Page 1

Colour Television Chassis

TES2.0E

LA

H_17490_000.eps

291007

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 12

6. Block Diagrams, Test Point Overviews, and

Waveforms

Block Diagram Main 13

Block Diagram ASSOS Chassis 14

Block Diagram Board Location 15

7. Circuit Diagrams and PWB Layouts Diagram PWB

Power Supply Panel (A)16 17

Main Board: HDMI & DVI-I Input (B1) 18 26

Main Board: DVD & DTT Input (B2) 19 26

Main Board: Scaler MST96889LD (B3) 20 26

Main Board: SCART Input (B4) 21 26

Main Board: LVDS Output (B5) 22 26

Main Board: Audio Amplifier & MUX (B6) 23 26

Main Board: Tuner & AV (B7) 24 26

Main Board: Power (B8) 25 26

Side I/O Panel (D) 27 (NA)

Keyboard & Control Panel (E) 27 (NA)

IR & LED Panel (J) 28 (NA)

8. Alignments 29

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 30

Abbreviation List 30

IC Data Sheets 31

10. Spare Parts List 39

11. Revision List 40

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JH 0771 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17491

Page 2

EN 2 TES2.0E LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 32" (82 cm), 16 : 9

: 42" (107 cm), 16 : 9

Resolution : 1366 × 768p

Viewing angle : 176 / 176

Brightness : 500 cd/m

Contrast ratio : 2000 : 1

Response time : 8 ms

Tuning system : PLL

TV Colour systems : PAL B/G, D/K, I

: SECAM B/G, D/K, L/L’

: DVB-T

Video playback : NTSC, SECAM, PAL

Presets/channels : 99 presets

Tuner bands : VHF

: UHF

: Hyper-band (S1-S41)

1.1.2 Sound

Sound systems : A2/NICAM/

A2+NICAM

Sound effects : SRS TrusurroundXT

®

: 3D Mono

: 3D Stereo

Maximum power (W

):2 × 12

RMS

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

- Mains frequency (Hz) : 50 - 60

) : 175 - 265

AC

Ambient conditions:

2

- Temperature range (°C) : 5 to +40

- Maximum humidity : 99% R.H.

Power consumption (values are indicative):

- Normal operation (W) : 155 (32"), 229 (42")

- Stand-by (W) : < 1

Dimensions incl. stand (W × H × D, in mm):

- 32PFL2302/62 : 827 × 597 × 100

- 42PFL2302/62 : 1135 × 800 × 101

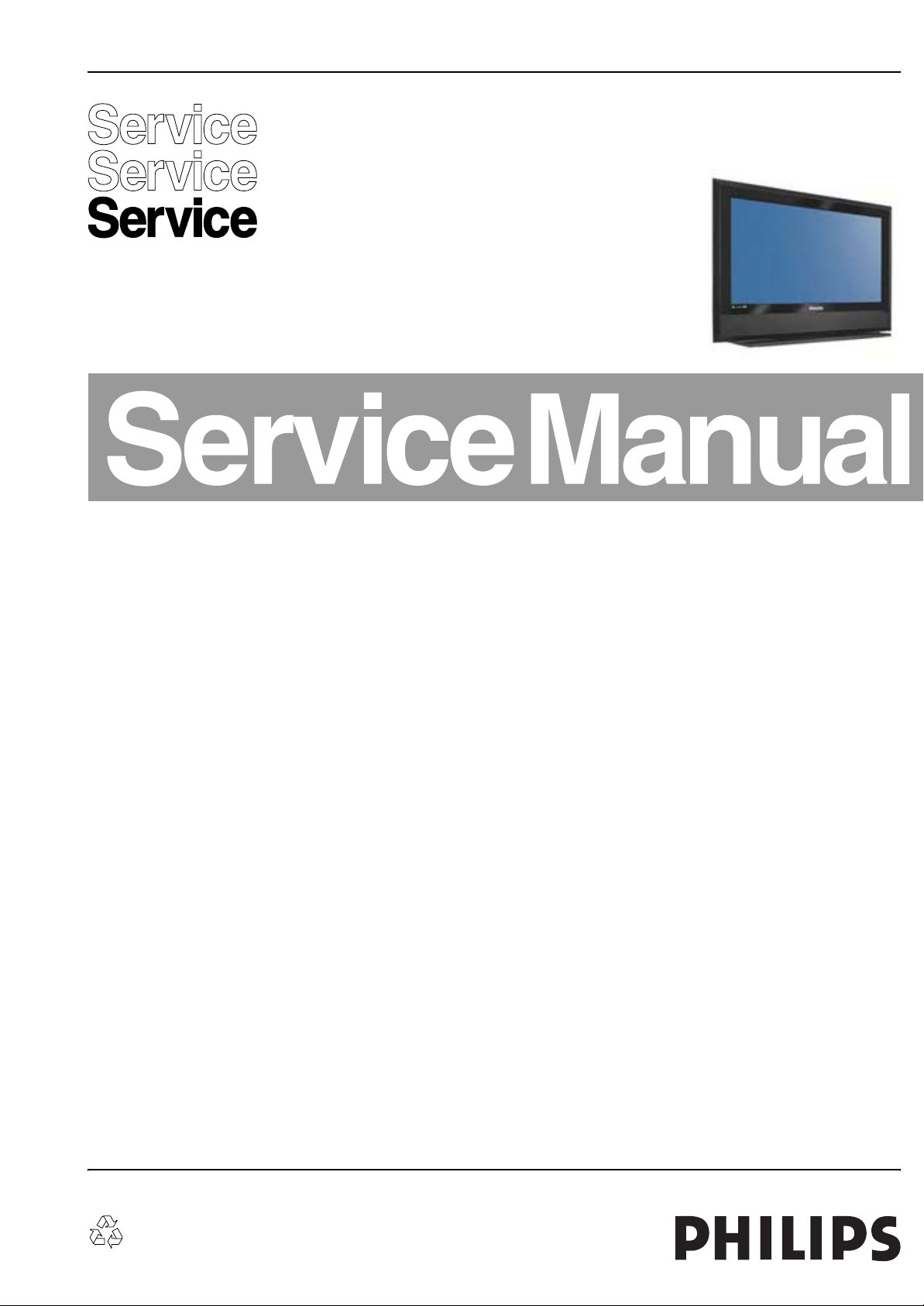

1.2 Connection Overview

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

Figure 1-1 Connection overview

H_17490_010.eps

291007

1.2.1 Side Connections

Mini Jack: Audio Head phone - Out

Bk - Head phone 32 - 600 ohm / 10 mW ot

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3TES2.0E LA 1.

