Philips VISTA AG30 Installation Instructions Manual

INSTALLATION INSTRUCTIONS

Surgical Troffer

MODEL: AG30

CAUTION! – READ THIS FIRST --- IMPORTANT SAFETY INSTRUCTIONS

11500 Melrose Avenue

Franklin Park, Illinois 60131

Phone: 800-576-2135

Fax: 800-576-2136

www.vistalighting.com

* Carefully read the instructions pertaining to your xture.

IF YOU HAVE ANY QUESTIONS REGARDING THE

PROPER INSTALLATION OR LOCAL CODES, CONSULT

A QUALIFIED ELECTRICIAN.

* To avoid shock hazard, do not work with live electrical wires.

* Install the xture in only dry, indoor applications.

* Do not install outdoors or in applications other than the

intended use.

* Install and wire the xture in locations in compliance with

the National Electric Code and any local codes.

WARNING: THIS PRODUCT MUST BE INSTALLED IN ACCORDANCE WITH THE APPLICABLE INSTALLATION

CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THE PRODUCT

AND THE HAZARDS INVOLVED.

WARNING: RISK OF FIRE, MINIMUM OF 90°C SUPPLY CONDUCTORS. CONSULT A QUALIFIED ELECTRICIAN

TO ENSURE CORRECT BRANCH CIRCUIT CONDUCTOR.

WARNING: TO AVOID SHOCK HAZARD DISCONNECT THE POWER AT THE PANEL BOARD (CIRCUIT BREAKER

BOX) BEFORE BEGINNING INSTALLATION.

A. GENERAL NOTES

1. Lens Orientation

AG30 supplemental surgical xtures can be ordered with either an asymmetric or symmetric lens option. If ordered with the

asymmetric lens, the xture must be oriented with the arrows on the “Light Direction” labels pointing to the side requiring more

light – typically toward the surgical eld in the center of the room. The “Light Direction” labels can be located on the lens’

protective wrapping and/or on the inside edge of the door frame. The door-housing assembly is factory assembled as a unit.

The door assembly can not be changed in the eld to change light direction so care must be taken to orient the xture

properly during installation. For the symmetric lens option, the xture can be positioned in either direction.

