose and gun. (Note: You can avoid unnecessary

expense and repairs by closing the hopper lid after filling with ice and prior to

blasting.) In order to properly inspect or replace the critical components, the airlock

assembly must be removed from the unit. To do this:

1. Remove air supply hose from the PHX-150. Also remove the gun and blast hose

assembly if attached. (pic 1)

2. To avoid spillage, remove the lubricator bowl/housing and set aside. (pic 2)

3. Carefully place the unit flat on the ground with the control panel facing down.

(pic 3). Be careful that hinged metal lid does not “flop” backwards suddenly during this

procedure.

4. Detach the inlet blast air hose coupling from airlock assembly inlet. (pic 4)

5. Remove the airlock motor air supply line from the push fitting. (pic 5)

6. Remove the large cotter pin from the airlock retaining latches. (pic 6)

Pic 1 Pic 2 Pic 3

Pic 4 Pic 5 Pic 6

**************************************************************************************************PPHHXX--115500*****************

*Page 21

Page 22

Replacing Airlock Critical Components (cont.)

7. Open airlock retaining latches. (pic 7)

8. Remove complete airlock assembly from unit and move it to a workbench. (pic 8)

9. Use a 3/16” hex key wrench to remove six housing bolts from bottom of airlock

assembly. (pic 9)

10. Separate the housing and set bottom half aside. (pic 10)

Pic 7 Pic 8 Pic 9 Pic 10

Rotor:

11. Carefully remove the rotor from the

spline and inspect. Replace if damaged.

Before installation of new rotor, clean and

inspect the pads, motor, spline and internal

walls of the housing for damage. If all parts

are good, install the new rotor onto the

spline. (pic 11)

12. Reinstall airlock assembly onto the

Pic 11

REINSTALL

AIRLOCK

ASSY. BY

REVERSING

STEPS 1-10

PHX-150 by reversing steps 1-10. (text box)

Page 22

Airlock Motor / Spline:

13. While the housing is disassembled, inspect the motor and spline. If replacement is

necessary, the motor will need to be removed from the housing. (pic 12)

14. Use a ¼” hex key wrench to remove the two mounting screws, then remove the motor

assembly from the housing. (pic 13)

15. Use two wrenches to remove the spline from the motor and install new one.

16. Be sure centering ring is in place and reinstall motor to housing.

17. Reinstall airlock assembly by reversing steps 1-11

REINSTALL

AIRLOCK

ASSY. BY

REVERSING

Pic 12 Pic 13

STEPS 1-11

**************************************************************************************************PPHHXX--115500*****************

*

Page 23

Replacing Airlock Critical Components (cont.)

Airlock Pads:

17. While the housing is disassembled, inspect the airlock pads (2) located in each half of

the housing. If damaged, they must be replaced. (pic 15)

18. Remove the pads from the housing. (pic 16)

19. Inspect the O-rings on both pads. Replace if worn or damaged. Before installing new

O-rings (or re-using existing ones), apply a thin coat of Dow-Corning 33 lubricant.

(pic 17)

20. Make sure that O-rings are seated properly in the pads. (pic 18)

21. Carefully install the pads into the airlock housing. Fully installed, they will be flush

with the housing walls, with no part of the O-rings showing. (pic 19)

22. Reinstall airlock assembly onto the PHX-150 by reversing steps 1-11. (text box)

Pic 15 Pic 16

Pic 17 Pic 18

REINSTALL AIRLOCK

ASSY. BY REVERSING

STEPS 1-11

Pic 19

**************************************************************************************************PPHHXX--115500*****************

*Page 23

Page 24

AIRLOCK MOTOR (P/N 50202-001) MAINTENANCE

Engine Lubrication- Be sure air lubricators are maintained as outlined in equipment

manual. If wet dirty air is being used, water, dirt, rust and emulsified oil can accumulate

in lubricator bowls, making it look like they are full of oil. A periodic “closer look” is

recommended and an oil change is recommended if it is contaminated with water.

Cleaning Engine- Water and rust in the compressed air or dust and wear particles can

cause sticking of vanes, valves etc. This can be prevented by removing muffler, flushing

with a few drops of oil, running the motor for 5-10 seconds and absorbing the oil in a

cloth. Replace or reinstall muffler. Protect the engine this way before long shutdown

periods. DO NOT RUN THE AIRLOCK FOR LONG PERIODS WITHOUT ICE.

Muffler-Over time the muffler can become clogged with particles and restrict exhaust

flow which will make the motor run slower. It is recommended to periodically replace the

muffler. (P/N 50203-001)

Maintenance and repairs must be carried out exclusively by authorized personnel.

Overhaul- To achieve the best service life under normal operating conditions, regular

overhaul and cleaning should be carried out every 12 months or 2000 hrs., whichever is

sooner. Overhaul should be carried out more frequently under more rigorous operating

conditions.

Lubrication- Planetary gears, ball and needle bearings and seal ring should be

lubricated with grease in conjunction with the regular overhaul of the motor. Molykote

BR2 Plus gives long intervals between lubrications.

Contact Phoenix Unlimited LLC or a qualified service center for motor overhaul options.

