Page 1

eW Flex Compact

Flexible strands of high-intensity LED nodes with solid white light

Page 2

eW Flex Compact

Flexible strands of high-intensity LED nodes with solid white light

eW Flex Compact is a versatile strand of 50 individually controllable LED nodes. The flexible form factor allows dynamic points of white light

to be installed across nearly any interior or exterior surface, including walls, ceilings, floors, three-dimensional sculptures, and set pieces. eW Flex

Compact can also light tight alcove spaces and signage, and in certain cases, can even display video.

• Daylight visible — At full brightness, each node

produces light output of up to 31.5 candela and

47679 nit s.

• Adaptable mounting — Strands can be mounted

directly to a surface, like traditional string lights.

Detachable leader cables in multiple lengths allow

you to install strings at the appropriate distance

from power/data supplies. Optional mounting

tracks ensure straight linear runs, while snapon spacers hide cabling and mounting hardware.

Single node mounts can be positioned individually

as anchor points for installations with uneven

node spacing or complex geometries.

• Outdoor rated — Fully sealed for maximum

xture life and IP66-rated for outdoor

applications.

• Supports cost-effective video displays — Flexible

form factor, offering maximum lighting control at

50 W per strand, accommodates unique lighting

installations, including two- and three-dimensional

video displays. White nodes enable classic black and

white video or reverse (shadow) video.

• Multiple lens options — Standard clear at and

translucent dome lenses. Optional translucent at,

clear dome, semi-frosted at, and semi-frosted

dome lenses are available.

• Standard and custom lengths and node

spacing — eW Flex Compact strands are available

with standard on-center node spacing of 102 mm

(4 in) or 305 mm (12 in) along a three-wire, 18

AWG cable. For information about custom orders,

see the eW Flex Compact Ordering Sheet at

www.philipscolorkinetics.com/ls/essentialwhite/

ewflexcompact/

• Custom Leader Cables — Custom Leader Cable

lengths are available in addition to standard cables

of 7.6 m (25 ft), 15.2 m (50 ft), and 30.5 m (100 ft).

• Industry-leading controls — eW Flex Compact

works seamlessly with the complete Philips line of

controllers, including Video System Manager Pro,

Light System Manager, and iPlayer 3, as well as

third-party DMX controllers.

Superior Light

Output

eW Flex Compact strands

consist of 50 individually

controllable, high-intensity

LED nodes. Each node

produces solid white

light output of up to 31.5

candela.

