Page 1

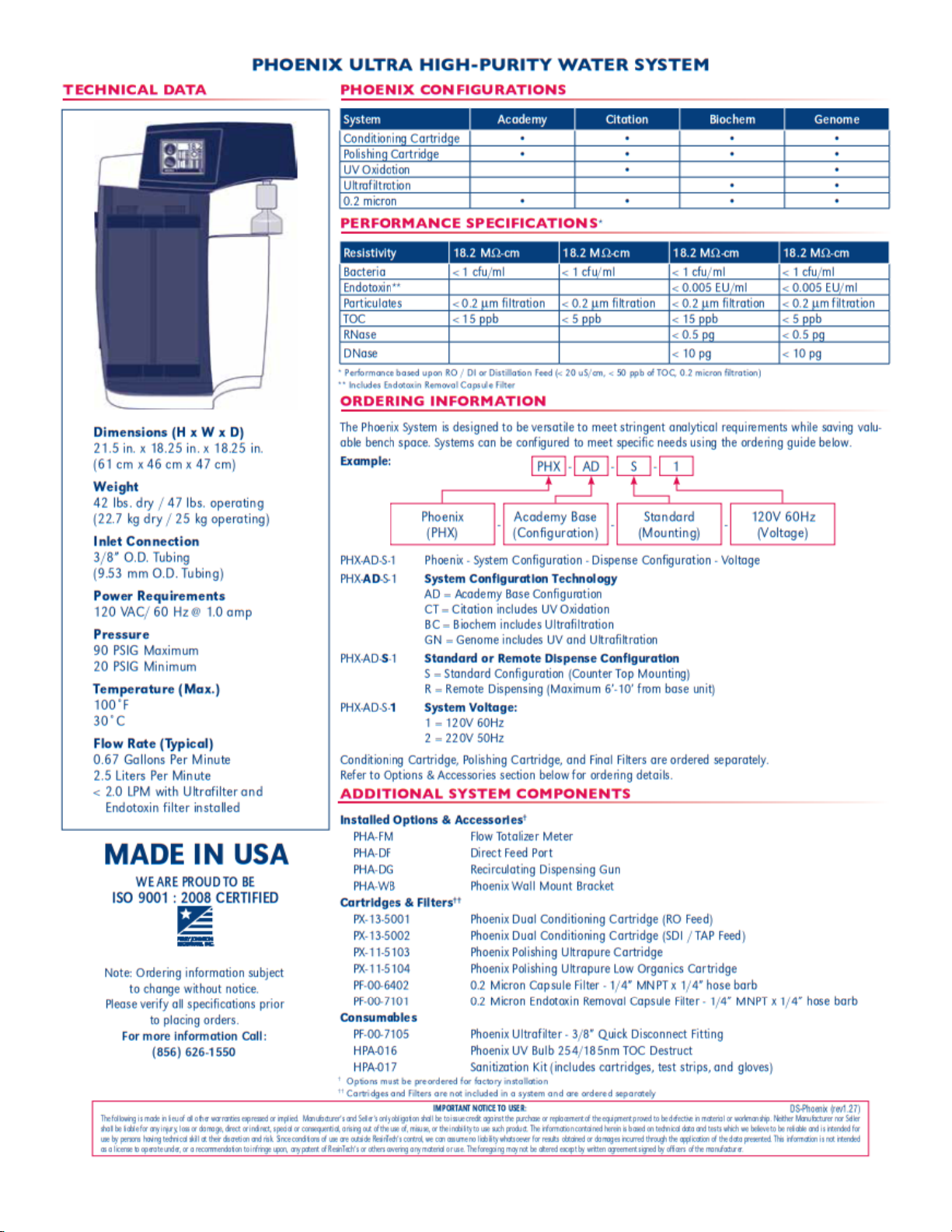

ACADEMY

CITATION

BIOCHEM

GENOME

USER MANUAL

Page 2

2

Phoenix User’s Manual

This manual contains details on installation and operation of your Phoenix Ultra-High Purity

water system. For optimum performance and safety please read and follow these instructions

carefully.

You have a quality, world class water treatment system that will provide ultrapure water for

many years of trouble free operation. Years of engineering and experience went into the

design and manufacture of this instrument which will dispense water exceeding Type I water

purity standards.

If you have any questions concerning the operation of the unit, or need service, refer

to "REQUESTING SERVICE".

In order that we may keep you informed regarding your unit, please take a moment to

complete the information below that will assist with support should it be needed.

Model Number: __________________________

Date: ________________________

Serial Number: ___________________________

Dealer: _______________________

Contact: _________________________________

Phone: _______________________

Conditioning Cartridge_____________________

Part Number ___________________

Polishing Cartridge _______________________

Part Number ___________________

Options Installed ________________________________________________________

Page 3

Contents

System Information ........................................................................................................................ 4

General Arrangement ................................................................................................................. 4

Flow Diagram .............................................................................................................................. 5

Safety Information .......................................................................................................................... 5

Installation ...................................................................................................................................... 8

System Wall Mounting: Requires PHA-WB Wall Mount Bracket ............................................................. 9

Water Connections – All Models ............................................................................................................ 10

Remote Dispense (If Equipped) .............................................................................................................. 11

Remote Dispense Water Connections .................................................................................................... 11

Direct Feed Water Connection ............................................................................................................... 12

Electrical Connection .............................................................................................................................. 13

UV Lamp (If not already installed) (ACADEMY and GENOME) ............................................................... 13

Dual Conditioning Cartridge ................................................................................................................... 14

Polishing Cartridge .................................................................................................................................. 15

Initializing the System for the First Time ................................................................................................ 16

Normal Operation ......................................................................................................................... 18

Home Screen .......................................................................................................................................... 19

Batch Operations .................................................................................................................................... 20

Main Menu ............................................................................................................................................. 24

System Information ................................................................................................................................ 24

Configuration Menu ............................................................................................................................... 25

Alarm Log (Example Screen) ................................................................................................................... 25

Filter Detection and Leak Detection Errors ............................................................................................ 26

Maintenance ................................................................................................................................. 27

Adjusting Resistivity Alarm Set Points .................................................................................................... 28

Adjusting Recirculation Options ............................................................................................................. 29

Sanitization ............................................................................................................................................. 30

Troubleshooting ............................................................................................................................ 33

Specification Sheet ................................................................................................................... 36

Reordering Information ................................................................................................................ 38

Requesting Service ........................................................................................................................ 38

Entering Your Service Professional’s Contact Info ................................................................................. 38

Page 4

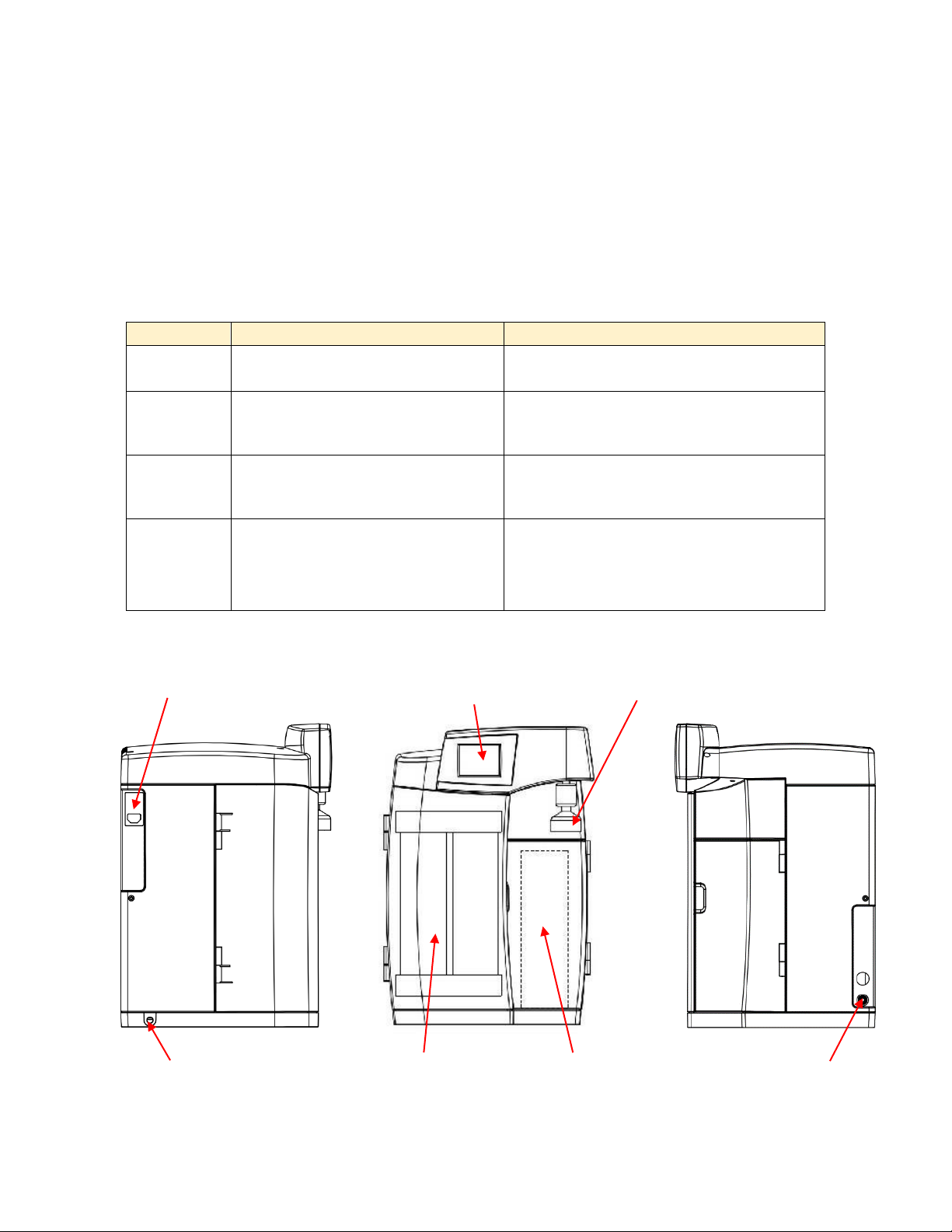

System Information

The Phoenix Ultra High Purity Lab Water System delivers Type 1, 18.2 MΩ quality water on

demand. Water is purified in a staged process consisting of high-purity ion exchange resins to

remove dissolved minerals and internal recirculation to maintain purity. At discharge a final

0.2µm filter removes particulates and bacteria to attain Type 1 water specifications. Additional

optional technologies are incorporated depending on model. Multiple sensors continuously

monitor system and final water quality.

