Page 1

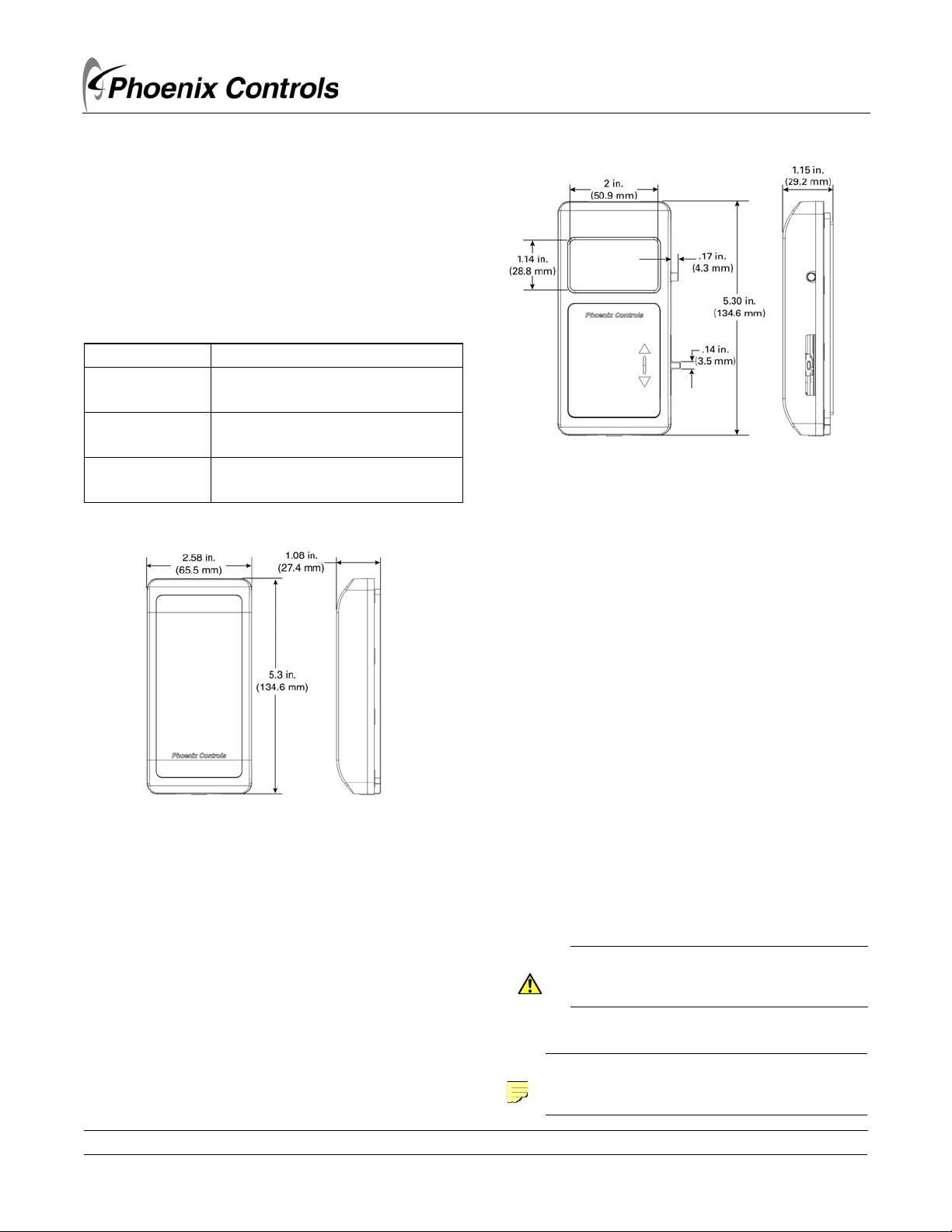

PHS/PCS300 SERIES INSTALLATION GUIDE

Section 1. Product Description

The PHS300-x is a room humidity sensor. The PCS300-x is a

combination temperature and humidity room sensor. The PCS300-xDOS has a large LCD display, slider setpoint adjustment, and override

button.

Depending on model, the analog outputs are a humidity sensor output

(defined in the table below), a 10 KΩ type 2 thermistor sensor,

0-20 KΩ temperature setpoint, and an override contact. All units come

standard with a 3.5 mm (1/8"), easy access communication jack

providing direct network access. All PCS units also include an internal

three position Low/Normal/High test and balance switch.

