Page 1

Thermal Design Guide V2.3!

Fortimo LED SLM platform!

Page 2

• Thermal specifications"

• How to measure T

case

at its critical temperature point Tc?"

• Thermal interface materials (TIM)"

• Designing a passive cooled luminaire"

• Designing an active cooled luminaire"

• Complementary partners for thermal solutions "

(passive/ active)!

Contents!

Page 3

Thermal specifications Fortimo SLM platform

Fortimo SLM Platform!

Electrical power (typical)"

Dissipated thermal power (typical)!

Max.Tcase of module!

Max. ambient temperature!

Thermal impedance requirement Tcase to Tambient!

800 Lm!

11 W!

9 W!

!

!

<3.33 °C/W!

!

1100 Lm!

17 W!

14 W!

!

!

<2.14 °C/W!

!

!

1500 Lm!

20 W!

17 W!

"

"

<1.76 °C/W!

!

!

2000 Lm!

32 W!

27 W"

65 °C!

35 °C!

<1.11 °C/W!

!

3000 Lm!

43 W!

36 W!

!

!

<0.83 °C/W!

!

!

Minimum performance requirement for total cooling solution including TIM, better performance is always preferred and recommended!

Lexel TW!

22 W!

18 W!

!

!

<1.67 °C/W!

!

Lexel RGB!

25 W!

20 W!

!

!

<1.50 °C/W!

!