Model

Technology

Typical Applications

ACADEMY

Ion exchange

Particulate filtration

Basic Chemistry; Academic, IC, Buffers

CITATION

Ion exchange

185/254 nm UV

Particulate filtration

HPLC, GC-MS, Trace Organics

BIOCHEM

Ion exchange

Particulate filtration

Bacterial ultrafiltration

Life Science, Cell Culture, Microbiology

GENOME

Ion exchange

185/254 nm UV

Particulate filtration

Bacterial ultrafiltration

DNA Sequencing, PCR, Electrophoresis

General Arrangement

Touch Screen Display

Power Input/Power Switch

Water Dispense Port

Feed Water Inlet

Conditioning

Cartridge

Polishing

Cartridge

Drain Port

Page 5

5

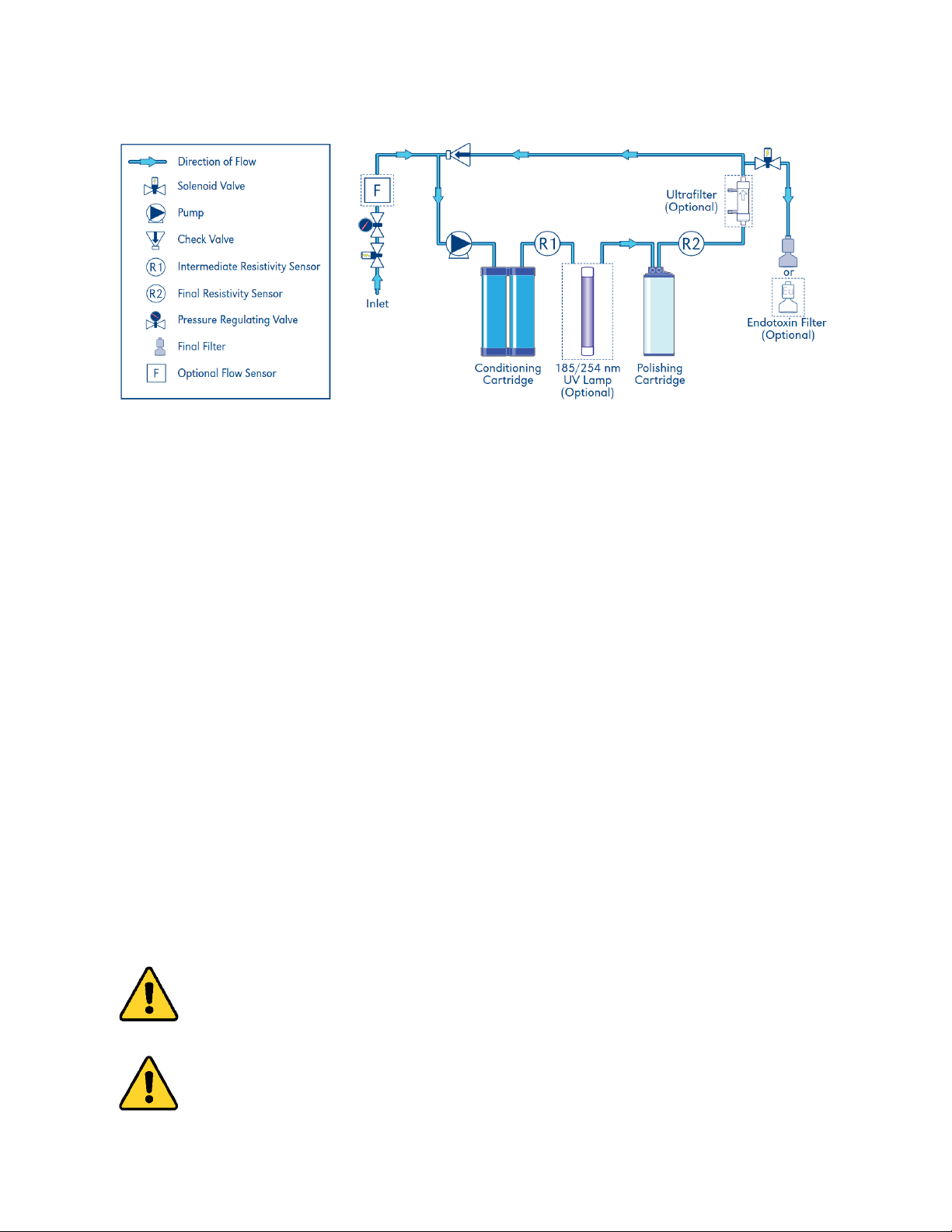

Flow Diagram

Safety Information

DO NOT immerse in water or other liquid. Use a soft cloth and mild detergent when cleaning the

cabinet.

DO NOT remove the top cover with unit power applied.

DO NOT remove the ultraviolet lamp side cover with unit power applied.

DO NOT look directly at the ultraviolet lamp with unit power applied.

DO NOT operate with a damaged or frayed power cord. To disconnect the power cord, grip the plug

and pull it from the wall outlet, NEVER PULL ON CORD!

DO NOT use outdoors. This instrument is intended for commercial, industrial, institutional, and

professional use. Use of this product in a manner other than recommended may void the warranty.

DO NOT operate without proper connection to an adequate water supply and purged of air or damage

to the pump may occur.

DO NOT allow power cord to hang over the edge of a counter top or to touch hot surfaces. NOTE: If an

extension cord is used, verify that the rating of the extension cord is equal to or greater than the rating

of the instrument.

Refer servicing of a defective or damaged unit to the factory.

The use of filters or attachments not recommended by the manufacturer may adversely affect water

purity, cause damage, and void the warranty.

Avoid contacting the dispensing point with foreign materials or hands to prevent contamination.

WARNING Warnings indicate failing to observe instructions could result in injury or death.

CAUTION Cautions indicate failing to observe instructions could result in damage to

equipment.

Page 6

Page 7

7

See Mounting Bracket Template

Page 8

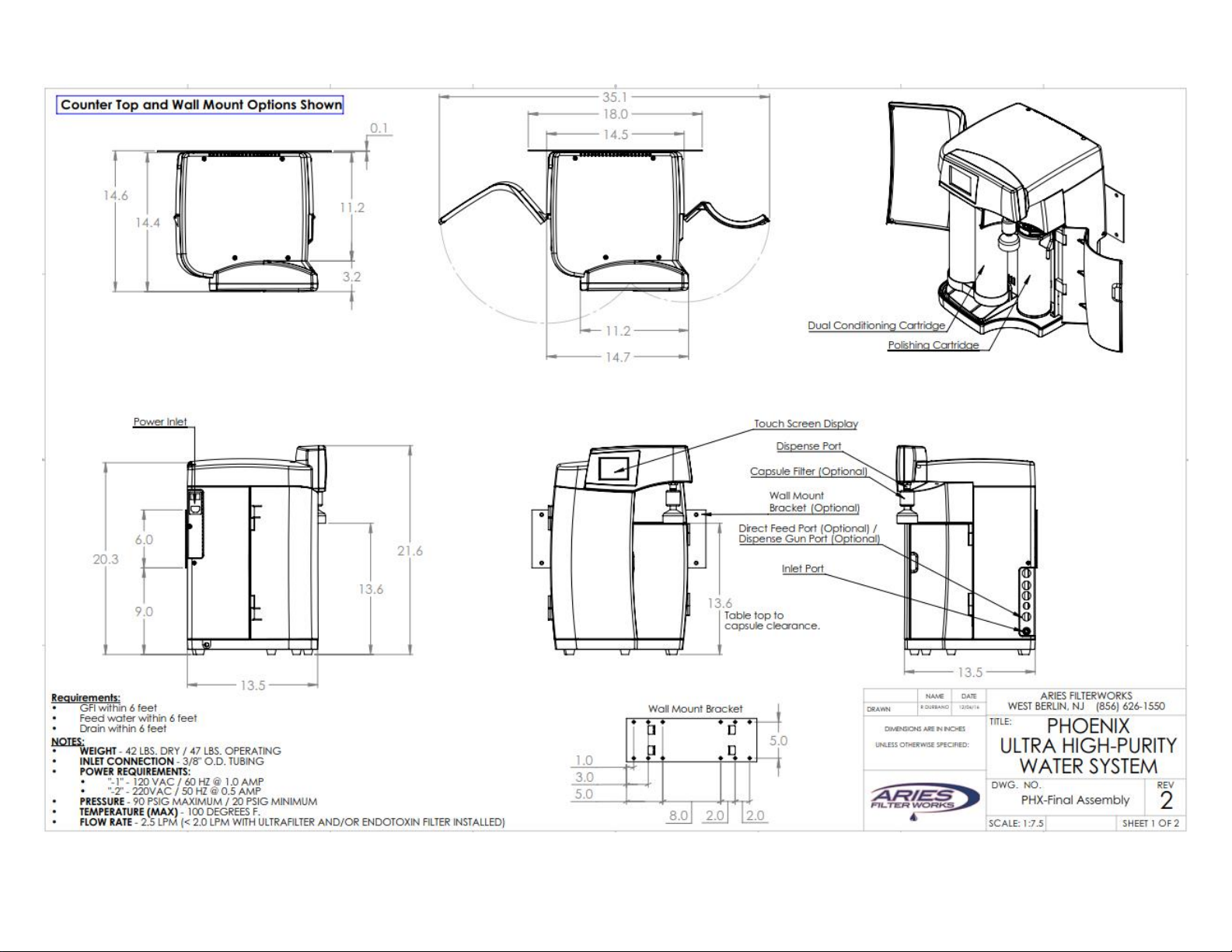

Installation

Installation Requirements

• Power Requirements:

o “-1” Option - 120 VAC/ 60 Hz @ 1.0 amp

o “-2” Option – 220VAC / 50 Hz @ 0.5 amp

• GFCI protected outlet within:

o 6 feet for system

WARNING: Must be a grounded electrical connection.