eW Flex Compact Product Guide2

Page 3

Specications

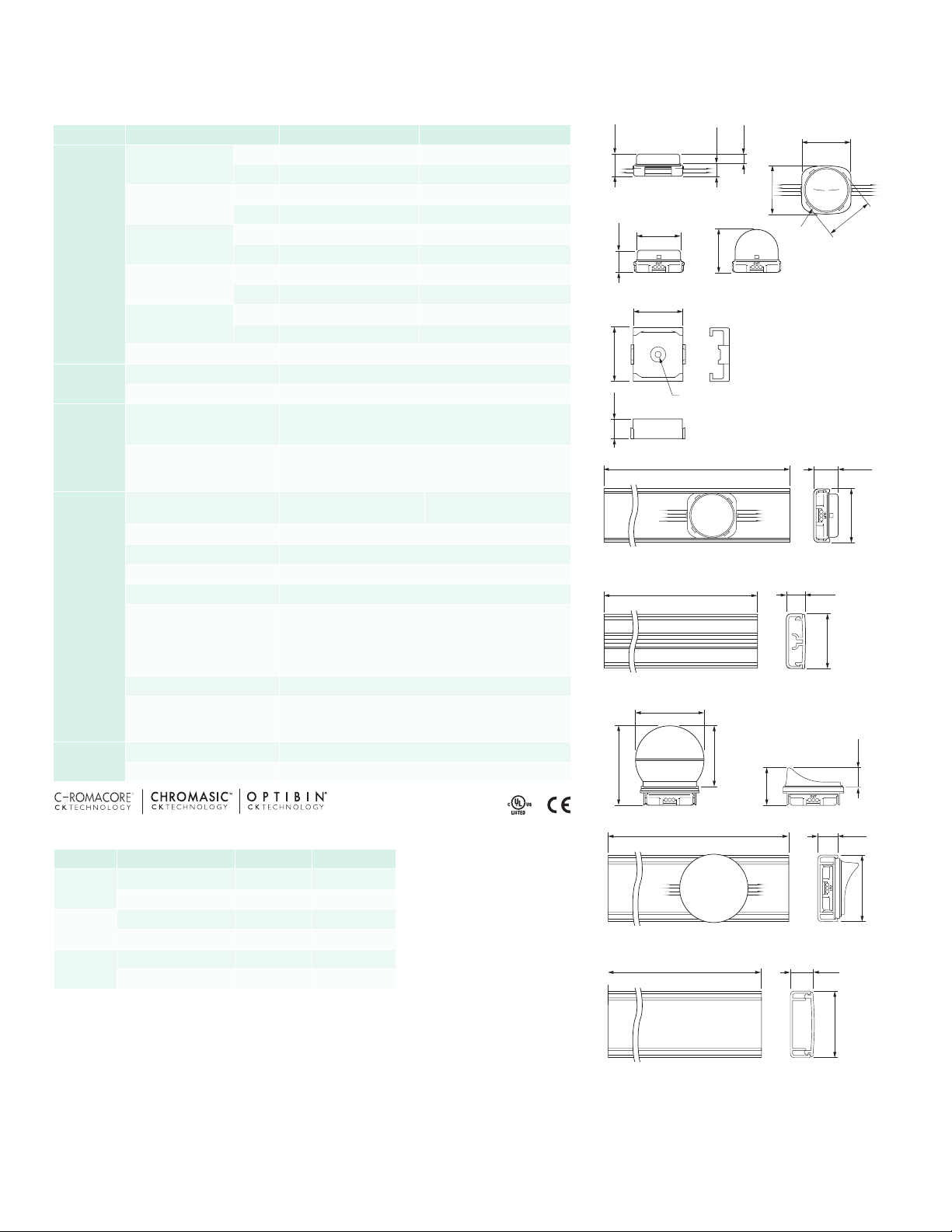

35 mm

34 mm (1.4 in

Dome Lens

25 mm

(1 in)

Flat Lens

Ø 29 mm

(1.1 in)

17 mm

(.67 in)

17 mm

7 mm

(.27 in)

10 mm

(.4 in)

17 mm

(.67 in)

32 mm

Ø 29 mm

(1.1 in)

32 mm

(1.25 in)

31 mm

(1.2 in)

31 mm

(1.2 in)

Clear Flat Lens Translucent Dome Accessory Single-Node Mount

Ø 29 mm

(1.1 in)

32 mm

(1.25 in)

31 mm

(1.2 in)

31 mm

(1.2 in)

Spacer shown in place on Track

48 mm (1.9 in

Screw mount

through hole

35 mm

(1.4 in)

13 mm

(.5 in)

35 mm

(1.4 in)

12 mm

(.48 in)

Spacer shown in place on Track

34 mm (1.4 in)

20 mm

(.77 in)

34 mm (1.6 in)

70 mm or 273 mm

(2.75 in or 10.75 in)

(.06 in ±)

Node shown in place on Track

1.2 m (48 in)

Dome Lens

25 mm

(1 in)

Dome Lens

25 mm

(1 in)

Flat Lens

Ø 29 mm

(1.1 in)

17 mm

(.67 in)

Flat Lens

Ø 29 mm

(1.1 in)

17 mm

(.67 in)

7 mm

(.27 in)

10 mm

(.4 in)

17 mm

(.67 in)

7 mm

(.27 in)

10 mm

(.4 in)

17 mm

(.67 in)

Ø 29 mm

(1.1 in)

32 mm

(1.25 in)

31 mm

(1.2 in)

31 mm

(1.2 in)

Ø 29 mm

(1.1 in)

32 mm

(1.25 in)

31 mm

(1.2 in)

31 mm

(1.2 in)

Clear Flat Lens Translucent Dome Accessory Single-Node Mount

Ø 29 mm

(1.1 in)

32 mm

(1.25 in)

31 mm

(1.2 in)

31 mm

(1.2 in)

Due to continuous improvements and innovations , specifications may change without notice.

Item Specication Clear Flat Lens Translucent Dome Lens

2700 K 80.9 35.0

4000 K 86.9 39.6

2700 K 29.8 7.1

4000 K 31.5 8.0

2700 K 45127 cd/m

4000 K 47679 cd/m

2700 K 82 85

4000 K 84 86

2700 K 110° 200°

4000 K 110° 200°

PDS-60ca 24V (Pre-programmed or DMX/Ethernet)

sPDS-60ca 24V (DMX/Ethernet)

sPDS-480ca 24V (Ethernet)

Philips full range of controllers, including Video System

Manager Pro, Light System Manager, and iPlayer 3, or third-

Lumens Per Node

Candela Per Node

Output

Electrical

Control

Luminance

CRI

Viewing Angle

LED Channels White

Input Voltage 24 VDC via sPDS-480ca, sPDS-60ca, and PDS-60ca

Power Consumption 1 W max. per node at full output, steady state

Interface

Control System

party controllers

Node Dimensions

Height x Width x Depth

Weight 2.2 lbs (1 kg) 50-node strand, 4 in on-center node spacing

Housing White or black polycarbonate

31 x 32 x 17 mm

(1.2 x 1.25 x .67 in)

Lens Clear or translucent plastic

Physical

Fixture Connections Integrated watertight 3-pin connector

Temperature Ranges

-30° – 50° C (-22° – 122° F) Operating

≥ 0° C (≥ 32° F) Handling

-20° – 50° C (-4° – 122° F) Startup

-30° – 85° C (-22° – 185° F) Storage

PDS-60ca 24V: 1 strand

sPDS-60ca 24V: 1 strand

sPDS-480ca 24V: 8 strands

Certication

and Safety

Humidity 0 – 95%, non-condensing

Maximum Fixtures Per

Power/Data Supply

Certication UL/cUL, FCC Class A, CE

Environment Dry/Damp/Wet Location, IP66

Lumen Maintenance

Threshold* Ambient Temperature Reported† Calculated†

L

90

L

80

L

70

* Lx x= xx% lumen maintenance (when light output drops below x x% of

initial output). All values are given at B50, or the median value where

50% of the LED population is better than the reported or calculated

lumen maintenance measurement.

