PHINX PASRW080-V, PASRW050SB-VTD, PASRW060SB-VTD, PASRW060-V, PASRW080SB-VTD Installation And Instruction Manual

...

Installation and Instruction Manual

Air Source Water Chiller and Heat Pump

Floor heating and Air-con Unit (with Super Heater)

This is for: PASRW050(SB)-V(-TD)

PASRW060(SB)-V(-TD)

PASRW080(SB)-V(-TD)

PASRW100S(B)-V(-TD)

PASRW130S(B)-V(-TD)

CONTENT

1 Preface

1

3 Specification

5

(3) Specification data

6

(4) Unit Dimension

7

8

4 Installation

9

12

5 Usage

7 Appendix

24

18

19

18

22

2 Safety Precaution

2

(1) Mark notes

2

(2) Icon Notes

2

(3) Warning

3

25

26

28

(1) Nomenclature of the heat pump

(2) Appearance and Structure of the unit

5

5

8

9

9

10

10

11

11

12

15

21

21

23

23

10

(1) Application of heat pump

(2) Choose a right heat pump unit

(3) Installation place

(4) Installation method

(5) Water loop connection

(6) Power supply connection

(7) Location of the unit

(8) Transit

(9) Trial Running

(1) The displaying of the wire controller

(2) Installation of remote controller

6 Maintenance

(2) Ordinary malfunctions and solution

(1) Maintenance

(1) Appendix 1

(2) Appendix 2

(3) Appendix 3

(4) Appendix 4

(5) Appendix 5

(6) Appendix 6

(7) Appendix 7

(8) Appendix 8

(4) Attention

4

(3) Symbol meaning

16

(4) Functions associated with the buttons

17

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure the lo w

noise level with insulation.

5 Good heat exchange rate

The heat pump unit use special designed heat exchanger to enhance whole efficiency.

The unit must be installed by qualified personnel.

Failure to comply with these recommendations will invalidate the warranty.

2 Nice appearance

The heat pump is designed with beautiful looking. The monobloc one has the water

pump included which is very easy for installation.

3 Flexible installation

The unit has smart structure with compact body, just simple outdoor installation is needed.

This series of heat pump unit owns following features:

1 Advanced controlling

The PC microcomputer based controller is available for the users to review or set the

running parameters of the heat pump. Centralized co ntrolling system can control several

units by PC.

It is vital that the below instructions are adhered to at all times to k eep the warranty.

6 Large working range

This series of heat pump is designed to work under different working conditions as low

as -15 degrees for heating.

Preface

1

The manufacture of this product will not be held responsible if someone is injured or

the unit is damaged, as a result of improper installati on, debugging, unnecessary

maintenance which is not in line with this man ual.

This manual includes all the necessary inf ormation about installation, debugging,

discharging and maintenance. Please re ad this manual carefully before you open or

maintain the unit.

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure the lo w

noise level with insulation.

5 Good heat exchange rate

The heat pump unit use special designed heat exchanger to enhance whole efficiency.

The unit must be installed by qualified personnel.

—The unit can only be opened or repaired by qualified installer or an authorised dealer.

—Use genuine standard spare parts only.

—Maintenance and operation must be carrie d out according to the recommended time and

frequency, as stated in this manual.

Failure to comply with these recommendations will invalidate the warranty.

2 Nice appearance

The heat pump is designed with beautiful looking. The monobloc one has the water

pump included which is very easy for installation.

3 Flexible installation

The unit has smart structure with compact body, just simple outdoor installation is needed.

This series of heat pump unit owns following features:

1 Advanced controlling

The PC microcomputer based controller is available for the users to review or s et the

running parameters of the heat pump. Centralized co ntrolling system can control several

units by PC.

It is vital that the below instructions are adhered to at a ll times to keep the warranty.

Air source water chiller and heat pump is a kind o f high efficiency, energy saving and

environment friendly equipment, whic h is mainly used for house warming. It can work with

any kind of indoor unit such fan coil, radiato r, or floor heating pipe, by provide warm or hot

water. One unit of monobloc heat pump can also wo rk with several indoor units.

The air source water heat pump unit is designe d to have heat recovery by using super

heater which can provide hot water for sanit ary purpose.

6 Large working range

This series of heat pump is designed to work under different working conditions as low

as -15 degrees for heating.

In order to provide the customers with high quality, strong reliability and good versatility

product, this heat pump is produced by strict design an d manufacture standards.

