Philips TZA3041U, TZA3041BHL, TZA3041AHL Datasheet

INTEGRATED CIRCUITS

DATA SH EET

TZA3041AHL; TZA3041BHL;

TZA3041U

Gigabit Ethernet/Fibre Channel

laser drivers

Product specification

Supersedes data of 1999 Aug 24

File under Integrated Circuits, IC19

2000 Feb 22

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

FEATURES

• 1.2 Gbits/s data input, both Current Mode Logic (CML)

and PositiveEmitter Coupled Logic (PECL) compatible;

maximum 800 mV (p-p)

• Adaptive laser output control with dual loop, stabilizing

optical 1 and 0 levels

• Optionalexternalcontroloflasermodulationandbiasing

currents (non-adaptive)

• Automatic laser shutdown

• Few external components required

• Rise and fall times of 120 ps (typical value)

• Jitter <50 mUI (p-p)

• RF output current sinking capability of 60 mA

• Bias current sinking capability of 90 mA

• Power dissipation of 430 mW (typical value)

• Low cost LQFP32 5 × 5 plastic package

• Single 5 V power supply.

TZA3041AHL; TZA3041BHL;

TZA3041U

APPLICATIONS

• Gigabit Ethernet/Fibre Channel optical transmission

systems

• Gigabit Ethernet/Fibre Channel optical laser modules.

GENERAL DESCRIPTION

The TZA3041AHL, TZA3041BHL and TZA3041U are fully

integrated laser drivers for Gigabit Ethernet/Fibre Channel

(1.2 Gbits/s) systems, incorporating the RF path between

the data multiplexer and the laser diode. Since the dual

loop bias and modulation control circuits are integrated on

the IC, the external component count is low. Only

decoupling capacitors and adjustment resistors are

required.

TheTZA3041AHL features an alarm function for signalling

extreme bias current conditions. The alarm low and high

threshold levels can be adjusted to suit the application

using only a resistor or a current Digital-to-Analog

Converter (DAC).

TZA3041AHL

• Laser alarm output for signalling extremely low and high

bias current conditions.

TZA3041BHL

• Extra 1.2 Gbits/s loop mode input; both CML and PECL

compatible.

TZA3041U

• Bare die version with combined bias alarm and loop

mode functionality.

ORDERING INFORMATION

TYPE

NUMBER

TZA3041AHL LQFP32 plastic low profile quad flat package; 32 leads; body 5 × 5 × 1.4 mm SOT401-1

TZA3041BHL

TZA3041U − bare die; 2000 × 2000 × 380 µm −

NAME DESCRIPTION VERSION

The TZA3041BHL is provided with an additional RF data

input to allow remote system testing (loop mode).

The TZA3041U is a bare die version for use in compact

laser module designs. The die contains 40 pads and

features the combined functionality of the TZA3041AHL

and the TZA3041BHL.

PACKAGE

2000 Feb 22 2

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

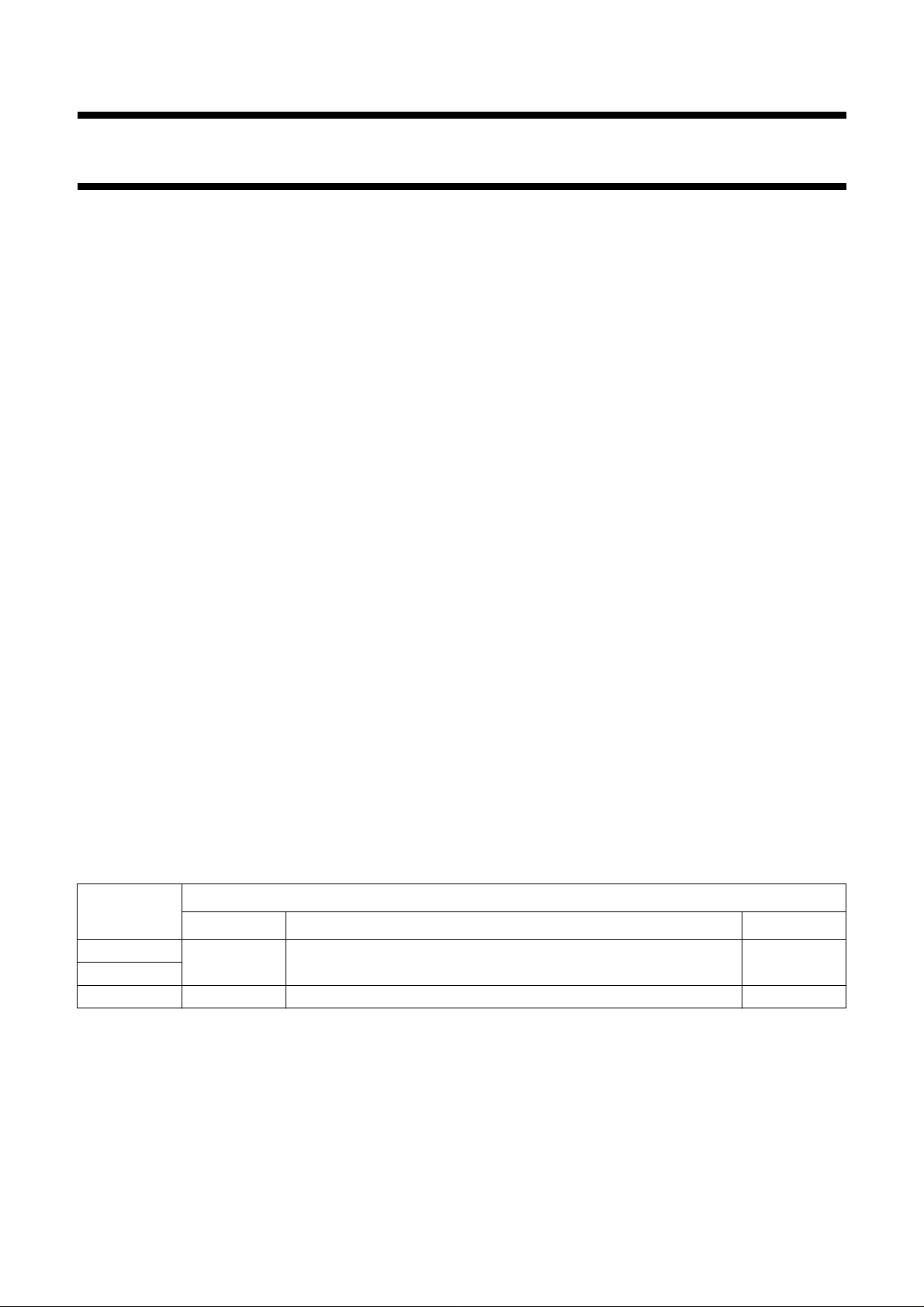

BLOCK DIAGRAM

TONE

handbook, full pagewidth

DIN

DINQ

ALARM

26

data input

(differential)

