Page 1

查询TJA1020T供应商

INTEGRATED CIRCUITS

DATA SH EET

TJA1020

LIN transceiver

Product specification

Supersedes data of 2001 Dec 17

2002 Jul 17

Page 2

Philips Semiconductors Product specification

LIN transceiver TJA1020

FEATURES

General

• Baud rate up to 20 Kbaud

• Very low ElectroMagnetic Emission (EME)

• High ElectroMagnetic Immunity (EMI)

• Low slope mode for an even further reduction of EME

• Passive behaviour in unpowered state

• Input levels compatible with 3.3 and 5 V devices

• Integrated termination resistor for Local Interconnect

Network (LIN) slave applications

• Wake-up source recognition (local or remote).

Low power management

• Very low current consumption in sleep mode with local

and remote wake-up.

Protections

• Transmit data (TXD) dominant time-out function

• Bus terminal and battery pin protected against

transients in the automotive environment (ISO7637)

• Bus terminal short-circuit proof to battery and ground

• Thermally protected.

GENERAL DESCRIPTION

The TJA1020 is the interface between the LIN

master/slave protocol controller and the physical bus in a

Local Interconnect Network (LIN). It is primarily intended

forin-vehiclesub-networksusingbaudratesfrom2.4 upto

20 Kbaud.

The transmit data stream of the protocol controller at the

TXD input is converted by the LIN transceiver into a bus

signal with controlled slew rate and wave shaping to

minimize EME. The LIN bus output pin is pulled HIGH via

an internal termination resistor. For a master application

an external resistor in series with a diode should be

connected between pin INH or pin BAT and pin LIN. The

receiver detects the data stream at the LIN bus input pin

and transfers it via pin RXD to the microcontroller.

In normal transceiver operation the TJA1020 can be

switched in the normal slope mode or the low slope mode.

In the low slope mode the TJA1020 lengthens the rise and

fall slopes of the LIN bus signal, thus further reducing the

already very low emission in normal slope mode.

In sleep mode the power consumption of the TJA1020 is

verylow,whereasin failure modes the power consumption

is reduced to a minimum.

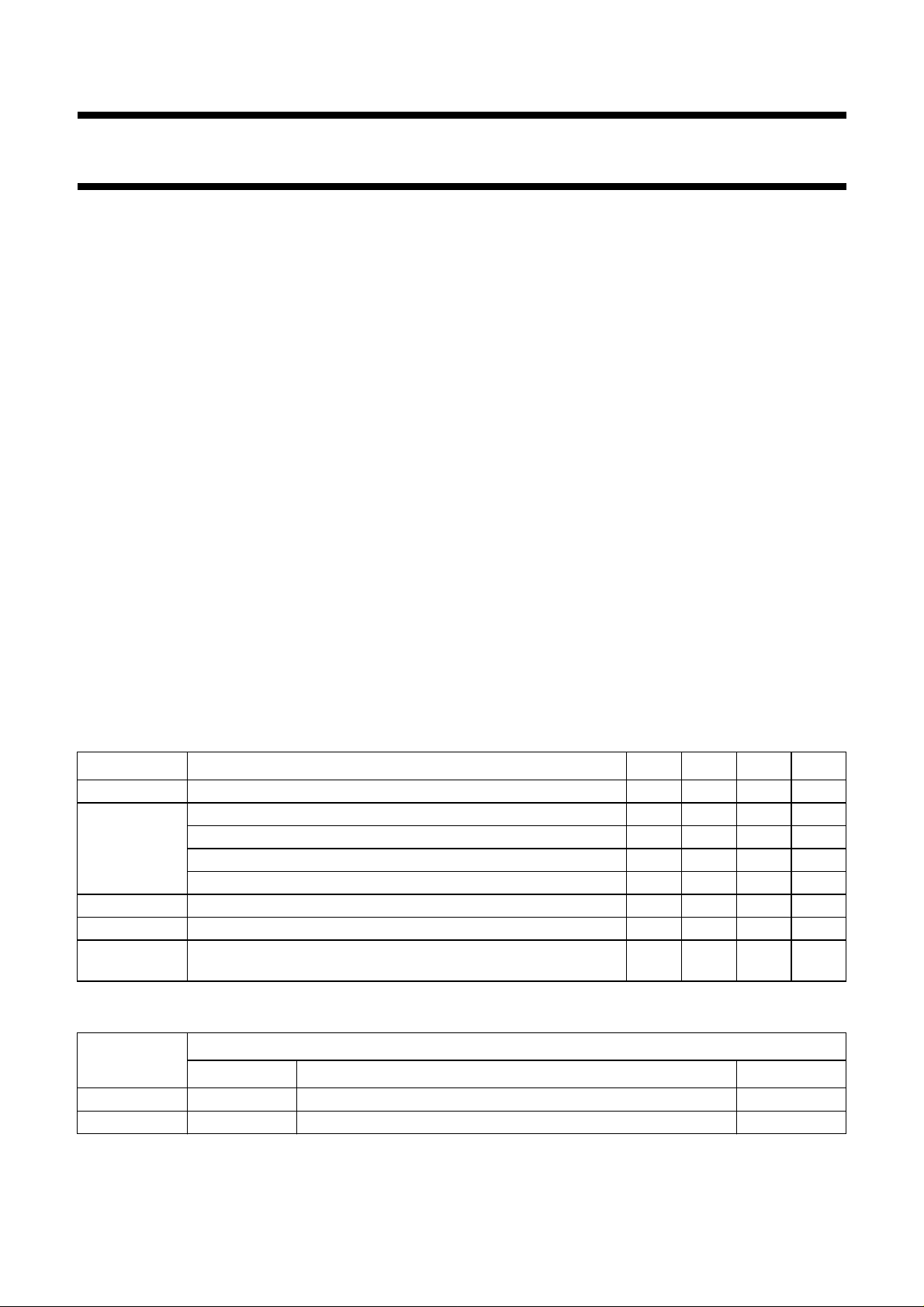

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

V

I

BAT

BAT

supply voltage on pin BAT 5 12 27 V

supply current on pin BAT in sleep mode 1 3 8 µA

supply current on pin BAT in standby mode; bus recessive 100 400 1000 µA

supply current on pin BAT in normal slope mode; bus recessive 100 400 1000 µA

supply current on pin BAT in normal slope mode; bus dominant 1 3.5 8.0 mA

V

LIN

T

vj

V

esd(HBM)