PPaaggee2244************************************************************************************************************************PPHHXX--115500*****************

*

Page 25

5

4

6

7

9

8

1. 50202-001 MOTOR

2. 30281-001 SPLINED SHAFT

3. 30278-001 CENTERING RING

4. 50203-001 MUFFLER

5. 50114-688 ELBOW

6. 50114-158 ELBOW

7. 50004-002 ELBOW

8. 50053-001 VALVE

9. 50015-002 CONNECTOR

10. 50002-F04 PLUG

11. 50057-628 ELBOW

10

11

FOLLOWING ITEMS NOT SHOWN

12. 10020-P12 BOLT (2)

1

2

13. 10018-005 LOCKWASHER (2)

3

PHOENIX UNLIMITED LLC

30275-002A

AIRLOCK MOTOR ASSEMBLY

COMPLETE

**************************************************************************************************PPHHXX--115500*****************

*Page 25

Page 26

TROUBLESHOOTING

Symptom Item Check Corrective Measure

The PHX-150 will

not start.

Air supply valve is not opened.

The unit is not armed (indicator will be

red).

Open the air supply valve (E-Stop valve).

Turn Arm/Disarm switch clockwise (indicator should

turn green).

The PHX-150 starts,

but no ice comes out.

Pellet screen is not properly installed.

Loose or kinked tubing in control panel.

Trigger lines improperly connected.

Trigger valve failure.

Inline filter plugged (trigger return line).

Contamination in the trigger lines.

There is no dry ice in the hopper.

Ice rate is set too low.

Possible ice bridging inside the hopper.

Water ice accumulation in hopper.

Make sure pellet screen fully engages safety interlock

switch when installed.

Check for loose or kinked tubes behind panel.

Reconnect if necessary.

Check trigger lines at machine and at the gun.

Check trigger valve for contamination. Clean or

replace as necessary. Correct cause of contamination.

Check filter and replace element if necessary.

Blow out trigger lines. Correct cause of contamination.

Load fresh dry ice into the hopper.

Turn Ice rate regulator clockwise to increase.

With pellet screen in place, use poker to break up the

bridge. This symptom is generally caused by poor ice

quality and high humidity areas.

Water ice forms in high humidity areas or when ice is

left in the hopper for long periods of time. Clean and

dry the hopper thoroughly before refilling.

Blast gun or hose plugged.

Incorrect auger rotation. (Auger should

turn counterclockwise when viewed from

the rear of the unit).

Airlock is not turning.

Decrease blast pressure to 45 psi. Remove blast hose

from unit. With trigger lines still attached, trigger the

unit to clear ice from the discharge outlet. Reattach

hose and remove nozzle from gun. Trigger again to

clear ice from hose and gun. Reattach nozzle.

Remove motor/chain guard and turn selector switch

on ratchet motor to reverse direction.

See section on “Airlock does not turn”- next page.

PPaaggee2266************************************************************************************************************************PPHHXX--115500*****************

*

Page 27

SSyymmttoommIItteemmCChheecckkCCoorrrreeccttiivveeMMeeaassuurre

PPeelllleettssssttooppfflloowwiinng

aafftteerraappeerriiooddoof

bbllaassttiinngg.

f

.

TROUBLESHOOTING (cont.)

g

TThheerreeiissnnooddrryyiicceelleeffttiinntthheehhooppppeerr.

PPeelllleettsshhaavveebbrriiddggeeddoovveerraauuggeerriinnssiidde

.

hhooppppeerr.

e

.

e

LLooaaddddrryyiicceeiinnttoohhooppppeerr.

WWiitthhppeelllleettssccrreeeenniinnppllaaccee,,uusseeppookkeerrttoobbrreeaakkuupptthhe

bbrriiddggee..PPoooorriicceeqquuaalliittyyaannddhhiigghhhhuummiiddiittyyggeenneerraalllly

ccaauusseetthhiisspprroobblleemm.

.

e

y

.

BBllaasstthhoosseeoorrgguunnpplluuggggeedd.

AAuuggeerrnnoottttuurrnniinngg.

AAiirrlloocckknnoottttuurrnniinngg.

BBllaassttgguunnpplluuggs

rreeppeeaatteeddllyy.

AAuuggeerrddooeessnnoottttuurrnn..IIcceerraatteesseettttoooollooww.

AAiirrlloocckkddooeessnnoottttuurrnn..LLoossssooffaaiirrssuuppppllyyttootthheeaaiirrlloocckkmmoottoorr.

s

.

IIcceerraatteesseettttoooohhiigghh.

PPoossssiibblleewwaatteerriicceeaaccccuummuullaattiioonniinnssiidde

.

gguunn.

IInnccoorrrreeccttddrriivveecchhaaiinntteennssiioonn.

LLoossssooffaaiirrssuuppppllyyttootthheeddrriivveemmoottoorr.

SSuuppppllyyaaiirriissttoooollooww.

.

.

.

.

.

.

.

.

DDeeccrreeaasseebbllaassttpprreessssuurreettoo4455ppssii..RReemmoovveebbllaasstthhoosse

ffrroommuunniitt..WWiitthhttrriiggggeerrlliinneessssttiillllaattttaacchheedd,,ttrriiggggeerrtthhe

uunniittttoocclleeaarriicceeffrroommtthheeddiisscchhaarrggeeoouuttlleett..RReeaattttaacch

hhoosseeaannddrreemmoovveennoozzzzlleeffrroommgguunn..TTrriiggggeerraaggaaiinntto

cclleeaarriicceeffrroommhhoosseeaannddgguunn..RReeaattttaacchhnnoozzzzllee.