28

29

TZA3041AHL

19, 20

7

27, 30

411

V

CC(R)

V

CC(G)

V

4

10

CC(B)

ALARMLO

31

ALS

TZA3041AHL; TZA3041BHL;

ALARMHITZERO

215

LASER

CONTROL

BLOCK

CURRENT

SWITCH

BAND GAP

REFERENCE

1, 3, 8, 9,

11, 14, 16, 17

24, 25, 32

GND

18

MBK874

TZA3041U

2

MONIN

22

ONE

23

ZERO

13

LA

12

LAQ

15

BIAS

6

BGAP

handbook, full pagewidth

DIN

DINQ

DLOOP

DLOOPQ

Fig.1 Block diagram of TZA3041AHL.

TONE

10

CC(B)

4

TZERO

31

ALS

LASER

CONTROL

BLOCK

CURRENT

SWITCH

BAND GAP

REFERENCE

1, 3, 8, 9,

11, 14, 16, 17

24, 25, 32

GND

22

23

13

12

15

MBK873

2

MONIN

ONE

ZERO

LA

LAQ

BIAS

6

BGAP

ENL

26 5

28

29

19

20

MUX

TZA3041BHL

18, 21

7

27, 30

411

V

CC(R)

V

CC(G)

V

Fig.2 Block diagram of TZA3041BHL.

2000 Feb 22 3

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

TZA3041AHL; TZA3041BHL;