DC voltage on pin LIN −27 − +40 V

virtual junction temperature −40 − +150 °C

electrostatic discharge voltage; human body model;

−4 − +4 kV

pins NWAKE, LIN and BAT

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGES

TJA1020T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

TJA1020U − bare die; die dimensions 1480 × 1760 × 375 µm −

2002 Jul 17 2

Page 3

Philips Semiconductors Product specification

LIN transceiver TJA1020

BLOCK DIAGRAM

handbook, full pagewidth

BAT

NWAKE

NSLP

TXD

RXD

7

3

2

4

WAKE-UP

TIMER

SLEEP/

NORMAL

TIMER

TXD

TIME-OUT

TIMER

CONTROL

TEMPERATURE

PROTECTION

8

INH

6

LIN

TJA1020T

1

RXD/

INT

BUS

TIMER

FILTER

MGU241

5

GND

Fig.1 Block diagram.

PINNING

SYMBOL PIN DESCRIPTION

RXD 1 receive data output (open-drain);

active LOW after a wake-up event

NSLP 2 sleep control input (active LOW);

controls inhibit output; resets

wake-up source flag on TXD and

wake-up request on RXD

NWAKE 3 local wake-up input (active LOW);

negative edge triggered

TXD 4 transmit data input; active LOW

output after a local wake-up event

GND 5 ground

LIN 6 LIN bus line input/output

BAT 7 battery supply

INH 8 battery related inhibit output for con-

trolling an external voltage regulator;

active HIGH after a wake-up event

handbook, halfpage

RXD

1

NSLP

2

NWAKE

TXD

3

4

TJA1020T

MGU242

Fig.2 Pinning diagram.

INH

8

BAT

7

LIN

6

5

GND

2002 Jul 17 3

Page 4

Philips Semiconductors Product specification

LIN transceiver TJA1020

FUNCTIONAL DESCRIPTION

The TJA1020 is the interface between the LIN master/slave protocol controller and the physical bus in a Local

Interconnect Network (LIN). The LIN transceiver is optimized for the maximum specified LIN transmission speed of

20 Kbaud providing optimum EMC performance due to wave shaping of the LIN output.

Operating modes

The TJA1020 provides two modes of normal operation, one intermediate mode and one very low power mode. Figure 3

shows the state diagram.

handbook, full pagewidth

t

(NSLP = 1; after 0−>1)

and TXD = 0

STANDBY

INH = HIGH

TERM. = 30 kΩ

RXD = LOW

> t

gotonorm

SLOPE MODE

INH = HIGH

TERM. = 30 kΩ

RXD = LINDATA

trx OFF

LOW

trx ON

t

(NSLP = 1; after 0−>1)

(t

(NWAKE = 0; after 1−>0)

t

(NSLP = 0; after 1−>0)

t

(NSLP = 1; after 0−>1)

and TXD = 1

t

(LIN = 0; after 1−>0)

and no wake-up event

or

and NSLP = 0

and TXD = 0

> t

gotonorm

> t

NWAKE

> t

)

BUS

t

(NSLP = 0; after 1−>0)

> t

gotosleep

and no

wake-up event

> t

gotosleep

> t

gotonorm

NORMAL

SLOPE MODE

INH = HIGH

TERM. = 30 kΩ

RXD = LINDATA

trx ON

t

(NSLP = 1; after 0−>1)

SLEEP

INH = FLOATING

TERM. =

HIGH-OHMIC

RXD = FLOATING

trx OFF

and TXD = 1

switching on BAT

MGU243

> t

gotonorm

trx: transmitter.

TERM.: slave termination resistor, connected between pins LIN and BAT.

Fig.3 State diagram.

2002 Jul 17 4

Page 5

Philips Semiconductors Product specification

LIN transceiver TJA1020

Table 1 Operating modes

MODE NSLP TXD (OUTPUT) RXD INH TRANSMITTER REMARKS

Sleep 0 weak pull-down floating floating off no wake-up request detected

Standby

Normal

slope

mode

Low slope

mode

(1)

0 weak pull-down if

LOW; note 3 HIGH off wake-up request detected; in

remote wake-up;

strong pull-down if

local wake-up;

note 2

1 weak pull-down HIGH:

recessivestate

LOW:

dominant state

1 weak pull-down HIGH:

recessivestate

LOW:

dominant state

this mode the microcontroller

can read the wake-up source:

remote or local wake-up

HIGH normal slope

notes 2, 3 and 4

mode

HIGH low slope mode notes 2, 3 and 5

Notes

1. The standby mode isentered automatically upon any local or remote wake-up event duringsleep mode. Pin INH and

the 30 kΩ termination resistor at pin LIN are switched on.

2. The internal wake-up source flag (set if a local wake-up did occur and fed to pin TXD) will be reset when entering

normal slope or low slope mode (NSLP goes HIGH).

3. The wake-up interrupt (on pin RXD) is released when entering normal slope or low slope mode (NSLP goes HIGH).

4. The normal slope mode is entered if TXD is set HIGH (set by the microcontroller to recessive) during a positive edge

on NSLP. In the event of a short-circuit to ground on pin TXD, the transmitter will be disabled.

5. The low slope mode is entered if pin TXD is pulled LOW (actively set dominant by the microcontroller or due to a

failure on TXD) during the positive edge on NSLP.

Sleep mode

This mode is the most power saving mode of the TJA1020

and the default state after power-up (first battery supply).

Despiteitsextremelowcurrentconsumption,theTJA1020

can still be waken up remotely via pin LIN, or waken up

locally via pin NWAKE, or activated directly via pin NSLP.