Model Humidity Sensor Signal

PHS300-x Default: 4-20 mA

Field selectable to: 0-5 or 0-10 Vdc

PCS300-x Default: 4-20 mA

Field selectable to: 0-5 or 0-10 Vdc

PCS300-x-DOS Default: 4-20 mA

Field selectable to: 0-5 or 0-10 Vdc

MODELS PHS300-x, PCS300-x, and PCS300-x-DOS

(where -x defines the enclosure style)

Figure 2. PCS300-x-DOS with display, override, and

slider temperature setpoint

Figure 1. PHS300-x and PCS300-x sensors only

Section 2. General Installation

Requirements

For proper installation and subsequent operation of each controller,

pay special attention to the following recommendations:

• It is recommended that the sensor(s) be kept at room temperature

for at least 24 hours before installation to allow any condensation

that may have accumulated due to low temperature during

shipping/storage to evaporate.

• Upon unpacking the product, inspect the contents of the carton

for shipping damages. Do not install damaged controllers.

• Allow for proper clearance of sensor enclosure, wiring terminals

and hardware configuration and maintenance.

• Each controller is designed to operate under the following

environmental conditions:

• Ambient temperature from 32°F to 122°F (0°C to 50°C)

• Relative humidity from 0% to 95%, non-condensing

• Ensure proper ventilation of each sensor and avoid areas where

corroding, deteriorating or explosive vapors, fumes or gases may

be present.

• Do not drop the sensor or subject it to physical shock.

If the controller is used and/or installed in a manner not specified by

Phoenix Controls, the functionality and the protection provided by the

sensor may be impaired.

CAUTION

Any type of modification to any Phoenix Controls

product will void the product's warranty.

NOTE

75 Discovery Way • Acton, MA 01720 • Tel (978) 795-1285 • Fax (978) 795-1111 • www.phoenixcontrols.com

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 1 OF 12

Take special care to keep the front and back plate aligned

when separating and joining them.

Page 2

WARNING

Take reasonable precautions to prevent electrostatic

discharges to each sensor when installing, servicing

or operating the controller. Discharge accumulated

static electricity by touching one's hand to a securely

grounded object before working with each

controller.

2.1 Mounting Instructions

NOTE

Mounting hardware is provided for both junction box

and drywall installation.

2.1.1 Junction Box

DO NOT CUT OUT THE ENTIRE JUNCTION BOX

DIMENSION. The base plate will not fully cover the opening.

1. Pull the wire through the wall and out of the junction box,

leaving about six inches free.

2. Pull the wire through the hole in the base plate.

3. Secure the base to the box using the #6-32 x 1/2" mounting

screws provided.

4. Terminate the unit according to the Termination section.

5. Attach Cover by latching it to the top of the base, rotating the

cover down and snapping it into place.

NOTE

In wall-mount applications, the wall temperature and

the temperature of the air within the wall cavity can

cause erroneous readings. The mixing of room air and

air from within the wall cavity can lead to

condensation, erroneous readings and premature

failure of the sensor. To prevent these conditions, do

the following for the mounting method used:

• Junction box - seal the conduit leading to the

electrical box

• Drywall - ensure that the foam insulating pad on

the back of the enclosure covers the hole in the

wall.

6. Secure the cover by backing out the lock-down screws using a

1/16" Allen wrench until they are flush with the bottom of the

cover.

2.1.2 Drywall Installation

1. Place the base plate against the wall where you want to mount

the sensor.

2. Using a pencil mark out the two mounting holes and the area

where the wires will come through the wall.

3. Drill two 3/16" holes in the center of each marked mounting

hole. Insert a drywall anchor into each hole.

4. Drill one 1/2" hole in the middle of the marked wiring area.

5. Pull the wire through the wall and out of the 1/2" hole, leaving

about six inches free.

6. Pull the wire through the hole in the base plate.

7. Secure the base to the drywall anchors using the #6 x 1 inch

mounting screws provided.

8. Terminate the unit according to the Termination section.

9. Attach cover by latching it to the top of the base, rotating the

cover down and snapping it into place.

10. Secure the cover by backing out the lock-down screws using a

1/16" Allen wrench until they are flush with the bottom of the

cover.

2 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Page 3

2.2 General Wiring Recommendations

CAUTION

Turn off power before any kind of servicing.

Please note that there may be multiple power sources.

2.2.1 Phoenix Controls Wiring Recommendations

• Use cables recommended by Phoenix Controls (refer to Phoenix Controls Cables on page 12).

• Stranded wire of at least 22 AWG is strongly recommended for all wire connections. Larger gauge wire may be required for long runs.

• Follow good wiring practices:

• Do not run the signal cable in the same conduit or wireway as the power cables.

• If the signal cable must cross power cables, it is best to do so at a 90-degree angle.