Page 4

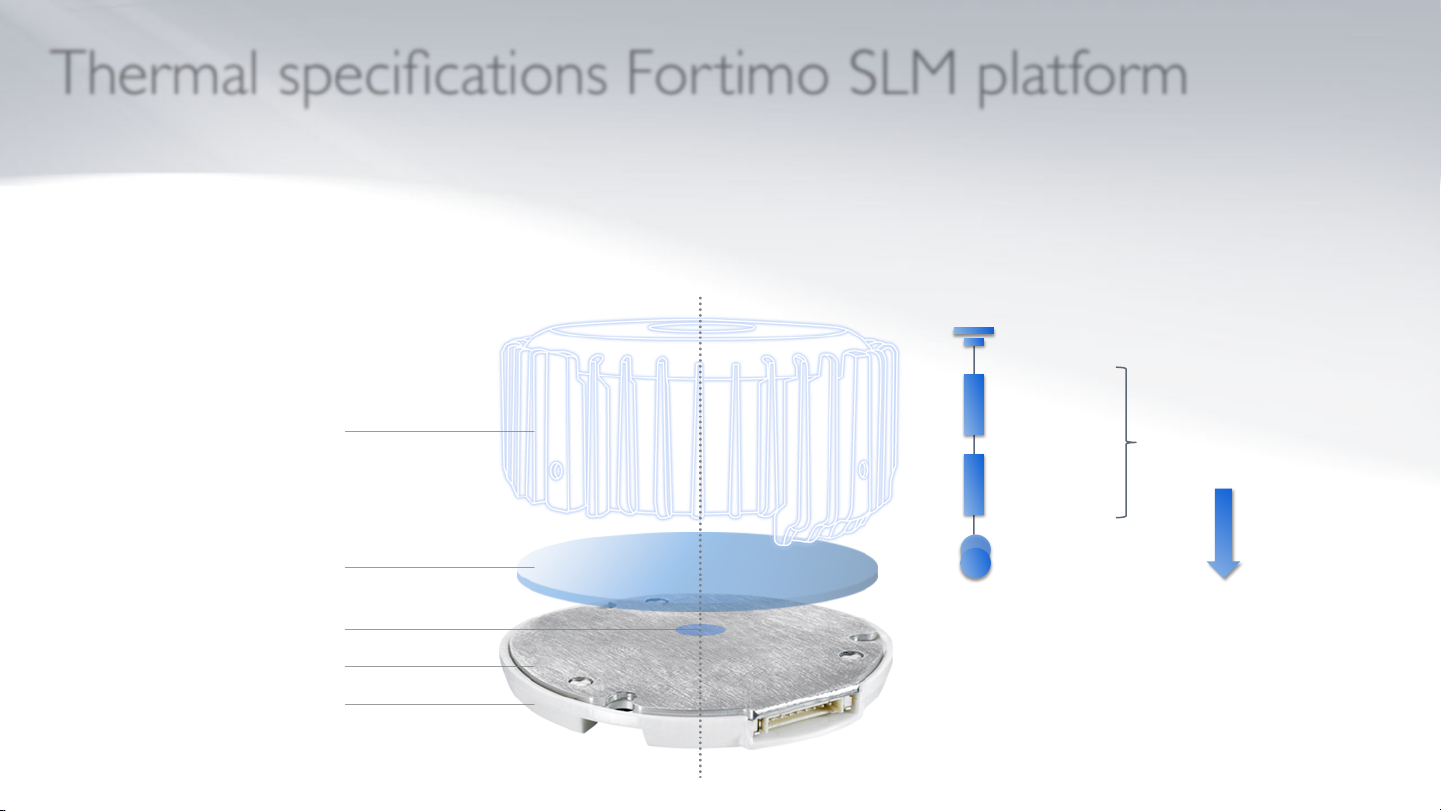

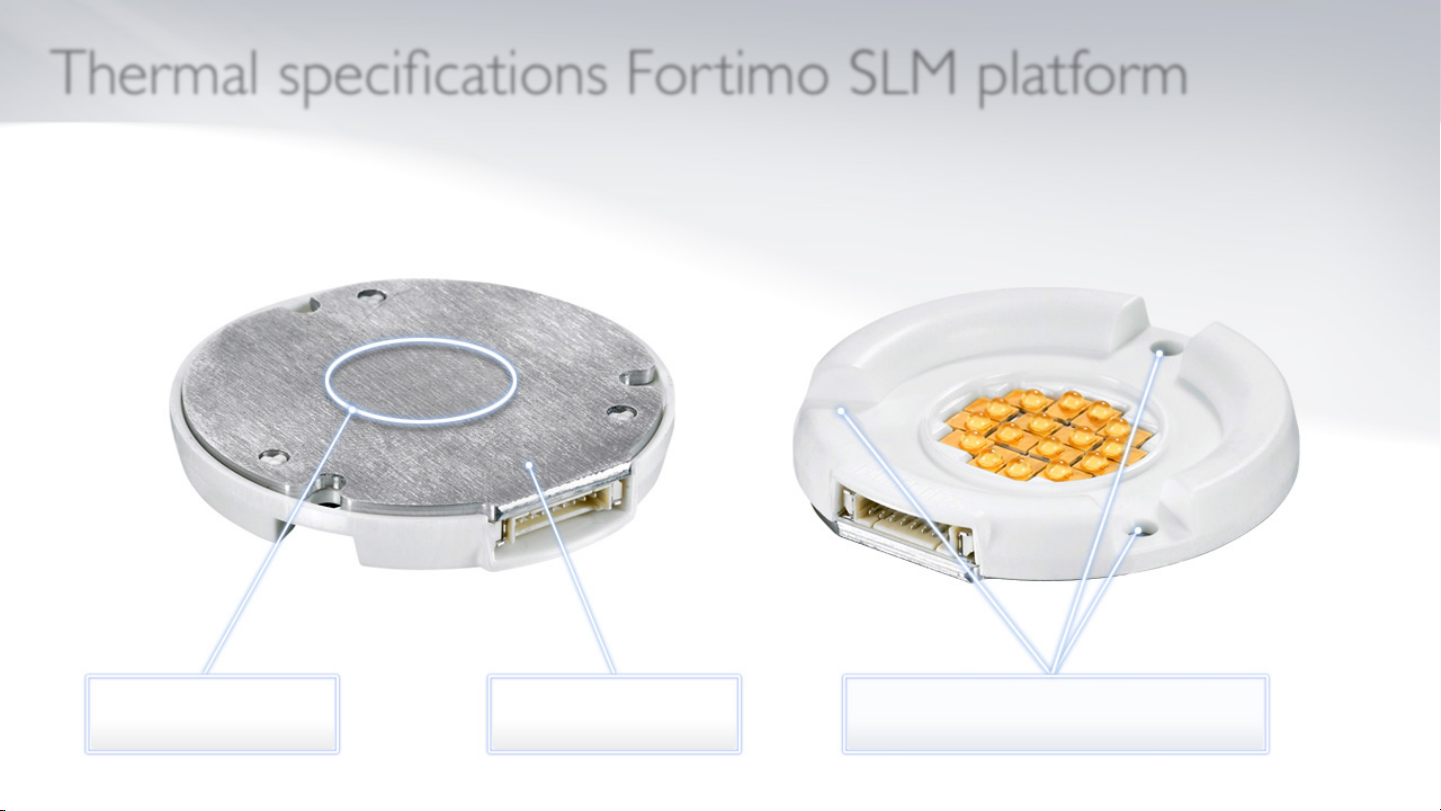

Fortimo SLM thermal specifications :"

• Tcase maximum +30°C above ambient"

• Max ambient 35°C"

• Maximum 65°C Tcase at 35°C ambient"

!

