Phoenix D385 Owner's Manual

4201 Lien Rd • Madison, WI 53704

Owner’s Manual — Phoenix D385

Installation, Operation & Service Instructions

Read and Save These Instructions

The Phoenix D385 provides the perfect combination of

features and performance the restoration industry has been

craving in a desiccant dehumidier. Designed to operate

vertically or horizontally, the Phoenix D385 provides the

wide operating range and ultra-low grains of a desiccant with

the water removal capacity of the largest LGR’s in cabinet

dimensions identical to our popular Phoenix

200 Max.

The D385 delivers 385 CFM of ultra-low grain process air and

removes an incredible 130 pints per day at AHAM conditions.

The true four hole conguration* allows the Phoenix D385 to

be located in the affected area with the 75 CFM re-activation

air stream isolated from the drying chamber. Three hole

designed units** inherently pull unaffected and/or outside

air into the drying chamber. The D385’s four hole design

allows the restoration contractor to set-up for effective

positive, neutral or negative pressure operation.

Able to operate vertically or horizontally, the D385 will t

inside most crawlspaces. Having the D385 securely inside,

rather than outside the crawlspace access, deters the

possibility of tampering with the dehumidier or the set-up.

The 385 CFM of process air will provide 3 ACH on an affected

area up to 7000 cubic feet.

The Phoenix D385 is easy to transport and set-up. The

D385 will t on your truck in the areas already designed

for your LGR’s and will move around the jobsite with the

same portability. All the power to the unit is provided by

two 115 volt grounded power cords. Simply plug the cords

into separate 15 amp circuits. Each cord draws only 12

amps to power the D385. The re-activation air stream is

ducted through 6” ex duct provided with the unit and stores

conveniently in the top of the unit.

*Having completely separate process and regeneration airstreams.

**Where regeneration airstream is pulled from the process airstream.

The Phoenix D385 Desiccant Dehumidifier

• Ultra low grains

• Wide operating range

• 130 pints per day @ AHAM

• Operates vertically or horizontally

• Process airow 385 CFM

• Two 23’ power cords:

12 Amps per cord

24 Amps

115 Volts/60 Hz

• Unlimited ducting possibilities

• Legendary stainless construction

Specifications subject to change without notice.

Phoenix D385

PN

1

4026700

TS-387

03/17

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Table of Contents

Introduction .............................................................................1

1. Safety Precautions .............................................................2

2. Specications ..................................................................2

3. Operation .........................................................................3

3.1 How The Phoenix D385 Works .................................3

3.2 Avoiding Secondary Damages ..................................3

3.3 Electrical Requirements ............................................3

3.4 Control Panel ............................................................. 4

3.4A Power Switch ..................................................... 4

3.4B Pilot Light ........................................................... 4

3.4C Hour Meter ........................................................ 4

3.5 Location ..................................................................... 4

3.6 Ducting Connections ................................................. 4

3.7 Ducting Options ......................................................... 4

3.8 Storage and Transportation ...................................... 4

4. Maintenance .................................................................... 4

4.1 Air Filter Replacement ...............................................4

4.2 Blower Motor and Rotor Drive Motors ...................... 5

4.3 Desiccant Rotor Cassette Assembly ........................5

5. Service .............................................................................. 5

5.1 Warranty .....................................................................5

5.2 Technical Descriptoin ................................................ 5

5.3 Normal Operation ......................................................6

5.4 Troubleshooting ......................................................... 6

6. Wiring Diagram ...............................................................6

7. Service Parts List ............................................................. 7

Warranty ........................................................................... 8

Serial No. ___________________________

Purchase Date ______/______/_____

Dealer’s Name ___________________________________

Read the operation and maintenance instructions carefully before

using this unit.

Proper adherence to these instructions is essential to

obtain maximum benefit from your Phoenix D385 dehumidifier.

1 Safety Precautions

• This appliance is not intended for use by persons

(including children) with reduced physical, sensory, or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety

• The appliance shall be installed in accordance with

national wiring regulations

• Please allow one foot of clearance for the inlets and

outlets of the unit

• Never operate a unit with a damaged cord. If the

power cord is damaged, it must be replaced by the

manufacturer, its service agent, or a similarly qualied

person in order to avoid a hazard

Toll-Free 1-800-533-7533

• In order to avoid hazard due to inadvertent resetting of

the thermal cutout, this appliance must not be supplied

through an external switching device, such as a timer, or

connected to a circuit that is regularly switched on and

off by the utility

• It is designed to be used INDOORS ONLY.