• Maintain a consistent color code or polarity all the way through the wiring system.

• All wiring must comply with the National Electric Code (NEC) and local codes.

• Do NOT run this device's wiring in the same conduit as AC power wiring of NEC class 1, NEC class 2, NEC class 3 or with wiring used to

supply highly inductive loads such as motors, contactors and relays.

• Tests show that fluctuating and inaccurate signal levels are possible when AC power wiring is present in the same conduit as the signal lines.

If you are experiencing any of these difficulties, please contact your Phoenix Controls Representative.

• Local and national electrical codes take precedence.

Sensor connections:

• Remove the front plate from the back plate to facilitate the wiring process.

• Use a small flat screwdriver to tighten the terminal connector screws once the wires have been inserted.

• The board connectors accept wires or flat cables ranging from 22 to 14 AWG (0.64-1.63 mm diameter) per pole. However, power cables

must remain between 18 and 14 AWG (1.02-1.63 mm diameter).

Power connections:

• Power type cables (i.e., for power, 2- and 3-wire voltage and current inputs and outputs, as well as triac outputs) should be kept apart from

other types of wiring to avoid any ambient noise transmission to other wires.

• Do not connect the universal inputs, analog/digital outputs or common terminals to earth or chassis ground (unless stated otherwise).

CAUTION

Phoenix Controls does not recommend wiring the sensor with power applied as accidental arcing may damage the product and

will void the warranty.

