Page 1

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Rev. 01 — 19 May 2006 Product data sheet

1. General description

The TZA3046 is a transimpedance amplifier with AutomaticGainControl(AGC), designed

to be used in Fiber Channel/Gigabit Ethernet (FC/GE) fiber optic links. It amplifies the

current generated by a photo detector (PIN diode or avalanche photodiode) and converts

it to a differential output voltage. It offers a current mirror of average photo current for

RSSI monitoring to be used in SFF-8472 compliant modules.

The low noise characteristics makes it suitable for FC/GE applications, but also for

FTTx applications.

CAUTION

This device is sensitive to ElectroStatic Discharge (ESD). Therefore care should be taken

during transport and handling.

2. Features

n Low equivalent input noise current, typically 126 nA (RMS)

n Wide dynamic range, typically 2.5 µA to 1.7 mA (p-p)

n Differential transimpedance of 7.5 kΩ (typical)

n Bandwidth from DC to 1050 MHz (typical)

n Differential outputs

n On-chip AGC with possibility of external control

n Single supply voltage 3.3 V, range 2.97 V to 3.6 V

n Bias voltage for PIN diode

n On-chip current mirror of average photo current for RSSI monitoring

n Identical ports available on both sides of die for easy bond layout and RF polarity

3. Applications

n Digital fiber optic receiver modules in telecommunications transmission systems, in

selection

high-speed data networks or in FTTx systems.