• If used on a water loss work site, plug it into GROUND

FAULT CIRCUIT INTERRUPT (GFCI) OUTLETS

• The air inlet on top and the side outlet must be at least 1

foot from walls and other air ow obstructions.

• DO NOT use the Phoenix D385 as a bench or table.

• Do not operate the Phoenix D385 at an altitude higher

than 32,800 ft (10,000m)

2 Specifications

Part No. 4026700

Power 2 circuits: 12 Amps, 115 VAC each

24 Amps total power consumption

Water 130 pints per day AHAM

Removal

Blower 385 CFM Process Airow

75 CFM Reactivation Airow

Operating 10-120°F

Range

Filters Process lter size: 16” x 20” x 2”

Reactivation lter size: 12” x 12” x 1”

Duct Process Inlet: 12” Flex-Duct (optional)

Connections Process Outlet: 10” Lay Flat collar (optional)

Reactivation Inlet: 6” Flex-Duct (optional)

Reactivation Outlet: 6” Flex-Duct (required)

External Static 0-0.4” WC Process

Pressure 0-0.25” WC Reactivation

Warranty One year Parts and Labor

Dimensions:

Machine Shipping

Width 24-1/4” 27-1/2”

Height 40” 45-1/2”

Depth 21-3/8” 22”

Weight 105 Lbs. 130 Lbs.

Popular Accessories

4026859 6” Metalized Polyester Flex-Duct 25’ (Standard)

4020128 6” Insulated Flex-Duct 25’

4024750 12” Metalized Polyester Flex Duct 25’

4022537 10” Lay Flat Duct 500’

4024935 10” Lay Flat Duct 250’

4024440 Kestrel 3000 Multi-Function Air Meter

2

www.UsePhoenix.com • sales@UsePhoenix.com

Process Air Filter Replacement

4021475 16” x 20” x 2” MERV 11 Filter (Standard)

4024969 16” x 20” x 2” MERV 6 Filter (Optional)

4022164 16” x 20” x 2” MERV 14 Filter (Optional)

Reactivation Air Filter Replacement

4026860 12” x 12” x 1” MERV 7 Filter (Standard)

4026315 12” x 12” x 1” MERV 8 Filter (Optional)

3 Operation

3.2 Avoiding Secondary Damages

The D385 is a powerful tool capable of removing a great deal

of water from most environments. Care must be taken to

avoid secondary damages of over-drying and or unexpected

condensation.

Your Phoenix D385 removes vapor water from the incoming

process air stream (Fig. 1) and transfers it to the outgoing

reactivation air stream (Fig. 2). The reactivation exhaust air is

hot and wet.

