Page 1

查询TJA1040供应商

INTEGRATED CIRCUITS

DATA SH EET

TJA1040

High speed CAN transceiver

Product specification

Supersedes data of 2003 Feb 19

2003 Oct 14

Page 2

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

FEATURES

• Fully compatible with the ISO 11898 standard

• High speed (up to 1 MBaud)

• Very low-current standby mode with remote wake-up

capability via the bus

• Very low ElectroMagnetic Emission (EME)

• Differential receiver with high common-mode range for

ElectroMagnetic Immunity (EMI)

• Transceiver in unpowered state disengages from the

bus (zero load)

• Input levels compatible with 3.3 V and 5 V devices

• Voltage source for stabilizing the recessive bus level if

split termination is used (further improvement of EME)

• At least 110 nodes can be connected

• Transmit Data (TXD) dominant time-out function

• Bus pins protected against transients in automotive

environments

• Buspinsandpin SPLIT short-circuitproofto batteryand

ground

• Thermally protected.

GENERAL DESCRIPTION

The TJA1040 isthe interface between theController Area

Network (CAN) protocol controller and the physical bus.

It is primarily intended for high speed applications, up to

1 MBaud, in passenger cars. The device provides

differential transmit capability to the bus and differential

receive capability to the CAN controller.

The TJA1040 is the next step up from the TJA1050 high

speed CANtransceiver. Beingpin compatible andoffering

the same excellent EMC performance, the TJA1040 also

features:

• An ideal passive behaviour when supply voltage is off

• A very low-current standby mode with remote wake-up

capability via the bus.

This makes the TJA1040 an excellent choice in nodes

which can be in power-down or standby mode in partially

powered networks.