Page 2

Philips Semiconductors

4. Ordering information

Table 1: Ordering information

Type number Package

TZA3046U - bare die, dimensions approximately

5. Block diagram

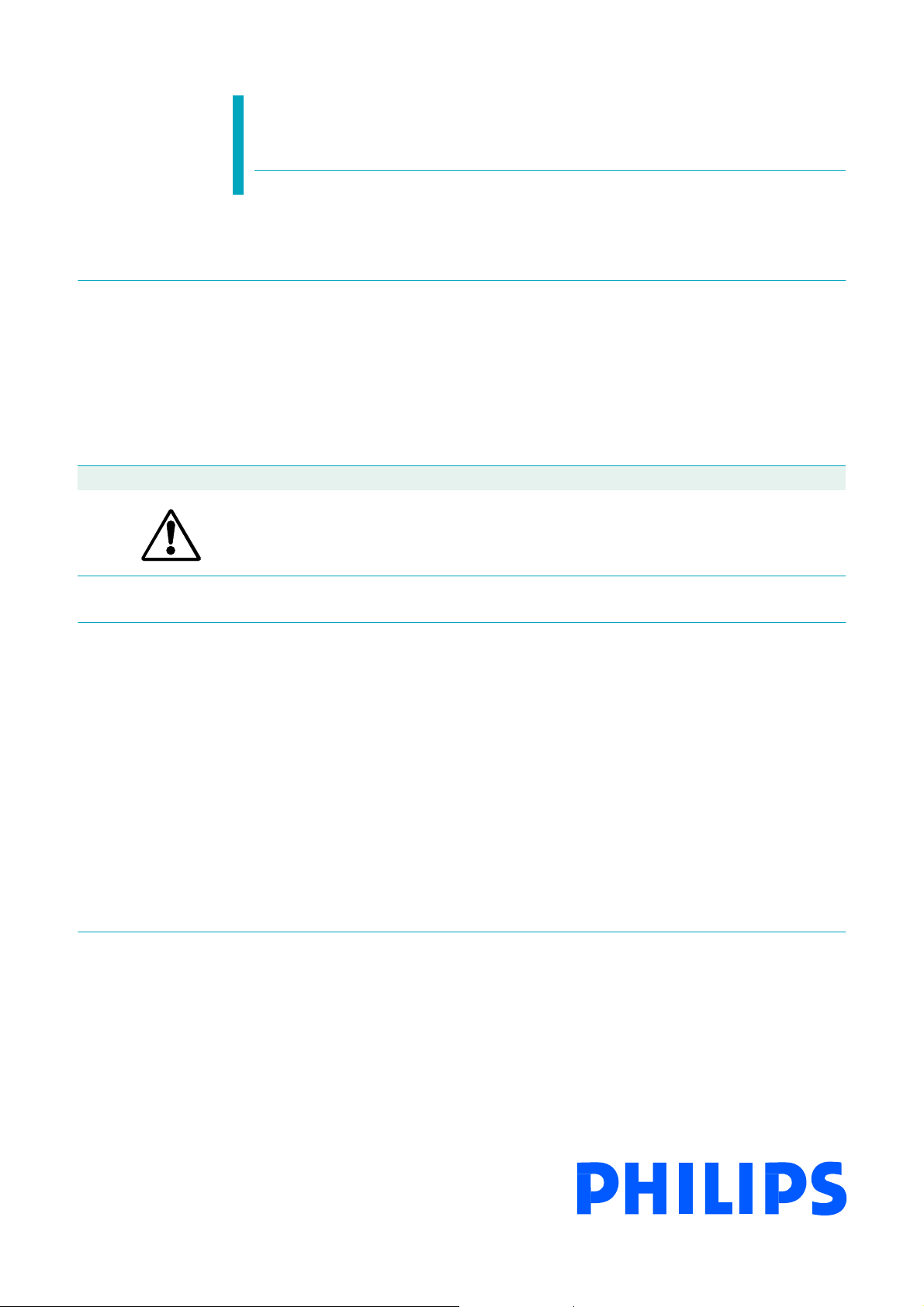

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Name Description Version

-

0.82 mm × 1.3 mm

I

IDREF_MON

R

IDREF_MON

C

DREF

Fig 1. Block diagram

C

VCC

IDREF_MON

DREF

D

PHOTO

I

PIN

IPHOTO

0.2 × I

5 or 16

1 or 3

2

DREF

low noise

amplifier

R

DREF

GAIN

CONTROL

V

4 or 17

I

DREF

290 Ω

AGC

CC

6 or 15

PEAK DETECTOR

single-ended to

differential converter

9, 10, 11, 12

GND

BIASING

buffers

output

TZA3046

7 or 13

8 or 14

OUTQ

OUT

001aae511

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 2 of 15

Page 3

Philips Semiconductors

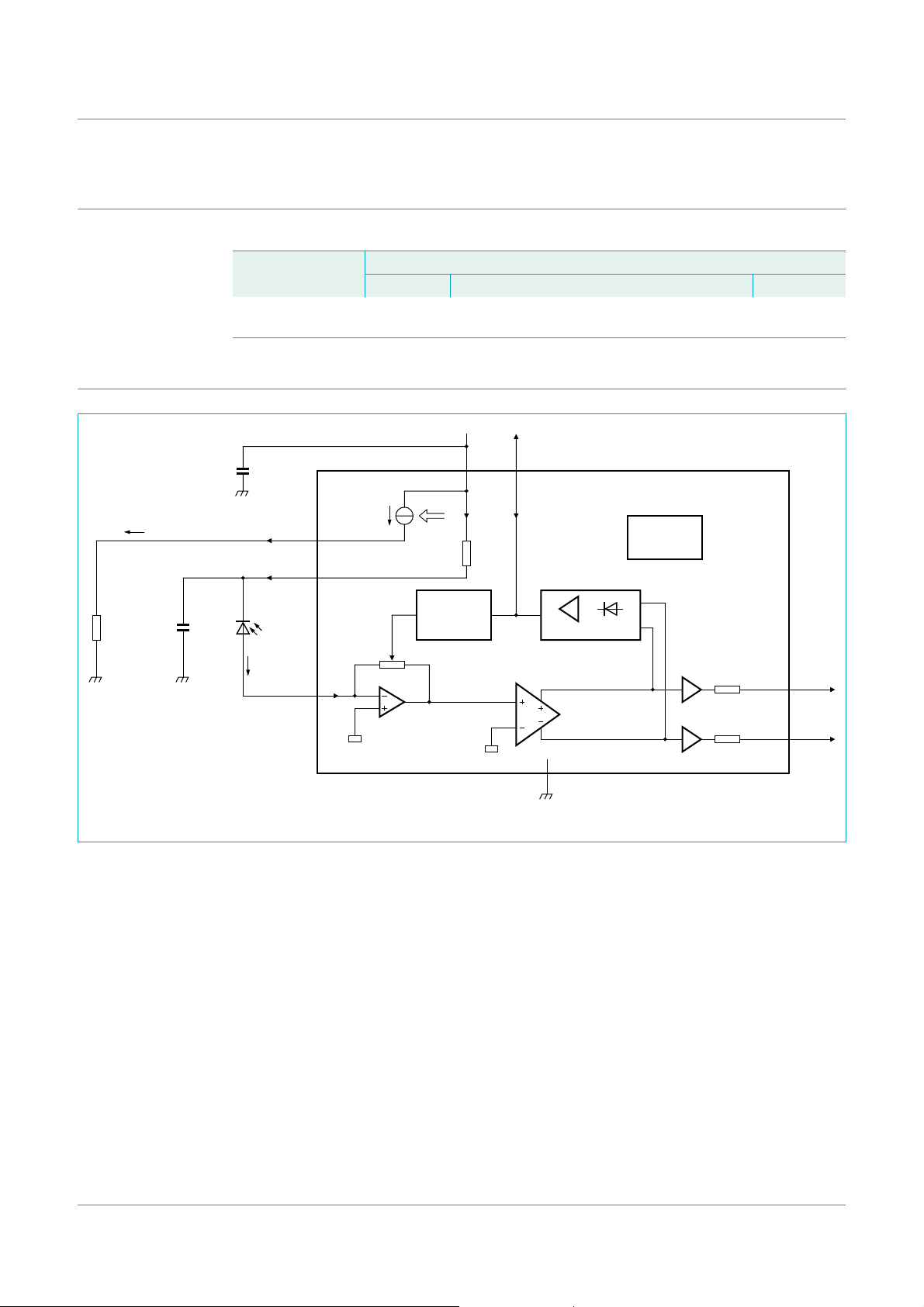

6. Pinning information

6.1 Pinning

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

DREF

IPHOTO

DREF

1

2

V

174

CC

IDREF_MON

165

AGC

156

OUT

14

OUTQ

13

129

GND

1110

GND

001aae512

V

CC

IDREF_MON

AGC

OUTQ

OUT

GND

GND

3

TZA3046

7

8

Fig 2. Pin configuration

6.2 Pin description

Table 2: Bonding pad description

Bonding pad locations with respect to the center of the die (see Figure 10); X and Y are inµm.

