22

23

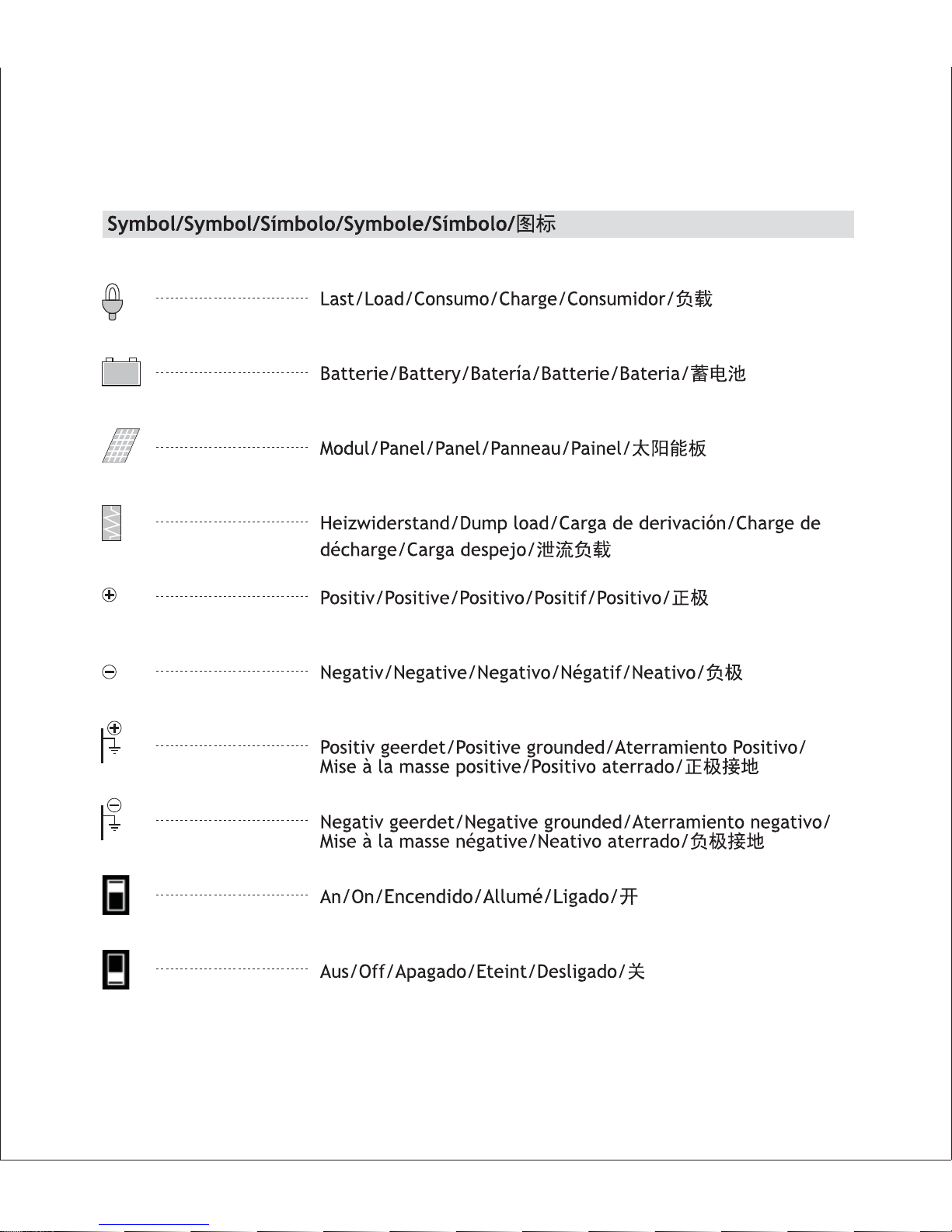

Contents

General Safety Information

Major Functions

Recommendations for Use

Mounting and Connecting

1. Using MPS as a DC load switch with deep-discharge protection

1.1 MPS features

1.2 Setting up your MPS as DC load switch with deep-discharge protection

1.3 Installation instruction

1.4 Starting up the Controller

2. Using MPS as PV Charge Controller

2.1 MPS features

2.2 Setting up your MPS as PV Charge Controller (stand-alone mode)

2.3 Installation instruction

2.4 Starting up the Controller

3.Using MPS as Wind/Hydro generator Charge Controller (Diversion control)

3.1 MPS features

3.2 Setting up your MPS as Wind/Hydro Charge Controller (stand-alone mode)

3.3 Installation instruction

3.4 Starting up the Controller

Safety Recommendations

Liability Exclusion

Technical Data

24

25

26

26

26

26

28

29

30

31

32

34

34

36

37

37

38

39

40

41

41

42

EN

With your new MPS Modular Power Switch, you own a state-of-the art device which was developed

according to the latest available technical standards. It comes with a number of outstanding

features, such as:

This manual gives important recommendations for installing, using and programming as well

as remedies in case of problems with the controller. Read it carefully in your own interest

and mind the safety and usage recommendations at the end of this manual.

General Safety Information

24

EN

This manual contains important installation, set up, and safe operating instructions.

Please read the instructions and warnings in this manual carefully before beginning any

installation.

Please do not disassemble or attempt to repair Phocos products. Phocos charge controllers do

not contain user serviceable parts.

Please observe all instructions with regards to external fuses/breakers as indicated.

The information contained in this manual must be observed in its extent. The manual contains

information regarding installation, set up, and operation.

Please read this manual carefully before using the product, and pay special attention to the

safety recommendations in it.

Maintenance and installation notes

When installing or working on the PV system, please disconnect the PV (solar) modules from

the charge controller first, to prevent damages to the charge controller!

Please verify that all cable/wire connections are done properly and well insulated and that

no water or humidity can ingress that is to avoid any bad or loose connections that would

result in excessive heating or further damage.

Please install a fuse or breaker near the battery before installing or adjusting the controller!

12 V, 24 V or 48 V (Automatic Detection)

Low Voltage Disconnect/Load Prioritization

Over-Charge Protection

Choose Regulation Between: Pulse-Width Modulation, Two-Point-Control (or bank switching

with MCU)

Diversion Control (dump loads) for Wind and Hydro Power Systems

Flexible grounding (negative or positive)

DIN Rail Mounting (possible to use with IP65 cabinet)

Five programmable voltage thresholds for load disconnect when used as a stand-alone unit.

More thresholds available when controlled by optional accessory MCU.

High voltage risks

Never touch any electrical conductors to avoid electrical shock.

Never work on live (energized) electrical equipment.

When working around a battery, do not allow tools to bridge the battery terminals, or short

circuit any part of the battery.

Use only tools with insulated handles.

Operation of this device may produce a high voltage which could cause severe injuries or death

in case of improper installation or operation of the device.

PV modules can generate high DC voltages!

Mains and charging current risks

Make sure the cables are always connected to the correct terminal. An electrical shock can

be lethal. In general, any electric shock can be dangerous to your health.

CE labeling

The product is CE compliant.

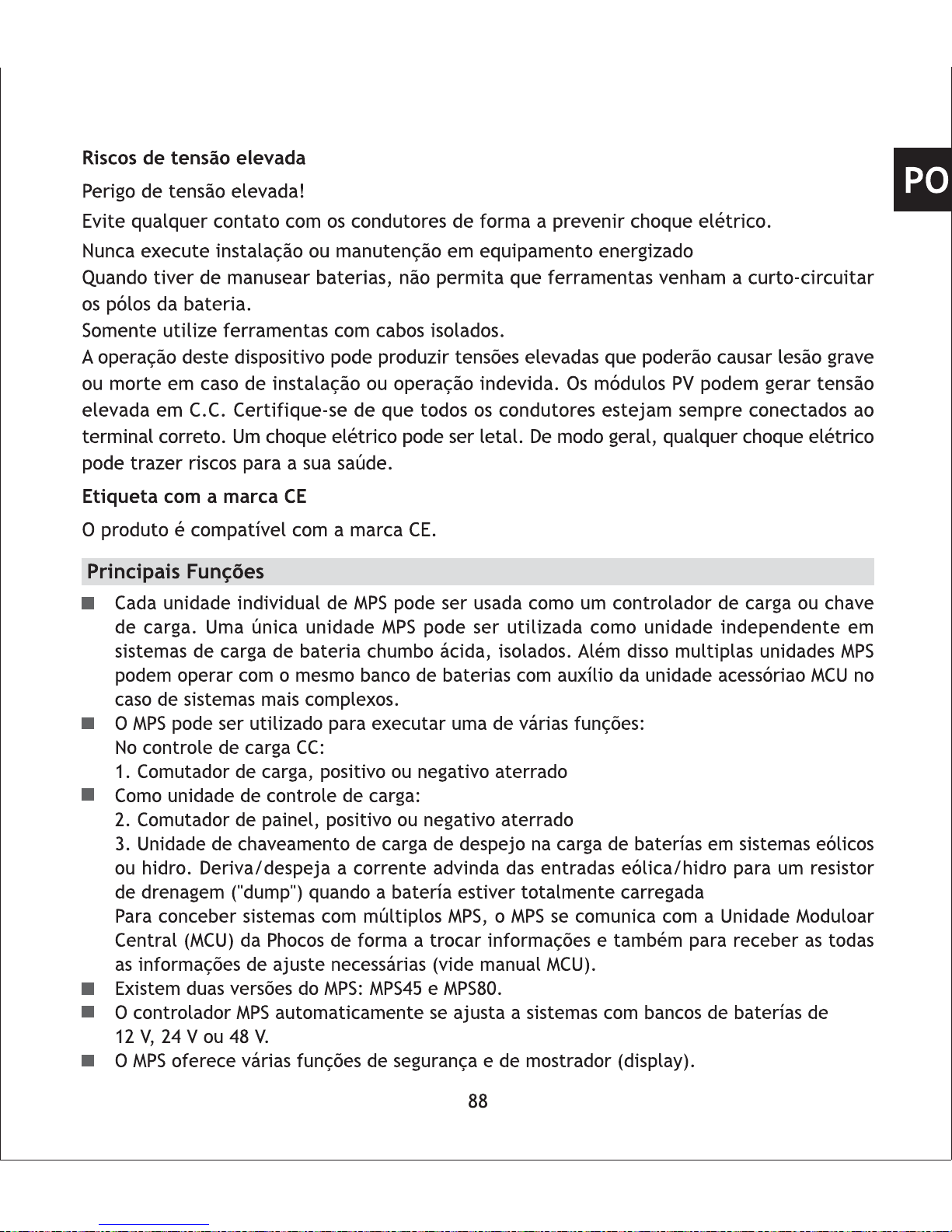

Major Functions

Individual MPS units can be used as charge controller or load-controlling switch. A single

MPS unit can be used as an independent device within off-grid battery charging systems

for lead acid batteries. Also, multiple MPS units can operate within the same battery-based

system with the help of optional accessory MCU for more complex system designs.