TZA3041U

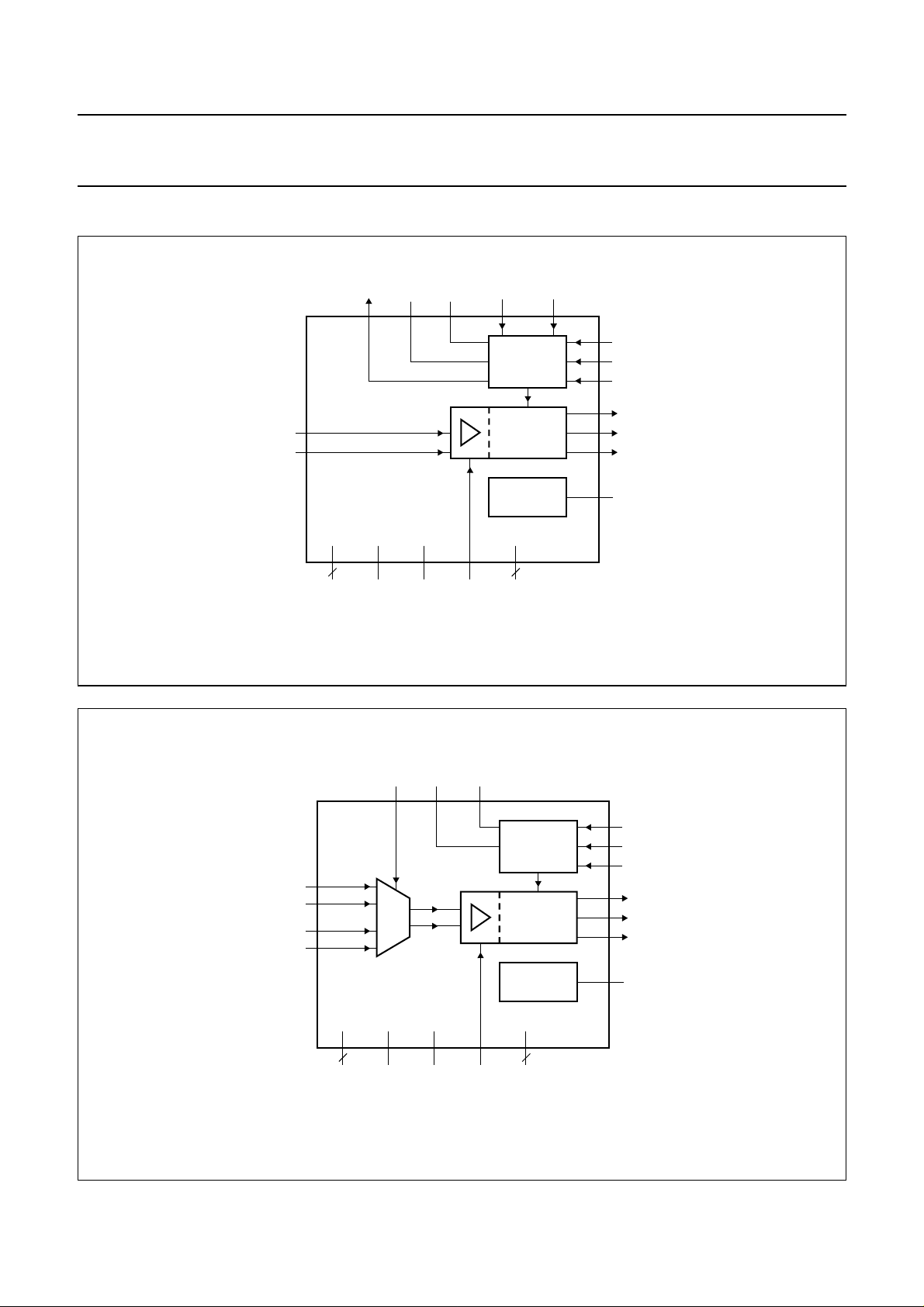

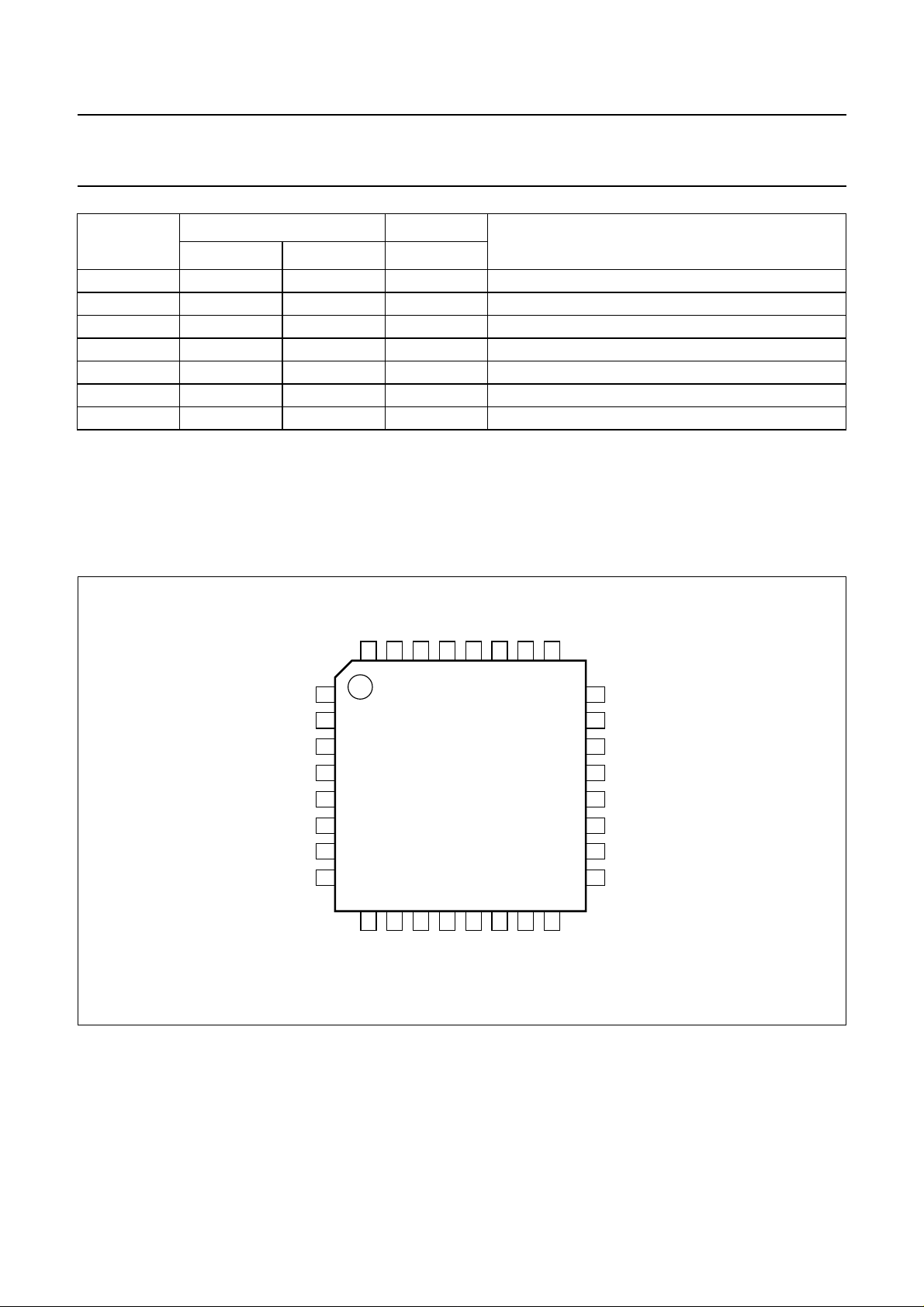

PINNING

PIN PAD

SYMBOL

DESCRIPTION

TZA3041AHL TZA3041BHL TZA3041U

GND 1 1 1 ground

MONIN 2 2 2 monitor photodiode current input

GND 3 3 3 ground

IGM −−4 not connected

TONE 4 4 5 connection for external capacitor used for setting

optical 1 control loop time constant (optional)

TZERO 5 5 6 connection for external capacitor used for setting

optical 0 control loop time constant (optional)

BGAP 6 6 7 connection for external band gap decoupling

capacitor

V

CC(G)

V

CC(G)

7 7 8 supply voltage (green domain); note 1

−−9 supply voltage (green domain); note 1

GND 8 8 10 ground

GND 9 9 11 ground

V

V

CC(B)

CC(B)

10 10 12 supply voltage (blue domain); note 2

−−13 supply voltage (blue domain); note 2

GND 11 11 14 ground

LAQ 12 12 15 laser modulation output inverted

LA 13 13 16 laser modulation output

GND 14 14 17 ground

BIAS 15 15 18 laser bias current output

GND 16 16 19 ground

GND 17 17 20 ground

GND −−21 ground

ALARMHI 18 − 22 maximum bias current alarm reference level input

V

CC(R)

V

CC(R)

− 18 23 supply voltage (red domain); note 3

19 −−supply voltage (red domain); note 3

DLOOP − 19 24 loop mode data input

V

CC(R)

20 −−supply voltage (red domain); note 3

DLOOPQ − 20 25 loop mode data input inverted

V

CC(R)

−−26 supply voltage (red domain); note 3

