Page 1

Advanced Pressure Monitor II

and Central Display Rough-In

Installation Guide

Page 2

Copyright 2011, 2012, 2013

Phoenix Controls

Accel, Phoenix, Phoenix Controls, Usage Based Controls, UBC, Celeris, Theris, Traccel, Zone Presence

Sensor and ZPS are registered trademarks, and LabPro, MacroServer, MicroServer and Neutralizer

are trademarks of Honeywell International, Inc.

Phoenix Controls products are covered by one or more of the following U.S. patents:

5,251,665 5,304,093 5,545,086 D642894

and other patents pending.

The material in this document is for information purposes only and is subject to change without

notice. Phoenix Controls assumes no responsibility for any errors or for consequential damages that

may result from the use or misrepresentation of any of the material in this publication.

BACnet is a registered trademark of the American Society of Heating, Refrigerating, and AirConditioning Engineers (ASHRAE).

Printed in USA

Page 3

APM2 Rough-In Installation Guide

Table of Contents

Section 1. Advanced Pressure Monitor II Rough-In Installation

1.1 Required Parts to be Supplied by the Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Parts Included with Your Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Installation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 Wiring Triple Gang Electrical Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.3 Plumbing Rough-In. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.4 Use of External Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.5 Remote Annunicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Plumbing (Finish). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5.1 Power, Labeled POWER, L1, L2, Ground Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.2 Analog Output, Labeled ANL OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.3 Analog Input, Labeled DOOR, INPUT2, INPUT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.3.1 Measuring Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.4 Optional Remote Transducer Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.5 Relay and Annunciator Output, Labeled RELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.6 Optional Remote Annunciator Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.7 Third Party Remote Annunciator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.8 Completing the Finish Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 2. Fitting an APM2 in an APM100 Enclosure

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.1 What Is Included In Your Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.1.1 Not Included - Tools You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.1 Turn Off Power To the APM100 Unit And Remove It From The Wall . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Ensure Existing APM1 Enclosure Is Prepared For APM2 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.3 Attach the Base APM2 Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.5 Remotely Switching Alarm Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.6 Modified Pressure Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.7 Complete the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 3. APM2 Central Display Rough-In Installation

3.1 Required Parts to be Supplied by the Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Parts included with Your Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3.1 Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3.2 Wiring Triple Gang Electrical Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

iii

MKT-0262 MPC-1748 Rev 02/13

Page 4

Table of Contents

3.4.1 Power, Labeled POWER, L1, L2, Ground Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.2 Completing the Finish Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Section 4. Ancillary Product Specifications

4.1 Model 264 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Model 267 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3 Remote Annunciator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4 Pressure Pickup Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Phoenix Recommended Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5.1 MS/TP Specifications for Alternate Cable Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

iv

MKT-0262 MPC-1748 Rev 02/13

Page 5

APM2 Rough-In Installation Guide

Advanced Pressure Monitor II Rough-In Installation

Required Parts to be Supplied by the Installer

Section 1. Advanced Pressure Monitor II Rough-In Installation

For the Advanced Pressure Monitor II (APM2) to be installed correctly, the rough-in phase of the project must

be completed properly. This section will outline the specific considerations the General Contractor must pay

attention to so that the final wiring and commissioning will go smoothly.

During rough-in installation, the field wiring and plumbing can be run in the walls and routed between the

triple gang electrical box, the Building Management System (BMS), door contact switch, remote sensors (if

applicable) power supply, earth ground and so on.

If you’re installing the APM2 monitor, continue to to Section 1.1 Required Parts to be Supplied by the Installer.

If you’re installing the APM2 Central Display, refer to APM2 Central Display Rough-In Installation on page 19.

1.1 Required Parts to be Supplied by the Installer

The following is a list of parts required and supplied by the installer for the APM2:

• Triple gang-double deep electrical box (RACO 697 or Appleton M3-350), quantity 1

• Green grounding screw, quantity 1

• Power (18 AWG recommended) and signal wiring (22 AWG recommended), as needed. Refer to Phoenix

Recommended Cables on page 33.

• 0.25" (6 mm) O.D. flame retardent polyethelyne control tubing (such as CPChem UL 1820)—to run from

the room(s) to the APM2 (maximum 250 feet [76.2 meters] length)

NOTE: Less that 10% or 10 feet (1.6 meters) of total control tubing can be used in a vertical rise. Maintain

tubing run on the same floor as the APM2.

• T-connectors

NOTE: Phoenix Controls recommends no more than five (5) T-connectors in a single run going to any

APM2.

• EMT conduit (if required by local code)

•24 Vac Transformer

• Door switch SPDT or SPST—normally open, as required

• Remote pressure transducers, as needed

• Remote Annunciators, as needed

The following is a list of part required and supplied by the installer for the Remote Annunciator and Pressure

Pickup Port:

• Single gang electrical box, as needed

• 0.25" (6 mm) O.D. flame retardent polyethelyne control tubing (such as CPChem UL 1820)—to connect

between the Pressure Pickup Port and the APM2

MKT-0262 MPC-1748 Rev 02/13

1

Page 6

Advanced Pressure Monitor II Rough-In Installation

Parts Included with Your Order

1.2 Parts Included with Your Order

The following are parts that are included in your order:

• Advanced Pressure Monitor II (APM2), including factory calibrated differential pressure sensor, quantity 1

• APM2 Faceplate, quantity 1

• Pressure Pickup Port (quantity 0, 1 or 2 - depending on order configuration)

• 0.25" O.D. Tubes, Silicone, with integrated springs and attached brass barbed couplings, quantity 2

• Mounting screws, 6-32 x 1/2 Phillips head, quantity 5

• Mating Electrical Connectors, Phoenix contact MC plug kit, quantity 1 with 3 green and 2 black connectors

1.3 Installation Overview

• Each APM2 consists of a room pressure pick-up, a reference space pressure pickup and a room pressure

monitor panel, which houses a differential pressure sensor.

• The two pressure pickup ports are installed in single gang electrical boxes, which are placed in the room

walls.

• Standard 0.25" (6 mm) O.D. flame retardent polyethelyne control tubing (such as CPChem UL 1820),

maximum 250 feet (76.2 meters) length, is run within the wall from the sensors to the monitor panel. In

some code jurisdictions, the tubing must be in EMT conduit. Tubing and conduit is provided by others.

NOTE: Less that 10% or 10 feet (1.6 meters) of total control tubing can be used in a vertical rise. Maintain

tubing run on the same floor as the APM2.