MPS can be used to perform one of several tasks:

DC Load Control:

1. Load switch, positive/negative grounded

Battery Charge Control:

2. Panel switch, positive/negative grounded

3. Diversion load switch for battery charging via wind/hydro inputs. Diverts current from

wind/hydro inputs to a dump load resistor when battery is fully charged.

To construct systems using multiple MPS units, MPS has the ability to communicate with

Phocos' Modular Central Unit (MCU) in order to exchange system information, to program

and to receive all necessary system settings (see MCU manual).

There are two available MPS versions: MPS45 and MPS80.

The MPS controller automatically detects the nominal system voltage when connected to

a 12 V, 24 V or 48 V battery bank.

The MPS has a number of safety and display functions.

25

EN

Mounting and Connecting

MPS is intended for indoor use only. Protect it from direct sunlight and place it in a dry

environment. Never install it in rooms with elevated humidity (bathrooms, etc.).

The controller warms up during operation and should therefore be installed on a non

flammable surface only.

Using MPS as a DC load switch for deep discharge protection (Chapter 1, page 24)

Using MPS as a photovoltaic charge controller (Chapter 2, page 29 )

Using MPS as a wind-/hydro generator charge controller (diversion control)(Chapter 3, page 35)

There are 3 different possible applications for using the MPS as stand-alone unit:

This chapter describes how to set up and install your MPS as stand-alone DC load switch with

deep-discharge protection and the available features when performing this duty.

As a stand-alone unit, MPS provides you five voltage thresholds (LVD1 to LVD5) for disconnecting

DC loads when battery state of charge becomes low.

Several independent MPS units can also operate in the same system, providing up to the nominal

current of each individual MPS unit to several different loads.

Do not use multiple MPS units in parallel to provide higher current to a single load in standalone systems without the use of optional accessory MCU. This is only possible by using MPS

together with MCU (see MCU manual).

1.1 MPS features:

Battery System Voltage Detection

MPS can be used in 12 V, 24 V, 48 V battery systems. The nominal system voltage is detected

automatically when connected to the battery bank.

1. Using MPS as a DC Load Switch with Deep-Discharge Protection

Recommendations for Use

The MPS controller warms up during normal operation. If there is insufficient ventilation

(e.g. in a cabinet), the controller has built-in overheating protection.

The MPS controller does not require any maintenance or service. Remove any dust with a

dry tissue.

It is important that the battery bank achieves fully charged status frequently (at least once

per month). Otherwise the battery may be permanently damaged.

A battery can only be fully charged if the average energy consumption of all loads is clearly

less than the average charging energy.

26

EN

After cut-off, the load will be reconnected automatically after one minute.

System Grounding:

MPS can control loads in positive and negative grounded systems. Grounding is selected by

wiring of your MPS, see details in chapter 1.3.2.

Load Current:

MPS is available in two versions:

Overtemperature Protection:

To protect MPS from damage due to overheating, MPS will switch off the load until cooled

down. Overheating can occur if MPS's ventilation grill is blocked or if the ambient temperature is

too high.

High Voltage Protection (HVD):

To protect the load from high

voltage, MPS will disconnect the

load if battery voltage is higher

than HVD level.

Nominal voltage

HVD level

12 V system

15.5 V

24 V system

31.0 V

48 V system

62 V

Deep Discharge Protection (LVD):

MPS provides five deep discharge

protection thresholds. This

allows you to select the load

disconnect level according to

your system requirements.

Nominal

voltage

LVD-level

12 V system

24 V system

48 V system

Type

Nominal load current

MPS80

80 A

MPS45

45 A

Overload and Short Circuit Protection:

MPS advanced overload protection allows overload for a limited

time, to enable inrush current

when switching on loads:

Load current in % of nominal current

110% to 150%

150% to 200%

Short circuit

Time to switch off

120 sec

12 sec

Immediately

Emergency Switch Off (EVD)

When battery voltage drops down

below EVD level, the load will

be switched off immediately.

The load will be reconnected

after battery is recharged and

battery voltage is above the load

reconnect level (LVR).

11.0 V

11.25 V

11.5 V

11.75 V

12.0 V

22.0 V

22.5 V

23.0 V

23.5 V

24.0 V

44.0 V

45.0 V

46.0 V

47.0 V

48.0 V

Level 1

Level 2

Level 3

Level 4

Level 5

27

Nominal voltage

EVD level

LVR level

12 V system

<10.5 V

>12.8 V

24 V system

<21.0 V

>25.6 V

48 V system

<42 V

>51.2 V

EN

1.2 Setting up your MPS as a DC load switch with deep-discharge protection

Please be sure to always follow this procedure in the following sequence:

Set the DIP switches according to the load switch function

Mount MPS on DIN rail or wall

Connect the load wiring to the unit with proper polarity.

Connect the battery wiring to the unit with proper polarity.

When disassembling perform the installation sequence in reverse order.

Note: Changes to DIP switches after connecting the unit to the battery do not affect the function

of the unit.

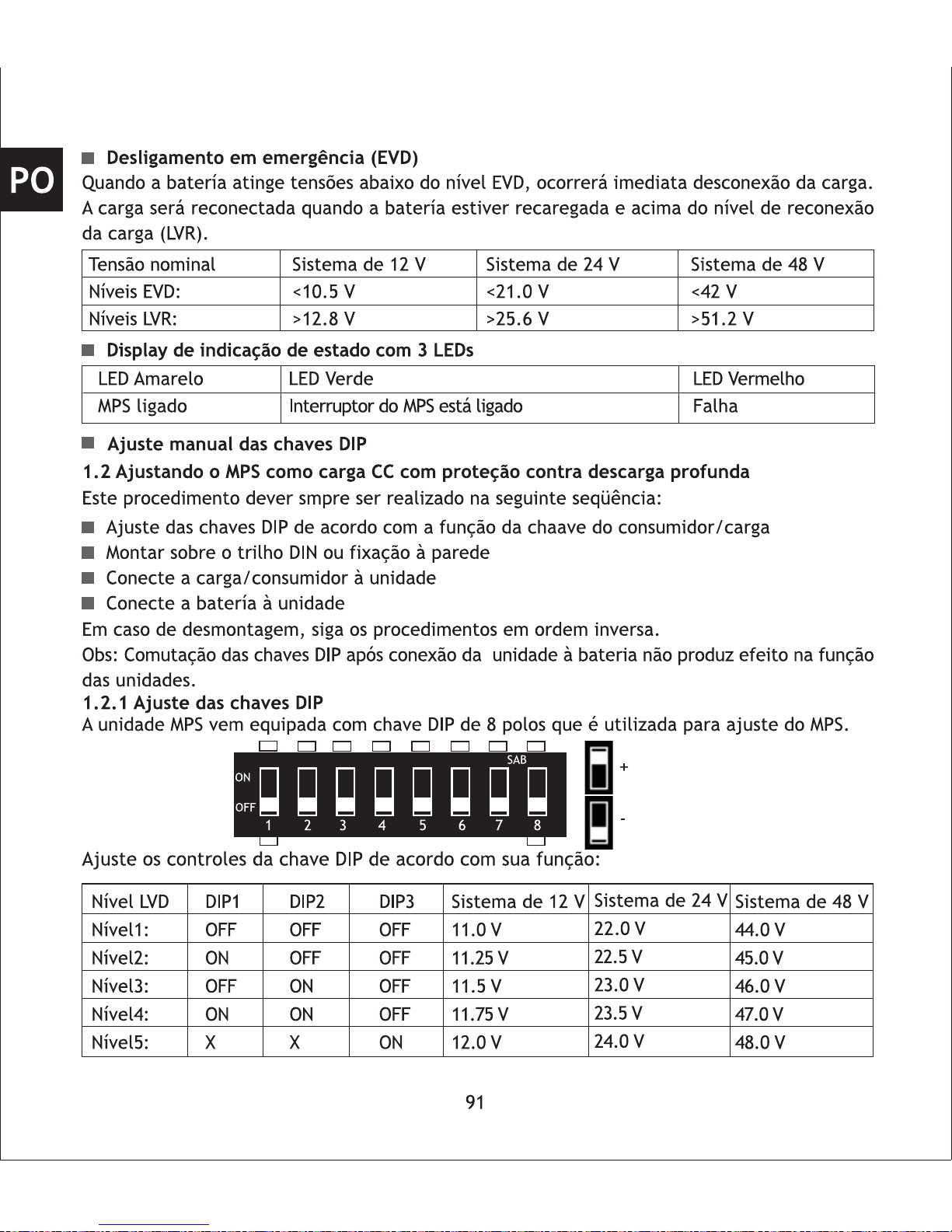

1.2.1 Set-up DIP Switches

The MPS comes with an eight

pole DIP-switch, which can be

used to set up your MPS.

Adjust the DIP switch settings according to load switch function:

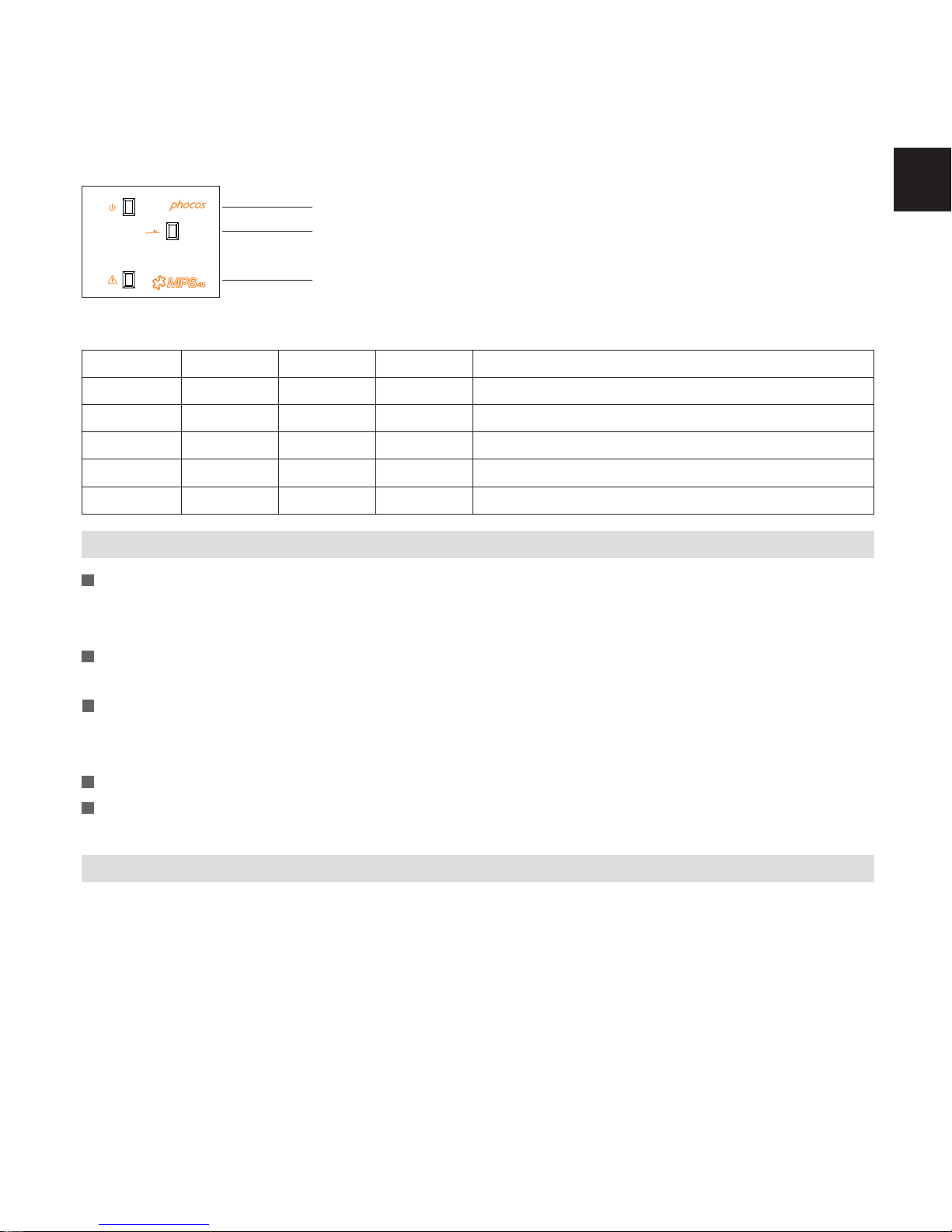

Three-LED Status Display

Manual Setting by DIP Switches

28

Yellow LED

MPS on

Green LED

MPS power switch is on

Red LED

Failure

Setting

OFF

X

X

OFF

X

Function

Activates MPS as load switch/deep discharge protection

Unused

Unused

Stand-alone function

Unused

DIP NO.

DIP 8

DIP 7

DIP 6

DIP 5

DIP 4

12 V system

11.0 V

11.25 V

11.5 V

11.75 V

12.0 V

DIP1

OFF

ON

OFF

ON

X

DIP2

OFF

OFF

ON

ON

X

DIP3

OFF

OFF

OFF

OFF

ON

EN

LVD level

Level1

Level2

Level3

Level4

Level5

24 V system

22.0 V

22.5 V

23.0 V

23.5 V

24.0 V

48 V system

44.0 V

45.0 V

46.0 V

47.0 V

48.0 V

+

-

12345678

SAB

ON

OFF

1 2

3

Please see fig 1, 2 and 3 which shows how to install the MPS controller on a standard 35 mm

DIN Rail.

Mount DIN Rail onto a vertical surface.

Mount MPS in a manner that ensures there is enough space above and below the unit to ensure

vertical air flow through the ventilation grill.

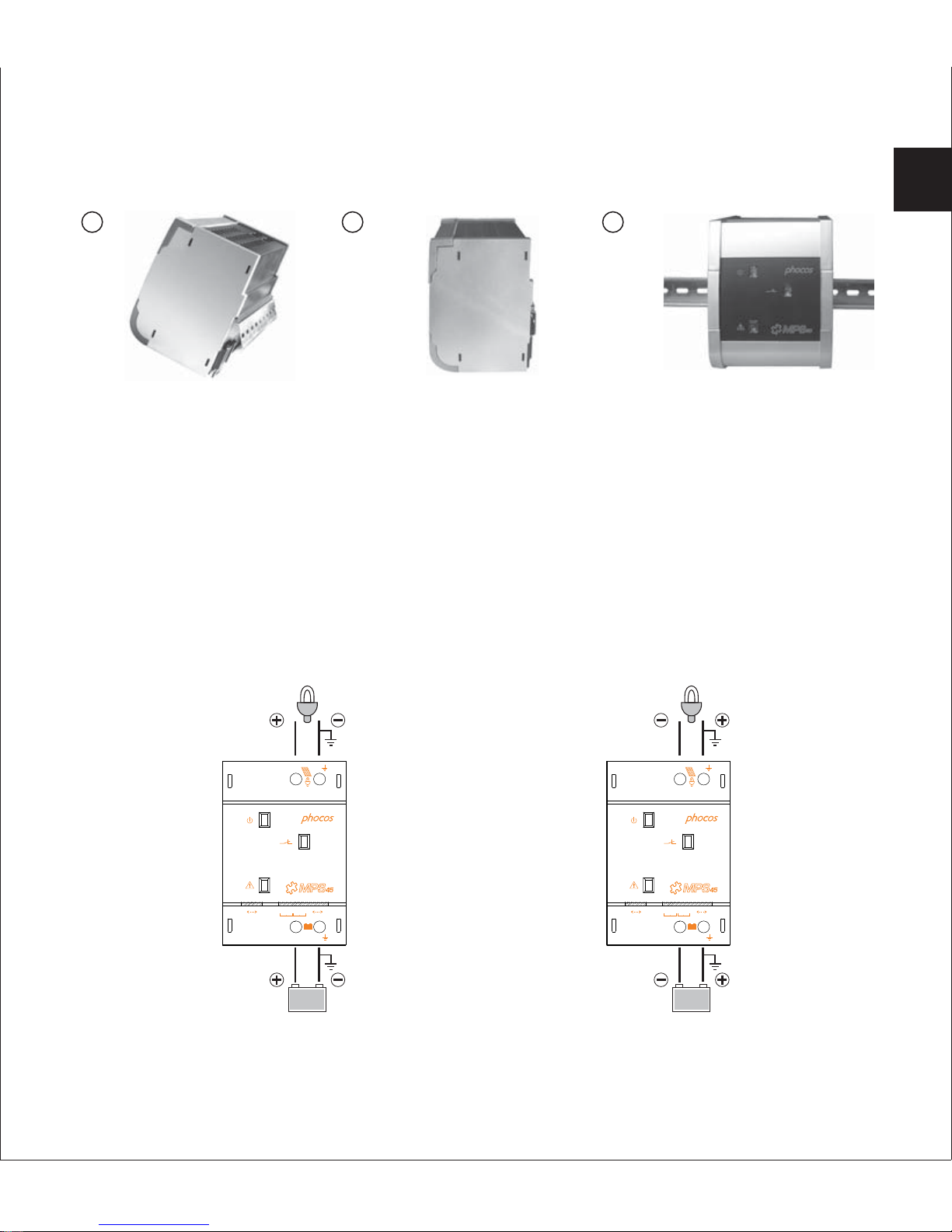

1.3.2 Grounding

MPS can work in negative or positive grounded systems.

Select the type of grounding according your system requirements. Respect that all components

in your system should use the same type of grounding!

1.3 Installation Instruction

1.3.1 Wall Mounting

Positive groundedNegative grounded

29

com

comAB

87654321

AddressMode

com

comAB

87654321

AddressMode

EN

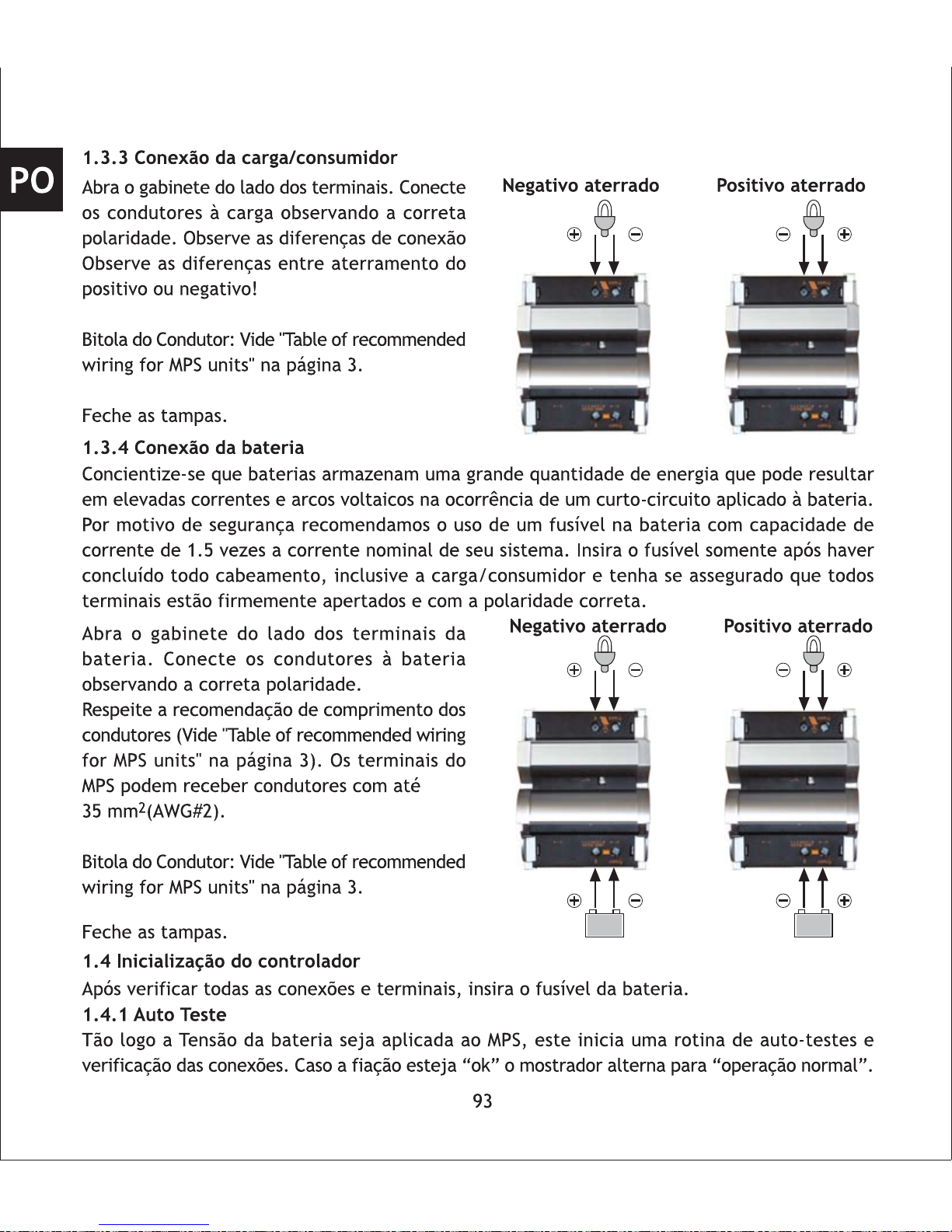

1.3.3 Connecting the Load

Negative grounded Positive grounded

Open the cover at the load terminals. Connect

the wires leading to the load with the correct

polarity. Respect the appropriate wiring for

negative and positive grounded systems!