ALARMLO 21 − 27 minimum bias current alarm reference level input

V

CC(R)

− 21 − supply voltage (red domain); note 3

ONE 22 22 28 optical 1 reference level input

ZERO 23 23 29 optical 0 reference level input

GND 24 24 30 ground

GND 25 25 31 ground

ALARM 26 − 32 alarm output

ENL − 26 33 loop mode enable input

2000 Feb 22 4

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

TZA3041AHL; TZA3041BHL;

TZA3041U

PIN PAD

SYMBOL

DESCRIPTION

TZA3041AHL TZA3041BHL TZA3041U

V

CC(R)

27 27 34 supply voltage (red domain); note 3

DIN 28 28 35 data input

DINQ 29 29 36 data input inverted

V

CC(R)

30 30 37 supply voltage (red domain); note 3

ALS 31 31 38 automatic laser shutdown input

GND 32 32 39 ground

GND −−40 ground

Notes

1. Supply voltage for the Monitor PhotoDiode (MPD) input current.

2. Supply voltage for the laser modulation outputs (LA, LAQ).

3. Supply voltage for the data inputs (DIN, DINQ), optical 1 and 0 reference level inputs (ONE, ZERO), and the bias

current alarm reference level inputs (ALARMHI, ALARMLO).

handbook, full pagewidth

GND

MONIN

GND

TONE

TZERO

BGAP

V

CC(G)

GND

CC(R)

ALS

GND

32

1

2

3

4

5

6

7

8

9

GND

V

31

30

TZA3041AHL

11

10

GND

CC(B)

V

DINQ

29

12

LAQ

DIN

28

13

LA

CC(R)

V

27

14

GND

ALARM

26

15

BIAS

GND

25

16

GND

Fig.3 Pin configuration of TZA3041AHL.