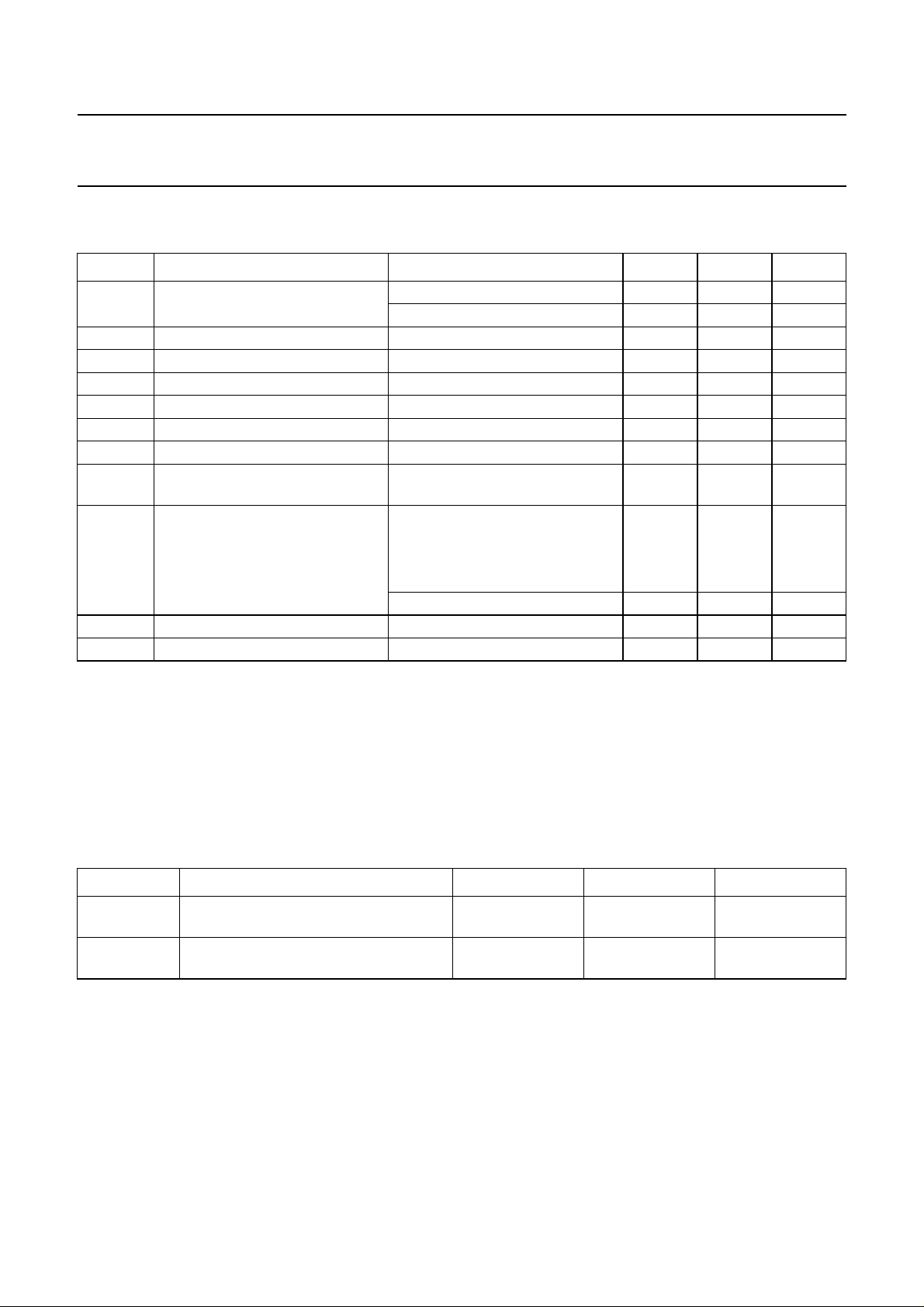

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

I

CC

V

CANH

V

CANL

V

SPLIT

V

esd

supply voltage operating range 4.75 5.25 V

supply current standby mode 5 15 µA

DC voltage on pin CANH 0 < VCC< 5.25 V; no time limit −27 +40 V

DC voltage on pin CANL 0 < VCC< 5.25 V; no time limit −27 +40 V

DC voltage on pin SPLIT 0 < VCC< 5.25 V; no time limit −27 +40 V

electrostatic discharge voltage Human Body Model (HBM)

pins CANH, CANL and SPLIT −6+6kV

all other pins −4+4kV

t

PD(TXD-RXD)

T

vj

propagation delay TXD to RXD V

virtual junction temperature −40 +150 °C

= 0 V 40 255 ns

STB

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGE

TJA1040T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

TJA1040U − bare die; die dimensions 1840 × 1440 × 380 µm −

2003 Oct 14 2

Page 3

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

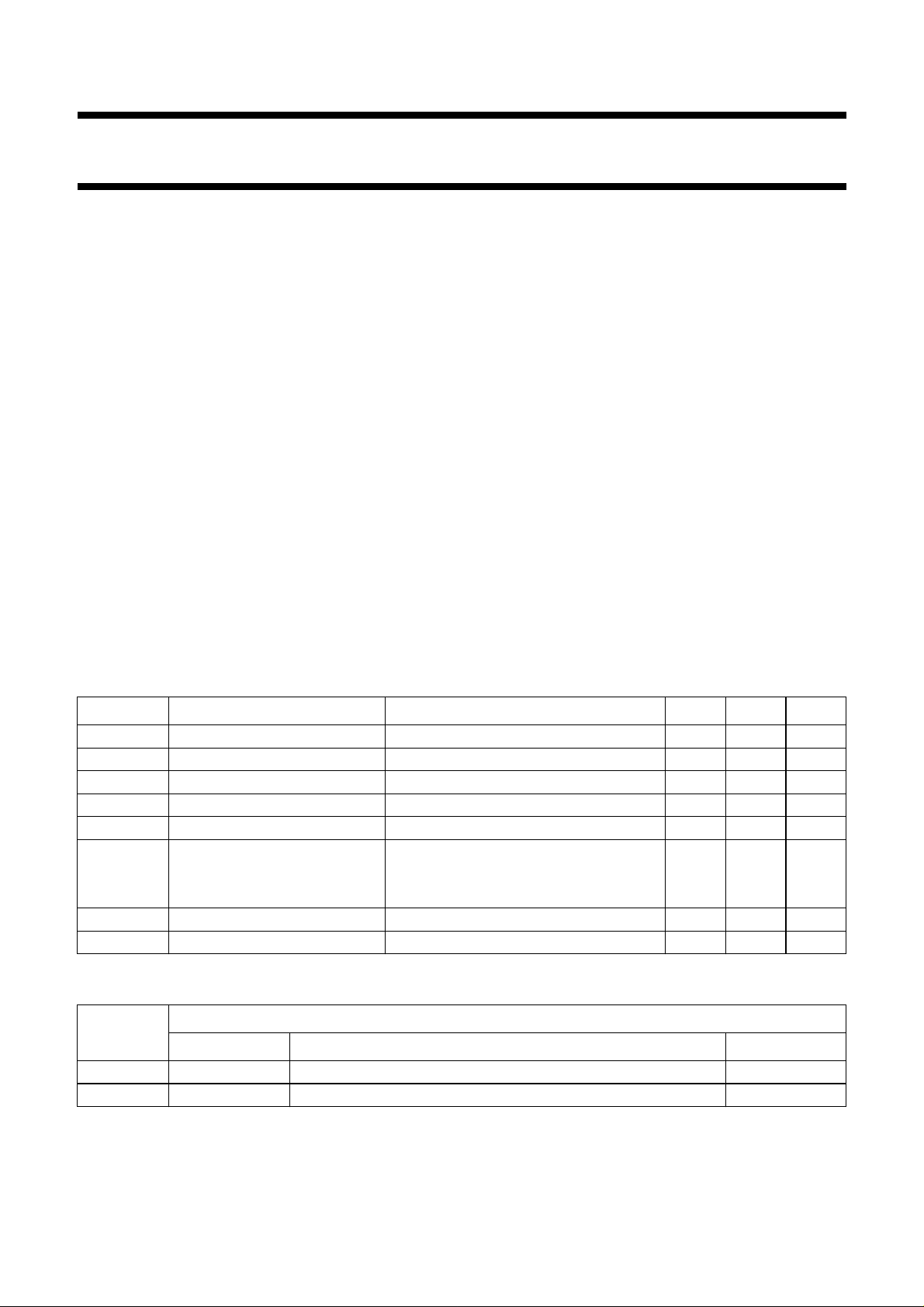

BLOCK DIAGRAM

handbook, full pagewidth

TXD

STB

RXD

GND

1

V

CC

8

4

2

TIME-OUT &

SLOPE

WAKE-UP

MODE CONTROL

MUX

TJA1040

TEMPERATURE

PROTECTION

DRIVER

WAKE-UP

FILTER

Fig.1 Block diagram.