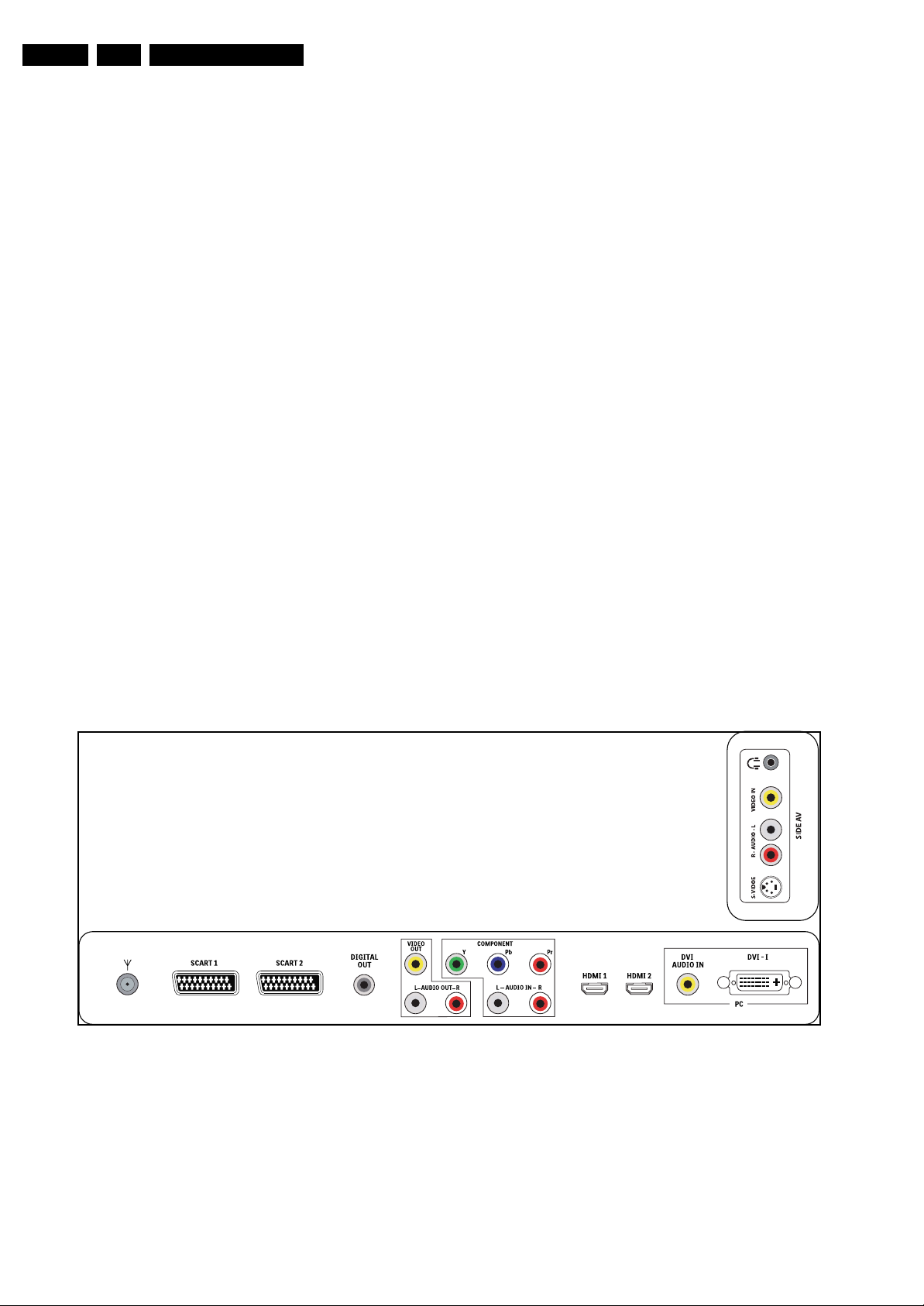

1.2.2 Rear Connections

Aerial - In

- - IEC-type Coax, 75 ohm D

EXT1: AV + RGB

21

20

E_06532_001.eps

2

1

050404

Figure 1-2 SCART connector EXT1

1 - Audio R 0.5 V

2 - Audio R 0.5 V

3 - Audio L 0.5 V

4 - Ground Gnd (audio) H

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

5 - Ground Gnd H

6 - Audio L 0.5 V

7 - Video Blue 0.7 V

8 - Function Select 0 - 2 V: INT

/ 10 kohm j

RMS

/ 75 ohm j

PP

4.5 - 12 V: EXT 4:3 j

9 - Ground Gnd H

10 - Res. Clock signals

11 - Video Green 0.7 V

12 - Res. Remote control

/ 75 ohm j

PP

13 - Ground Gnd H

14 - Ground Gnd (switch RGB) H

15 - Video Red 0.7 V

16 - Switch RGB j

/ 75 ohm j

PP

17 - Ground Gnd (video) H

18 - Ground Gnd (video out) H

19 - Video out 1 V

20 - Video in 1 V

21 - Shield Gnd H

/ 75 ohm k

PP

/ 75 ohm j

PP

EXT2: AV + S-Video

1 - Audio R 0.5 V

2 - Audio R 0.5 V

3 - Audio L 0.5 V

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

4 - Ground Gnd (audio) H

5 - Ground Gnd H

6 - Audio L 0.5 V

7 - Video Blue 0.7 V

8 - Function Select 0 - 2 V: INT

/ 10 kohm j

RMS

/ 75 ohm j

PP

4.5 - 12 V: EXT 4:3 j

9 - Ground Gnd H

10 - Res. Clock signals

11 - Video Green 0.7 V

/ 75 ohm j

PP

12 - Res. Remote control

13 - Ground Gnd H

14 - Ground Gnd (switch RGB) H

15 - Video Red 0.7 V

16 - Switch RGB j

/ 75 ohm j

PP

17 - Ground Gnd (video) H

18 - Ground Gnd (video out) H

19 - Video out 1 V

20 - Video in 1 V

/ 75 ohm k

PP

/ 75 ohm j

PP

21 - Shield Gnd H

Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

Cinch: Video CVBS - Out, Audio - Out

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm kq

PP

/10 kohm kq

RMS

/ 10 kohm kq

RMS

Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

/ 75 ohm jq

PP

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

PC: Mini Jack: PC/DVI Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

PC: DVI-I: Digital/Analogue Video - In

1 8

916

17

C1 C2

C5

24

C3 C4

E_06532_004.eps

050404

Figure 1-4 DVI-I connector

1-D2- j

2-D2+ j

3 - Shield Gnd H

4-D4- j

5-D4+ j

6 - DDC_SCL DDC clock k

7 - DDC_SDA DDC data jk

8 - V-sync 0 - 5 V j

9-D1- j

10 - D1+ j

11 - Shield Gnd H

12 - D3- j

13 - D3+ j

14 - +5V j

15 - Ground Gnd H

16 - HPD Hot Plug Detect j

17 - D0- j

18 - D0+ j

19 - Shield Gnd H

20 - D5- j

21 - D5+ j

22 - Shield Gnd H

23 - CLK+ j

24 - CLK- j

C1 - Video Red 0.7 V

C2 - Video Green 0.7 V

C3 - Video Blue 0.7 V

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

C4 - H-sync 0 - 5 V j

Page 4

EN 4 TES2.0E LA1.