24

23

22

21

20

19

18

17

MBK870

GND

ZERO

ONE

ALARMLO

V

CC(R)

V

CC(R)

ALARMHI

GND

2000 Feb 22 5

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

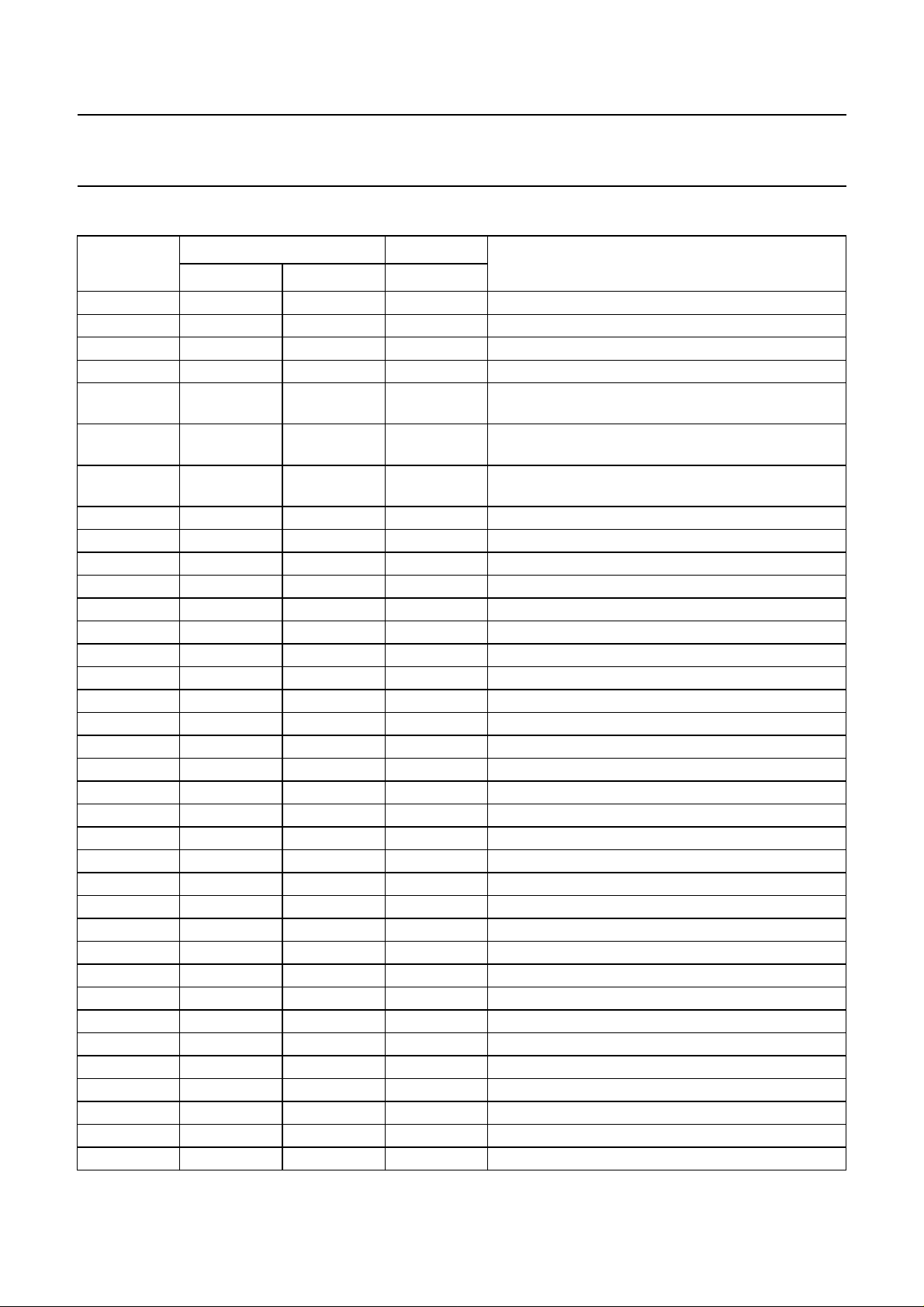

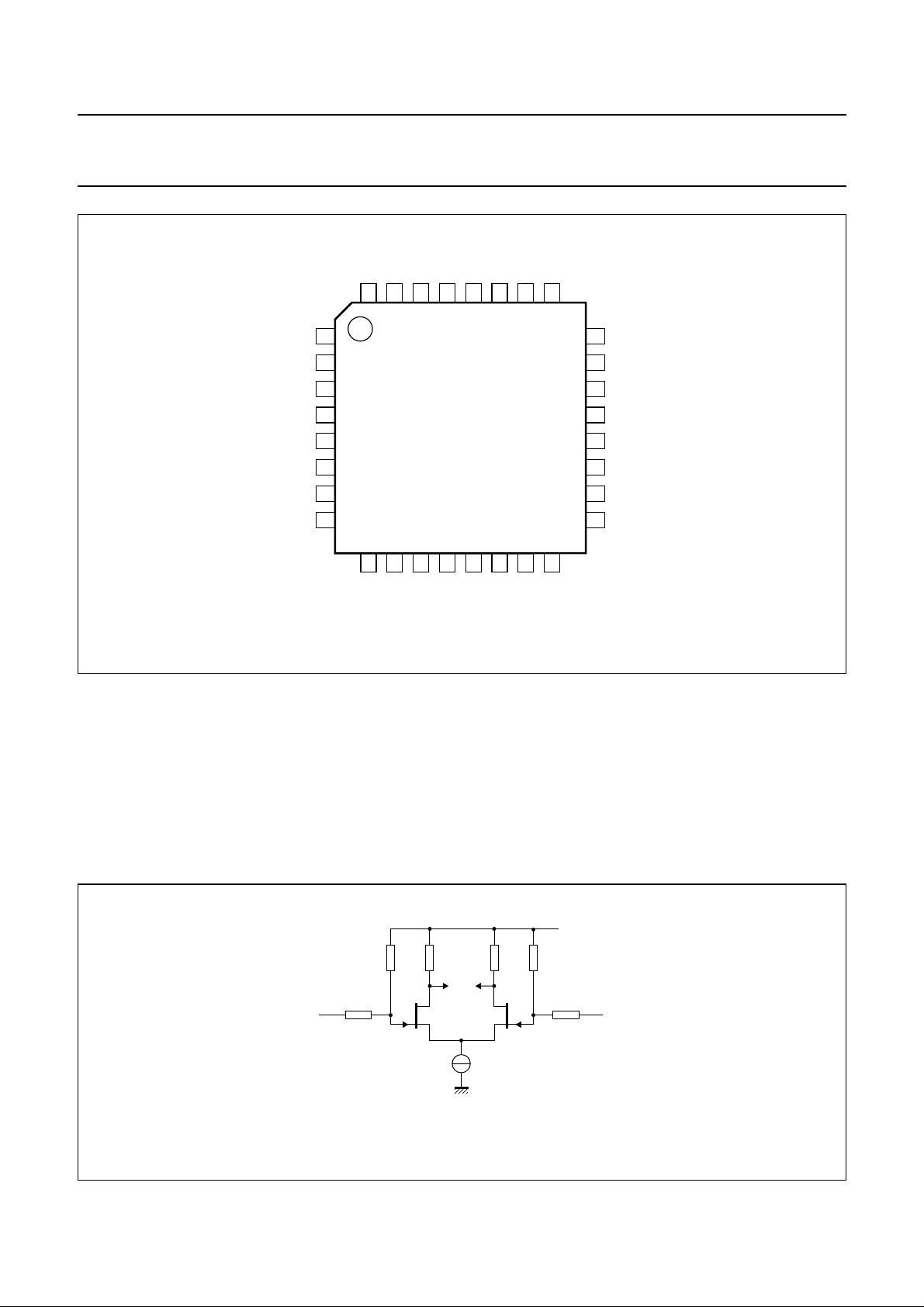

handbook, full pagewidth

ALS

GND

31

32

1

GND

GND

TONE

BGAP

CC(G)

GND

2

3

4

5

6

7

8

9

10

GND

CC(B)

V

MONIN

TZERO

V

CC(R)

V

30

DINQ

29

DIN

28

TZA3041BHL

11

12

13

LA

LAQ

GND

TZA3041AHL; TZA3041BHL;

TZA3041U

CC(R)

ENL

V

27

14

GND

26

15

BIAS

GND

25

16

GND

24

23

22

21

20

19

18

17

MBK875

GND

ZERO

ONE

V

CC(R)

DLOOPQ

DLOOP

V

CC(R)

GND

Fig.4 Pin configuration of TZA3041BHL.

FUNCTIONAL DESCRIPTION

The TZA3041AHL, TZA3041BHL and TZA3041U laser

drivers accept a 1.2 Gbits/s Non-Return to Zero (NRZ)

input data stream, and generate an output signal with

sufficient current to drive a solid state Fabry Perot (FP) or

Distributed FeedBack (DFB) laser. They also contain dual

loop control circuitry for stabilizing the true laser optical

power levels representing logic 1 and logic 0.

