Page 1

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

SERVICE REPAIR SUPPORT

PROCEDURE

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 1 out of 24

SERVICE MANUAL

Repair for Cellular Telephone

XENIUM DUAL BAND

LEVEL 1

- 1 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 2

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

Last updates:

DATE MODIFICATION PAGE

19/06/2000 CREATION

SERVICE REPAIR SUPPORT

PROCEDURE

Service Manual

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 2 out of 24

Revision 2 : 26/07/2000 - Modification of components list Page 23

CONTENTS

- 2 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 3

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

1.0 PURPOSE--------------------------------------------------------------------------------------------------------------------------------------4

2.0 SCOPE------------------------------------------------------------------------------------------------------------------------------------------4

3.0 REFERENCE----------------------------------------------------------------------------------------------------------------------------------4

4.0 GLOSSARY/ACRONYM LIST-----------------------------------------------------------------------------------------------------------4

5.0 TEST EQUIPMENT AND TOOLS------------------------------------------------------------------------------------------------------4

6.0 TEST AND INSPECTION PLAN--------------------------------------------------------------------------------------------------------5

6.1 USER INTERFACE TEST................................................................................................................................................................5

6.2 RF TEST...................................................................................................................................................................................5

7.0 BEFORE STARTING-----------------------------------------------------------------------------------------------------------------------6

7.1 DESCRIPTION OF THE TRANSCEIVER................................................................................................................................................6

7.2 DESCRIPTION OF THE DISPLAY.......................................................................................................................................................7

7.3 USING THE CAROUSEL ...............................................................................................................................................................8

7.4 INSERTING THE MICRO-SIM CARD.............................................................................................................................................8

7.5 INSERTING ON THE BATTERY.........................................................................................................................................................9

7.6 REMOVING THE BATTERY..............................................................................................................................................................9

7.7 CHARGING THE BATTERY..............................................................................................................................................................9

8.0 TEST PROCEDURES---------------------------------------------------------------------------------------------------------------------10

8.1 INITIAL FUNCTIONAL CHECK FOR TCD989/J XENIUM..............................................................................................................10

8.2 RF TEST...............................................................................................................................................................................13

8.3 CHARGING IGN (IGNITION) – BATTERY......................................................................................................................................15

9.0 ASSEMBLY / DISMANTLEMENT PROCEDURES----------------------------------------------------------------------------15

9.1 DISMANTLEMENT......................................................................................................................................................................16

9.2 ASSEMBLY...............................................................................................................................................................................16

10.0 DEFAULTS SETTINGS-----------------------------------------------------------------------------------------------------------------16

10.1 RESET CUSTOMER PARAMETERS. ...............................................................................................................................................16

10.2 USE OF THE GSM STRING *#RSAV*# OR *#7728*#.............................................................................................................16

11.0 SOLUTIONS IN CASE OF PROBLEMS DURING THE TESTS-------------------------------------------------------------17

11.1 THE PHONE DOES NOT SWITCH ON..............................................................................................................................................17

11.2 CHARGE DOES NOT START OR NO DETECTION OF THE CHARGER.......................................................................................................17

11.3 THE DISPLAY SHOWS “NO SIM CARD. PLEASE INSERT YOUR SIM CARD.” OR “SIM FAILURE” .................................................17

11.4 DISPLAY PROBLEMS.................................................................................................................................................................18

11.5 BUZZER PROBLEMS..................................................................................................................................................................18

11.6 NO SOUND IN LOUDSPEAKER....................................................................................................................................................18

11.7 COMMUNICATION PROBLEMS.....................................................................................................................................................18

11.8 DEFECTIVE ANTENNA...............................................................................................................................................................18

11.9 KEYBOARD PROBLEMS.............................................................................................................................................................18

11.10 PROBLEMS TO SEND SMS MESSAGES.......................................................................................................................................18

12.0 RECOMMENDED PART LIST- TCD 989 XENIUM DB------------------------------------------------------------------------18

12.1 COMMON PARTS – OUT OF WARRANTY........................................................................................................................................18