Preface

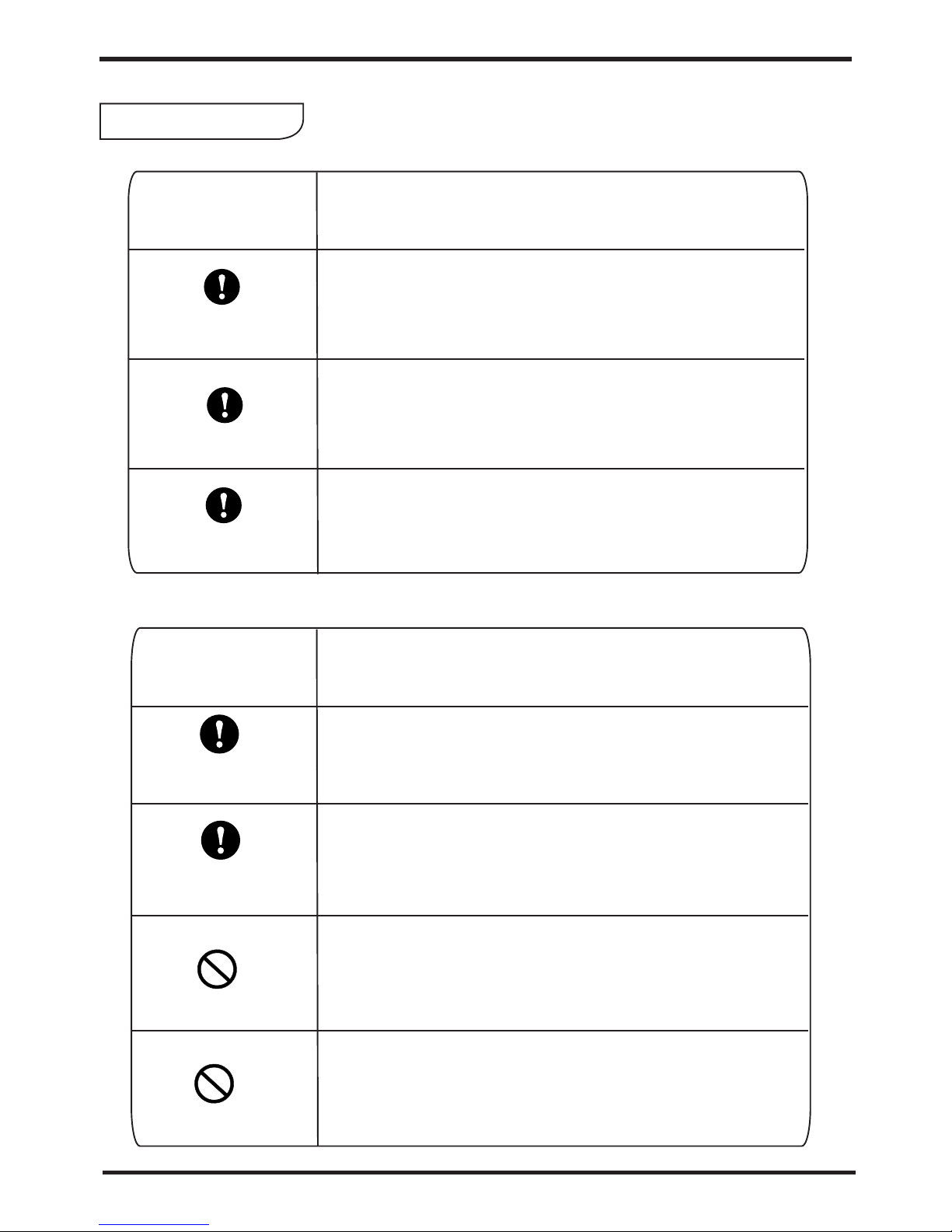

Mark

Icon

Meaning

Meaning

A wrong operation may lead to death or heavy injury on people.

A wrong operation may lead to harm on people or loss of material.

Prohibition. What is prohibited will be nearby this icon

Compulsory implement. The listed action need to be taken.

ATTENTION (include WARNING)

Please pay attention to what is indicated.

Mark Notes

Icon notes

WARNING

ATTENTION

To prevent the users and others from the harm of this unit, and avoid damage

on the unit or other property, and use the heat pump properly, please read this

manual carefully and understand the following information correctly.

Safety Precaution

Safety Precaution

安装前注意事项

The heat pump must be installed by qualified personals,

to avoid improper installation which can lead to water

leakage, electrical shock or fire.

Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical shock.

Installation

Professional installer

is required.

Earthing is required

Warning

Safety Precaution

Meaning

Operation

Meaning

PROHIBITION

Shut off the power

DO NOT put fingers or others into the fans and evaporator

of the unit, otherwise harm may be occurred.

When there is something wrong or strange smell, the power

supply need to be shut off to stop the unit. Continue to run

may cause electrical short or fire.

Move and repair

Entrust

Prohibit

Entrust

When the heat pump need to be moved or installed again,

please entrust dealer or qualified person to carry it out.

Improper installation will lead to water leakage, electrical

shock, injury or fire.

It is prohibited to repair the unit by the user himself, otherwise

electrical shock or fire may be occur.

When the heat pump need to be repaired, please entrust

dealer or qualified person to carry it out. Improper movement

or repair on the unit will lead to water leakage, electrical

shock, injury or fire.

Meaning

32

Switch off

the power

Prohibition

Please switch off the power for clean or maintenance.

It is prohibited to use copper or iron as fuse. The right fuse

must be fixed by electrician for the heat pump.

It is prohibited to spray the flammable gas to the heat pump,

as it may cause fire.

Installation

Operation

Prohibition

安装前注意事项

ATTENTION

Check the

installation basement

Please check the installation basement in a period (one month),

to avoid any decline or damage on the basement, which may

hurt people or damage the unit

Safety Precaution

Meaning

Fix the unit

Installation Place

Need

circuit breaker

The unit CANNOT be installed near the flammable gas.

Once there is any leakage of the gas, fire can be occur.

Make sure that the basement of the heat pump is strong

enough, to avoid any decline or fall down of the unit

Make sure that there is circuit breaker for the unit, lack of

circuit breaker can lead to electrical shock or fire.

Meaning

Specification

1 Nomenclature of the heat pump

4

Specification

2 Appearance and structure of the unit:

1 Nomenclature of the heat pump

4: mode C--cooling only R--heating and cooling D--a ux-electrical heater

3: system loop X--gas loop S--water loop

6: capacity nominated cooling or heating capacity ( 3 figures,horsepower/10)

2: heat source A--air source W--water source

1: P--Product

5: outdoor unit type W--monobloc type F--split type

7: power supply (omit)--single phase power S--thr ee phase power

For example: PASCW060B-V stand for air source water chiller with 6 horsepower

cooling capacity(15kw) and with water pump

8: water pump (omit)-no water pump B--water pump included

9: Appendix V- the shape of condenser

P A S R W 050 S B- V- T D

1 2 3 4 5 6 7 8 9 10 11

Wire

controller

The maximum cable for

the wire controller is 200

metres from the heat pump.

