Phoenix 4800 E Owner's Manual

4201 Lien Rd. • Madison, WI 53704

Owner’s Manual — Phoenix 4800 E

Industrial Desiccant Dehumidifier

Installation, Operation & Service Instructions

Read and Save These Instructions

Congratulations on your purchase of the Phoenix 4800E

dehumidier. This dehumidier offers the nest in air-drying

equipment. However, this machine can only provide maximum

service and performance if properly installed, operated and

maintained.

This owner’s manual is provided to acquaint you with the

dehumidier so that the installation, operation and maintenance

can proceed successfully. Ultimate satisfaction depends on the

quality of the installation and thorough understanding of the

operation of this equipment. The dehumidier is built around

tested engineering principles and has passed a thorough

inspection for quality of workmanship and function.

• 3032 pints/day AHAM

• 4800 CFM process airow

• Dries in temperatures to 140ºF

• Reaches dew points as low as -40ºF

Specifications subject to change without notice.

Phoenix 4800E

(with Frame)

PN 4028003

Phoenix 4800E

(without Frame)

PN 4029191

The Phoenix 4800 E

• 48”W x 120”L x 74”H

• 1600 lbs. (Standard

machine weight only)

• 480 volt 3-phase

• 106 full load amps

TS-451d 06/11

1

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Table of Contents

Introduction .............................................................................1

1. Specications ..................................................................2

2. Operation .........................................................................2

2.1 How the Phoenix 4800E Works ............................... 3

3. Installation .......................................................................3

3.1 Inspection ..................................................................3

3.2 Location .....................................................................3

3.3 Set-Up.........................................................................3

3.4 Ducting ....................................................................... 4

3.5 Avoiding Secondary damage .................................... 4

3.6 Electrical Requirements ............................................4

4. Operation Instructions ....................................................4

4.1 Connect and Start-Up Procedure .............................4

4.2 Cool Down .................................................................. 5

4.3 Shut Down and Disconnect Procedure .................... 5

5. Control Panel ...................................................................5

5.1 Main Disconnect ........................................................5

5.2 Standby Light ............................................................. 5

5.3 Phase Out ..................................................................5

5.4 Selector Switch .......................................................... 5

5.5 Alarm (Light and Horn) .............................................. 5

5.6 Hour Meter ................................................................. 5

6. Maintenance .................................................................... 5

6.1 General Maintenance ...............................................5

6.2 Cabinet ....................................................................... 5

6.3 Filter ...........................................................................5

6.4 Blower and Motor ...................................................... 6

6.5 Drive Motor ................................................................ 6

6.6 Rotor Drive Chain ...................................................... 6

6.7 Seals ..........................................................................6

6.8 Desiccant Media .......................................................6

7. Wiring Diagram ...............................................................7

8. Trouble Shooting ............................................................10

9. Detailed Sequence of Events .......................................11

10. Service Parts List ...........................................................12

11. Warranty .........................................................................13

Serial No.__________________________________

Purchase Date_____________________________

1 Specifications

Specifications for 4800E

Part No. 4028003 (with Frame)

Part No. 4029191 (without Frame)

Power 480 VAC, 3-Phase, 106 FLA

Water 3032 pints/day @ AHAM

Removal

Blower 4800 CFM Process Air Flow

2000 CFM Reactivation Air Flow

Operating -10ºF to 140ºF

Range

Filters Process lter size: (2) 20” x 20” x 2”

Reactivation lter size: (1) 20” x 20” x 2”

Duct Options Process Inlet: 18” Flex-Duct

Process Outlet: 18” Flex-Duct/Lay Flat

Reactivation Inlet: 18” Flex-Duct

Reactivation Outlet: 10” Flex-Duct

Warranty 2 years:

1st year Parts and Service

2nd year Silica Gel Rotor

Dimensions

Width 48”

Height 74”

Length 120”

Weight 1600 lb

Accessories

4028361 10” Flex-Duct

4028364 18” Flex-Duct

4028374 18” Lay Flat Duct

4024440 Kestrel 3000 Multi-Function Air Meter

4027327 External Temperature control

4020175 External Dehumidistat

4029003 Power Cord Grip

Air Filter Replacement

4028635 20” x 20” x 2” Filter

Machine

Dealer’s Name_____________________________

Read the operation and maintenance instructions carefully

before using this unit. Proper adherence to these instructions

is essential to obtain maximum benet from your Phoenix

4800E.

