Phoenix 200 HT LGR Owner's Manual

PO Box 8680 • Madison, WI 53708

Owner’s Manual — 200 HT LGR Dehumidifier

Installation, Operation and Service Instructions

Read and Save These Instructions

The Phoenix 200 HT features LGR (low grain refrigerant) technology. This technology enables the 200 HT to remove more

water and create more grain depression than standard refrigerant dehumidifiers.

Combined with this performance, the multiple ducting and the superior high temperature performance makes the Phoenix

200 HT the most effective and versatile drying device made.

Patented

BYPASS

The Phoenix 200 HT

LGR Dehumidifier

In-Board Wheels - Reduces outer dimensions for

tighter storage setups and does not catch on

obstructions for easier movement around the jobsite.

Recessed Condensate Hose - Does not catch on

obstructions and allows for dense storage setups by

reducing overall width of the unit.

Patented Bypass Technology

Increased Capacity - The Phoenix 200 HT removes 5%

more water than the 200 MAX.

Improved High-Ambient Performance - Patent pending

technology allows superior efficiency in high-ambient

conditions.

Focused Airflow - Patent pending focused outlet directs

air toward the most wet surface.

335 CFM - More processed air speeds drying and

provides superior static pressure for ducting.

More Grain Depression - The driest air from an LGR

gets your jobs drier quicker.

Air Filter - A MERV-11 is standard.

Multiple Ducting Options - 12” intake, 10” exhaust.

Energy Efficiency - Draws 7.5 amps.

Skid Plate - Protects the 200 HT from damage while

transporting, loading and unloading.

Specifications subject to change without notice.

Phoenix 200 HT

PN 4025900

Patent 7,246,503

TS-302

Revised 10/07

1

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

Table of Contents

Introduction ................................................................1

1. Specifications ........................................................2

2. Operation .............................................................2

2.1 Transporting ...................................................2

2.2 Electrical Requirements ..................................2

2.3 Condensate Removal ......................................2

2.4 Ducting ...........................................................2

2.5 Power Switch .................................................3

2.6 Pump Purge Switch .........................................3

2.7 Hour Meter ....................................................3

2.8 Temperature Specific Operation .......................3

2.9 Low Pressure Control ......................................4

3. Maintenance .........................................................4

3.1 Air Filter .........................................................4

3.2 Storage .........................................................4

4. Service .................................................................4

4.1 Technical description ......................................5

4.2 Troubleshooting ..............................................5

4.3 Blower Replacement .......................................6

4.4 Defrost Thermostat and Timer .........................6

4.5 Condensate Pump ..........................................6

4.6 Gravity Drain Option ........................................6

4.7 Relay ..............................................................7

5. Options and Accessories .......................................7

6. Wiring Diagram ....................................................7

7. Service Parts .......................................................8

8. Warranty ..............................................................9

1 Specifications

Part No. 4025900

Power 7.5 amps, 110-120 VAC, Grounded

Water 140 pints/day @ AHAM (80°F, 60%)

Removal

32 gal/day maximum @ saturation

Blower 335 CFM without external ducting

310 CFM @ .15 IWG external static

Operating 33°F min., 125°F max.

Range

Refrigerant 1 lbs., 14 oz. R-22

Charge

Filters

Duct Options Intake – 12” Flex-Duct

Supply – 10” Lay-Flat

Warranty Five years;

1st year 100% of Parts and Labor

2nd–5th year 100% of Parts of sealed

refrigeration system.

Dimensions

Machine Shipping

Width 20.25” 24”

Height 40” 45.25”

Depth 21.375” 25.5”

Weight 138 lb 164 lb

26 gal/day @ saturation

16” x 20” x 2” Pleated Media MERV-11

2 Operation

Serial No. ___________________________

Purchase Date ______/______/_____

Dealer’s Name ___________________________________

Read the operation and maintenance instructions

carefully before using this unit. Proper adherence to these

instructions is essential to obtain maximum benefit from

your Phoenix 200 HT dehumidifier.

• It is designed to be used INDOORS ONLY.

• If used in a wet area, plug it into a GROUND FAULT

NTERRUPTER.