SSeeeesseeccttiioonn““AAuuggeerrddooeessnnoottttuurrnn””bbeellooww.

SSeeeesseeccttiioonn““AAiirrlloocckkddooeessnnoottttuurrnn””bbeellooww.

DDeeccrreeaasseeiicceerraattee.

e

DDeeffrroosstt,,cclleeaann,,aannddddrryytthheegguunn..CChheecckkiinnccoommiinnggaaiir

ssuuppppllyyffoorrccaauusseeooffccoonnttaammiinnaattiioonnaannddccoorrrreecctt.

IInnccrreeaasseeiicceerraattee.

CChheecckkaannddaaddjjuussttcchhaaiinntteennssiioonn..((ppaaggeess1199--2200)

CChheecckkssuuppppllyyaaiirrttootthheeddrriivveemmoottoorriinnppuutt..IIffnneeeeddeedd,

ccoonnttaaccttPPhhooeenniixxUUnnlliimmiitteeddffoorrssuuppppoorrtt.

MMaakkeessuurreessuuppppllyyaaiirriissaattlleeaasstt7755ppssiitthhrroouugghhaa11”

uunnrreessttrriicctteeddlliinnee.

.

CChheecckkssuuppppllyyaaiirrttootthheeaaiirrlloocckkmmoottoorriinnppuutt..IIffnneeeeddeedd,

ccoonnttaaccttPPhhooeenniixxUUnnlliimmiitteeddffoorrssuuppppoorrtt.

.

.

.

e

e

h

o

.

.

.

r

.

)

,

.

”

,

.

.

.

.

RReemmoovvee,,ddiissaasssseemmbbllee,,cclleeaann,,aannddrreeiinnssttaallll.

.

RReemmoovveeaaiirrlloocckk,,cclleeaannoorrrreeppllaacceeppaarrttss..((ppaaggeess2211--2233)

s

CChheecckkssuuppppllyyttoovveerriiffyyaa11””uunnrreessttrriicctteeddlliinneeffrroommtthhe

e

uunniittttootthheeccoommpprreessssoorr..DDiissttaanncceessoovveerr110000ffeeeettmmaay

eevveennbbeeooffllaarrggeerrddiiaammeetteerr.

IIfftthheepprreessssuurreeddrroopphhaassaassiiggnniiffiiccaannttaaddvveerrsseeeeffffeecct

oonncclleeaanniinnggppeerrffoorrmmaannccee,,aallaarrggeerrccoommpprreessssoorrmmaay

bbeerreeqquuiirreedd.

.

.

BBllaassttpprreessssuurreeaanndd//oor

iicceerraatteeddrrooppssqquuiicckklly

wwhheennttrriiggggeerriissppuulllleedd.

BBllaassttpprreessssuurreeaanndd//oor

iicceerraatteeddrrooppsssslloowwlly

wwhheennttrriiggggeerriissppuulllleedd.

r

y

r

y

EExxhhaauussttmmuufffflleerriisspplluuggggeedd.

EExxcceessssiivveeccoonnttaammiinnaattiioonnoofftthheeaaiirrlloocckk.

AAiirrssuuppppllyylliinneeiisslleesssstthhaann11””oorrtthheerreeiis

aarreessttrriiccttiioonnssmmaalllleerrtthhaann11””bbeettwweeeenntthhe

.

uunniittaannddtthheeccoommpprreessssoorr.

IInnddiiccaatteessaannuunnddeerrssiizzeeddccoommpprreessssoorr.

.

************************************************************************************************************************PPHHXX--115500*****************

.

)

e

y

t

y

*Page 27

Page 28

PHX-150DRAWING REFERENCE

30089-001

POKER

ASSEMBLY

30029-001

CONTROLPANEL

30016-001

CONTROLSHELF

(BEHINDPANEL)

30024-001

AIRSYSTEM

30006-001

AUGERDRIVE

ASSEMBLY

30100-KIT

HOPPER LIDKIT

20011-K35

BUMPER

30

40

2

0

10

50

0

0

6

PSI

PHOENIX

UNLIMITEDLLC

BLASTAIRICERATE

80

40 120

0

PSI

www.phoenixunlimitedllc.com

6

0

1

PHX-150

DRY ICECLEANING SYSTEM

30060-001

FILTER/REGULATOR

30049-001

AIRLOCK SUPPLYHOSE

30031-001

VIBRATOR PAD

30028-001

VIBRATOR

ASSEMBLY

30016-001

AIRLOCK

ASSEMBLY

20013-012

WHEEL

RIGHT LEFT

30002-002

PELLET/SAFETY

SCREEN ASSEMBLY

30114-001

TRIGGER RETURN

FILTERASSEMBLY

30113-001

AIR TANK

ASSEMBLY

20009-B04

CASTER,

CONDUCTIVE

30003-001

SAFETYSCREEN

VALVE ASSEMBLY

50061-001

HOSE WHIP CHECK

Page 28************************************************************************************************************************PPHHXX--115500******************

Page 29

21

---21

30030

-

001B

CONTROL PANEL, PHX

-

150

1

3

4

5

6

30

2

0

40

10

50

0

6

0

PSI

80

40 120

0

PSI

160

7

8

BLAST AIRICE RATE

PHOENIX

UNLIMIT ED LL C

12 13

10

17

1

11

NC

NO

14

www.phoenixunlimitedllc.com

5

9

************************************************************************************************************************PPHHXX--115500*****************