† Lumen maintenance gures are based on lifetime prediction graphs

supplied by LED source manufacturers. Whenever possible, gures

use measurements that comply with IES LM-80- 08 testing procedures.

In accordance with TM-21-11, reported values represent the

interpolated value based on six times the LM-80- 80 total test duration

(in hours). Calculated values represent time durations that exceed six

times the total test duration.

@ 25° C 50,600 hours >100,000 hours

@ 50° C 50,600 hours >100,000 hours

@ 25° C 50,600 hours >100,000 hours

@ 50° C 50,600 hours >100,000 hours

@ 25° C 50,600 hours >100,000 hours

@ 50° C 50,600 hours >100,000 hours

Ø 29 mm

(1.1 in)

(1.25 in)

31 mm

(1.2 in)

20 mm

(.77 in)

(.67 in)

Ø 29 mm

2

2

10660 cd/m

12106 cd/m

2

2

17 mm

(.67 in)

(1.4 in)

(.5 in)

13 mm

(1.1 in)

Flat Lens

35 mm

(1.4 in)

Screw mount

through hole

1.2 m (48 in)

25 mm

(.4 in)

10 mm

(1 in)

7 mm

(.27 in)

31 mm

Dome Lens

(1.2 in)

31 x 32 x 25 mm

(1.2 x 1.25 x 1 in)

16 mm

(.64 in)

)

(.6 in)

.15 mm

15 mm

(.6 in)

)

34 mm (1.6 in)

48 mm (1.9 in)

Node shown in place on Track

70 mm or 273 mm

(2.75 in or 10.75 in)

(.06 in ±)

52 mm

65 mm

(2.05 in)

(2.6 in)

1.2 m (48 in)

55 mm, 81 mm, 259 mm, 462 mm

(2.2 in, 3.2 in, 10.2 in, 18.2 in)

(.5 mm ±)

53 mm

(2.08 in)

29 mm

(1.1 in)

12 mm

(.48 in)

Spacer shown in place on Track

eW Flex Compact Product Guide 3

Page 4

Fixtures and Power/Data Supplies

eW Flex Compact is part of a complete system which includes fixtures and:

• One or more power/data supplies.

Included in the box

eW Flex Compact strand (50 nodes)

Extra termination cap

Installation Instructions

• One Leader Cable to attach each strand of eW Flex Compact to a power/data

supply port.

• Optional mounting tracks, spacers, or single-node mounts.

• Any Philips controller, including Video System Manager, Light System Manager, and

iPlayer 3, or any third-party controller.

Fixtures, 4 inch on-center node spacing

Item Type Item Number Philips 12NC

White 500-000012-00 912400130619

Black 500-000012-01 912400130620

White 500-000012-02 912400130621

Black 500-000012-03 912400130622

White 500-000012-08 912400130627

Black 500-000012-09 912400130628

White 500-000012-10 912400130629

Black 500-000012-11 912400130630

White 500-000012-16 912400130635

Black 500-000012-17 912400130636

White 500-000012-18 912400130637

Black 500-000012-19 912400130638

White 500-000012-24 912400130643

Black 500-000012-25 912400130644

White 500-000012-26 912400130645

Black 500-000012-27 912400130646

White 500-000012-48 912400133735

Black 500-000012-49 912400133736

White 500-000012-50 912400133737

Black 500-000012-51 912400133738

White 500-000012-32 912400130651

Black 500-000012-33 912400130652

White 500-000012-34 912400130653

Black 500-000012-35 912400130654

White 500-000012-40 912400130659

Black 500-000012-41 912400130660

White 500-000012-42 912400130661

Black 500-000012-43 912400130662

Use Item Number when ordering in North America.

eW Flex Compact

50 nodes

Clear Flat Lens

2700 K

Translucent

Dome Lens

Clear Flat Lens

3000 K

Translucent

Dome Lens

Clear Flat Lens

3500 K

Translucent

Dome Lens

Clear Flat Lens

4000 K

Translucent

Dome Lens

Clear Flat Lens

5000 K

Translucent

Dome Lens

Clear Flat Lens

5700 K

Translucent

Dome Lens

Clear Flat Lens

6500 K

Translucent

Dome Lens

Custom Configurations

In addition to the standard configurations discussed in this product

guide, custom configurations are also available. See the eW Flex

Compact Ordering Information sheet at www.philipscolorkinetics.

com/ls/ew/flexcompact/ for more information.