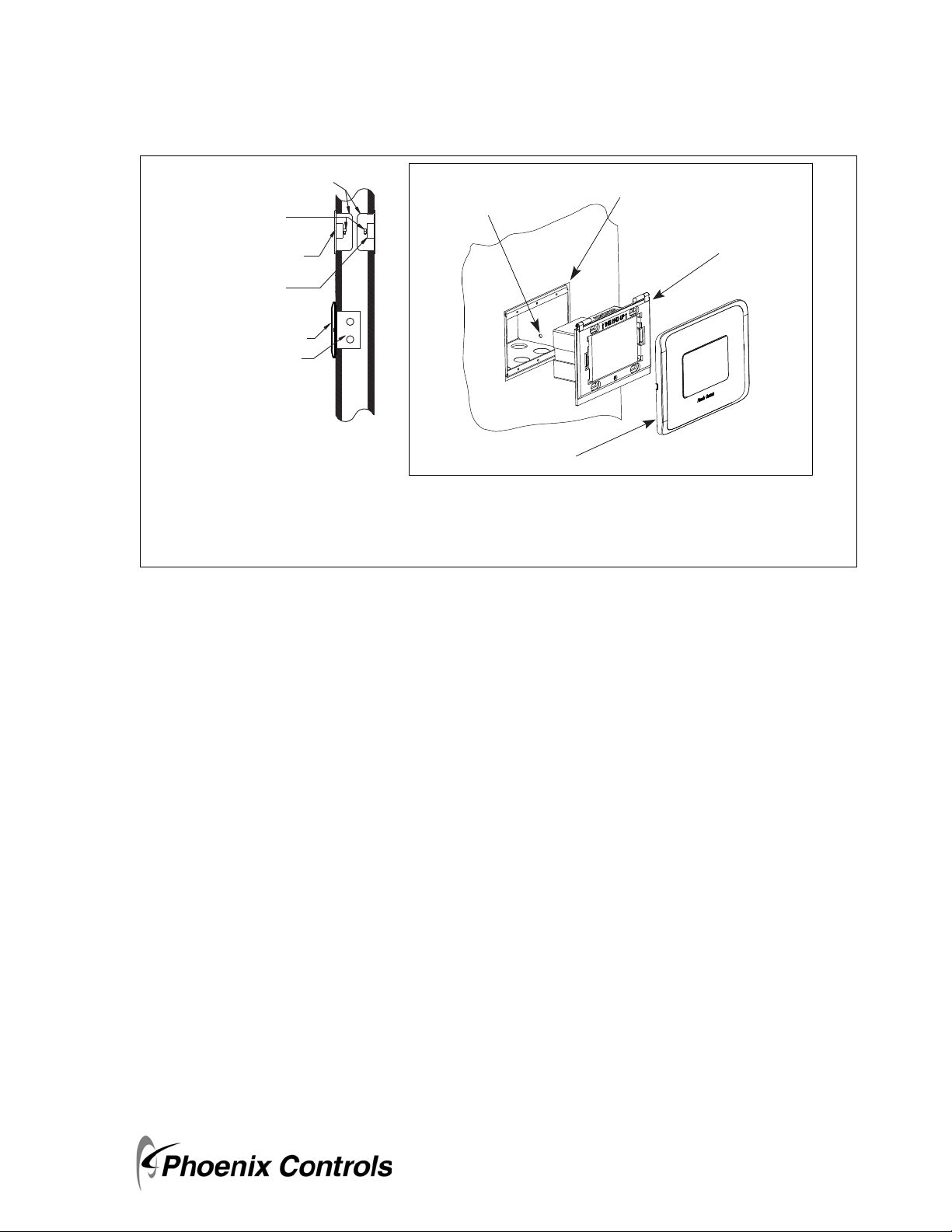

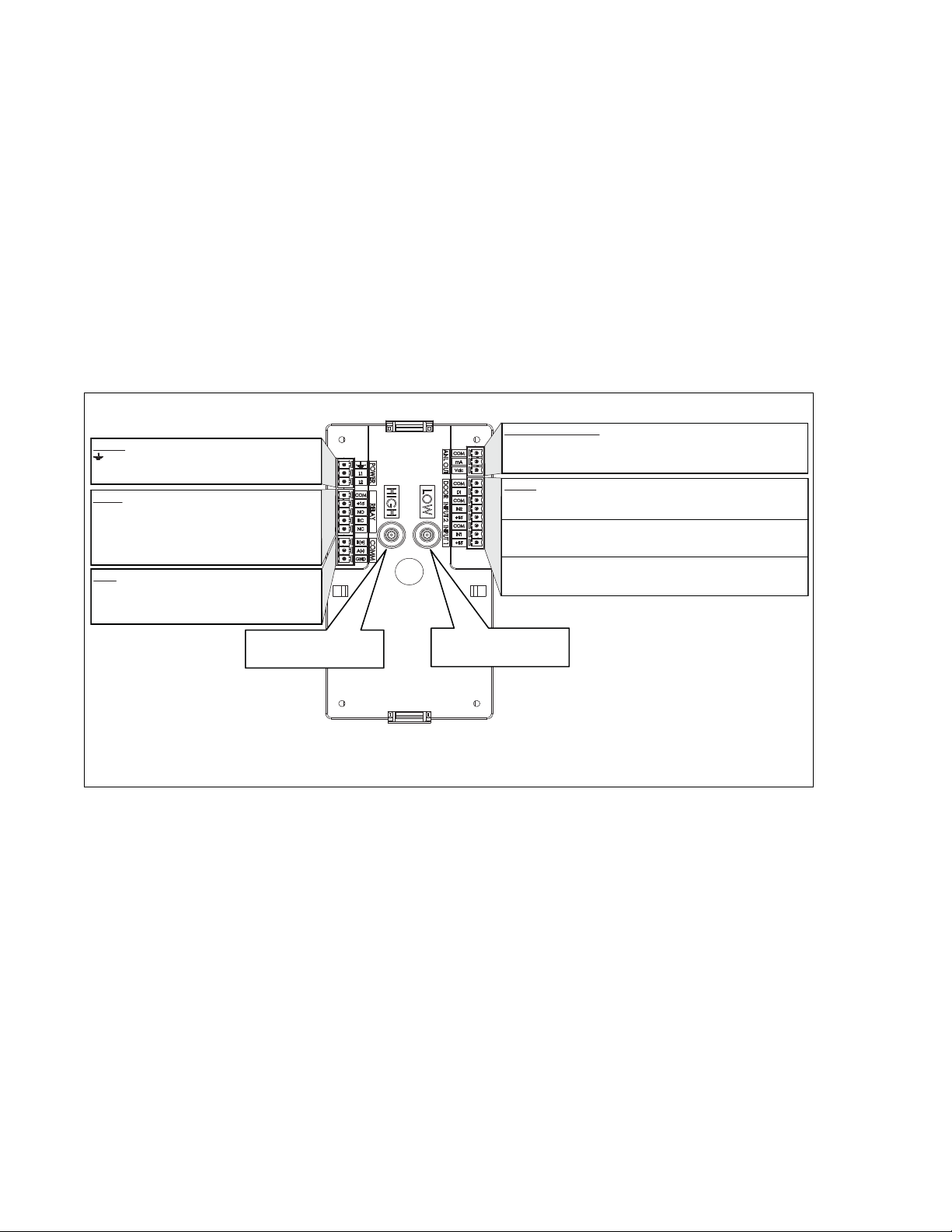

• Install in a triple gang-double deep electrical box (RACO 697, Appleton M3-350 or equivalent).

• Secure the triple gang-double deep electrical box to the stud(s) by using the mounting hole in the side of

the electrical box (see figure below for mounting hole location). Drive the mounting screws from the inside

of the electrical box into the wall studs to prevent sharp objects from protruding into the electrical box.

• Ensure the mounting is level and flush to the wallboard surface.

2

MKT-0262 MPC-1748 Rev 02/13

Page 7

APM2 Rough-In Installation Guide

Single Gang

Electrical Box

1/4" x .170 Tube Barb

(Conduit between

sensors and monitor

panel may be required.)

Reference

Pressure Pickup

Room

Pressure Pickup

APM2

NOTE: Connecting tubing and electrical

boxes are field-supplied.

Triple Gang Double Deep

Electrical Box

WALL MOUNT DIMENSIONS

Triple gang double deep electrical box—5.625" (220 mm) W x 3.5" (114.3 mm) H x 3.5" (63.5 mm) D

Single gang electrical box—2" (51 mm) W x 3" (76 mm) H x 3.5" (63.5 mm) D*

* Dimensions are approximate.

Advanced Pressure Monitor II Rough-In Installation

Installation Overview

Electrical Box

Mounting Hole

Figure 1-1. Wall Mount Installation Overview

1.3.1 Wiring Recommendations

APM2 Faceplate

Rough-in Electrical Box

- Raco 697

- Appleton M3-350

APM2

• All circuits must conform to the requirements of an NEC Class 2 (dry) circuit.

• Use multiple transformers instead of larger transformers when more than 100 VA is required.

• Each pressurization zone should have either a dedicated single-phase primary circuit, or a secondary circuit

disconnect.

•Refer to Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types.

• Use stranded wire for ease of installation.

• Follow good wiring practices:

• Locate cables away from sources of electrical interference (EMI/RFI).

• Do not run signal or communication cable in the same conduit or wire way as power cables.

• If signal cable must cross power cables place these at a 90-degree angle.

• Shield or drain wires, if required, should be wrapped with insulating tape to prevent contact with exposed

conductors or contacts.

• Maintain a consistent color code or polarity all the way through the wiring system.

• Power supply and signal isolation on I/O devices vary from manufacturer to manufacturer. Verify the

wiring device manufacturer’s recommendations for isolating power and signal common connections and

maintain polarity.

• Local and national electrical codes take precedence.

3

MKT-0262 MPC-1748 Rev 02/13

Page 8

Advanced Pressure Monitor II Rough-In Installation

Installation Overview

• Strip 0.25" (6.4 mm) of insulation from each conductor, twist the strands, insert the conductor fully into

the terminal block, and tighten the terminal.

•Test the wire connection by pulling on each conductor.

WARNING: Wiring must be performed by a licensed electrician according to local and state codes.

1.3.2 Wiring Triple Gang Electrical Box

USE ONLY THE KNOCKOUTS ON THE TOP OR BOTTOM AT THE BACK OF THE ROUGH-IN

ELECTRICAL BOX. The front knockouts will be inaccessible once the APM2 is installed. Strain relief and seal

box as required.

NOTE: Install power and signal wires into separate knockouts to avoid noise.

Figure 1-2. Wiring in the Triple Gang Electrical Box

1.3.3 Plumbing Rough-In

If the internal pressure sensor will be used, then typically a Pressure Pickup Port is installed in the monitored

room and another one is installed in the reference area (typically a hallway). 0.25" nylon tubing is typically used

to bring the pressure signal from this point of measurement to the pressure inputs on the back of the APM2.

Install a single gang electrical box anywhere inside the room, typically high on the wall in an inconspicuous area.

This will be used for the room pressure signal (room monitor pressure port labeled HIGH). Run 0.25" tubing

from this electrical box to the triple gang box that the pressure monitor will be mounted to in the finish stage

of the installation.

CAUTION: Be careful in running the tubing in a way that the tube is protected from being damaged by being cut

or penetrated by screws or nails or being crimped so that the pressure signal integrity is affected. Do

not tighten strain reliefs so that they crimp the tubing. Tape the open ends of the tubes closed to

prevent contamination of the inside of the tubing.

Install a second single gang box on the corridor, ante room or other reference pressure area. This will be used

for the low pressure side or reference side pressure signal. This will be run to the triple gang box and connected

to the APM2 pressure port labeled LOW.

4

MKT-0262 MPC-1748 Rev 02/13

Page 9

APM2 Rough-In Installation Guide

Advanced Pressure Monitor II Rough-In Installation

Installation Overview

If an external sensor will be used then run the pressure signals (room and reference) to the remote transducer.

Figure 1-3. Pressure Pickup Port Installation

1.3.4 Use of External Transducers

The APM2 has the option to use the internal pressure sensor or external pressure transducers (ordered

separately). If external pressure sensors are being used then no tubing needs to be run into the electrical box.

Instead the remote pressure transducer will be separately mounted, plumbed and wired. Only the wire for the

analog output of that transducer(s) will be run to the APM2. If two rooms are being monitored, you have the

choice to use the internal pressure sensor and an external (remote) transducer for the second room, or two

external remote transducers may be used and wired to the analog inputs in the back of the unit.

NOTE: See Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types.

Layout the system in terms of wiring:

• Power: 24 Vac, 9 VA

• Annunciator/relay: remote alarm wiring if being used

• Analog output: 0-5 or 0-10 Vdc or 4-20 mA.

• Analog Input wiring: there are two analog inputs that can be used to bring signals from remote pressure

transducers

• Digital Input: the digital input can be used as a door status indication, these would be wired to a door switch

mounted in the door jamb.

Once the installation has been planned, locate and mount the electrical box and bring all tubing, power, earth

ground, analog input, digital input, relay/annunciator, analog output communications wiring into the triple

gang box.