Filters at the inputs of the receiver (LIN), of pin NWAKE

andofpin NSLP are preventing unwanted wake-up events

due to automotive transients or EMI. All wake-up events

have to be maintained for a certain time period (t

t

NWAKE

and t

gotonorm

).

BUS

,

The sleep mode is initiated by a falling edge on the pin

NSLP driven by the microcontroller. After a filter time

continuously driven sleep command (pin NSLP = LOW),

pin INH becomes floating.

The sleep mode can be activated independently from the

actual level on pin LIN or NWAKE. So it is guaranteed that

the lowest power consumption is achievable even in case

of a continuous dominant level on pin LIN or a continuous

LOW on pin NWAKE.

Standby mode

The standby mode is entered automatically whenever a

local or remote wake-up occurs while the TJA1020 is in its

sleep mode. These wake-up events activate pin INH and

enable the slave termination resistor at the pin LIN. As a

result of the HIGH condition on pin INH the voltage

regulator and the microcontroller can be activated.

Thestandby mode is signalledby a LOW levelon pin RXD

which can be used as an interrupt for the microcontroller.

In sleep mode the internal slave termination between

pins LIN and BAT is disabled to minimize the power

dissipation in case pin LIN is short-circuited to ground.

Only a weak pull-up between pins LIN and BAT is present.

2002 Jul 17 5

In the standby mode (pin NSLP is still LOW), the condition

of pin TXD (weak pull-down or strong pull-down) indicates

thewake-up source: weak pull-down for aremotewake-up

request and strong pull-down for a local wake-up request.

Page 6

Philips Semiconductors Product specification

LIN transceiver TJA1020

Settingpin NSLPHIGHduring standby mode results in the

following events:

• An immediate reset of the wake-up source flag; thus

releasing the possible strong pull-down at pin TXD

before the actual mode change (after t

gotonorm

) is

performed

• A change into normal slope mode if the HIGH level on

pin NSLP has been maintained for a certain time period

(t

gotonorm

) and pin TXD is HIGH

• A change into low slope mode if the HIGH level on pin

NSLP has been maintained for a certain time period

(t

gotonorm

) and pin TXD ispulled LOW by the application.

In the event of a short-circuit to ground or an open-wire

on pin TXD, the LIN output remains recessive (fail safe).

• A reset of the wake-up request signal on pin RXD if the

HIGH level on pin NSLP has been maintained for a

certain time period (t

gotonorm

).

Normal slope mode

In the normal slope mode the transceiver is able to

transmitandreceivedata via the LIN bus line. The receiver

detects the data stream at the LIN bus input pin and

transfers it via pin RXD to the microcontroller (see Fig.1):

HIGH at a recessive level and LOW at a dominant level on

the bus. The receiver has a supply voltage related

threshold with hysteresis and an integrated filter to

suppress bus line noise. The transmit data stream of the

protocol controller at the TXD input is converted by the

transmitter into a bus signal with controlled slew rate and

wave shaping to minimize EME. The LIN bus output pin is

pulled HIGH via an internal slave termination resistor. For

a master application an external resistor in series with a

diode should be connected between pin INH or BAT on

one side and pin LIN on the other side.

The normal slope mode is entered by a HIGH level on

pin TXD and a HIGH level on pin NSLP maintained for a

certain time period (t

), coming from the sleep or

gotonorm

standby mode.

The TJA1020 switches to sleep mode in case of a LOW

level on pin NSLP, maintainedduring a certain time period

(t

gotosleep

).

Low slope mode

In the low slope mode the transmitter output stage drives

the LIN bus line with lengthened rise and fall slopes. This

will further reduce the already outstanding EME in the

normalslopemode. The low slope mode is perfectly suited

for applications where transmission speed is not critical.

The mode selection is done by the LIN transceiver after a

positive edge on pin NSLP, maintained for a certain time

period (t

gotonorm

). If pin TXD is LOW at that time, the low

slope mode is entered, otherwise the normal mode is

entered. The transition to the low slope mode will be

executedduring an open pin TXD (fail-safe),ashort-circuit

from pin TXD to ground (fail-safe) or an intended LOW

level of pin TXD programmed by the microcontroller. The

transmitter is enabled after a LOW-to-HIGH transition on

pin TXD. In the event of a short-circuit to ground on pin

TXD, the transmitter will be disabled.