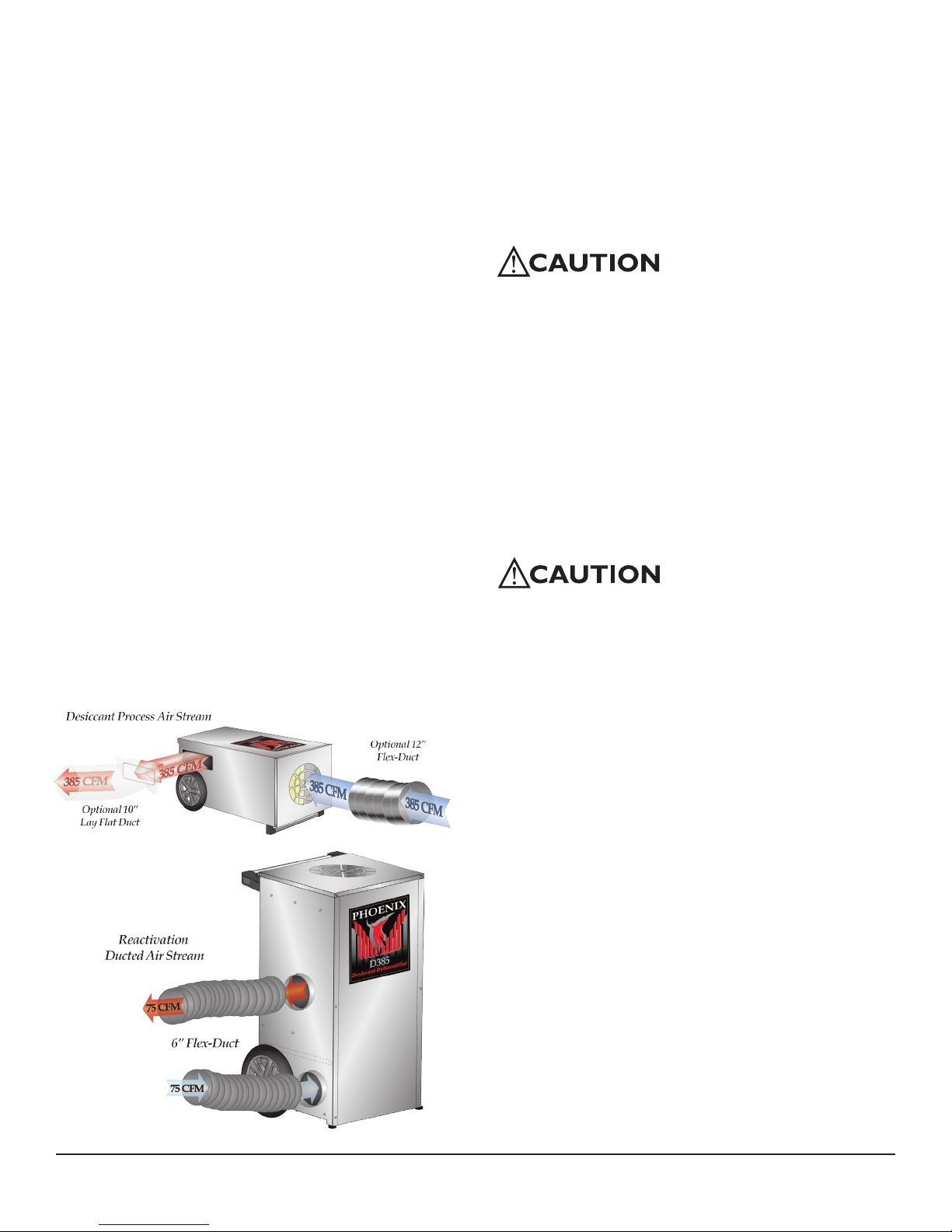

3.1 How the Phoenix D385 works

Your Phoenix D385 has two separate air streams that run

through it – Process (Fig. 1) and Reactivation (Fig. 2).

Note: Check for airflow at all inlets and outlets. DO NOT run

unit if no airflow is detected.

Process Air Stream:

P1 – 385 CFM of air enters (12”ex) the top of the machine

and...

P2 – ...water vapor from incoming air is deposited on the

desiccant wheel.

P3 – 385 CFM of dry air exits (10” lay at) the machine.

Reactivation Air Stream:

R1 – 75 CFM of air enters (6”ex) the lower-side of the

machine and...

R2 – passes over the heater coils.

R3 – Water vapor is picked up from the desiccant wheel by

the hot air and...

R4 – ...75 CFM of wet air exits (6”ex) the machine.

P3

P2

Figure 1: Desiccant process air stream.

R3

R2

R1

Figure 2: Desiccant reactivation air stream.

P1

Take care to prevent the reactivation exhaust air stream

from causing secondary damage due to condensation.

If the reactivation exhaust air stream cools below its

dewpoint liquid water will condense inside the duct work

creating puddles. If the reactivation exhaust air stream is not

exhausted completely from the structure it can also cause

secondary water damage.

Your Phoenix D385 does not produce liquid water internal

to the machine. There is no condensate pump and no drain

hose.

The D385 desiccant dehumidier will continue to remove

water from already dry, cold air. It is possible to over-dry

objects and or structures.

Care must be taken to avoid secondary damages due to

over-drying.

3.3 Electrical Requirements

When used on a water loss work site, ground fault circuit

interrupter (GFCI) outlets are required.

Your Phoenix D385 requires a total of 24 amps, 115VAC. In

order to run at all, this machine must be plugged into two

separate circuits each with a minimum of 12 amps dedicated

capacity available.

The D385 has two separate power cords, each cord must be

plugged into its own 15 amp circuit. If both cords are plugged

into the same 15 amp circuit this circuit will trip when the

unit is turned on.

Another situation to avoid is that one or both of the circuits

which the D385 is using can be tripped by other appliances

drawing power from either circuit. This can happen well

after a job site has been set-up as in the case with a freezer

compressor turning on.

Care must be taken to insure that the D385 always has

sufcient power available to run without tripping breakers or

blowing fuses.

If your location requires the use of an extension cord, use

safe techniques in selection and connection. Such cords

must be grounded and rated for carrying 12 amps: 14 gauge

minimum for one extension less than 25ft in length or 12

gauge for one extension less than 50ft in length.

3

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Loading...

Loading...