10: water tank (omit)--no water tank T--water tank included

11: Auxiliary electrical heater (omit)--without auxiliary electrical heater

D--with auxiliary electrical heater

5

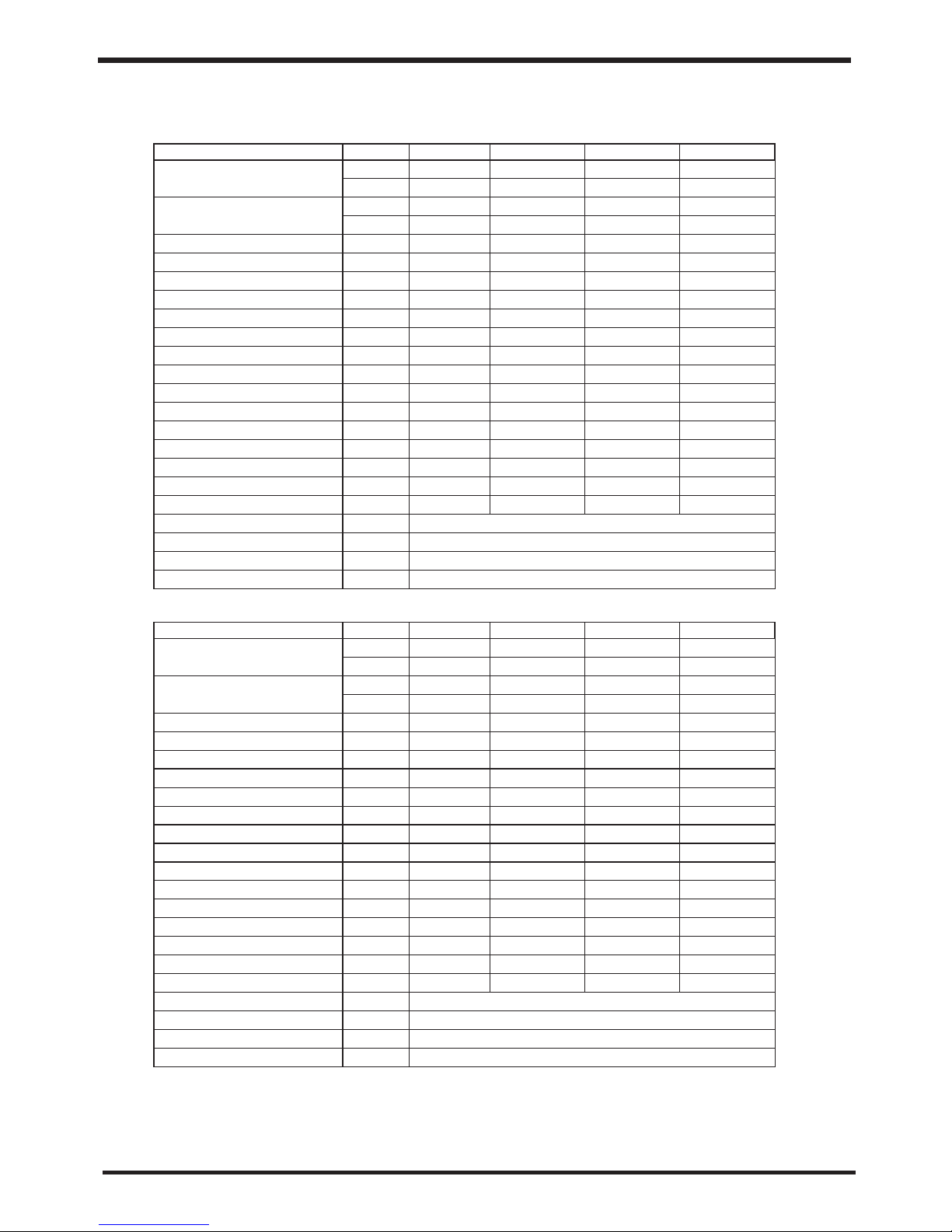

Specification

Unit Mo del

Cooli ng Ca pacit y

Heati ng Ca pacit y

Cooli ng Po wer Inp ut

Heati ng Po wer Input

Runni ng Cu rrent (Co oli ng/He ati ng)

Power S upp ly

Compr ess or Quantit y

Compr ess or

Fan Qua nti ty

Fan Pow er In put

Fan rot ate s peed

Noise

Wat er Pu mp Inpu t

Wat er he ad

Wat er Co nnect ion

Wat er Fl ow Volum e

Wat er Pr essur e Dro p

Unit Ne t Dim ensio ns( L/W /H)

Unit Sh ipp ing Dim ens ion s(L/W /H)

Net Weight

Shipp ing W eig ht

PASR W

kW

BTU/h

kW

BTU/h

kW

kW

A

V/Ph/ Hz

W

RPM

dB(A)

kW

m

inch

3

m / h

kPa

mm

mm

kg

kg

Cooling: temperature:35℃/24℃,Inter/outlet water temperature:12℃/7℃

Heating: tempe ra tu re :7℃/ 6℃,I nt er /outlet water temperature:30℃/35℃

Ambient

Ambient

(Above information just for your reference , Pl ea se s ub je ct t o na me pl at e on t he u ni t)

050(B )-V( -TD)

11.5

40000

15.0

52000

4.2

3.6

18.3/ 15. 7

230/1 /50

2

Rotar y

1

390×1

900

56

0.2

10

1

2.3

34

060S( B)-V (-TD)

13.5

46000

17.0

58000

4.9

4.1

8.4/7 .1

380/3 /50

1

Scrol l

1

390×1

900

56

0.2

10

1

2.8

34

060(B )-V (-TD)

13.5

46000

17.0

58000

4.7

4.1

20.4/ 17. 8

230/1 /50

2

Rotar y

1

390×1

900

56

0.2

10

1

2.8

34

Unit Mo del

Cooli ng Ca pacit y

Heati ng Ca pacit y

Cooli ng Po wer Inp ut

Heati ng Po wer Input

Runni ng Cu rrent (Co oli ng/He ati ng)

Power S upp ly

Compr ess or Quantit y

Compr ess or

Fan Qua nti ty

Fan Pow er In put

Fan rot ate s peed

Noise

Wat er Pu mp Inpu t

Wat er he ad

Wat er Co nnect ion

Wat er Fl ow Volum e

Wat er Pr essur e Dro p

Unit Ne t Dim ensio ns( L/W /H)

Unit Sh ipp ing Dim ens ion s(L/W /H)

Net Weight

Shipp ing W eig ht

PASR W

kW

BTU/h

kW

BTU/h

kW

kW

A

V/Ph/ Hz

W

RPM

dB(A)

kW

m

inch

3

m / h

kPa

mm

mm

kg

kg

080S( B)- V(-TD)

18.0

61500

23.0

78000

6.4

5.6

11.0 /9.7

380/3 /50

2

Scrol l

2

390×2

900

59

0.75

24

1.5

3.8

36

100S( B)- V(-TD)

22.5

76700

28.0

95500

8.6

6.8

14.8/ 11.7

380/3 /50

2

Scrol l

2

390×2

900

60

0.75

24

1.5

4.6

37

130S( B)- V(-TD)

25.5

87000

35.0

12000 0

10.2

8.5

17.6/ 14. 7

380/3 /50

2

Scrol l

2

390×2

900

60

0.75

24

1.5

5.8

38

080(B )-V (-TD)

18.0

61500

23.0

78000

6.4

5.6

27.8/ 24. 3

230/1 /50

2

Scrol l

2

390×2

900

59

0.75

24

1.5

3.8

36

050S( B)-V (-TD)

11.6

40000

15.0

52000

4.1

3.7

7.1/6 .4

380/3 /50

1

Scrol l

1

390×1

900

56

0.2

10

1

2.3

34

See the d raw ing of the uni ts

see pac kag e label

see nam epl ate

see pac kag e label

See the d raw ing of the uni ts

see pac kag e label

see nam epl ate

see pac kag e label

3. Specification data

Specification

4.Unit Dimension

Specification

Water inlet

Water outlet

Drainage

73

5

4

8

0

985

1015

1

130

3

With water tank

of the units

Without water tank

of the units

3

1

2

5

1

2

4

5

4

5

4

3

2

1

Sanitary hot water outlet

Sanitary hot water inlet

Remark:

7

3

5

48

0

985

1015

1

1

3

0

With water tank

of the units

Without water tank

of the units

Water inlet

Water outlet

Drainage

5

4

3

2

1

Sanitary hot water outlet

Sanitary hot water inlet

Remark:

3

3

1

2

5

1

2

4

5

4

4.Unit Dimension

Model:PASRW050/060(B)-V(-TD)

Model: PASRW050/060S(B)-V(-TD)

735

480

1464

1490

1130

With water tank

of the units

Without water tank

of the units

Water inlet

Water outlet

Drainage

5

4

3

2

1

Sanitary hot water outlet

Sanitary hot water inlet

Remark:

5

4

3

1

2

5

4

3

2

1

Model: PASRW080/100/130S(B)-V(-TD)

76

Installation

1 Application of heat pump

1.1 Only for air-con

WATER COUPLING

AUTOMATIC AIR VENT

CHECK-VALVE FOR WATER

FLEXIBLE CONNECTION FOR WATER

DIRTY DRAI N

WATER THERMOMETER

WATER PRESSURE METER

WATER FILTER

4 Installation method

2 Choose a right heat pump unit

2.1 Based on the local climate condition, co nstruction features and insulation level,

calculate the required cooling(heati ng) capacity per square meter.