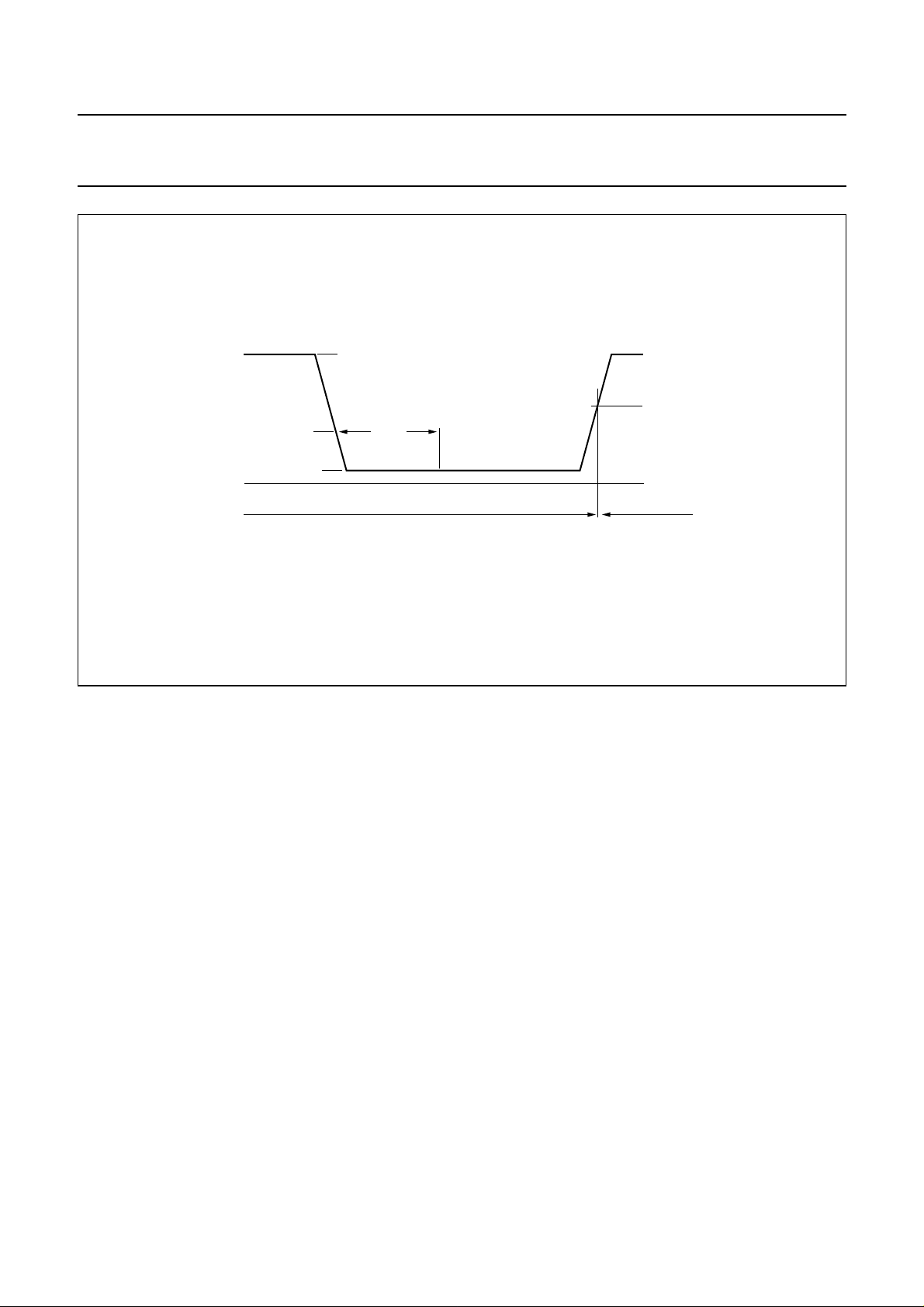

Wake-up

There are three ways to wake-up a TJA1020 which is in

sleep mode:

1. Remote wake-up via a dominant bus state

2. Local wake-up via a negative edge at pin NWAKE

3. Mode change (pin NSLP is HIGH) from sleep mode to

normal slope/low slope mode.

Remote and local wake-up

A falling edge at pin NWAKE followed by a LOW level

maintained for a certain time period (t

NWAKE

) results in a

local wake-up. The pin NWAKE provides an internal

pull-up towards pin BAT.

If, during power-up, pin NWAKE is LOW for a certain

period of time (t

) this will also result in a local

NWAKE

wake-up.

A falling edge at pin LIN followed by a LOW level

maintained for a certain time period (t

) and a rising

BUS

edge at pin LINrespectively (see Fig.4) results in a remote

wake-up.

After a local or remote wake-up pin INH is activated (it

goes HIGH) and the internal slave termination resistor is

switched on. The wake-up request is indicated by a LOW

active wake-up request signal on pin RXD to interrupt the

microcontroller.

The only difference between the normal slope mode and

the low slope mode is the transmitter behaviour.

2002 Jul 17 6

Page 7

Philips Semiconductors Product specification

LIN transceiver TJA1020

Wake-up via mode transition

It is also possible to set pin INH HIGH with a mode

transition towards normal slope/low slope mode via pin

NSLP. This is useful for applications with a continuously

powered microcontroller.

Wake-up source recognition

The TJA1020 can distinguish between a local wake-up

request on pin NWAKE and a remote wake-up request via

a dominant bus state. The wake-up source flag is set in

case the wake-up request was a local one. The wake-up

source can be read on pin TXD in the standby mode. If an

external pull-up resistor on pin TXD to the power supply

voltage of the microcontroller has been added a HIGH

level indicates a remote wake-up request (weak pull-down

at pin TXD) and a LOW level indicates a local wake-up

request (strong pull-down at pin TXD; much stronger than

the external pull-up resistor).

The wake-up request flag (signalled on pin RXD) as well

as the wake-up source flag (signalled on pin TXD) are

reset immediately, if the microcontroller sets pin NSLP

HIGH.

TXD dominant time-out function

A ‘TXD Dominant Time-out’ timer circuit prevents the bus

line from being driven to a permanent dominant state

(blocking all network communication) if pin TXD is forced

permanently LOW by a hardware and/or software

application failure. The timer is triggered by a negative

edge on pin TXD. If the duration of the LOW level on pin

TXDexceedstheinternaltimervalue(t

),thetransmitter

dom

is disabled, driving the bus line into a recessive state. The

timer is reset by a positive edge on pin TXD.

Fail-safe features

Pin TXD provides a pull-down to GND in order to force a

predefined level on input pin TXD in case the pin TXD is

unsupplied.

Pin NSLP provides a pull-down to GND in order to force

the transceiver into sleep mode in case the pin NSLP is

unsupplied.

Pin RXD is set floating in case of lost power supply on pin

BAT.

The current of the transmitter output stage is limited in

order to protect the transmitter against short-circuit to pins

BAT or GND.

A loss of power (pins BAT and GND) has no impact to the

bus line and the microcontroller. There are no reverse

currents from the bus. The LIN transceiver can be

disconnected from the power supply without influencing

the LIN bus.

The output driver at pin LIN is protected against

overtemperature conditions. If the junction temperature

exceeds the shutdown junction temperature T

j(sd)

, the

thermal protection circuit disables the output driver. The

driver is enabled again if the junction temperature has

been decreased below T

and a recessive level is

j(sd)

present at pin TXD.

2002 Jul 17 7

Page 8

Philips Semiconductors Product specification

LIN transceiver TJA1020

handbook, full pagewidth

V

LIN

LIN recessive

0.4V

BAT

LIN dominant

sleep mode standby mode

t

BUS

Fig.4 Wake-up behaviour.