• DO NOT use the Phoenix 200 HT as a bench or table.

• It must always be used in the upright position.

2.1 Transporting

The Phoenix 200 HT must always be upright when

transported by vehicle. It may be tipped onto its handle

and back for loading and moving by hand. The Phoenix

200 HT features a high-impact plastic skid plate which

protects the unit while navigating obstacles such as curbs,

stairways, and while loading into vehicles.

2.2 Electrical Requirements

The Phoenix 200 HT plugs into a common grounded outlet

on a 15 Amp circuit. It draws 7.5 Amps at 80°F, 60% RH.

If used in a wet area, a ground fault interrupter (GFI) is

required. If an extension cord is required, it must have a

minimum of 14 gauge conductors if 25 feet long or less

and 12 gauge conductors if greater than 25 feet long.

2

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

2.3 Condensate Removal

The Phoenix 200 HT is equipped with an internal

condensate pump to remove the water that is condensed

during dehumidification. This allows the condensate to be

pumped 30’ with the attached hose. If the condensate

must be pumped more than 20 feet above the unit, a

second pump must be added to relay the condensate. If

the pump fails and the unit must be used before it can be

replaced, the condensate can be drained by gravity.

The air inlet on top and the side outlet must be at least

1 foot from walls and other obstructions to air flow. If the

humid area is very large, dehumidification can be improved

by adding an outlet duct to circulate air to stagnant areas.

2.4 Ducting

A detachable rectangular exhaust collar is supplied to

allow 10” round lay-flat duct to be attached to the Phoenix

200 HT outlet. Lay-flat plastic ducting is available. See

accessories on page 6. To attach ducting to a collar, put

the plastic duct end through the collar center and roll the

duct end outward so that it overlaps the outside of the

collar. The duct and collar may then be quickly attached to

the Phoenix 200 HT by snapping the collar over the four

screws at the blower outlet.

2.5 Power Switch

The power switch (right of hour meter) lights up when

the unit is turned on. The unit will continue to run in

all conditions until the switch is turned off; there is no

dehumidistat. If the unit is going to run for more than 2

hours in an area below 50°F, the defrost timer should be

adjusted to improve performance.

2.6 Purge Switch

Pressing and holding the purge switch (left of hour meter)

will cause the condensate pump to run. This pump

minimizes the water left in the condensate reservoir prior

to moving or storage. Hold the switch in until the flow from

the condensate hose stops.

is directed across the evaporator. This airflow lowers

the refrigerant pressure in the condenser and improves

dehumidifier efficiency. The relative reduction or slowing

of airflow across the evaporator allows more time for the

air temperature to be lowered to the dew point, which

also increased dehumidifier efficiency. These higher

temperatures are often found after the first 24 hours.