16

15 14

1515

1 50007-001 LOGIC ELEMENT "OR" 17

1 50016-002 ELBOW 16

3 50018-001 ELBOW, FEMALE 15

2 50057-628 ELBOW 14

1 50011-912 VALVE BODY, NP (NC) 13

1 50110-001 MOUNTING RING, VALVE BODIES/SELECTOR 12

1 50111-911 VALVE BODY, NNP (NO) 11

1 50017-002 TEE 10

1 50027-212 INDICATOR. PRESSURE 9

1 50025-160 GAUGE, BLAST AIR PILOT, 160 PSI 8

1 50051-001 REGULATOR, BLAST AIR PILOT 7

1 50025-060 GAUGE, ICE RATE, 60 PSI 6

2 50069-001 NUT, REGULATOR 5

1 30032-001A REGULATOR, ICE RATE 4

1 50109-005 SELECTOR, ARM/DISARM 3

_-001 Part No. Description Item No.

30029-001D PARTS LIST

*Page 29

Page 30

DATE:

3/3/17

A

1 OF 2

4 REQ

D

25

6 8 9

22

12

8 8 9 8 8

10

26

9

B

23,24,27

NOT

SHOWN

19

a

18

20

a

A

b

a

A

A

b

b

X

a

a

a

A

A

b

b

X

X

a

A

A

b

b

X

a

a

A

A

b

b

X

X

11

23

21

20

1

7

2

5

5

X

b

A

a

3

4

C

(30025-SHELFA)

DRAW

N BY: SAS

NOTES:

A. REMOVERESET JUMPERON LCD TIMER

CONNECTWIRESTO LCD TIMERSTART TERMINALS

B. BE SURE PNEUMATICTIMER ISSET TO 10

C. TIGHTEN SPEEDCONTROLLER

UNTILWASHER ISSLIGHTLYCOMPRESSED

D. SETLUBRICATORADJUSTMENT TOITS MIDPOINT

10048-190

2

30290-001

1

30291-0021

40003-003

8"

10007-H04

6

40002-K121 END CLAMP 22

1 30105-001 LUBRICATOR 21

1 - CABLE TIE

1 40007-001 TIMER, LCD 18

QTY

CAPTIVENUT

TIMERBRACKET

VIBEON STARTAIR TANK ASSY

DIN RAIL

SCREW,BTN HD,10-32 X1/4"

SHELF ASSY,PHX-200-001

27

26

25

24

23

20ELBOW,3/8TX 3/8NPT50057-6382

19

17

-

1

1

1

50023-006

1

50023-001

3

5 50023-004 8

REGULATOR ASSY30291-004

PRESS. SWITCHASSY30288-001

TIMERELEMENT

LOGICVALVE "NOT"50023-003

LOGICVALVE "OR"

LOGICVALVE "YES"

ELBOW,4WAY,5/32TX 1/8NPT

1450029-003 BULKHEAD, 1/4TX 1/8NPT 5

1 50021-002 SPEED CONTROL

10019-0151 FLATWASHER, 3/8" 3

1 50026-001 AIR RESERVIOR, 1 CI 2

QTY

SHELF ASSY,PHX-200-001

16

15

14

13

12

11

10

9

750030-0021

61 30133-003 TRIGGERON DIST.ASSY

1ELBOW,5/32TX 1/8NPT50016-0021

-

Page 30************************************************************************************************************************PPHHXX--115500******************

Page 31

DISTRIBUTION ASSEMBLY

WITH VIBE ON START

50015-002

AIRLOCK/VIBE/PURGE

REGULATOR ASSY

CONNECTOR

50026-001

AIRTANK

50015-001

CONNECTOR

50197-001

PULSE VALVE

50016-001

ELBOW

50030-002

ELBOW

4WAY

50026-CP1

DUALAIR TANK CLIP

50002-001

PIPEPLUG

30291-002

VIBE ON START

AIR TANK ASSEMBLY

50019-002

WYE

CONNECTOR

50055-628

TEE

50044-001

REGULATOR

50037-001

ELBOW

50037-001

ELBOW

30291-003

"TRIGGER ON"

50057-628

ELBOW

30291-004

PHX-150

50122-001

TEE

50029-001

BULKHEAD

50063-003

VIBRATOR

50059-002

MUFFLER

DRAWN BY: SAS 2/13/04

CHECKED BY:

50060-131

NIPPLE

50053-001

POPPET VALVE

50016-002

ELBOW

50056-628

CONNECTOR

50002-Z04

PIPE PLUG

PHOENIX UNLIMITED LLC

VIBRATOR ASSY

30028-001

************************************************************************************************************************PPHHXX--115500*****************

*Page 31

Page 32

4

5

6

1

2

3

7

AI

PHOENIX UNLIMIT

R SYSTEM ASSY,

8

30024

ED LLC

PHX-150

B

QTY

1 50043-105 PIPE NIPPLE, 1" X 10.