Symbol Pad X Y Type Description

DREF 1 −493.6 140 output bias voltage output for PIN diode; connect cathode of PIN diode to

pad 1 or pad 3

IPHOTO 2 −493.6 0 input current input; anode of PIN diode should be connected to this pad

DREF 3 −493.6 −140 output bias voltage output for PIN diode; connect cathode of PIN diode to

pad 1 or pad 3

V

CC

IDREF_MON 5 −213.6 −278.6 output current output for RSSI measurements; connect a resistor to pad 5

AGC 6 −73.6 −278.6 input AGC voltage; use pad 6 or pad 15

OUTQ 7 66.4 −278.6 output data output; complement of pad OUT; use pad 7 or pad 13

OUT 8 206.4 −278.6 output data output; use pad 8 or pad 14

GND 9 346.4 −278.6 ground ground; connect together pads 9, 10, 11 and pad 12 as many as

GND 10 486.4 −278.6 ground ground; connect together pads 9, 10, 11 and pad 12 as many as

4 −353.6 −278.6 supply supply voltage; connect supply voltage to pad 4 or pad 17

or pad 16 and ground

[1]

possible

possible

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 3 of 15

Page 4

Philips Semiconductors

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Table 2: Bonding pad description

Bonding pad locations with respect to the center of the die (see Figure 10); X and Y are inµm.

Symbol Pad X Y Type Description

GND 11 486.4 278.6 ground ground; connect together pads 9, 10, 11 and pad 12 as many as

GND 12 346.4 278.6 ground ground; connect together pads 9, 10, 11 and pad 12 as many as

OUTQ 13 206.4 278.6 output data output; complement of pad OUT; use pad 7 or pad 13

OUT 14 66.4 278.6 output data output; use pad 8 or pad 14

AGC 15 −73.6 278.6 input AGC voltage; use pad 6 or pad 15

IDREF_MON 16 −213.6 278.6 output current output for RSSI measurements; connect a resistor to pad 5

V

CC

[1] These pads go HIGH when current flows into pad IPHOTO.

17 −353.6 278.6 supply supply voltage; connect supply voltage to pad 4 or pad 17

…continued

possible

possible

[1]

or pad 16 and ground

7. Functional description

The TZA3046 is a TransImpedance Amplifier (TIA) intended for use in fiber optic receivers

for signal recovery in FC/GE or FTTx applications. It amplifies the current generated by a

photo detector (PIN diode or avalanche photodiode) and converts it to a differentialoutput

voltage.

The most important characteristics of the TZA3046 are high receiver sensitivity, wide

dynamic range and large bandwidth. Excellent receiver sensitivity is achieved by

minimizing transimpedance amplifier noise.

The TZA3046 has a wide dynamic range to handle the signal current generated by the

PIN diode which can vary from 2.5 µA to 1.7 mA (p-p). This is implemented by an AGC

loop which reduces the preamplifier feedback resistance so that the amplifier remains

linear over the whole input range. The AGC loop hold capacitor is integrated on-chip, so

an external capacitor is not required.

The bandwidth of TZA3046 is optimized for FC/GE application. It works from DC onward

due to the absence of offset control loops. Therefore the amount of Consecutive Identical

Digits (CID) will not effect the output waveform. A differential amplifier converts the output

of the preamplifier to a differential voltage.

7.1 PIN diode connections

The performance of an optical receiver is largely determined by the combined effect of the

transimpedance amplifier and the PIN diode. In particular, the method used to connect the

PIN diode to the input (pad IPHOTO) and the layout around the input pad strongly

influences the main parameters of a transimpedance amplifier, such as sensitivity,

bandwidth, and PSRR.

Sensitivity is most affected by the value of the total capacitance at the input pad.

Therefore,to obtain the highest possible sensitivity the total capacitance should be as low

as possible.

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 4 of 15

Page 5

Philips Semiconductors

The parasitic capacitance can be minimized through:

1. Reducing the capacitance of the PIN diode. This is achieved by proper choice of PIN

diode and typically a high reverse voltage.

2. Reducing the parasitics around the input pad. This is achieved by placing the PIN

diode as close as possible to the TIA.