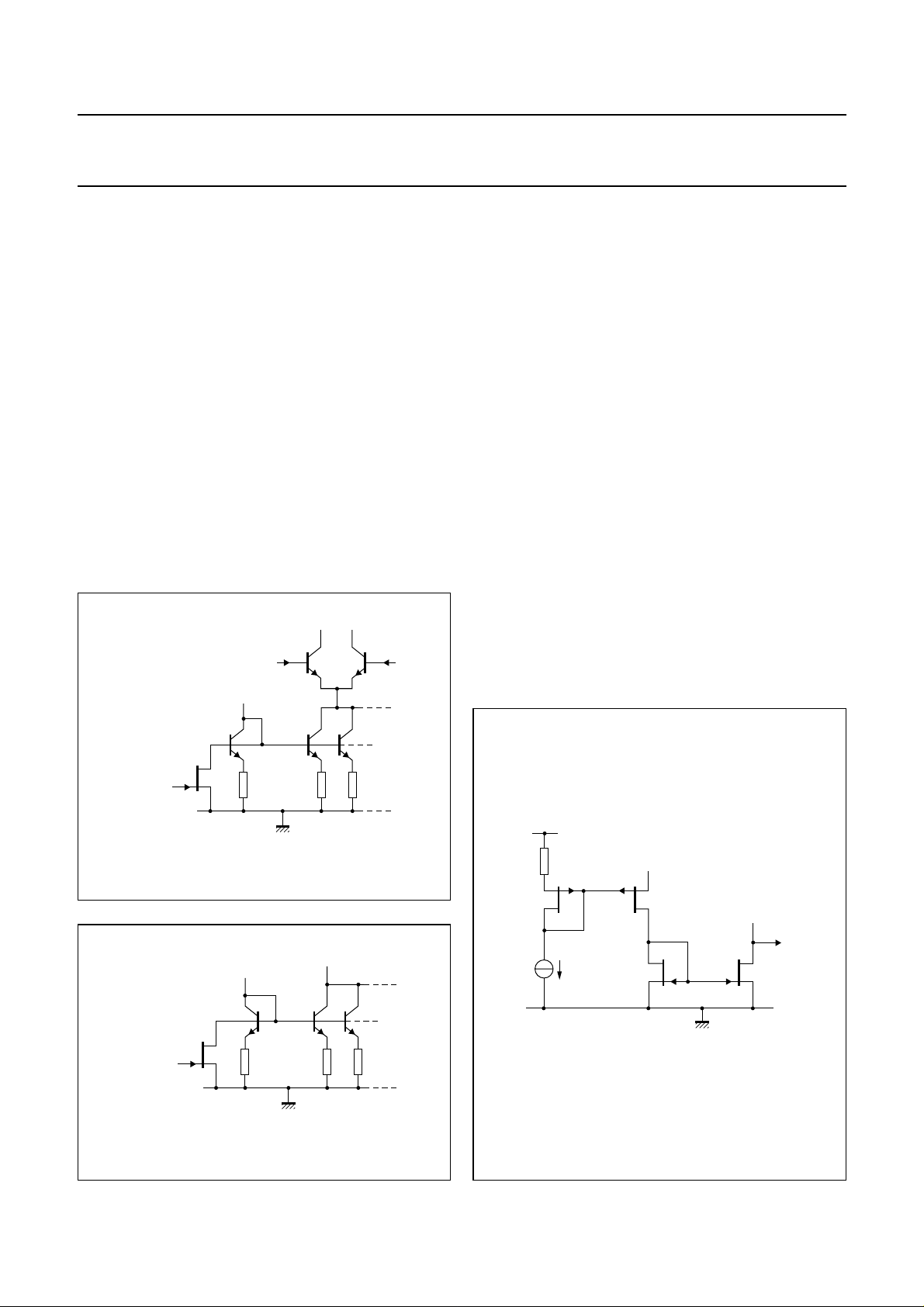

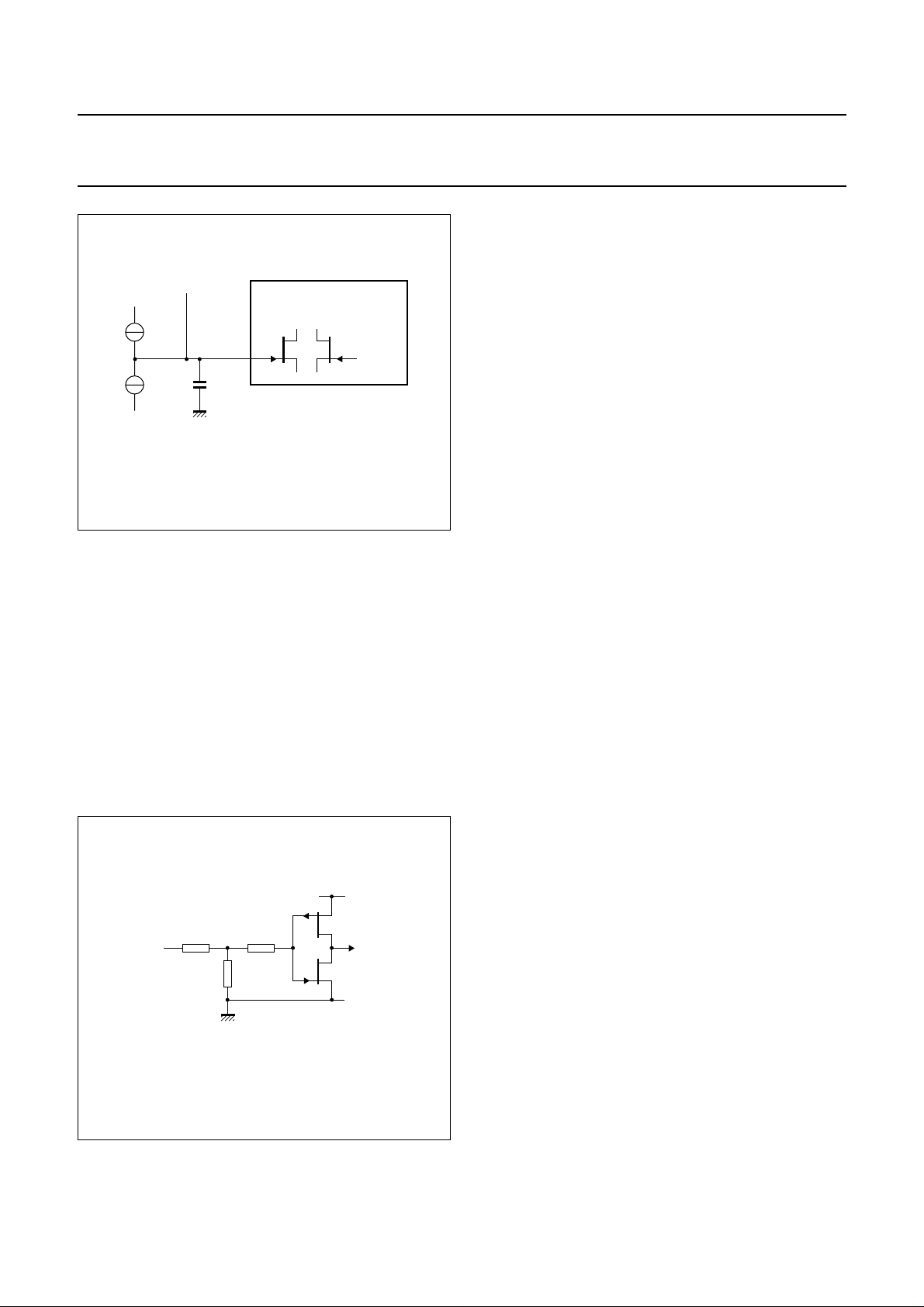

handbook, full pagewidth

10 kΩ 10 kΩ

100 Ω

The input buffers present a high impedance to the data

stream on the differential inputs (pins DIN and DINQ);

see Fig.5. The input signal can be at a CML level of

approximately 200 mV (p-p) below the supply voltage, or

at a PECL level up to 800 mV (p-p). The inputs can be

configured to accept CML signals by connecting pins DIN

and DINQ to V

via external 50 Ω pull-up resistors.

CC(R)

If PECL compatibility is required, the usual Thevenin

termination can be applied.

V

CC(R)

100 Ω

DINQ, DLOOPQDIN, DLOOP

GND

Fig.5 DIN/DINQ and DLOOP/DLOOPQ inputs.

2000 Feb 22 6

MGS910

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

For ECL signals (negative and referenced to ground), the

inputs should be AC-coupled to the signal source.

If AC-coupling is applied, a constant input signal (either

LOW or HIGH) will cause the device to be in an undefined

state. To avoid this, it is recommended to apply a slight

offset to the input stage. The applied offset must be higher

than the specified value in Chapter “Characteristics”, but

much lower than the applied input voltage swing.

The RF path is fully differential and contains a differential

preamplifier and a main amplifier. The main amplifier is

able to operate at the large peak currents required at the

output laser driver stage and is insensitive to supply

voltage variations. The output signal from the main

amplifier drives a current switch which supplies a

guaranteed maximum modulation current of 60 mA to

pins LA and LAQ (see Fig.6). The BIAS pin outputs a

guaranteed maximum DC bias current of up to 90 mA for

adjusting the optical laser output to a level above its light

emitting threshold (see Fig.7).

handbook, halfpage

LA LAQ

TZA3041AHL; TZA3041BHL;

TZA3041U

Automatic laser control

A laser with a Monitor PhotoDiode (MPD) is required for

the laser control circuit (see application diagrams

Figs 18 and 19).

The MPD current is proportional to the laser emission and

is applied to pin MONIN. The MPD current range is

100 to 1000 µA (p-p). The inputbufferisoptimized to cope

with an MPD capacitance of up to 50 pF. To prevent the

input buffer from oscillating if the MPD capacitance is low,

thecapacitance should be increased to the minimum value

specified in Chapter “Characteristics”, by connecting a

capacitor between pin MONIN and V

DC reference currents are applied to pins ONE and ZERO

to set the MPD reference levels for laser HIGH and laser

LOW respectively. This is adequately achieved by using

resistors to connect V

to pins ONE and ZERO

CC(R)

(see Fig.8), however, current DACs canalso be used. The

voltages on pins ONE and ZERO are held at a constant

level of 1.5 V below V

. The reference current applied

CC(R)

to pin ONE is internally multiplied by 16 and the reference

current flowing into pin ZERO is internally multiplied by 4.

The accuracy of the V

− 1.5 V voltage at pins ONE

CC(R)

and ZERO is described in Section “Accuracy of voltage on

inputs: ONE, ZERO, ALARMLO, ALARMHI”.

CC(G)

.

GND

TR

n

TR

ALS

Fig.6 LA and LAQ outputs.

GND

TR

BIAS

n

handbook, halfpage

TR

ALS

Fig.7 Laser driver bias current output circuit.