1 50004-002 ELBOW,MALE,1/4NPT1

1 50060-221 NIPPLE,1"NPT X 1.5" 8

1

1 ELBOW,5/32T X1/4NPT1 50005-004 TEE,MALE BRANCH,1/4N

30087-0011 ELBOW,STREET,1"NPT

-001

AIR SYSTEM ASSY, PH

X-150

1ELBOW,1"NPT50009-0161

-

50067-002 FILTER,1/4" 5

5 "

,SP

2

3

D,1"NPT

NPT

4

61 50066-228 CONNECTOR,5/32T X 1/4

1050016-003

750042-0161 BALVE VALVE,VENTE

9FILTER/REGULATOR, PHX30060-001

1

1

1

5

5

50037-001 ELBOW,STREET,1/8NP

0057-628

0003-001

E

R

LBOW,3/8T X 1/4NPT

EDUCER,1/4NPT X 1/8NPT

T

PT

2T

1

1650039-016 ELBOW,1"JIC X 1"NPT1

131

1450052-002 REGULATOR,1/8NPT X 5/3

11

1

5

2

9

1

5

10

1

1

12

13

16

14

Page 32************************************************************************************************************************PPHHXX--115500******************

Page 33

SIGHT GAUGE KIT

30060-001

FILTER/REGULATOR SERVICE INSTRUCTIONS

BONNET

P

MOUNTING SCREWS (4)

TORQUETO 13-18INCH POUNDS

PISTON SEAL

UPPER

FLANGE

BE SURE THAT ALIGNMENT

NOTCH AROUNDSCREWHOLE

IS PROPERLY ALIGNED

POPPET

C

P

P

B

E

C

P

P

ASSEMBLY

50008-BS1

BOWL SEAL

MAIN BODY

50008-DF1

DEFLECTOR

30061-001

PISTON

P

10031-001

LOWER

P

PISTON SEAL

30062-001

SLEEVE

O-RING

C

P

P

POPPET

SPRING

O-RING

50008-BL1

BOWL LATCH

SnapFit TabDetent must snap into

groovefor proper assembly.

To removebowl depresstab, turn

& pullbowl down

P

B

C

50008-E01

ELEMENT KIT

50008-BK1

P

BOWL KIT

To removebowl depresstab,

turn& pull bowl down

50008-BFL

C

P

BAFFLE

TORQUETO 3-5 INCH POUNDS

BE POSITIVE THATALLAIR

PRESSUREIS RELIEVED FROM

SYSTEMAND ALL SAFETYLOCKOUT

REQUIREMENTSHAVE BEEN MET

INSPECT FILTERELEMENTAND CLEANBOWL REGULARLY.

A DIRTY FILTERCAN COLLAPSEAND ALLOW

CONTAMINATIONOF SYSTEM CONTROLS.

KEEPSPARE ELEMENTON HAND.

REFERTO ILLUSTRATIONFOR

DISASSEMBLING,SERVICING

ANDRE-ASSEMBLY.

INCLUDEDWITH50008-E01ELEMENTKIT

E

INCLUDEDWITH50008-BK1BOWL KIT

B

50008-STM

STEM ASSEMBLY

50008-SGK

50008-AD1

AUTODRAIN KIT

APPLYLOW STRENGTH

PLASTIC THREADLOCKER

TONUT

LIGHTLY GREASEWITH PROVIDED LUBRICANT

INSPECT FOR NICKS,SCRATCHES, AND SURFACE

P

IMPERFECTIONS.IF PRESENT, REDUCED SERVICE

LIFEIS PROBABLE AND FUTUREREPLACEMENT

SHOULDBE PLANNED.

CLEANWITHA LINTFREE CLOTH

C

B

B

************************************************************************************************************************PPHHXX--115500*****************

*Page 33

Page 34

5

1

22

10

14

9

8

4

2

3

5

7

15

2 REQ

2 REQ

Q

TY

1

1 NIPPLE 3

1 50053-001 VALVE,POPP

2

50057-62

50060-13

50002-Z04 PIPE PLUG,1/4" 5

50001-0051

-001

8

1

ELBOW,STRE

DRIV

E ASSY,AUGER,PHX-15

/8T X 1/4NPT

ET,1/4"

ET,1/4NPT

0

1ELBOW,3

2

-

4

2 R

EQ

1 TE

1 30088-0

2

1 CLAMP,SUPPOR

10005-546

040-002

01

RATCH

E, MALE RUN,1/4NPT

ET ASSY

HD,1/4-20 X 1.75"

T BLOCK

61 50016-002 ELBOW,5/32T X 1/8NPT

1030007-001

750

8

9SCREW,FLT

11

121312

6

1

1

30008-001 SUPPORT BLOCK 11

10005-5404

30006-0021

BEARING & S

PROCKET ASSY

.75"

131415

12SCREW,FLTHD,1/4-20 X

3 10019-013 FLATWASHER

1

10007-I124

10020-N2

30081-00

1

8

SCREW,BTN

SCREW,

CHAIN A

SOC HD,1/4-20 X 1.75"

SSY

HD,1/4-20 X .75"

,1/4"

16

17

1

1

10009-0103

30009-0

01

TENSIO

LO

CKNUT,1/4"

N BLOCK

19

18

30012-0

10027-001A/R

01

FLATWASH

ADJUSTMENT P

ER,THICK,1/4"

LATE

202122

1

30010-0011

30011-0

01

PL

ATE,AUGER DRIVE

23BRACKET

1718

2 REQ

2 REQ

20

21

A/R

19 18 17

23

2 REQ

16

Page 34************************************************************************************************************************PPHHXX--115500******************