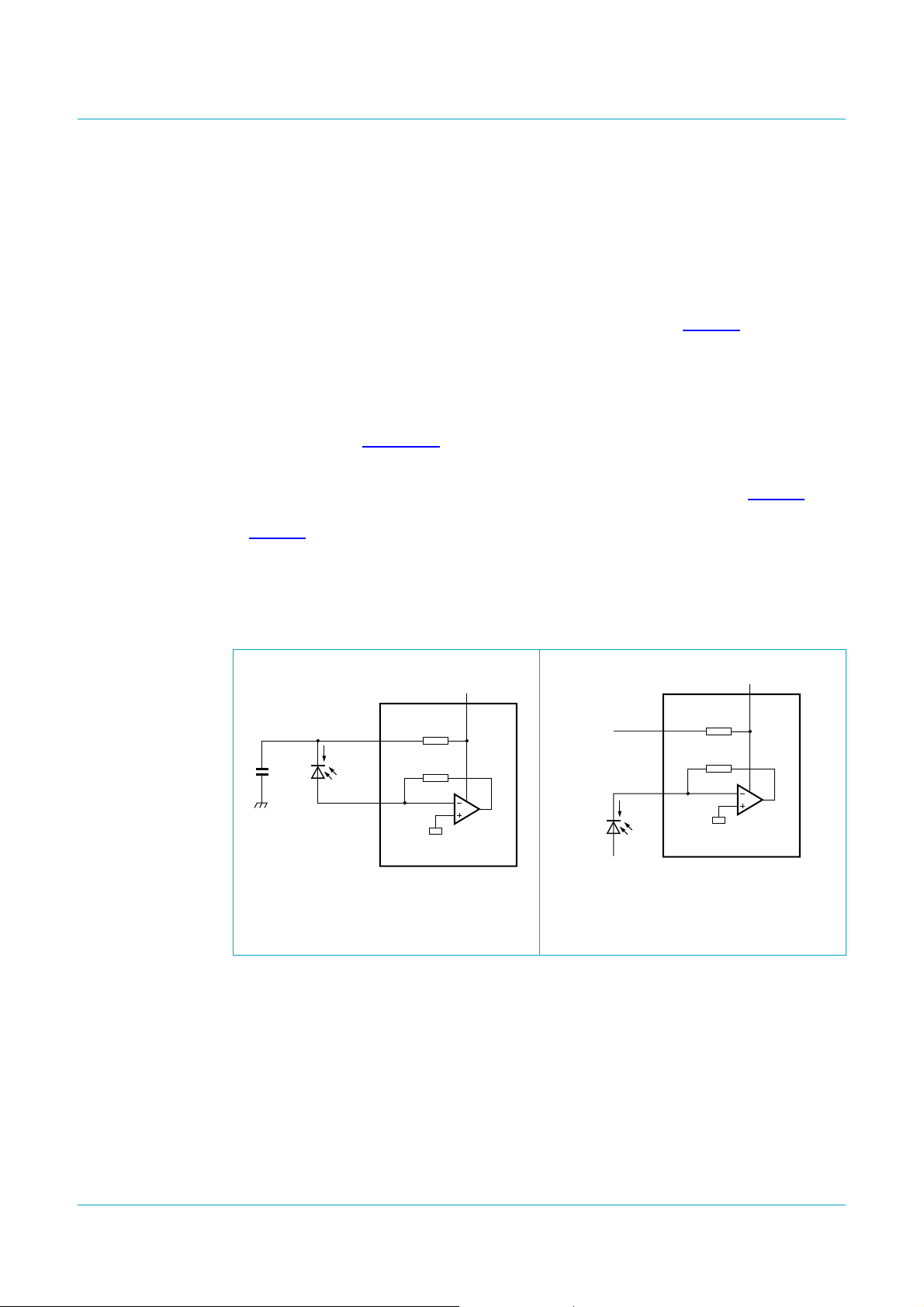

The PIN diode can be biased with a positive or a negative voltage.Figure 3 shows the PIN

diode biased positively, using the on-chip bias pad DREF. The voltage at DREF is derived

from VCCby a low-pass filter comprising internal resistor R

which decouples any supply voltage noise. The value of external capacitor C2 affects the

value of PSRR and should have a minimum value of 470 pF. Increasing this value

improves the value of PSRR. The current through R

IDREF_MON, see Section 7.3.

If the biasing for the PIN diode is done external to the IC, pad DREF can be left

unconnected. If a negative bias voltage is used, the configuration shown in Figure 4 can

be used. In this configuration, the direction of the signal current is reversed to that shown

in Figure 3. It is essential that in these applications, the PIN diode bias voltage is filtered to

achieve the best sensitivity.

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

and external capacitor C2

DREF

is measured and sourced at pad

DREF

For maximum freedom on bonding location, 2 outputs are available for DREF (pads 1

and 3). These are internally connected. Both outputs can be used if necessary. If only one

is used, the other can be left open.

V

R

DREF

290 Ω

TZA3046

CC

4 or 17

001aae514

V

CC

4 or 17

R

DREF

1 or 3

DREF

C2

470 pF

I

PIN

IPHOTO

290 Ω

2

TZA3046

001aae513

Fig 3. The PIN diode connected between

the input and pad DREF

1 or 3

DREF

IPHOTO

negative

bias voltage

2

I

PIN

Fig 4. The PIN diode connected between

the input and a negative supply

voltage

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 5 of 15

Page 6

Philips Semiconductors

7.2 Automatic gain control

The TZA3046 transimpedance amplifier can handle input currents from 2.5 µA to 1.7 mA

which is equivalent to a dynamic range of 56 dB (electrical equivalent with 28 dB optical).

At low input currents, the transimpedance must be high to obtain enough output voltage,

and the noise should be low enough to guarantee a minimum bit error rate. At high input

currents however,thetransimpedanceshouldbelowtoprevent excessive distortion at the

output stage. To achieve the dynamic range, the gain of the amplifier depends on the level

of the input signal. This is achieved in the TZA3046 by an AGC loop.

The AGC loop comprises a peak detector and a gain control circuit. The peak detector

detects the amplitude of the signal and stores it in a hold capacitor. The hold capacitor

voltage is compared to a threshold voltage. The AGC is only active when the input signal

level is larger than the threshold level and is inactive when the input signal is smaller than

the threshold level.

When the AGC is inactive, the transimpedance is at its maximum. When the AGC is

active,thefeedbackresistorvalueofthetransimpedanceamplifieris reduced, reducing its

transimpedance, to keepthe output voltage constant. Figure 5 shows the transimpedance

as function of the input current.

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

To reduce sensitivity to offsets and output loads, the AGC detector senses the output just

before the output buffer. Figure 6 shows the AGC voltage as function of the input current.

10

001aae515

3

I

PIN

4

(µA)

10

transimpedance

(kΩ)

1

−1

10

110

10 10

2

Fig 5. Transimpedance as function of the PIN diode

current

10

001aae516

3

I

PIN

(µA)

3.5

V

AGC

(V)

2.5

1.5

0.5

110

10 10

2

Fig 6. AGC voltage as function of the PIN diode

current

4

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 6 of 15

Page 7

Philips Semiconductors

For applications where the transimpedance is controlled by the TIA it is advised to leave

the AGC pads unconnected to achieve fast attack and decay times.