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the wire cover.

1.3.4 Connecting the Battery

Respect that batteries store a substantial amount of energy which can produce high current

and electric arc when a short circuit is applied to the battery. It is recommended to install a

battery fuse which must be able to carry currents of 1.5 times of your nominal system current

for safety considerations. Insert the fuse after you have connected all wires including the load

and make sure that all terminals are fixed tightly with proper polarity.

Negative grounded Positive grounded

Open the cover on the battery terminal side.

Connect the wires leading to the battery with

the proper polarity.

Mind the recommended wire length (See "Table

of recommended wiring for MPS units" on page

3). MPS terminals can connect up to 35 mm

2

wire (AWG#2).

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the wire cover.

1.4 Starting up the Controller

After double-checking all wires and terminals insert battery fuse.

1.4.1 Self test

As soon as battery voltage is applied to MPS, the unit begins a self test routine and wiringcheck. If system passes wiring-check, the LED display changes to "normal operation".

30

EN

2. Using MPS as PV Charge Controller

This chapter describes how to set up and install your MPS as an independent PV charge controller

and the available features when performing this duty.

Several independent MPS units can be used as PV charge controllers in your system increasing

the available charge current to the battery bank.

Do not operate several MPS in parallel to one solar-array. Each MPS unit should only be used

with a solar-array that produces equal or less than the nominal current rating of your MPS

unit at peak conditions. In stand-alone mode (without MCU), up to three MPS units can be

operated as PV charge controllers connected to the same battery bank.

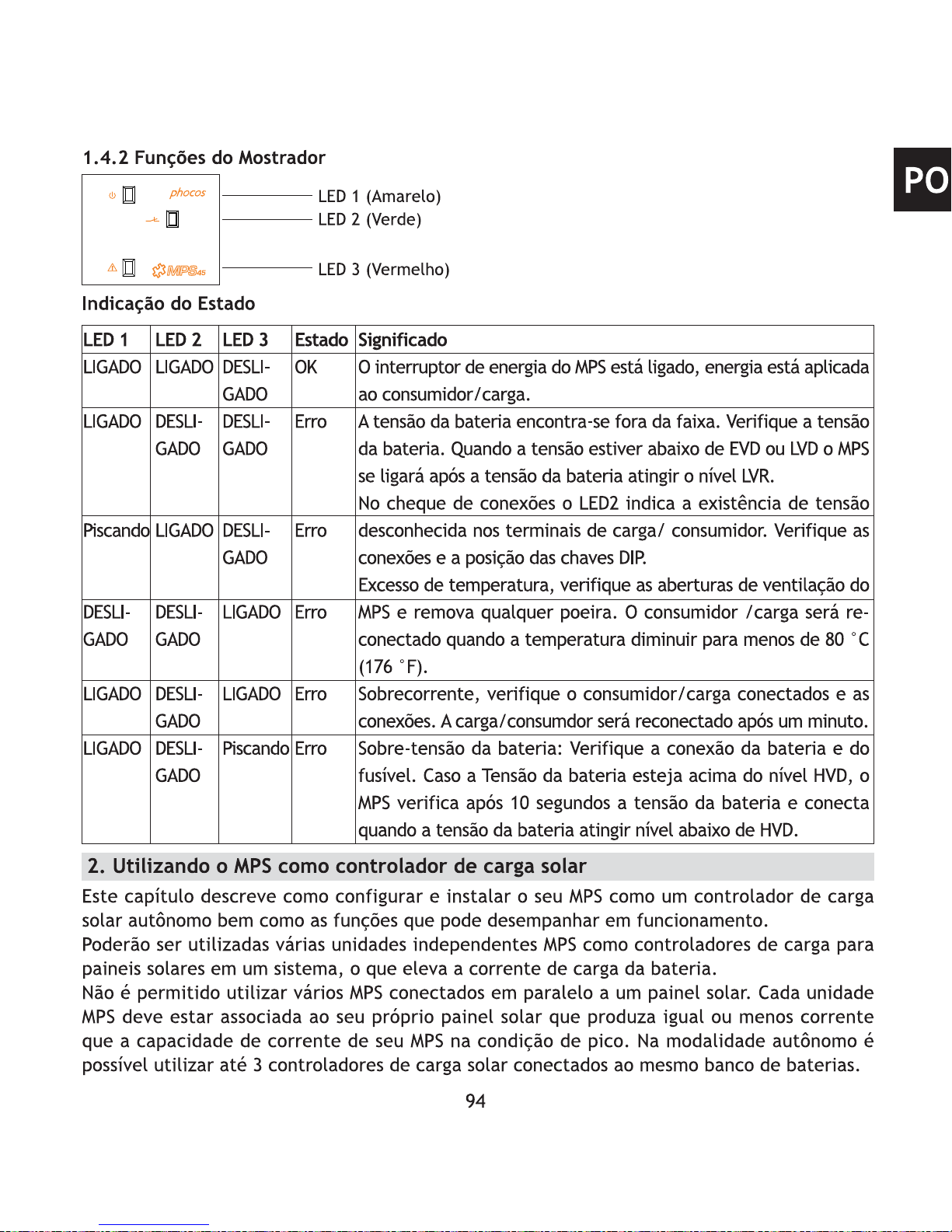

1.4.2 Display Functions

Status indication

LED 1

ON

ON

Flash

OFF

ON

ON

LED 2

ON

OFF

ON

OFF

OFF

OFF

LED 3

OFF

OFF

OFF

ON

ON

Flash

Status

OK

Error

Error

Error

Error

Error

Meaning

MPS power switch is on (active), power applied to connect

load.

Battery voltage out of range. MPS switched off. Check

battery voltage when voltage is below EVD or LVD. MPS

switches on after battery voltage reaches LVR level.

On wiring check LED 2 indicates an unuaual voltage is

on the load output. Check load wiring and DIP settings.

Overtemperature, check ventilation grill of your MPS and

remove any visible dust. Load will be reconnected after

temperature is lower than 80°C (176 F).

Overcurrent, check your connected load and wiring. Load

will be reconnected after one minute.

Battery over-voltage: check battery, fuse and battery wiring.

If battery voltage is higher than HVD-level MPS checks

battery voltage after 10 seconds and switches on, when

battery voltage is lower than HVD-level.

LED 3 (Red)

LED 1 (Yellow)

LED 2 (Green)

31

EN

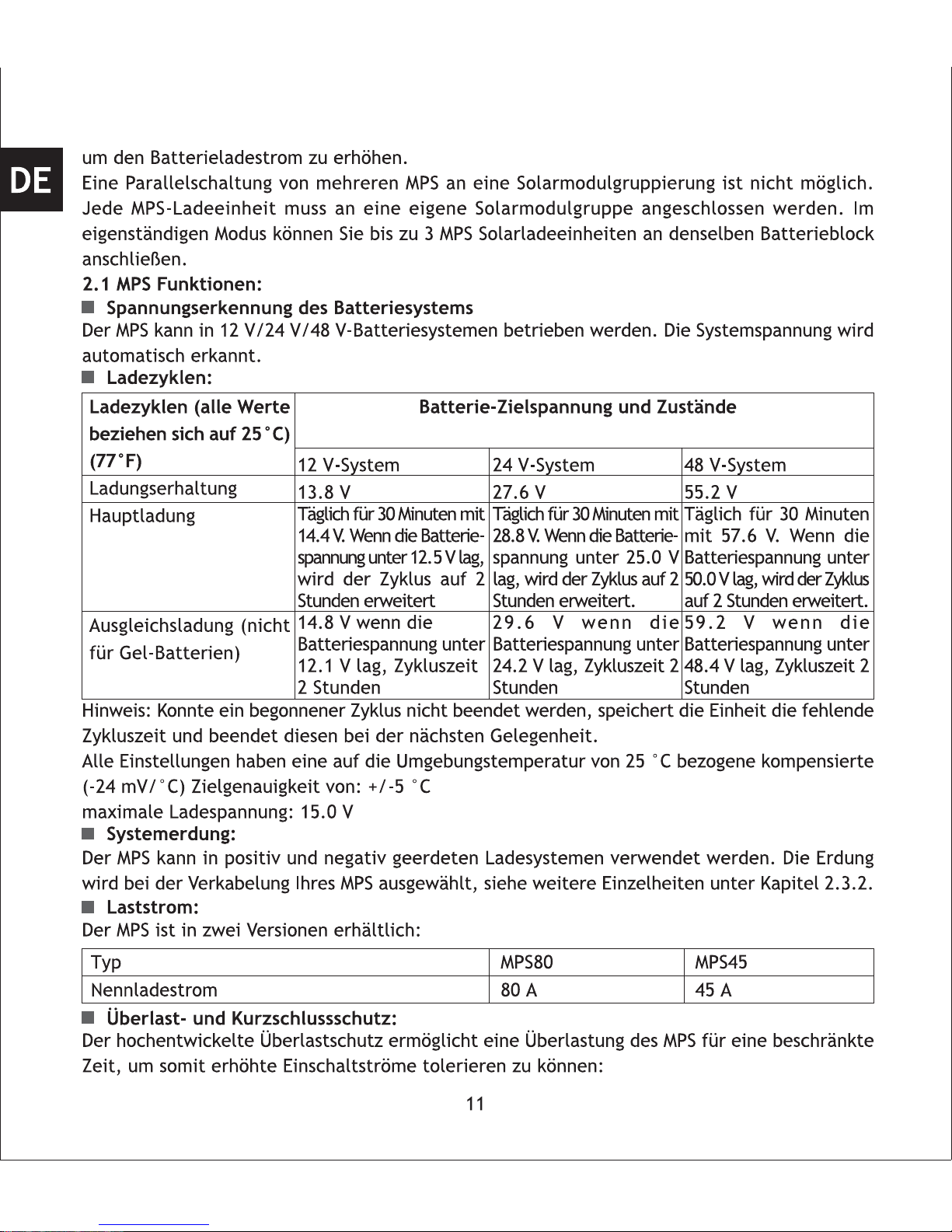

2.1 MPS features:

Battery System Voltage Detection

MPS can be used in 12 V, 24 V, or 48 V battery systems. The nominal system voltage is detected

automatically when connected to the battery bank.