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 3 OF 12

Page 4

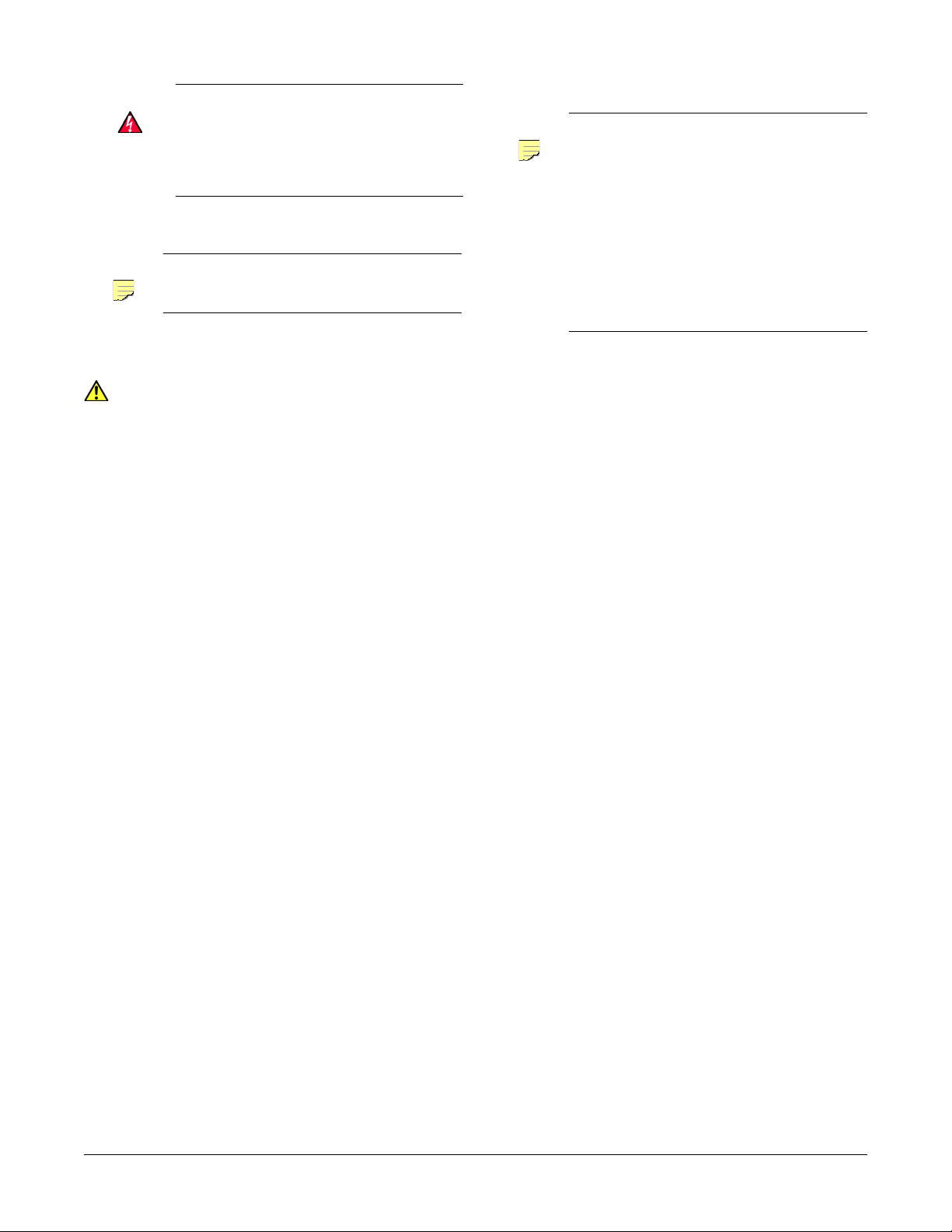

2.2.2 PHS300-x, PCS300-x, and PCS300-x-DOS Wiring

Figure 3. PHS300-x, PCS300-x, and PCS300-x-DOS connections

NOTE

PHS300-x, PCS300-x, and PCS300-x-DOS Wiring with Jumper in: 4 to 20 mA Setting

The PHS300-x and PCS300-x do not have OVR or SET terminals and the EXT-OVR and SEN terminals are non-functional.

Terminal Applicable to: Option Description

OVR1 and OVR2 PCS300-x-DOS

only

SET1 and SET2 PCS300-x-DOS

only

SEN1 and SEN2 PCS300-x and

PCS300-x-DOS

EXT-OVR PCS300-x-DOS

only

O Occupancy override status:

N.O. contact output (300 mA @ 24 Vdc)

S Temperature setpoint:

0 -20 KΩ output

Temperature sensor:

10K-2 thermistor output

D External "person" icon override:

Bypass control (from Phoenix valve) indication; "person" icon is solid (occupied) when

this pin is switched to power ground (see Bypass/External "Person" Icon Control on page 7 )

VOUT All Not used

V+ All Humidity sensor: 4-20 mA output

GND All 24 Vdc power (see Specifications on page 10 for details)

4 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Page 5

PHS300-x, PCS300-x, and PCS300-x-DOS Wiring with Jumper in: 0-5 Vdc or 0-10 Vdc Settings

Terminal Applicable to: Option Description

OVR1 and OVR2 PCS300-x-DOS

only

SET1 and SET2 PCS300-x-DOS

only

SEN1 and SEN2 PCS300-x and

PCS300-x-DOS

EXT-OVR PCS300-x-DOS

only

O Occupancy override status:

N.O. contact output (300 mA @ 30 Vdc)

S Temperature setpoint:

0 -20 KΩ output

Temperature sensor:

10K-2 thermistor output

D External "person" icon override:

Bypass control (from Phoenix valve) indication; "person" icon is solid (occupied) when

this pin is switched to power ground (see Bypass/External "Person" Icon Control on page 7)

VOUT All Humidity sensor: 0-5 Vdc or 0-10 Vdc output

GND All Power ground

V+ All 24 Vdc power (see Specifications on page 10 for details)

2.2.3 Communication Jack Wiring

Figure 4. Communication jack pinout

Communication Female Jack Wiring

Communication Jack Pin Wire Color

Ground Black (Net B)

Tip White (Net A)

Ring Red (Not used)

2.2.4 Test and Balance (T&B)

Moving the Test and Balance (T&B) switch to the Normal position provides the actual room temperature. Moving the switch to HI forces a high

temperature value for the balancer or point-to-point checkout. Moving the switch to LO forces a low temperature value.

Test and Balance Switch Settings

Switch Position Description

HI Sets the sensor value HIGH for full cooling (5.11Ω, 105.8°F)

NORMAL Allows sensor to operate normally; reports actual temperature

LOW Sets sensor value low for full heating (26.7KΩ, 39.2°F)

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 5 OF 12

Page 6

2.3 Display Segments (PCS300-x-DOS only)

The normally active segments are:

• INSIDE on upper left: signifies that actual space temperature or humidity is being displayed

• SETPOINT on upper right: signifies that temperature setpoint is being displayed

• Four (4) number digits

• Three (3) integer

• One (1) decimal

•Units

• Occupancy "person" icon (solid icon = Occupied; hollow icon = Unoccupied)

Figure 5. Display segments

º

F or ºC, or relative humidity

2.3.1 Display, Setpoint, and Override Descriptions

The PCS300-x-DOS sensor comes with a display, override button, and slider setpoint adjustment.

2.3.1.1 Numerical Display

The default display shows current temperature toggled every 5 seconds with space humidity. When the setpoint slider is moved enough to change

the setpoint by 0.5 degrees, the setpoint will be displayed (as an integer) for 3 to 4 seconds. If desired, the unit can be set up to:

• to toggle between all three parameters (temperature, humidity, or temp setpoint), or

• any two parameters, or

• display one parameter only

Refer to section Humidity and Temperature Offset and Display Adjustments: PCS300-x-DOS on page 8 for details.