SERVICE REPAIR SUPPORT

PROCEDURE

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 3 out of 24

- 3 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 4

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

SERVICE REPAIR SUPPORT

PROCEDURE

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 4 out of 24

1.0 PURPOSE

This document establishes the functional test and inspection procedures for the first level service repair of the

XENIUM DB transceiver

2.0 SCOPE

The test plan is applicable to all levels of service repair of the XENIUM DB transceiver

3.0 REFERENCE

4.0 GLOSSARY/ACRONYM LIST

Window or Bezzel Protective plastic over the LCD display

SW Software

PN Hardware Configuration of the Mobile

CN Matrix for Types of SW used on the different hardware

HW Hardware

ASC Authorized Service Center

NSC National Service Center

Test SIM Card Used for functionality of PHILIPS Mobiles

Test SIM Card “SP” SIM Card that is used to stimulate the user interface and allow radio tests

5.0 TEST EQUIPMENT AND TOOLS

Equipment / Tools

Production Test SIM Card - Part No. : 4311 255 00781

Test SIM Card “SP” - Part No. : 4311 255 00782

RF Cable - Part No. : 941-555-1 (AMP).

Digital Multimeter - Recommended Model : Fluke

Specification with current reading in mA.

Digital Radiocommunication Tester.

- 4 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 5

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

SERVICE REPAIR SUPPORT

PROCEDURE

6.0 TEST AND INSPECTION PLAN

The test plan is derived from the Product Test Reference for XENIUM DB.

6.1 User Interface Test

Use the Test SIM card “SP” / Production to test the transceiver as follows :

♦ On/off Button

♦ LCD Backlight

♦ Keyboard Test

♦ Buzzer Test

♦ Audio Test

♦ Antenna Test (levels 5 &10)

♦ LCD

♦ LED Test (On/Off)

♦ IMEI

♦ Tester Status/Eeprom Status

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 5 out of 24

With a fast charger connected with the PRODUCT’s bottom connector, check the full scrolling from one mode to the

next when charging IGN (Ignition)-Battery.

6.2 RF Test

The radio test must be performed with a Digital Radio Test Set connected to the mobile RF connector with the