MKT-0262 MPC-1748 Rev 02/13

5

Page 10

Advanced Pressure Monitor II Rough-In Installation

Green LED

Red LED

Acknowledge

Switch

Audible

Alarm

Soft Silicon

Tubing with

Integrated

Springs

Plumbing (Finish)

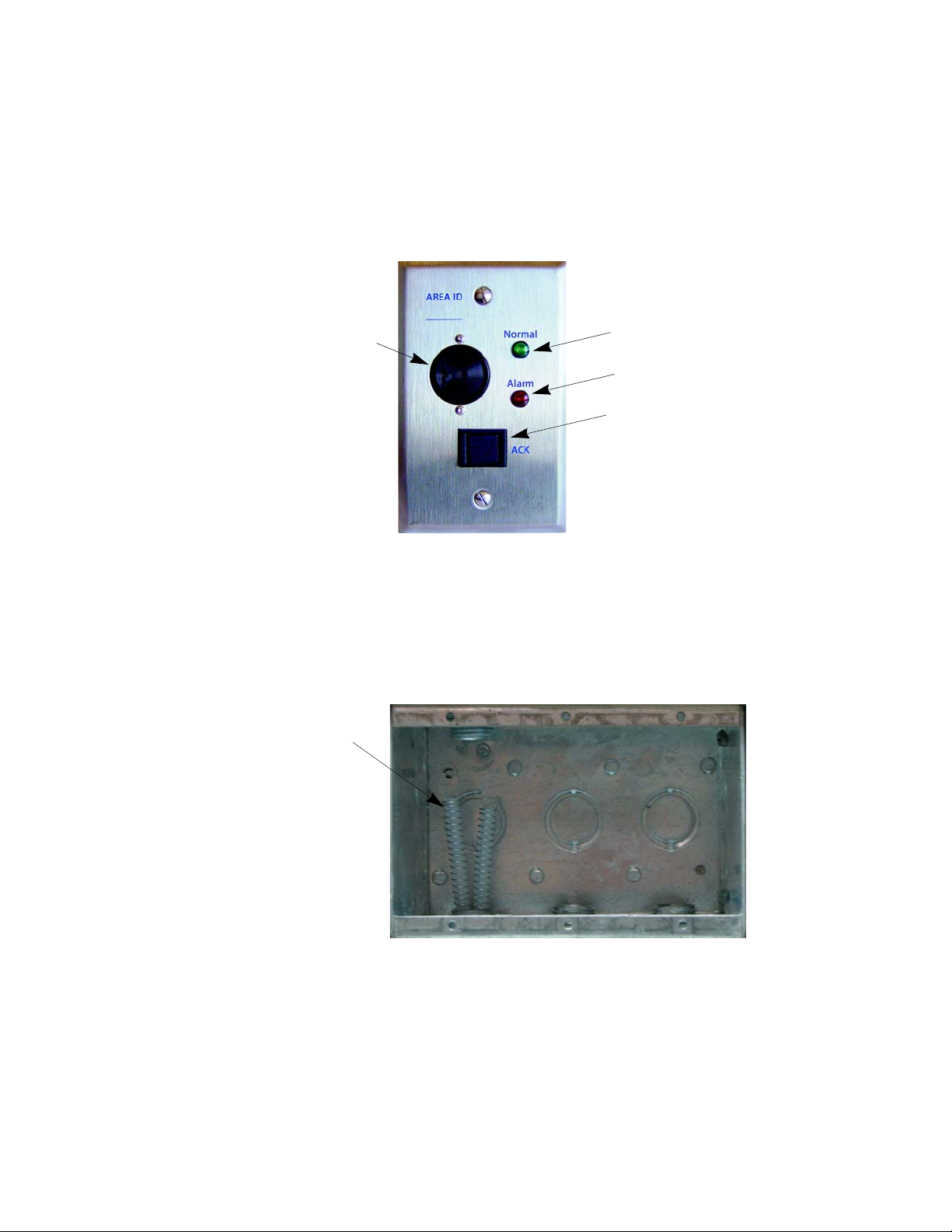

1.3.5 Remote Annunicator

If an remote annunciator will be used, then mount a single gang electrical box in the desired location and run

wires to it.

Figure 1-4. Remote Annunciator

1.4 Plumbing (Finish)

Use the following procedure for all room types positive, negative or neutral.

The biggest problem that can occur during plumbing is kinking of the often stiff nylon 0.25" tubing that is used

for running pressure signals from the APM2 to the monitored spaces. To prevent buckling and collapse of this

stiff tubing inside the electrical box, use the supplied soft silicone tubing with integrated springs and tubing

adapters to transition from the field tubing to the pressure fittings on the APM2.

6

MKT-0262 MPC-1748 Rev 02/13

Page 11

Advanced Pressure Monitor II Rough-In Installation

Wiring

Attach pressure tubing as follows:

1. Install the supplied silicone tube (with integrated spring) and attached barbed tube adaptor onto the end of

the 0.25 field tubing. Thread the tubes, with installed adaptor, through the conduit opening at the bottom

of the electrical box.

2. Next push the open end of the soft silicone tubing onto the APM2 pressure tube port labeled "HIGH".

3. For the most pressure stable operation, a Pressure Pickup Port installed in the reference pressure area is also

recommended. In this case, install the Pressure Pickup Port in a hallway or reference space.

4. Next push the open end of the soft silicone tubing onto the APM2 pressure tube port labeled "LOW".

1.5 Wiring

ANALOG (ANL) OUTPUT

POWER

L1 24 Vac

L2 24 Vac

RELAY

COM COM

+15 +15 Vdc

NO Normally Open

RC Relay COM

NC Normally Closed

COM BACnet APM2-xx-ENG-BAC Products

B (+)

A (-)

GND

Earth Ground

THIS PAGE INTENTIONALLY LEFT BLANK.

COM COM

mA Current Output (4-20 mA)

Vdc Voltage Output (0-5 Vdc, 0-10 Vdc)

INPUTS (wired to door N.O. contact)

COM COM Door

DI Digital Input

COM COM Analog Input2

IN2 Analog Input2 (0-5, 0-10Vdc)

+15 15 Vdc

COM COM Analog Input1

IN1 Analog Input1 (0-5, 0-10Vdc)

+15 15 Vdc

HIGH or room pressure tubing

contacts here

REAR VIEW

LOW or re ference pressure tubing

connects here

Figure 1-5. Rear View of the APM2 (BACnet) Showing Wiring and Plumbing Connections

MKT-0262 MPC-1748 Rev 02/13

7

Page 12

Advanced Pressure Monitor II Rough-In Installation

ANALOG (ANL) OUTPUT

COM COM

mA Current Output (4-20 mA)

Vdc Voltage Output (0-5 Vdc, 0-10 Vdc)

INPUTS (wired to door N.O. contact)

COM COM Door

DI Digital Input

COM COM Analog Input2

IN2 Analog Input2 (0-5, 0-10Vdc)

+15 15 Vdc

COM COM Analog Input1

IN1 Analog Input1 (0-5, 0-10Vdc)

+15 15 Vdc

Earth Ground

L1 24 Vac

L2 24 Vac

HIGH or room pressure tubing

connects here

LOW or re ference pressure tubing

connects here

POWER

RELAY

COM COM

+15 +15 Vdc

NO Normally Open

RC Relay COM

NC Normally Closed

COM NOT AVAILABLE

B (+)

A (-)

GND

REAR VIEW

Wiring

Figure 1-6. Rear View of the APM2 (Analog) Showing Wiring and Plumbing Connections

The back of the APM2 has electrical connectors labeled with their function. The mating electrical connectors

(supplied) are color coded and labeled with the matching function.

1.5.1 Power, Labeled POWER, L1, L2, Ground Symbol

Starting with the 3 pin Power connector:

1. Connect the 24 Vac lines to L1 and L2.

2. Connect a ground wire, GND, from the ground lug to the GND on the connector.

3. Install Connector.

The APM2 operates at 18-32 Vac, 50/60 Hz and consumes 2.6 W nominal, 9.6 W max.

1.5.2 Analog Output, Labeled ANL OUT

If using the analog output and want Voltage output, connect to the terminals labeled VDC and COM.

If using the analog out and want a 4-20 mA signal, connect to terminals labeled mA and COM. Connect this

output to the BMS system or other monitoring device.

8

MKT-0262 MPC-1748 Rev 02/13

Page 13

APM2 Rough-In Installation Guide

+

-

+ 15 Vdc

IN1

COM

APM2

Setra Model 264

Current Output

249

Ohm

Advanced Pressure Monitor II Rough-In Installation

Wiring

1.5.3 Analog Input, Labeled DOOR, INPUT2, INPUT1

There are two analog inputs available for remotely mounted transducer inputs. These are INPUT1 and

INPUT2.

A 15 Vdc (14.8 to 15.2) excitation is available to power up to two transducers. They can source 90 mA max.

combined. It is labeled as +15 on the connectors.

If using this to power a remote transducer, connect this to the positive excitation terminal of the transducer.

1.5.3.1 Measuring Analog Inputs

There are three potential analog inputs that can be measured, 0-5, 0-10 and 4-20 mA.

• For 0-5 or 0-10 Vdc inputs connect the positive (+) output of the transducer to terminal labeled IN1, connect the common output of the transducer to the terminal labeled COM.

• For 4-20 mA loops install a 250 ohm resistor between the terminals labeled In1 or IN2 (whichever input

you’re going to) and COM. The monitor will be measuring the voltage across this resistor as 1-5 Vdc corresponding to 4-20 mA.

If you will be monitoring the status of a door position, then wire the contacts labeled DOOR to the normally

open contacts on a door jamb switch. The monitor will show the door "Warning" (when enabled) when the

door is open. The door jamb switch should be closed when the door is closed and open when the door is open.