Thermal specifications Fortimo SLM platform!

Spot module ø 50mm •

Aluminum thermal interface ø 47mm •

Tcase 65°C •

Cooling solution i.e. heat sink •

Thermal Interface Material (TIM) •

SLM 800lm 9W => Rth case to ambient ≤ 3.33 (°C/W)

SLM 1100lm 14W => Rth case to ambient ≤ 2.14 (°C/W)

SLM 1500lm 17W => Rth case to ambient ≤ 1.76 (°C/W)

SLM 2000lm 27W => Rth case to ambient ≤ 1.11 (°C/W)

SLM 3000lm 36W => Rth case to ambient ≤ 0.83 (°C/W)

SLM LX TW 18W => Rth case to ambient ≤ 1.67 (°C/W)

SLM LX RGB 20W => Rth case to ambient ≤ 1.50 (°C/W)

Note: this includes the TIM

Simplified model! Thermal network!

35oC!

65oC!

Rth heat sink!

Rth TIM!

Rth case to

ambient!

Page 5

• A maximum surface temperature of 65°C to be guaranteed on the interface between "

the ‘Module’ and the ‘TIM + cooling solution’ at maximum ambient of 35°C"

"

• All types of Fortimo SLM drivers will dim when a temperature over 65°C is sensed by the SLM module!

Thermal specifications Fortimo SLM platform!

Max. Tcase 65°C

Specification on surface

Aluminum thermal

interface ø47 mm

3 screw holes for attachment of module

onto heatsink (M3, bolt circle ø42mm)

Page 6

• The Tcase should be measured at its critical temperature point, centre point at the bottom of the module"

"

• This can be done by making a thin v-groove in the heat sink or a small drill hole in the heat sink to reach "

bottom of the module at its critical temperature point, make sure to measure the bottom of the module and not the TIM!

How to measure critical temperature point Tc?!

Critical temperature point Tc Thin v-groove in the heatsink

to embed a thermocouple

Tip of thermocouple sticking

out on top of the thermal pad

(TIM)