Page 35

32

31

30

PHOENIX UNLIMITED LLC

AIRLOCK ASSEMBLY

PHX-150

11

25

26

28

27

29

22

20

19

18

17

16

10

9

21

8

4

5

7

32

2 REQ

26

2 REQ

222324

25

23

24

15

1

2-3

45647

8

9

15

181920121

10

SHAFT, AIRLOCK DRIVE

SADDLE, AIRLOCK

SCREW,FLT HD,8/32 X 3/8

1

2

3

2 REQ

2 REQ

2 REQ

6

4 REQ

3

6 REQ

30022-001

30021-001

30115-001 LATCH

10005-192

6

HOUSING, AIR IN

O-RING

30019-001

30018-001

10013-222

10011-327

30034-001

10013-035

111

2272282291301312

HOUSING, ICE IN/OUT

QUAD RING

PAD, AIRLOCK

O-RING

ROTOR, AIRLOCK

CONNECTOR,5/32 TUBE

POPPET VALVE

PIPE PLUG, 1/4"

ELBOW, 1"50039-016

50004-002 ELBOW,1/4"

50053-001

50015-002

50002-Z04

50057-628 ELBOW,3/8 TUBE

50202-001 MOTOR

30281-001

1

1161171

1

1

1

1118

DISCHARGE TUBE, ICE/AIR

CENTERING RING

50114-688 ELBOW,TUBE STEM

50114-158 ELBOW

30278-001

2

SCREW,SOC HD,5/16-18 X .75"

MUFFLER50203-001

1

SCREW,SOC HD,1/4-20 X 1.5"

SCREW,SOC HD,10-24 X 3/8

10025-B10 DOWELL PIN

10020-N24

10020-P12

10018-005 LOCKWASHER, 5/16

10020-K06

30036-001A

2

2

2

1

8

************************************************************************************************************************PPHHXX--115500*****************

AIRLOCK ASSY,PHX-150

SCREW,SOC HD,1/4-20 X 3/4

-001

10020-N12

2

QTY

*Page 35

Page 36

AUGER SECTION

ITEM

P/N

DESCRIPTION

QTY

12

11

10

9

2 REQ

8

2 REQ

1

2

3

4

7

1 20004-005 Bearing,Auger Output 1

2 30004-001 Auger,PHX 1

3 10012-029 Standoff/Bearing Retainer 1

4 10007-I06 Screw,1/4 x 3/8 1

5 10019-013 Flatwasher,1/4" 1

6 10018-004 Lock washer, 1/4" 1

7 30035-001 Sprocket,Auger 1

8 30090-001 Key,Auger 1

9 10032-812 Screw,Bearing Retainer 2

10 10006-240 Set Screw,Sprocket 2

11 30005-001 Bearing,Auger Input 1

12 10019-017 Flatwasher,1/2" 1

13 30025-GRD CHAIN GUARD 1

Page 36************************************************************************************************************************PPHHXX--115500******************

Page 37

GUN ASSEMBLY

A

1

A

2

6

3

4

5

7

B

8 9

15

16

17

19

18

20

16 21

6 REQ

22

23

24

8

3 REQ

SECTIONA-B

10

11

4

2 REQ

12

13

14

SECTION A-A

26

27

************************************************************************************************************************PPHHXX--115500*****************

25

*Page 37

Page 38

GUN ASSY PARTS LIST

11

50068

-

0011TRIGGER VALVE

30083-001D ITEM LIST

ITEM P/N QTY DESCRIPTION

1 30091-001 1 THERMAL BREAK/ GASKET

2 50065-001 1 UNION, 5/32" TUBE

3 50065-003 1 UNION, 1/4" TUBE

4 10020-G12 8 SCREW, SOCKET HEAD, 6-32 X 3/4" LONG, SS

5 30057-001B 1 HANDLE, GUN

6 50022-2BK 18" TUBING, POLYURETHANE, 5/32", BLACK

7 50070-4BK 18" TUBING, POLYURETHANE, 1/4", BLACK

8 10020-I20 4 SCREW, SOCKET HEAD, 8-32 X 1 1/4" LONG, SS

9 10037-009 1 LOCKNUT, 8-32

10 50014-002 1 CONNECTOR, BARBED, 1/4"

12 10028-006 1 SPRING, LEVER RETURN

13 20001-001 1 TRIGGER LEVER

14 50014-001 1 CONNECTOR, BARBED, 5/32"

15 30052-001A 1 SHAFT, GUN

16 20008-001 2 BEARING, FLANGED

17 10029-213 1 RETAINING RING, SPIRAL

18 30067-001 A/R SHIM, GUN

19 30051-001 1 RETAINING COLLAR, GUN

20 20002-001 1 THRUST BEARING

21 10030-219 1 O-RING, DOUBLE SEAL

22 10020-I10 6 SCREW, SOCKET HEAD, 8-32 X 5/8" LONG, SS

23 30054-001 1 RETAINER, CAP

24 30053-001B 1 CAP, NOZZLE RETAINER

25 30055-001A 1 OUTLET, GUN

26 10007-H06 1 SCREW, BUTTON HEAD, 10-32 X 3/8"

27 30056-001A 1 GUN BODY

A

= APPLY LOCTITE 242 TO THREADS

B

= COAT SEAL AND SHAFT EDGE WITH DC33

C

= PRESS BEARING INTO HOUSING

D

= PACK BEARING AND COAT WASHERS WITH DC-33

E

= ADD SHIMS TO REDUCE "IN/OUT" PLAY IN SHAFT

F

= PRESS BEARING INTO RETAINING COLLAR

Page 38************************************************************************************************************************PPHHXX--115500******************