1.5.4 Optional Remote Transducer Wiring

The figure below references the Setra remote sensors equipped with 4-20 mA output. The instruction booklets

supplied with the sensors cover both the

3-wire voltage output configuration and 2-wire current configuration. The figure below clarifies the 2-wire 420 mA connection between the Setra 264 or 267 and APM2 inputs. The same connection applies to IN2 (AI2).

If the APM2 output is configured for 4-20 mA on the AO, the users can use either 249 or 500 Ohm resistors

depending on whether they desire 1-5 or 2-10 Vdc.

Figure 1-7. Optional Remote Transducer Wiring

9

MKT-0262 MPC-1748 Rev 02/13

Page 14

Advanced Pressure Monitor II Rough-In Installation

Wiring

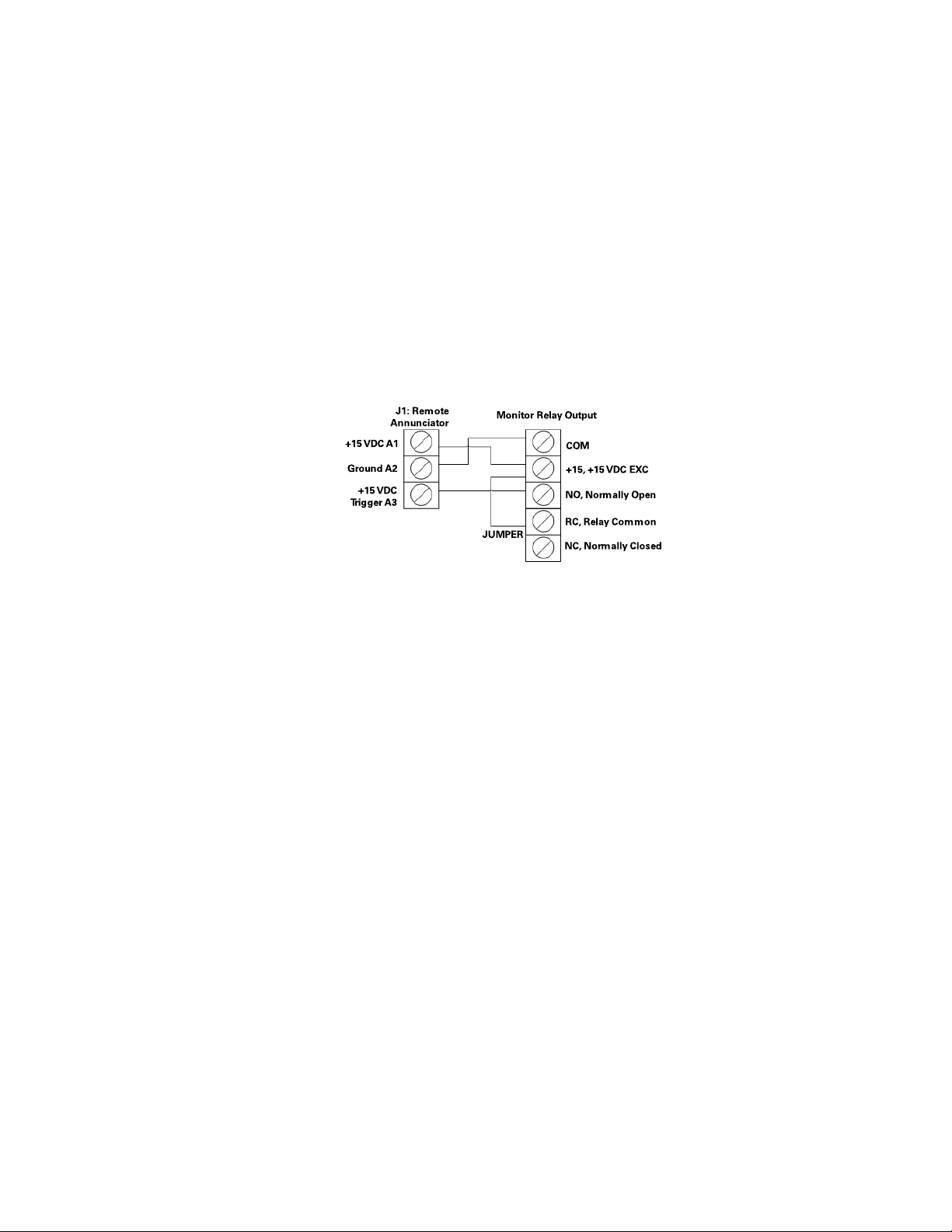

1.5.5 Relay and Annunciator Output, Labeled RELAY

There is an SPDT dry contact available. When an alarm occurs the Normally Open (NO) and the Common

(COM) internal contacts will be closed. During no alarm conditions the Normally Closed (NC) and COM are

shorted.

This relay can also drive a Remote Annunciator.

1.5.6 Optional Remote Annunciator Wiring

In the figure below, the Remote Annunciator connector is at left, and the APM2 connector is at right.

Figure 1-8. Remote Annunciator Wiring Diagram

• To connect +15 Vdc power, connect the +15 Vdc from the relay connector to +15 Vdc, A1 at the Remote

Annunciator. This supplies 15 V exc. to the Remote Annunciator for powering the circuit during normal

conditions.

• To connect power return, connect the COM of relay connector to Ground, A2 at the Remote Annunciator.

• On of the relay connector, connect a short jumper between the +15 and relay connector. This will connect

the internal 15V supply to the common of the internal alarm relay.

• Connect the NO on the relay output to the +15 Vdc Trigger, A3 terminal on the Remote Annunciator.

When an alarm occurs and after the programmed alarm delay times out, the internal relay will supply 15 V to

the Remote Annunciator circuit to actuate the audible buzzer and the red LED.

10

MKT-0262 MPC-1748 Rev 02/13

Page 15

APM2 Rough-In Installation Guide

Advanced Pressure Monitor II Rough-In Installation

1.5.7 Third Party Remote Annunciator

The APM2 can drive other annunciators that are powered by a 15V supply, 50 mA max current draw, and

accept a 15V trigger. If purchased separately, the Remote Annunciator can also be driven as shown below.

Figure 1-9. 3rd Party Remote Annunciator Wiring Diagram

1.5.8 Completing the Finish Wiring

1. Connect all the electrical connectors matching the wiring connector with the mates on the back of the

unit. Connectors are color coded and keyed.

2. Connect the pressure signals to the HIGH and LOW ports on the back of the unit. The springs on the

outside of the tubing are there to prevent buckling of the tube. As you push the unit into the electrical box

push the black instrument tubing into the conduit tube or into the wall, Ideally the supplied silicone tube

is the only tubing in the electrical box after the unit is slid in as far as it will go.

Wiring

Figure 1-10. Connecting Electrical Connectors to Back of APM2

3. Mount the unit cover to the electrical box using four of the supplied mounting screws. Leaving screws

slightly loose adjust the cover so that it is square. Securely tighten so that the back of the cover is tight to

the finish wall surface.

MKT-0262 MPC-1748 Rev 02/13

11

Page 16

Advanced Pressure Monitor II Rough-In Installation

Wiring

Figure 1-11. Mounting APM2 in Triple Gang Electrical Box

4. Mount the front cover assembly.

Figure 1-12. Installed APM2

12

MKT-0262 MPC-1748 Rev 02/13

Page 17

APM2 Rough-In Installation Guide

Fitting an APM2 in an APM100 Enclosure

Overview

Section 2. Fitting an APM2 in an APM100 Enclosure

2.1 Overview

APM100 pressure monitors from Phoenix Controls can be replaced in the field using the newer APM2 units.

However, it is important to order the Retrofit Kit version of the APM2 product for compatibility with the

existing enclosure. The APM2 Retrofit Kit includes additional parts and modifications to the standard APM2

product that permits easy installation in the field.

These instructions outline how to replace an APM100 series pressure monitor with APM200 series units.

APM100 models installed in the field are housed in a 5-gang single-deep electrical box. The APM2 models

require a 3-gang double-deep electrical box for new installations, so it will not fit directly into the APM1

enclosure without this adapter kit.

2.1.1 What Is Included In Your Kit

• APM2 model with the pressure range you ordered with 90 degree pressure taps on the rear of the unit for

proper seating in the APM100 enclosure

• Stainless steel adapter plate to cover the larger APM100 wall opening

• Four (4) phillips head screws to secure APM2 to the adapter plate

• Four (4) Allen head screws to secure adapter plate to the existing APM100 enclosure

• APM2 white faceplate

• APM2 installation instructions

• APM2 connector kit

• APM2 calibration certificate

2.1.1.1 Not Included - Tools You Will Need

• Small blade terminal screwdriver

• Phillips head screwdriver

• 1/8" Allen wrench

13

MKT-0262 MPC-1748 Rev 02/13

Page 18

Fitting an APM2 in an APM100 Enclosure

Instructions

2.2 Instructions

IMPORTANT: As part of the site preparation, any wiring or tubing coming into the APM100 unit may

need to be moved to accomodate the depth of the APM2.

Figure 2-1. APM100 Display

2.2.1 Turn Off Power To the APM100 Unit And Remove It From The Wall

1. Remove the four allen head screws from the APM100.

CAUTION: Carefully, pull the APM100 out of the APM100 box.

2. Disconnect power and all connectors. Label connectors so it will be clear how to reconnect them to the

APM2 unit.

3. Disconnect pressure tubing from the APM100 and label room side and reference side tubing.

14

MKT-0262 MPC-1748 Rev 02/13

Page 19

APM2 Rough-In Installation Guide

Four phillips head

screws provided

Fitting an APM2 in an APM100 Enclosure

Instructions

2.2.2 Ensure Existing APM1 Enclosure Is Prepared For APM2 Unit

1. Make sure the wall surface around the existing enclosure is flat and clean with no wall damage or holes

beyond the electrical box.