Page 7

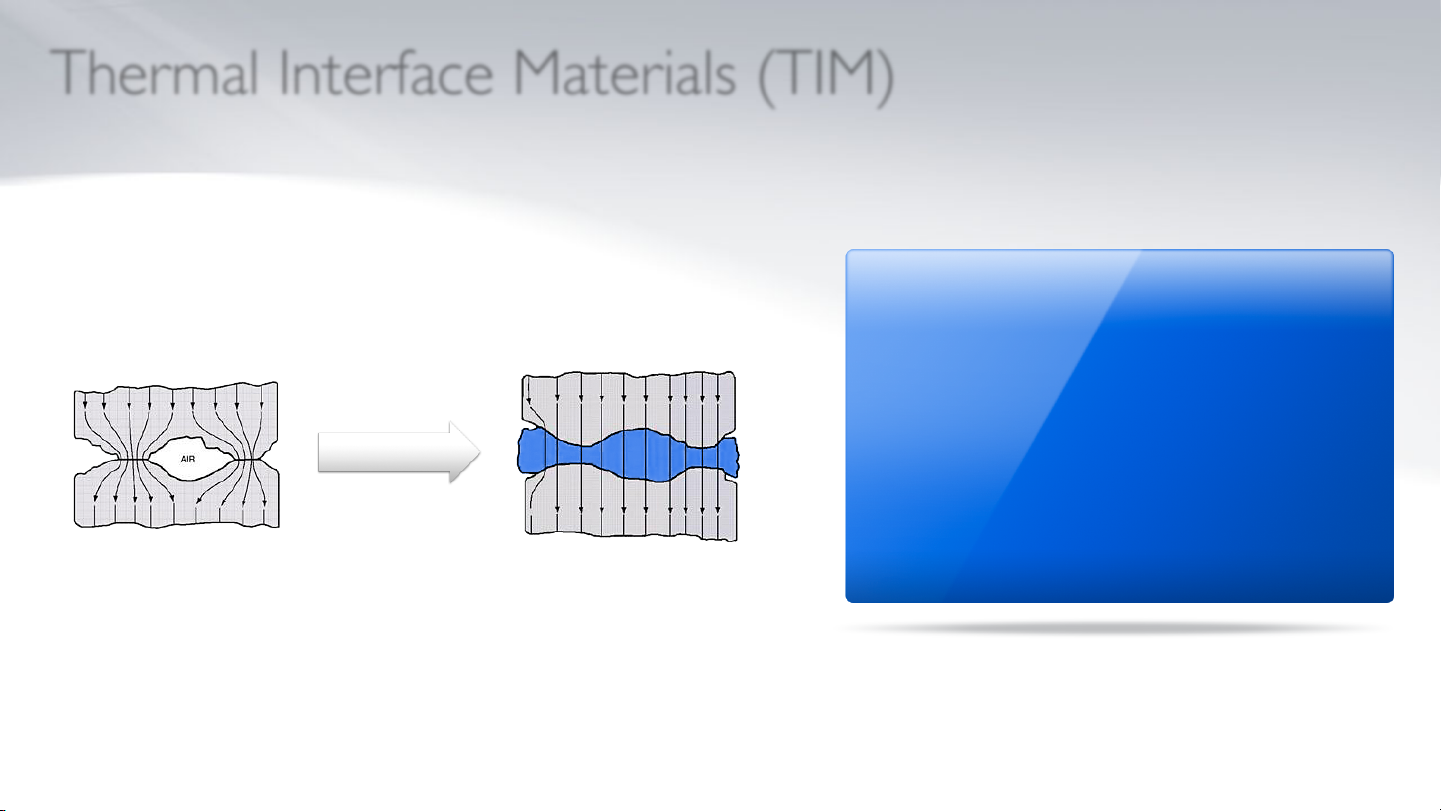

• Function is to reduce thermal impedance between two solid surfaced"

"

• Replaces air (thermal insulator c=0.024W/mK) by filling the gaps with "

better conductive thermal interface material (order c=1W/mK)!

Thermal Interface Materials (TIM)!

• In general:!

- Thermal pastes performs better than thermal pads!

- The higher the thermal conductivity the better!

- The thinner the TIM the better!

• In practice:!

- Actual thermal impedance [°C/W] of TIM in "

application is more important than conductivity "

of material!

- Each thermal interface can have a significant "

contribution to the total thermal impedance "

of module to ambient!

- Limiting the # of thermal interfaces from "

module to ambient is strongly recommended)!

Page 8

• The Bergquist Company"

www.bergquistcompany.com!

Contact information complementary partners"

Thermal interface materials (TIM)

North American Headquarters"

18930 W. 78th Street "

Chanhassen, MN 55317 USA !!

Contact person for Europe"

Nico Bruijnis!

Phone: +31 35 538 0684!

Cell: +31 6 5316 0688!

E-mail: n.bruijnis@bergquist-europe.com

!!

• Chomerics"

www.chomerics.com!

Chomerics North America"

Parker Hannifin Corp."

77 Dragon Court"

Woburn, MA 01801USA !!

Contact person for Europe"

Luc Coupet!

Phone: +33 134323900!

Cell: +33 670765480!

E-mail: luc.coupet@parker.com !!

• Laird Technologies"

www.lairdtech.com!

Corporate Headquarters"

Laird Technologies (Corporate)

16401 Swingley Ridge Road"

Suite 700!

Chesterfield, MO 63017!!

Contact person for Europe"

Philip Blazdell!

Phone: +49 803124600!

Cell: +44 7595710316!

E-mail: philip.blazdell@lairdtech.com !!