NOTE

2.3.1.2 Setpoint

Slide the setpoint lever up or down to the desired setpoint. When programmed to be displayed, the setpoint display changes in one degree

increments.

NOTE

The default temperature unit is Fahrenheit. To switch to Celsius, change the setting of Mode P2 as detailed in section 2.4.3

Even when the temperature setpoint is not displayed, the terminations SET1 and SET2 are active, sending a 0 to 20 KΩ, signal

out.

6 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Page 7

2.3.1.3 Local Occupancy Override

When the override button is pressed, the "person" icon is solid while the output (OVR1 and OVR2) shorts. When the button is released, the icon

blanks. This functionality is seen when a ground has never been applied to the EXT OVR pin during the current power cycle. Refer to section

2.3.1.4 Bypass/External "Person" Icon control for the effect of grounding EXT OVR.

2.3.1.4 Bypass/External "Person" Icon Control

The occupancy "person" icon can be used to display bypass status from the Phoenix valve. Configure the valve's DO to output bypass occupancy

status then wire the DO between the room unit's EXT OVR and GND pins.

Once the DO closes (grounds EXT OVR), the "person" icon will become hollow (unoccupied). The icon will remain hollow until either the DO

closes again or the local occupancy override button is pushed.

NOTE

Prior to the first closing of the DO (EXT OVR grounded), the unit will behave as described in Local Occupancy Override above.

Once the EXT OVR has been grounded, the "person" icon will display continuously (either solid or hollow depending upon the

current control). The only way to blank the "person" icon from the display (after EXT OVR has been switched to ground), is to

cycle power.

2.4 Optional Technicians Adjustments

This section details optional adjustments a technician can make for:

• Changing the humidity output signal

• Adjusting humidity output (ie, offset), and

• For the PCS300-x-DOS only:

• Adjusting temperature (i.e., offset)