Page 39

30295-TUBE

PHX-150 TUBE DIAGRAM

SHEET 1 OF 4

REFERENCE

DRAWN BY: SAS 3/3/17

CHECKED BY:

REFERENCE DESCRIPTION FUNCTION PART # SHEET #

************************************************************************************************************************PPHHXX--115500*****************

*Page 39

Page 40

L-10

7

1

8

6

PI-2

7

6

REG-1

12

20

14

NC

PI-1

26

SEE CONTROL

REG-5

NO

25

21

3

VB-

1

VB-

2

3

7

SHELF

SEE COMPONE

#37 FROM REG-4 INLET TEE

#12 FROM F-1

#32 FROM AUGER DRIVE

NTS

DRAWN BY: SAS 3/8/17CHECKED BY:

302

PHX-150 TU

SHEET

CONTROL PAN

#36 TO PV-3

SEE CONTROL

#26 FROM RED 4WAY ELBOW

#25 TO INLET BARB ON V-2

#21 FROM LOGIC 5A

#14 FROM BLACK TEE MANIFOLD

#20 TO LOGIC 5a

SHELF

#3 TO LOGIC 1a

#8 FROM REG-4 Y FITTING

PI-3

32

36

95-TUBE

2 OF 4

BE DIAGRAM

EL

Page 40************************************************************************************************************************PPHHXX--115500******************

Page 41

#11 FROM REG-3

CONTROLAIR REGULATOR

17

52

53

41

49

48

X

a

b

A

T-1

49

50

b

a

A

#17 TO PV-1

AIRLOCKMOTOR

CONTROL VALVE PILOT

#30 FROMF-3

TRIGGERFILTER

53

19

ETM

SWITCH

PS-1

#5 TOREG-2 PILOT PORT

SEE

COMPONENTS

30295-TUBE

PHX-150 TUBE DIAGRAM

SHEET 3 OF 4

CONTROL SHELF

VIBE

"NOT"

b

a

A

41

1113

10

48

52

47

154216

28

9

14 13

a

b

A

10

24

b

a

A

47

22

23

b

a

A

21

20

9

15

A

b

a

a

b

A

5162

2

b

A

a

4

VALVE

X

31

19

L-8

X

L-7

27

X

REG-4

4

8

L-6

30

ARM LATCH

"OR" VALVE

X

PURGE "YES"

VALVE

18

X

AIR "YES"

VALVE

L-3 L-4 L-5

1

BLAST/

PURGE

"OR"

VALVE

L-2

#39 TO AIRLOCK/VIBE TEE

#37 TO REG-5

37

35

ICE RATE REGULATOR

AIRLOCK MOTOR/

AUGER MOTOR/

38

LUBE-1

VIBRATOR LUBRICATOR

#38 FROM REG-2

FILTEREDPORT

AIRLOCKSPEED/

VIBESTRENGTH/

PURGEPRESSURE

REGULATOR

DRAWN BY: SAS 3/7/17

CHECKED BY:

SEE CONTROL

PANEL

SEE

COMPONENTS

3

a

29

X

L-1

BLAST

"YES"

b

A

1

VALVE

26,24

23,22

4-WAY

ELBOW

35

#40 TO TRIGGER SUPPLY

BULKHEADFITTING

#8 TO L9 "OR" VALVE

#26 TOPI1 ARM INDICATOR

#20 FROM VB1 ARM SELECTOR

#21 TO VB2 DISARM SELECTOR

#3 FROMREG-1 OUTLET TEE

#14 TO VB1 ARM SELECTOR

#25 FROM VB2 DISARM SELECTOR

#42 TOTIMING TANK WYE

#19 FROMTIMINGTANK ELBOW

#33 TOAUGER MOTOR

POPPET VALVE PILOT

4-WAY

ELBOW

46,29

31,28

VIBE

ON START

SAFETY SCREEN

VALVE

25

V-2

27

VALVE

CV-1

50

51

AT-3

33

PURGE

DELAY

SPEED

CONTROL

FCV-1

18

46

AT-1

************************************************************************************************************************PPHHXX--115500*****************

SEE CONTROL

PANEL

SEE

COMPONENTS

*Page 41

Page 42

SEE

CONTROL PANEL

#36 F

#32 TO PI-3

ROM REG-5

SEE

#42 FROM T-1

#19 TO L-8 X

#1

2 TO REG-1

#33 FROM 5/

#38 TO LUBE-1

#5 FROM L-3 A

#11 TO BLACK TEE M

CONTROL SHELF

#

#39 FROM REG-4

#17 FROM BLUE MAN

30 TO L-6 X

#40 FROM RE

RES-1

42

AT-2

19

PORT 2

12

F-1

43

32 BULKHEAD OUTLE

T

REG-2

REG-3

38

ANIFOLD

IFOLD

11

V-1

D 4WAY ELBOW BUL

KHEAD OUTLET

F-2

HOPPER

VIBRATOR

45

43

39

45

44

PV-2

VB-1

32

17

30

30

44

TRIGGER

SUPPLY

F-3

34

40

34

PV-3

33

PV-1

36

M-2

M-1

TRIGGER RETURN

DRAWN BY: SAS 1/2

CHECKED BY:

1/10

30295-TUBE

PHX-150 TUB

SHEE

COMPONENTS

AIRLOCK

T 4 OF 4

E DIAGRAM

AUGER DRIVE

Page 42************************************************************************************************************************PPHHXX--115500******************

Page 43

FACTORY SETTINGS

There are two factory set and locked regulators on the PHX. Problems can stem from these regulators

being out of adjustment.