Page 9

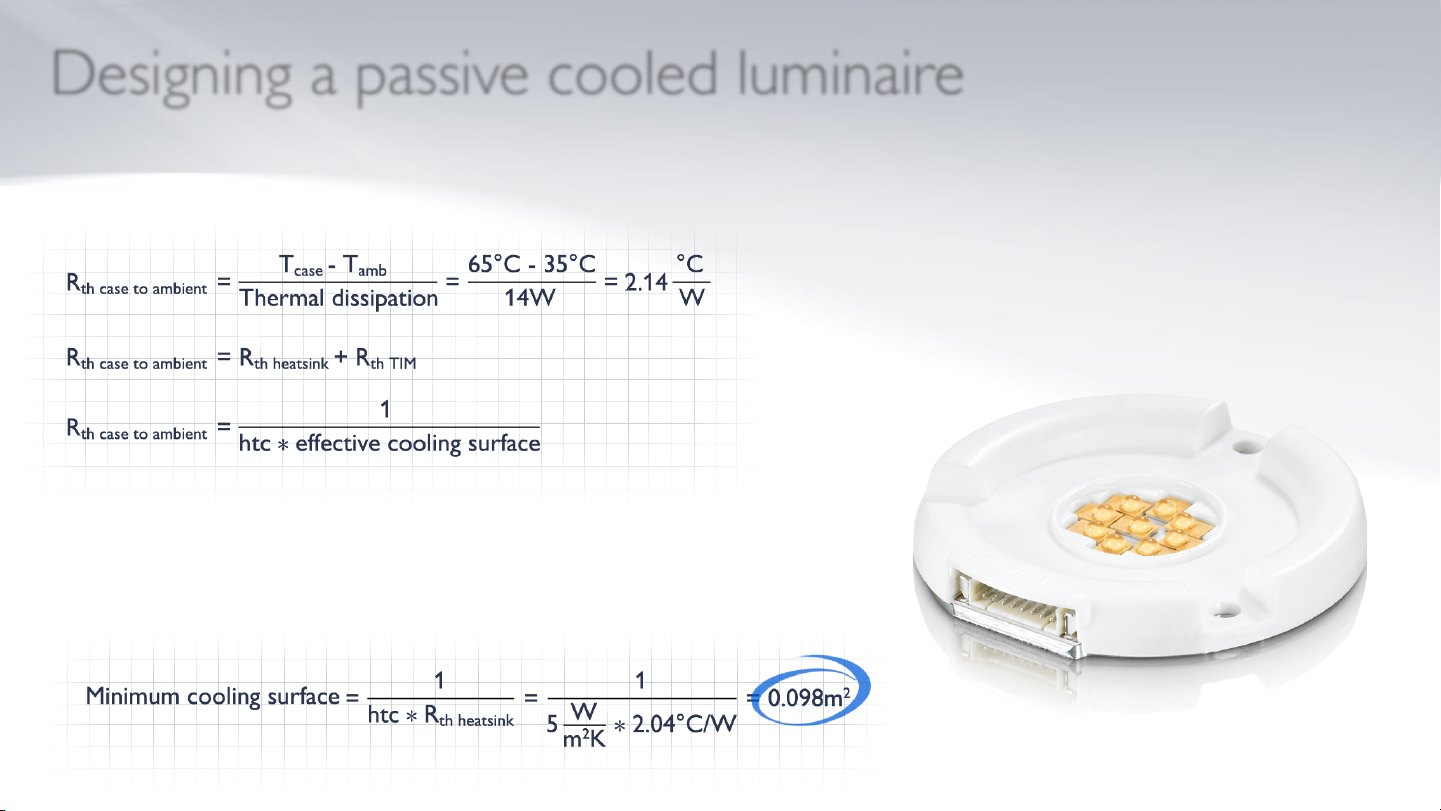

Design based on Fortimo SLM 1100lm:"

• Performance requirement cooling Rth< 2.14 °C/W!

Designing a passive cooled luminaire!

• Assuming a conservative heat transfer coefficient (htc) = 5 W/m2K and!

the contribution of the thermal interface material R

thTIM

= 0.1 °C/W!

a first estimate of the required cooling surface can be calculated!

Page 10

• Based on the previous calculation a minimum surface area of 0.098 m2 is required"

"

• This corresponds to a cylinder of ø120mm and 260mm long"

"

• In order to reduce overall size of the luminaire, cooling fins should be introduced"

"

• To optimization the thermal performance a DoE should be set up"

"

• Example of simple DoE with CFD analysis:"

- Comparison of Design A and B"

- Effect of thermal radiation, blank metal surface or black anodized!

Design of Experiments (DoE)!

Page 11

Results DoE ! !!!!Design A ! !!!!Design B !"

"

"

"

"

"

"

!"

Area (m2) ! !!!0.236 ! !!0.236 ! !!0.158 ! !!0.158"

Emissivity (-) ! !!!0.1 ! !!0.9 ! !!0.1 ! !!0.9"

R

th heatsink

(°C/W) ! !!1.33 ! !!0.99 ! !!1.76 ! !!1.39"

HTC average (W/m2K) ! !3.2 ! !!4.3 ! !!3.6 ! !!4.6"

"

"

A DoE can of course be much more extensive:"

• Different material (thermal conductivity)"

• Orientation; horizontal or vertical (here horizontal is assumed as worst case, "

so both heat sinks will also work in vertical orientation)"

!