2 Operation

The function of the dehumidier is to remove moisture (in

the vapor state) from an air stream. This is accomplished

by exposing the air to an adsorbing media (desiccant) in

a sealed air stream (process). After the desiccant has

2

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

adsorbed moisture, it is exposed to a second air stream at an

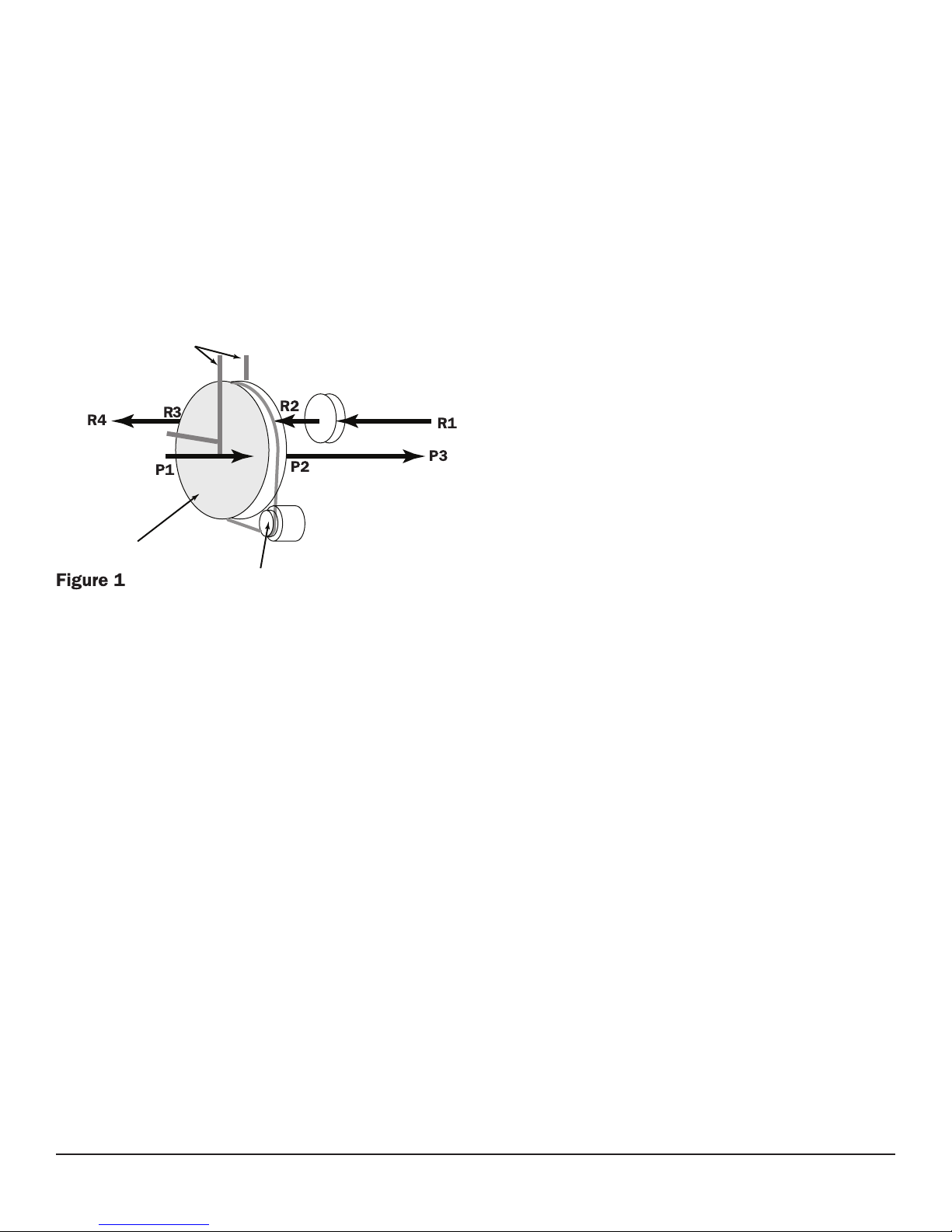

Principle of Operation

Drive and Chain

elevated temperature (reactivation). This causes the moisture

to be driven out of the desiccant preparing it for more

moisture adsorption. This process is done on a continuous

basis, providing a constant drying process. The two air

streams (process and reactivation) are separated by seals,

which contact the desiccant media. Figure 1 illustrates the

relationship of the seals and airow pattern. The dehumidier

is designed with the two air streams owing in opposite

directions (counter ow) thereby maximizing the energy

efciency of the equipment.

Cabinet Divider

and Seals

Heater

Reactivation Air Outlet

Reactivation Air Inlet

3 Installation

Proper installation is critical to the performance of the

Phoenix 4800E. Follow the guidelines below to maximize

service life and performance.

3.1 Inspection

Thoroughly inspect the machine to insure no damage has

occurred during shipping or on the job site.

3.2 Location

Note the following precautions when locating the Phoenix

4800E:

The 4800E is designed to be used indoors or outdoors.

If the humid area is very large, dehumidication can be

improved by adding an outlet duct to circulate process air to

stagnant areas.

Process Air Inlet

Process Air Outlet

Desiccant Wheel

Desiccant Wheel

2.1 How the Phoenix 4800E Works

The Phoenix 4800E has two separate air streams that run

through it – Process and Reactivation (Fig. 1).

Process Air Stream:

P1 – 4800 CFM of air enters the machine (Process Air Inlet)