specific RF cable

- 5 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 6

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

SERVICE REPAIR SUPPORT

7.0 BEFORE STARTING

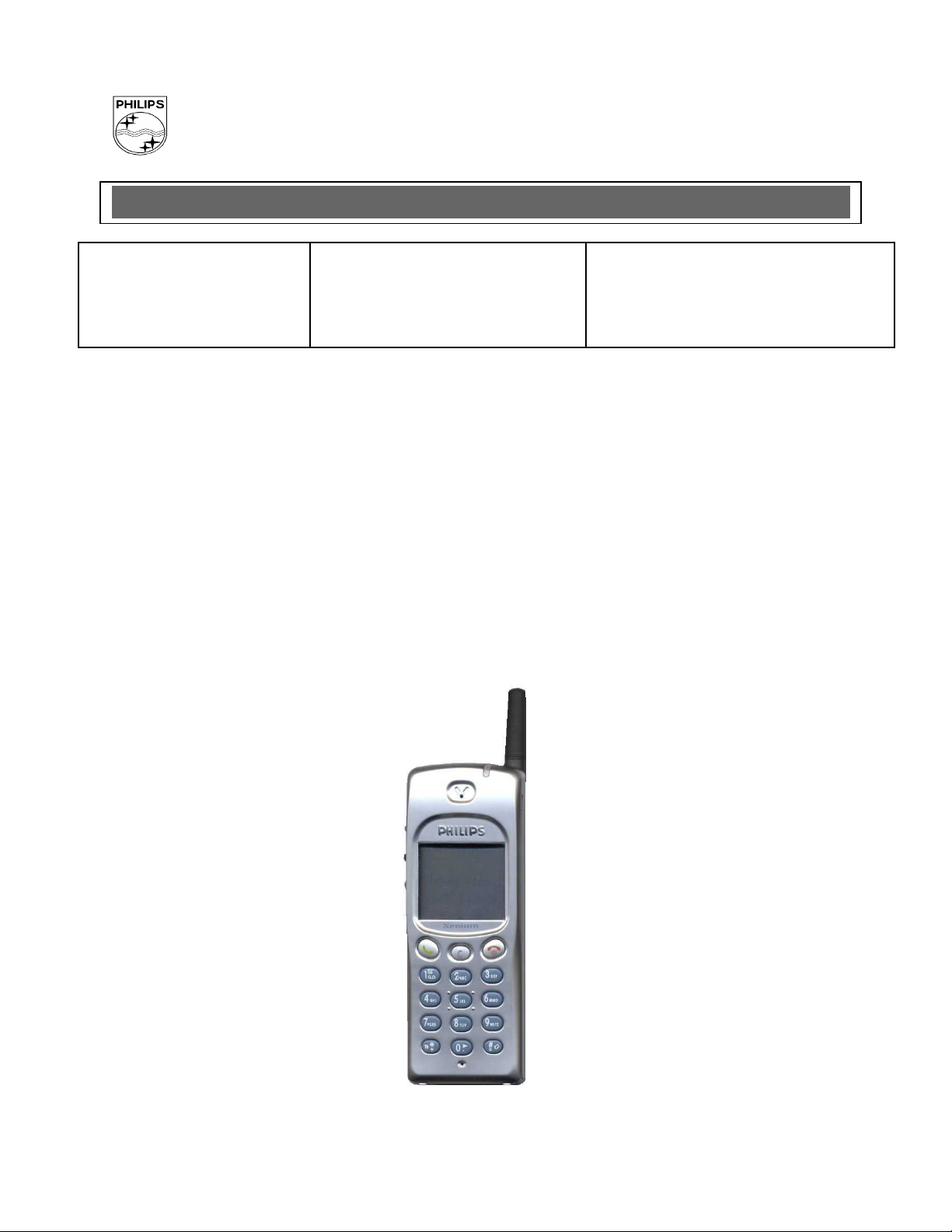

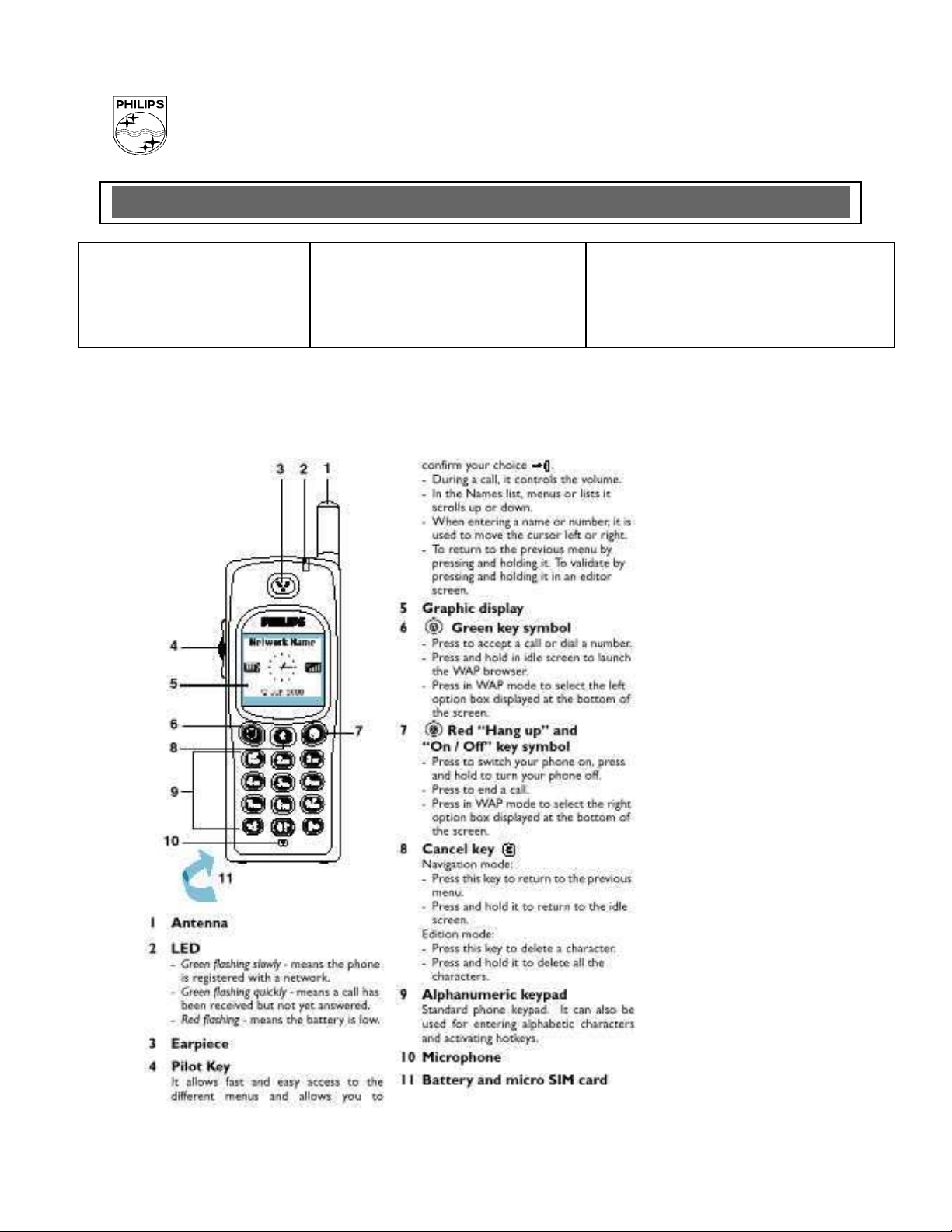

7.1 Description of the transceiver

PROCEDURE

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 6 out of 24

- 6 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Page 7

Philips Consumer Communications

PHILIPS

CUSTOMER SERVICES

Author : Fabrice TANT

Approval : Jean Pierre HOLLANDE

Operational manager

7.2 Description of the display

SERVICE REPAIR SUPPORT

PROCEDURE

Indicates the Network on which

your phone is registered.

Clock : Indicates an hour.

Reception quality : The more bars shown

the better the reception.

Indicates the date

PCC/VY/691/E/XENIUMDB989LVL1/0025/MLD/MLD

Revision : 2

Date : 19/06/2000

Page 7 out of 24

- 7 -

PCC/VY/691/E/XENIUM989/0025/MLD/MLD

Battery level : The bars indicate the battery level

(4 Bars means full, no bars means recharging is

needed.)

Page 8

7.3 Using The Carousel

The carousel is a circular loop of icons displayed on the screen. These icons provide access to the different

menus and sub menus used to operate your phone.

7.4 Inserting the MICRO-SIM card

7.4.1 The mobile supports only the mini “plug-in” SIM card.

Push the metal retaining clip to the right and lift the cardholder. Slide in the SIM card between the retaining

clip and the plastic tongue with the cut corner of the card at the top left. Close the cardholder and push the

retaining clip to the left.

Page 9

7.5 Inserting on the battery

7.5.1 Place the battery on the back of the phone (connectors downward, the top near the arrow inside the case).

7.5.2 Then push the battery into place in the direction of the antenna.

7.6 Removing the battery

7.6.1 Press the locking button located alongside the antenna while pushing the battery in the direction of the

7.6.2 Remove battery.

7.7 Charging the battery

arrow.

7.7.1 Plug the battery onto the transceiver

7.7.2 Plug the charger into the connector at the base of the transceiver.

Page 10

7.7.3 Plug the transformer unit into the main AC power sockets.

7.7.4 The battery charge symbol indicates the state of the charge process :

• Bars moving - means the battery is being charged

• Steady - means the battery is fully charged

If the battery is totally discharged, the battery icon will show and start scrolling 2 to 3 minutes only after

connecting to the charger.

8.0 TEST PROCEDURES

8.1 Initial Functional check for TCD989/J XENIUM

8.1.1 Insert the Test Production Card into the SIM Reader at the back of the cellular phone and clip a charged battery on the phone.