2.2 Conclude the total capacity which will b e needed by the construction.

2.3 According to the total capacity needed, c hoose the right model by consulting the heat.

pump features as below:

Heat pump features

Cooling only unit: chilled water outlet tem p. at 5-15 , maximum ambient temp. at 43 .

Heating and Cooling unit:for cooling chilled water outlet temp. at 5-15 ,maximum

ambient temp. at 43 . For heating, warm water inlet temp. at 40-50 , minim um ambient

temp. at -10 .

Unit application

Air source water chiller and heat pump is used fo r house, office, hotel, and so forth, which

need heating or cooling separately, with each area need to be control led.

The unit can be installed on any place outdoor which can carry heavy mac hine such

as terrace, housetop, ground and so on.

3 Installation place

Installation

4 Installation method

The heat pump can be installed onto the concrete basement by expansi on screws, or

onto a steel frame with rubber feet which can be p laced on the ground or housetop.

Make sure that the unit is placed horizontal ly.

2 Choose a right heat pump unit

2.1 Based on the local climate condition, co nstruction features and insulation level,

calculate the required cooling(heati ng) capacity per square meter.

2.2 Conclude the total capacity which will b e needed by the construction.

2.3 According to the total capacity needed, c hoose the right model by consulting the heat.

pump features as below:

Heat pump features

Cooling only unit: chilled water outlet tem p. at 5-15 , maximum ambient temp. at 43 .

Heating and Cooling unit:for cooling chill ed water outlet temp. at 5-15 ,maximum

ambient temp. at 43 . For heating, warm water inlet temp. at 40-50 , minim um ambient

temp. at -10 .

℃ ℃

℃

℃ ℃

℃

Unit application

Air source water chiller and heat pump is used fo r house, office, hotel, and so forth, which

need heating or cooling separately, with each area need to be control led.

There must be enough space around the unit for maintenance.

The place is free from heat radiation and othe r fire flame.

There must be not obstacles near the air inlet a nd outlet of the heat pump.

A place which is free from strong air blowing.

There must be water channel around the heat pu mp to drain the condensing water .

The location must have good ventilation.

The unit can be installed on any place outdoor which can carry heavy mac hine such

as terrace, housetop, ground and so on.

A pall is needed in winter to protect the heat pump from snow.

3 Installation place

Installation

98

5 Water loop connection

Please pay attention to below matters when the water pipe is connected:

Try to reduce the resistance to the water from the piping.

The piping must be clear and free from dirty and b locks. Water leakage test must be

carried out to ensure there is no water leakin g. And then the insulation can be made.

Attention that the pipe must be tested by pressure separately. DO NOT test it together

with the heat pump.

The flow switch is installed inside of the hea t pump, check to ensure that the wiring and

action of the switch is normal and controlle d by the controller.

Try to avoid air stayed inside of the water pipe, and there must be air vent on the top

point of the water loop.

There must be thermometer and pressure met er at the water inlet and outlet, for easy

inspection during running.

There must be expansion tank on the top point of t he water loop, and the water level in

the tank must be at least 0.5 meter higher than the top point of the water loop.

6 Power supply connection

Open the front panel, and open the power supply access.

If the outside water pump is needed, please insert the power supply wire into the wire

access also and connect to the water pump term inals.

The power supply must go through the wire acce ss and be connected to the power

supply terminals in the controlling box. Then connect the 3-sign al wire plugs of the

wire controller and main controller.

If an additional auxiliary heater is need to be controlled by the heat pump controller,

the relay (or power) of the aux-heater must be c onnected to the relevant output of

the controller.

7 Location of the unit

A

B

Air inlet

Air outlet

C

Mai ntena nce

spa ce

Requirement:

A>500mm; B>500mm;

C>1000mm;D>500mm。

ATTENTION

wall

wall

wall

wall

Installation

Inl et wate r

Out let w ate r

Air inlet

D

Installation

9 Trial Running

8 Transit

When the unit need to be hung up during installa tion, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent dama ge to

the heat pump cabinet. (See picture 1)

DO NOT touch the heat exchanger of the heat pump with fingers or other objects!

10 11

Installation

Inspection before trial running

Check the indoor unit, and make sure that the pipe connection is right and the relevant

valves are open .

Check the heat pump unit including all of the sc rews and parts of the heat pump to see if

they are in good order. When power on, review the i ndicator on the controller to see if

there is any failure indication. The gas gauge can be connected to the check valve to

see the high pressure(or low pressure) of th e system during trial running.

Check the water loop, to ensure that the water inside of th e expansion tank is enough, the

water supply is good, the water loop is full of wa ter and without any air. Also make sure

there is good insulation for the water pipe.

Check the electrical wiring. Make sure tha t the power voltage is normal, the screws are

fastened, the wiring is made in line with the di agram, and the earthing is connected.

Trial running

Start the heat pump by press " " key on the controller. Check whether the water

pump is running, if it runs normally there wil l be 0.2 MPa on the water pressure meter.

When the water pump runs for 1 minutes, the compressor wi ll start. Hear whether there is

strange sound from the compressor. If abnormal sound occurs please stop the unit and

check the compressor. If the compressor runs well please look for the pressure meter

of the refrigerant.

9 Trial Running

Then check whether the power input and runni ng current is in line with the manual. If not

please stop and check.

Review whether the outlet water temperat ure is stable.

The parameters of the controller are set by the factory, it is not allowed to change then

by user himself.

Adjust the valves on the water loop, to make sure that the ho t(cool) water supply to each

door is good and meet the requirement of heati ng(or cooling).

8 Transit

When the unit need to be hung up during installa tion, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent dama ge to

the heat pump cabinet. (See picture 1)

WARNING

DO NOT touch the heat exchanger of the heat pump with fingers or other objects!