2. A full 5.18" of the center of the existing enclosure will be occupied by the APM2 unit when it is installed.

Any wires or tubing in this region of the electrical box should be moved to the outer perimeter of the

enclosure so the APM2 can slide in without obstructions. You may need to use the knockouts on either

sides, tops or bottom as shown below.

Figure 2-2. APM100 Knockout Locations

2.2.3 Attach the Base APM2 Unit

Mount the base APM2 unit to the adapter plate using the four supplied phillips head screws. Leaving screws

slightly loose adjust the cover so that it is square. Securely tighten so that the back of the cover is tight to the

finish wall surface.

Figure 2-3. Installing APM2 to the Adapter Plate

15

MKT-0262 MPC-1748 Rev 02/13

Page 20

Fitting an APM2 in an APM100 Enclosure

Instructions

2.2.4 Wiring

POWER

L1 24 Vac

L2 24 Vac

RELAY

COM COM

+15 +15 Vdc

NO Normally Open

RC Relay COM

NC Normally Closed

COM BACnet APM2-xx-ENG-BAC Products

B (+)

A (-)

GND

Earth Ground

ANALOG (ANL) OUTPUT

COM COM

mA Current Output (4-20 mA)

Vdc Voltage Output (0-5 Vdc, 0-10 Vdc)

INPUTS (wired to door N.O. contact)

COM COM Door

DI Digital Input

COM COM Analog Input2

IN2 Analog Input2 (0-5, 0-10Vdc)

+15 15 Vdc

COM COM Analog Input1

IN1 Analog Input1 (0-5, 0-10Vdc)

+15 15 Vdc

HIGH or room pressure tubing

contacts here

REAR VIEW

LOW or re ference pressure tubing

connects here

Figure 2-4. Rear View of the APM2 Showing Wiring and Plumbing Connections

The back of the APM2 has electrical connectors labeled with their function. The mating electrical connectors

(supplied) are color coded and labeled with the matching function.

Refer to the Advanced Pressure Monitor II User’s Guide (MKT-0263) for detailed wiring instructions.

2.2.5 Remotely Switching Alarm Setpoints

The APM100 model uses dry contacts to switch pressure setpoints between positive and negative, whereas the

APM2 uses an input voltage: 0, 5 or 10 Volts to switch pressure setpoints between negative-neutral-positive

respectively. If this function was used on the APM100 product, adaptations will need to be made to restore their

function with other equipment or devices that will generate the 0, 5 or 10 Volt signal.

16

MKT-0262 MPC-1748 Rev 02/13

Page 21

APM2 Rough-In Installation Guide

1/8" Allen head

screws supplied

Fitting an APM2 in an APM100 Enclosure

Instructions

2.2.6 Modified Pressure Taps

The APM2 retrofit unit differs from the standard APM100 product. The rear of the unit uses 90º pressure taps

instead of straight-through pressure taps. This allows the unit to be installed in the shallower APM100 box. The

shallower APM100 box permits enough space for existing pressure tubes in the back to be connected.

Figure 2-5. APM2 Retrofit Kit Pressure Taps

2.2.7 Complete the Installation

1. Complete the installation following the instructions in the Advanced Pressure Monitor II User’s Guide

(MKT-0263), which can be obtained from the Partner Login area of http://www.phoenixcontrols.com/.

2. Once wiring and pressure tubes are connected, verify functionality of the APM2 before sliding it into the

wall enclosure.

3. Install the adapter plate to the wall enclosure by using the four 1/8" Allen head screws supplied.

Figure 2-6. Installing Adapter Plate to APM100 Box

17

MKT-0262 MPC-1748 Rev 02/13

Page 22

Fitting an APM2 in an APM100 Enclosure

Instructions

4. Mount the front cover assembly.

Figure 2-7. Installed APM2

18

MKT-0262 MPC-1748 Rev 02/13

Page 23

APM2 Rough-In Installation Guide

APM2 Central Display Rough-In Installation

Required Parts to be Supplied by the Installer

Section 3. APM2 Central Display Rough-In Installation

For the APM2 Central Display to be installed correctly, the rough-in phase of the project must be completed

properly. This section will outline the specific considerations the General Contractor must pay attention to so

that the final wiring and commissioning will go smoothly.

During rough-in installation, the field wiring can be run in the walls and routed between the triple gang

electrical box, the Building Management System (BMS), power supply, earth ground and so on.

3.1 Required Parts to be Supplied by the Installer

The following is a list of parts required and supplied by the installer for the APM2 Central Display:

• Triple gang-double deep electrical box (RACO 697 or Appleton M3-350), quantity 1

• Green grounding screw, quantity 1

• Power (18 AWG recommended) and signal wiring (22 AWG recommended), as needed. Refer to Phoenix

Recommended Cables on page 33.

• EMT conduit (if required by local code)

•24 Vac Transformer

3.2 Parts included with Your Order

The following are parts that are included in your order:

• APM2 Central Display, quantity 1

• APM2 Faceplate, quantity 1

• Mounting screws, 6-32 x 1/2 Phillips head, quantity 5

• Mating Electrical Connectors, Phoenix Contact MC plug kit, 2 green connectors

3.3 Installation Overview

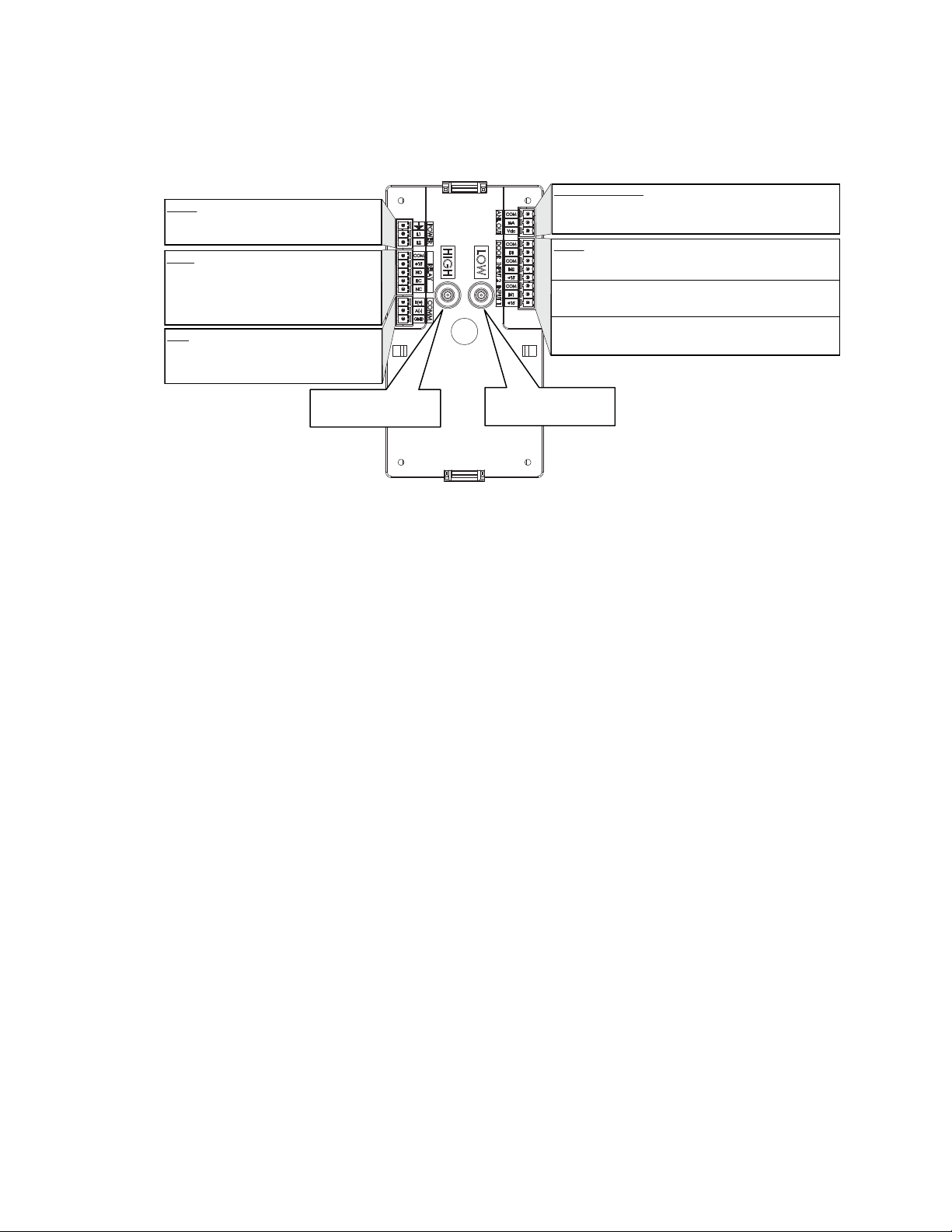

• Install in a triple gang-double deep electrical box (RACO 697, Appleton M3-350 or equivalent).

• Secure the triple gang-double deep electrical box to the stud(s) by using the mounting hole in the side of

the electrical box (see figure below for mounting hole location). Drive the mounting screws from the inside

of the electrical box into the wall studs to prevent sharp objects from protruding into the electrical box.

• Ensure the mounting is level and flush to the wallboard surface.

19

MKT-0262 MPC-1748 Rev 02/13

Page 24

APM2 Central Display Rough-In Installation

Faceplate

Main Unit

Rough-in Electrical Box

- Raco 697

- Appleton M3-350

Electrical Box

Mounting Hole

WALL MOUNT DIMENSIONS

Triple gang double deep electrical box—5.625" (142.9 mm) W x 3.5" (88.9 mm) H x 3.5" (88.9 mm) D

* Dimensions are approximate.