Design of Experiments (DoE)!

Page 12

• Both designs are feasible, but choice is to focus on design B"

"

• The fins are place in line with the flow direction for maximum efficiency, "

this way it is possible to keep the overall luminaire size and weight small."

"

• Analysis with CFD can further optimize the design:"

- i.e. optimization of fin thickness and fin spacing!

Detailed analysis!

Page 13

• After design optimization a passive"

luminaire design could look like this:!

Passive cooled luminaire designs!

• Another passive cooled design,!

but with heat pipes:!

Page 14

• Limit the # of thermal interfaces in the thermal path "

from module to ambient => strongly recommended"

"

• Thick fins conduct heat better than thin fins"

"

• Large spacing between fins is better than small spacing between fins"

"

• Make cooling surfaces more effective by using proper conductive materials, "

appropriate thickness and sound orientation"

"

• Thermal radiation plays a significant role => anodized surfaces "

are preferred over blank surfaces!

Some design guidelines for passive cooling!

Page 15

Design based on Fortimo SLM 2000lm:"

"

• Performance requirement cooling Rth< 1.11 °C/W"

"

• Assuming passive cooling conditions:"

- Heat transfer coefficient (htc) = 5 W/m2K and"

- Contribution R

thTIM

= 0.1 °C/W"

"

• A calculated cooling surface of 0.180m2 is required"

"

• This corresponds to the surface a cylinder of "

ø120mm and 478mm long!"

"

"

Goal of an active solution is to actively move air over the "

cooling surfaces to increase the heat transfer coefficient, "

therefore enabling small, compact and light weight cooling "

solutions (and systems)!

Designing an active cooled luminaire!

Page 16

• CFD analysis can be a great way to help design a good active cooled luminaire"

"

• A possible design is shown below"

"

• The complete cooling solution has reduced to a small, compact and light weight solution of ø70mm and 40mm in height!

CFD analysis!

Page 17

• Goal of an active solution is to actively move air over the cooling surfaces to"

increase the heat transfer coefficient, therefore enabling small, compact and"

light weight cooling solutions (and systems)"

"

After optimization an active cooled luminaire design could look like this:!

Active cooled luminaire designs!

Base plate •

Power supply •

Driver housing •

Bracket •

Optic cover •

Reflector •

Front glass •

Front ring •

• Base cover

• Fan

• Hinge

• Heat sink

• Fortimo SLM (2000 Lumens)

• Mounting frame

Page 18

Design considerations for active cooling are:"

• Provisions in luminaire design for inlet and outlet "

of respectively cool and hot air"

• Ensure smooth airflow from inlet to outlet and prevent "

restrictions in the flow path (to limit vibration, recirculation "

and possible noise)!

Some design guidelines "

for active cooling!

Always take care to:!

• Design for reliability (dusty environments)!

• Design for performance (differentiator)!

• Design for low noise (differentiator)!

Page 19

Design considerations for active cooling are:"

"

• Provisions in luminaire design for inlet and outlet of respectively cool and hot air (1) Ensure smooth airflow from inlet "

to outlet and prevent restrictions in the flow path (to limit vibration recirculation and possible noise)"

"

• Avoid recirculation of hot air (2) inside the luminaire, which leads to lower thermal performance and higher noise level."

"

• Enclose fan noise avoiding unnecessary openings near the fan in the luminarie’s housing (3)!

Some design guidelines for active cooling!

1 2 3

✓ ✗ ✗

Page 20

When testing the thermal performance of your luminaire pay "

special attention to these 2 numbers!"

• Max temperature of the module Tc=65C°"

• Max ΔT 30°C (Tc=65°C when your ambient temperature is 35°C)"

"

Operating the system under those parameters will "

guarantee its proper performance in terms of:"

- Lumen output"

- Light consistency"

- Life time!

Thermal solution validation!

Page 21

Overview of our complementary partners and their cooling solutions "

that are especially designed for the Fortimo SLM platform"

"

• AVC (active and passive solutions)"

"

• Sunon (active solutions)"

"

• Nuventix (active solutions)"

"

• Wisefull (active solutions)"

"

• FrigoDynamics (passive solutions)!

Complementary partners for thermal solutions!