V

CC

3

MGU161

5

SPLIT

7

CANH

6

CANL

V SPLIT

PINNING

SYMBOL PIN DESCRIPTION

TXD 1 transmit data input

GND 2 ground supply

V

CC

3 supply voltage

RXD 4 receive data output; reads out data

from the bus lines

SPLIT 5 common-mode stabilization output

CANL 6 LOW-level CAN bus line

CANH 7 HIGH-level CAN bus line

STB 8 standby mode control input

2003 Oct 14 3

handbook, halfpage

TXD

GND

V

CC

RXD

1

2

3

4

TJA1040T

8

7

6

5

MGU160

Fig.2 Pin configuration.

STB

CANH

CANL

SPLIT

Page 4

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

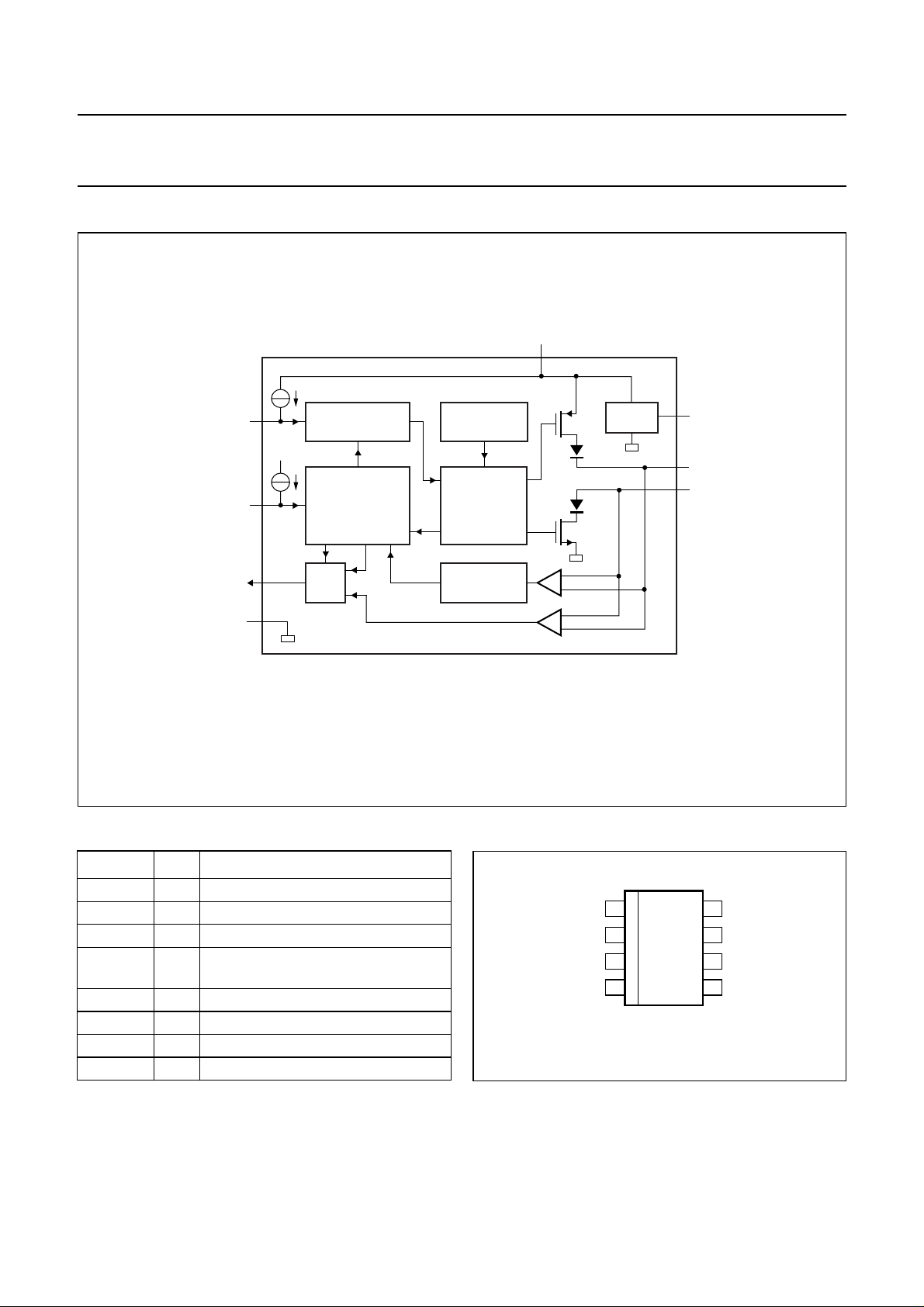

FUNCTIONAL DESCRIPTION

Operating modes

The TJA1040 provides two modes of operation which are

selectablevia pin STB.See Table 1for adescriptionof the

modes of operation.