Component Available Non-Standard Options

Node Spacing

Strand Length 5 – 60 nodes

Node/Cable Color Clear

Lens Clear flat, translucent flat

51 mm (2 in) – 610 mm (24 in)

on-center

eW Flex Compact Product Guide4

Page 5

Fixtures, 12 inch on-center node spacing

Item Type Item Number Philips 12NC

White 500-000012-04 912400130623

Black 500-000012-05 912400130624

White 500-000012-06 912400130625

Black 500-000012-07 912400130626

White 500-000012-12 912400130631

Black 500-000012-13 912400130632

White 500-000012-14 912400130633

Black 500-000012-15 912400130634

White 500-000012-20 912400130639

Black 500-000012-21 912400130640

White 500-000012-22 912400130641

Black 500-000012-23 912400130642

White 500-000012-28 912400130647

Black 500-000012-29 912400130648

White 500-000012-30 912400130649

Black 500-000012-31 912400130650

White 500-000012-52 912400133739

Black 500-000012-53 912400133740

White 500-000012-54 912400133741

Black 500-000012-55 912400133742

White 500-000012-36 912400130655

Black 500-000012-37 912400130656

White 500-000012-38 912400130657

Black 500-000012-39 912400130658

White 500-000012-44 912400130663

Black 500-000012-45 912400130664

White 500-000012-46 912400130665

Black 500-000012-47 912400130666

eW Flex Compact

50 nodes

Clear Flat Lens

2700 K

Translucent

Dome Lens

Clear Flat Lens

3000 K

Translucent

Dome Lens

Clear Flat Lens

3500 K

Translucent

Dome Lens

Clear Flat Lens

4000 K

Translucent

Dome Lens

Clear Flat Lens

5000 K

Translucent

Dome Lens

Clear Flat Lens

5700 K

Translucent

Dome Lens

Clear Flat Lens

6500 K

Translucent

Dome Lens

Use Item Number when ordering in North America.

eW Flex Compact Product Guide 5

Page 6

Power/Data Supplies

Item Type Item Number Philips 12NC

PDS-60ca 24V Power/

Data Supply

sPDS-60ca 24V Power/

Data Supply

sPDS-480ca 24V Power/

Data Supply

Item Type Color Item Number Philips 12NC

Leader Cable

Mounting Track 1.2 m (1 4 ft.) track

Spacers

Single-Node

Mounts

Pre-programmed 109-000016-00 910503700095

DMX/Ethernet 109-000016-04 912400133526

DMX/Ethernet

Ethernet 109-000026-01 912400133528

7.6 m (25 ft) Black 108-000045-00 910503700696

15.2 m (50 ft) Black 108-000045-01 910503700697

30.5 m (100 ft) Black 108-000045-02 910503700698

50 102 mm (4 in)

spacers

50 305 mm (12 in)

spacers

50 mounts

109-000021-04 (NA Cord)

109-000021-05 (EU/UK Cord)

White 101-000057-00 910503700044

Black 101-000057-01 910503700045

White 101-000059-00 910503700048

Black 101-000061-02 910503700052

White 101-000059-01 910503700049

Black 101-000061-01 910503700053

White 101-000058-00 910503700046

Black 101-000058-01 910503700047

912400133527

912400133636

Accessories

Item Type Color Item Number Philips 12NC

White 999-007997-00 910503702308

Black 999-007997-01 910503702309

White 999-007997-04 910503702312

Black 999-007997-05 910503702313

White 999-007997-02 910503702310

Black 999-007997-03 910503702311

Black 120-000179-00 912400130036

White 101-000057-03 910503704266

Black 101-000057-04 910503704267

White 101-000075-00 910503704272

Black 101-000075-02 910503704274

White 101-000075-01 910503704273

Black 101-000075-03 910503704275

Marquee Lens

Kits

Qty 50

Glare Shield

Kits

Qty 50

Accessory

Mounting Track

Qty 1

Accessory

Spacers

Qty 50

Clear

Semi-Frosted

Translucent

(1.2 m) 4 ft

102 mm (4 in)

305 mm (12 in)

eW Flex Compact Product Guide6

Page 7

E Clean lenses with water and mild detergent

using a soft cleaning cloth. Wipe lenses dry.

Do not use paper towels, abrasive cleaning

products, or window cleaners. Abrasive cleaning

products will scratch lenses, and window

cleaners will soften and mar the polycarbonate.

Do not use cleaning solutions that contain

ammonia, sodium hydroxide, or isopropyl alcohol,

which can scratch, pit, haze, yellow, or crack

lenses.

E Refer to the eW Flex Compact Installation

Instructions for specific warning and caution

statements.

Installation

eW Flex Compact can be used in a wide range of two-dimensional and threedimensional configurations, including portable video screens and permanent buildingcovering displays. eW Flex Compact installations are not constrained by fixture size,

shape, or architectural space.

Because of their potential complexity, eW Flex Compact installations require up-front

planning for configuring, positioning, and mounting the fixture strands. Planning includes

understanding how to position strands in relation to power/data supplies and the

number of strands each power/data supply can support. Planning for video displays

involves additional considerations, such as how to space eW Flex Compact nodes to

achieve the desired pixel pitch, minimum and maximum viewing distances, sampling, and

display resolution.

All installations involve three main steps:

1. Create a lighting design plan and layout grid

2. Mount xture strands

3. Test xture strands

Owner/User Responsibilities

It is the responsibility of the contractor, installer, purchaser, owner, and user to

install, maintain, and operate strands of eW Flex Compact in such a manner as to

comply with all applicable codes, state and local laws, ordinances, and regulations.

Consult with the appropriate electrical inspector to ensure compliance.