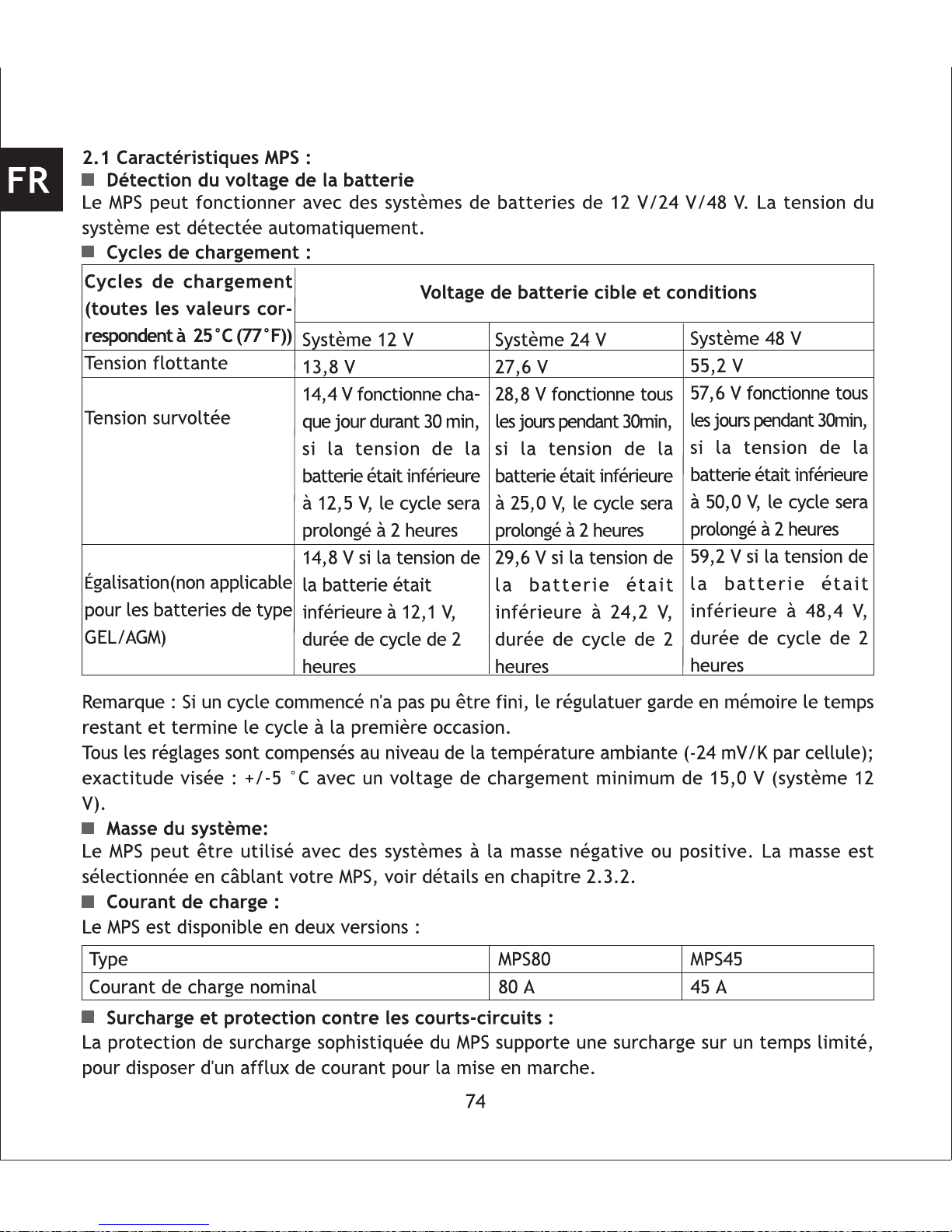

Charge Cycles:

Note: If a started cycle could not be finished, the controller stores the lacking cycle time and

uses the next chance to finish.

All settings are ambient temperature compensated (-24 mV/K per cell) target accuracy: +/-5°C,

maximum charging voltage 15.0 V (12V system).

System Grounding:

MPS can be used in positive and negative grounded charging systems. Grounding is selected

by wiring of your MPS, see details in chapter 2.3.2.

Charging Current:

MPS80

80 A

MPS45

45 A

MPS is available in two versions:

Overload and Short Circuit Protection:

MPS advanced overload protection allows overload for a limited time, to enable inrush current

when switching on:

Type

Nominal charging current

32

12 V system

13.8 V

14.4 V (runs every day

for 30 min, if battery was

below 12.5 V cycle will

be extended to 2 hours)

14.8 V (if battery was

below 12.1 V cycle

duration 2 hours)

Charging Cycles [all values

correspond to 25°C (77 F)

operation temperature]

Float

Boost

Equalize (not applied for

GEL/AGM type batteries)

Battery Target Voltage and Conditions

24 V system

27.6 V

28.8 V (runs every day

for 30 min, if battery was

below 25.0 V cycle will

be extended to 2 hours)

29.6 V (if battery was

below 24.2 V cycle

duration 2 hours)

48 V system

55.2 V

57.6 V (runs every day

for 30 min, if battery was

below 50.0 V cycle will

be extended to 2 hours)

59.2 V (if battery was

below 48.4 V cycle

duration 2 hours)

EN

Battery Over-Voltage Protection:

Activates over-voltage procedure if battery voltage is more than three times per second higher

than 15.5 V in 12 V systems, 31 V in 24 V systems or 62 V in 48 V systems. Optional accessory

MCU can adjust this parameter.

Charge current in %

of nominal current

Action

Temperature-controlled current reduction by PWM. (If power electronic

temperature is below 80 °C (176 F), no limitation of current occurs).

Charge current reduction by PWM to < 100 % and temperature controlled

current reduction.

Switches off, waits for one minute and tries again

Overtemperature Protection:

Possible failure reason

Defective battery

Action

Reduces charge voltage. If this does not correct the issue, charging

stops and LED indicates a failure(tries charging again one minute later)

If after charging stopped failure disappears, MPS starts a new procedure.

Night Detection

Three-LED Status Display

Manual Setting by DIP Switches

Additional features available if MPS is used together with Phocos Modular Control Unit

MCU (see MCU manual )

Discharge current protection at night by FET switch off.

Panel open circuit voltage measured during day and night.

33

<110%

110% to 150%

>150%

PCB temperature Action

Switches off charge current

Reduces charge current by applying PWM to keep temperature below

90 °C (194 F)

Normal charge function

>95 °C

80 °C (176 F) to

90 °C (194 F)

< 80 °C

Yellow LED

MPS ready

Green LED

MPS FET is on

Red LED

Failure

EN

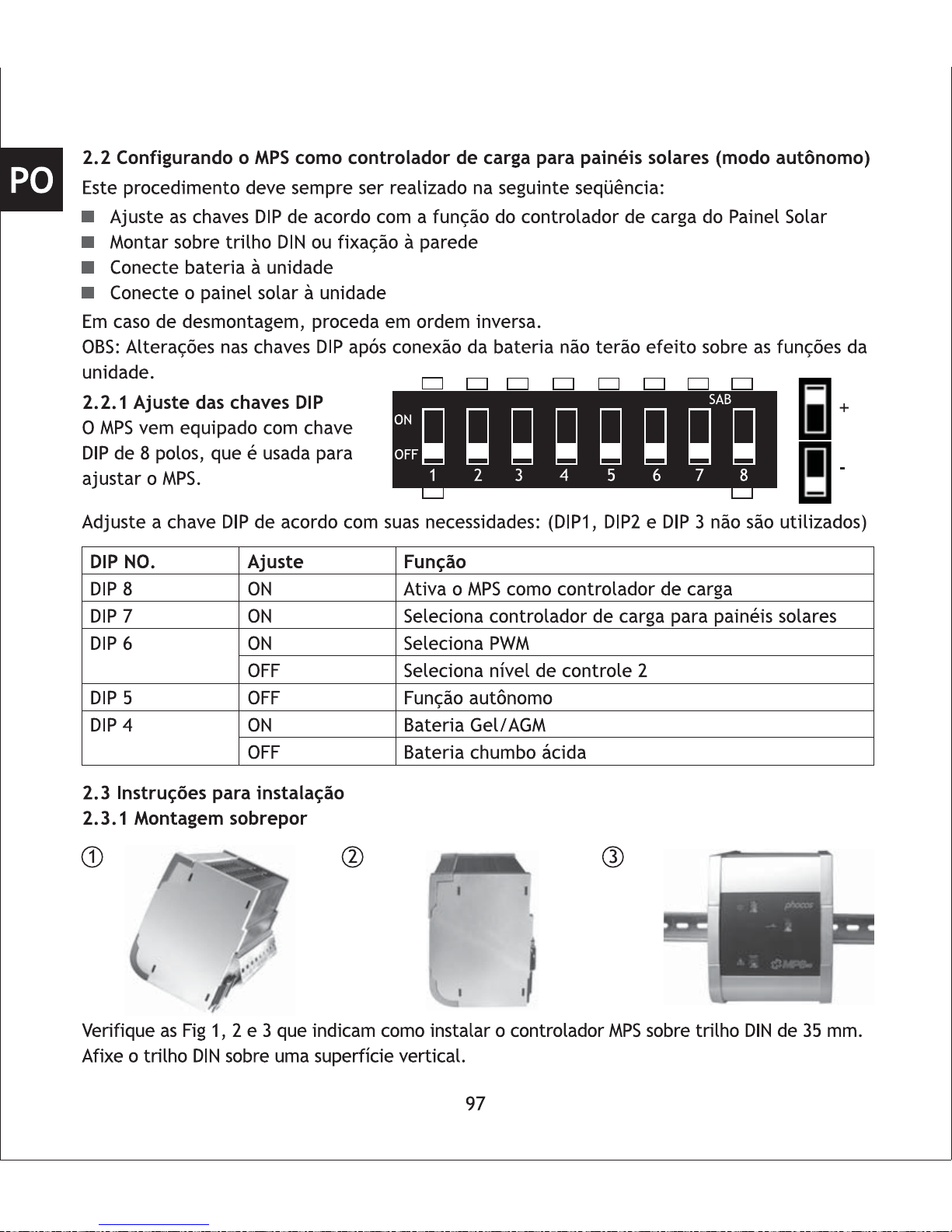

2.2 Setting up your MPS as PV Charge Controller (stand-alone mode)

Please be sure to always follow this procedure in the following sequence:

Set the DIP switches according to the PV charge controller function

Mount MPS on DIN Rail or wall

Connect the battery to the unit with proper polarity

Connect the solar array to the unit

When disassembling, perform the installation sequence in reverse order.

Note: Changes to DIP switches after connecting the unit to the battery do not affect the function

of the unit.

2.2.1 Setup DIP Switches

The MPS comes with an eight pole

DIP-switch, which can be used to

set up your MPS.