Table 1 Operating modes

MODE

PIN

STB

LOW HIGH

PIN RXD

normal LOW bus dominant bus recessive

standby HIGH wake-uprequest

detected

no wake-up

request detected

NORMAL MODE

In thismode thetransceiver is ableto transmitand receive

data via the bus lines CANH andCANL. See Fig.1 for the

block diagram. The differential receiver converts the

analog data on the bus lines into digital data which is

output to pin RXD viathe multiplexer (MUX). The slope of

the output signals on the bus lines is fixed and optimized

in a way that lowest ElectroMagnetic Emission (EME) is

guaranteed.

STANDBY MODE

In this modethe transmitter and receiver are switched off,

and thelow-power differentialreceiver will monitorthe bus

lines. A HIGH level on pin STB activates this low-power

receiver and the wake-up filter, and after t

the state of

BUS

the CAN bus is reflected on pin RXD.

The supply current on VCC is reduced to a minimum in

such a way that ElectroMagnetic Immunity (EMI) is

guaranteed and a wake-up event on the bus lines will be

recognized.

In this mode the bus lines are terminated to ground to

reduce the supply current (ICC) to a minimum. A diode is

added inseries withthe high-side driverof RXDto prevent

areverse currentfrom RXDto VCCinthe unpoweredstate.

In normal mode this diode is bypassed. This diode is not

bypassed instandby modeto reducecurrent consumption.

Split circuit

Pin SPLIT providesa DC stabilizedvoltage of 0.5VCC.Itis

turnedon onlyinnormal mode.Instandby modepin SPLIT

is floating. The V

circuit can be used to stabilize the

SPLIT

recessivecommon-mode voltagebyconnecting pin SPLIT

tothe centretap ofthe splittermination (seeFig.4). Incase

of arecessive bus voltage<0.5VCCdue tothe presence of

an unsupplied transceiverin the network witha significant

leakage current from the bus lines to ground, the split

circuit will stabilize this recessive voltage to 0.5VCC. So a

start of transmission does not cause a step in the

common-mode signal which would lead to poor

ElectroMagnetic Emission (EME) behaviour.

Wake-up

In the standby mode the bus lines are monitored via a

low-power differential comparator. Once the low-power

differential comparator has detecteda dominant bus level

for more than t

, pin RXD will become LOW.

BUS

Over-temperature detection

The outputdrivers areprotected againstover-temperature

conditions. If the virtual junction temperature exceeds the

shutdownjunction temperatureT

,the outputdriverswill

j(sd)

be disableduntil the virtualjunction temperature becomes

lower than T

and TXD becomes recessive again.

j(sd)

By including the TXD condition, the occurrence of output

driver oscillation due to temperature drifts is avoided.

TXD dominant time-out function

A ‘TXD dominant time-out’ timer circuit prevents the bus

lines from being driven to a permanent dominant state

(blocking all network communication) if pin TXD is forced

permanently LOW by a hardware and/or software

application failure. The timer is triggered by a negative

edge on pin TXD.

If the duration of the LOW level on pin TXD exceeds the

internal timer value (t

), the transmitter is disabled,

dom

driving the bus lines into a recessive state. The timer is

reset by a positive edge on pin TXD. The TXD dominant

time-out timet

defines theminimum possible bitrate of

dom

40 kBaud.

Fail-safe features

Pin TXD providesa pull-uptowards VCCin orderto forcea

recessive level in case pin TXD is unsupplied.

Pin STB provides a pull-up towards VCC in order to force

the transceiver into standby mode in case pin STB is

unsupplied.

In the event that the VCC is lost, pins TXD, STB and RXD

will become floating to prevent reverse supplying

conditions via these pins.