The AGC function can be overruled by applying a voltage to pad AGC. In this

configuration, connecting pad AGC to ground gives maximum transimpedance and

connecting it to VCC gives minimum transimpedance. This is depicted in Figure 7. The

AGC voltage should be derived from the VCC for proper functioning.

Formaximum freedom on bonding location, 2 pads are availablefor AGC (pads 6 and 15).

These pads are internally connected. Both pads can be used if necessary.

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

10

transimpedance

(kΩ)

1

−1

10

0.3 0.90.70.5

Fig 7. Transimpedance as function of the AGC voltage

001aae517

V

AGC/VCC

7.3 Monitoring RSSI via IDREF_MON

To facilitate RSSI monitoring in modules (e.g. SFF-8472 compliant SFP modules), a

current output is provided. This output gives a current which is 20 % of the average DREF

current through the 290 Ω bias resistor. By connecting a resistor to the IDREF_MON

output, a voltage proportional to the average input power can be obtained.

The RSSI monitoring is implemented by measuring the voltage over the 290 Ω bias

resistor. This method is preferred over a simple current mirror because at small photo

currents the voltage drop over the resistor is very small. This gives a higher bias voltage

yielding better performance of the photodiode.

For maximum freedom on bonding location, 2 pads are available for IDREF_MON (pads 5

and 16). These pads are internally connected. Both pads can be used if necessary. If only

one is used, the other can be left open.

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 7 of 15

Page 8

Philips Semiconductors

8. Limiting values

Table 3: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CC

V

n

I

n

P

tot

T

amb

T

j

T

stg

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

supply voltage −0.5 +3.8 V

voltage on any other

pin

current on any other

pin

total power dissipation - 300 mW

ambient temperature −40 +85 °C

junction temperature - 150 °C

storage temperature −65 +150 °C

pad

IPHOTO −0.5 +2.0 V

OUT, OUTQ −0.5 V

AGC, IDREF_MON −0.5 V

DREF −0.5 V

+ 0.5 V

CC

+ 0.5 V

CC

+ 0.5 V

CC

pad

IPHOTO −4.0 +4.0 mA

OUT, OUTQ −10 +10 mA

AGC, IDREF_MON −0.2 +0.2 mA

DREF −4.0 +4.0 mA

9. Characteristics

Table 4: Characteristics

Typical values at Tj=25°C and VCC= 3.3 V; minimum and maximum values are valid over the entire ambient temperature

range and supply voltage range; all voltages are measured with respect to ground; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

V

CC

I

CC

P

tot

T

j

T

amb

R

tr

f

-3dB(h)

I

n(rms)(itg)(tot)

Automatic gain control loop: pad AGC

t

att

t

decay

V

th(AGC)(p-p)

supply voltage 2.97 3.3 3.6 V

supply current AC-coupled; R

excluding I

DREF

L(dif)

and I

= 100 Ω;

IDREF_MON

-21 23 mA

total power dissipation VCC= 3.3 V - 70 76 mW

junction temperature −40 - +125 °C

ambient temperature −40 +25 +85 °C

small-signal

transresistance

high frequency

measured differentially;

AC-coupled, R

C

= 0.5 pF 800 1050 - MHz

PIN

L(dif)

= 100 Ω

5.5 7.5 10.5 kΩ

−3 dB point

totalintegratedRMS noise

current over bandwidth

referenced to input;

C

= 0.5 pF;

PIN

f

-3dB(min)

= 875 MHz

[1]

- 126 164 nA

attack time AGC pad unconnected - 14 - µs

decay time AGC pad unconnected - 40 - µs

peak-to-peak AGC

threshold voltage

referenced to output;

measured differentially

- 125 - mV

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 8 of 15

Page 9

Philips Semiconductors

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Table 4: Characteristics

…continued

Typical values at Tj=25°C and VCC= 3.3 V; minimum and maximum values are valid over the entire ambient temperature

range and supply voltage range; all voltages are measured with respect to ground; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Bias voltage: pad DREF

R

(DREF-VCC)

TC

RDREF

resistance between pin

DREF and pin V

CC

temperature coefficient of

R

DREF

tested at DC level;

T

=25°C

amb

260 290 320 Ω

- 0.33 - Ω/°C

Input: pad IPHOTO

I

IPHOTO(p-p)

peak-to-peak current on

[2][3]

−1000 +1700 - µA

pad IPHOTO

V

bias(i)

input bias voltage 700 850 1000 mV

Monitor: pad IDREF_MON

V

mon

I

IDREF_MON/IDREF

I

offset(mon)

TC

I(offset)mon

monitor voltage 0 - VCC− 0.4 V

monitor current ratio ratio I

monitor offset current T

amb

temperature coefficient of

IDREF_MON

=25°C 0 10 20 µA

/ I

DREF

19.5 20 20.5 %

- 30 - nA/°C

monitor offset current

Data outputs: pads OUT and OUTQ

V

O(cm)

common mode output

AC-coupled; R

= 100 Ω -VCC− 1.2 - V

L(dif)

voltage

V

o(dif)(p-p)

R

O(dif)

peak-to-peak differential

output voltage

differential output

AC-coupled; R

= 2.5 µA (p-p) × R

I

PIN

= 100 µA (p-p) - 120 - mV

I

PIN

= 1500 µA (p-p)

I

PIN

L(dif)

= 100 Ω

tr

14 19 - mV

[4]

- 325 600 mV

tested at DC level - 100 - Ω

resistance

t

r

t

f

rise time 20 % to 80 %;

I

= 100 µA (p-p)

PIN

fall time 80% to 20 %;

I

= 100 µA (p-p)

PIN

- 150 - ps

- 150 - ps

[1] Guaranteed by design.

amb

−10

= 25°

[2] Max input current is guaranteed for BER < 10

[3] Max input current is guaranteed for T

[4] Max value of 500 mV belongs to I

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 9 of 15

= 1250 µA (p-p)

PIN

Page 10

Philips Semiconductors

10. Application information

For maximum freedom on bonding location, 2 outputs are available for OUT and OUTQ.