Picture 1

or

Usage

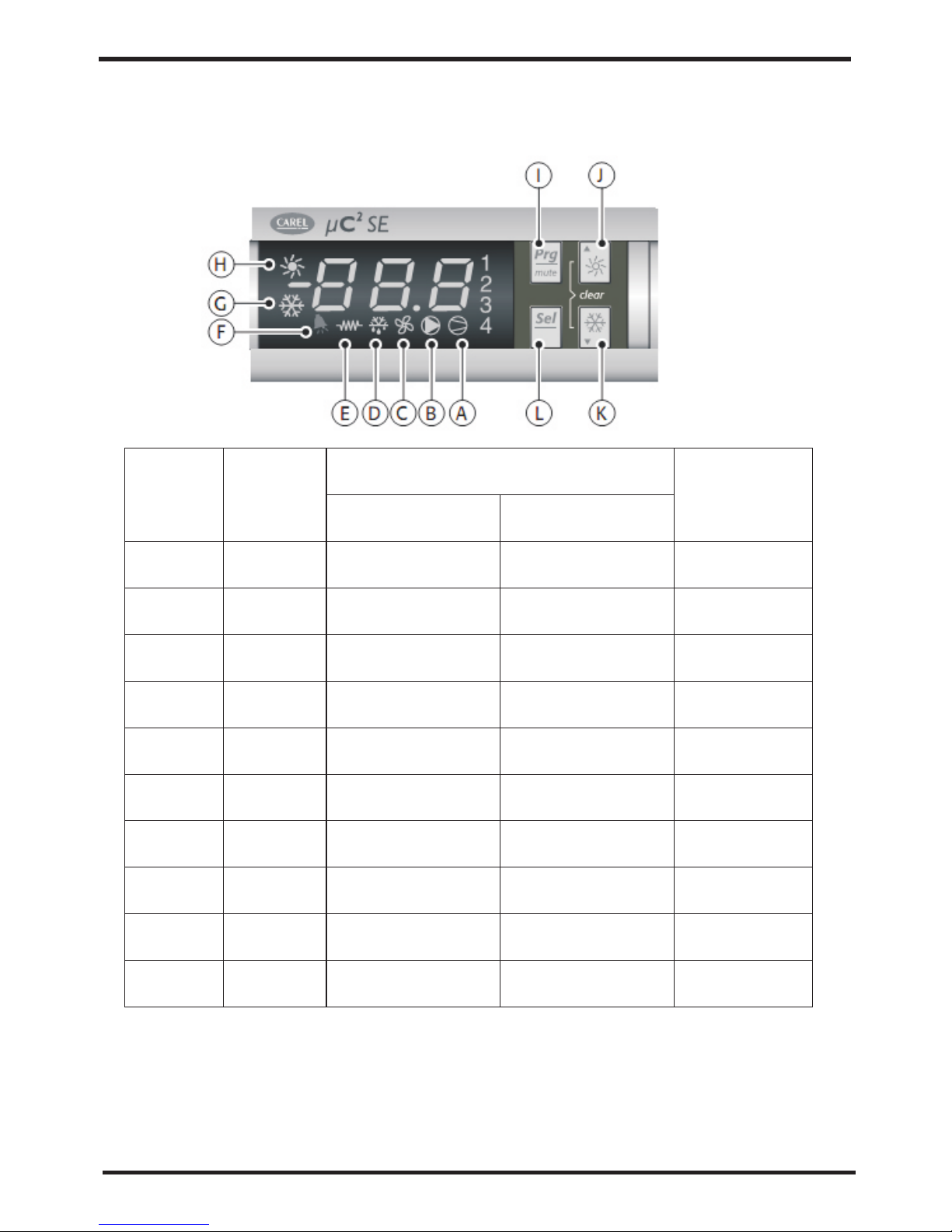

5.1 The displaying of the wire controller

Symbol

Colour

Meaning

Reference

refrigerant

circuit

1;2

3;4

A

B

C

D

E

F

G

H

Amber

Amber

Amber

Amber

Amber

Amber

Amber

Amber

Amber

Red

With LED ON With LED flashing

Compressor 1and/or

2ON

Compressor 3and/or

4ON

At least one

compressor ON

Pump ON

Condenser fan ON

Defrost active

Heater ON

Alarm active

Heat pump mode

Chiller mode

Start up request

Start up request

Start up request

Defrost request

Heat pump mode

request

Chiller mode request

1

2

1/2

1/2

1/2

1/2

1/2

1/2

1/2

1/2

Usage

2 Functions associated with the buttons

12

Usage

2 Functions associated with the buttons

Button

Unit status

Button press

I

L

I+L

J

K

J+K

L+J

Loading default values

Go up a sub-group inside the programming

area, until exiting (saving changes to EEPROM)

In the event of alarms, mute the buzzer

(if present) and deactivate the alarm relay

Access the direct parameters

Select item inside the programming area and

display value of direct parameters/conirm the

changes to the parameters

Program parameters afters entering password

Select top item inside the programming area

Increase value

Switch from standby to chiller mode (P6=1) and

vice versa

Provides immediate access to the condenser and

evaporator pressure and temperature probes and

DTE, DTC1-2

Select bottom item inside the programming area

Decrease value

Switch from standby to heat pump mode (P6=1)

and vice versa

Provides immediate access to the condenser

and evaporator pressure and temperature probes

and DTE, DTC1-2

Manual alarm reset

Mmediately reset the hour counter (inside the

programming area)

Force manual defrost on both circuits

Press at power ON

Press once

Press once

Press for 5s

Press once

Press for 5s

press once or press

and hold

press once or press

and hold

Press for 5s

Press once

press once or press

and hold

press once or press

and hold

Press for 5s

Press once

Press for 5s

Press for 5s

Press for 5s

13

Usage

3 Programming and saving the parameters

1

If you press“ ”,the unit will be heating mode;

If you press“ ”,the unit will be cooling mode;

[1]Start or stop unit

press“ ” lasts 3 seconds to start or stop unit, the

LED display as following:

or

[2]Check the setting data and amend the setting

2) press“ ” to go into parameter group.

1

1) press“ ” to go into data setting.

3)use“ ”and“ ”to select the

parameter group and then press“ ”.

4)use“ ”and“ ”to select the

parameter and then press“ ”.

5)after making the changes to the parameter,

press“ ”to confirm or “ ”to cancel the

changes.

6)Press“ ”to return to the previous menu

to save the modiications, press“ ”repeatedly

until reaching the main menu

1

Usage

5.2 Installation of remote controller

RJ12

Power supply

14

Usage

5.2 Installation of remote controller

(1)Connection

Telephone cable

Max.l.=40m

RJ12

Power supply

G0 G

G0

G

N F

24Vac 17VA

Fuse 250mA

Max.l.=250m

(min.cross-section

1.5mm2/AWG16)

RS485

twisted pair + shield

Rx/Tx+, Rx/Tx-, Gnd

Insert 120 ohm

terminal resistor

between Tx/Rx+

and Tx/Rx- for lines

longer than 20 m

To install the remote terminal, no

configuration is required on the UC2,

as the terminal works with any serial

address set for parameter H10.

Check, however, that is fitted with the

serial interface the Uc2 FCSER00000

.When first switched on the display

will show the. firmware version of the Uc2

After around 4 s the main screen will be

displayed, with the symbols that represent

he status of the Uc2.

1

15

Usage

Usage

In the event where the RS485 connection

is not performed correctly or the controller

is off, the terminal will clear the display and

show the message“OFFLINE”

Pressing the “Up”+“Down”+“Sel”

buttons together for more than 6 seconds

displays the“INFO”screen containing

information on the UC2 system and on the

communication.

Pressing the“Prg”button returns to the

main screen.