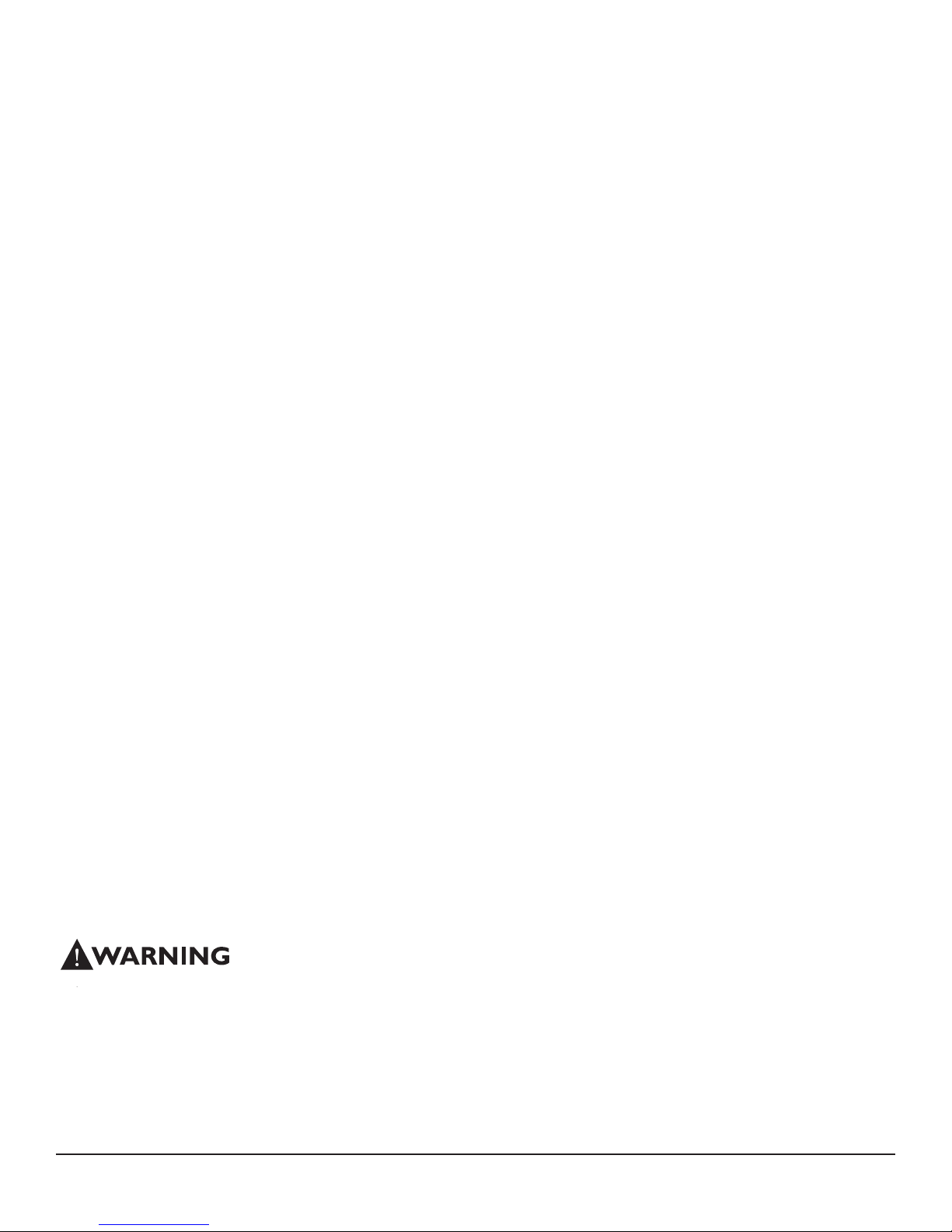

See Figure 1 for correct grain control magnet position for

operating in temperatures above 90°F.

Figure 1: Defrost timer and grain control magnet position for

operating in temperatures above 90°F.