C5 - Ground Gnd H

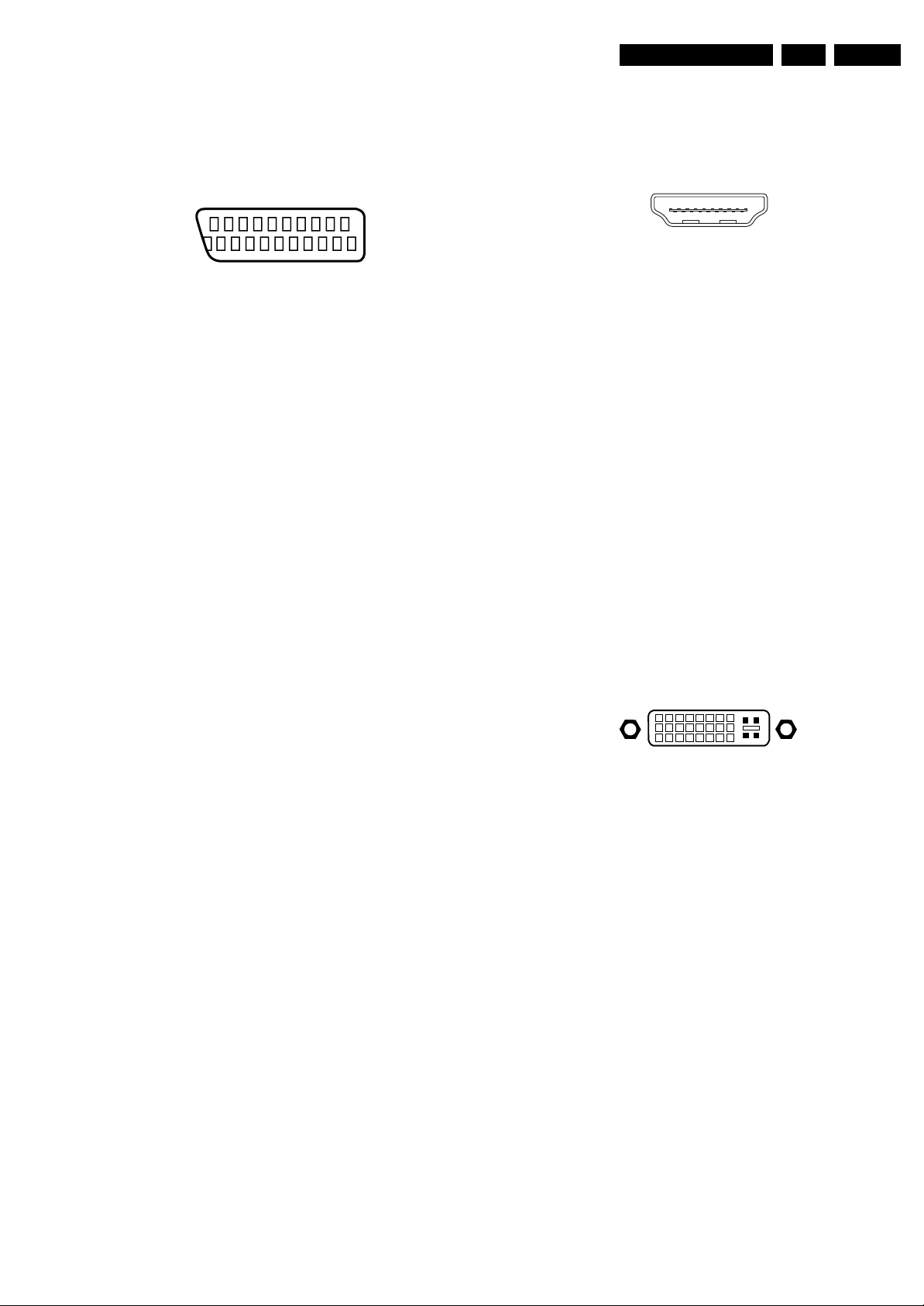

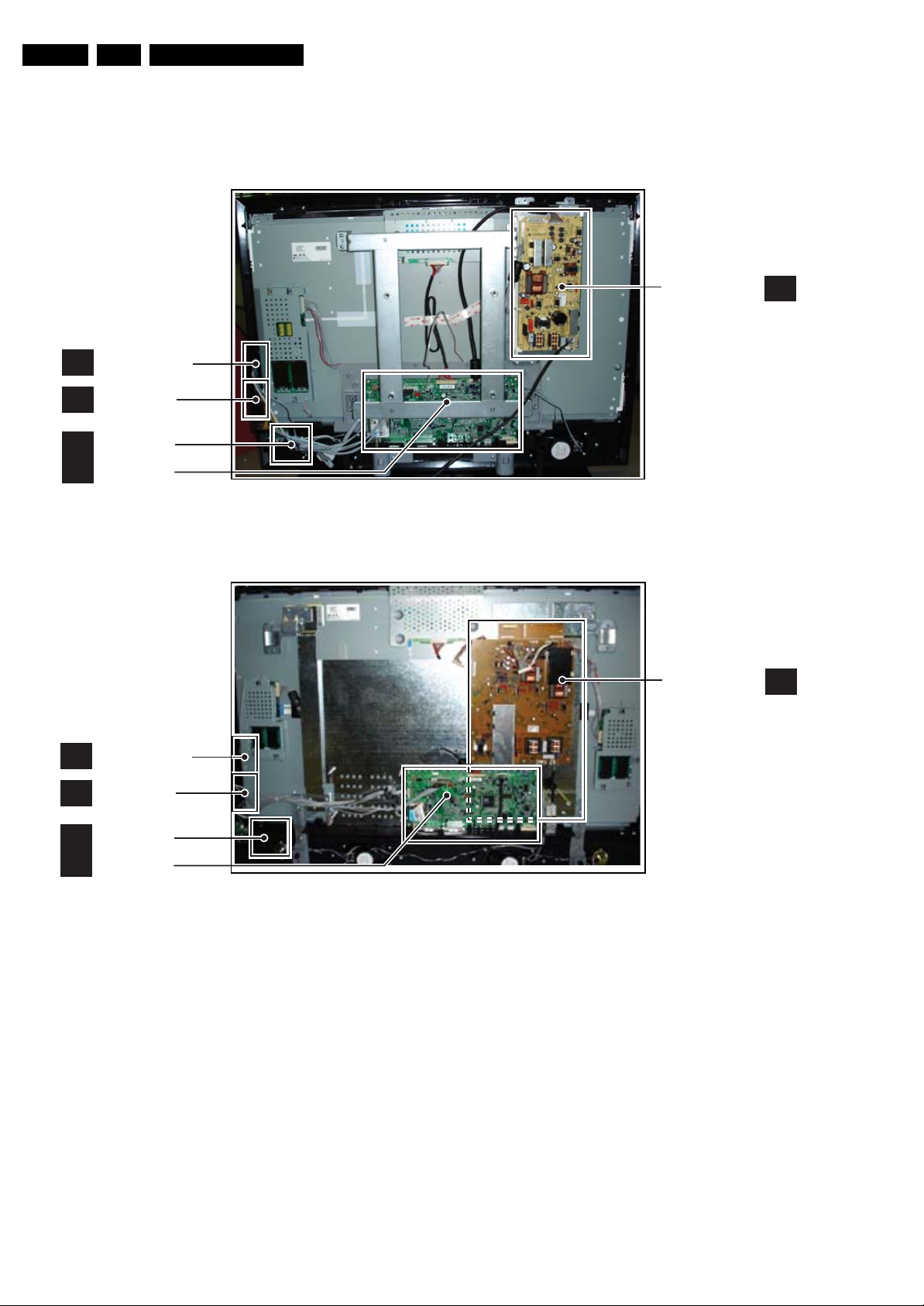

1.3 Chassis Overview

Technical Specifications, Connections, and Chassis Overview

CONTROL BOARD

E

SIDE I/O PANEL

D

LED PANEL

J

MAIN BOARD

B

(incl ext. I/O)

Figure 1-5 PWB locations 32"

H_17490_012.eps

291007

POWER SUPPLY

BOARD

POWER SUPPLY

BOARD

A

A

CONTROL BOARD

E

SIDE I/O PANEL

D

LED PANEL

J

MAIN BOARD

B

(incl ext. I/O)

Figure 1-6 PWB locations 42"

H_17490_014.eps

291007

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5TES2.0E LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= × 10

nano-farads (n= × 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

-9

), or pico-farads (p= × 10

-12

-6

),

).

Page 6

EN 6 TES2.0E LA3.

Directions for Use

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

E_06532_024.eps

128W

130606

Page 7

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.2 Set Dis-assembly

4.3 Set Re-assembly

4.1 Cable Dressing

Mechanical Instructions

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

EN 7TES2.0E LA 4.

Figure 4-1 Cable Dressing 32" sets

H_17490_011.eps

291007

Page 8

EN 8 TES2.0E LA4.

Mechanical Instructions

4.2 Set Dis-assembly

Following figures (“exploded view”) indicate the mechanical

construction of the sets.

Figure 4-2 Cable Dressing 42" sets

H_17490_013.eps

291007

Page 9

Mechanical Instructions

EN 9TES2.0E LA 4.

291007

H_17490_015.eps

Figure 4-3 Exploded View 32" sets

Page 10

EN 10 TES2.0E LA4.

Mechanical Instructions

291007

H_17490_016.eps

Figure 4-4 Exploded View 42" sets

Page 11

4.3 Set Re-assembly

Note:

While re-assembling, make sure that all cables are placed and

connected in their original position. See figures “Cable

dressing”.

Mechanical Instructions

EN 11TES2.0E LA 4.