The outputs should be used in pairs: pad 14 with pad 7 or pad 8 with pad 13. Pad 8 is

internally connected with pad 14, pad 7 is internally connected with pad 13. The device is

guaranteed with only one pair used. The other pair should be left open. Two examples of

the bonding possibilities are shown in Figure 8.

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

V

C

CC

OUT

PIN

TZA3046U

GND

IDREF_MON

C

OUTQ

Fig 8. Application diagram highlighting flexible pad lay out

IDREF_MON

OUTQ

C

PIN

TZA3046U

GND

V

CC

OUT

C

001aae518

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 10 of 15

Page 11

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 11 of 15

xxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx x xxxxxxxxxxxxxx xxxxxxxxxx xxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx

xxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxxxx xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxx xxxxxxxxxxxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxx x x

NETWORK ANALYZER

S-PARAMETER TEST SET

PATTERN

GENERATOR

CLOCK

DATA

DC-IN

22 nF

55 Ω

8.2

PORT1

V

CC

4 or 17

OUT

8 or 14

kΩ

330 Ω

IPHOTO

R

TZA3046

2

9, 10, 11, 12

7 or 13

GND

OUTQ

22 nF

22 nF

PORT2

Z

= 50 ΩZo = 50 Ω

o

SAMPLING OSCILLOSCOPE

Z

= 50 Ω

o

21

TRIGGER

INPUT

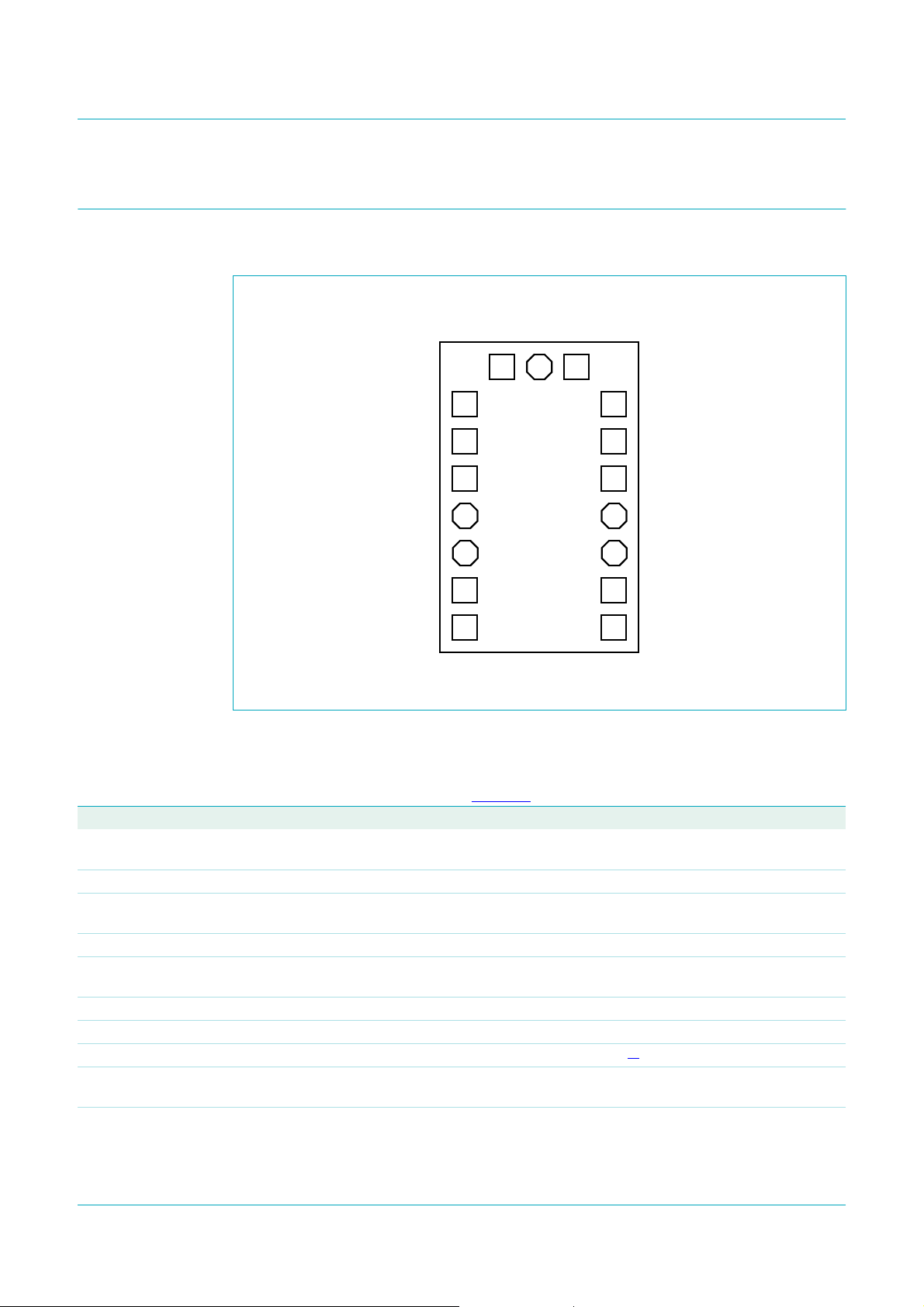

11. Test information

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Philips Semiconductors

Total impedance of the test circuit (Z

Typical values: R = 330 Ω, Zi=30Ω.