2003 Oct 14 4

Page 5

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

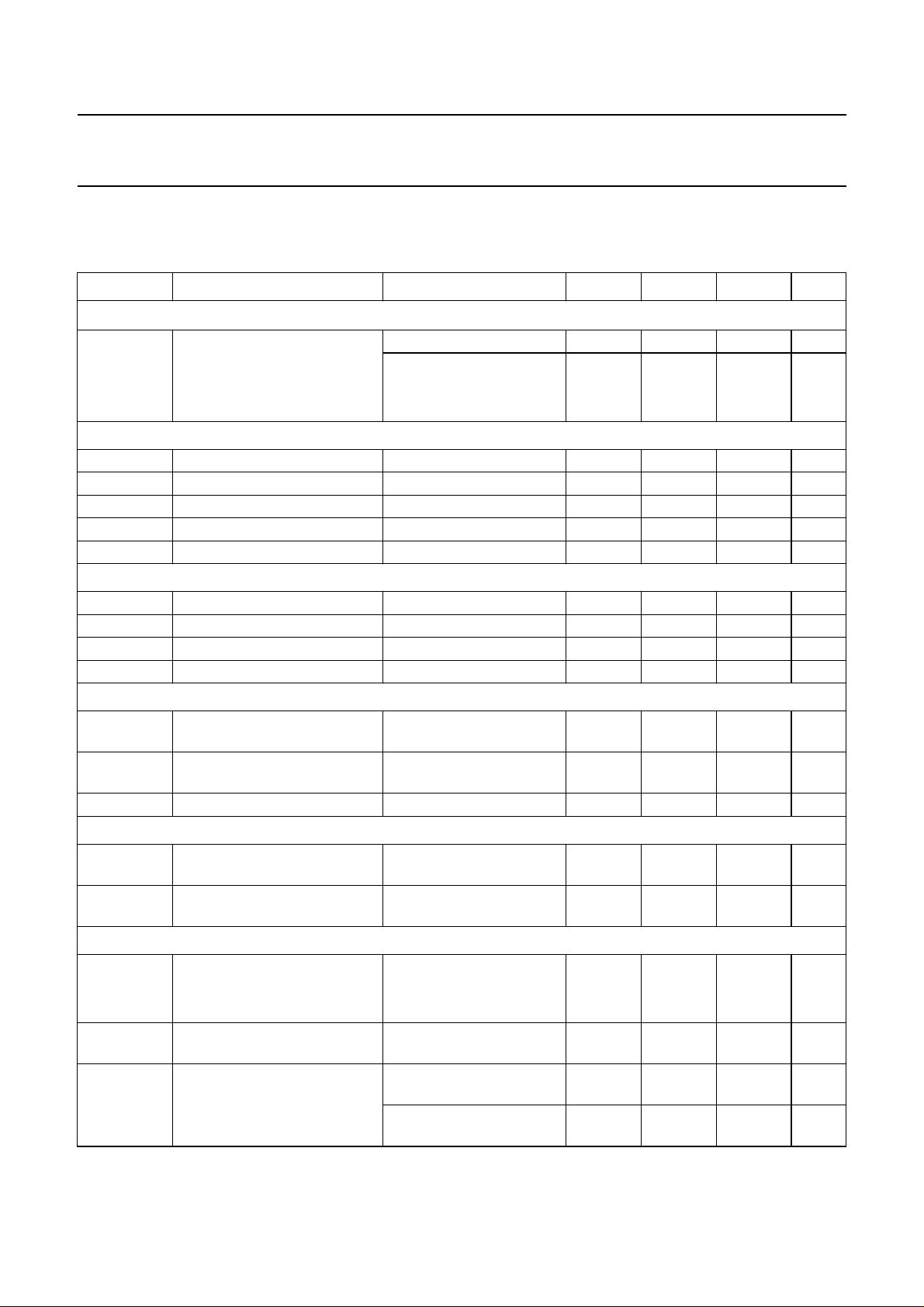

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

V

TXD

V

RXD

V

STB

V

CANH

V

CANL

V

SPLIT

V

trt

V

esd

T

vj

T

stg

supply voltage no time limit −0.3 +6 V

operating range 4.75 5.25 V

DC voltage on pin TXD −0.3 VCC+ 0.3 V

DC voltage on pin RXD −0.3 VCC+ 0.3 V

DC voltage on pins STB −0.3 VCC+ 0.3 V

DC voltage on pin CANH 0 < VCC< 5.25 V; no time limit −27 +40 V

DC voltage on pin CANL 0 < VCC< 5.25 V; no time limit −27 +40 V

DC voltage on pin SPLIT 0 < VCC< 5.25 V; no time limit −27 +40 V

transient voltages on pins CANH,

according to ISO 7637; see Fig.5 −200 +200 V

CANL and SPLIT

electrostatic discharge voltage Human Body Model (HBM); note 1

pins CANH and CANL

−6+6kV

and SPLIT

all other pins −4+4kV

Machine Model (MM); note 2 −200 +200 V

virtual junction temperature note 3 −40 +150 °C

storage temperature −55 +150 °C

Notes

1. Equivalent to discharging a 100 pF capacitor via a 1.5 kΩ series resistor.

2. Equivalent to discharging a 200 pF capacitor via a 0.75 µH series inductor and a 10 Ω series resistor.

3. Junction temperature in accordance with IEC 60747-1. An alternative definition of Tvjis: Tvj=T

where R

th(vj-amb)

combinations of power dissipation (P) and ambient temperature (T

is a fixed value to be used for the calculating of Tvj. The rating for Tvj limits the allowable

).

amb

amb

+P×R

THERMAL CHARACTERISTICS

In accordance with IEC 60747-1.