V

BAT

0.6V

ground

MBL371

BAT

2002 Jul 17 8

Page 9

Philips Semiconductors Product specification

LIN transceiver TJA1020

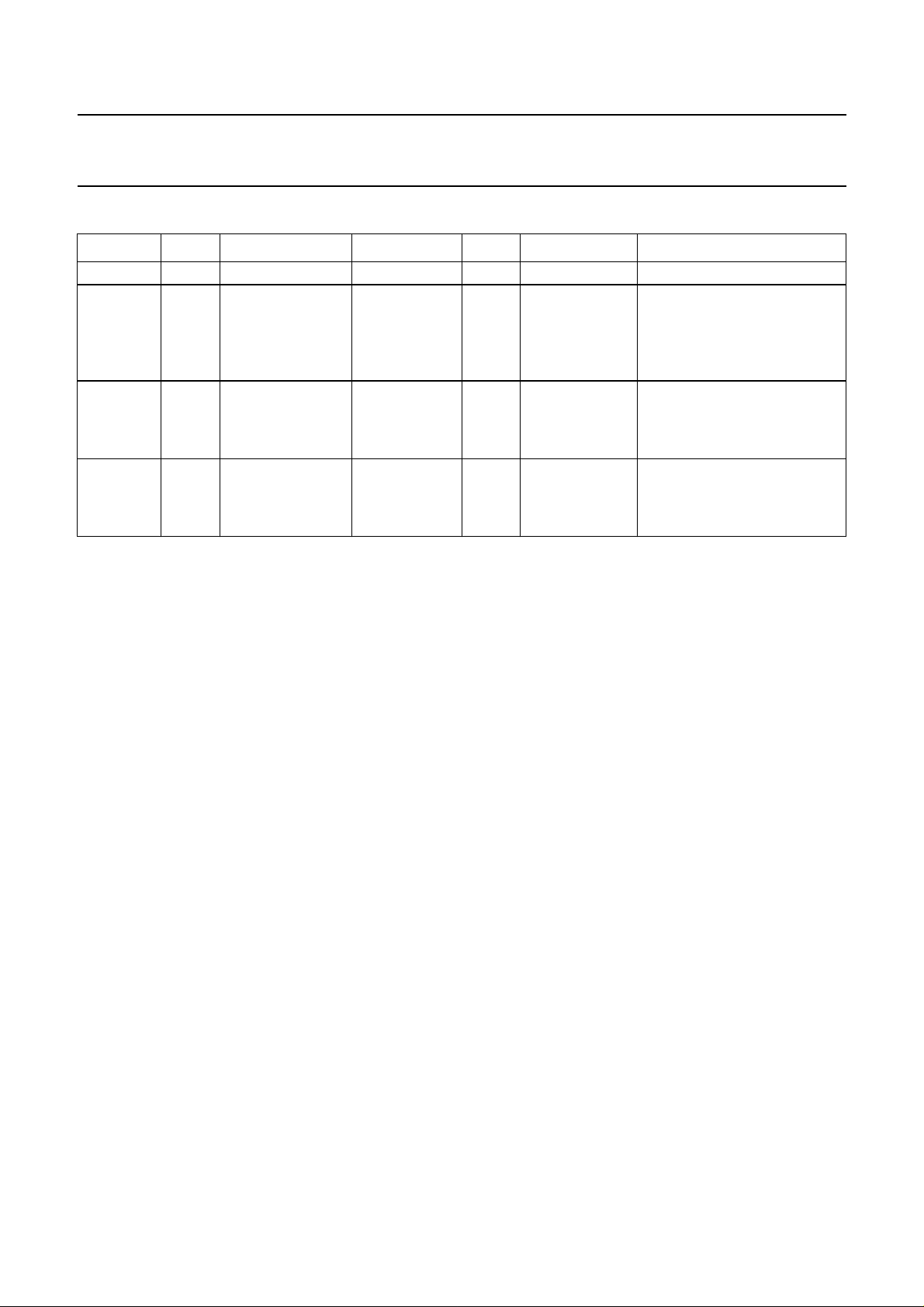

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134); all voltages are referenced to pin GND.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

BAT

V

, V

TXD

V

LIN

V

NWAKE

I

NWAKE

V

INH

I

INH

V

trt(LIN)

T

vj

T

stg

V

esd(HBM)

V

esd(MM)

RXD

, V

supply voltage on pin BAT −0.3 +40 V

DC voltage on pins TXD, RXD and NSLP −0.3 +7 V

NSLP

DC voltage on pin LIN −27 +40 V

DC voltage on pin NWAKE −1 +40 V

current on pin NWAKE (only relevant if

V

NWAKE<VGND

− 0.3 V; current will flow into

−15 − mA

pin GND)

DC voltage on pin INH −0.3 V

BAT

output current at pin INH −50 +15 mA

transient voltage on pin LIN (ISO7637) −150 +100 V

virtual junction temperature −40 +150 °C

storage temperature −55 +150 °C

electrostatic discharge voltage; human body

note 1

model

on pins NWAKE, LIN and BAT −4+4 kV

on pins RXD, NSLP, TXD and INH −2+2 kV

electrostatic discharge voltage; machine

note 2 −200 +200 V

model; all pins

+ 0.3 V

Notes

1. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ resistor.

2. Equivalent to discharging a 200 pF capacitor through a 10 Ω resistor and a 0.75 µH coil. In the event of a discharge

from pin INH to pin BAT: −150V<V

esd(MM)

< +150 V.

THERMAL CHARACTERISTICS

According to IEC747-1.

SYMBOL PARAMETER CONDITION VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in

in free air 145 K/W

SO8 package

base thermal resistance from junction to substrate

R

th(j-s)

in free air tbf K/W

bare die

QUALITY SPECIFICATION

Quality specification in accordance with

“AEC - Q100”

.