Page 12

EN 12 TES2.0E LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Service Mode

5.2 Error Codes

5.3 Fault Finding and Repair Tips

5.1 Service Mode

The Service Mode is activated by pressing ‘1923’ on the

Remote Control, while the set is in the Main User Menu.

The software provides menu flexibility and full control to the

software. Service persons can adjust the TV in all manners. In

the Service Menu (see chapter 8), you find a list of parameters.

All functions of the Service Mode, and the default parameter

settings, are listed in Chapter “Alignments”.

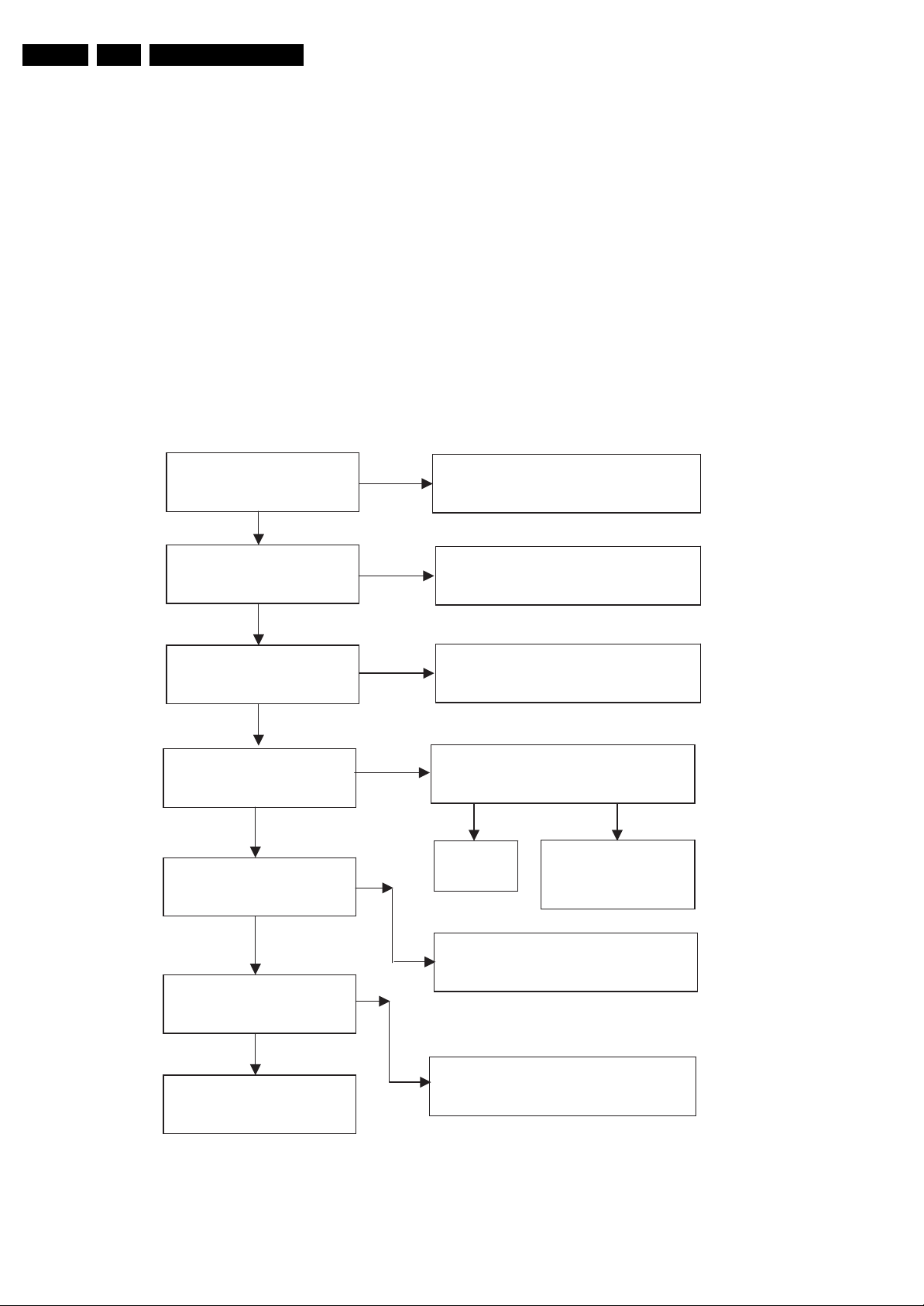

FAULT TRACING DIAGRAM FOR POWER SUPPLY

Check 220 V AC Mains

YES

Check C 020 Voltage

NO

NO

5.2 Error Codes

These sets do not generate Error Codes.

5.3 Fault Finding and Repair Tips

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options

are set.

• The Service Menu (see chapter 8), contains some useful

tests, that generates patterns.

Check AC Power Cable is Plugged

Check X102 Fuse

YES

Check 5VSTBY

YES

Check 5V_OFF

YES

Check 24V,33V,12V

8V

YES

Check 3.3V,2.5V and 1.8V

YES

NO

NO

NO

NO

Check T530 and Peripheral

Components

Check P_CTRL Pin

LOW HIGH

StandBy

Mode

Normal Mode

Check Components

For 5V

Check Related Components for

Defective Outputs

POWER IS OK

Check Related Components

Figure 5-1 Fault finding power supply

H_17490_017.eps

291007

Page 13

Block Diagrams, Test Point Overviews, and Waveforms

6. Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram Main

EN 13TES2.0E LA 6.

H_17490_018.eps

291007

Page 14

Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram ASSOS Chassis

220 V AC

POWER BOARD

EN 14TES2.0E LA 6.

IDTV CHASSIS DIAGRAM

24 V

S300

CN16

CN15

CN17

CN19

*

*

*

*

5V

5V STD

12V

STD BY

Back light On/Off

Back light Dimm

CN7

MAIN BOARD ASSOS

CN20 CN21

CN5

Speaker

CN4

CN18

LVDS

J7

Dyn. Cont.