2. Door Frame and Hardware

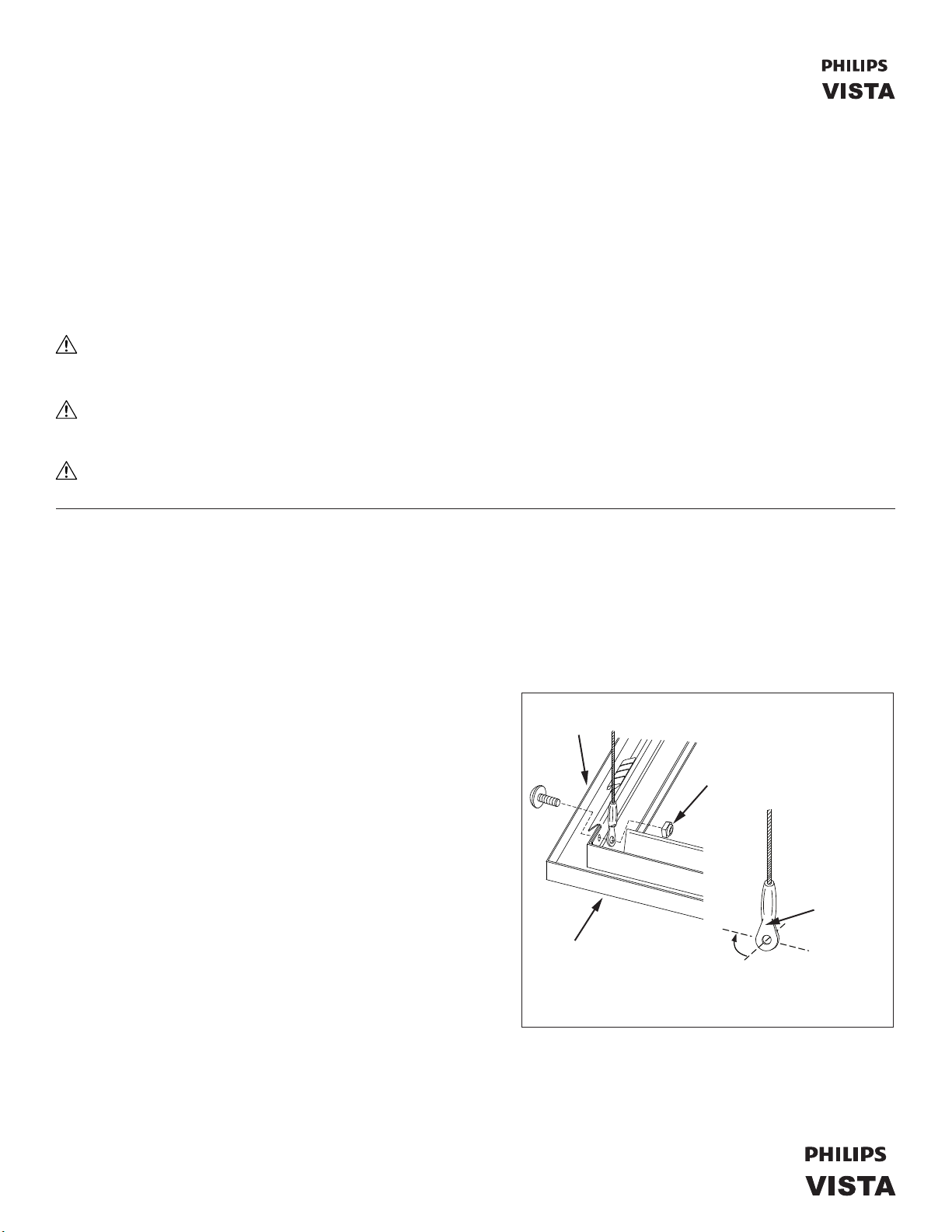

Some AG30 models utilize screws to secure the door frame to the

housing. To prevent cross-threading of the screws, start threading

each screw by hand to ensure proper threading of the screw into

end of door

frame

the nut. Once started, continue tightening the screws with a

screw driver – alternating between screws until they are all tight.

When opening or closing the door frame, support the door in the

closed position until all fasteners are completely tightened or

completely unthreaded from nut inserts.

Some door frame options are supplied with a cable lanyard to

support the door in an open position. The eyelets on these cables

are secured to the housing and door frame with screws and

lock-nuts. If it becomes necessary to completely remove the door

frame from the housing, disconnect the cable from the door

frame. Follow the steps below to ensure that the cable is

reconnected properly to the door frame.

a.) Insert the screw through the hole on the door frame.

side of door

frame

The head of the screw should be near the end of the

door frame.

b.) Slide the eyelet over the screw orientating the eyelet

as shown in Figure 1. The eyelet will need to be rotated

Figure 1

90° to t properly. At other end of door rotate eyelet in

opposite direction.

c.) Tighten the lock-nut onto the screw making sure that it is loose enough for the eyelet to swivel freely. This is important to

ensure that the cable lanyard tucks away properly when the door is closed. When closing the door, always tuck the cable

lanyard inside main compartment of the xture by ipping the eyelet and cable toward the center of the door.

tighten lock-nut and then

loosen 1/4 to 1/2 turn so

eyelet moves freely

lock-nut (nylon insert)

other end of

cable fastened

to fixture

flat side

of eyelet

rotate flat side of

eyelet 90° to align

ring with hole in

door frame

B. INSTALLATION OF GRID STYLE (“G” Versions) FIXTURES

Grid style (or “G” version) AG30 Series xtures are designed to install into standard suspended grid ceilings with a standard 1" or 1½"

high grid. The AG30 grid xtures are sized to t within standard 2x2 and 2x4 ceiling systems. Fixtures can be installed in any pattern

necessary within the ceiling grid layout. The weight of the xture is supported by the grid and supplemented with direct connection to

the building AG30ucture. The steps for installation are as follows:

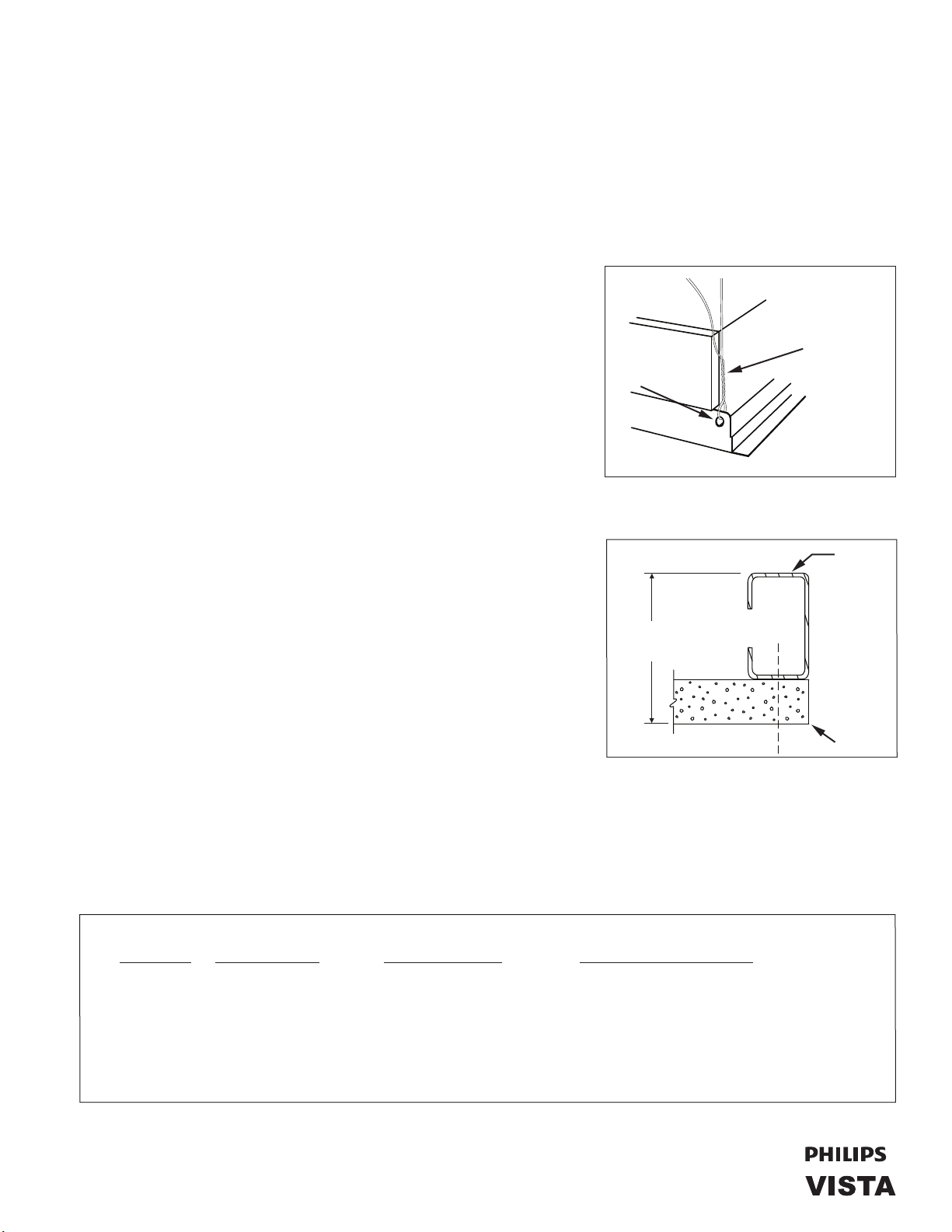

1. Inspect the ceiling grid to make sure it is supported from the building structure as recommended by the ceiling grid manufactuer's

instructions. This must be approved before bearing the weight of the lighting xture.

2. Angle the xture up through the opening in the grid making sure that the door frame is facing the room. Once the xture is

positioned through the opening, it can be leveled out and lifted down until the anges of the xture rest on the corresponding

anges of the ceiling grid. For 2x2 xtures being installed within a 2x4 ceiling system or for 1x4 xtures, additional grid pieces

may need to be installed. All four sides of the xture must rest on the grid.

3. The xture is to be connected directly to the building structure, independent

of the ceiling grid. Locate the hanger support tab at each corner of the xture

as shown in Figure 2. Use a hanger wire at all four support tabs to tie the

xture to the building structure. Use 12 gauge minimum hangar wire rated

for such application. In addition, follow local building codes regarding

required additional support of xtures.

Retainer Clips or Earthquake Clips can be ordered as accessories with the

hanger

suPPorts

hanger

suPPort

tab

wire hanger

1 at each

corner

(by others)

AG30 Series xtures for additional support with grid ceilings. When using

these accessories, the xture should still be installed per the instructions

above. Specic instructions for installing and using these accessories are

supplied with the packaging for the clips.