Setting

ON

ON

ON

OFF

OFF

ON

OFF

Function

Activates MPS as charge controller

Activates MPS as PV charge controller

Activates PWM

Activates two-point control

Stand-alone function

Gel/AGM battery

Liquid lead acid battery

DIP NO.

DIP 8

DIP 7

DIP 6

DIP 5

DIP 4

2.3 Installation Instruction

2.3.1 Wall Mounting

Please see fig 1, 2 and 3 showing how to install the MPS controller on a standard 35 mm DIN Rail.

Mount DIN Rail onto a vertical surface.

Adjust the DIP switch settings according to your requirements: (DIP1,DIP2 and DIP3 are unused)

34

1 2

3

EN

+

-

12345678

SAB

ON

OFF

Mount MPS in a way that ensures there is enough space below and above for the air to vertically

air flow through the ventilation grill.

35

2.3.2 Grounding

MPS can work in negative or positive grounded systems.

Select the type of grounding according your system requirements. Respect that all components

in your system should use the same type of grounding!

Positive groundedNegative grounded

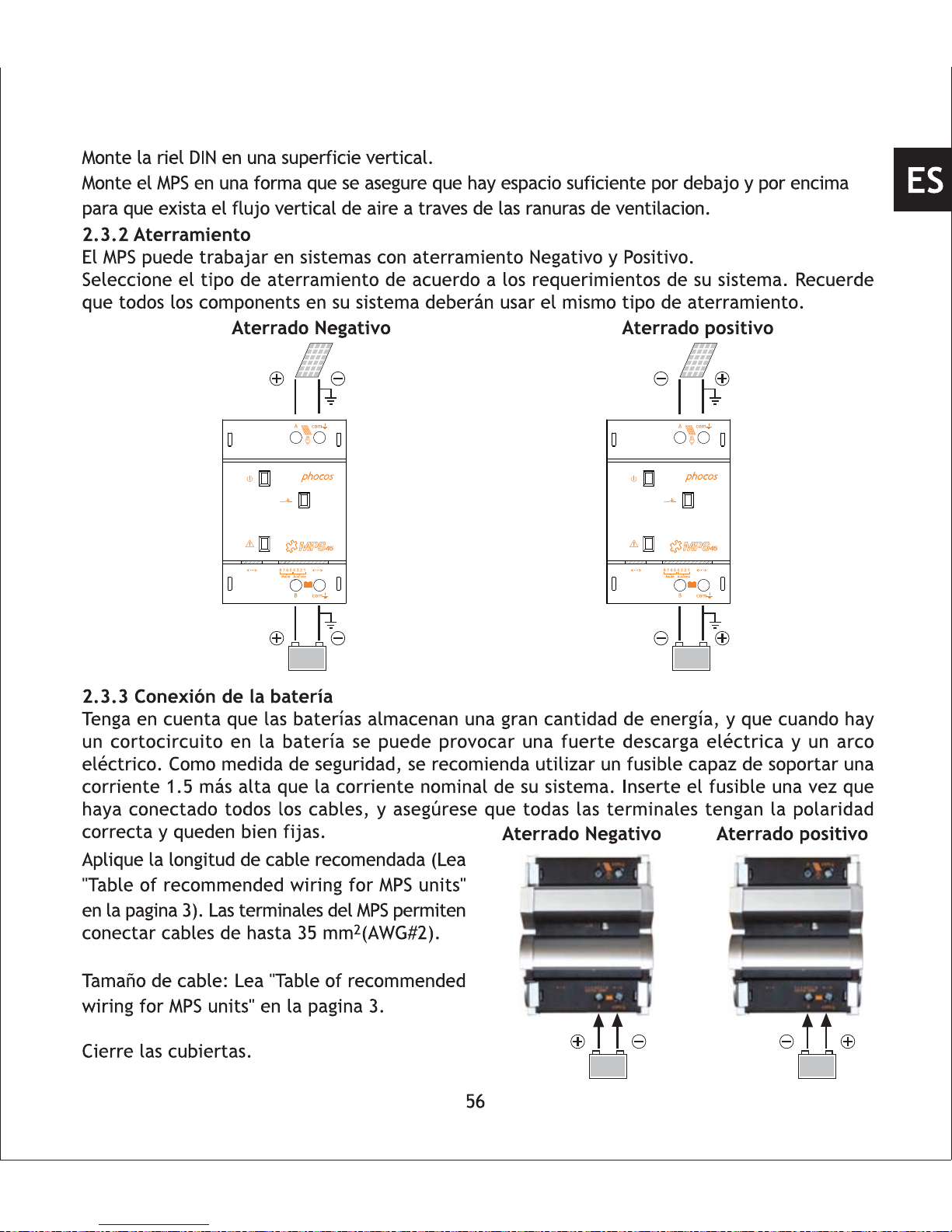

2.3.3 Connecting the Battery

Respect that batteries store a substantial amount of energy which can produce high current

and electric arc when a short circuit is applied to the battery. It is recommended to install a

battery fuse which must be able to carry currents of 1.5 times of your nominal system current

for safety considerations. Insert the fuse after you have connected all wires including the load

and make sure that all terminals are fixed tightly with proper polarity.

Negative grounded Positive grounded

Open the cover on the battery terminals side.

Connect the wires leading to the battery with

the proper polarity.

Mind the recommended wire length (See "Table

of recommended wiring for MPS units" on page

3). MPS terminals can connect up to 35 mm

2

wires (AWG#2).

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the covers.

com

comAB

87654321

AddressMode

com

comAB

87654321

AddressMode

EN

2.4 Starting up the Controller

After double-checking all wires and terminals, insert battery fuse.

2.4.1 Self Test

As soon as battery voltage is applied to MPS, the unit begins a self test routine and wiringcheck. If system passes wiring-check, the LED display changes to "normal operation."

2.4.2 Display Functions

Status indication

Meaning

Battery charging

In PWM mode:

solar-array voltage < battery voltage

On two-point control:

solar-array voltage < battery voltage

In PWM mode: current limited by PWM

Over-current or over-temperature

Negative grounded Positive grounded2.3.4 Connecting Solar-Array

Open the cover at the solar-array terminals.

Connect the wires leading to the solar-array

with the correct polarity. Respect the different

wiring for negative and positive grounded

systems!

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the covers.

36

LED 1

ON

ON

ON

OFF

LED 2

ON

OFF

FLASH

OFF

LED 3

OFF

OFF

OFF

ON

Status

OK

Error

LED 3 (Red)

LED 1 (Yellow)

LED 2 (Green)

EN

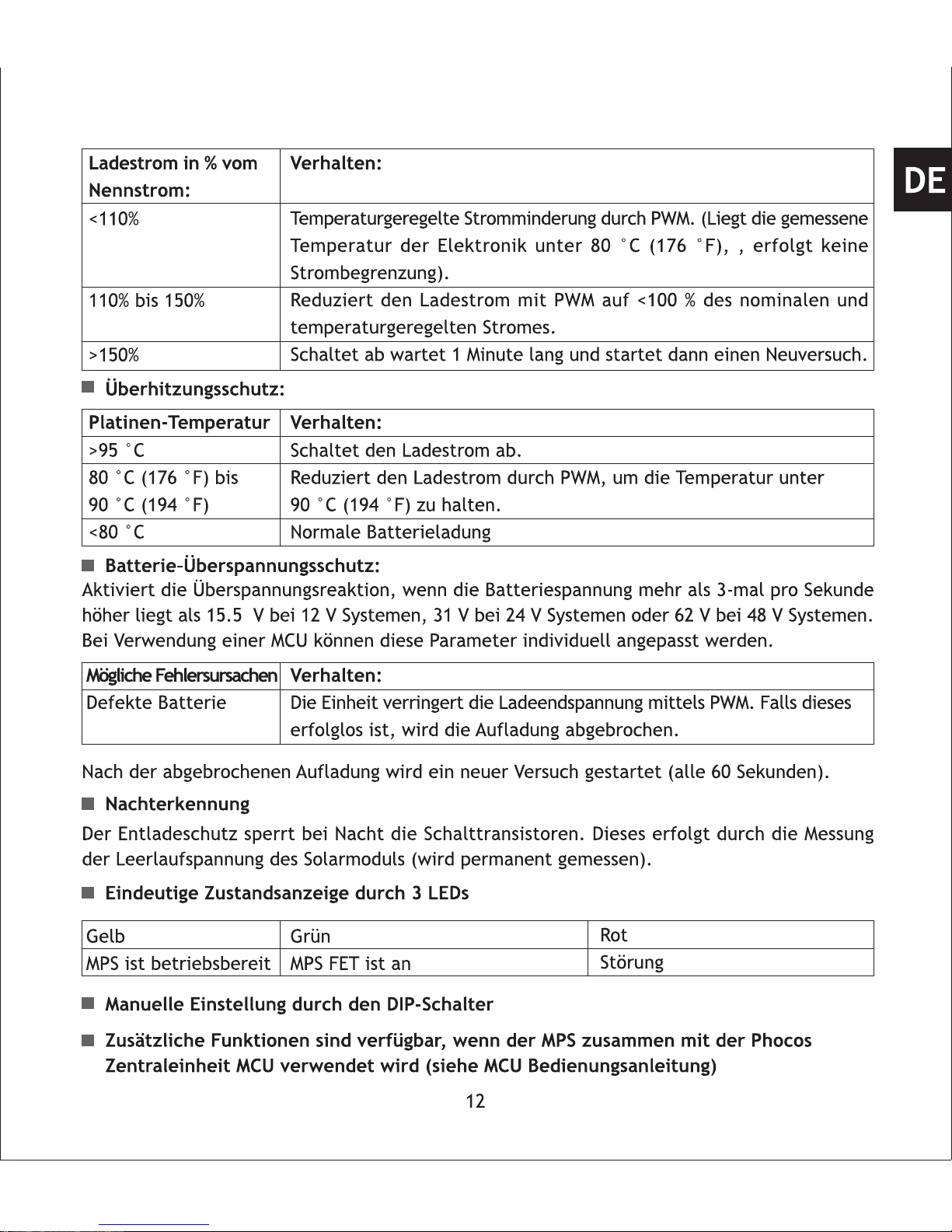

3.Using MPS as Wind/Hydro Generator Charge Controller (Diversion Control)

This chapter describes the available features and how to set up and install your MPS as dumpload

switch for diversion control in stand-alone mode.

3.1 MPS Features:

Battery System Voltage Detection

MPS can be used in 12 V, 24 V, or 48 V battery systems. The nominal system voltage is detected

automatically when connected to the battery bank.

System Grounding:

MPS can control diversion loads in positive and negative grounded systems. Grounding is selected

by wiring of your MPS, see details in chapter 3.3.2.

Diversion Load Current:

MPS is available in two versions:

Overload and Short-Circuit Protection:

Diversion load will be reconnected automatically after one minute.