CN24

24 V

Back light Dimm

LCD

PANEL

Back light On/Off

*

Service

IR

MULTI

BUTTON

CN15-16-17-19 are for optional DVB connections

SIDE

AV

H_17490_019.eps

291007

Page 15

Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram Board Location

EN 15TES2.0E LA 6.

CN12

CN20

CN21

CN15

CN11

CN13

CN17

CN16

CN9 CN8

CN18 (CN22)

CN19

J7

J10

CN7

CN4

CN5

TUNER

SCART1 SCART2

SPDIF

OUT

LINE OUT

COMPONENT INPUT

HDMI1

HDMI2

PC

SOUND

DVI

H_17490_020.eps

291007

Page 16

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Power Supply Panel

1

POWER SUPPLY PANEL

A A

D

C

B

A

12

S303

POWER

2

HS33

SMPS HEATSINK

1

TP56

2

1

F300

T3.15AL/250V

2

TP57

C308

100nF 275VAC

HS34

SMPS HEATSINK

1

TP58

VR30

V320

3

2

1

23

L800

2X27mH

R300

8.2K

100nF 275VAC

L310

4

23

C357

TP59

1

TP60

2X27mH

J304

TP130

R400

C400

8.2K

10pF

J317

3

TP1

R301

56K

IC30

1

NC

2

PCS

3

RZI

TP2

4

SRC

TP3

4

TP131

100nF 275VAC

R402

56K

J302

ICE1QS01

TP4

C302

330pF

TP61

C337

TP62

IC40

1

NC

2

PCS

TP132

3

RZI

SRC4OFC

ICE1QS01

R403

J316

1M

TP133

C403

330pF

C301

C300

47nF

10pF

C401

100nF

EN 16TES2.0E LA 7.