Installing in Damp or Wet Locations

When installing in damp or wet locations, seal all fixture connections, power/data

supplies, and junction boxes with electronics-grade RTV silicone sealant so that water

or moisture cannot enter or accumulate in wiring compartments, cables, or other

electrical parts. Use suitable outdoor-rated junction boxes when installing in wet

or damp locations. Additionally, use gaskets, clamps, and other parts required for

installation to comply with all applicable local and national codes.

DMX or Ethernet Control?

eW Flex Compact installations can be controlled via either DMX or Ethernet. DMX is

appropriate for relatively simple installations, or for installations where all lights operate

in unison — for example, for accent, perimeter, or cove lighting applications.

Each node in a strand of eW Flex Compact is identified by a light number. A light

number corresponds to three sequential DMX addresses. A DMX universe consists of

512 addresses, so the maximum number of light numbers available in a DMX universe is

170 (170 x 3 = 510).

Because Ethernet is not subject to the DMX addressing limitations, it is the preferred

environment for dynamic light shows and video displays, both of which require

numerous unique light numbers. In an Ethernet environment, each power/data supply

effectively acts as its own universe.

DMX installations require the use of a PDS-60ca 24V or sPDS-60ca 24V

supply, while the sPDS-480ca 24V power/data supply is Ethernet only.

power/data

eW Flex Compact Product Guide 7

Page 8

Considerations for Video Displays

In addition to the planning required for all eW Flex Compact installations, planning

for video displays involves special considerations such as pixel pitch, minimum and

maximum viewing distances, sampling, and display resolution.

Determining Pixel Pitch and Viewing Distances for Video Displays

When using eW Flex Compact strands to display video, each node acts as a pixel in

the display. Images on an LED video display appear to be sharper to the human eye

as the distance from the display increases. Likewise, images appear less visible as the

distance decreases. The spacing between pixels, known as the pixel pitch, determines the

minimum and maximum viewing distances for discernible video output. Pixel pitch is

measured center-to-center. For an eW Flex Compact strand, you determine pixel pitch

by measuring from the center of one node to the center of the next.

Designing a layout with overlapping strands is a common technique for increasing pixel

pitch. For example, to create a dense line of nodes, place multiple runs close to each

other vertically, with a slight horizontal offset between the nodes. Philips offers eW Flex

Compact with both 102 mm (4 in) and 305 mm (12 in) spacing between nodes. Using

strands with made-to-order node spacing is another method for adjusting pixel pitch.

The following calculations and examples are general guidelines for determining

minimum and maximum viewing distances, based on video displays using grids of evenly

spaced pixels:

• To determine minimum viewing distance, multiply pixel pitch by 100 distance units.

For example, if the pixel pitch is 76 mm (3 in), the minimum viewing distance is

7.6 m (25 ft).

Measure from the center of one

node to the center of an adjacent

node to determine pixel pitch

• To determine the maximum viewing distance for discernible video, multiply the

screen height by 20 distance units. For example, if the screen height is 20 m (65.6 ft),

then the maximum viewing distance for recognizable video is 400 m (1312.3 ft).

• LED screens are visible beyond the maximum viewing distance for discernible video.

To determine the maximum viewing distance that still creates visual impact, multiply

the screen height by 50 distance units. For example, a screen 20 m (65.6 ft) high will

continue to create visual impact at 1000 m (3280.8 ft).

Working with Video Display Resolutions

The resolution of an LED video display equals the total number of vertical and

horizontal pixels — the greater the pixel count, the greater the resolution.

• The resolution of VSE digital video is 1024 x 768

• The resolution of PAL video is 704 x 576

• The resolution of NTSC video is 704 x 480

eW Flex Compact Product Guide8

Page 9

E For designs where the acceptable

Terminator

level of discernible video may be more

or less demanding, or for help with your

specific installation, contact Philips Color

Kinetics Application Engineering Services for

assistance.

Reproducing a video signal with 1:1 pixel mapping on an LED display requires a

substantial pixel count. For example, true NTSC video output requires 337,920 pixels,

PAL output requires 405,504 pixels, and digital video output requires 786,432 pixels.

However, you can use a controller such as Philips Video System Manager Pro to reduce

the required pixel count for any video format by sampling and distributing pixels from

the source video to match your installation.

For example, if you retain the horizontal resolution of a digital video source (1024 lines

wide), but sample every tenth line of pixels vertically (76 lines high instead of 768 lines),

you can retain the correct aspect ratio while exponentially reducing the pixel count.

From a distance, even with only 76 lines of vertical output, the human eye can still

discern video images because the horizontal resolution is dense.

An installation using 1024 x 76 nodes would have a pixel count of 77,824 yet still

display high-quality digital video output. This method is especially effective when creating

an installation that covers a building which, by necessity, already has spacing between

lines of video due to windows and other architectural features.

Create a Lighting Design Plan

and Layout Grid

Even for relatively simple installations, it’s good practice to create a lighting design plan.

For complex installations displaying light shows with dynamic effects, and especially

for Ethernet-based video displays, such a plan is essential. A lighting design plan is

typically an architectural diagram or other diagram that shows the physical layout

of the installation, including the appropriate positioning and spacing of all fixtures,

power/data supplies, power sources, controllers, cables, and other required hardware.

For DMX installations, the plan should record the DMX base number and node

count for each eW Flex Compact strand. For Ethernet installations, the plan should

record the IP address of each power/data supply and the number of nodes per

power/data supply port.