• Feed Water Supply: Water source meeting minimum requirements as shown

below and located within 3 feet of the system.

Parameter

Requirement

Source/Type

Reverse osmosis (RO) or Service deionization (SDI) preferred. 0.2µm

particulate prefiltering is recommended for SDI and tap water feeds.

Conductivity

RO: < 20µS/cm

SDI: > 1 MΩ (Resistivity)

TOC (Using appropriate

conditioning as necessary)

RO: < 50 ppb

SDI: < 200 ppb

Temperature

20° F to 100°F (5° C to 38°C)

Pressure

20 psig minimum/90 psig maximum (1.38 to 6.21 bar)

Fouling Index

Silt Density Index: < 3

Dissolved Carbon Dioxide

< 30 ppm

Free Chlorine

< .05 ppm

• An upstream isolation shut off valve is highly recommended to facilitate future

servicing

• The Phoenix is supplied with an inlet connection for 3/8” OD tubing

• The Phoenix is supplied with an outlet drain port for 3/8” OD tubing

What you will need:

• #2 Phillips Head Screw Driver

• Teflon Tape

• Upstream Isolation Valve (Recommended)

• Basic Hand Tools (Adjustable wrench)

What you’ll find in the box:

• Phoenix System

• Certificates of Conformance

• Instructions

• Power cord

• Final Filter (Point of Use Filter)

• Drain Fitting

• 6’ Length of 3/8” Diameter Inlet Tubing & Drain Tubing

Page 9

9

Optional (Depending on Model):

• UV Lamp (CITATION and GENOME)

• Dispensing Gun (PHA-DG)

• Remote dispense module and tubing (Models with –RMT-S Option)

• Wall mount bracket (PHA-WB)

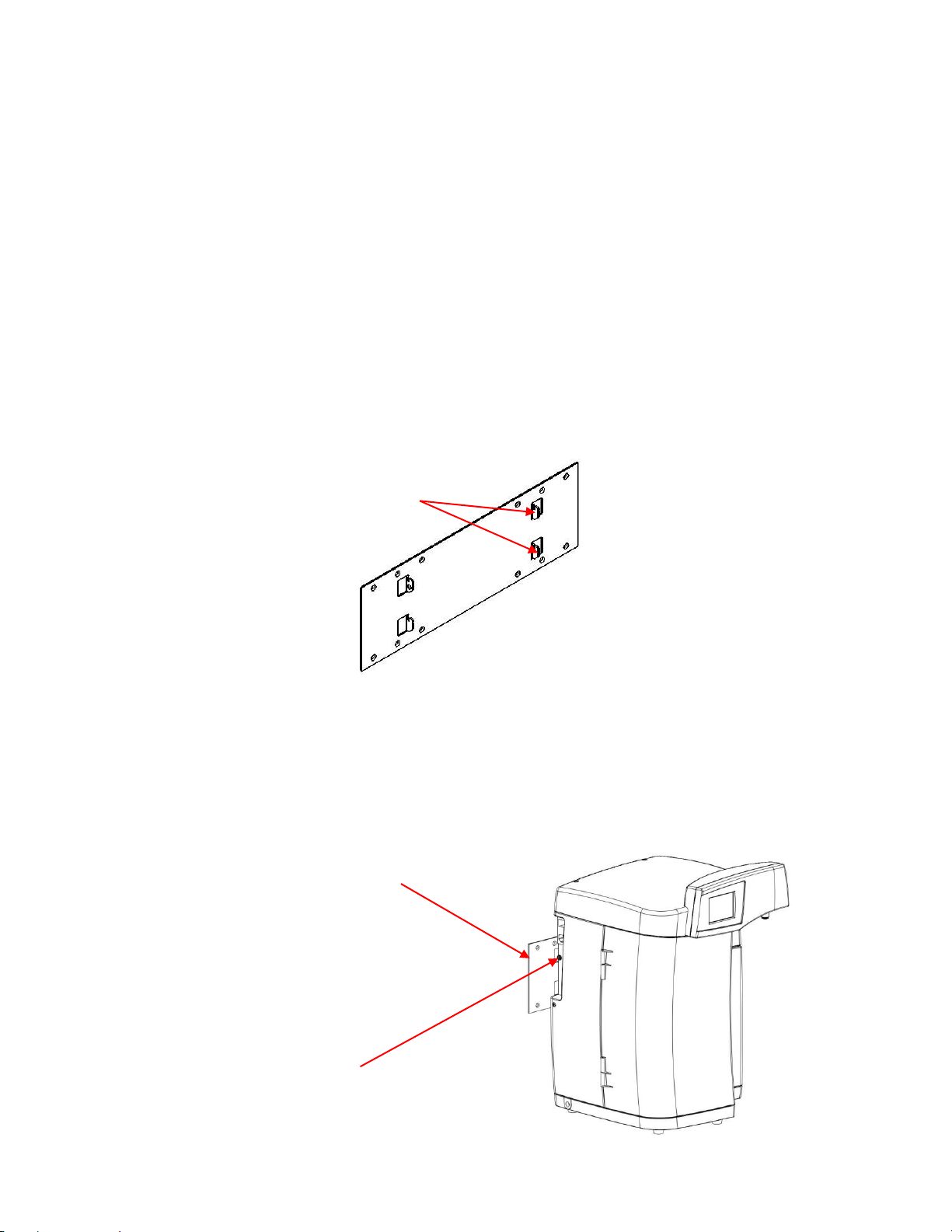

System Wall Mounting: Requires PHA-WB Wall Mount Bracket

• Mount on a wall capable of supporting 50 lbs. Mounting directly to sheet rock is not

recommended.

• Mount bracket to wall. Holes in bracket are provided at 8”, 12” and 16” centers for

wall studs. If wall does not have studs mount proper backing, such as a plywood sheet

to the wall before mounting the bracket to it.

• Mount bracket with small slots in tabs pointing up.

• Align slots in system back plate with tabs on mounting bracket. Insert tabs into slots

and slowly lower system. Ensure all tabs are fully engaged and base of system is

parallel to floor.

• To lock PHOENIX system to the bracket, insert rubber bushing with screw and washer

(provided) into frame as shown. Tighten screw to lock wall bracket to frame.

Wall mount bracket

Insert bushing assembly

here to lock system to

bracket

Tabs pointing up

Page 10

10

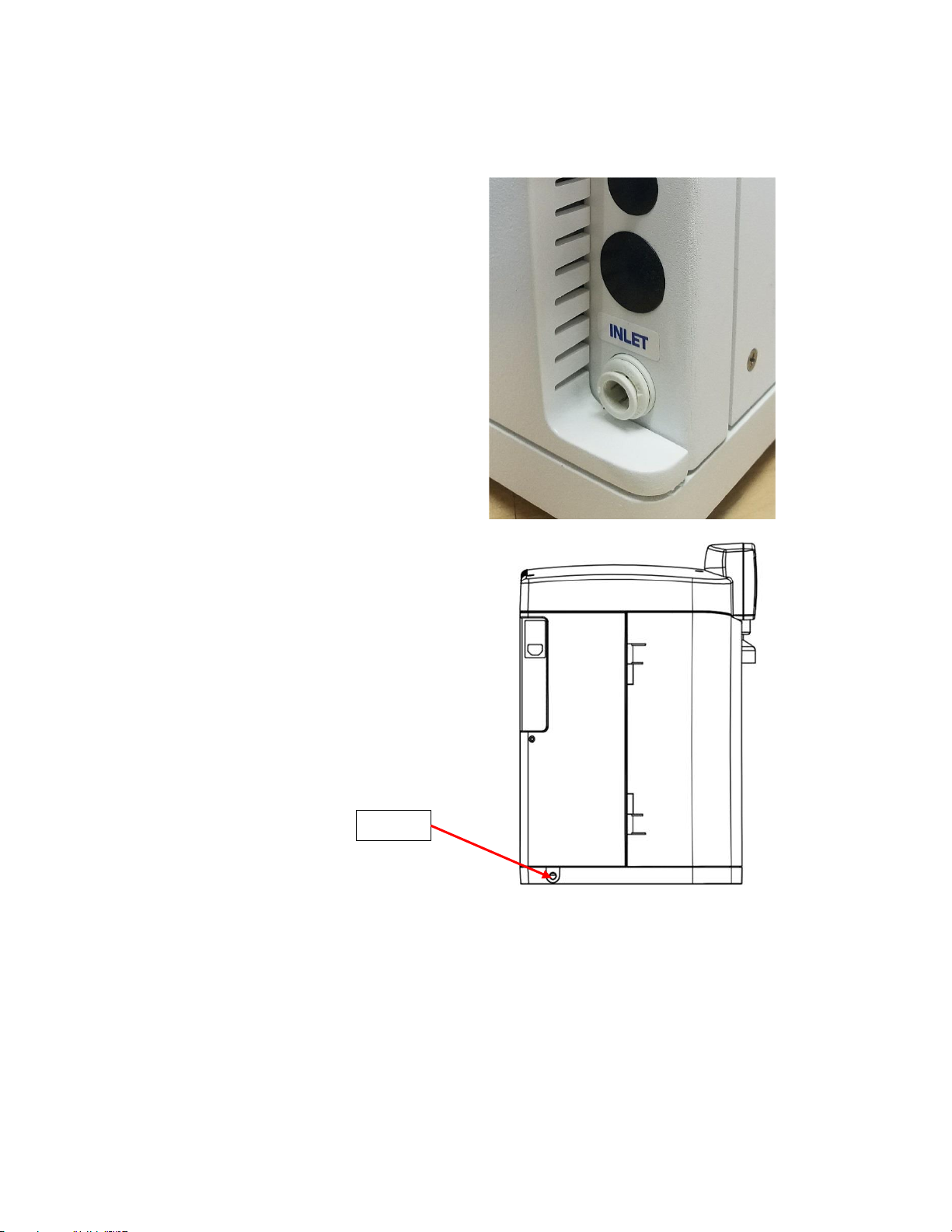

Water Connections – All Models

• 6 feet of tubing is provided for inlet

and drain connections.

• Feedwater inlet connection is made

through a 3/8” OD push to connect

fitting.

• Feedwater source should be located

within 3 feet of the Phoenix.

• The inlet is the bottom most fitting

on the right side of the Phoenix.

• Ensure tubing is pushed all the way

into fitting.