TP26

D302

MBR20200CT

TP27

T301

BC848B

TP73

TP116

MBR20200CT

TP141

T400

BC848B

F301

TP29

5VSTBY

TP74

TP75

STPS5L40

TP117

R201

1K

TP118

D404

5VOC

D320

5.1V

TP142

76

R308

100R

R309

100R

5A

D305

MBR1045

TP78

D304

BAT85

TP79

R344

47R

TP76

R314

1K

R315

470R

J308

R317

1K

TP77

R326

1K

D200

C210

470uF/35V

R202

470R

D202

TL431

R412

10R

TP119

R413

10R

TP144

R416

1K

R417

470R

D403

TL431

R414

1K

TP143 TP147

R415

1K

TP35

5VMAIN

TP80

J310 J318J306

TP145

TP37

C305

220pF

TP30

C303

220pF

R320

100R

D310

MBR1045

D306

BAT85

R345

47R

C359

100nF

D303

TL431

TP81

TP82

C204

100nF

C207

47pF

TP120

TP121

TP146

C408

100nF

STB

J328 J326

TP34 TP38

C314

C329

100nF

2200uF/25V

TP31TP28

C336

220pF

1000uF/16V

TP32

R310

C330

12K

C343

10uF

TP83TP72

C342

47pF

TP85

R321

33K

STB

R346

3.3K

TP84 TP86

T302

BC848B

R203

1K

L200

J320

20uH 2.5A

C211

470uF/16V

TP122

C208

R200

15nF

2.4K 1%

TP123

R205

33K

TP126

R337

2.4K 1%

C416

1nF 1KV

TP124

C417

1nF 1KV

C414

2200uF/35V

C421

10uF

J323

C418

C419

47pF

15nF

R418

33K

TP148

J325

54

R304

R305

150K

150K

Q300

TP10

BC337

J315

TP7

10uF/25V

C356

C317

100nF

D318

C345

33pF

8

VCC

7

OUT

TP6

6

GND

TP8

J307

5

OFC

R302

1M

3

4

TP5

L311

PFC

1

6

TP63

TP100

C304

22pF

8

VCC

7

OUT

TP134

6

GND

TP135

5

2.4V

TP11

D315

12V

R306

100R

D300

R307

33R

TP9

1N4148

C306

10pF

TP12

C320

1nF/1KV

4

C321

1nF/1KV

23

TP64

R332

R316

150K

150K

TP101 TP111

10uF/25V

C360

C335

100nF

D319

2.4V

TP102

D317

12V

R404

100R

D400

R405

33R

TP137

TP136

1N4148

TP18

R333

TP19

4.7K

TP14

TP15

R339

4.7K

Q302

BC848B

23

1

TP13

TP16

J313

C318

IC36

1nF/1KV

C319

RS406

1nF/1KV

Q301

BC337

TP103

TP104

Q303

BC848B

23

1

C307

10pF

T300

SPP07N60

TP17

1

TP65

TP105

R334

4.7K

R340

TP109

T401

SPP07N60

33nF/630V

J303

R319

D325

1.2M

1N4007

J300

J301

D326

1N4007

R343

1.2M

4.7K

L305

BEAD

L306

BEAD

C411

TP20

R341

270R

TP21

L304

BEAD

L301

BEAD

TP22

TP23

TP66

100uF/400V

VB3

TP107

TP108

R342

270R

TP139 TP140

D321

33V

D322

12V

D308

BYW76

R329

68K 1W

VB

C324

270uF/400V

TP110

7

8

D

VST

GND1GND2GND3VFB

C362

D323

33V

D324

8.2V

D402

BYW76

TP138

R410

68K 1W

C404

8.2nF 400V

C341

33nF 630V

R204

68K 1W

5

VCC

4

C413

680pF 2000V

C322

47uF/50V

IC21

FSD200

C203

100nF

47uF/50V

D301

BYV36C

L302

BEAD

C325

680pF 2000V

L303

BEAD

C328

8.2nF 400V

2.2nF 400VAC

TP112

TP113

C410

L400

BEAD

L401

BEAD

D401

BYV36C

C202

D201

BYV36C

C213

33uF

J319Comment

J305

J311

TP24

J314

TP25

VB2

C361

8.2nF 400V

TP114TP106

TP115

C402

8.2nF 400V

J312

TP67

TP68

TR30

6

5

3

1

SMPS LCD MAIN

IC37

6

5

4

1nF 400VAC

1nF 400VAC

TP69 TP71

2.2nF 400VAC

TR20

4

1

SMPS STANDBY LCD

IC20

6

5

4

TCDT1101G

TR40

3

4

1

6

SMPS LCD BL

IC41

6

5

4

TCDT1101G

6

5

TCDT1101G

R303

4.7M 1/2W

C206

1nF 400VAC

6

5

4

6

5

15

13

16

13

14

12

9

11

10

11

5VOC

1

1

2

2

334

C338

TP70

C339

C340

GND

6

10

1

1

2

2

3

3

11

7

12

8

1

1

2

2

334

4567

1000uF 16V

C344

15nF

J322

STDBY

R347

33K

5VSTBY

TP125

R419

30K 1%

L307

20uH 2.5A

C948

TP87

100nF

C200

47nF

8

12V

R327

2.2K

C334

1000uF/16V

C347

100nF

5VMAIN

C316

100nF

1

FD1 FD2 FD3

J324

C332

1000uF/25V

J309

OPS.

TP41

C312

100nF

HS30

2

POWER HEATSINK

1

C354

C351

1000uF/25V

100nF/50V

L308

10uH 7A

TP36

C315

100nF

TP88

R322

5.6K 1%

TP89

R330

22K 1%

C205

R331

C358

4.7K 1%

47nF

R336

1K 1%

109

HS32

POWER HEATSINK

2

HS35

POWER HEATSINK

1

2

1

2

5VMAIN

5VSTBY

STDBY

TP43

12V

A_DIM

BL_ON/OFF

J330

12V

5VMAIN

TP50

J331

J329

BL_ON/OFF

11

S300

1

2

3

4

5

6

7

8

9

10

11

12

POWER

24V

1

TP53

2

3

4

5

BGND

6

7

TP92

8

9

10

11

TP93

12

13

14

A_DIM

TP95

4

3

2

1

24V

S305

TP55

TP96

TP97

TP98

TP99

CON14

S301

CON4

12

D

S302

1

2

3

4

5

6

7

8

9

10

CON10_W

C

B

5VOC

TP127

D309

1N4148

TP128

R335

24V

2.7K

L402

10uH 7A

C405

100nF

TP129

470uF/35V

J327

C420

C406

100nF

24V

TP149

C409

47nF

R338

3.4K 1%

H_17490_021.eps

8

910

2111

A

161007

Page 17

Circuit Diagrams and PWB Layouts

EN 17TES2.0E LA 7.

Layout Power Supply Panel (Top Side)

Layout Power Supply Panel (Top Side)

H_17490_022.eps

161007

H_17490_023.eps

161007

Page 18

Circuit Diagrams and PWB Layouts

EN 18TES2.0E LA 7.

Main Board: HDMI & DVI-I Input

5

4

3

2

1

HDMI & DVI-I INPUT

CN14

SHELL1

NC1

DATA2DATA2+

DATA2/4_SHLD

DATA4DATA4+

DDC_CLK

DDC_DATA

A_VSYNC

DATA1DATA1+

DATA1/3_SHLD

DATA3-

DATA3+

H_PLUG_DET

DATA0DATA0+

DATA0/5_SHLD

DATA5DATA5+

CLK_SHLD

A_RED

A_GREEN

A_BLUE

A_HSYNC

A_GND1

A_GND2

NC2

SHELL2

DVI_AD_CON

GND

CLK+

CLK-

VSS5

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

+5V

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

B1 B1

D D

C C

33

34

HDMI 1

GND

202122

23

J2

T1T2T3

T4

19

HPDET

18

+5V

17

CEC/GND

16

SDA

15

SCL

14

NC

13

CEC

12

CLK-

11

CLKS

10

CLK+

9

DATA0-

8

DATA0S

7

DATA0+

6

DATA1-

5

DATA1S

4

DATA1+

3

DATA2-

2

DATA2S

1

DATA2+

HDMI_CONN_RA

B B

R561 0R

HDMI2HDMI1

VSS5

HDMI2

GND

202122

23

J3

T1T2T3

T4

19

HPDET

18

+5V

17

CEC/GND

16

SDA

15

SCL

14

NC

13

CEC

12

CLK-

11

CLKS

10

CLK+

9

DATA0-

8

DATA0S

7

DATA0+

6

DATA1-

5

DATA1S

4

DATA1+

3

DATA2-

2

DATA2S

1

A A

DATA2+

HDMI_CONN_RA

VSS5

HDMI1

D11

BAV70

2

1

D2

BAV70

2

1

C24

10uF_2012

R20 1K

D3

BAV70

2

1

C27

10uF_2012

R341K

HDMI2

R466

1K

3

R468

R467

C376

C377

10uF_2012

100nF

3

3

C28

100nF

10K

R475 100

R476 100

R15

47K

C25

100nF

R30

47K

10K

R469 0R

12

R470 0R

12

R471 100

R472 100

R16

47K

R17 0R

R19 0R

C43 22pF(NU)

C44 22pF(NU)

R31

47K

R320R

R33 0R

C47 22pF(NU)

C48 22pF(NU)

U29

6 8

SCL VCC

5

SDA

1

A0

2

A1

3

A2

24C02

DVI_RX2DVI_RX2+

C448 22pF(NU)

C449 22pF(NU)