Fig 9. Test circuit

) is calculated by the equation Z

tot(tc)

tot(tc)=s21

001aae519

TZA3046

× (R+Zi) × 2, where s21 is the insertion loss of ports 1 and 2.

Page 12

Philips Semiconductors

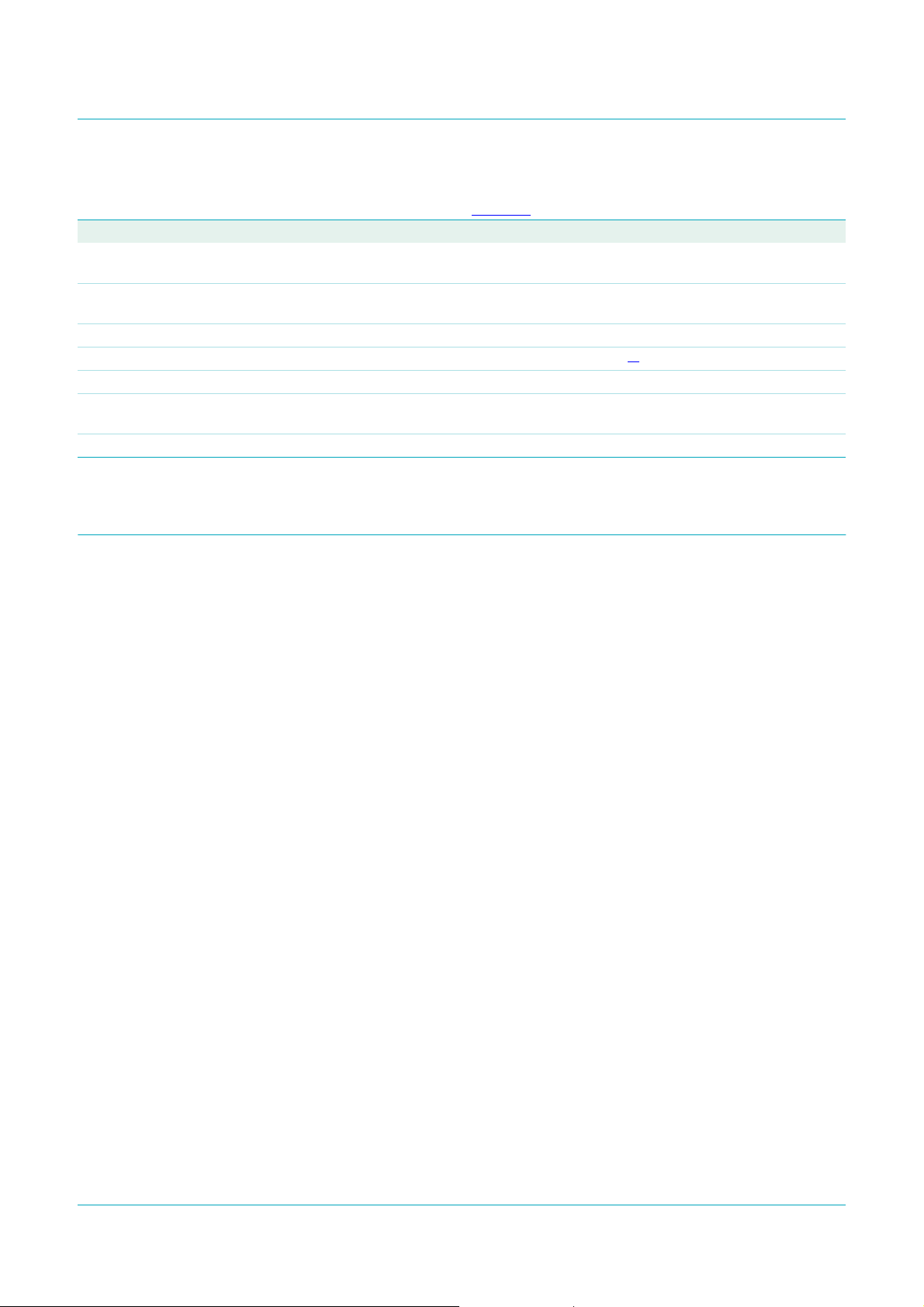

12. Bare die information

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

17 16 15 14 13 12 11

1

2

3

456

Origin is center of die.

Y

X

(0,0)

78910

001aac627

Fig 10. Bonding pad locations

Table 5: Physical characteristics of the bare die

Parameter Value

Glass passivation 0.3 µm PSG (PhosphoSilicate Glass) on top of 0.8 µm silicon nitride

Bonding pad

dimension

minimum dimension of exposed metallization is 90 µm × 90 µm

(pad size = 100 µm × 100 µm) except pads 2 and 3 which have exposed

metallization of 80 µm × 80 µm (pad size = 90 µm × 90 µm)

Metallization 2.8 µm AlCu

Thickness 380 µm nominal

2

Die dimension 820 µm × 1300 µm (± 20 µm

)

Backing silicon; electrically connected to GND potential through substrate contacts

Attach temperature < 440 °C; recommended die attach is glue

Attach time < 15 s

13. Package outline

Not applicable.