• Changing temperature units, and

• Changing what is shown on its display

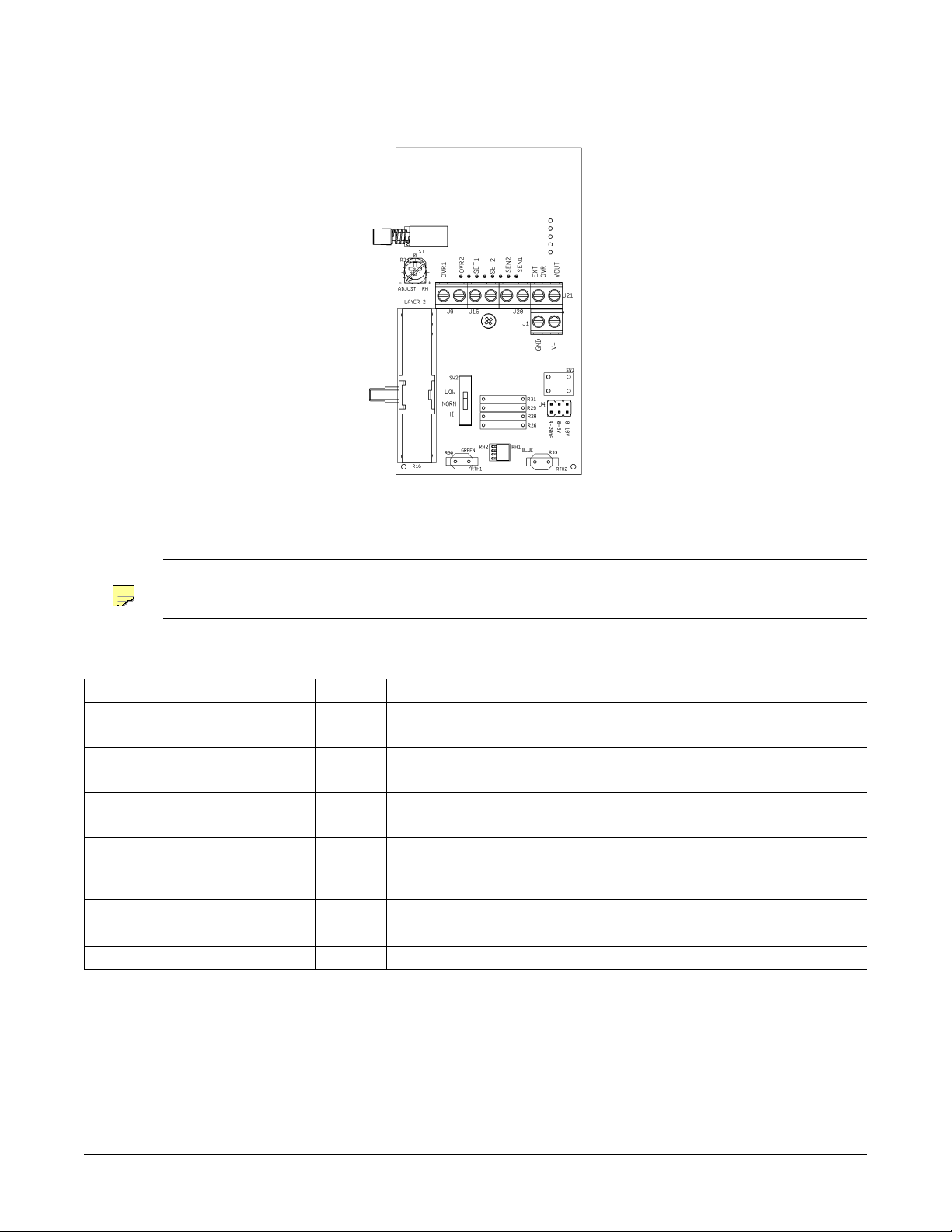

2.4.1 Humidity Output Selection

Moving the jumper on connector J4 will change the humidity output from 4 to 20mA, 0 to 5Vdc or 0 to 10Vdc depending on jumper position.

Figure 7 below shows the jumper in the 4-20mA position.

Figure 6. Humidity output jumpers

2.4.2 Humidity Offset Adjustment: PHS300-x and PCS300-x

Potentiometer R34 (Figure 8) can be used to adjust the humidity output by ±5%. A high accuracy humidity reference is recommended.

Figure 7. R34 relative humidity (%RH) adjustment potentiometer

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 7 OF 12

Page 8

2.4.3 Humidity and Temperature Offset and Display Adjustments: PCS300-x-DOS

When the unit is powered up, pressing SW1 (Figure 9)will enter the user calibration adjustment mode. When pressed, the LCD will show the

mode as page zero, P0.

The mode page numbers auto-scroll to P5 and then the unit returns to the normal run mode. Pressing SW1 when the page number is displayed

will show the calibration value that is associated with that mode. The variable will auto-scroll to show all allowed values for the selected page.

Pressing SW1 when the variable value you need is shown will record that value and return to showing page numbers.

Figure 8. SW1 calibration button

PCS300-x-DOS Adjustment Parameters

Parameter

Temperature Offset

Humidity Offset

Mode Default Adjustment

P0 0 ±5° in 0.1° increments. A high accuracy reference is recommended.

P1 0 ±5% in 0.1% increments or R34 when R34 is selected, humidity offset is set by

turning potentiometer R34 situated just to the left of the OVR1 terminal. See

Figure 12. A high accuracy reference is recommended.

Display Units

Display RH to Temp Toggle Time

Display Resoultion

P2 F °F or °C

P3 5 3 to 11 seconds

P4 0 0 = 0.5

1 = 0.1

Display Section

P5 0 0 = Temperature, Humidity and Temperature Setpoint when active

1 = Temperature and Temperature Setpoint when active

2 = Humidity and Temperature Setpoint when active

3 = Temperature, Humidity and Temperature Setpoint

4 = Temperature and Temperature Setpoint

5 = Humidity and Temperature Setpoint

2

6 = Temperature Setpoint

7 = Temperature and Humidity

2, 3

8 = Temperature3

9 = Humidity

1

When Active means moving the setpoint slider

2

Display toggles through selections

3

Even when the temperature setpoint is not displayed the terminations SET1 and SET2 are active, sending a 0 to 20 KΩ signal out.

3

1

1

1

2

2

8 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Page 9

2.5 Troubleshooting

Possible Problems Possible Solutions

General troubleshooting

Incorrect humidity

Incorrect temperature

Unit does not operate

• Determine that the input is set up correctly in the controller's and building automation software.

• Check wiring at the sensor and controller for proper connections.

• Check for corrosion at either the controller or the sensor. Clean off the corrosion, re-strip the interconnecting wire and

reapply the connection. In extreme cases, replace the controller, interconnecting wire and/or sensor.

• Label the terminals that the interconnecting wires are connected to at the sensor end and the controller end. Disconnect

the interconnecting wires from the controller and the sensor. With the interconnecting wires separated at both ends

measure the resistance from wire-to-wire with a multimeter. The meter should read greater than 10 Meg-ohms, open or

OL depending on the meter you have. Short the interconnecting wires together at one end. Go to the other end and

measure the resistance from wire-to-wire with a multimeter. The meter should read less than 10 ohms (22 gauge or

larger, 250 feet or less). If either test fails, replace the wire.