• An isolation shut off valve is

recommended for servicing purposes.

• Install supplied barbed drain fitting in

labeled drain opening on left side of

Phoenix.

• Insert 3/8” OD tubing (supplied) into

drain fitting and route the other end

to a suitable drain. If a leak occurs, it

will be contained by directing water

to the drain.

DRAIN

Page 11

11

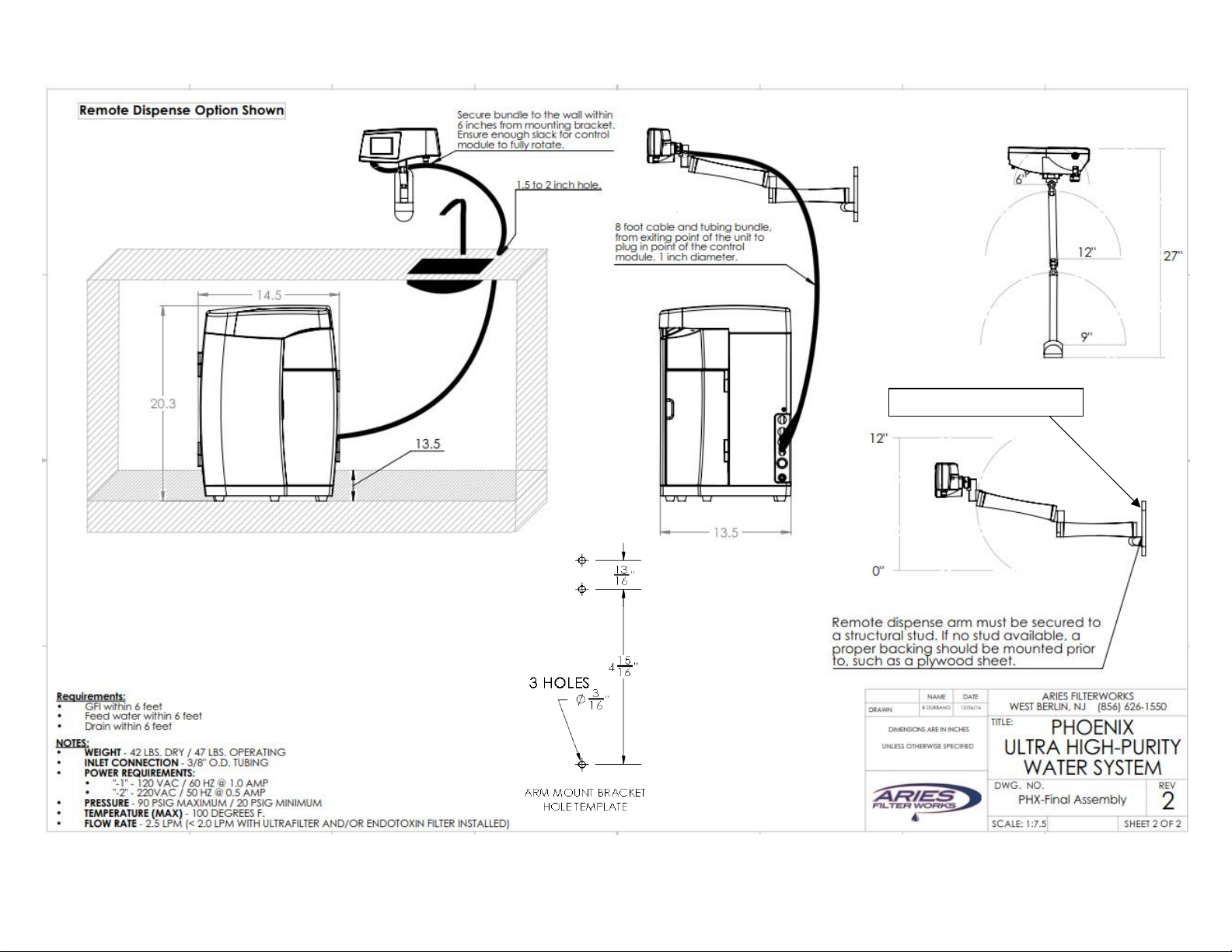

Remote Dispense (If Equipped)

Consideration should be given to location of the remote dispense module. Reference the diagram on

page 7. For example, the module can be mounted next to a sink so it would provide access to the sink

and adjacent countertop. The module can be mounted near the end of a countertop to provide access

to rolling carts for larger container fills as well as the countertop. Module should be mounted at a

height that provides access to the tallest container that will be used without blocking access to

cabinets.

For mounting the module, select a wall that is capable of supporting 20 lbs. The wall plate should be

mounted to a stud. Mounting directly to sheet rock is not recommended. If there is no stud at the

mounting location, mount proper backing such as a plywood sheet that is secured to studs before

mounting the plate to it.

Once a stud is located or support plate installed mark two holes on 5-13/16” centers and use a 3mm or

1/8” diameter drill to pre-drill holes to a depth of 2”. Use the two provided lag bolts to affix the plate.

While tightening the bolts ensure the mount is level.

10 feet of tubing is provided to connect the system and module. The system must located within this

distance bearing in mind that some slack should be allowed to provide access to the system for service.

Excess tubing can be coiled. 6 feet of drain tubing is also provided. Since the drain fitting is in the base

of the system, either access to a gravity fed floor drain or sump pump must be provided if the system is

installed below a sink. A 1-1/2” to 2” diameter hole must be provided where the umbilical containing

the water flow tubing and electrical connections will pass through a countertop.

Remote dispense electrical connection: Rotate connector to align tabs on umbilical plug with slots on

Phoenix socket and then insert plug. Repeat with the outer locking sleeve. When slots and tabs are

aligned, push and turn to lock connector in place.

Remote Dispense Water Connections

• Install upstream isolation valve in

feedwater line (recommended).

• Connect 3/8” OD white recirculation

return tubing from umbilical into

Return fitting.

• Connect 3/8” OD clear tubing from

umbilical into Outlet fitting.

• Make sure tubing is fully seated into

fittings.

Page 12

12

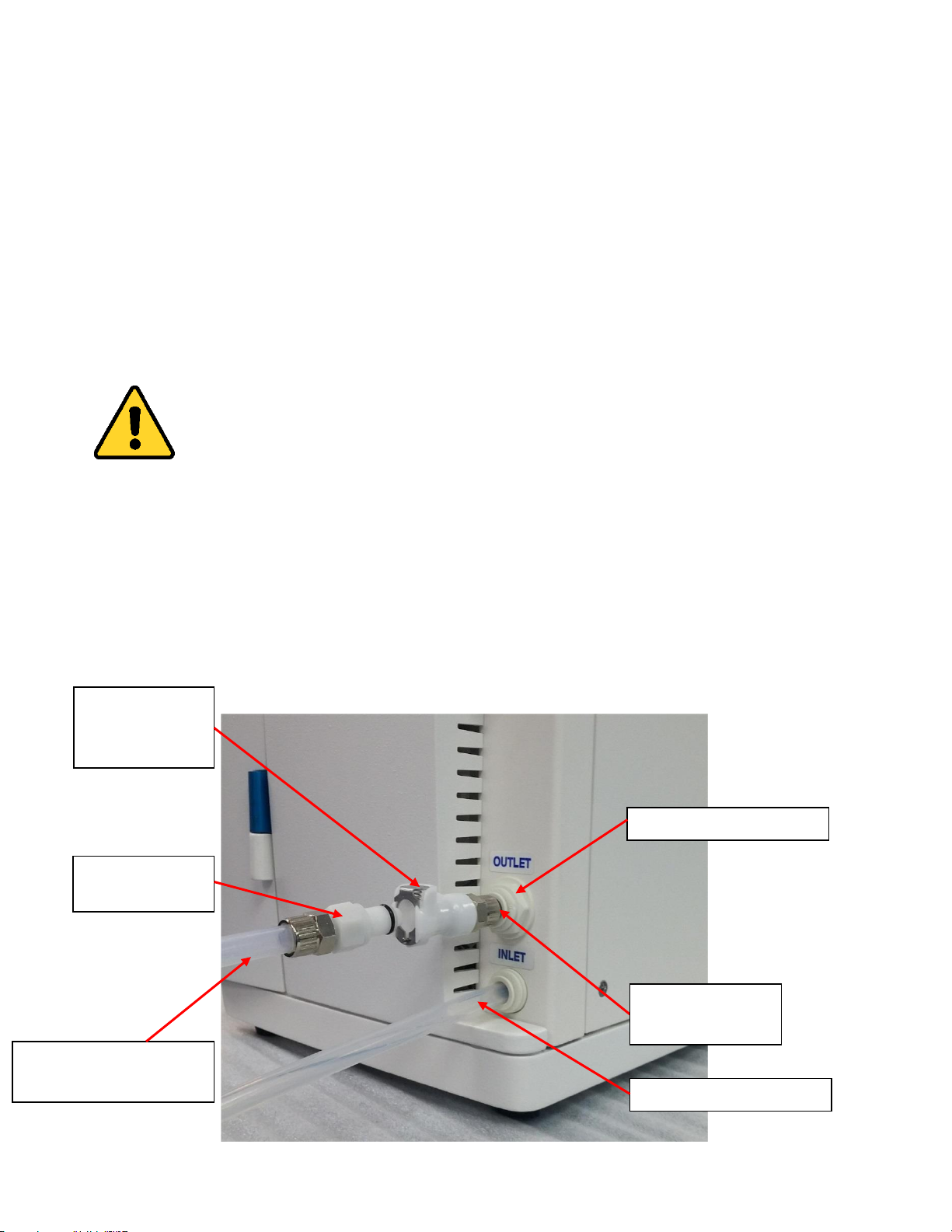

Direct Feed Water Connection

For systems plumbed with a direct feed option, an additional outlet port is provided on the side of

the system above the feed water inlet. To connect the system to the remote demand, a

male/female valved fitting has been supplied. When the two halves are detached water will not

flow from the direct feed outlet port.

The female side has a short 3/8” tube extension. This tube is inserted into the outlet port.

The male side (with O Ring) is provided already attached to a length of 3/8” OD plastic tubing.