E Refer to the Installation Instructions

or Specification Sheet of your power/data

supply for guidelines on configuring and

positioning the power/data supply in relation

to a controller or Ethernet switch.

Power / Data Supply eW Flex CompactLeader Cable

Keep the following considerations in mind when creating a lighting design plan and

layout grid:

• Determine the appropriate location of each power/data supply in relation to the

xtures, and of the xtures in relation to each other. You connect a strand of eW

Flex Compact xtures to an available power/data supply port using a Leader Cable

of 7.6 m (25 ft), 15.2 m (50 ft), or 30.5 m (100 ft).

• eW Flex Compact Leader Cables can be shortened, and strands can be cut to any

node length. An extra termination cap is included for sealing the cut end of the

strand.

Do not trim the Leader Cable between the power/data supply connector and the

PCA transmitter junction box. Do not trim strands between the connector and

the rst node.

1423 50

C Do not trim

eW Flex Compact Product Guide 9

Page 10

• On an architectural diagram or other diagram that shows the physical layout of

1 in

1 in

(25 mm)

the installation, identify the locations of all switches, controllers, power supplies,

and xtures.

• Nodes in each strand are sequentially addressed beginning with the node closest

to the Leader Cable. Orientation of the power/data supply is therefore especially

critical when using dynamic effects.

• In Ethernet environments, each power/data supply is identied with a unique IP

address. We recommend recording the IP address of each power/data supply

on a layout grid. For complex installations with many power/data supplies, we

recommend assigning meaningful IP addresses to each power/data supply, so their

locations are easy to identify.

Start the Installation

1. Install all power/data supplies, including any interfaces with controllers. Power/data

supplies send power and control signals to xtures over the Leader Cable.

2. Verify that all additional supporting equipment (switches, controllers) is in place.

3. Ensure that all additional parts (for example, optional single node mounts, spacers,

mounting track, and mounting hardware) and tools are available.

Cut and Seal eW Flex Compact Strands

(Optional)

You can cut eW Flex Compact strands to any desired node length. We recommend

cutting and sealing the strands before mounting them.

1. Using a wire cutter, cut the cable to the desired length, leaving at least 25 mm (1 in)

of cable after the last node. Ensure the cut is clean and there are no frayed wires

touching other wires.

(25 mm)

2. Apply a liberal amount of electronics-grade RTV silicone sealant to the cable ends

and to the opening of the rubber seal boot included with the extra termination cap.

Insert the boot onto the cable.

3. Sit the sealed cable boot into the base of the provided termination cap.

4. Firmly press the termination cap onto the base until the top snaps into place. If using

pliers, be careful not to crack the housing.

E Never cut a strand between the three-

pin connector and the first node.

E Never reuse a termination cap.

RTV Silicone

eW Flex Compact Product Guide10

Page 11

E Optional Marquee Lens and Glare

Shield Kits use their own mounting tracks

and spacers. Refer to “Mount eW Flex

Compact Strands with Accesories” for

details.

E You cannot use single-node mounts

with marquee lenses or glare shields.

Mount the Fixtures

You can mount eW Flex Compact strands directly to a mounting surface, or you can

mount them using eW Flex Compact mounting accessories (available separately):

• Optional mounting tracks ensure straight runs in linear applications. Spacers snap

to the mounting tracks for a clean, nished look that hides cables and mounting

hardware between nodes.

• Single node mounts can be positioned individually to provide anchor points for

nodes in installations with uneven node spacing or complex geometries.

Make sure the power is OFF before mounting and connecting eW Flex Compact

fixtures.

1. Using a pencil or chalk line, mark a center-line path for the nodes to follow.

Do not twist or loop cable

Do not overstretch cable

Do not pull cable away from node

2. (Optional) To install mounting track, cut the track to the desired length with a

saw or snips. Using athead screws suitable for the mounting surface, drive screws

through the plastic track into the attaching surface. Recommended maximum

spacing between screws is 406 mm (16 in). Snap optional spacers into the track to

hide mounting hardware and wires.

3. (Optional) Ensure that the spacing between single node mounts is sufcient to

accommodate cable length between nodes and to allow for cable bending as

necessary.

Using double-sided tape on the base of the mounts, adhere the mounts to the

attaching surface. Reinforce installation with #6 athead screws suitable for the

mounting surface.

4. If using mounting track or single node mounts, push the xture nodes into the

mounts.

5. If mounting directly to a mounting surface, install eW Flex Compact strands using

a suitable mounting method. For example, you can mount strands to a pipe or

cable using plastic cable ties.

Use caution when handling cable

in sub-freezing temperatures

C

≤ 0ºC

Mounting track and spacers

Single-node mounts

eW Flex Compact Product Guide 11

Page 12

Mount eW Flex Compact Strands

with Accessories

Marquee lenses and glare shields clip onto eW Flex Compact strands with flat lenses.

Available with clear, semi-frosted, or translucent finshes, marquee lenses create the

appearance of bulbs on a traditional theatre marquee. Glare shields block unwanted

spill light, and can shield the light sources from being directly visible in certain

mounting situations.