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 12 of 15

Page 13

Philips Semiconductors

14. Handling information

14.1 General

Inputs and outputs are protected against electrostatic discharge in normal handling.

However, to be completely safeyou must take normal precautions appropriate to handling

MOS devices; see

14.2 Additional information

Pad IPHOTO has limited protection to ensure good RF performance. This pad should be

handled with extreme care.

15. Abbreviations

Table 6. Abbreviations

Acronym Description

BER Bit Error Rate

FTTx Fiber To The “x”

OC3 Optical Carrier level 3 (155.52 Mbit/s)

PIN Positive Intrinsic Negative

PSRR Power Supply Rejection Ratio

RSSI Received Signal Strength Indicator

SDH Synchronous Digital Hierarchy

SFP Small Form-factor Pluggable

SONET Synchronous Optical NETwork

STM1 Synchronous Transport Module 1 (155.52 Mbit/s

Fiber Channel/Gigabit Ethernet transimpedance amplifier

JESD625-A and/or IEC61340-5

TZA3046

.

16. Revision history

Table 7. Revision history

Document ID Release date Data sheet status Change notice Supersedes

TZA3046_1 20060519 Product data sheet - -

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 13 of 15

Page 14

Philips Semiconductors

17. Legal information

17.1 Data sheet status

TZA3046

Fiber Channel/Gigabit Ethernet transimpedance amplifier

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] Theproduct status of device(s) described in this document may have changed since this document was published and may differin case of multiple devices. The latest product status

information is available on the Internet at URL

[1][2]

Product status

17.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. Philips Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall haveno liability for the consequences of

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with the same product type number(s)and title. A short data sheet isintended

for quick referenceonly and should not be relied upon to contain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local Philips Semiconductors

sales office. In case of any inconsistency or conflict with the short data sheet,

the full data sheet shall prevail.

17.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However, Philips Semiconductors does not give any representations

or warranties, expressed or implied, as to the accuracy or completeness of

such information and shall have no liability for the consequences of use of

such information.

Right to make changes — Philips Semiconductors reserves the right to

make changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — Philips Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of a Philips Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. Philips Semiconductors accepts no liability for inclusion and/or use

of Philips Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is for the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. Philips Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

[3]

http://www.semiconductors.philips.com.

Definition

Limiting values — Stress above one or more limiting values (as defined in

the Absolute Maximum Ratings System of IEC 60134) may cause permanent

damage to the device. Limiting values are stress ratings only and and

operation of the device at these or any other conditions above those given in

the Characteristics sections of this document is not implied. Exposure to

limiting values for extended periods may affect device reliability.

Terms and conditions of sale — Philips Semiconductors products are sold

subject to the general terms and conditions of commercial sale, as published

at

http://www.semiconductors.philips.com/profile/terms, including those

pertaining to warranty, intellectual property rights infringement and limitation

of liability, unless explicitly otherwise agreed to in writing by Philips

Semiconductors. In case of any inconsistency or conflict between information

in this document and such terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyanceor implication of any license under any copyrights, patents

or other industrial or intellectual property rights.

Bare die — All die are tested on compliance with all related technical

specifications as stated in this data sheet up to the point of wafer sawing for a

period of ninety (90) days from the date of delivery by Philips

Semiconductors. If there are data sheet limits not guaranteed, these will be

separately indicated in the data sheet. There are no post-packing tests

performed on individual die or wafers.

Philips Semiconductors has no control of third party procedures in the

sawing, handling, packing or assembly of the die. Accordingly, Philips

Semiconductors assumes no liability for device functionality or performance

of the die or systems after third party sawing, handling, packing or assembly

of the die. It is the responsibility of the customer to test and qualify their

application in which the die is used.

All die sales are conditioned upon and subject to the customer entering into a

written die sale agreement with Philips Semiconductors through its legal

department.

17.4 Trademarks

Notice: All referencedbrands, product names, service names and trademarks

are the property of their respective owners.

18. Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, send an email to: sales.addresses@www.semiconductors.philips.com

TZA3046_1 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet Rev. 01 — 19 May 2006 14 of 15

Page 15

Philips Semiconductors

Fiber Channel/Gigabit Ethernet transimpedance amplifier

19. Contents

1 General description . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 3

6.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Functional description . . . . . . . . . . . . . . . . . . . 4

7.1 PIN diode connections . . . . . . . . . . . . . . . . . . . 4

7.2 Automatic gain control . . . . . . . . . . . . . . . . . . . 6

7.3 Monitoring RSSI via IDREF_MON . . . . . . . . . . 7

8 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 8

10 Application information. . . . . . . . . . . . . . . . . . 10

11 Test information. . . . . . . . . . . . . . . . . . . . . . . . 11

12 Bare die information . . . . . . . . . . . . . . . . . . . . 12

13 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 12

14 Handling information. . . . . . . . . . . . . . . . . . . . 13

14.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

14.2 Additional information . . . . . . . . . . . . . . . . . . . 13

15 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . 13

16 Revision history. . . . . . . . . . . . . . . . . . . . . . . . 13

17 Legal information. . . . . . . . . . . . . . . . . . . . . . . 14

17.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 14

17.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

17.3 Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

17.4 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

18 Contact information. . . . . . . . . . . . . . . . . . . . . 14

19 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TZA3046

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

For more information, please visit: http://www.semiconductors.philips.com.

For sales office addresses, email to: sales.addresses@www.semiconductors.philips.com.

Date of release: 19 May 2006

Document identifier: TZA3046_1

Loading...

Loading...