and...

P2 – ...water vapor from incoming air is deposited (adsorbed)

on the desiccant wheel.

P3 – 4800 CFM of dry air exits the machine (Process Air

Outlet).

Reactivation Air Stream:

R1 – 2000 CFM of air enters the machine (Reactivation Air

Inlet) and...

R2 – passes over the heater coils.

R3 – Water vapor is picked up (desorbed) from the desiccant

wheel by the hot air and...

R4 – ... 2000 CFM of wet air exits the machine (Reactivation

Air Outlet).

3.3 Set-Up

When conditions warrant the use of a desiccant dehumidier,

use one of the setups described below to achieve efcient

drying, while avoiding secondary damage. Review Section

2.1 to understand the desiccant drying process. Always

ensure that the Reactivation Outlet duct is vented to the

outdoors to minimize the possibility of secondary damage.

Neutral Pressure Setup

Many drying applications require neutral pressure operation.

In this setup, the Process Air Inlet pulls air from the affected

area (drying chamber) and returns dried, processed air to the

affected area via the Process Air Outlet.

The Reactivation Air Inlet and Outlet are both ducted to the

outdoors (or left open if the unit is set up outside).

Positive Pressure Setup

For Positive Pressure operation, the Process Air Inlet pulls air

from outside the drying chamber, while the Process Air Outlet

is ducted into the chamber.

The Reactivation Air Inlet and Outlet are both ducted to the

outdoors (or left open if the unit is set up outside).

3

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

3.4 Ducting

The duct requirements of the 4800E are much more critical

than those of refrigerant-based dehumidiers. ALL SUPPLY

AND RETURN AIR DUCTING FOR THE 4800E MUST BE

AIR AND VAPOR TIGHT. This is extremely important for

proper performance. Ensure that reactivation discharge air

does not enter the process or reactivation inlets.