You can mount strands with marquee lenses and glare shields directly to a mounting

surface, in front of a substrate, or using optional Accessory Mounting Tracks and

Accessory Spacers. Mounting tracks ensure straight runs in linear applications. If

using strands with standard 4-in or 12-in on-center spacing, you can snap spacers to

the mounting tracks for a clean, nished look that hides cables and mounting hardware

between nodes.

Mounting eW Flex Compact Strands with Accessories Directly

to a Mounting Surface

1. Using a pencil or chalk line, mark a center-line path for the nodes to follow.

2. Clip a lens or glare shield holder over each eW Flex Compact node.

3. Do one of the following:

• Screw a marquee lens onto the lens holder. Hand tighten to approximately 10 to

15 in-lbs (1.1 to 1.7 Nm).

• Align the tabs on the glare shield with the slots in the glare shield holder, and

snap the glare shield onto the glare shield holder.

(Optional)

E You cannot use eW Flex Compact

accessories on strands with with dome

lenses, or with standard mounting tracks or

single node mounts.You can install either

a marquee lens or glare shield on a node,

but not both.

4. Fasten assembled eW Flex Compact strands to the mounting surface using a

suitable mounting method, For example, you can mount strands to a pipe or cable

using plastic cable ties.

2.125 in Diameter

(54 mm)

Marquee Lens Kit

2.125 in Diameter

(54 mm)

Glare Shield Kit

eW Flex Compact Product Guide12

Page 13

Mounting eW Flex Compact Strands with Accessories in Front of

a Substrate

1. Prepare the substrate by cutting openings of the appropriate diameter in the

required locations.

To accommodate the threads on the marquee lens holder or the ridges on

the glare shield holder, the recommended substrate thickness is 1.6 mm

(.0625 in), and the maximum thickness is 3.2 mm (.125 in). We recommend

using a 1 3/8 in diameter hole saw to cut openings in the substrate. Openings

should be a minimum of 35.6 mm (1.4 in) in diameter, and a maximum of

38 mm (1.5 in) in diameter.

2. Peel the backing from a lens or glare shield holder to expose the adhesive

surface.

3. Insert the lens or glare shield holder through an opening in the substrate, and

temporarily afx the lens holder by pressing the adhesive surface to the back

of the substrate. Make sure that the holder is oriented in the direction of the

eW Flex Compact strand.

1.0 mm (.039 in) min

3.2 mm (.125 in) max

35.6 mm (1.4 in diameter) min

38 mm (1.5 in diameter) max

1⅜ in diameter hole saw recommended

eW Flex Compact Product Guide 13

Page 14

4. Do one of the following:

• Screw a marquee lens onto the lens holder. Hand tighten to approximately 10

to 1.1 to 1.7 Nm (15 in-lbs).

• Align the tabs on the glare shield with the slots in the glare shield holder, and

snap the glare shield onto the glare shield holder.

5. Repeat steps 2 – 4 for each opening.

6. Once all accessories are installed on the substrate, mount eW Flex Compact

strands by inserting one node into the back of each lens or glare shield holder.

Press until the nodes snap rmly into the lens or glare shield holders.

eW Flex Compact Product Guide14

Page 15

Mounting Marquee Lenses and Glare Shields to Accessory Mounting

Track

1. Clip a lens or glare shield holder to each node.

2. Do one of the following:

• Screw a marquee lens onto the lens holder. Hand tighten to approximately

1.1 to 1.7 Nm (10 to 15 in-lbs).

• Align the tabs on the glare shield with the slots in the glare shield holder, and

snap the glare shield onto the glare shield holder.

3. Cut the Accessory Mounting Track to the desired length with a saw or snips.

Using athead screws suitable for the mounting surface, drive screws through

the plastic track into the attaching surface. Recommended maximum spacing

between screws is 406 mm (16 in).

4. Snap the assembled eW Flex Compact nodes into the mounting track.

5. If using strands with standard 4-in or 12-in on-center spacing, you can snap

optional Accessory Spacers into the track to hide mounting hardware and

wires.

eW Flex Compact Product Guide 15

Page 16

3.69 in

Make Power and Data Connections

eW Flex Compact fixtures are designed to work with 24 VDC power/data supplies

from Philips Color Kinetics. Power/data supplies send power and data to eW Flex

Compact strands over a Leader Cable. Each sPDS-480ca 24V can power up to 8 fixture

strands in Ethernet installation, while each PDS-60ca 24V or sPDS-60ca 24V can power

1 strand in either Ethernet or DMX installations.

PDS-60ca 24V is an IP66-rated power/data supply, suitable for use in damp and wet

locations. Although sPDS-480ca 24V is rated for use in dry locations only, you can

install it in a watertight enclosure for outdoor applications.

Make sure the power is OFF before connecting eW Flex Compact fixture strands.

Connecting eW Flex Compact Leader Cables

Connect a Leader Cable to the three-pin connector on the end of each eW Flex

Compact strand by turning the fixture strand’s grommet clockwise. In wet or damp

environments, tighten the grommet on the male connector sufficiently to ensure a

watertight seal. Use caution when handling the Leader Cable or eW Flex Compact

strand in sub-freezing temperatures, as the wiring can become brittle and break.