MGS906

MGS907

handbook, halfpage

V

CC(R)

30 kΩ

50 µA

ONE, ZERO, ALARMLO, ALARMHI

MGS908

Fig.8 ONE, ZERO, ALARMLO and ALARMHI

inputs.

GND

2000 Feb 22 7

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

The reference current and the resistor for the optical 1

modulation current control loop is calculated using the

following formulae:

1

I

ref ONE()

R

== Ω[]

ONE

×= A[]

I

------

MPD(ONE)

16

1.5

----------I

ONE

-----------------------I

MPD(ONE)

24

The reference current and resistor for the optical 0 bias

current control loop is calculated using the following

formulae:

I

ref ZERO()

R

ZERO

In these formulae, I

1

×= A[]

I

-- -

MPD(ZERO)

4

1.5

== Ω[]

-------------I

ZERO

6

--------------------------I

MPD(ZERO)

MPD(ONE)

and I

MPD(ZERO)

represent the

MPD current during an optical 1 and an optical 0 period,

respectively.

EXAMPLE

A laser operates at optical output power levels of 0.3 mW

forlaser HIGH and 0.03 mW for laserLOW(extinctionratio

of 10 dB). Suppose the corresponding MPD currents for

this particular laser are 260 and 30 µA, respectively.

In this example, the reference current flowing into

pin ONE is:

I

ref ONE()

1

× 16.25 µA==

260 10×

-----16

6–

This current can be set using acurrent source or simply by

a resistor of the appropriate value connected between

pin ONE and V

CC(R)

.

In this example, the resistor is:

R

ONE

1.5

-------------------------------- -

16.25 106–×

92.3 kΩ==

In this example, the reference current at pin ZERO is:

I

ref ZERO()

1

-- 4

30 10

6–

×× 7.5 µA==

and can be set using a resistor:

R

ZERO

1.5

--------------------------

7.5 106–×

200 kΩ==

It should be noted that the MPD current is stabilized rather

than the actual laser optical output power. Any deviations

between optical output power and MPD current, known as

‘tracking errors’, cannot be corrected.

(1)

(2)

(3)

(4)

TZA3041AHL; TZA3041BHL;

TZA3041U

Designing the modulation and bias current control

loop

The optical 1 and 0 current controlloop time constants are

determined by on-chip capacitances. If the resulting time

constants are found to be too small in a specific

application, they can be increased by connecting a

capacitor between pins TZERO and TONE.

The optical 1 modulation current control loop time

constant (τ)and bandwidth (B) can be estimated using the

following formulae:

τ

ONE

B

ONE

B

ONE

40 10

1

= Hz[]

------------------------- 2πτ

×

------------------------------------------------------------------------------------------------2π 40 10

12–

C

+×()

TONE

ONE

η

LASER

12–

× C

80 10

×= s[]

----------------------

+()× 80× 103×

TONE

The optical 0 bias current control loop time constant and

bandwidth can be estimated using the following formulae:

τ

ZERO

B

B

= Hz[]

ZERO

ZERO

The term η

40 10

---------------------------2πτ

---------------------------------------------------------------------------------------------------2π 40 10

LASER

12–

C

+×()

TZERO

×= s[]

1

×

ZERO

η

LASER

12–

C

+×()× 50× 103×

TZERO

(dimensionless) in the above formulae is

the product of the following two terms:

•ηEO is the electro-optical efficiency which accounts for

thesteepnessof the laser slope characteristic. It defines

the rate at which theoptical output power increases with

modulation current, and is measured in W/A.

• R is the MPD responsivity. It determines the amount of

MPD current for a given value of optical output power,

and is measured in A/W.

EXAMPLE

A laser with an MPD has the following specifications:

PO= 1 mW, Ith= 25 mA, ηEO= 30 mW/A, R = 500 mA/W.

The term I

is the required threshold current to switch on

th

the laser. If the laser operates just above the threshold

level, it may be assumed that η

is 50% of η

near the optical 1 level, due to the slope

EO

EO

decreasing near the threshold level.

3

×

η

LASER

Hz[]=

η

LASER

3

×

50 10

----------------------

Hz[]=

near the optical 0 level

(5)

(6)

(7)

(8)

2000 Feb 22 8

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

In this example, the resulting bandwidth for the optical 1

modulation current control loop, without an external

capacitor, is:

B

ONE

The resulting bandwidth for the optical 0 bias current

control loop, without an external capacitor, is:

B

ZERO

It is not necessary to add additional capacitance with this

type of laser.

Control loop data pattern and bit rate dependency

The constants in equations (1) and (3) are valid when the

data pattern frequently contains a sufficient number of

‘constantzeroes’and‘constantones’.Asinglecontrolloop

time period (τ

for at least approximately 6 ns. When using the IC in

1.2 Gbits/s applications, the optical extinction ratio will be

slightly higher when compared with slower line rates.

Therefore, it is important to use the actual data patterns

and bit rate of the final application circuit for adjusting the

optical levels.

30 103–× 500× 103–×

--------------------------------------------------------------------2π 40× 10

0.5 30× 103–× 500× 103–×

------------------------------------------------------------------------2π 40× 10