5.3 Symbol meaning

Symbol

Meaning

ON

Flashing

Refrigerant circuit

involved

1,2

3,4

Alarm button

red LED

Compressor 1

and/or 2 ON

Start request

1

2

Start request

Compressor 3

and/or 4 ON

At least one

compressor ON

1 and/or 2

1 and/or 2

1 and/or 2

1 and/or 2

1 and/or 2

1 and/or 2

1 and/or 2

1 and 2

1 and 2

Pump ON

Start request

Condenser fan ON

Start request

Defrost active

defrost request

Heater ON

Start request

Alarm active

EEPROM alarm

Alarm active

Warning relay

activated

Alarm relay active

Heat pump mode

(P6=1)

Chiller mode

(P6=1)

Season changeover

reques

Season changeover

reques

5.4 Functions associated with the buttons

16

Usage

5.4 Functions associated with the buttons

Press for 5 s

Button Button operationUnit status

Switch off buzzer or alarm relay,

if alarm active

Press once

Enter parameter programming mode

after entering password

Return to higher subgroup inside the

programming environment until

exiting, saving to EEPROM

Press once

Manual reset of alarms that are no

longer active

Press once

Select higher item inside the

programming environmen

Switch from standby to heat pump

mode (P6= 1) and vice-versa

Press once or

hold

Press for 5 s

Access direct parameters:selection

(as for button on Uc2)

Select item inside the programming

environment and display direct

parameter values/confirm the changes

to the parameter

Press for 5 s

Press once

Select lower item inside the

programming environmen

Switch from standby to chiller mode

(P6= 1) and vice-versa

+

Immediately reset the hour counter

(inside the programming environment)

Start manual defrost on both circuits

Display the terminal Info screen

Press once or

hold

Press for 5 s

Press for 5 s

Press for 5 s

Press for 6 s

17

1、Maintenance

Check the water supply and air vent frequently, to avoid lack of water or air in the water loop.

Clean the water filter in a certain period to keep good water quality. Lack of water and dirty

water can damage the unit. The heat pump will start the water pump per 72 hours when it is

not running, to avoid freezing.

Keep the unit in a place which is dry and clean, and h as good ventilation. Clean the heat

exchanger in 1 or 2 month and keep good heat excha nge rate and save energy.

Check each part of the unit and the pressure of the system. Replace the failure part if there

is any, and recharge the refrigerant if it is needed.

If the heat pump is not used for a long time, please drain out al l the water in the unit and

seal the unit to keep it good. Please drain the water from th e lowest point of the heat

exchanger to avoid freezing in winter. Water recharge and full inspection on the heat

pump is needed before it is restarted.

Check the power supply and the electrical sy stem, mak e sure the electrical components are

good, the wiring is well. If there is any part failed with wr ong action or smell, please replace

in time.

The water loop of the heat pump MUST be protected from freezing in winter time.Please

pay attention to below suggestions.Nonobservance on below suggestion will invalid the

warranty for the heat pump.

(1) Please do not shut off the power supply to the heat pump in winter. When the ai r

temperature is below 0 ℃, if the inlet water temperature is above 2 ℃ and b elow 4℃,

the water pump will start for freezing protect, if the inlet water is lower than 2 ℃, the

heat pump will run for heating.

(2) Use anti-freezing liquid (glycol water)

1) look for below table for the volume of the glycol water

2) the glycol water can be added into the system from the expansion ta nk of the water loop.

Note: if the glycol water is too much, the water flow and water pump will be influenced

and the heat exchange rate will be decreased. This table is for reference, please

use anti-freezing water according to the real condition of the local climate.

Please drain out the water in the super heater of the heat pu mp unit in winter, when the

super heater is not used.

50

-33

0.946

0.966

1.178

1.308

40

-22

0.961

0.976

1.121

1.263

30

-14

0.972

0.986

1.074

1.181

20

-8

0.982

0.992

1.040

1.129

10

-3

0.991

0.996

1.013

1.070

Glycol percentage (%)

ambient temp. (℃)

cooling/heating capacity fluctuati on

power input fluctuation

water flow fluctuation

water drop fluctuation

Maintenance

2.Ordinary malfunctions and solution

Maintenance

18 19

1) According to failure code of the controller,we can judge

and solute the failure.

2.Ordinary malfunctions and solution

Maintenance

malfunction

display

Water inlet temp.

Sensor failure

Evaporator sensor

failure

Anti freezing

under cooling mode

E1

E2

E3

tC1

Reason

The sensor is open

or short circuit

Check or change the sensor

resolution

Water flow rate

is not enough

Ambient temp. too low

Water outlet temp.

Sensor failure

The sensor is open

or short circuit

Check or change the sensor

The sensor is open

or short circuit

Check or change the sensor

Check the water flow volume,or

water system is jammed or not

The antifreezing

protection in winter

High pressure

protect

Check through each pressure

switch and return circuit

High pressure

switch action

Normal working

Flow switch failure

No water/little water

in water system.

Check the water flow volume,

water pump is failure or not

Low pressure

protect

Low pressure

switch action

Check through each pressure

switch and return circuit

Exhaust

temperature protect

HP1

LP1

FL

A1

A1

Exhaust temperature

is too high

Check through each temp.

switch and return circuit

2)、Look over and clear the failure according to below information.

Failure

Possible causes for the failure

Solutions

Heat pump

cannot

be starte d

1 Wrong p ower supp ly

2 power sup ply cable l oose

3 circuit b reaker op en

1 shut off the power a nd check po wer suppl y;

2 check pow er cable an d make righ t connect io n

3 check for t he cause an d replace t he fuse or

circuit b reaker

Wat er pump is

running w ith

high nois e or

without w ater

1 lack of wat er in the pip ing

2 much air in t he water lo op

3 water vav les close d

4 dirt and bl ock on the wa ter filte r

1 check the w ater supp ly and char ge water

to the pipi ng;

2 dischar ge the air in t he water lo op;

3 open the va lves in wat er loop;

4 clean the w ater filt er.

Heat pump

capacit y is low,

compres sor

do not stop

1 lack of ref rigeran t;

2 bad insul ation on wa ter pipe;

3 low heat ex change ra te on air sid e

exchang er;

4 lack of wat er flow

1 check for t he gas leak age and rec harge the

refrige rant;

2 make good i nsulati on on water p ipe;

3 clean the a ir side hea t exchang er;

4 clean the w ater filt er

High comp ressor

exhaust

1 too much re frigera nt

2 low heat ex change ra te on air sid e

exchang er

1 dischar ge the redu ndant gas

2 clean the a ir side hea t exchang er

Low press ure

problem

of the syst em

1 lack of gas

2 block on fi lter or cap illary

3 lack of wat er flow

1 check the g as leakag e and recha rge freon ;

2 replace f ilter or ca pillary ;

3 clean the w ater filt er and disc harge the a ir in

water loo p.

Compres sor do

not run

1 power sup ply failu re

2 compres sor conta ctor brok en

3 power cab le loose

4 protect ion on comp ressor

5 wrong set ting on ret urn water t emp.