Page 22

Module Type !Fortimo SLM 800Lm !Fortimo SLM 1100Lm !Fortimo SLM 1100Lm !Fortimo SLM Lexel !Fortimo SLM 2000Lm ! !Fortimo SLM 3000Lm"

!Passive Solution !Passive Solution !Active Solution !1500Lm Active Solution !Active Solution ! !Active Solution"

! !+ ø9mm heatpipe"

"

Heatsink Type !Sunflower Heatsink !Sunflower Heatsink !Sunflower Heatsink !Sunflower Heatsink !Sunflower Heatsink !Sunflower Heatsink"

Heatsink Model !FSLM-P1000-1 !FSLM-HP1100 !FSLM-A1100-G1 !FSLM-ALexel-G1 !FSLM-A2000-G2 !FSLM-A3000-G3"

Total Height (Heatsink + module) ! !105mm !30mm !40mm !40mm !40mm"

Heatsink Geometry !Extrusion !Extrusion !Extrusion !Extrusion !Extrusion !Extrusion"

Heatsink Dimensions !ø70mm*H30mm !ø100mm*H105mm !ø65mm*H10mm !ø65mm*20mm !ø70mm*20mm !ø75mm*H50mm"

Dimensions Weight (kg) ! !0.685 !0.080 !0.128 !0.150 !TBC"

Heatsink Material !AL6063-T5 !AL6063-T5 !AL6063-T5 !AL6063-T5 !AL6063-T5 !AL6063-T5"

Surface finish !Black Anodized !Anodized !Anodized !Anodized !Black Anodized !Black Anodized"

LED Thermal Power !10W !17W !17W !18W !31W !40W"

Ambient Temperature !35°C !35°C !35°C !35°C !35°C !35°C"

Case Temperature !<=65°C !<=65°C !<=65°C !<=65°C !<=65°C !<=65°C"

Thermal Resistance !<3°C/W !<1.75°C/W !<1.75°C/W !<1.65°C/W !<0.95°C/W !<0.95°C/W"

Lower-noise FAN !N/A !N/A !DS0520_12L !DS0520_12L !DS6020_12E !DS0715"

Fan dimensions !N/A !N/A !50mm*50mm*H20mm !50mm*50mm*H20mm !60mm*60mm*H20mm !70mm*70mm*H15mm"

Fan rated voltage !12V !N/A !12 VDC !12 VDC !12 VDC !12 VDC"

Fan Noise Level !N/A !N/A !<21dB !<21dB !<21dB !<21dB"

Fan RPM speed !N/A !N/A !3000RPM±15% !3000RPM±15% !2200RPM±15% !2200RPM±15%"

Thermal interfaces materials !TIG780-50 !TIG780-50 !TIG780-50 !TIG780-50 !TIG780-50 !TIG780-50!

AVC!

Page 23

LED Fortimo SLM 2000Lm"

LED Power 31W"

Cooling Module Model No. TA003-10001"

Cooling Module Diameter ø86x37mm"

Fan Dimension 60x60x15mm"

Fan Rating Voltage 12VDC"

Fan Rating Current 24mA"

Fan Speed 2200RPM"

Cooling Module Noise @ 1M 18dB(A)"

Heat Sink Material Aluminum"

Weight 235g!

Sunon!

SLM 2000Lm gen 2 (TA003-10003) solution "

improved for use in track luminaires!

SLM 3000lm (TA004-10003)!

• Prototypes available!

• Limited engineering samples available "

end march 2011!

• MP release in April 2011!

SLM 1100Lm + SLM 1500Lm also to be released March April!

Page 24

Track and! !!Spotlight! !Spotlight ! !Spotlight ! !Spotlight ! !Spotlight ! !Spotlight ! !Spotlight ! !Spotlight"

Recessed! !!Cooler 38W !Cooler 34W !Cooler 34W !Cooler 34W !Cooler 31W !Cooler 31W !Cooler 31W !Cooler 21W"

Applications ! !Standard ! !High Performance !Mid Performance !Standard ! !High Performance !Mid Performance !Standard ! !Standard"

"

Fortimo LED SLM 1100 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ "

840, Tamb = 35°C"

Fortimo LED SLM 1100 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ "

835, Tamb = 35°C"

Fortimo LED SLM 1100 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !✓ "

830, Tamb = 35°C"

Fortimo LED SLM 2000 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !"

840, Tamb = 35°C"

Fortimo LED SLM 2000 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !"