Installation Overview

Figure 3-1. Wall Mount Installation Overview

3.3.1 Wiring Recommendations

• All circuits must conform to the requirements of an NEC Class 2 (dry) circuit.

• Use multiple transformers instead of larger transformers when more than 100 VA is required.

• Each pressurization zone should have either a dedicated single-phase primary circuit, or a secondary circuit

disconnect.

•See Phoenix Recommended Cables on page 33 for approved cable manufacturers and wire types.

• Use stranded wire for ease of installation.

• Follow good wiring practices:

• Locate cables away from sources of electrical interference (EMI/RFI).

• Do not run signal or communication cable in the same conduit or wire way as power cables.

• If signal cable must cross power cables place these at a 90-degree angle.

• Shield or drain wires, if required, should be wrapped with insulating tape to prevent contact with exposed

conductors or contacts.

• Maintain a consistent color code or polarity all the way through the wiring system.

• Power supply and signal isolation on I/O devices vary from manufacturer to manufacturer. Verify the

• Local and national electrical codes take precedence.

wiring device manufacturer’s recommendations for isolating power and signal common connections and

maintain polarity.

20

MKT-0262 MPC-1748 Rev 02/13

Page 25

APM2 Rough-In Installation Guide

APM2 Central Display Rough-In Installation

Installation Overview

• Strip 0.25" (6.4 mm) of insulation from each conductor, twist the strands, insert the conductor fully into

the terminal block, and tighten the terminal.

•Test the wire connection by pulling on each conductor.

WARNING: Wiring must be performed by a licensed electrician according to local and state codes.

3.3.2 Wiring Triple Gang Electrical Box

USE ONLY THE KNOCKOUTS ON THE TOP OR BOTTOM AT THE BACK OF THE ROUGH-IN

ELECTRICAL BOX. The front knockouts will be inaccessible once the APM2 is installed. Strain relief and seal

box as required.

NOTE: Install power and signal wires into separate knockouts to avoid noise.

Figure 3-2. Wiring in the Triple Gang Electrical Box

21

MKT-0262 MPC-1748 Rev 02/13

Page 26

APM2 Central Display Rough-In Installation

Earth Ground

L1 24 Vac

L2 24 Vac

POWER

COMM

B (+)

A (-)

GND

REAR VIEW

BACnet Communications

(See Detail A)

DATA +

DATA -

COMM

B (+)

GND

A (-)

DETAIL "A"

GROUND SHIELD - ONE END ONLY

Wiring

3.4 Wiring

Figure 3-3. Rear View of the APM2 Central Display Showing Wiring Connections

The back of the APM2 Central Display has electrical connectors labeled with their function. The mating

electrical connectors (supplied) are color coded and labeled with the matching function.

3.4.1 Power, Labeled POWER, L1, L2, Ground Symbol

Starting with the 3 pin Power connector:

1. Connect the 24 Vac lines to L1 and L2.

2. Connect a ground wire, GND, from the ground lug to the GND on the connector.

3. Install Connector.

The APM2 operates at 18-32 Vac, 50/60 Hz and consumes 2.6 W nominal, 9.6 W max.

22

MKT-0262 MPC-1748 Rev 02/13

Page 27

APM2 Rough-In Installation Guide

APM2 Central Display Rough-In Installation

3.4.2 Completing the Finish Wiring

1. Connect all the electrical connectors matching the wiring connector with the mates on the back of the

unit. Connectors are color coded and keyed.

2. Mount the unit cover to the electrical box using four of the supplied mounting screws. Leaving screws

slightly loose adjust the cover so that it is square. Securely tighten so that the back of the cover is tight to

the finish wall surface.

Wiring

Figure 3-4. Mounting APM2 Central Display in Triple Gang Electrical Box

3. Mount the front cover assembly.

Figure 3-5. Installed APM2 Central Display

23

MKT-0262 MPC-1748 Rev 02/13

Page 28

APM2 Central Display Rough-In Installation

Wiring

THIS PAGE INTENTIONALLY LEFT BLANK.

MKT-0262 MPC-1748 Rev 02/13

24

Page 29

APM2 Rough-In Installation Guide

Ancillary Product Specifications

Model 264 Pressure Transducer

Section 4. Ancillary Product Specifications

NOTE: The following specifications are subject to changes without notice.

4.1 Model 264 Pressure Transducer

Table 1. Model 264 Pressure Transducer (Remote Transducer 0-5 V Output)

Model 264 Pressure Transducer

Performance Data

Standard Optional

1

Accuracy

Non-linearity (BFSL) ± 0.96 % FS ± 0.38 % FS ± 0.22 % FS

Hysteresis 0.10% FS 0.10% FS 0.10% FS

RSS (at constant temperature)

± 1.0 % FS ± 0.4 % FS ± 0.25 % FS

Non-repeatability 0.05% FS 0.05% FS 0.05% FS

3

°F (°C)

°F (°C)

2

0 - 150 (-18 - 65)

°F (°C)

0.033 (0.06)

To 0.5" WC 0.60

To 1.0" WC 0.50

0 - +175 (-18 - +79)

-65 - +250 (-54 - +121)

Thermal Effects

Compensated Range °F (°C)

Zero/Span Shift % FS/

Maximum Line Pressure 10 psi

Overpressure Up to 10 psi (range dependent)

Long-term Stability 0.5% FS / year

Position Effect Range Zero Offset (% FS/G)

Unit is factory calibrated at 0g effect in the

vertical position

Environmental Data

Temperature

Operating

Storage

Physical Description

Case Fire-retardant glass filled polyster (UL94 V-0 Approved)

Dimensions 2.75" (69.85 mm) W x 5.062" (128.57 mm)H x 2.40" (61.07 mm) D

Mounting

Electrical Connection Screw type terminal strip

Four screw holes on removable zinc-plated steel base (designed for 2.75"

snap track)

MKT-0262 MPC-1748 Rev 02/13

25

Page 30

Ancillary Product Specifications

Model 264 Pressure Transducer

Pressure Fittings 3/16" OD barbed brass pressure fitting for 1/4" push-on tubing

Zero and Span Adjustments Accessible on top of case

Weight (approximate) 10 ounces

Pressure Media

Typically air or similar non-conducting gases

Electrical Data—Voltage

Circuit 3-wire (Com, Exc, Out)

Excitation 9 - 30 Vdc

4

Output

Bi-directional output at zero pressure

Output impedance 100Ω

Electrical Data—Current

Circuit 2-wire

7

Output

Bi-directional output at zero pressure

0 - 5 Vdc

2.5 Vdc

4 - 20 mA

12 mA

5

6

8

9

Minimum supply voltage (Vdc) 9+0.02 x (resistance of receiver plus line)

Maximum supply voltage (Vdc) 30+0.004 x (resistance of receiver plus line)

1

RSS of non-linearity, hystereis and non-repeatability.

2

Units calibrated at nominal 70 °F. Maximum thermal error computed from this datum.

3

Operating temperature limits of the electronics only. Pressure media temperatures may be considerably higher.

4

Calibrated into a 50KΩ load, operable into a 5KΩ load or greater.

5

Zero output factory set to within ± 50 mV (± 25 mV for optional accuracies).

6

Span (full scale) output factory set to within ± 50 mV (± 25 mV for optional accuracies).

7

Calibrated at factory with a 24 Vdc loop supply voltage and a 250Ω load.

8

Zero output factory set to within ± 0.16 mA (± 0.08 mA for optional accuracies).

9

Span (full scale) output factory set to within ± 0.16 mA (± 0.08 mA for optional accuracies).

26

MKT-0262 MPC-1748 Rev 02/13

Page 31

APM2 Rough-In Installation Guide

+

SPAN

+

ZERO

INSTALLATION WARNING!

2.750 in.

(69.85 mm)

5.062 in.

(128.57 mm)

4.562 in.

(115.87 mm)

R0.078 in.

(R1.98 mm)

1.624 in.

(41.25 mm)

0.594 in.

(15.08 mm)

1.811 in.

(45.99 mm)

1.187 in.

(30.15 mm)

TYP.

TYP.

TYP.

1.662 in.

(42.21 mm)

0.312 in.

(7.92 mm)

0.385 in.

(9.78 mm)

TYP.

LOW

Model 264

HIGH

Serial Number:

Part Number:

Range:

Excitation:

Output:

Date Code: 3599

0-5 VDC

9-30 Vdc

0-5.0" WC

1015990

2641005WD2DT1C

COM

EXC OUT

PRESSURE PORTS

TOP VIEW

SIDE VIEW

#6 SCREW

WIRE CLAMP

3 PLACES

Ancillary Product Specifications

Model 264 Pressure Transducer

Figure 4-1. Model 264 Pressure Transducer

27

MKT-0262 MPC-1748 Rev 02/13

Page 32

Ancillary Product Specifications

Model 267 Pressure Transducer

4.2 Model 267 Pressure Transducer

Table 2. Model 267 Pressure Transducer

Performance Data

Standard Optional

1

Accuracy

Non-linearity (BFSL) ± 0.98 % FS ± 0.38 % FS ± 0.22 % FS

Hysteresis 0.10% FS 0.10% FS 0.10% FS

Non-repeatability 0.05% FS 0.05% FS 0.05% FS

RSS (at constant temperature)

Thermal Effects

2

± 1.0 % FS ± 0.4 % FS ± 0.25 % FS

Compensated Range °F (°C)

Zero/Span Shift % FS/

Maximum Line Pressure 10 psi

Overpressure Up to 10 psi (range dependent)

Warm-up Shift ± 0.1% FS Total

Position Effect Range Zero Offset (% FS/G)

Unit is factory calibrated at 0g effect in the

vertical position

Environmental Data

Temperature

3

Operating

Storage

Physical Description

Case IP65/NEMA plastic-filled polycarbonate (UL94 V-0 Approved)