The direct feed connection must be bled during initial rinse after bleeding the

cartridges. Place the outlet end of the tubing in a drain or container. Insert and

connect the male/female fittings as shown. The female fitting has a metal locking

collar to prevent separation. Pull on the connection to verify it is engaged and does

not leak.

Observe the water stream. When air bubbles no longer appear disconnect the fittings.

It is the user’s responsibility to connect the outlet tubing to their demand instrumentation

providing appropriate sizing adapters as necessary. After doing so, reconnect the male and female

connectors.

Caution: Using the standard dispense port while the direct feed option is in use will reduce the

system flow rate.

`

Direct feed outlet port

System feedwater inlet

To direct feed demand

(tubing provided)

Male connector

(provided)

Valved female

connector

(provided)

Insert tubing end

into outlet port

Page 13

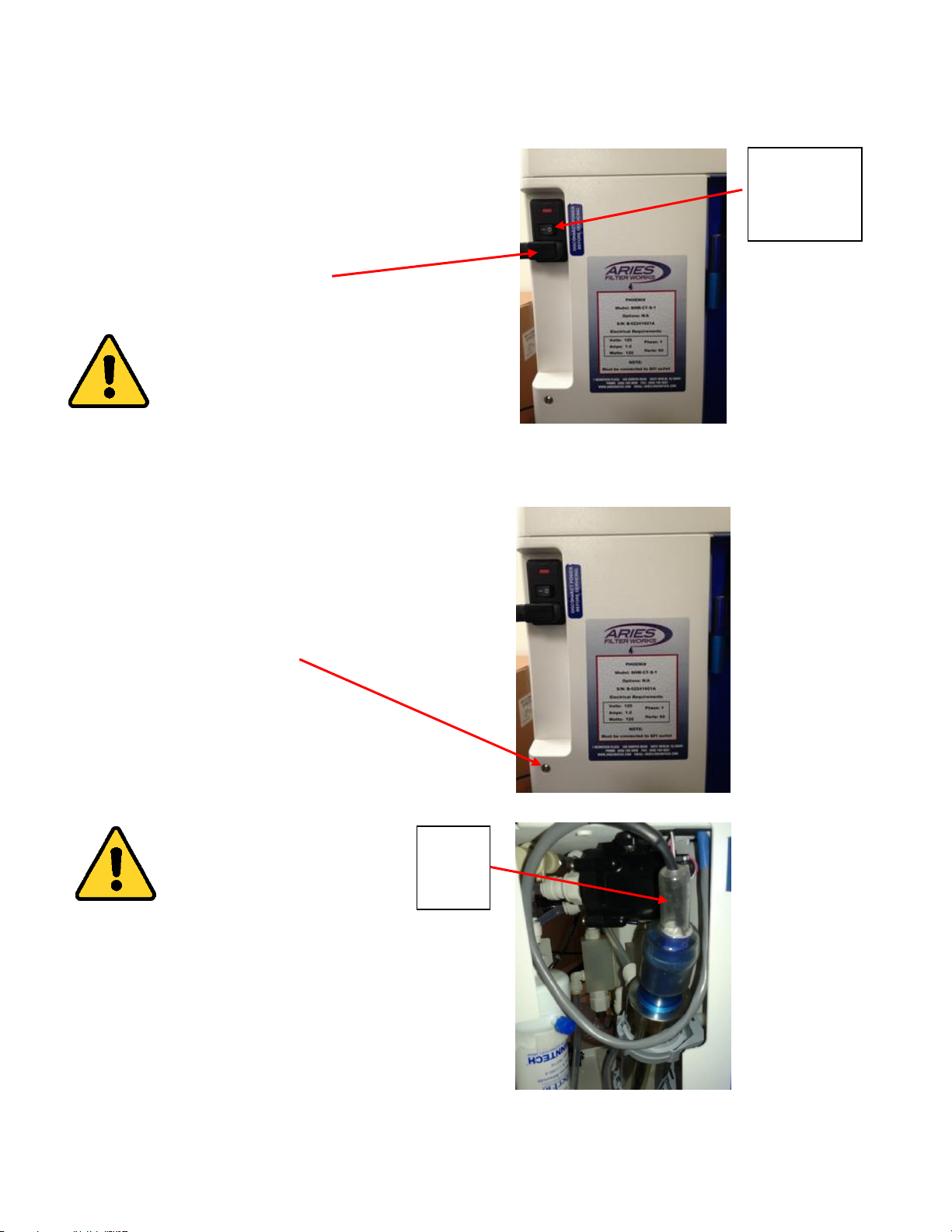

Electrical Connection

• Power switch is located on left side

of system

• Ensure power switch is in OFF

position

• Insert power cord into electrical

connection module

• Insert other end of cord into GFCI

power source

WARNING: Must be a grounded

electrical connection

UV Lamp (If not already installed) (ACADEMY and GENOME)

To install lamp:

• Remove left side panel access screw

• Remove left side panel

CAUTION: Wear gloves when

handling UV lamp to avoid

contaminating lamp

• Slide boot away from socket to

provide access for plug connection

• Connect lamp to socket before

placing lamp in UV chamber

• Insert lamp slowly into chamber

• Secure boot fully over socket

• Replace side panel

UV

lamp

boot

Electrical

connection

module

Page 14

14

Dual Conditioning Cartridge

• Remove cartridge from packaging

`

Caution: Remove plastic plugs

from inlet and outlet before

proceeding

• Open blue door and lift lever on left

side of dual conditioning cartridge

mechanism

• Insert conditioning cartridge. Align

base of cartridge with contour in

base of system

• Slowly lower lever making sure

fittings align with the openings in

the cartridge.

Caution: DO NOT APPLY

EXCESSIVE FORCE when

lowering lever or damage

may occur. Realign cartridge

and fittings if significant

resistance is felt.

• Ensure lever is in its fully down and

locked position

Page 15

15

Polishing Cartridge

• Remove cartridge from packaging

Caution: Remove plastic plugs

from inlet and outlet before

proceeding

• Open right side white door (It may be

convenient to open blue door as well)

• Raise and hold lever on right side of

mechanism

• Insert cartridge with openings facing

system

• Flanges on sides of cartridge cap rest

on alignment guide

• Push cartridge toward system until it

stops

• Slowly lower lever to secure cartridge.

Cartridge will be drawn into final

position by mechanism

• Ensure lever is in its fully down and

locked position

Alignment

guide

Page 16

16

Initializing the System for the First Time

Note: This is for the first time set-up only. In the on-screen directions you will be skipping steps

that would normally be required during consumable replacement.

Note: Some steps are applicable only to individual PHOENIX models. If your PHOENIX does not

have a UV lamp and/or Ultrafilter, these components will be greyed out on the Home Screen

Display.

• Ensure feed water supply is on and connected to system.

• Turn on power switch. Splash screen will display.

• Press START. Home Screen will display.

• After a 10 second delay, the pump will start and the system will begin the initial rinse cycle.

TO ACTIVATE THE ULTRAFILTER FOR BIOCHEM AND GENOME Models:

• Press and hold the ULTRA FILTER icon and press NEXT to initialize the Ultra Filter.

• Follow the instructions displayed.

o Skip on-screen instruction for Steps 5 and 6 as the ultrafilter is already installed.

o During Step 9, the purging process may take several minutes.

o Complete the procedure by pressing RESTART to return to the Home Screen.

TO ACTIVATE THE UV LAMP FOR CITATION and GENOME Models:

• From the Home Screen, press and hold the UV LAMP icon. Press NEXT to continue.

o Follow instructions displayed. It will not be necessary to replace lamp.

o Complete the procedure by pressing RESTART to return to the Home Screen.

TO ACTIVATE THE FILTER PACKS FOR ALL MODELS:

• From the Home Screen, press and hold the CONDITIONING icon. Press NEXT to continue.

o Follow instructions displayed. As this is the first time initialization process a new

pack should have been installed. It will not be necessary to replace the pack as

specified in the instructions.

o Complete the procedure by pressing RESTART to return to the Home Screen.

• From the Home Screen, press and hold the POLISHING icon. Press NEXT to continue.

o Follow instructions displayed. As this is the first time initialization process a new

filter should have been installed. It will not be necessary to replace the filter as

specified in the instructions.

o Complete the procedure by pressing RESTART to return to the Home Screen.

Page 17

17

• Remove the final filter from its packaging

• Wrap 3 to 5 turns of Teflon tape on the filter threads and install into the outlet.

o Place container under final filter.

o Press the dispense button.

o Purge air by slowly turning the vent port CCW until a steady stream of water is seen.

o Press the dispense button and retighten vent port once all air is purged.

Vent

Final filter (Point of Use Filter)

Page 18

18

Normal Operation

Normal sequence of operation:

Resistivity display will flash during the 2 hour initial rinse. After completion, the system enters

Polishing mode for 2 minutes in which the inlet solenoid is open and the pump is on. The UV lamp

is also on if equipped. Polishing mode recirculates water internally to maintain water purity. The

system continuously monitors water quality, system performance and consumable health. System

parameters for recirculation can be adjusted. See “Adjusting Recirculation Options”.

NOTE: Initial rinse can be bypassed to enter Polishing mode by holding the Initial Rinse button at

the bottom of the display for 3 seconds. This is useful if the system is restarted with previously

rinsed consumable packs.

Following Polishing, the system will automatically enter Standby mode and will display WAKE. This

is a 10 minute dwell to conserve system power and consumables. If equipped, the UV lamp is also

turned off. Standby mode can be bypassed by pressing the WAKE button to refresh water before

dispensing. If not bypassed the system will automatically enter Polishing mode at the end of the

dwell and will continue to alternate between Polishing and Standby.

Dispensing water will bring the system into Polishing mode if it is in Standby.

Final water quality after the Polishing filter (resistivity) is shown on the Home Screen. The value is

shown against a white background. Resistivity at the output of the conditioning pack can be

displayed by pressing the resistivity value. The display will change to a colored background

indicating it is the value after the conditioning pack. The display will return to final output water

quality after 5 seconds.

Direct feed operation (If equipped):

The system is equipped with a pressure switch that senses downstream water demand. When this

occurs the system enters direct feed mode and Direct Feed will display. The inlet solenoid and

pump will come on and remain running. The system will monitor the direct feed pressure and will

enter Polishing mode when demand stops for more than one minute.