8.1.2 Press the «ON» button for 2 seconds at least and the LCD will show a message which contains information of FA and 12NC. (see

8.1.3 Follow the instructions as mentioned below :

Step Procedure Observation

1 Press Key 1

Press Key 1 again

2 Press key 2

(Audio loop local effect)

Press key 2 again

3 Press key 3

Audio loop test (Speak to

Mic and listen echo from

Speaker)

Press key 3 again.

4 Press key 4 (LEDs Test)

Check for the Backlight

function in the same time.

Press key 4 again

Continue Buzzer signal

Left corner displays 1

00

"LocalEffect"

" XX XX “

Left corner displays 2

01

"AUDIO xx xx xx ”

"EEP x xx xx xx ”

Left corner displays 3

02

Red and green LED blinking

Left corner displays 4

03

Page 11

5 Press Key 5

(Checkerboard test)

Checkerboard 1 pixel on

Press Key 5 again

6 Press Key 6

(Inverted Checkerboard)

Press Key 6 again

7 Press Key 7

Press key 7 again

8 Press key 8 (Eeprom

Status)

Press Key 8 again

9 Press Key 9 Product

information

Compare information with

label printed on back case

Left corner displays 5

04

Checkerboard 2 pixel on

Left corner displays 6

05

All pixels and hard icons on

Left corner displays 7

06

"EEPROM STAT” (Must be Good)

H-XXXX-XXXX (Eeprom Status)

L-XXXXXX-XX

SimLk XXXXX (Sim lock Status)

Left corner display 8

07

“PROD INFO”

“XXXXXXXXX” (Product 12NC)

“XXXXXXXX” (PN Number)

VY made in Le Mans

SA made in Singapore

EO made in Shenzhen

Press key 9 again

10 Press key 0

Press key 0 again

11 Press * (IMEI Test)

Compare IMEI with label

printed on back case

Press * again

Left corner displays 9

08

“ADC MEASURES”

“XXXX XXXX”

“XXXX XXXX”

Left corner displays 0

09

"IMEI TEST"

" XXXXXX/ 50 / XXXXXXX" for (TCD989/J)

06 made in Singapore

50 made in Le-Mans

69 made in China

Left corner displays *

12

Page 12

12 Press # (FA Status)

"FA/12NC”

FA GOOD (Must be good) X

XXXXXXXXXXX (12NC)

Press # again

13 Press C

Press C again

14 Go to the UP with the

Scanswitch

(Melody Test)

Go to the UP again

15 Go to the DOWN with the

Scanswitch

(Memory Test)

Go to the DOWN again

16 Press the Scanswitch

Left corner displays #

13

Key without Test

Left corner displays C

14

User Melody

Left corner displays 0A

“MEMORY TEST”

“XXXXXXXX”

“XXXXXXXX”

“RAM OK”

Left corner displays 0B

“PAGE”

“SELECTION”

“XX”

Press the Scanswitch

17 Press Green button

Press Green button again

18 Press Red button

Press Red button again

8.1.4 If any of the step failed functional, refer to Chapter 10.

8.1.5 Perform visual check on battery connectors, car kit connectors and casing.

If corrosion or deform send to NSC for repair.

8.1.6 If the product is good, it is considered as a NFF product.

All the NFF products must be directly returned to the customer.

Left corner display OK

0E

“ MANUAL TEST”

“ GOOD “

Left corner displays

0F

“ MANUAL TEST”

“ BAD “

Left corner displays

10

Page 13

8.2 RF TEST

8.2.1 The Test SIM Card “SP” must be inserted into the phone before starting the tests.

8.2.2 Set the equipment as shown on the picture in chapter 6.2.

8.2.3 Set in the offset field of the radio tester a – 0.3 dBm lose for GSM Test

8.2.4 The following operations must be done:

- Synchronization/Registration

- Call set up from the mobile

- Voice loopback ( to check the sound quality)

- Call release

- Call set up from tester

- Call release from tester

8.2.5 The following parameters must be checked in TCH loop mode :

Emission parameters :

- Power level

- RMS phase error

- Peak phase error

- Frequency error

- Power ramping

Reception parameters :

- Rx level

- Rx quality

- BER (Byte Error Rate)

- FER (Frequency Error Rate)

Generally the test sequences built inside the testers will be used to check the mobile. You must assess that the test

sequences limits comply with the standard specifications.