2002 Jul 17 9

Page 10

Philips Semiconductors Product specification

LIN transceiver TJA1020

CHARACTERISTICS

V

= 5 to 27 V; Tvj= −40 to +150 °C; R

BAT

L(LIN-BAT)

currents flow into the IC; typical values are given at V

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

I

BAT

supply current on

pin BAT

Pin TXD

V

IH

V

IL

V

hys

R

TXD

HIGH-level input voltage 2 − 7V

LOW-level input voltage −0.3 − +0.8 V

TXD hysteresis voltage 0.03 − 0.5 V

TXD pull-down resistor V

= 500 Ω; all voltages are defined with respect to ground; positive

= 12 V; unless otherwise specified; notes 1 and 2.

BAT

sleep mode

(V

LIN=VBAT

V

NWAKE=VBAT

V

TXD

;

=0V; V

;

NSLP

=0V)

standby mode; bus

recessive (V

V

LIN=VBAT

V

NWAKE=VBAT

V

TXD

;

=0V; V

INH=VBAT

;

=0V)

NSLP

standby mode; bus

dominant (V

V

= 12 V; V

INH

V

V

V

NWAKE

=0V;

TXD

= 0 V); note 3

NSLP

=12V;

BAT

=12V;

=0V;

LIN

low slope mode; bus

recessive (V

V

LIN=VBAT

V

NWAKE=VBAT

V

TXD

;

=5V; V

INH=VBAT

;

=5V)

NSLP

normal slope mode; bus

recessive (V

V

LIN=VBAT

V

NWAKE=VBAT

V

TXD

;

=5V; V

INH=VBAT

;

=5V)

NSLP

low slope mode; bus

dominant (V

V

=12V;

INH

V

V

V

NWAKE

=0V;

TXD

= 5 V); note 3

NSLP

=12V;

BAT

=12V;

normal slope mode; bus

dominant (V

V

=12V;

INH

V

V

V

=12V;

NWAKE

=0V;

TXD

= 5 V); note 3

NSLP

= 5 V 125 350 800 kΩ

TXD

BAT

=12V;

138µA

100 400 1000 µA

;

300 900 2000 µA

100 400 1000 µA

;

100 400 1000 µA

;

1 3.5 8 mA

1 3.5 8 mA

2002 Jul 17 10

Page 11

Philips Semiconductors Product specification

LIN transceiver TJA1020

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

IL

I

OL

Pin NSLP

V

IH

V

IL

V

hys

R

NSLP

I

IL

Pin RXD (open-drain)

I

OL

I

LH

Pin NWAKE

V

IH

V

IL

I

IL

I

LH

Pin INH

R

sw(INH)

I

LH

Pin LIN

V

o(reces)

V

o(dom)

I

LH

I

IL

R

SLAVE

LOW-level input current V

LOW-level output current

(local wake-up request)

=0V −50+5µA

TXD

standby mode;

V

V

V

=0V;

NWAKE

LIN=VBAT

= 0.4 V

TXD

;

1.5 3 − mA

HIGH-level input voltage 2 − 7V

LOW-level input voltage −0.3 − +0.8 V

NSLP hysteresis voltage 0.03 − 0.5 V

NSLP pull-down resistor V

LOW-level input current V

LOW-level output current normal slope mode;

HIGH-level leakage

current

HIGH-level input voltage V

LOW-level input voltage −0.3 − V

NWAKE pull-up current V

HIGH-level leakage

current

switch-on resistance

between pins BAT and

INH

HIGH-level leakage

current

LIN recessive output

= 5 V 125 350 800 kΩ

NSLP

=0V −50+5µA

NSLP

1.3 3.5 − mA

V

=0V; V

LIN

normal slope mode;

V

LIN=VBAT

=0V −30 −10 −3 µA

NWAKE

V

V

NWAKE

=27V

BAT

=27V;

standby; low slope or

; V

RXD

RXD

= 0.4 V

=5V

−50+5µA

− 1 − V

BAT

+ 0.3 V

BAT

− 3.3 V

BAT

−50+5µA

− 30 50 Ω

normal slope mode;

I

= −15 mA;

INH

V

=12V

BAT

sleep mode;

V

= 27 V; V

INH

V

=5V; I

TXD

=27V

BAT

= 0 mA 0.9V

LIN

−50+5µA

BAT

− V

BAT

V

voltage

LIN dominant output

voltage

HIGH-level leakage

V

=0V;

TXD

V

=8to27V

BAT

V

=0V; V

TXD

V

LIN=VBAT

0.6 − 0.15V

= 7.3 V 0.6 − 1.2 V

BAT

−10+1µA

BAT

V

current

LIN pull-up current sleep mode; V

V

=0V

NSLP

slave termination

resistance to pin BAT

standby, low slope or

normal slope mode;

V

=0V; V

LIN

BAT

=0V;

LIN

=12V

−2 −5 −10 µA

20 30 47 kΩ

2002 Jul 17 11

Page 12

Philips Semiconductors Product specification

LIN transceiver TJA1020

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

I

o(sc)

V

th(rx)

V

cntr(rx)

V

thr(hys)

Thermal shutdown

T

j(sd)

AC characteristics

∆t

d(TXD-BUSon/off)

∆t

d(TXD-BUSon/off)

∆t

d(BUSon/off-RXD)

t

f(slope)(dom)

t

r(slope)(rec)

∆t

slope(norm)

short-circuit output

current

receiver threshold

V

LIN=VBAT

V

TXD

V

LIN=VBAT

V

TXD

V

BAT

=12V;

=0V; t<t

dom

=27V;

=0V; t<t

dom

= 7.3 to 27 V 0.4V

voltage

receiver centre voltage V

receiver threshold

= 7.3 to 27 V 0.475V

BAT

V

= 7.3 to 27 V 0.145V

BAT

hysteresis voltage

shutdown junction

temperature

TXD propagation delay

failure

normal slope mode;

CL= 10 nF; RL= 500 Ω;

(see Fig.5)

TXD propagation delay

failure

t

PropTxDom

low slope mode;

CL= 10 nF; RL= 500 Ω;

− t

PropTxRec

(see Fig.5)