Caution: The direct feed outlet connection must be bled during initial rinse after

bleeding the Dual Conditioning Cartridge and Polishing Cartridge. See the Direct

Feed Connection Section.

Water can be dispensed from the main outlet port during direct feed operation.

Page 19

19

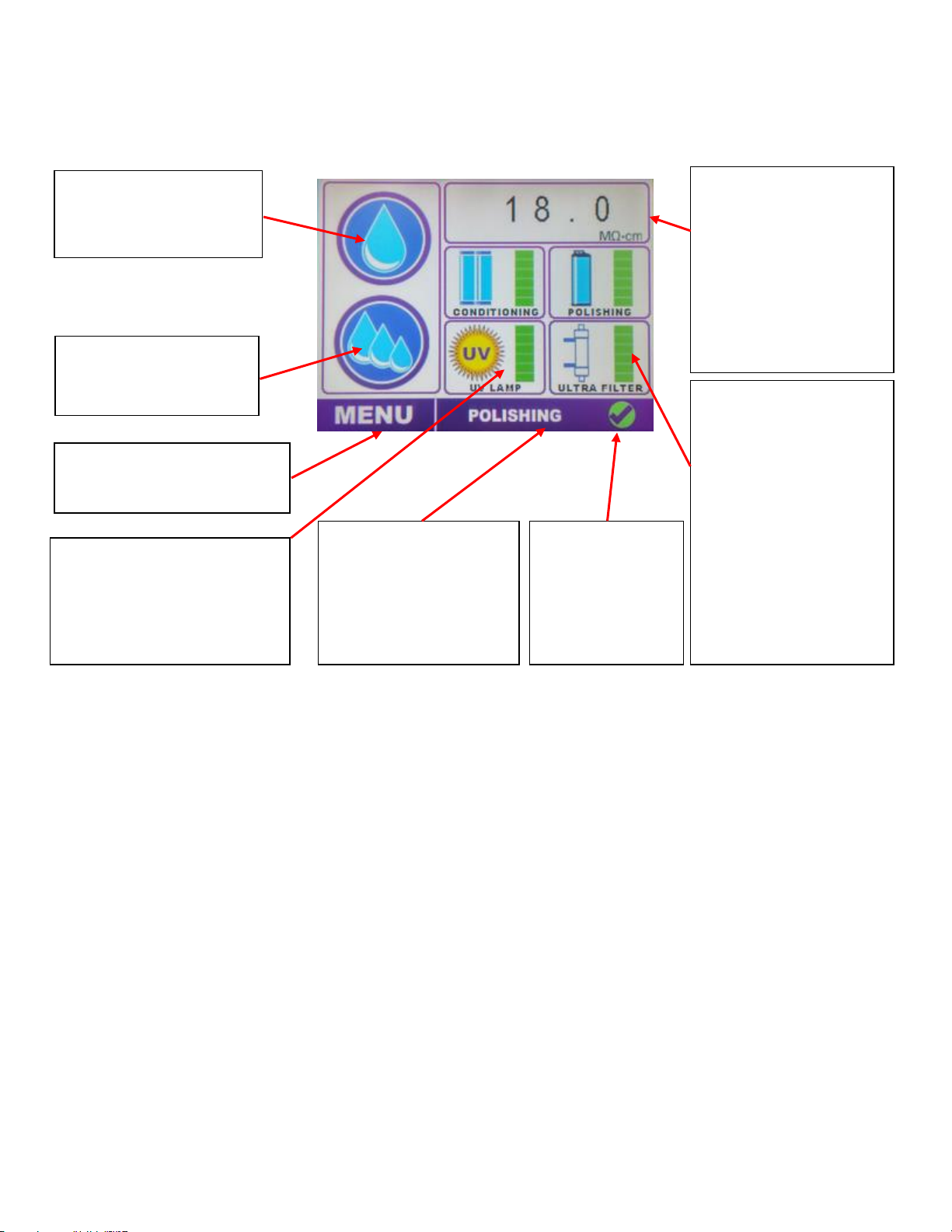

Home Screen

RECIRCULATION MODE

• INITIAL RINSE

• POLISH

• STANDBY

• DIRECT FEED

DISPENSE

Press to toggle

dispensing of water

RESISTIVITY

Displays Polishing

Cartridge resistivity.

Press to display

Conditioning Cartridge

resistivity. Press and

hold to display Alarm

set points

CONSUMABLE REPLACEMENT

ICONS

Press and hold any

component to display

replacement information

CONSUMABLE HEALTH

Displays current status

of consumables:

•

GREEN – Full life

•

YELLOW – Partial

life

•

RED – Needs

replacement

See MAINTENANCE

Section for more

details

BATCH

Press to display the

BATCH SELECT menu

MENU

Press to display Main Menu

ALARM STATUS

GREEN CHECK:

No Alarms

RED “X”:

Alarm present

Page 20

20

Batch Operations

To Dispense, Modify, Teach, Label or Clear a batch press the “Batch” button (the button showing 3 water

droplets). The Batch Select screen opens.

Main Screen

Batch Select Screen

To use a batch (1 through 6), to dispense a designated volume of water, press and release on its number

icon on the Batch Select screen.

To modify / teach / clear / label a batch, press and hold (about 3 seconds) the desired batch number icon

until a long beep is heard. The Batch Edit screen opens.

Batch

Button

Batch

Number

Icon

Displays Polishing

Cartridge resistivity

Page 21

21

Here a batch can be:

• Modified – changing a pre-recorded dispense time.

• Taught – manually dispense water while the system records the time. This will enable repeated

dispensing of a specific volume of water.

• Cleared – deleting saved batch information.

• Labeled – giving a specific batch a name.

• Saved – saving input information for future use.

Batch Edit Screen

To teach a batch, press the “Teach” button on the Batch Edit screen. The Batch Teach screen will appear.

• Place a volume measuring container capable of holding the desired volume underneath the

dispensing point of the system.

• Press the dispense button to begin flow.

• Monitor the volume output.

• Once the desired amount is reached, press the dispense button again. The system will

automatically retain the amount of time the dispense button was active, and return to the “Batch

Edit” screen.

Batch Teach Screen

Dispense

Button

Page 22

22

To modify a batch, press the “Modify” button on the Batch Edit screen. The Batch Modify screen will appear.

There are two ways to adjust the dispense time on this screen.

• Press the up and down buttons until the desired time (in seconds) is displayed.

Or:

• Press inside the time display box. Once pressed, a keypad will appear. Enter the desired time (in

seconds) and then press “ENT”. The system will return to the Batch Modify screen.

• Once the dispensing time is set, press “Enter”.

• The system will return to the Batch Edit screen.

Batch Modify Screen

To clear a batch, press the “Clear” button on the Batch Edit screen. The Batch Clear screen will appear.

• Press the “Clear” button. The saved information will be cleared.

• The system will return to the Batch Edit screen.

Batch Clear Screen

Up &

Down

Time

Page 23

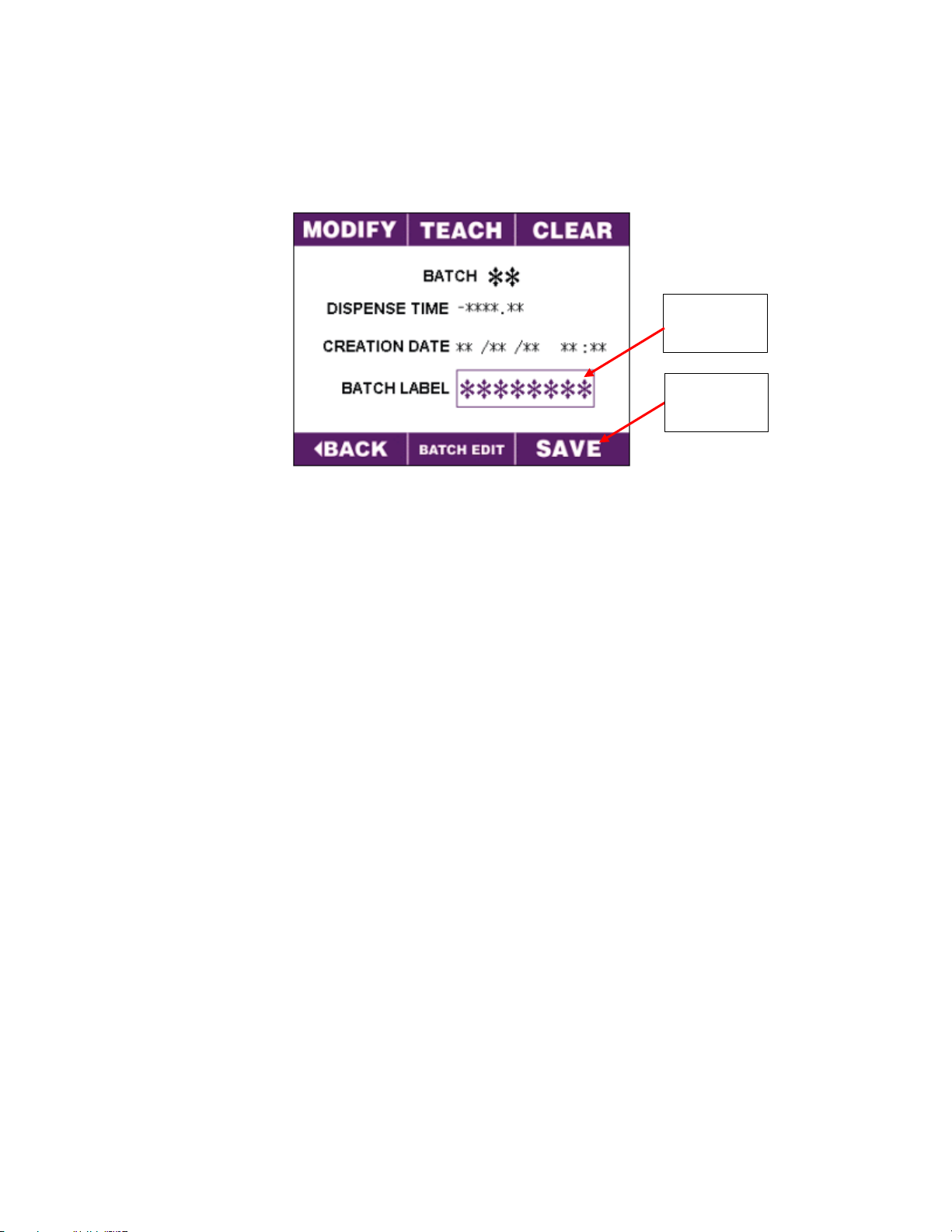

23

To Label a batch, press inside the “Batch Label” box.