8.2.6 GSM Specification (900 Mhz)

Test Parameters Channel Level Standard Specification

EMISSION

Phase Error RMS 1, 62, 124 5, 10, 15 0 to 5 degrees

Phase Error Peak 1, 62, 124 5, 10, 15 -20 to +20 degrees

Frequency Error 1, 62, 124 5, 10, 15 -90 Hz to +90 Hz

Power Ramping 1, 62, 124 5, 10, 15 Mask

Modulation 1, 62, 124 5, 10, 15 Mask

Switching Transients 1, 62, 124 5, 10, 15 Mask

Power Reading

Page 14

Output Power Average 1, 62, 124 Level 15 11.2 dBm to 14.8 dBm

1, 62, 124 Level 10 21.2 dBm to 24.8 dBm

1, 62, 124 Level 5 31 dBm to 34.1 dBm

RECEPTION

Rx Level 1, 62, 124 -83 dBm +/-2.5 dBm

Rx Level 1, 62, 124 -60 dBm +/-2.5 dBm

Rx Level 1, 62, 124 -40 dBm +/-2.5 dBm

TCH LOOP

SENSITIVITY

BER 1, 62, 124 -85 dBm 0%

FER 1, 62, 124 -85 dBm 0%

BER 1, 62, 124 -102 dBm < 2.44%

FER 1, 62, 124 -102 dBm 0%

BER 1, 62, 124 -103 dBm < 2.44%

FER 1, 62, 124 -103 dBm 0%

If a phone is out of the specifications, it must be sent to the Repair Center.

8.2.7 PCN Specification (1800 Mhz)

Test Parameters Channel level Standard Specification

EMMISSION

Phase error RMS 512, 635, 760,885 0,5,10 0 to 5 degree

Phase error Peak 0,5,10 -20 to +20 degree

Frequency Error 0,5,10 -180 Hz to + 180 Hz

Power Ramping 0,5,10 Mask

Modulation 0,5,10 Mask

Switching Transcients 0,5,10 Mask

Power reading

Output Power level 0 30 +/- 2 dbm

RECEPTION

Rx Level 512, 635, 760,885 -100dbm 8 to 13

Rx Qual -100dbm 0 to 1

Rx Level 512, 635, 760,885 -80dbm 28 to 33

Rx Qual -80dbm 0 to 1

Rx Level -60dbm 48 to 53

Rx Qual -60dbm 0 to 1

level 10 10 +/- 4.0 dbm

level 19 0 +/- 5.0 dbm

TCH LOOP

Page 15

SENSITIVITY

BER at -85dbm 512,635,760,885 0%

FER at -85dbm 0%

BER at -103dbm 2.44%

FER at -103dbm 0%

If a phone is out of the specifications, it must be sent to the Repair Center.

8.3 Charging IGN (Ignition) – Battery

8.3.1 Plug the connector of the charger into the round socket set at the base of the transceiver.

The battery symbol should indicate the state of the charge process :

• Bars moving - means the battery is being charged.

• Steady - means the battery is fully charged.

If the battery is totally discharged, the battery icon will start scrolling 2 to 3 minutes only

after being connected to charger.

8.3.2 Remove the charger by unplugging the connector from the round socket at the base of the transceiver.

8.3.3 Remove the battery.

8.3.4 Lift the bottom left side of Production Test SIM Card with a tweezer.

8.3.5 Gently slide the card out away from the grooves of the Product

9.0 ASSEMBLY / DISMANTLEMENT PROCEDURES

During dismantlement and assembly operations, an antistatic bracelet must be used.

Page 16

9.1 Dismantlement

9.1.1 Unscrew the ANTENNA

9.1.2 Take the product, remove BATTERY

9.1.3 Remove the SIM card

9.2 Assembly

9.2.1 Check the REAR HOUSING on the product

9.2.2 Check the LABEL on the back

9.2.3 Screw the ANTENNA

10.0DEFAULTS SETTINGS

10.1 Reset customer parameters.

To reset customer parameters, it must use a GSM String. This Gsm String is

*#RSAV*# or *#7728*#.