4. Follow the instructions in section “E. Making Electrical Connections”. If the

xture has an emergency ballast and/or dimming ballasts, also follow the

instructions in sections “F. Emergency Ballast Connections” and “G. Low

Figure 2

t grid not shown

Voltage Dimming Circuits”.

C. INSTALLATION OF AN INDIVIDUAL FLANGED (“F” Version) FIXTURE

Flange style (or “F” version) AG30 Series xtures are designed to install into dry

wall (i.e. gypsum board, sheetrock) ceilings. It is important to carefully review

and follow the instructions in this section to ensure a successful installation.

1. Determine the required ceiling opening.

Installation requires a clean and accurate opening to be cut into the ceiling

min. 1-1/16"

max. 3-1/16"

rigid

framing

around

ceiling

oPening

surface for the xture to be installed into. Openings need to be cut square

and accurate to 1/16" of the provided dimensions. The cut openings should

be into whole pieces of ceiling material to minimize seams and joints inter-

secting the cut opening. This limits the stress on taped joints and ensures a

better t of the xture ange against the ceiling surface.

The ceiling surface should be free of bowing and the area around the ceiling

opening should be nished to a smooth and at surface free of imperfections.

Figure 3

edge

of

oPening

The elevation of the ceiling surface should not deviate more than 1/32" over 2'

of horizontal surface.

Rigid framing (i.e. C-channel) around the cut opening should be installed with the inside edge of the frame positioned ush

with the cut opening. The ceiling material should be secured to the bottom surface of the frame. The combined thickness of

the ceiling material should be a minimum of 1-1/16" but no greater than 3-1/16". (See Figure 3)

The ceiling opening for individual xtures are listed in Chart 1 below.

Nominal Fixture Required Ceiling Required Ceiling Opening

Model Size Opening

(when using Plaster Frame*)

AG30F24 2' x 4' 22-7/8" x 48-5/8" 23" x 48-3/4"

AG30F22 2' x 2' 22-7/8" x 24-5/8"** 23" x 24-3/4"**

AG30F14 1' x 4' 10-7/8" x 48-5/8" 11" x 48-3/4"

* The Plaster Frame kit is packaged separately from the xture with installation instructions.

** The 24-5/8" dimension (or 24-3/4" when using a Plaster Frame) represents the length of the opening running parallel to the side ange

(or lamps) of the surgical xture.