• A keypad will appear, allowing you to enter in a desired name using up to 8 characters.

• Press “ENT” when done. The system will return to the Batch Edit screen.

To save new batch information or to complete batch deletion, press and hold the “Save” button on the

Batch Edit screen for 3 seconds until a long beep is heard. The system will return to the Batch Select

screen. If label was assigned, it will appear under the specific batch number icon. By pressing and

releasing the icon the modified/taught batch will dispense.

Batch

Label Box

Save

Button

Page 24

24

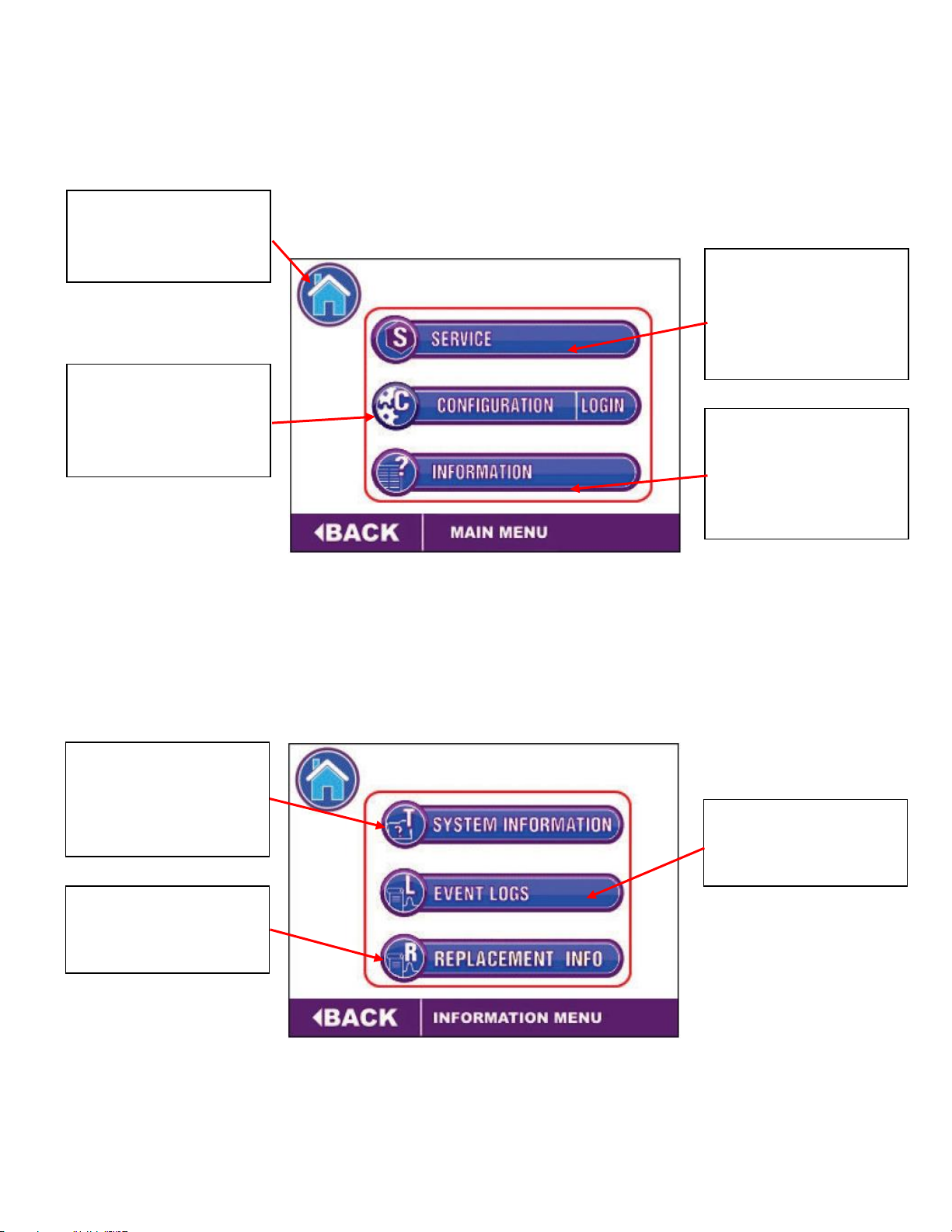

Main Menu

System Information

SERVICE

Displays Consumable

Replacement,

Sanitization, and

Service Information

HOME

Press to return to the

Home Screen

INFORMATION

Displays System

Information, Event

Logs, and Replacement

Info options

CONFIGURATION

Displays Alarm Setup,

Recirculation, and

Password options

SYSTEM INFORMATION

Displays system and

service contact

information

REPLACEMENT INFO

Displays projected

service dates

EVENT LOGS

Displays maintenance

log and alarm log

Page 25

25

Configuration Menu

Alarm Log (Example Screen)

PASSWORD

Factory preset

password for service

personnel only.

ALARM SETUP

Set resistivity alarm

options for

conditioning and

polishing cartridges

RECIRCULATION

Set Initial rinse time,

polish time, standby

time and sample delay

CLEAR

Clears the selected line

RESET

Resets alarm

conditions displayed on

home screen

Page 26

26

Filter Detection and Leak Detection Errors

CAUTION: After pressing OVERRIDE, the leak detector will NOT shut down the unit

even if water is detected.

LEAK DETECTED ERROR – Indicates a leak has been detected. Press

RESOLVE when the leak has been fixed or press OVERRIDE to override the

error for the next 4 hours.

FILTER PACK ERROR – Indicates one of the cartridges is not correctly engaged in the

system. Once the cartridge is in place, the user can proceed to reset the system.

Page 27

27

Maintenance

The system continuously monitors approximate remaining life of cartridges, UV lamp and

Ultrafilter. Current consumable condition and water resistivity is displayed on the HOME SCREEN.

A Maintenance Log is provided in the software. If preferred, a Maintenance Log template is

provided as an addendum that can be copied for future use, printed and distributed as required.

Sample software maintenance log

ALL MODELS:

Cartridge life is determined by a combination of elapsed time since installation and water

resistivity. The point at which the conditioning pack and polishing filter transition from green

health status to yellow can be adjusted. See the next section for adjustment instructions.

See the table below for default health meter resistivity settings:

Cartridge

Resistivity

Health Meter Color

Conditioning

> 12 MegΩ

Green

Between 2 MegΩ and 12 MegΩ

Yellow*

< 2 MegΩ (default alarm set point)

Red

Polishing

> 16 MegΩ

Green

Between 10 MegΩ and 16 MegΩ

Yellow*

< 10 MegΩ (default alarm set point)

Red

*If set point is adjusted, (see Resistivity Alarm Setup), yellow health meter color will appear at the

new set point.

Typical conditioning and polishing cartridge life is estimated at 4 - 6 months from date of

installation depending on usage. After six months a cartridge replacement alarm will be displayed.

It is the user’s prerogative to replace cartridges bearing in mind the currently displayed water

resistivity may still be acceptable. It is highly recommended cartridges be replaced at six months to

prevent biofilm generation that may occur over time.

Page 28

28

CITATION and GENOME:

UV lamp life is estimated at 2 years of normal use from date of installation. The UV lamp health

meter on the HOME SCREEN displays the proportional remaining life in this 2 year period as shown

below:

UV Lamp

Life Remaining

Health Meter Color

> 2 months

Green

Between 1 month and 2 months

Yellow

< 1 Month

Red

A replacement alarm will be displayed at 1 month remaining. It is recommended that the UV lamp

be replaced at that time to maintain low TOC levels.

GENOME Model:

Ultrafilter life is estimated at 1 year of normal use from date of installation. The Ultrafilter health

meter on the HOME SCREEN displays the proportional remaining life over this time period as

shown below:

0.05µm Ultrafilter

Life Remaining

Health Meter Color

> 6 months

Green

Between 1 months and 6 months

Yellow

< 1 Months

Red

A replacement alarm will be displayed at 2 months remaining. It is recommended the Ultrafilter be

replaced at that time to maintain acceptable bioburden.

Adjusting Resistivity Alarm Set Points

The point at which the conditioning pack and polishing filter transition from green health status to yellow

can be adjusted. Note: Software allows for a 2 MΩ range above the set point in which to change the health

meter display. Always make the set point 2MΩ below the desired display transition resistance. Maximum

set point allowed for conditioning is 10 MΩ and 14 MΩ for polishing.

To adjust the set points:

• Home Screen – Press Menu

• Main Menu – Press Configuration

• Configuration Menu – Press Alarm Setup

• Press appropriate field box; key pad will open

• Adjust values as required

• Press ENT to exit key pad

• Press and hold SAVE until beep is heard

• Press Home icon to return to Home Screen

Page 29

29

Adjusting Recirculation Options

The following operating parameters can be adjusted:

Initial Rinse – The time the system recirculates when restarted before converting to alternating

polishing and standby cycling. Default setting is 120 minutes.

NOTE: Initial rinse can be bypassed to enter Polishing mode by holding the Initial Rinse button at

the bottom of the display for 3 seconds. This is useful if the system is restarted with previously

rinsed consumable packs.

Polish Time – The time the system recirculates water to maintain purity. Default setting 2 minutes

Standby Time – Dwell time between polishing cycles to conserve resin life. Default setting 10

minutes

Sample Delay – The amount of time the system alternates between reading resistivity at the output

of the conditioning pack and the final water quality at the output of the polishing filter. Default

time is 10 seconds.

To adjust settings:

• Home Screen – Press Menu

• Main Menu – Press Configuration

• Press the appropriate field box; key pad will open

• Adjust value as required

• Press ENT to exit key pad

• Press and hold SAVE until beep is heard

• Press BACK to return to Configuration Menu

Press to adjust

conditioning

cartridge set point

Press to adjust

polishing filter set

point

Page 30

30

Sanitization

Sanitization is performed by circulating a chlorine dioxide (ClO2) solution throughout the system in

three sequential cycles of 10 minute dwell (standby) and 5 minute recirculation.