• Check power supply/controller voltage supply

• Disconnect sensor and check power wires for proper voltage (see specifications page)

• Check all adjustments

• If available, check the sensor against a calibrated instrument such as a hygrometer

• Determine if the sensor is exposed to an external environment different from the room (conduit draft)

Determine that the temperature sensor's wires are connected to the correct controller input terminals and are not loose.

• Check the wires at the sensor and controller for proper connections.

• Determine if the sensor is exposed to an external environment different from the room (conduit draft)

• Measure the physical temperature at the temperature sensor's location using an accurate temperature standard.

Check the Temperature Sensor's Resistance

Disconnect the temperature sensor's wire (Terminals SEN1 & SEN2) and measure the temperature sensor's

resistance across the sensor output pins with an ohmmeter. Put the ohmmeters black lead on Terminal SEN2

and the red lead on Terminal SEN1. Compare the temperature sensor's resistance to the thermistor output

table on the Temperature and Humidity Sensors Product Data Sheet (MKT-0165). If the measured resistance is

different from the temperature table by more than 5%, call Phoenix Controls Technical Support. Don't forget

to reconnect the wires.

Check power for proper polarity.

• Disconnect the power wires at the controller. Measure controller output for proper power (see specifications), if the

voltage is outside the limits trouble shoot controller. Reconnect power wires to controller when finished. If the measured

voltage is above the specification limit, you may have damaged the sensor, call Phoenix Controls Technical Support.

• Disconnect the power wires at the sensor. Measure the wires for the same voltage as at sensor. If the voltage is different

from that measured at the controller troubleshoot wire. Reconnect power wires to sensor when finished.

• Measure the power at the sensor with the power connected for proper power (see specifications), if the voltage is outside

the specification limits call Phoenix Controls Technical Support

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 9 OF 12

Page 10

2.6 Specifications

PHS300-x PCS300-x PCS300-X-DOS

POWER

POWER

CONSUMPTION

With humidity output of:

0 to 5 Vdc or to 10 Vdc

SENSING ELEMENTS Thermistor

Temperature Range

Temperature Accuracy

Temperature Stability

Heat Dissipation

Humidity

Humidity Range 0-100% RH

Humidity Accuracy

Response Time 20 seconds for a 63% step

FEATURES Display

Te m pe r a t u r e

Humidity

Tem p Se t p oi n t

Temp Setpoint Display Range

Override

Override Display

Tes t a nd B a l an c e

Network Connection 1.8" (3.5 mm) phone jack in base

OUTPUTS Temperature

Tem p er a t ur e S et p oi n t

Occupancy

Humidity as Voltage 0-5 or 0-10 Vdc; Impedance > 10 KΩ

Humidity as Current 4-20 mA; Impedance <500 ohm @ 24 Vdc

ENCLOSURE Material Type ABS Plastic

Material Rating UL 94, V-0

MOUNTING Drywall Anchor and screws provided

Junction Box Standard 2" x 4" J-box; screws provided (not box)

ENVIRONMENTAL Temperature

Humidity 0 to 95%, non-condensing

10 to 35 Vdc (24 Vdc recommended)

Note: Use of PVC350-HW is required for LON applications

———

4-20 mA

20 mA (0.5 VA)

4 mA (0.1 VA)

— 10 KΩ @ 25

—

— ±0.36

— <0.036

— 4.9 mW /

± 2.0% RH (from 10 to 90% RH at 77

——

——

Forma t

——

——

——

Feature 2

——

Feature 3

——

Feature 7

——

Feature 8

——

Feature 9

——

——

——

— 3-position slide switch (High / Norm / Low)

—

——

——

º

to 122ºF (0º to 50ºC)

32

º

to 122ºF (0º to 50ºC)

32

º

F, ( ±0 .2ºC)

º

F / Year (<0.02º C / Year)

º

º

F (25ºC)

Resistance, NTC

º

C, Type 2

F (2.7 mW / ºC)

LDC; 3.5 digits at 0.6" H

º

to 122º F (0º to 50º C)

32

º

in 0.5

increments

0 to 100% RH in 0.5% increments

Default: Temperature and Humidity

toggled every 5 seconds; Temp Setpoint

only when slider moved

Slide pot

Cool / Warm (Down / Up)

Configurable at valve UI:

Absolute 32-122

Relative -18 to +18

Shown in 1

º

± 2

F (± 2º C)

º

± 3

F (± 3º C)

55 to 85

60 to 80

65 to 80

º

F (0-50º C)

º

F (-7 to +7º C)

º

increments:

º

F (13 to 30º C)

º

F (15 to 27º C)

º

F (18 to 27º C)

N.O. Pushbutton (closed during push)

Occupancy "person" icon

Solid=Occupied

0-20 KΩ

N.O. contact

10 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Page 11

2.7 Maintenance

CAUTION

Each controller requires minimal maintenance, but it is important to take note of the following:

• If it is necessary to clean the outside of the front plate and/or the inside of the back plate, use a dry cloth.