Overtemperature Protection:

To protect MPS from overheating and damage due to overtemperature, MPS will switch off

the diversion load. Overheating can happen if MPS's ventilation grill is blocked or ambient

temperature is too high.

High Voltage Protection (HVD):

To protect the diversion load from

high voltage, MPS will disconnect

the diversion load if battery

voltage is higher than HVD level.

Diversion Load Funcionality:

MPS can control a wind/hydro generator input, which always has to be directly connected to

the battery. This is done by switching a diversion load in parallel to the battery if the battery

37

Type

Nominal load current

MPS80

80 A

MPS45

45 A

MPS advanced overload protection

allows overload for a limited time,

to enable inrush current when

switching on loads:

Load current in % of nominal current

110% to 150%

150% to 200%

Short circuit

Time to switch off

120 sec

12 sec

Immediately

Nominal voltage

HVD level

12 V system

15.5 V

24 V system

31.0 V

48 V system

62.0 V

EN

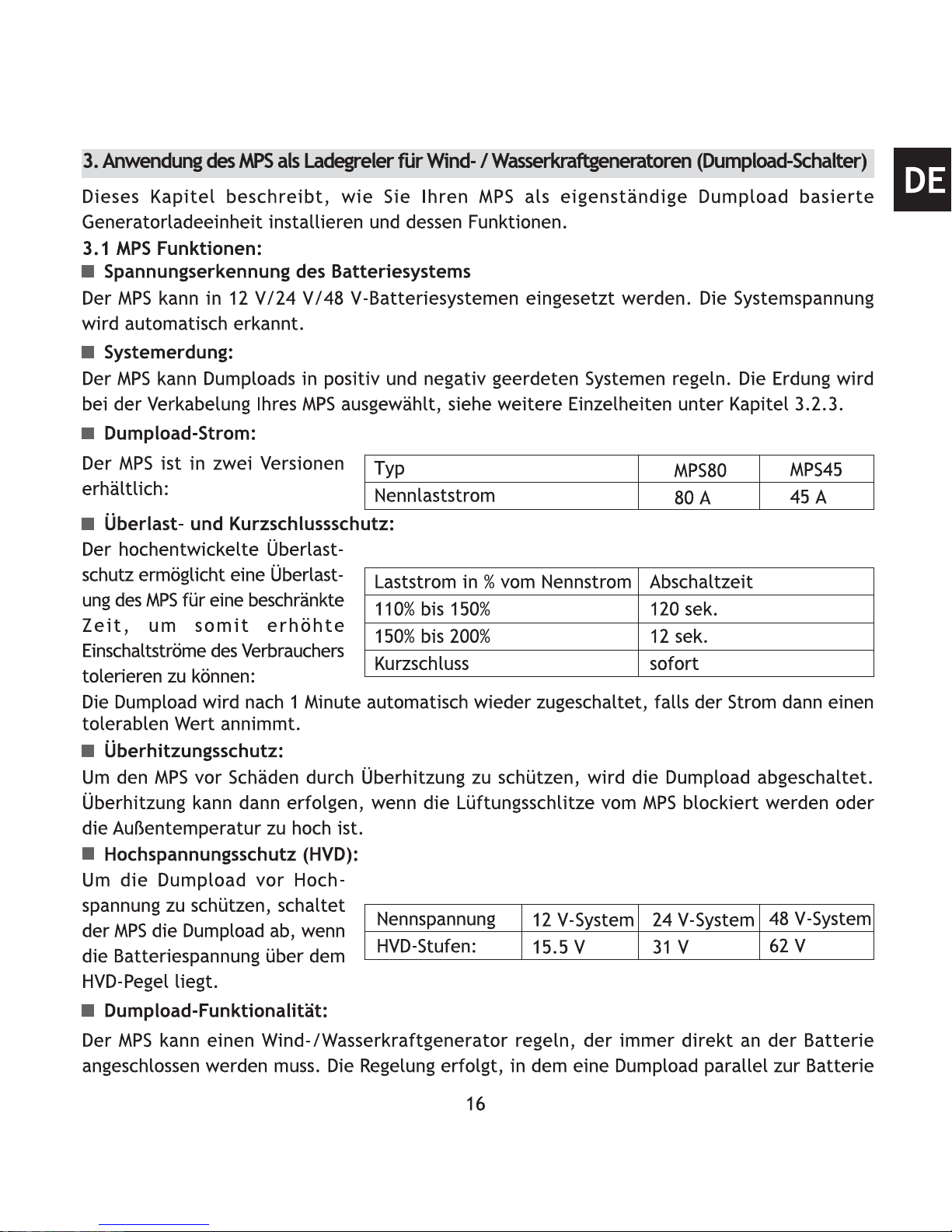

3.2 Setting up your MPS as Wind/Hydro Charge Controller (stand-alone mode)

Please be sure to always follow this procedure in the following sequence:

Set the DIP switches according to the wind/hydro charge controller function

Mount MPS on DIN Rail or wall

Connect the battery to the unit

Connect the diversion load to the unit

When disassembling, perform the installation sequence in reverse order.

Note: Changes to DIP switches after connecting the unit to the battery do not affect the function

of the unit.

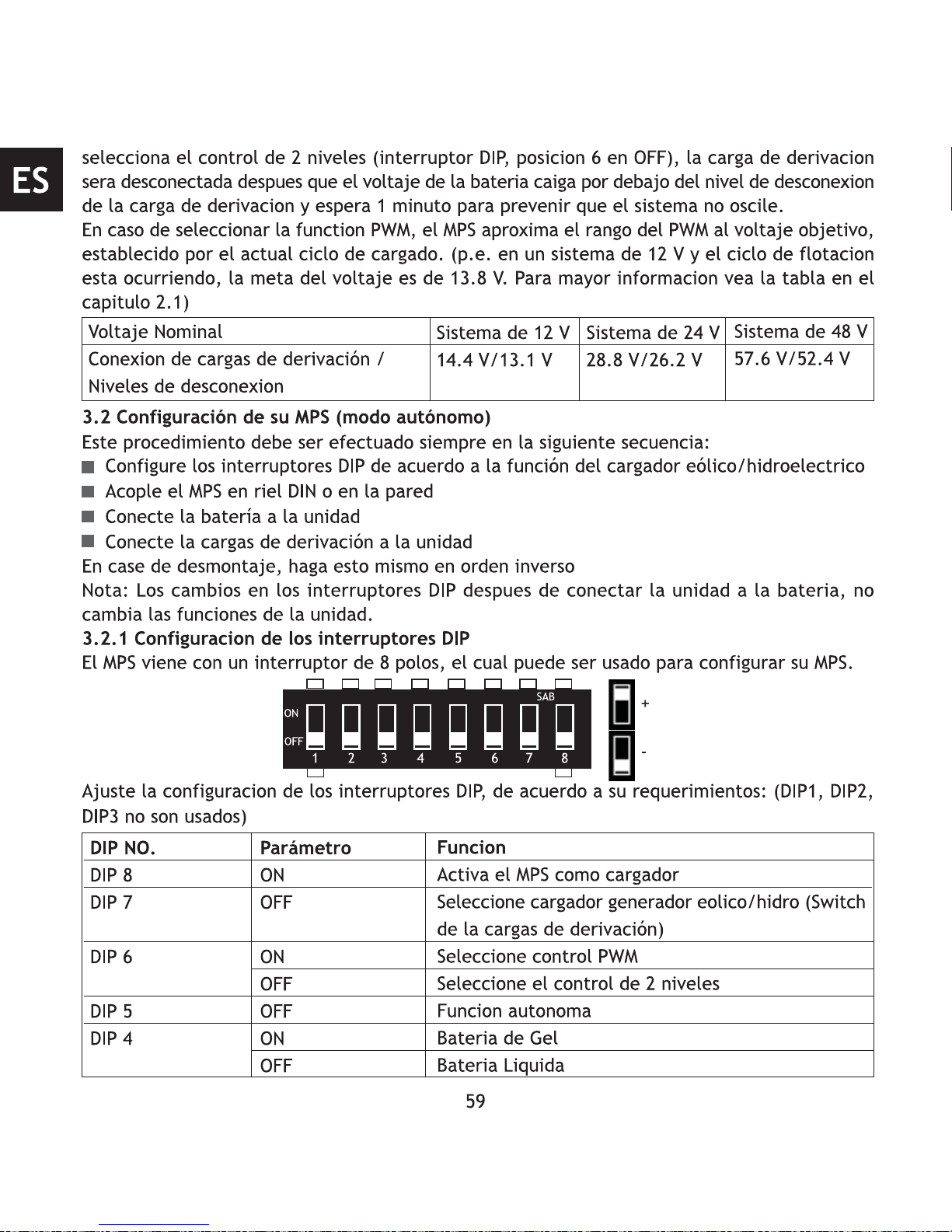

3.2.1 Setup DIP Switches

The MPS comes with an eight pole DIP-switch, which can be used to set up your MPS.

Adjust the DIP switch settings according to your requirements:(DIP1,DIP2 and DIP3 are unused)

voltage rises over the diversion load connect voltage. If two-point control is selected (DIP switch

6 OFF), the diversion load will be switched off after the battery voltage drops below the

diversion load disconnect level and pauses one minute to prevent the system from oscillation.

When PWM function is selected, the MPS approximates the PWM range to the actual running

charge cycle target voltage ( e.g. in a 12 V system and float cycle is running -> target voltage

is 13.8 V. For further information see the table in chapter 2.1)

38

Nominal voltage

Diversion load connect/disconnect level

12 V system

14.4 V/13.1 V

24 V system

28.8 V/26.2 V

48 V system

57.6 V/52.4 V

Setting

ON

OFF

ON

OFF

OFF

ON

OFF

Function

Activates MPS as charger

Activates wind/hydro charge controller (Diversion control)

Activates PWM control

Activates two-point control

Stand-alone function

Gel/AGM battery

Liquid lead acid battery

DIP NO.