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(vj-a)

thermal resistance from virtual junction

in free air 145 K/W

to ambient in SO8 package

R

th(vj-s)

thermal resistance from virtual junction

in free air 50 K/W

to substrate of bare die

QUALITY SPECIFICATION

Quality specification in accordance with

“AEC-Q100”

.

th(vj-amb)

,

2003 Oct 14 5

Page 6

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

CHARACTERISTICS

VCC= 4.75 to 5.25 V, Tvj= −40 to +150 °C and RL=60Ω unless specified otherwise; all voltages are defined with

respect to ground; positive currents flow into the IC; note 1.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply (pin V

I

CC

)

CC

supply current standby mode 5 10 15 µA

normal mode

recessive; V

dominant; V

Transmit data input (pin TXD)

V

IH

V

IL

I

IH

I

IL

C

i

HIGH-level input voltage 2 − VCC+ 0.3 V

LOW-level input voltage −0.3 − +0.8 V

HIGH-level input current V

TXD=VCC

LOW-level input current normal mode; V

input capacitance not tested − 510pF

Standby mode control input (pin STB)

V

IH

V

IL

I

IH

I

IL

HIGH-level input voltage 2 − VCC+ 0.3 V

LOW-level input voltage −0.3 − +0.8 V

HIGH-level input current V

LOW-level input current V

STB=VCC

=0V −1 −4 −10 µA

STB

Receive data output (pin RXD)

V

OH

I

OH

I

OL

HIGH-level output voltage standby mode;

I

= −100 µA

RXD

HIGH-level output current normal mode;

V

RXD=VCC

LOW-level output current V

= 0.4 V 2 6 12 mA

RXD

Common-mode stabilization output (pin SPLIT)

V

O

output voltage normal mode;

−500 µA<IO< +500 µA

I

leakage current standby mode;

L

−22V<V

Bus lines (pins CANH and CANL)

V

O(dom)

dominant output voltage V

TXD

=0V

pin CANH 3 3.6 4.25 V

pin CANL 0.5 1.4 1.75 V

V

O(dom)(m)

V

O(dif)(bus)

matching of dominant output

voltage (VCC-V

CANH-VCANL

differential bus output voltage

(V

CANH

− V

CANL

)

)

V

= 0 V; dominant;

TXD

45 Ω <RL<65Ω

V

TXD=VCC

no load

TXD=VCC

TXD

TXD

− 0.4 V

< +35 V

SPLIT

; recessive;

2.5 5 10 mA

=0V305070mA

−50 +5µA

=0V −100 −200 −300 µA

− 0 −µA

VCC− 1.1 VCC− 0.7 VCC− 0.4 V

−0.1 −0.4 −1mA

0.3V

CC

0.5V

CC

0.7V

CC

V

− 05µA

−100 0 +150 mV

1.5 − 3.0 V

−50 − +50 mV

2003 Oct 14 6

Page 7

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

O(reces)

I

O(sc)

I

O(reces)

V

dif(th)

V

hys(dif)

I

LI

R

i(cm)

R

i(cm)(m)

R

i(dif)

C

i(cm)

C

i(dif)

Timing characteristics; see Fig.8

t

d(TXD-BUSon)

t

d(TXD-BUSoff)

t

d(BUSon-RXD)

t

d(BUSoff-RXD)

t

PD(TXD-RXD)

t

dom(TXD)

t

BUS

t

d(stb-norm)

Thermal shutdown

T

j(sd)

Note

1. All parametersare guaranteedover thevirtualjunction temperaturerange bydesign, but only100% testedat 125 °C

ambient temperature for dies on wafer level, and in addition to this 100% tested at 25 °C ambient temperature for

cased products; unless specified otherwise. For bare dies, all parameters are only guaranteedwith the backside of

the die connected to ground.

recessive output voltage normal mode;V

TXD=VCC

;

2 0.5V

3V

CC

no load

standby mode; no load −0.1 0 +0.1 V

short-circuit output current V

recessive output current −27V<V

differential receiver threshold

voltage

=0V

TXD

pin CANH; V

pin CANL; V

−12V<V

−12V<V

=0V −40 −70 −95 mA

CANH

= 40 V 40 70 100 mA

CANL

< +32 V −2.5 − +2.5 mA

CAN

< +12 V;

CANL

< +12 V

CANH

normal mode(see Fig.6) 0.5 0.7 0.9 V

standby mode 0.4 0.7 1.15 V

differential receiver hysteresis

voltage

input leakage current VCC=0V;

common-mode input

normal mode;

−12V<V

−12V<V

CANL

CANH

< +12 V;

< +12 V

50 70 100 mV

−50 +5µA

V

CANH=VCANL

=5V

standby or normal mode 15 25 35 kΩ

resistance

common-mode input

V

CANH=VCANL

−3 0 +3 %

resistance matching

differential input resistance standby or normal mode 25 50 75 kΩ

common-mode input

V

TXD=VCC

; not tested −−20 pF

capacitance

differential input capacitance V

TXD=VCC

; not tested −−10 pF

delay TXD to bus active normal mode 25 70 110 ns

delay TXD to bus inactive 10 50 95 ns

delay bus active to RXD 15 65 115 ns

delay bus inactive to RXD 35 100 160 ns

propagation delay TXDto RXD V

TXD dominant time-out V

dominant time for wake-up via

=0V 40 − 255 ns

STB

= 0 V 300 600 1000 µs

TXD

standby mode 0.75 1.75 5 µs

bus

delay standby mode to normal

normal mode 5 7.5 10 µs

mode

shutdown junction temperature 155 165 180 °C

2003 Oct 14 7

Page 8

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

APPLICATION AND TEST INFORMATION

handbook, full pagewidth

BAT

More application information isavailable in aseparateapplication note.