Chart 1

2

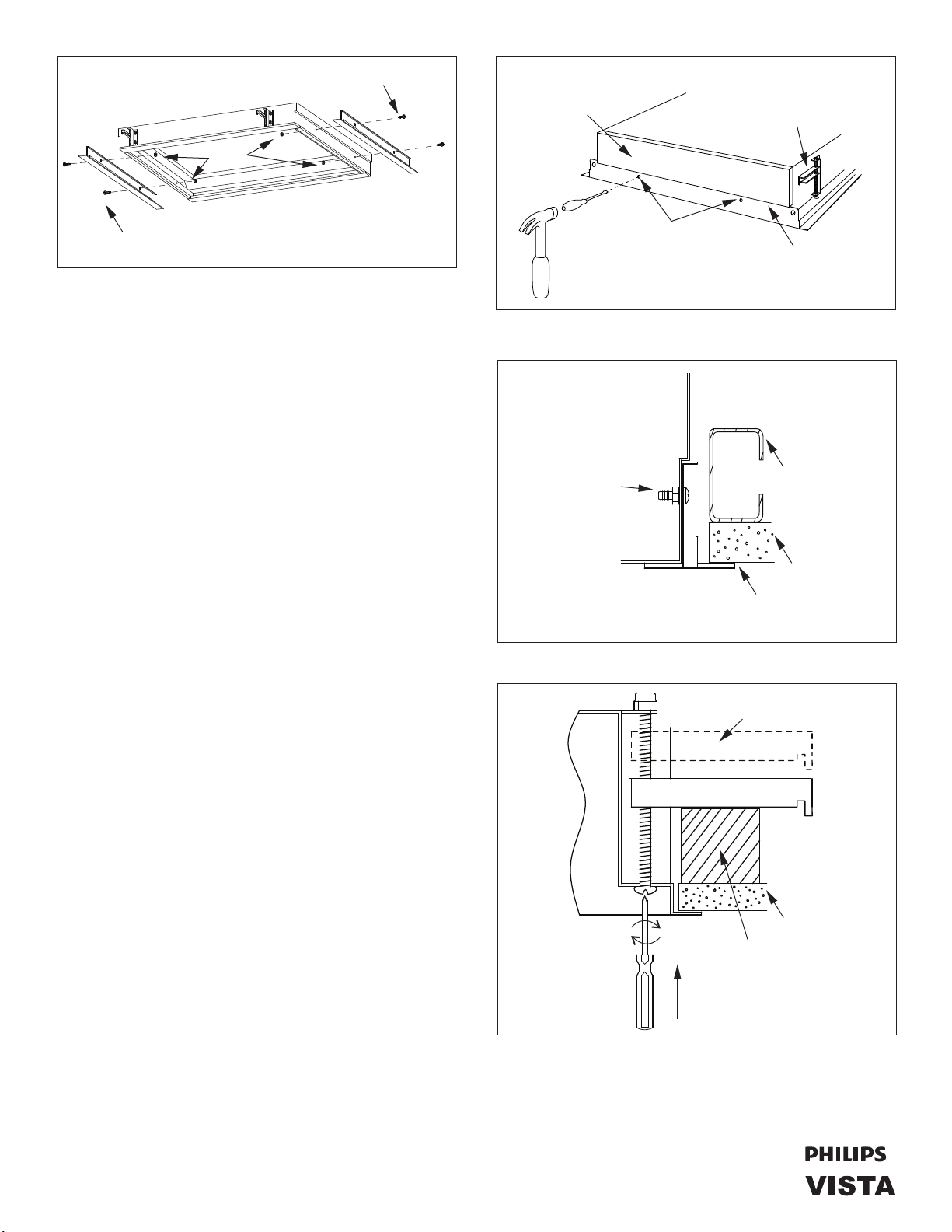

nuts

screws

housing

endPlate

keeP sway hanger

against housing

during insertion

into ceiling

screws

Figure 4

2. The AG30 anged xture has been supplied with two

end trims that need to be installed on the xture before

securing it to the ceiling. The trims pieces are secured

to the end cap of the xture as shown in Figure 4. (The

end cap can be identied by its offset prole.)

Install trims by locating the two mounting hole knock

outs and use a pointed tool and hammer to push in and

breakout all the knockouts from each of the xture

endplates. (See Figure 5) Position the trim piece so

that its center spline rests against the end cap (as

illustrated in Figure 6) with the mounting holes aligned

with the holes in the end cap. Insert the screws through

the trim piece and through the end cap from the outside

of the xture. Thread the nut onto the screw and tighten.

Repeat this step on the other end of the xture.

3. Check to make sure the sway bracket hangers, mounted

on the outside walls of the xture (See Figure 5), are

resting against the side of the xture. Carefully lift the

xture resting it on a support surface just below the ceiling.

4. Follow the instructions in section “E. Making Electrical

Connections” before beginning Step 5 below. If the xture

has an emergency ballast and/or dimming ballasts, also

follow the instructions in sections “F. Emergency

Ballast Connections” and “G. Low Voltage Dimming

Circuits”.

5. Once the conduit is connected to the xture, you can lift

the xture through the ceiling opening. The door of the

xture will need to be opened to gain access to the sway

bracket adjustment screws. Turn these screws in a clock

wise direction to swing the wing of the sway bracket out

from the xture as shown in Figure 7. When this has been

done at all four of the sway brackets the xture can

support itself on the framing around the opening.

7. Continue turning the sway bracket adjustment screws

clockwise, alternating between locations, until the xture

ts snug against the ceiling. Make sure the end trim

ts against the ceiling as shown in Figure 6.

8. If the xture has an emergency ballast and/or dimming

ballasts, follow the instructions in sections “F.

Emergency

Ballast Connections” and “G. Low Voltage

Dimming Circuits”.

remove knock outs

on end trims for

flange mounting

Figure 5

housing

install

screw

from

outside

(nut inside)

end trim

ensure end trim gaskets are in good

contact with fixture housing and

ceiling at locations indicated

Figure 6

turn clockwise

to swing out

and lower bar

turn counter

clockwise to

raise bar

Figure 7

offset in

endPlate

ceiling oPening

suPPort

ceiling

make gasket

contact here

hanger bars

ceiling

ceiling suPPort

insert

screwdriver

uP into

access hole

3

Loading...

Loading...