Maximum strands per power/data supply

PDS-60ca 24V 1

sPDS-60ca 24V 1

sPDS-480ca 24V 8

Leader Cable connector dimensions

94 mm

1.1 in

28 mm

Connecting to the sPDS-60ca 24V or sPDS-480ca 24V Power/Data Supply

• Connect a Leader Cable to an available power port on the back of the power/data

supply housing.

sPDS-60ca 24V

.25 in

6 mm

E If using conduit, remove the transmitter

PCA junction box cover from the Leader

Cable, as described here, before pulling the

cable through the conduit, then replace the

junction box cover.

sPDS-480ca 24V

eW Flex Compact Product Guide16

Page 17

Connecting to the PDS-60ca 24V Power/ Data Supply

.98 in

25 mm

.63 in

16 mm

5

1

2

4

6

5

3

RTV Silicone

The PDS-60ca 24V is an IP66-rated power/data supply, suitable for use in damp

and wet locations. The following procedure describes how to connect and seal a

PDS-60ca 24V power/data supply for outdoor applications.

1. Remove the power/data supply cover.

2. Remove the cover of the transmitter PCA junction box on the Leader Cable

by expanding the four tabs on the side and sliding the cover from the base.

3. Connect line, common, ground, and data to the provided terminal block,

then replace the cover of the transmitter PCA junction box.

Transmitter PCA junction box dimensions

3.06 in

77.8 mm

E You can download the QuickPlay Pro

software and the Addressing and Configuration

Guide from www.philipscolorkinetics.com/

support addressing/

+

Data

Data

–

Red

Blue

Blue

Stripe

Black

4. Connect the Leader Cable connector to an available port inside the power/

data supply housing.

5. Secure the power/data supply cover. If installing in a wet or damp location,

seal the power/data supply with electronics-grade RTV silicone sealant.

3

Red

Blue

Blue/

White

Black

Red

Blue

Blue/

White

Black

6

4

2

1

PDS-60ca 24V

PDS-60ca 24V

6. Repeat steps 1 – 5 for each power/data supply in the installation.

eW Flex Compact Product Guide 17

Page 18

Address and Congure the Fixtures

Make sure the power is ON before addressing and configuring fixtures.

Power/data supplies and controllers work together to stream data to the eW Flex

Compact strands in your installation.

• Each individual eW Flex Compact node is assigned three sequential DMX addresses.

A DMX universe consists of 512 addresses, so the maximum number of eW Flex

Compact nodes that can be individually addressed in a DMX universe is 170 (170 x

3 = 510).

When using a PDS-60ca 24V power/data supply with DMX control, you program the

power/data supply rather than addressing the eW Flex Compact strings directly. Use

SmartJack Pro (or iPlayer 3) with QuickPlay Pro addressing software to set a base

DMX address for the power/data supply, and to specify the node quantity of each

attached eW Flex Compact strand.

For lighting designs where nodes work in unison, all nodes should be set to

the same DMX addresses. For dynamic light show designs that show different

brightness levels on different nodes simultaneously, you must assign unique

DMX addresses to each node. Starting with its base DMX address, PDS-60ca

automatically assigns addresses to each eW Flex Compact node in sequence, from

the rst node on output port 1 through the last node on output port 2.

Because you are limited to 170 uniquely addressed nodes per DMX universe (less

than four strands of 50 nodes each), Ethernet is the preferred environment for

video displays and dynamic lighting effects.

• Each Ethernet-based power/data supply comes pre-programmed with a unique

IP address, so the power/data supply effectively functions as its own universe.

When creating a light map with a controller or media server, such as Light

System Manager or Video System Manager Pro, each eW Flex Compact node

automatically receives a unique identifier.

You can discover all power/data supplies by IP address using QuickPlay Pro,

Light System Manager, or Video System Manager Pro. For large installations, and

especially for video displays, we recommend giving power/data supplies meaningful

IP addresses to streamline installation, mapping, testing, and troubleshooting.

When readdressing power/data supplies, you will need the layout grid you created

when you recorded each power/data supply’s IP address during installation

planning.

For complete details on addressing and configuring fixtures, controllers, and

power/data supplies, refer to the Addressing and Configuration Guide or the User

Guide, or Specification Sheet for your controller or power/data supply.

Copyright © 2016 Philips Solid-State Lighting Solutions, Inc. All rights reserved.

Chromacore, Chromasic, CK, the CK logo, Color Kinetics, the Color Kinetics

logo, ColorBlast, ColorBlaze, ColorBurst, ColorGraze, ColorPlay, ColorReach, iW

Reach, eW Reach, DIMand, EssentialWhite, eW, iColor, iColor Cove, IntelliWhite,

iW, iPlayer, Optibin, and Powercore are either registered trademarks or

trademarks of Philips Solid-State Lighting Solutions, Inc. in the United States and/or

other countries. All other brand or product names are trademarks or registered

trademarks of their respective owners. Due to continuous improvements and

innovations, specifications may change without notice.

DAS-000142-00 R05 04 APR 2016

Philips Color Kinetics

3 Burlington Woods Drive

Burlington, Massachusetts 01803 USA

Tel 888.385.5742

Tel 617.423.9999

Fax 617.423.9998

www.philipscolorkinetics.com

Loading...

Loading...