6 lack of wat er flow

1 check off the powe r supply;

2 replace c ompress or contac tor;

3 tighten t he power ca ble;

4 check the c ompress or exhaus t temp.;

5 reset the r eturn wat er temp.;

6 clean the w ater filt er and disc harge the a ir i n

water loo p.

High nois e of

compres sor

1 liquid re frigera nt goes int o compres so r

2 compres sor failu re

1 bad evapo ration, c heck the ca use for bad

evapora tion and ge t rid of this ;

2 use new com pressor ;

Fan do not ru n

1 failure o n fan relay

2 fan motor b roken

1 replace t he fan rela y;

2 replace f an motor.

The compr essor

runs but he at

pump has no t

heating o r

cooling c apacity

1 no gas in the h eat pump;

2 heat exch anger bro ken;

3 compres sor failu re.

1 check sys tem leaka ge and rech arge refr ig erant ;

2 find out th e cause and r eplace th e heat

exchang er;

3 replace c ompress or.

Low outle t water

tempera ture

1 low water f low rate;

2 low setti ng for the de sired wat er temp.;

1 clean the w ater filt er and disc harge the a ir in

water loo p.

2 reset the d esired wa ter tempe rature.

Low water f low

protect ion

1 lack of wat er in the sys tem;

2 failure o n flow swit ch

1 clean the w ater filt er and disc harge the a ir in

water loo p.

2 replace t he flow swi tch.

Maintenance

Appendix 1 Install sketch map

Appendix

20

Especial installation( expandable water tank)

Appendix 1 Install sketch map

Appendix

Remark

1 main unit

2 fan coil

3 rubber flexible connection

4 thermometer

5 manometer

6 Y type filter

8 ball valve

10 bypass valve

1/2'

Technical request:

1.Each connection must be connected tightly and have no leakage.

2.the arrowhead orientation of automatic filled- water

must accord with water supply.

3.The pressure of automatic filled-water has been

set,and please do not remove screw.

autom ati c

fill- wat er

valve

Press ure

leaka ge

valve

2

1 4

1 5

1 3

1 7

Installation request:

1 The factory only offers main unit (1)in the legend, and the other modules

which are indispensable fittings, are provided by users or installation company.

2 The unit which of code contains the letter "B" ,has water pump inside and need

not install water pump outside (16)

3 Automatic ventilation(15)is installed on the top point of the water system。

4 The quantity proportion of two-way valve(13)and three-way valve(14)is

referred to the technical regulation, and there is three-way valve installed on the

farthest place of water system.

5 The ball valve (17) is used when it is swashed, filled water in the water system

and so on.

1

3

4

5

1 0

1 2

1 8

1 6

2 0

6

1 1

1 9

Conne ct supp ly pi pe

1/2'

inlet

outlet

8

11 drain valve

12 filter

13 two-way valve

14 three-way valve

15 automatic ventilation

16 water pump

17 ball valve

18 ball valve

19 expandable water tank

20 automatically filled-water

21

Appendix 2:

The installation explanation of automatic filled-water

1 When automatic filled-water valve is installed,the arrowhead orientation of inlet water must

accord with the orientation of valve ;

2 Automatic filled-water has been adjusted in advance to 1.5bar;

3 If readjust the pressure of inlet water,please operate as follows:

* open the screw cap(C);

* If reduce the pressure of water supply,pease unscrew the pressure to adjust the screw(B);

* If increese the pressure of waer supply,please screw down the pressure to adjust the screw (B)

4 When the system need fill water at first,wrest the handle(A) of filled-water.Then the handle(A)

can return(close) when the system is full of water.

5 Automatic filled-water Valve need clean in a periodic time and then you must close the tap,

unscrew the plug(D),remove the inside filter net.Please assemble them again after cleaning.

NOTICE: There are two connections for water pressure meter in the central section of

automatic filled-water,where the water pressure meter can be connected directly

and display the set pressure.The screw cap(C) must be tweaked after adjusting

the filled-water pressure.

B

C

1/4'

D

A

1/2'

Appendix

Appendix 3:

The installation explanation of the leakage pressure valve.

Appendix

Appendix 4:The way of assistant heat source connection

Unit provides the connection of assistant heat source which ca n not be only for gas-fired

boiler,but also for electronic boiler or warm-net pipe for city accordingly.

The way to the connection is as follows:

22

Appendix 3:

The installation explanation of the leakage pressure valve.

1 The action pressure of leakage pressure valve 'is more than 3bar(valve is open),

but the pressure can not be adjusted.

2 The valve will open automatically to make sure that the water loop of air-con system

is safe when the water pressure in the backwater side is higher than t he set pressure.

Appendix

Appendix 4:The way of assistant heat source connection

Unit provides the connection of assistant heat source which ca n not be only for gas-fired

boiler,but also for electronic boiler or wa rm-net pipe for city accordingly.

The way to the connection is as follows:

2)water chiller and heat pump+assistant el ectronic boiler

electro nic boile r

inlet

cable

water chiller and heat pump

gas-fir ed boiler

inlet

outlet

1) w ater chiller and heat pump+assistant gas-fired boiler

Three -wa y val ve

control w ire

outle t

water chiller and heat pump

inlet

cable

outle t

inlet

outlet

outlet

inlet

23

Appendix5、 The unit's parameter

Please set according the below table:

Appendix

Par

Description

Limits

Unit

R01

R02

R03

R04

12

2

40

2

℃

℃

℃

℃

Cooling set-point

Cooling differential

Heating set-point

Heating differential

Appendix

Appendix 6、Compensate temperature chart

Heating mode:

Cooling mode:

24

Appendix

15 20 25 30 35 40

45

50

55

22.1(20 )

19.6(17 .5)

17.1(15 )

14.6(12 .5)

12.1(10 )

9.6(7.5 )

7.1(5)

4.6(2.5 )

2.1(0)

0

2.5

5

A2

TgA2=-0.5

When the parameter set :

R01=20 R02=2 R03=30 R04=2

R17=-0.5 R18=20 R19=15 R20=20 R31=-0.8,

The compensate graphs in the heating and cooling mode are as follows:

-5

0

5 10 15 20

47.8(50 )

43.8(46 )

39.8(42 )

35.8(38 )

31.8(34 )

27.8(30 )

0

4

5

A1

TgA1=-0.8=R31

Appendix 6、Compensate temperature chart

Heating mode:

starting(stopping) temp.( C)

Ambient temp.( C)

Cooling mode:

Ambient temp.( C)

starting(stopping) temp.( C)

R19

R20

R03

R01

25

Appendix

Connections explanation:

1

2

3

4

No.