Dimensions 6.20" (158 mm) W x 2.68" (68 mm) H x 3.65" (93 mm) D

Electrical Connection Screw type terminal strip

°F (°C)

°F (°C)

°F (°C)

40 - 150 (5 - 65)

± 0.033 (± 0.06)

To 0.5" WC 0.60

To 1.0" WC 0.50

0 - +150 (-18 - +65)

+65 - +180 (-54 - +82)

PG-9/PG13.5 Strain relief, 1/2" conduit opening, or 9-pin D-sub connector

Electrical Termination

NOTE: 9-pin D-sub connector is not suitable for NEMA4/IP-65 environments

Pressure Fittings

Weight (approximate) 9 ounces (255 g)

Pressure Media

Typically air or similar non-conducting gases

3/16" O.D. barbed brass for 1/4" push-on tubing (Standard)

Static Pressure Probe (Optional)

1/4" NPTF brass (Optional)

28

MKT-0262 MPC-1748 Rev 02/13

Page 33

APM2 Rough-In Installation Guide

Electrical Data—Voltage

Circuit 3-wire (Exc, Gnd, Sig)

Excitation/Output

Excitation/Output

Bi-directional output at zero pressure Mid-range of specified output

Output impedance 100Ω

Re-ranging 5 position dip switches (inside case)

Electrical Data—Current

Circuit 2-wire protected from miswiring

6

Output

External Load 0 - 800Ω

Bi-directional output at zero pressure 12 mA

Minimum loop supply voltage (Vdc) 9 + 0.02 x (resistance of receiver plus line)

Maximum supply voltage (Vdc) 30 + 0.004 x (resistance of receiver plus line)

(0-5 Vdc output)

(0-10 Vdc output)

9 - 30 Vac / 12 - 40 Vdc

11 - 30 Vac / 13 - 40 Vdc

4 - 20 mA

7

Ancillary Product Specifications

Model 267 Pressure Transducer

Re-ranging 4 position dip switches (inside case)

1

RSS of non-linearity, hystereis and non-repeatability.

2

Units calibrated at nominal 70 °F. Maximum thermal error computed from this datum.

3

Operating temperature limits of the electronics only. Pressure media temperatures may be considerably higher or lower.

4

Calibrated into a 50K Ω load, operable into a 5K Ω load or greater.

5

Zero output factory set to within ± 50 mV (± 25 mV for optional accuracies).

Span (full scale) output factory set to within

6

Calibrated at factory with a 24 Vdc loop supply voltage and a 250 Ω load.

7

Zero output factory set to within ± 0.16 mA (± 0.08 mA for optional accuracies).

± 50 mV (± 25 mV for optional accuracies).

Span (full scale) output factory set to within ± 0.16 mA (± 0.08 mA for optional accuracies).

29

MKT-0262 MPC-1748 Rev 02/13

Page 34

Ancillary Product Specifications

Model 267 Pressure Transducer

2.68 in.

(68 mm)

1.34 in.

(34 mm)

6.10 in.

(155 mm)

5.60 in.

(142 mm)

0.18 in.

(Ø4.5 mm)

0.75 in.

(19 mm)

0.50 in.

(13 mm)

3/16" O.D. PRESSURE FITTING

FOR 1/4" PUSH-ON TUBING

1.73 in.

(44 mm)

0.93 in.

(24 mm)

Figure 4-2. Model 267 Pressure Transducer

0.80 in.

(20 mm)

Ø7/8 in.

(Ø22 mm)

1.18 in.

(30 mm)

1.29 in.

(33 mm)

2.36 in.

(60 mm)

30

MKT-0262 MPC-1748 Rev 02/13

Page 35

APM2 Rough-In Installation Guide

4.52 in.

(114.78 mm)

.20 in.

(5.08 mm)

2.77 in.

(70.23 mm)

.74 in.

(18.69 mm)

.43 in.

(10.80 mm)

2.68 in.

(68 mm)

1.97 in.

(50 mm)

4.3 Remote Annunciator

Table 3. Remote Annunciator

Enclosure 2.75" W x 4.5" H stainless steel wall cover plate

External Supply 15 Vdc, 50 mA maximum

Display Panel Green and red LED indicators and Acknowledge (ACK) switch

Audible Alarm 0-85 dBA measured 4" from annunciator

Acknowledge Switch Momentarily turns off audible alarm

Ancillary Product Specifications

Remote Annunciator

Figure 4-3. Remote Annunciator

31

MKT-0262 MPC-1748 Rev 02/13

Page 36

Ancillary Product Specifications

2.77 in.

(70.23 mm)

4.52 in.

(114.78 mm)

.20 in.

(5.08 mm)

.82 in.

(21 mm)

Pressure Pickup Port

4.4 Pressure Pickup Port

Table 4. Pressure Pickup Port

Cover Stainless steel standard wall cover plate

Mounting Standard single gang electrical box (2 screws included)

Dimensions 2.77" (70.23 mm) W x 4.52" (114.78 mm) H x 1.02" (26.08 mm) D

Pressure Fitting 1/4" flexible push-on tubing (Standard)

Figure 4-4. Pressure Pickup Port

32

MKT-0262 MPC-1748 Rev 02/13

Page 37

APM2 Rough-In Installation Guide

4.5 Phoenix Recommended Cables

Ancillary Product Specifications

Phoenix Recommended Cables

Cable

Ty p e

2C

Round

2C

Round

TP No FTT-10 (4500’)

TP Yes FTT-10 (4500’)

TSP No I/O signal

2 TSP No I/O signal

3C

Round

3C or

4C

Round

4C

Round

5C

Round

Plenum

Rated

No 24 Vac power to

Yes 24 Vac power to

No Signal 22 Belden 8443 1: Red

Yes Signal 22 Belden 88444 Windy City

No Signal 22 Belden 8444 Manhattan

No Signal 22 Belden 8445 Manhattan

Function

LOSEA or

Pneumatic (110’

max at load

24 Vac power to

HiSea (288’ max

1, 2

at load

LOSEA or

Pneumatic (110’

max at load

24 Vac power to

HiSea (288’ max

at load

TP1250 (425’)

FTT-10 (8800’) 16 Windy City

TP1250 (425’)

FTT-10 (8800’) 16 Windy City

wiring

wiring

)

1, 2

)

1

2

Wire

Gauge

18 Belden 9409 1: Red

1, 2

)

14 Belden 9411

18 Belden 82740 Windy City

1, 2

)

14 Windy City

22 Windy City

22 Windy City

22 Belden 9501 1: Black&Red Twisted

22 Belden 9502 1: Black&Red

Primary

Vendor/Part #

NP007960

107500

109600

105500

109500

Alternate

Vendor/Part #

NP002360

Connect-Air

W221P-1002

Connect-Air

W221P-2001

004380

M13304

M13305

Color Code Notes

2: Black

1: Red

2: Black

1: White/Blue stripe

2: Blue/White stripe

1 : W h i t e / B l u e s t r i p e

2: Blue/White stripe

2: Black&White

2: Black

3: Green

1: Red

2: Black

3: Green

4: White (not used as

3C)

1: White

2: Green

3: Black

4: Red

1: White

2: Brown

3: Black

4: Red

5: Green

Must be

stranded

Must be

stranded

For more

alternatives

visit:

echalon.com

For more

alternatives

visit:

echalon.com

Shielded Pair

Two Twisted

Pair,

Shielded

Must be

stranded

Must be

stranded

Must be

stranded

Must be

stranded

33

MKT-0262 MPC-1748 Rev 02/13

Page 38

Ancillary Product Specifications

Phoenix Recommended Cables

Cable

Ty p e

8C No Signal 22 Belden 9421 Manhattan

8C Yes Signal 22 Comtran 4956 1: White

3C

MS/TP

3C MS/TPYe s Shielded 22 Connect-Air

4C

MS/TP

4C

MS/TP

4C

MS/TP

Plenum

Rated

No Shielded 22 Belden 3106A

Yes Armored

Yes Armored

Yes Armored

Function

Shielded

Shielded

Shielded

Wire

Gauge

22 Belden 1269A

22 Belden 123107A

24 Belden 82842

Primary

Vendor/Part #

(120 ohm)

W223C2060YPC

(100 ohm)

(100 ohm)

(100 ohm)

Alternate

Vendor/Part #

M13308

See

specifications

below for

alternate cable

solutions

See

specifications

below for

alternate cable

solutions

See

specifications

below for

alternate cable

solutions

See

specifications

below for

alternate cable

solutions

See

specifications

below for

lternate cable

a

solutions

Color Code Notes

1: White

2: Orange

3: Black

4: Red

5: Green

6: Yellow

7: Blue

8: Brown

2: Orange

3: Black

4: Red

5: Green

6: Yellow

7: Blue

8: Brown

1: White with Orange

stripe

2: Orange with White

stripe

3: Blue with White

stripe

1: Black

2: White

3: Red

1: Red

2: Blue

3: Black

4: Yellow

1: White with Blue

stripe

2: Blue with White

stripe

3: White with Orange

stripe

4: Orange with White

stripe

1: White with Blue

stripe

2: Blue with White

stripe

3: White with Orange

stripe

4: Orange with White

stripe

No

substitutes

No

substitutes

Shielded

with drain

Foil shield

with drain

wire

Foil and

braided

shield with

drain

Foil and

braided

shield with

drain

Foil and

braided

shield with

drain

Low smoke

34

MKT-0262 MPC-1748 Rev 02/13

Page 39

APM2 Rough-In Installation Guide

Ancillary Product Specifications

Phoenix Recommended Cables

Cable

Ty p e

4C

MS/TP

4C

MS/TP

1

Load is 96 VA when power is provided by a 100 VA transformer with external 4 amp slow blow fuse.

2

Load is 100 VA when power is provided by a 100 VA transformer with internal circuit breaker.