RXD propagation delay

failure

t

PropTxDom

normal slope mode and

low slope mode; CL=0;

− t

PropTxRec

RL=∞; voltage on LIN

externally forced; LIN

slope time <500 ns;

C

= 20 pF;

RXD

R

= 2.4 kΩ; (see

RXD

Fig.5)

fall time LIN

(100% to 0%)

t

PropRxDom

normal slope mode;

CL= 10 nF; RL= 500 Ω;

V

BAT

− t

PropRxRec

= 12 V; transition

from recessive to

dominant; note 4; (see

Fig.5)

rise time LIN

(0% to 100%)

normal slope mode;

CL= 10 nF; RL= 500 Ω;

V

= 12 V; transition

BAT

from dominant to

recessive; note 5; (see

Fig.5)

normal slope symmetry normal slope mode;

CL= 10 nF; RL= 500 Ω;

V

=12V;

BAT

t

f(slope)(dom)

− t

r(slope)(rec)

27 40 60 mA

60 90 125 mA

BAT

− 0.6V

0.5V

BAT

0.16V

BAT

BAT

BAT

BAT

0.525V

0.175V

BAT

BAT

V

V

V

160 175 190 °C

−20+2µs

−50+5µs

−20+2µs

− 16 27 µs

− 16 27 µs

−50+5µs

2002 Jul 17 12

Page 13

Philips Semiconductors Product specification

LIN transceiver TJA1020

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

t

f(slope)(norm)(dom)

normal slope fall time LIN

(100% to 0%)

t

r(slope)(norm)(rec)

normal slope rise time

LIN (0% to 100%)

∆t

slope(norm)

t

f(slope)(low)(dom)

normal slope symmetry normal slope mode;

low slope fall time LIN

(100% to 0%)

t

r(slope)(low)(rec)

low slope rise time LIN

(0% to 100%)

t

BUS

dominant time for

wake-up via bus

t

NWAKE

dominant time for

wake-up via pin NWAKE

t

gotonorm

time period for mode

change from sleep or

standby mode into

normal/low slope mode

t

gotosleep

time period for mode

change from normal/low

slope mode into sleep

mode

t

dom

TXD dominant time out V

Notes

1. All parameters are guaranteed over the virtual junction temperature by design, but only 100% tested at 125 °C

ambient temperature for dies on wafer level and above this for cased products 100% tested at 25 °C ambient

temperature, unless otherwise specified.

2. For bare die, all parameters are only guaranteed if the backside of the bare die is connected to ground.

3. If V

is higher than 12 V, the battery current increases due to the internal LIN termination resistor. The minimum

BAT

value of this resistor is 20 kΩ. The maximum current increase is therefore:

normal slope mode;

− 12 22.5 µs

CL= 6.8 nF;RL= 660 Ω;

V

= 12 V; transition

BAT

from recessive to

dominant; note 4

normal slope mode;

− 12 22.5 µs

CL= 6.8 nF;RL= 660 Ω;

V

= 12 V; transition

BAT

from dominant to

recessive; note 5

−40+4µs

CL= 6.8 nF;RL= 660 Ω;

V

=12V;

BAT

t

f(slope)(dom)

low slope mode;

− t

r(slope)(rec)

− 30 62 µs

CL= 10 nF; RL= 500 Ω;

V

= 12 V; note 4

BAT

low slope mode;

− 30 62 µs

CL= 10 nF; RL= 500 Ω;

V

= 12 V; note 5

BAT

sleep mode 30 70 150 µs

sleep mode 7 20 50 µs

2510µs

2510µs

= 0 V 6 12 20 ms

TXD

V

I

BAT increase()

=

------------------------------- -

BAT

20 kΩ

12 V–

t

t

4. ; see Fig.6

f(slope)(dom)

t

5. ; see Fig.6

r(slope)(rec)

=

-------------------------------------------------------------------------------------

t

VLIN

=

---------------------------------------------------------------------------------

40%=()t

VLIN

0.55

60%=()t

0.55

95%=()–()

VLIN

5%=()–()

VLIN

2002 Jul 17 13

Page 14

Philips Semiconductors Product specification

LIN transceiver TJA1020

TIMING DIAGRAMS

handbook, full pagewidth

V

RXD

50% 50%TXD

BAT

t

PropTxRec

5%

50%

LIN

t

PropTxDom

100%

95%

0.5 V

0%

t

PropRxDom

Fig.5 Timing diagram for AC characteristics, bus loaded.

0.5 V

BAT

t

PropRxRec

50%

t

MGW323

handbook, full pagewidth

V

LIN

100%

95%

0%

t

slope(Dom)

40%

Fig.6 Definition of slope timing.

2002 Jul 17 14

5%

60%

t

slope(Rec)

t

MGU433

Page 15

Philips Semiconductors Product specification

LIN transceiver TJA1020

APPLICATION INFORMATION

handbook, full pagewidth

V

DD

MICROCONTROLLER

GND

More information is available in a separate application note.

(1) C

master

= 1 nF; C

slave

= 220 pF.

RX0

TX0

Px.x

NSLP

Fig.7 Typical application of the TJA1020.

+5 V/

+3.3 V

RXD

TXD

BATTERY

INH

8

1

4

2

TJA1020T

5

GND

ECU

7

BAT

3

6

LIN BUS

LINE

only for

master node

NWAKE

1 kΩ

LIN

(1)

MGU244

handbook, full pagewidth

BAT

TJA1020

GND

R

RXD

C

NWAKE

NSLP

TXD

RXD

RXD

Fig.8 Test circuit for AC characteristics.

2002 Jul 17 15

INH

LIN

100 nF

R

L

MGT992

C

L

Page 16

Philips Semiconductors Product specification

LIN transceiver TJA1020

handbook, full pagewidth

The waveforms of the applied transients on pin 6 (LIN) and pin 7 (BAT) are according to ISO7637 part 1, test pulses 1, 2, 3a, 3b, 4, 5, 6 and 7.