Symbol

Meaning

System1 mangtic valve outlet(220-230VAC)

System 2 economizer outlet temp.failure(input)

7

8

9

10

11

12

13

14

15

5

6

Ambient temp.(input)

RO02

RO04

RO03

RO01

AI03 GND

AI04 GND

AI05 GND

AI06 GND

AI07 GND

AI08 GND

AI09 GND

System 2 exhaust temp.(input)

System 1 exhaust temp.(input)

System 2 economizer inlet temp.failure(input)

System 1 economizer inlet temp.failure(input)

System 1 economizer outlet temp.failure(input)

Wire controller

System 2 economizer outlet temp.failure(input)

16

17

18

19

Ambient temp.(input)

NET GND 12V

DI01 GND

AI01 GND

AI02 GND

AI03 GND

AI04 GND

AI05 GND

AI06 GND

AI07 GND

AI08 GND

AI09 GND

System 2 exhaust temp.(input)

System 1 exhaust temp.(input)

System 2 economizer inlet temp.failure(input)

System 1 economizer inlet temp.failure(input)

System 1 economizer outlet temp.failure(input)

System 2 anti-freeze temp.(input)

System 1 anti-freeze temp.(input)

Mode/conmunication

System2 mangtic valve outlet(220-230VAC)

System1 alert outlet(220-230VAC)

System2 alert outlet(220-230VAC)

CC01

CC02

CC03

CC04

System1 mangtic valve inlet(220-230VAC)

System2 mangtic valve inlet(220-230VAC)

System1 alert inlet(220-230VAC)

System2 alert inlet(220-230VAC)

9

10

11

12

13

14

15

CN2

BHB10

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1 CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC01

AI09

GND

CC02 RO01 R O02RO03RO04 C C03 CC0 4

Appendix 7、Connection of PCB illustration

2.SYSB malfunction Table

System 2 ec onomize r

outlet te mp.fail ure

System 1 an ti-free ze protec tion

System 2 an ti-free ze protec tion

Ambient t emp.sen sor failu re

Communi cation fa ilure

System 1 ex haust tem p.failu re

System 2 ex haust tem p.failu re

System 1 an ti-free ze temp.f ailure

System 2 an ti-free ze temp.f ailure

System 1 ec onomize r

inlet tem p.failu re

System 2 ec onomize r

inlet tem p.failu re

System 1 ec onomize r

outlet te mp.fail ure

System 1 cu rrent pro tection

System 2 cu rrent pro tection

System 1 ex haust hig h

temp.pr otectio n

System 2 ex haust hig h

temp.pr otectio n

26

2.SYSB malfunction Table

The common failure cause and solution.

System 2 ec onomize r

outlet te mp.fail ure

System 1 an ti-free ze protec tion

System 2 an ti-free ze protec tion

Malfunction

Ambient t emp.sen sor failu re

Communi cation fa ilure

System 1 ex haust tem p.failu re

System 2 ex haust tem p.failu re

System 1 an ti-free ze temp.f ailure

System 2 an ti-free ze temp.f ailure

System 1 ec onomize r

inlet tem p.failu re

System 2 ec onomize r

inlet tem p.failu re

System 1 ec onomize r

outlet te mp.fail ure

P202

P29

Display

P04

E08

P181

P281

E171

E271

P101

P201

P102

Wat er flow vol ume not eno ugh

Canse

Communi cation fa ilure bet ween

remote wi re contro ller and ma in board

The senso r is open or sh ort circu it

Solution

Check the w ire conne ction bet ween

remote wi re contro ller and ma in board

Check or ch ange the se nsor

Check the f low volum e,water

system is j ammed or no t

System 1 cu rrent pro tection

E151

Current t hrough co mpresso r too heavy

Check thr ough the po wer suppl y for

compres sor or shor t circuit

E251

Current t hrough co mpresso r too heavy

Wat er flow vol ume not eno ugh

Check the f low volum e,water

system is j ammed or no t

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

The senso r is open or sh ort circu it

Check or ch ange the se nsor

System 2 cu rrent pro tection

Check thr ough the po wer suppl y for

compres sor or shor t circuit

P19

P182

Compres sor exhau st temp.t oo high

System 1 ex haust hig h

temp.pr otectio n

Check thr ough the re frigera nt system

P282

System 2 ex haust hig h

temp.pr otectio n

Compres sor exhau st temp.t oo high Check thr ough the re frigera nt system

Appendix

27

Appendix

Appendix 8

1. The unit can only be repaired by qualified installer centre personnel or an authorised

dealer.(for Europe market)

2. This appliance is not intended for use by persons (including children) wit h reduced physical

sensory or mental capabilities, or lack of experien ce and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. (for Europe market)

Children should be supervised to ensure that they do not play with the appliance.

3. Please make sure that the unit and power connection have good earthing, otherwise may

cause electrical shock.

4. If the supply cord is damaged, it must be replaced by the manufactu rer or our service agent

or similarly qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled sepa rately from domestic

waste, must be taken to a recycling centre for electric and electr onic devices or handed

back to the dealer when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is compliant with directive 2002/95 /EC (RoHs)

concerning restrictions for the use of harmful substances in e lectric and electronic devices.

7. The unit CANNOT be installed near the flammable gas. Once there is any leakage of the gas

, fire can be occur.

8. Make sure that there is circuit breaker for the unit, lack of circu it breaker can lead to

electrical shock or fire.

9. The heat pump located inside the unit is equipped with an over-load protecti on system. It

does not allow for the unit to start for at least 3 minutes from a previous stoppage.

10. The unit can only be repaired by the qualified personnel of an installer cent er or an

authorized dealer. (for North America market)

11. Installation must be performed in accordance with the NEC/CEC by authorized perso n only.

(for North America market)

12. USE SUPPLY WIRES SUI TABLE FOR 75℃.

13. Caution: Single wall heat exchanger, no t suitable for potable water connection.

(1) Caution & Warning

Appendix

(2) Cable specification

Nameplate

maximum

current

1. Single phase unit

2. Three phase unit

When the unit will be installed at outdoor, please use the cable which can against UV.

28

Appendix

(2) Cable specification

13~25A

25~30A

30~40A

40~55A

55~70A

Phase line

2

2×1.5mm

2

2×4mm

2

2×6mm

2

2×10mm

2

2×16mm

2

2×25mm

2

1.5mm

2

4mm

2

6mm

2

10

mm

2

16

mm

2

25

mm

MCB

20A

40A

40A

63A

80A

100A

Creepage protector

30mA less than 0.1 sec

Signal line

2

×

n 0.5mm

Nameplate

maximum

current

Earth line

No more

than 13A

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

13~25A

25~30A

30~40A

40~55A

55~70A

Phase line

2

3×1.5mm

2

3×4mm

2

3×6mm

2

3×10mm

2

3×16mm

2

3

×

25mm

2

1.5mm

2

4mm

2

6mm

2

10mm

MCB

20A

40A

40A

63A

80A

100A

Creepage protector

Signal line

2

×

n 0.5mm

Nameplate

maximum

current

Earth line

No more

than 13A

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

2

1.5mm

2

4mm

2

4mm

2

4mm

2

4mm

2

4mm

Neutral line

1. Single phase unit

2. Three phase unit

When the unit will be installed at outdoor, please use the cable which can against UV.

2

16mm

2

25mm

29

code:20 090713- 0003

Loading...

Loading...