DIP 8

DIP 7

DIP 6

DIP 5

DIP 4

EN

+

-

12345678

SAB

ON

OFF

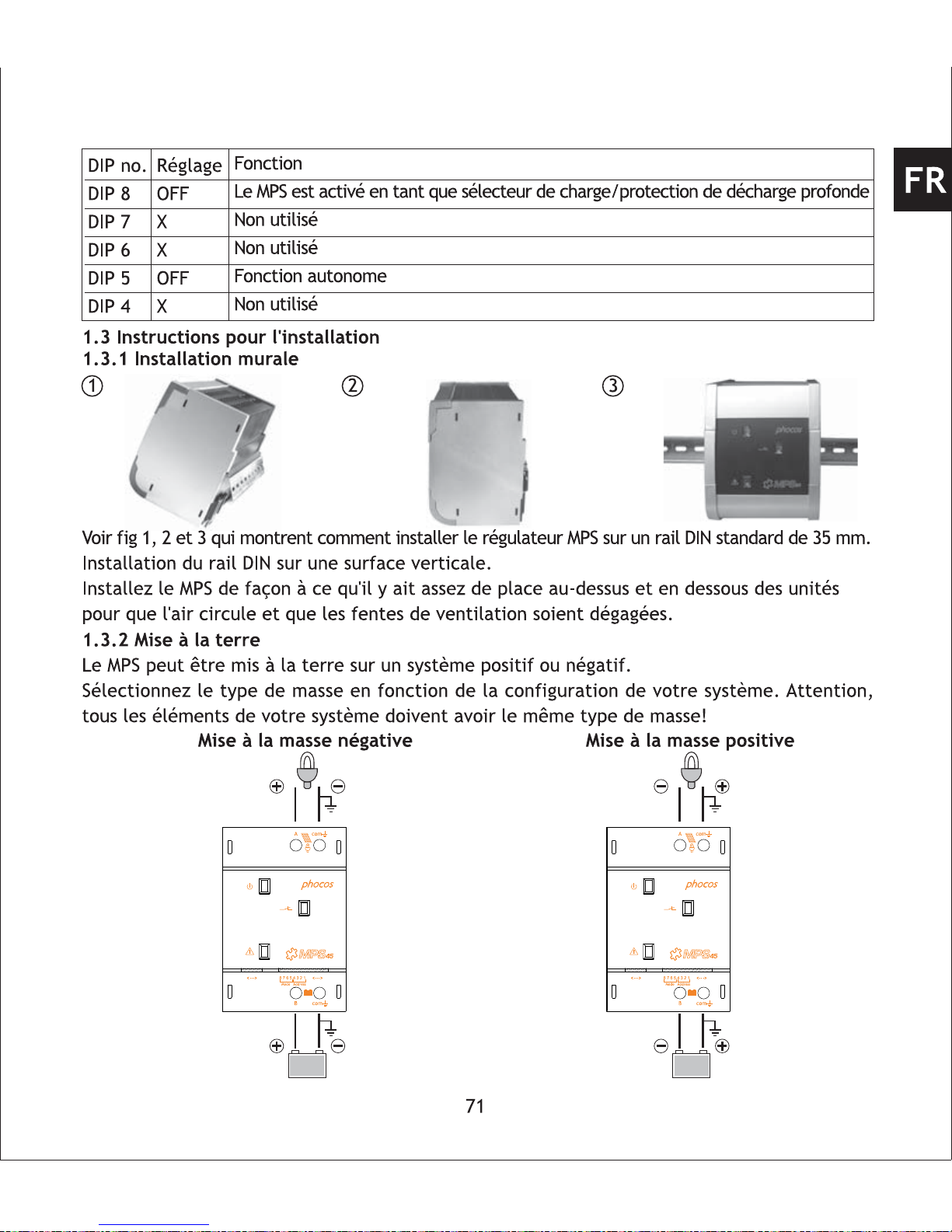

Please see fig .1, 2 and 3 showing how to install the MPS controller on a standard 35 mm DIN Rail.

Mount Din Rail onto a vertical surface.

Mount MPS in a way that ensures there is enough space below and above for the air to vertically

air flow through the ventilation grill.

3.3.3 Connecting the battery

Respect that batteries store a substantial amount of energy which can produce high current

and electric arc when a short circuit is applied to the battery. It is recommended to install a

battery fuse which must be able to carry currents of 1.5 times of your nominal system current

1 2

3

3.3.2 Grounding

MPS can work in negative or positive grounded systems.

Select the type of grounding according to your system requirements. Respect that all components

in your system should use the same type of grounding!

Positive groundedNegative grounded

com

comAB

87654321

AddressMode

com

comAB

87654321

AddressMode

Dump load Dump load

39

EN

3.3 Installation Instruction

3.3.1 Wall Mounting

40

3.3.4 Connecting the Diversion Load

Open the cover at the load terminals. Connect

the wires leading to the diversion load with the

correct polarity. Respect the different wiring

for negative and positive grounded systems.

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the covers.

Positive groundedNegative grounded

3.4 Starting up the Controller

After double-checking of all wires and terminals

insert battery fuse.

3.4.1 Self Test

As soon as battery voltage is applied to MPS, the unit begins a self test routine and wiringcheck. If system passes wiring-check, the LED display changes to "normal operation".

for safety considerations. Insert the fuse after you have connected all wires including the load

and make sure that all terminals are fixed tightly with proper polarity.

Negative grounded Positive grounded

Open the cover on the battery terminal side.

Connect the wires leading to the battery with

the proper polarity.

Mind the recommended wire length (See "Table

of recommended wiring for MPS units" on page

3.). MPS terminals can connect up to 35 mm

2

wire (AWG#2).

Wire size: See "Table of recommended wiring

for MPS units" on page 3.

Close the covers.

Dump

load

Dump

load

EN

Safety Recommendations

Batteries store a large amount of energy. Under all circumstances, never short-circuit a

battery. We recommend connecting a fuse (slow acting type, according to the nominal

controller current) directly to the battery terminal.

Batteries can produce flammable gases. Avoid making sparks, or using fire or any open

flame around the battery. Make sure that the battery room is ventilated.

Avoid touching or short circuiting wires or terminals. Be aware that the voltages on specific

terminals or wires can be as much as 95 V. Use isolated tools, stand on dry ground, and

keep your hands dry.

Keep children away from batteries and the MPS unit.

Please observe the safety recommendations of the battery manufacturer. If in doubt, consult

your dealer or installer.

Liability Exclusion

The manufacturer shall not be liable for damages, especially on the battery, caused by use

other than as intended or as mentioned in this manual, or if the recommendations of the battery

manufacturer are neglected. The manufacturer shall not be liable if there has been service

or repair carried out by any unauthorized person, unusual use, incorrect installation, or poor

system design.

Opening the case voids the warranty.

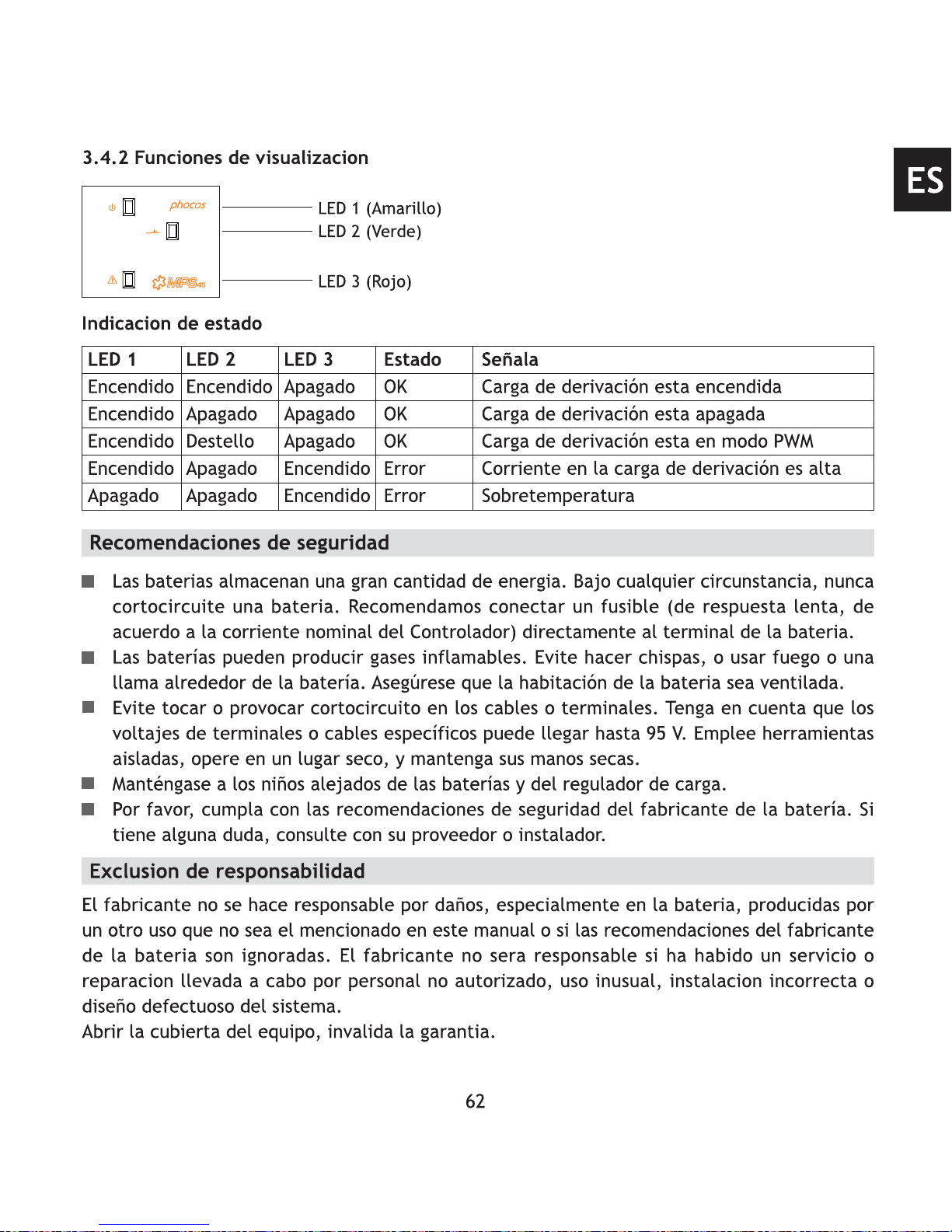

3.4.2 Display Functions

Status indication

Meaning

Diversion load is switched on

Diversion load is switched off

Diversion load is in PWM mode

Diversion load current too high

Over-temperature

LED 1

ON

ON

ON

ON

OFF

LED 2

ON

OFF

FLASH

OFF

OFF

LED 3

OFF

OFF

OFF

ON

ON

Status

OK

OK

OK

Error

Error

LED 3 (Red)

LED 1 (Yellow)

LED 2 (Green)

41

EN

Technical Data

12 V / 24 V / 48 V

MPS45: 45 A

MPS80: 80 A

30V in 12V system

50V in 24V system

95V in 48V system

<6 mA

-25 °C to + 50 °C

109 mm x 150 mm x 112 mm

MPS45: 1007 g

MPS80: 1100 g

IP 22

Nominal voltage

Max. current

Max. panel voltage

Self power consumption

Ambient temperature range

Dimensions

Weight

Case protection

RoHS

ISO9001

Subject to change without notice.

Version: 20140110

Made in one of the following countries:

China - Germany

Phocos AG - Germany

www.phocos.com

42

EN

Loading...

Loading...