835, Tamb = 35°C"

Fortimo LED SLM 2000 !✓ ! !✓ ! !✓ ! !✓ ! !✓ ! !"

830, Tamb = 35°C!

Nuventix!

• Solution for SLM 800Lm, 1100Lm and 1500Lm!

• Solution for SLM 2000Lm, 3000Lm recommended for open air applications,"

for track applications design-in guidelines of Nuventix to be followed to"

ensure performance, assess case by case!

Page 25

• Inlet vents can either be on back, sides or both"

"

• Exhaust vents can be on sides, front or both"

"

• Vents should be designed to allow maximum airflow "

into and out of the enclosure"

"

• T

room

is the temperature around the outside of the fixture "

far enough removed to not be impacted by fixture"

"

• T

local

is the temperature within the fixture near the nozzles "

and is higher in temperature than Troom"

"

• Enclosure should be designed to minimize the difference "

between T

room

and T

local!

SynJet

®

Airflow Basics"

Enclosure Guidelines!

• LED Module!

• Reflector!

• Exhaust Air!

• Tlocal!

• Intake Air!

• Exhaust Vent!

• Troom!

• Inlet Vent!

Page 26

Active solution!

Wisefull Technology Ltd.!

But also Passive!

P/N WF1006-16-24"

For Philips Fortimo LED SLM 1100Lm"

"

LED Power: 17W!

Thermal resistance: 1.584 °C/W "

Material: AL6063"

Weight: 417g!

Dimension: Ø 110mm x 65mm!

Finish: Black anodize!

!

Thermal solutions for Philips LED module!

!

Solutions for SLM 800lm, 1100lm and 1500lm"

"

Solution for SLM 2000lm only suitable in free air!

Page 27

Frigo Dynamics GmbH!

• Tested solution suitable for SLM 800lm, 1100lm and 1500lm in free air"

"

"

"

Please contact FrigoDynamics for commercial information!

Page 28

Contact information complementary partners 1/2"

Cooling solutions

Contact person for Europe!

Beatrice Tseng!

Phone: +31208932195!

Cell: +31 646688175!

E-mail: beatrice_tseng@avc.com.tw!

Contact person for N.A. & Asia"

Jeff Chou!

Phone: +86-21-50270508 ext. 68528!

Cell: +86 13916680014!

E-mail: jeff_chou@avc.com.cn!

Contact person for Europe"

Alipio Marques!

Phone: +33 146 154 494!

Cell: +33 616 795 314!

E-mail: alipio.marques@sunon.fr!!

Contact person for Asia"

Sandra Lin!

Phone: +886-7-813-5888 ext 1257!

Cell: +886-911-739-507!

E-mail: sandra@email.sunon.com.tw!

Contact person for Europe"

Francois Jaegle!

Phone: +33 624734646!

E-mail: fjaegle@nuventix.com!

Contact person for US"

Jeff Kelly!

Phone: +33 624734646!

E-mail: fjaegle@nuventix.com!

Headquarter AVC Kaohsiung"

No.248-27, Hsin-Sheng Rd.,!

80672 Kaohsiung City, Taiwan!

Sunonwealth Electric Machine Industry Co.,"

Ltd !"

No.30, Lane 296 Shin-YaRoad,!

Chyan-JennDt., Kaohsiung 806,!

Ta i wa n !!

Corporate Headquarters Nuventix"

Worldwide Sales Office "

4635 Boston Lane"

Austin, Texas 78735!

USA !!

Page 29

Contact information complementary partners 2/2"

Cooling solutions

Contact person!

Wilson Peng!

No. 3, Hong-Yeh South 9thRd. "

Hong-Yeh138 Industrial Park, Tang Xia Town, "

Dongguan City, Guangdong Province, P.R. China!

Email: weihua@wisefull.com"

!

Tel: (86)76987725315~6 Ext: 678!

Fax: (86) 76986853535!

Mobile: (86)13926896210!

Wisefull!

www.wisefull.com!

Wisefull Technology Ltd. –"

Your Reliable Thermal Partner!

Contact person!

Hans Kunstwadl!

Email: h.kunstwadl@frigodynamics.com!

Tel:+49-8121-973730!

Fax: +49-8121-973731!

Mob: +49-171-6505418!

Frigo Dynamics GmbH!

Bahnhofstr. 16!

D-85570 Markt-Schwaben!

Germany!

Page 30

Loading...

Loading...