There is also a speed control valve that controls the duration of the purge delay. This allows the Airlock

Motor and the purge air pressure to continue to run for a time period to clear the airlock and hose of ice.

Control Air Regulator

This regulator protects the entire control system. This setting is critical as the system needs 70-80 PSI,

and settings over 90 PSI can damage control system components. It is located on the right side of the air

system, mounted on the main filter regulator. This regulator has a built in gauge and should be set to 5.5

BAR (70-80 PSI).

Control Air Regulator

Set to 5.5 BAR (70-80 PSI)

Airlock Speed/Vibrator Strength/Purge Pilot Regulator

This regulator controls the RPM of the Airlock Motor, the vibrating force of the Vibrator and the Purge

Air Pilot pressure to the Filter/Regulator.

To check or set pressure,

1.Back off Blast Air Regulator all the way. {If locked, pull knob

to unlock. Turn counterclockwise until knob stops. Do not force

knob} Gauge will now show the pressure that controls the rpm of

the airlock motor, strength of the vibrator and blast hose purge

pressure. The gauge should read 40-45 PSI.

2.To adjust, pull Airlock Regulator knob to unlock, Observe

Blast Air Gauge and turn knob to adjust pressure to about 40–45

PSI. Push knob back in to lock.

Purge Delay Speed Controller

The factory setting of this delay is 3 seconds. This time period can be easily adjusted, as the Speed

Controller is readily accessible, located under the Control Shelf just to the left of the Lubricator.

To Adjust:

1.Locate Speed Controller knob, loosen knurled jam nut. 2. Adjust

knob. Turn valve in to increase delay or back valve out to shorten

the delay. 3. Cycle the trigger on and off. Repeat until purge cycle

stops 3 seconds after trigger is released. To lock setting, tighten the

jam nut. WARNING: If valve is closed completely the purge cycle

will not disengage.

**************************************************************************************************PPHHXX--115500*****************

*Page 43

Page 44

RECOMMENDED SPARE PARTS

Preventive Maintenance (Class I)

Part# Description Qty.

50067-00E Element, Blast Air Pilot/Trigger Return 5

50067-001 Filter, Trigger Return 1

50067-002 Filter, Blast Air Pilot 1

50008-E01 Element Kit, Main Filter 2

Repair (Class II)

Part# Description Qty.

30032-001 Regulator, Ice Rate 1

50051-001 Regulator, Blast Air Pilot 1

50036-001 Restrictor, Vibration Duration 1

50053-001 Valve, Poppet, ¼” 1

30003-002 Valve, Pellet/Safety Screen 1

50028-003 O-Ring, Lubricator Bowl 1

50027-212 Indicator, ARM/DISARM 1

50045-2BK Tubing, Trigger Return 60 ft.

50045 4BK Tubing, Trigger Supply 60 ft.

50068-001 Trigger Valve 1

30022-001 Rotor, Airlock, PHX-150 1

30031-001 Pad, Vibrator 1

Critical Downtime (Class III)

Part# Description Qty.

50202-001 Motor, Airlock, PHX-150 1

50111-911 Valve Body, Normally Non-Passing 1

50111-912 Valve Body, Normally Passing 1

50007-001 Logic Element, “OR” 1

50044-001 Regulator, Airlock/Vibration/Purge 1

50023-001 Logic Element, “OR” 1

50023-003 Logic Element, “NOT” 1

50023-004 Logic Element, “YES” 1

50021-002 Speed Controller, Purge Delay 1

30088-001 Ratchet Assembly, PHX-150 1

30081-001 Chain Assembly 1

30006-002 Bearing and Sprocket Assembly 1

30034-001 Pad, Airlock, PHX-150 2

10013-035 O-ring, Airlock Pad 2

10011-327 Quad-Ring, Airlock Pad 2

30175-025 Hose Assembly, 25’, Blast, PHX-150 1

Page 44************************************************************************************************************************PPHHXX--115500******************

Page 45

SPECIFICATIONS

Dimensions: 18” x 20” x 47” (W x L x H)

(47cm x 51cm x 120cm)

Dry Weight: 140 lbs. (63.5 kg)

Hopper Capacity: Over 100 lbs. (45.5 kg) of pellets

Ice Consumption Range: 0.5 lbs. – 5 lbs. (0.23 kg – 3.2 kg) / min.

Supply Air Pressure Range: 70 psi – 125 psi (4.8 bar – 8.6 bar)

Air Consumption Range: 100 CFM – 250 CFM

Blast Pressure Range: 50 psi – 125 psi (2.8 bar – 8.6 bar)

Inlet Air Temperature: 140°F (60°C) maximum

Inlet Air Connection: 1” NPT

Customer Support:

(951) 278-2229

************************************************************************************************************************PPHHXX--115500*****************

*Page 45

Page 46

310 N. Cota Street, Suite H Corona, CA. 92880

Telephone: (951) 278-2229 Fax: (951) 278-0084

http://www.phoenixunlimitedllc.com

Loading...

Loading...