• Verify the tension of all wires and cables whenever the controller is serviced.

Turn off power before any kind of servicing.

Note that there may be multiple power sources.

2.8 Disposal

The Waste Electrical and Electronic Equipment (WEEE) Directive sets out regulations for the recycling and disposal of products. The WEEE2002/

96/EG Directive applies to standalone products, i.e., products that can function entirely on their own and are not a part of another system or piece

of equipment.

For this reason Phoenix Controls products are exempt from the WEEE Directive. Nevertheless, Phoenix Controls products are marked with the

WEEE symbol, indicating that disposal of the devices shall not be done together with municipal waste.

Figure 9. WEEE Directive symbol

Products must be disposed of at the end of their useful life according to local regulations and the WEEE Directive.

2.9 FCC Statement

CAUTION

FCC: This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

©2014 Phoenix Controls Specifications subject to change without notice. Rev. C 650-321-017 08/16 PCS300 SERIES INSTALLATION GUIDE 11 OF 12

Page 12

2.10 Phoenix Controls Cables

Cable

Ty p e

2C Round No 24 Vac power 18 Belden 9409 1: Red

2C Round Yes 24 Vac power 18 Belden 82740 Windy City

TP NO FTT-10 (4,500 FT)

TP Yes FTT-10 (4,500 FT)

3C Round No Signal 22 Belden 8443 1: Red

3C or 4C

Round

4C Round No Signal 22 Belden 8444 Manhattan M13304 1: White

5C Round No Signal 22 Belden 8445 Manhattan M13305 1: White

8C No Signal 22 Belden 9421 Manhattan M13308 1: White

8C Yes Signal 22 Comtran 4956 1: White

3C

MS/TP

3C

MS/TP

Plenum

Rated

Yes Signal 22 Belden 88444 Windy City 004380 1: Red

No Shielded 22 Belden 3106A

Yes Shielded 22 Connect-Air W223C-

Function

24 Vac power 14 Belden 9411

24 Vac power 14 Windy City NP007960

TP1250 (425 FT)

FTT-10 (8,000 FT) 16 Windy City 109600

TP1250 (425 FT)

FTT-10 (8,000 FT) 16 Windy City 109500

Wire

Gauge

22 Windy City 107500

22 Windy City 105500

Primary

Vendor/Part #

www,smartwire.com

www,smartwire.com

S=SPOOL B=BOX

www,smartwire.com

(120 ohm)

2060YPC

Alternate Vendor/

Part #

NP002360

2: Black

1: Red

2: Black

1: White with Blue Stripe

2: Blue with White Stripe

1: White with Blue Stripe

2: Blue with White Stripe

2: Black

3: Green

2: Black

3: Green

4: White (not used as 3C)

2: Green

3: Black

4: Red

2: Brown

3: Black

4: Red

5: Green

2: Orange

3: Black

4: Red

5: Green

6: Yellow

7: Blue

8: Brown

2: Orange

3: Black

4: Red

5: Green

6: Yellow

7: Blue

8: Brown

1: White with Orange stripe

2: Orange with White stripe

3: Blue with White stripe

1: Black

2: White

3: Red

Color Code Notes

Must be stranded

Must be stranded

Must be stranded

Must be stranded

Must be stranded

Must be stranded

No substitutes

No substitutes

Shielded with

drain

Foil shield with

drain wire

Phoenix and Phoenix Controls are trademarks of Honeywell International, Inc.

The material in this document is for information purposes only and is subject to change without notice. Phoenix Controls assumes no responsibility for any errors

or for consequential damages that may result from the use or misrepresentation of any of the material in this publication.

Phoenix Controls is a business of Honeywell International, Inc.

For additional information and a listing of our global offices, please visit our Web site at www.phoenixcontrols.com or call (800) 340-0007.

12 OF 12 PCS300 SERIES INSTALLATION GUIDE 650-321-017 08/16 ©2014 Phoenix Controls Specifications subject to change without notice. Rev. C

Loading...

Loading...