5 V

CANH

SPLIT

CANL

Fig.3 Typical application for 5 V microcontroller.

7

TJA1040

5

6

V

CC

STB

3

8 Port x

RXD

4

TXD

1

2

V

CC

MICROCONTROLLER

RXD

TXD

MGU164

V

handbook, full pagewidth

CC

TJA1040

V

= 0.5V

SPLIT

in normal mode;

otherwise floating

CC

R

R

GND

Fig.4 Stabilization circuitry and application.

2003 Oct 14 8

CANH

60 Ω

SPLIT

60 Ω

CANL

MGU162

Page 9

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

+

handbook, full pagewidth

5 V

500 kHz

TXD

RXD

15 pF

100 nF47 µF

1

TJA1040

4

V

CC

3

82

GND STB

7

6

5

CANH

CANL

SPLIT

MGW336

1 nF

1 nF

TRANSIENT

GENERATOR

The waveforms of the applied transients will be in accordance with ISO 7637 part 1, test pulses 1, 2, 3a, 3b, 5, 6 and 7.

Fig.5 Test circuit for automotive transients.

handbook, full pagewidth

V

RXD

hysteresis

0.5 0.9

V

i(dif)(bus)

MGS378

HIGH

LOW

(V)

Fig.6 Hysteresis of the receiver.

2003 Oct 14 9

Page 10

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

+

handbook, full pagewidth

5 V

TXD

SPLIT

RXD

15 pF

100 nF47 µF

1

5

TJA1040

4

V

CC

3

82

GND STB

7

6

CANH

CANL

MGW335

R

L

60 Ω

C

L

100 pF

handbook, full pagewidth

TXD

CANH

CANL

V

i(dif)(bus)

RXD

t

d(TXD-BUSon)

t

d(BUSon-RXD)

Fig.7 Test circuit for timing characteristics.

0.9 V

(1)

0.5 V

0.7V

t

d(TXD-BUSoff)

)

t

PD(TXD-RXD

0.3V

)

CC

t

PD(TXD-RXD

HIGH

LOW

dominant

(BUS on)

recessive

(BUS off)

HIGH

CC

LOW

t

d(BUSoff-RXD)

MGS377

(1) V

i(dif)(bus)=VCANH

− V

CANL

.

Fig.8 Timing diagram.

2003 Oct 14 10

Page 11

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

BONDING PAD LOCATIONS

COORDINATES

(1)

SYMBOL PAD

xy

TXD 1 119.5 114.5

GND 2 648.5 85

V

CC

3 1214.25 114.5

RXD 4 1635.25 114.5

SPLIT 5 1516.5 1275

CANL 6 990.5 1273.75

CANH 7 530.25 1273.75

STB 8 113.75 1246

Note

1. All x/y coordinatesrepresent the positionof the centre

of each pad (in µm) with respect to the left hand

bottom corner of the top aluminium layer (see Fig.9).

8

handbook, halfpage

x

0

0

y

The backside of the bare die must be connected to ground.

76 5

TJA1040U

1

234

Fig.9 Bonding pad locations.

test pad 1

test pad 2

MBL584

2003 Oct 14 11

Page 12

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

PACKAGE OUTLINE

SO8: plastic small outline package; 8 leads; body width 3.9 mm

SOT96-1

y

Z

8

pin 1 index

1

D

c

5

A

2

A

1

4

e

w M

b

p

E

H

E

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT96-1

A

max.

1.75

0.069

A1A2A

0.25

1.45

0.10

1.25

0.010

0.057

0.004

0.049

IEC JEDEC JEITA

076E03 MS-012

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

UNIT

inches

Notes

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

eHELLpQZywv θ

4.0

1.27

3.8

0.16

0.05

0.15

2003 Oct 14 12

6.2

5.8

0.244

0.228

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

99-12-27

03-02-18

o

8

o

0

Page 13

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

SOLDERING

Introduction to soldering surface mount packages

Thistext givesa verybriefinsight toa complextechnology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurface mountICs, butitis notsuitable forfinepitch

SMDs. In these situations reflow soldering is

recommended.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuitboard byscreen printing,stencilling or

pressure-syringe dispensing before package placement.

Driven by legislation and environmental forces the

worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 270 °C depending on solder paste material. The

top-surface temperature of the packages should

preferably be kept:

• below 220 °C (SnPbprocess) or below 245 °C (Pb-free

process)

– for all BGA and SSOP-T packages

– for packages with a thickness ≥ 2.5 mm

– for packages with a thickness < 2.5 mm and a

volume ≥ 350 mm3 so called thick/large packages.