5 V

10

kΩ

10

kΩ

5 V

INH

RXD

TXD

NSLP

BAT

TJA1020

GND

NWAKE

LIN

500 Ω

10 µF

1 nF

TRANSIENT

GENERATOR

MGT993

Fig.9 Test circuit for automotive transients.

2002 Jul 17 16

Page 17

Philips Semiconductors Product specification

LIN transceiver TJA1020

BONDING PAD LOCATIONS

handbook, full pagewidth

1

2

y

3

4

0

0

8

7

x

6

5A 5B 5C

MGW322

Fig.10 Bonding pad locations.

Table 2 Bonding pad locations (dimensions in µm). All x and y co-ordinates are referenced to the bottom left hand

corner of the die.

CO-ORDINATES

SYMBOL PAD

xy

RXD 1 111 1570

NSLP 2 111 1395

NWAKE 3 165 424

TXD 4 134 134

GND1 5A 1075 90

GND2 5B 1185 90

GND3 5C 1295 90

LIN 6 1318 419

BAT 7 1235 1133

INH 8 1125 1490

2002 Jul 17 17

Page 18

Philips Semiconductors Product specification

LIN transceiver TJA1020

PACKAGE OUTLINE

SO8: plastic small outline package; 8 leads; body width 3.9 mm

SOT96-1

y

Z

8

pin 1 index

1

D

c

5

A

2

A

1

4

e

w M

b

p

E

H

E

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

UNIT

mm

inches

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

A

max.

1.75

0.069

OUTLINE

VERSION

SOT96-1

A1A2A

0.25

1.45

0.10

1.25

0.010

0.057

0.004

0.049

IEC JEDEC EIAJ

076E03 MS-012

0.25

0.01

b

3

p

0.49

0.25

0.36

0.19

0.019

0.0100

0.014

0.0075

(1)E(2)

cD

5.0

4.8

0.20

0.19

REFERENCES

4.0

3.8

0.16

0.15

1.27

0.050

2002 Jul 17 18

eHELLpQZywv θ

1.05

1.0

0.4

0.039

0.016

0.7

0.6

0.028

0.024

0.25 0.10.25

0.010.010.041 0.004

EUROPEAN

PROJECTION

6.2

5.8

0.244

0.228

(1)

0.7

0.3

0.028

0.012

ISSUE DATE

97-05-22

99-12-27

o

8

o

0

Page 19

Philips Semiconductors Product specification

LIN transceiver TJA1020

SOLDERING

Introduction to soldering surface mount packages

Thistextgivesavery brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurfacemountICs,butitisnot suitable for fine pitch

SMDs. In these situations reflow soldering is

recommended.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

tothe printed-circuit board by screen printing,stencillingor

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 220 °C for

thick/large packages, and below 235 °C for small/thin

packages.

Wave soldering

Conventional single wave soldering is not recommended

forsurfacemountdevices(SMDs)orprinted-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackageswithleadsonfoursides,the footprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

2002 Jul 17 19

Page 20

Philips Semiconductors Product specification

LIN transceiver TJA1020

Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

(1)

SOLDERING METHOD

WAVE REFLOW

(2)

BGA, LBGA, LFBGA, SQFP, TFBGA, VFBGA not suitable suitable

HBCC, HBGA, HLQFP, HSQFP, HSOP, HTQFP, HTSSOP, HVQFN,

not suitable

(3)

suitable

HVSON, SMS

(4)

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

, SO, SOJ suitable suitable

(4)(5)

suitable

(6)

suitable

Notes

1. Formoredetailed information on the BGA packagesrefertothe

“(LF)BGAApplication Note

”(AN01026);order a copy

from your Philips Semiconductors sales office.

2. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

.

3. These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the solder

cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink on the top side,

the solder might be deposited on the heatsink surface.

4. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

The package footprint must incorporate solder thieves downstream and at the side corners.

5. Wave soldering is suitable for LQFP, TQFP and QFP packages with a pitch (e) larger than 0.8 mm; it is definitely not

suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

6. Wave soldering is suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

2002 Jul 17 20

Page 21

Philips Semiconductors Product specification

LIN transceiver TJA1020

DATA SHEET STATUS

PRODUCT

DATA SHEET STATUS

Objective data Development This data sheet contains data from the objective specification for product

Preliminary data Qualification This data sheet contains data from the preliminary specification.

Product data Production This data sheet contains data from the product specification. Philips

(1)

STATUS

(2)

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change

Notification (CPCN) procedure SNW-SQ-650A.

DEFINITIONS

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

2002 Jul 17 21

Page 22

Philips Semiconductors Product specification

LIN transceiver TJA1020

DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

attheseor at any other conditions above those given inthe

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentationorwarrantythatsuchapplicationswillbe

suitable for the specified use without further testing or

modification.

DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected toresult in personal injury. Philips

Semiconductorscustomersusingorsellingtheseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes, without notice, in the

products, including circuits, standard cells, and/or

software, described or contained herein in order to

improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for

theuseofanyoftheseproducts,conveys no licence or title

under any patent, copyright, or mask work right to these

products,andmakes no representations or warranties that

these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

BARE DIE DISCLAIMER

All die are tested and are guaranteed to comply with all

data sheet limits up to the point of wafer sawing for a

periodof ninety (90) daysfrom the date of Philips'delivery.

If there are data sheet limits not guaranteed, these will be

separately indicated in the data sheet. There are no post

packing tests performed on individual die or wafer. Philips

Semiconductorshas no control of third partyproceduresin

the sawing, handling, packing or assembly of the die.

Accordingly, Philips Semiconductors assumes no liability

for device functionality or performance of the die or

systems after third party sawing, handling, packing or

assembly of the die. It is the responsibility of the customer

to test and qualify their application in which the die is used.

2002 Jul 17 22

Page 23

Philips Semiconductors Product specification

LIN transceiver TJA1020

NOTES

2002 Jul 17 23

Page 24

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2002

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 04/pp24 Date of release: 2002 Jul 17 Document order number: 9397 750 10028

SCA74

Loading...

Loading...