Plenum

Rated

Yes Shielded 24 Belden 82729

Yes Shielded 24 Belden 88102

Function

Wire

Gauge

Primary

Vendor/Part #

(100 ohm)

(100 ohm)

Alternate

Vendor/Part #

See

specifications

below for

alternate cable

solutions

See

specifications

below for

alternate cable

solutions

Color Code Notes

1: White with Blue

stripe

2: Blue with White

stripe

3: White with Orange

stripe

4: Orange with White

stripe

1: White with Blue

stripe

2: Blue with White

stripe

3: White with Orange

stripe

4: Orange with White

stripe

Shield with

drain

Shield with

drain

4.5.1 MS/TP Specifications for Alternate Cable Solutions

1. An MS/TP (EIA-485) network shall use shielded, twisted-pair cable with characteristic impedance

between 100 and 130Ω..

2. Distributed capacitance between conductors shall be less that 100 pF per meter (30 pf per foot).

3. Distributed capacitance between conductors and shield shall be less that 200 pF per meter (60 pF per

foot).

4. Foil or braided shields are acceptable. The maximum recommended length of an MS/TP segment is 1200

2

meters (4000 feet) with AWG 18 (0.82 mm

conductor area) cable.

5. The use of greater distances and/or different wire gauges shall comply with the electrical specifications of

EIA-485 for MS/TP cable requirements.

35

MKT-0262 MPC-1748 Rev 02/13

Page 40

Ancillary Product Specifications

Phoenix Recommended Cables

THIS PAGE INTENTIONALLY LEFT BLANK.

MKT-0262 MPC-1748 Rev 02/13

36

Page 41

APM2 Rough-In Installation Guide

Index

Numerics

15 Vdc 9

24 Vac 5

24 Vac Transformer 1, 19

249 or 500 Ohm Resistors 9

3 pin Power Connector 8, 22

3-gang Double-deep Electrical Box 13

3rd Party Remote Annunciator Wiring 11

5-gang Single-deep Electrical Box 13

9 VA

Power 5

A

Adapter Plate

Stainless Steel 13

Adapter Plate Install 17

Alarm Setpoints

Remotely Switching 16

Alternate Cable Solutions

MS/TP Specifications 35

Analog Input 9

Analog Input Wiring 5

Analog Output 5, 8

Ancillary Product 25

ANL OUT 8

Annunciator 5

Remote 31

APM100 Enclosure 13

APM100 Pressure Monitors 13

APM2 Calibration Certificate 13

APM2 Central Display 1, 19

APM2 Connector Kit 13

APM2 Front Cover 18

APM2 Pressure Monitor 13

APM2 Retrofit Kit 13

APM2 White Faceplate 13

Attach

Base Unit 15

Audible Buzzer

Remote Annunciator 10

B

Base APM2 Unit 15

BMS 1, 19

Building Management System 1, 19

C

Cables

Phoenix Recommended 33

Calibration Certificate

APM2 13

Central Display

APM2 1, 19

Certificate

APMS Calibration 13

Complete Installation 17

Conectors

Label 14

Connect Power Return 10

Connections

Plumbing and Wiring 7, 8, 16, 22

Connector Kit

APM2 13

Cover

APM2 Front 18

Install Front 12, 23

Current

Model 264 Electrical Data 26

Model 267 Electrical Data 29

D

Data

Model 264 Environmental 25

Model 264 Performance 25

Model 267 Environmental 28

Model 267 Performance 28

Description

Model 264 Physical 25

Model 267 Physical 28

Digital Input 5

Dimensions

Model 264 Pressure Transducer 25

Model 267 28

Wall Mount 3

Door 9

Door Switch

SPDT 1, 19

SPST 1, 19

E

Effect

Model 264 Position 25

Model 267 Position Effect 28

Effects

Model 264 Thermal 25

Model 267 Thermal 28

Electrical Box 1, 19

3-gang Double-deep 13

5-gang Single deep 13

Appleton M3-350 1, 2, 19

RACO 697 1, 2, 19

Electrical Connectors (supplied) 8, 16, 22

EMT Conduit 1, 2, 19

IX-1

MKT-0262 MPC-1748 Rev 02/13

Page 42

Enclosure

APM100 13

External Sensor 5

External Transducers

Use of 5

F

Faceplate

APM2 White 13

Field Wiring 1, 19

Finish Plumbing 6

Pressure Tubing 7

Finish Wiring 11, 23

Front cover

Install 11, 23

G

General Contractor 1, 19

Ground 8, 22

I

Included Parts 2, 19

0.25" O.D. Tubes 2

Advanced Pressure Monitor II 2, 19

APM2 2, 19

Barbed Couplings 2

Faceplate 2, 19

Mating Electrical Connectors 2, 19

Mounting Screws 2, 19

Phoenix Contact MC plug kit 2, 19

Pressure Pickup Port 2, 19

Input1 9

Input2 9

Inputs

Measuring Analog Inputs 9

Install

Adapter Plate 17

Unit to Electrical Box 11, 23

Install Fron Cover 11, 23

Install Front Cover 12, 23

Installation 2, 19

Complete 17

Overview 2, 19

Pressure Pickup Port 5

Remote Annunciator 6

Rough-in 1, 19

Installer Required Parts 1, 19

Instructions 14

J

Jumper 10

K

Kit

APM2 Connector 13

APM2 Retrofit 13

L

L1 8, 22

L2 8, 22

Label Connectors 14

M

Measuring Analog Inputs 9

COM 9

IN1 9

Media

Model 264 Pressure 26

Model 267 Pressure 28

Model 264 Electrical Data

Current 26

Voltage 26

Model 264 Environmental Data 25

Model 264 Performance Data 25

Model 264 Physical Description 25

Model 264 Position Effect 25

Model 264 Pressure Media 26

Model 264 Pressure Transducer 25

Model 264 Pressure Transducer Dimensions 25

Model 264 Thermal Effects 25

Model 267 Dimensions 28

Model 267 Electrical Data

Current 29

Voltage 29

Model 267 Environmental Data 28

Model 267 Performance Data 28

Model 267 Physical Description 28

Model 267 Position Effect 28

Model 267 Pressure Media 28

Model 267 Pressure Transducer 28

Model 267 Thermal Effects 28

Modified 17

Modified Pressure Taps 17

MS/TP 35

MS/TP Specifications

Alternate Cable Solutions 35

O

Optional Remote Annunciator Wiring 10

Optional Remote Transducer Wiring 9

Output

Relay and Annunciator 10

P

Phoenix Recommended Cables 33

Plate

Adapter 13

Plumbing 1

Finish 6

Plumbing Rough-In 4, 22

Polyethelyne Control Tubing 1

Port

Pressure Pickup 32

Power 5, 8, 22

Turn Off 14

Power Return

Connect 10

Power Wiring 1, 19

Pressure Monitor

AMP2 13

APM100 13

IX-2

MKT-0262 MPC-1748 Rev 02/13

Page 43

APM2 Rough-In Installation Guide

Pressure Pickup Port 1, 4, 32

Pressure Pickup Port Installation 5

Pressure Signals 5, 11

Pressure Taps 17

Pressure Transducer

Model 264 25

Model 267 28

Pressure Tubing 14

R

Recommendations

Wiring 3, 20

Relay 5, 10

Relay and Annunciator Output 10

Relay Connector 10

COM 10

Relay Output

NO 10

Remote Alarm 5

Remote Annunciator 10, 31

Third Party 11

Remote Annunciators 1

Remote Annunicator Installation 6

Remote Pressure Tansducers 1

Remote Transducer 5

Remotely Switching Alarm Setpoints 16

Required Parts

Installer 1, 19

Room Pressure Signal 4

Rough-in

Wiring 4, 21

Rough-in Installation 1, 19

Rough-in Plumbing 4, 22

S

Sensors

Setra Remote 9

Setpoints 16

Setra Remote Sensors 9

Side

Reference 14

Signal Wiring 1, 19

Signals

Pressure 11

Single Gang Electrical Box 1

Specifications

Ancillary Product 25

Stainless Steel Adapter Plate 13

Room Side 14

Turn Off Power 14

U

Use of External Transducers 5

V

Voltage

Model 264 Electrical Data 26

Model 267 Electrical Data 29

W

Wall Mount Dimensions 3

Warni ng 9

Wiring 7, 17, 22

3rd Party Remote Annunciator 11

Dedicated Single-phase Primary Circuit 3, 20

Electrical connectors 7, 22

Finish 11, 23

Knockouts 4, 21

Multiple Transformers 3, 20

NEC Class 2 3, 20

Optional Remote Annunciator 10

Optional Remote Transducer 9

Power 1, 19

Relay Connector 10

Secondary Circuit Disconnect 3, 20

Signal 1, 19

Stranded Wire 3, 20

System Layout 5

Wiring and Plumbing Connections 7, 8, 16, 22

Wiring Practices 3, 20

Wiring Recommendations 3, 20

Wiring Rough-in 4, 21

Wiring Triple Gang Electrical Box 4, 21

T

T-connectors 1

Too l s N ee d ed 1 3

Tr a n s d u c e r

Model 264 Pressure 25

Model 267 Pressure 28

Tr a n s f o r m e r

24 Vac 1, 19

Tu b i n g

Polyethelyne control 1

Pressure 14

Reference Side 14

IX-3

MKT-0262 MPC-1748 Rev 02/13

Page 44

THIS PAGE INTENTIONALLY LEFT BLANK.

MKT-0262 MPC-1748 Rev 02/13

IX-4

Page 45

Page 46

For additional information and a listing of our global offi ces, please visit our Web site at www.phoenixcontrols.com or call (800) 340-0007.

Phoenix Controls is a business of Honeywell International, Inc.

© 2010 Phoenix Controls 2/13 Printed in U.S.A.

MKT-0262 MPC-1748

Loading...

Loading...