So, the defaults settings of the manufacturer are actived.

10.2 Use of the GSM string *#RSAV*# or *#7728*#.

Procedure to follow :

- Turn on the mobile (a SP SIM card is not necessary).

- Enter the Gsm String *#RSAV*# or *#7728*#.

- You can see “Reset” but the customer parameters are not reset yet.

- Turn off the mobile.

- When you will turn on, the defaults settings will be actived.

Page 17

11.0SOLUTIONS IN CASE OF PROBLEMS DURING THE TESTS

If for any reasons the phone needs to be disassembled (on level 2 only) to fix a defect detected during the test

procedure, a complete functional test and a RF test must be done.

11.1 The phone does not switch on.

- Check the tactile feeling of the “ON/OFF” button.

- Remove the battery. Check that both the contacts of the phone and those of the battery are not damaged.

- Clean the contacts.

- Plug the battery again, making sure that it is securely fitted. Charge the mobile until the icon has stopped

flashing.

Then unplug from the charger and attempt to switch the mobile on.

If it still does not switch on, send the mobile for repair.

11.2 Charge does not start or no detection of the charger.

- Check the charger contacts for dust or missing pins.

- Check the mobile connector.

- Remove the battery. Check that both the contacts of the phone and those of the battery are not damaged.

- Check the charger individually with a reference mobile. If the charger works properly try to charge the

customer mobile with a reference battery.

If neither of the battery and the charger can be incriminated, send the mobile for repair.

11.3 The display shows “No SIM card. Please insert your SIM card.” or “SIM FAILURE”

- If the SIM card cannot be inserted, check for any foreign part and try to remove it.

- Check the SIM Card connector. All the contacts must be at the same level. Make sure that there is no dust

on the connector contacts and the SIM card contacts.

Page 18

- If the test SIM card can be detected but the message “SIM Failure” remains on the customer’s card, his

card must be damaged. Ask him to contact his network operator.

Otherwise send the mobile for repair

11.4 Display problems

Contrast, icons and matrix of the display can be checked with the test SIM card by pressing keys ”5”, “6” and

“7” .

If everything works in test configuration it then means that a phone setting is disabled or does not suit well. It

can be solved in the phone menu.

Otherwise send the mobile for repair

11.5 Buzzer problems

Buzzer tone can be checked with the test SIM card by pressing key “1” and “2”.

- If it does not sound properly send the mobile for repair.

11.6 No sound in Loudspeaker

The sound from the loudspeaker can be checked with the test SIM card by pressing key “3”.

- Check the microphone and the earpiece, If the failure cannot be found out, send the mobile for repair.

11.7 Communication problems

- Sound quality can be checked in audio loop test (sound distortion, whistling, echo, …)

- If the mobile passes the radio tests successfully, we can assume that the phone works properly. The

customer must check the coverage area of his network operator or that he does not use the phone in a radio

shadow (outside the coverage area, in a tunnel or between tall buildings, …)

- If the mobile does not pass the radio tests, send the mobile for repair.

11.8 Defective antenna

- If the antenna is broken or curved => replace it

11.9 Keyboard problems

-The keyboard can be checked with the test SIM card.

- If a key or a row does not respond, check the keyboard.

11.10 Problems to send SMS messages

Check the Center number. It may be empty or wrong.

12.0RECOMMENDED PART LIST- TCD 989 XENIUM DB

12.1 Common parts – out of warranty

REFERENCE DESIGNATION POSITION

REPAIR LEVEL

Page 19

4311 257 61141 Antenna ass’y X16 DB 0906 1

4311 258 72846 Battery Slim 800mAh (Li-on)

4311 258 75075 Vibra Battery (900 mAh Li-on)

3122 427 20946 Fast Charger Europe

3122 427 21206 Fast Charger UK

-

-

-

-

1

1

1

1

ANNEXE 1

Page 20

Each returned product must have an IRIS code to identify the failure.

Loading...

Loading...