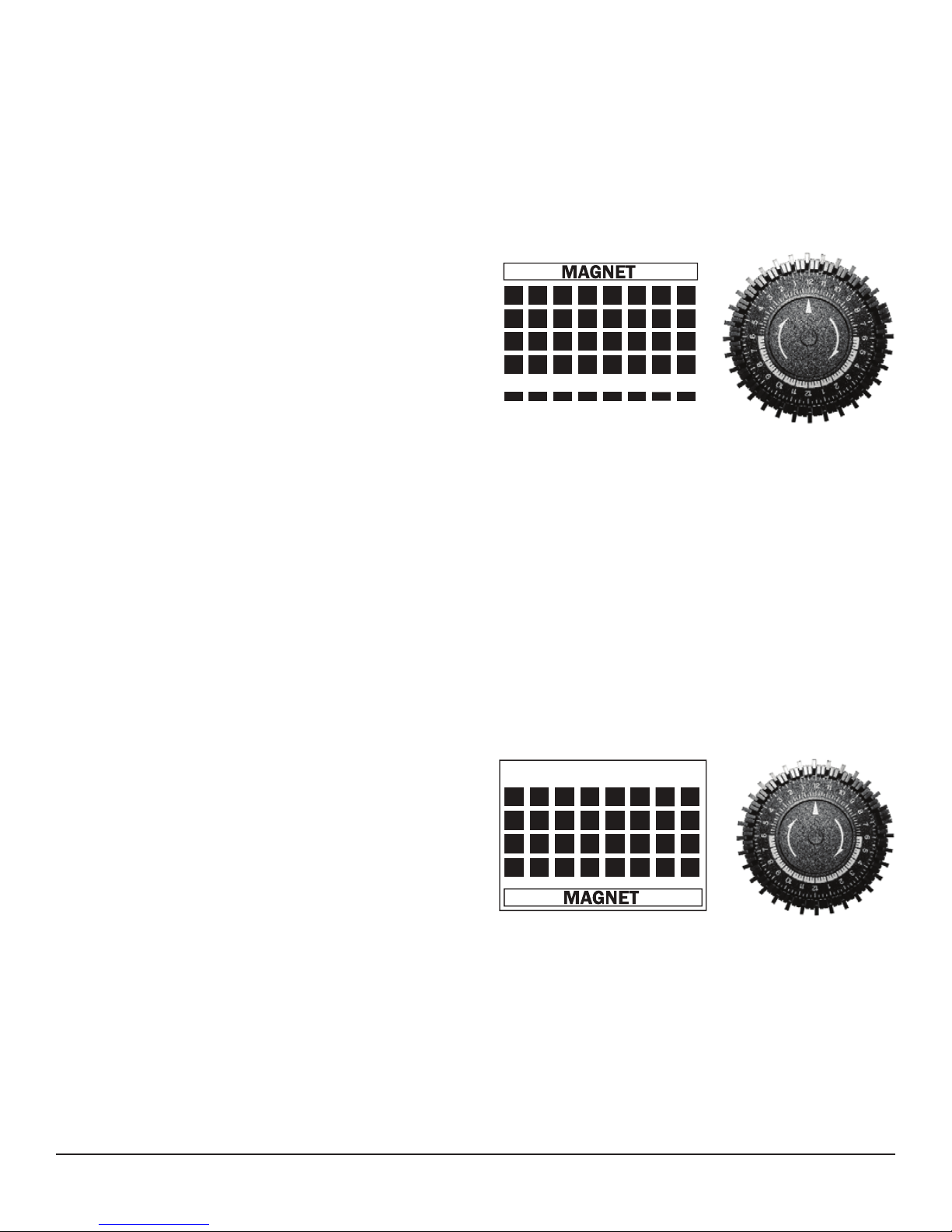

Between 50°F - 90°F - When the Phoenix 200 HT is used

in normal dehumidifier operating temperatures (70°F to

90°F), the grain control magnet should cover the bypass

openings.

This allows increased airflow across the evaporator and

increases performance by increasing the amount of air

that is dehumidified. This temperature range is often

found during the first 24 hours of a drying job. When the

Phoenix 200 HT is used in cooler operating temperatures

(50°F to 70°F), the grain control magnet increases airflow

across the evaporator and reduces frost formation. See

Figure 2 below for correct grain control magnet position for

operating in temperatures from 50°F to 90°F.

2.7 Hour Meter

The digital hour meter measures the cumulative time that

the unit is turned on to tenths of an hour. It stores its

total when the unit is unplugged; the previous total will be

displayed when the unit is next turned on. It resets to zero

after 99,999.9 hours of operation.

2.8 Temperature Specific Operation

Above 90°F - When the Phoenix 200 HT is used in high

temperature conditions (above 90°F), the refrigerant

pressure inside the condenser rises. By removing the

grain control magnet from the bypass openings, additional

airflow is directed over the condenser and less airflow

Figure 2: Defrost timer and grain control magnet position for

operating in temperatures above 50°F to 90°F.

Below 50°F -When the Phoenix 200 HT is used in very cool

operating temperatures (below 50°F), frost will form on

the evaporator coil as it dehumidifies. When enough frost

forms, the defrost thermostat will initiate the timed defrost

cycle. The cycle periodically turns off the compressor while

allowing the blower to run. The grain control magnet should

cover the bypass openings in this operating range because

the increased airflow and static pressure will help defrost

3

www.usephoenix.com • sales@thermastor.comToll-Free 1-800-533-7533

Loading...

Loading...