• below 235 °C (SnPbprocess) or below 260 °C (Pb-free

process) for packages witha thickness < 2.5 mm and a

volume < 350 mm3 so called small/thin packages.

Moisture sensitivity precautions, as indicated on packing,

must be respected at all times.

Wave soldering

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering isusedthe following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wavewith high upward pressurefollowed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackages withleads onfoursides, thefootprint must

be placedat a 45° angle tothe transport direction ofthe

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placementand beforesoldering, the packagemust

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time of the leads in the wave ranges from

3 to 4 seconds at 250 °C or 265 °C, depending on solder

material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads.Use a low voltage(24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

Conventional single wave soldering is not recommended

forsurface mountdevices (SMDs)orprinted-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

2003 Oct 14 13

Page 14

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

BGA, LBGA, LFBGA, SQFP, SSOP-T

(1)

(3)

, TFBGA, VFBGA not suitable suitable

DHVQFN, HBCC, HBGA, HLQFP, HSQFP, HSOP, HTQFP,

not suitable

SOLDERING METHOD

WAVE REFLOW

(4)

suitable

(2)

HTSSOP, HVQFN, HVSON, SMS

(5)

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO, VSSOP not recommended

PMFP

, SO, SOJ suitable suitable

(5)(6)

suitable

(7)

suitable

(8)

not suitable not suitable

Notes

1. Formore detailedinformation onthe BGApackages refertothe

“(LF)BGAApplication Note

”(AN01026); ordera copy

from your Philips Semiconductors sales office.

2. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporizationof the moisture in them (the so called popcorn effect). For details,refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

3. These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no account

be processedthrough more thanone soldering cycleor subjected toinfrared reflow solderingwith peak temperature

exceeding 217 °C ± 10 °C measured in the atmosphere of the reflow oven. The package body peak temperature

must be kept as low as possible.

4. These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the solder

cannot penetrate between the printed-circuit boardandthe heatsink. On versions with the heatsink on the top side,

the solder might be deposited on the heatsink surface.

5. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

6. Wave solderingis suitable forLQFP, TQFP andQFP packages witha pitch (e) largerthan 0.8 mm; itis definitely not

suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

7. Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger than

0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

8. Hot bar or manual soldering is suitable for PMFP packages.

REVISION HISTORY

REV DATE CPCN DESCRIPTION

6 20031014 200307014 Product specification (9397 750 11837)

Modification:

• Change ‘V

= 0.5 V’ in standby mode into ‘V

th(dif)

• Add Chapter REVISION HISTORY

5 20030219 − Product specification (9397 750 10887)

2003 Oct 14 14

dif(th)

= 0.4 V’

Page 15

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

DATA SHEET STATUS

LEVEL

DATA SHEET

STATUS

(1)

PRODUCT

STATUS

(2)(3)

DEFINITION

I Objective data Development This data sheet contains data from the objective specification for product

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

II Preliminary data Qualification This data sheet contains data from the preliminary specification.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

III Product data Production This data sheet contains data from the product specification. Philips

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Relevant changes will

be communicated via a Customer Product/Process Change Notification

(CPCN).

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

3. For datasheets describingmultipletype numbers,the highest-level productstatus determines thedata sheetstatus.

DEFINITIONS

DISCLAIMERS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting valuesdefinition Limitingvalues givenare in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese orat anyother conditionsabovethose givenin the

Characteristics sectionsof the specification isnot implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentation orwarrantythat suchapplications willbe

suitable for the specified use without further testing or

modification.

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably beexpected toresult inpersonal injury.Philips

Semiconductorscustomers usingorselling theseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes in the products including circuits, standard cells, and/or software described or contained herein in order to improve design

and/or performance.When theproduct is infull production

(status ‘Production’), relevant changes will be

communicated via a Customer Product/Process Change

Notification (CPCN). Philips Semiconductorsassumes no

responsibility or liability for the use of any of these

products, conveys no licence or title under any patent,

copyright, or mask work right to these products, and

makes no representations or warranties that these

products are free from patent, copyright, or mask work

right infringement, unless otherwise specified.

2003 Oct 14 15

Page 16

Philips Semiconductors Product specification

High speed CAN transceiver TJA1040

Bare die All die are tested and are guaranteed to

comply with all data sheet limits up to the point of wafer

sawing for a period of ninety (90) days from the date of

Philips' delivery. If there are data sheet limits not

guaranteed, these will be separately indicated in the data

sheet. There are no post packing tests performed on

individual die or wafer. Philips Semiconductors has no

control of third party procedures in the sawing, handling,

packing or assembly of the die. Accordingly, Philips

Semiconductors assumes no liability for device

functionality or performance of the die or systems after

third party sawing, handling, packing or assembly of the

die. It is the responsibility of the customer to test and

qualify their application in which the die is used.

2003 Oct 14 16

Page 17

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2003

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document doesnot formpart of any quotation or contract, isbelieved tobe accurate and reliable and may bechanged

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands R16/06/pp17 Date of release: 2003 Oct 14 Document order number: 9397750 11837

SCA75

Loading...

Loading...