A sanitization kit is installed that contains the ClO2 in deactivated, packet form sealed inside a

polishing filter housing. It is not fully activated until exposed to water for approximately 20

minutes during the sanitization cycle. Under these conditions the sanitization kit is safe for

handling and installation without specialized PPE.

WARNING

Do not remove the orange sealing plugs from the sanitization polishing filter

housing until just before installation. If removed, moisture from the

environment will begin activation of the ClO2.

To begin the Sanitization cycle:

• Home Screen – Press Menu

• Main Menu – Press Service

• Service Menu – Press Sanitization

• Sanitization Information Screen – Press NEXT

• Sanitization Maintenance Screen – Follow on-screen directions

On-screen instructions call for installation of the kit. The kit contains a polishing filter replacement

housing that contains the ClO2 packet. NOTE: Save the orange plugs after removal from the

polishing filter housing. They will be used after sanitization to dispose of the filter.

The kit also contains a bypass tube that replaces the conditioning pack. This reduces the system

volume and speeds the overall sanitization process. To install the bypass tube after removing the

conditioning pack:

Page 31

31

Lower the conditioning pack lever to

expose the connectors and position the

bypass tube.

The locking tabs on the bypass tube

fittings should be facing outward

(towards you).

Insert one side of the bypass tube into

the connector until the locking tab

snaps into position. It will be necessary

to exert downward pressure on the

inner “U” frame to make this

connection.

Insert the other side of the bypass tube

until the locking tab snaps into

position. It will be necessary to exert

downward pressure on the inner “U”

frame to make this connection.

To remove the bypass tube after

sanitization, depress and hold each

locking tab and pull downward on the

tube to disconnect. Wear gloves

provided.

Connector

Lever

Locking tab

Bypass tube

Page 32

32

Sampling and completion of Sanitization:

• When you reach Sanitization Instruction Screen 5 you will start the 45 minute cycle by pressing

START CYCLE. The display shows the time remaining in the cycle.

• As water enters the polishing filter housing it will begin to activate the ClCO2.

• Install the supplied 3/8” barbed fitting into the dispense solenoid valve (where the POU filter was

removed)

• 6 feet of 3/8” ID clear vinyl tubing is provided in the kit. Connect the tubing to the barbed fitting.

Place the other end in a drain. NOTE: Insert the tubing directly into the drain, if possible, to

minimize odors.

WARNING

Chlorine dioxide gas is a respiratory irritant. Avoid breathing fumes. Ensure

area is sufficiently ventilated.

• When 20 - 25 minutes remaining is displayed put on gloves provided in the kit and dispense a small

amount of water from the drain tubing into a small, clean container. Do not allow tubing to touch

the collected water. Replace the tubing into the drain.

• Chlorine Dioxide test strips are provided in the kit. Use the white vial high range test strips to

confirm a minimum of 30 ppm chlorine in the sample by dipping a strip into the sample container.

Do not place the test strip directly under the running dispense water stream. Run water from the

sink when disposing of the water sample to minimize odor.

• When the cycle ends, follow instructions to dispense 2 – 4 liters of water to drain. Wearing gloves,

take an additional water sample from the drain tubing into a small, clean container as above and use

the blue vial low range test strips to confirm <10 ppm of chlorine. If a greater amount is present

dispense an additional 2 – 4 liters and retest. Continue this process until <10 ppm is obtained.

• Follow on-screen instructions to return system to normal operation.

NOTE: Dispose of the polishing filter by emptying into a sink while flushing with tap water or by

replacing the orange plugs and discarding. In this case no additional precautions are required. If

emptying, replace orange plugs before discarding.

Blue vial test strips for low range chlorine

White vial test strips for high range chlorine

Page 33

33

Troubleshooting

This troubleshooting guide contains information that pertains to all PHOENIX models. Some

symptoms and remedies refer to specific models based on their installed technology.

TROUBLESHOOTING GUIDE

SYMPTOM

CAUSE

REMEDY

Display is off.

No power to the unit or

unit in Stand By mode.

Check that the unit is plugged

into a live outlet.

Check the unit’s fuse – replace it

if it is blown.

Unit blows fuses.

An electrical short exists

in the unit or there is a

defective component.

Return the unit to the factory for

repairs or have the unit serviced

by an authorized dealer.

Unit will not dispense

water.

Supply water is not on.

Confirm that the supply water is

turned on.

A cartridge is loaded

with particles and is

plugged.

Replace the cartridge(s).

Air trapped in the

system.

Refer to symptom “Air is getting

trapped in system”

Defective solenoid

valve.

Have unit serviced by an

authorized dealer or return to

factory.

Low flow rate.

Water supply is

blocked.

Clear restriction or check water

supply.

Air is getting trapped in

the system.

Refer to symptom “Air is getting

trapped in system”

Sub-micron point of use

filter is clogged.

It is recommended to replace

sub-micron filters at scheduled

intervals not to exceed one year.

Low water pressure.

If line pressure is below 30 psi,

install booster pump.

Display indicates water

purity is below set-point.

The supply water is

improperly treated.

Measure supply water TDS in

grains per gallon, ppm, or mg/L

and compare to system spec

sheet requirements. Add

additional pretreatment to

obtain higher quality.

Resin is exhausted.

Install fresh cartridges.

Page 34

34

SYMPTOM

CAUSE

REMEDY

Resin cartridges exhaust

quickly.

Improper flow rate.

Check flow rate using a timed fill

test or by directly measuring with

an inline flow meter. Compare

results to filter or system spec

sheet and adjust flow as

necessary.

Internal pressure regulator may

be out of adjustment. Have unit

serviced by an authorized dealer

or return to factory.

The supply water has colloids

and is improperly treated.

Perform a Silt Density Test. If it is

higher than 1 add additional

pretreatment.

Bacteria exceeds operating

specifications.

UV lamp is not working

(CITATION and GENOME)

Confirm lamp is functioning by

checking the LED indicator light

above conditioning pack.

Confirm lamp is seated in the

socket.

Confirm lamp has not been in

service for more than one (1)

year.

Replace lamp with part number

HPA-016

The system has been stagnant

for an excessive period of

time.

Follow sanitization procedure in

Menu using Sanitization Kit P/N

HPA-017

The feed water supply is

grossly fouled.

Sanitize feed water supply

system. Then follow sanitization

procedure in Menu using

Sanitization Kit P/N HPA-017

The system is fouled with

contaminants.

Replace the point of use 0.2

micron filter.

Replace cartridges according to

the product number appearing

on each cartridge.

Replace the internal 0.05 micron

filter. (BIO)

Replace the 0.2 micron filter

attached to the dispense gun

(systems with this option)

Pyrogen levels are

excessive after the optional

0.05 micron filter.

Contaminated 0.05 micron

ultrafilter.

Autoclave or replace the

Ultrafilter.

Page 35

35

SYMPTOM

CAUSE

REMEDY

Unit does not rinse-up to

desired resistivity.

New units or cartridge

replacements require more

time to rinse-up.

Allow more time when installing

or replacing media.

Use a hand-held resistivity meter

to check that the resistivity is

increasing over time

Air is getting trapped in the

system.

The system is open to

atmosphere.

Bleed air at high points in

plumbing system and/or filter

housing. Use vent valve supplied

where applicable.

Excessive flow, turbulence,

and/or cavitation can cause

gases to come out of solution.

Check flow and velocity

throughout system to ensure it

does not exceed filter

requirements or industry

standards.

The point of use 0.2 micron

filter is bound with air.

Bleed the filter by opening the

bleed valve and allowing water

to flow until all air is expelled.

The 0.05 micron filter is

bound with air. (BIOCHEM

and GENOME)

Bleed the filter by opening the

bleed valve and allowing

water to flow until all air is

expelled.

Page 36

Specification Sheet

Page 37

Page 38

38

Reordering Information

Cartridges and Filters

PX-13-5001

Phoenix Dual Conditioning Cartridge (RO Feed)

PX-13-5002

Phoenix Dual Conditioning Cartridge (SDI / Tap Water Feed)

PX-11-5103

Phoenix Polishing Ultrapure Cartridge

PX-11-5104

Phoenix Polishing Ultrapure Low Organics Cartridge

PF-00-6402

0.2µm Capsule Filter – ¼” MNPT x ¼” hose barb

PF-00-7101

0.2µm Endotoxin Removal Capsule Filter – ¼” MNPT x ¼” hose barb

Consumables

PF-00-7105

Phoenix Ultrafilter – 3/8 Quick Disconnect Fittings

HPA-016

Phoenix UV Bulb 254/185 nm TOC Destruction

HPA-017

Sanitization Kit (includes cartridges, test strips and gloves)

Requesting Service

Should the PHOENIX water purification system require maintenance or repairs not addressed in the

Troubleshooting or Maintenance routines, turn power to PHOENIX unit off and contact Technical Support

or your Service Professional

117 Jackson Road

West Berlin, NJ 08091

Phone: (856) 626-1550

Fax: (856) 626-1551

www.ariesfilterworks.com

Email: ariescs@resintech.com

Entering Your Service Professional’s Contact Info

You may add your Service Professional’s contact info on the Service Information screen as follows:

• Home Screen – Press Menu

• Main Menu – Press Information

• Information Menu – Press System Information

• Press Company Name field box; keypad appears

• Enter Service Contact’s Information; Press ENT to return to System Information Screen

• Press Phone Number field box; keypad appears

• Enter Service Contact’s Information; Press ENT to return to System Information Screen

• Press Home to return to the Home Screen

Be prepared to provide the representative with the model number, serial number, date of purchase and any

options that may have been purchased with or added to the unit after purchase; as recorded on page (3)

of this manual. This information may also be found on the system label.

Next, be prepared to describe to our service representative the symptoms that the unit exhibits.

Page 39

PHOENIX WATER PURIFICATION SYSTEM MAINTENANCE LOG

S/N:

DATE INSTALLED:

ASSET # or ID:

LOCATION:

DATE

MAINTENANCE PERFORMED

BY

COMMENTS

Page 40

40

DATE

MAINTENANCE PERFORMED

BY

COMMENTS

Page 41

41

DATE

MAINTENANCE PERFORMED

BY

COMMENTS

Loading...

Loading...