ONE

12–

× 80× 103×

12–

× 50× 103×

and τ

) must contain ones and zeros

ZERO

750 Hz≈=

600 Hz≈=

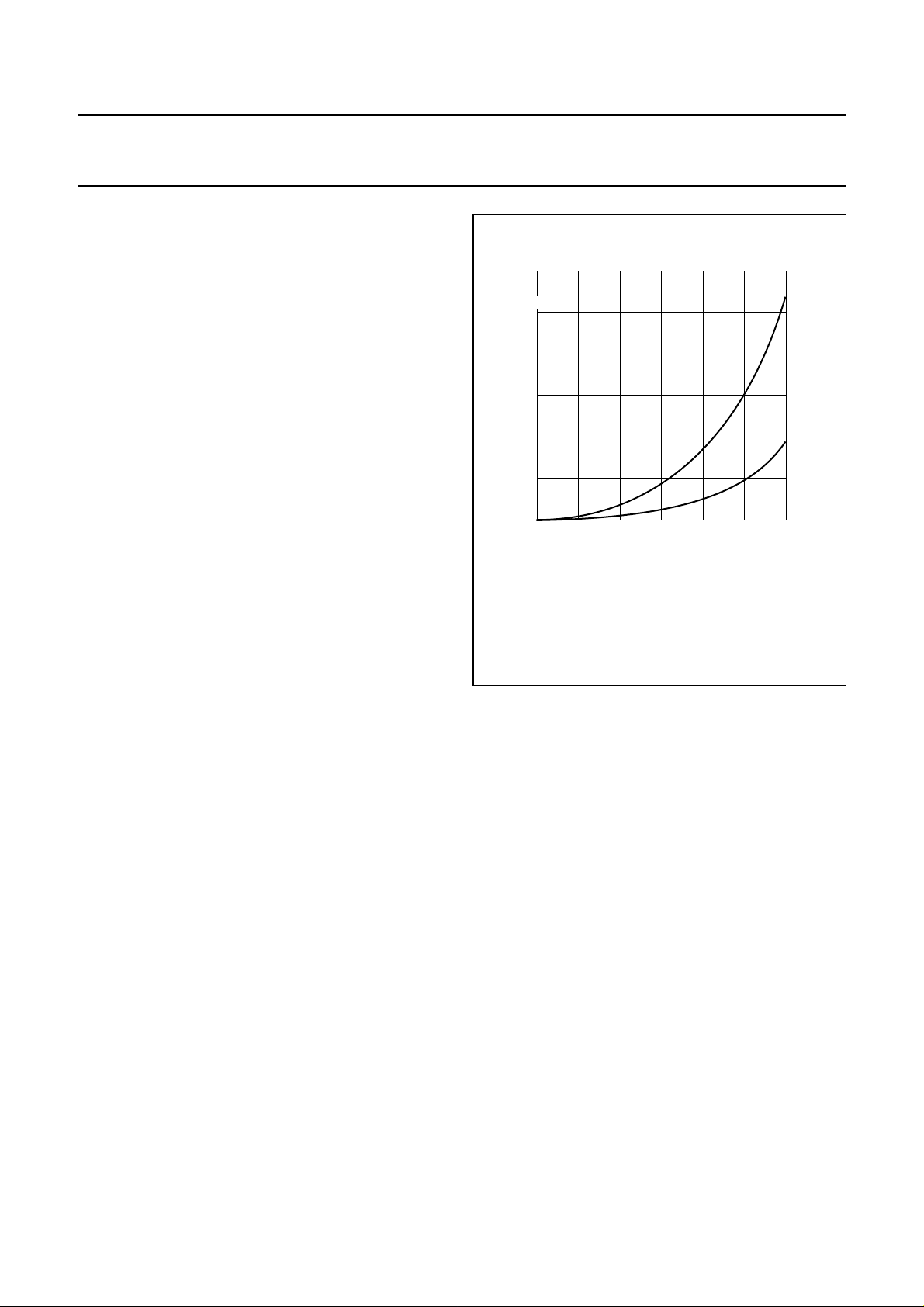

TZA3041AHL; TZA3041BHL;

handbook, halfpage

3

I

o(mod)(off)

(mA)

2

1

0

0 204060

(1) Worst case operation (Tj= 125 °C, VCC= 5.5 V

and worst case parameter processes).

(2) Typical operation.

Fig.9 I

o(mod)(off)

as a function of I

I

o(mod)(on)

TZA3041U

MGS902

(1)

(2)

(mA)

o(mod)(on)

.

The laser driver peak detectors are able to track MPD

output current overshoot and undershoot conditions.

Unfortunately, these conditions affect the ability of the IC

to correctly interpret the high and low level MPD current.

In particular, the occurrence of undershoot can have a

markedly adverse effect on the interpretation of the low

level MPD current.

Additional bias by modulation ‘off’ current

Although during operation, the full modulation current

switches between outputs LA and LAQ, a small amount of

modulation current continues to flow through the inactive

pin.

For example, when the laser,whose cathode is connected

to LA, is in the ‘dark’ part of its operating cycle (logic 0),

someof the modulation ‘off’ current flowsthrough LA while

most of the current flows through LAQ. This value

I

o(mod)(off)

is effectively added to the bias current and is

subtracted from the modulation current. Fortunately, the

value correlates closely with the magnitude of the

modulation current. Therefore, applications requiring low

bias and low modulation are less affected. Figure 9 shows

the modulation ‘off’ current as a function of the modulation

‘on’ current.

Monitoring the bias and modulation current

Although not recommended, the bias and modulation

currentsgenerated by the laser driver can be monitored by

measuring the voltages on pins TZERO and TONE,

respectively (see Fig.10). The relationship between these

voltages and the corresponding currents are given as

transconductance values and are specified in

Chapter “Characteristics”. The voltages on pins TZERO

and TONE range from 1.4 to 3.4 V. Any connection to

these pins should have a very high impedance value. It is

mandatory to use a CMOS buffer or an amplifier with an

input impedance higher than 100 GΩ and with an

extremely low input leakage current (pA).

2000 Feb 22 9

Philips Semiconductors Product specification

Gigabit Ethernet/Fibre Channel laser

drivers

handbook, halfpage

Automatic laser shut-down and laser slow start

TZERO, TONE

<

1 nA

<

1 nA

GND

40 pF

LINEAR VOLTAGE TO

CURRENT CONVERTER

2.4 V

MGS905

Fig.10 TZERO and TONE internal configuration.

TZA3041AHL; TZA3041BHL;

TZA3041U

Manual laser override

The automatic laser control function can be overridden by

connecting voltage sources to pins TZERO and TONE to

take direct control of the current sources for bias and

modulation respectively. The control voltages should

range from 1.4 to 3.4 V to swing the modulation current

over the range 1 to 60 mA and the bias current over the

range 1 to 90 mA. These current ranges are guaranteed.

Due to the tolerance range in the manufacturing process,

some devices may have higher current values than those

specified, as shown in Figs 12 and 13. Both figures show

thattemperature changes cause a slight tiltingof the linear

characteristic around an input voltage of 2.4 V.

Consequently, the manually controlled current level is

most insensitive to temperature variations at around this

value. Bias and modulation currents in excess of the

specified range are not supported and should be avoided.

Currentsintooroutofpins TZERO and TONE in excess of

10 µA must be avoided to prevent damage to the circuit.

The laser modulation and bias currents can be rapidly

switched off when a HIGH level (CMOS) is applied to

pin ALS. This function allows the circuit to be shut-down in

the event of an optical system malfunction. A 25 kΩ

pull-down resistor defaults pin ALS to the non active state

(see Fig.11).

When a LOW level is applied to pin ALS, the modulation

and bias currents slowly increase to the desired values at

the typical time constants of τ

ONE

and τ

, respectively.

ZERO

This can be used to slow-start the laser.

MGS911

V

CC(R)

handbook, halfpage

ALS

100 Ω

100 Ω

25 kΩ

GND

Fig.11 ALS input.

2000 Feb 22 10

Loading...

Loading...