Using excess duct length signicantly reduces air ow volume

through duct. This is true in any application. If the job at hand

needs a short length of duct, cut a section to the appropriate

length. If air ow is restricted by excess length, performance

will suffer. The same can be said of excess bends in the

ducting.

Two different duct sizes are used on the 4800E. All ducting

materials are available from Therma-Stor LLC

(see accessories list in Section 1).

Process inlet / Reactivation inlet: 18” flex duct.

To attach ex ducts to the process air intake, push the wire

of the rst few loops beyond the 2 holes in the duct collar.

Push the metal rod through the duct and duct collar piercing

the duct in two places. Tape or a hose clamp can be used

to create an airtight seal. Alternatively, the duct wire can be

pushed past the weld beads on the duct collar and the duct

can be secured with hose clamps or ratcheting straps. If

using only one inlet connection, the other can be left closed.

Process outlet: 18” flex or lay flat plastic duct.

To attach ex ducts to the process air outlet, push the wire

of the rst few loops beyond the 2 holes in the duct collar.

Push the metal rod through the duct and duct collar piercing

the duct in two places. Tape or a hose clamp can be used

to create an airtight seal. Alternatively, the duct wire can be

pushed past the weld beads on the duct collar and the duct

can be secured with hose clamps or ratcheting straps.

When using 18” lay at ducting, slip over the outlet collar and

zip-tie or duct tape in place.

Reactivation outlet: 10” flex duct.

To attach ex duct to the reactivation air outlet, push the

wire of the rst couple of loops beyond the weld beads on an

outlet collar. Secure with hose clamp.

3.5 Avoiding Secondary Damage

The Phoenix 4800E is a powerful tool capable of removing

a great deal of water from most environments. Care must

be taken to avoid secondary damage of over-drying and or

unexpected condensation.

The Phoenix 4800E removes vapor water from the

incoming process air stream and transfers it to the outgoing

reactivation air stream. The reactivation exhaust air is hot

and wet.

Take care to prevent the reactivation exhaust air stream from

causing secondary damage due to condensation.

If the exhaust from reactivation air stream cools below its

dew point, liquid water will condense inside the duct work

creating puddles. If the reactivation exhaust air stream is not

exhausted completely from the structure it can also cause

secondary water damage.

The Phoenix 4800E does not produce liquid water internal

to the machine. There is no condensate pump and no drain

hose.

The 4800E desiccant dehumidier will continue to remove

water from already dry, cold air. It is possible to over-dry

objects and or structures.

Care must be taken to avoid secondary damage due to overdrying.

3.6 Electrical Requirements

A 480 volt, 3 phase power source is required to operate the

Phoenix 4800E.

All local and state codes must be strictly adhered to and

good electrical practices should be followed to achieve the

best installation possible. The 4800E must be properly wired

to an adequate power source. Serious damage to the motors

and controls can occur if incorrect voltage is applied.

(See Electrical Schematic drawing in the back of this manual

for internal wiring.)

4 Operating Instructions

Refer to the Operating Instructions label located next to the

control panel of your 4800E.

User-supplied power cord, cord grip, and branch protection

appropriate for the electrical load must be supplied. See

device for FLA rating.

The Phoenix 4800E dehumidier comes complete and ready

for operation. All that is required is to provide the proper

power source and duct connections (described above).

4.1 Connect and Start-Up Procedure

1) Lockout Power Source.

2) Wire unit 480 Volt 3 Phase.

3) Verify Selector Switch is set to STANDBY.

4) Engage Power Source and turn Main Disconnect to ON.

5) Verify PHASE OUT light is off, if not, re-wire power

source to correct phase order.

6) COOL DOWN light will come on for 5 minutes.

7) Set Selector Switch to RUN.

8) Set process damper to obtain a maximum of 1.5”

water column pressure as read on pressure gauge.

4

www.UsePhoenix.com • sales@UsePhoenix.comToll-Free 1-800-533-7533

Loading...

Loading...