DVI_DDC_CLK

DVI_DDC_DATA

DVI_RX1DVI_RX1+

DVI_HPD

DVI_RX0DVI_RX0+

DVI_RXC+

DVI_RXC-

HS_MST4

VS_MST4

232_RXD 8

232_TXD 8

U4

6 8

SCL VCC

5

SDA

1

A0

A1

A2

24C02

U5

SCL VCC

SDA

A0

A1

A2

GND

24C02

HDMI_DDC_DATA_2

HDMI_DDC_CLK_2

WP

GND

HDMI1_HPD

HDMI_DDC_DATA_1

HDMI_DDC_CLK_1

WP

HDMI2_HPD

HDMI_RXC-_2

HDMI_RXC+_2

HDMI_RX0-_2

HDMI_RX0+_2

HDMI_RX1-_2

HDMI_RX1+_2

HDMI_RX2-_2

HDMI_RX2+_2

2

3

6 8

5

1

2

3

7

WP

4

GND

7

4

HDMI_RXC-_1

HDMI_RXC+_1

HDMI_RX0-_1

HDMI_RX0+_1

HDMI_RX1-_1

HDMI_RX1+_1

HDMI_RX2-_1

HDMI_RX2+_1

7

4

C29

100nF

C378

100nF

C379

10pF

C380

10pF

C381

10pF

C26

100nF

12

R473

75_1%

12

R474

75_1%

12

R477

75_1%

VGA_B 4

DVI_HPD

MMBT3904

HDMI2_HPD

MMBT3904

HDMI1_HPD

MMBT3904

VGA_R 4

VGA_G 4

Q30

Q31

Q32

J1

PHONE_JACK

PC_L

R1

R2

GND

PC_R

R564 5.1K(NU)

32

1

R565 5.1K(NU)

32

1

R566 5.1K(NU)

32

1

3

L1

4

L2

2

5

1

DVI_RX2+

DVI_RX2DVI_RX1+

DVI_RX1DVI_RX0+

DVI_RX0DVI_RXC+

DVI_RXC-

HDMI_RX2+_2

HDMI_RX2-_2

HDMI_RX1+_2

HDMI_RX1-_2

HDMI_RX0+_2

HDMI_RX0-_2

HDMI_RXC+_2

HDMI_RXC-_2

HDMI_RX2+_1

HDMI_RX2-_1

HDMI_RX1+_1

HDMI_RX1-_1

HDMI_RX0+_1

HDMI_RX0-_1

HDMI_RXC+_1

HDMI_RXC-_1

HPD1

HPD2

HPD3

DVI_DDC_CLK

DVI_DDC_DATA

HDMI_DDC_CLK_2

HDMI_DDC_DATA_2

HDMI_DDC_CLK_1

HDMI_DDC_DATA_1

ED3

BAV99(NU)

R567 15K

R568 15K

R569

0

R570

0

R571

0

2

3

HPD1

HPD2

HPD3

ED4

1

BAV99(NU)

HDMI_MUX

VSS_M3V :

190mA

U3

15

A14

14

B14

12

A13

11

B13

9

A12

8

B12

6

A11

5

B11

77

A24

76

B24

74

A23

73

B23

71

A22

70

B22

68

A21

67

B21

58

A34

57

B34

55

A33

54

B33

52

A32

51

B32

49

A31

48

B31

80

HPD1

62

HPD2

44

HPD3

3

SCL1

2

SDA1

64

SCL2

63

SDA2

46

SCL3

45

SDA3

2

1

3

NC

NC

20161

ED1

BAV99(NU)

1

12

12

NC

NC

41

60

3

R6

220K

R8

220K

7

VCC

2

13

VCC

VSS_M3V

17

27

VCC

GND

4

10

ED2

BAV99(NU)

3

2

1

C5

1nF

C6

1nF

33

43

50

VCC

VCC

VCC

TMDS341A

GND

GND

GND

24

30

VCC

GND

56

VCC

GND

36

69

61

VCC

VCC

GND

GND

37

47

PC/DVI_L_IN 8

PC/DVI_R_IN 8

79

75

VCC

VCC

GND

GND

GND

GND

53

59

66

65

S5VESD5V

U1

AP1117_3.3V-SOT223(NU)

3

VSS_M3V

12

C8

+

100nF

Output

de-emphass.

(VSADJ)

high : 3dB

low : 0dB

HDMI_RX2+ 4

HDMI_RX2- 4

HDMI_RX1+ 4

HDMI_RX1- 4

HDMI_RX0+ 4

HDMI_RX0- 4

HDMI_RXC+ 4

HDMI_RXC- 4

HDMI_DDC_DATA 4

HDMI_DDC_CLK 4

R456 100K

R28 0R(NU)

Q1

1

MMBT3904

VI

C1

100nF(NU)

VS_3V

FB1

600 Ohm 0.5A 2012(NU)

C7

100uF/16V

VSS_M3VA3.3V

FB63

600 Ohm 0.5A 2012

VSS_M3V

R18 4.64K_1%

18

VSADJ

19

PRE

25

Y4

26

Z4

28

Y3

29

Z3

31

Y2

32

Z2

34

Y1

35

Z1

39

SDA_SINK

38

SCL_SINK

40

HPD_SINK

21

S1

22

S2

23

S3

42

OE

GND

GND

78

72

R27

32

0R

2

VO

4

TAB

GND

1

100uF/16V(NU)

C10

C11

C9

10nF

10nF

10nF

R14 0RR13 10K

TMDS MUX OPTION(R18)

TI 4.64K(F grade)

PARADE 4.11K(F grade)

VSS_M3V

R454 47K(NU)

R455 47K(NU)

VSS_M3V

HPD_SINK 4

C3

C12

10nF

VSS_M3V

R21 4.7K(NU)

R22 4.7K(NU)

R23 4.7K(NU)

+

12

C13

10nF

VS_3V

C4

100nF(NU)

C14

10nF

DVI_ SEL 4

HDMI2_SEL 4

HDMI1_SEL 4

C15

10nF

C16

10nF

C17

10nF

C18

10nF

C19

10nF

H_17490_001.eps

5

4

3

2

1

161007

Page 19

Circuit Diagrams and PWB Layouts

EN 19TES2.0E LA 7.

Main Board: DVD & DTT Input

5

E

SD5V

2

3

1

3

2

1

BAV99(NU)

5VD

5VD

ED14

ED9

BAV99

R405

3.6K

R407

4.7K

R414

3.6K

R416

4.7K

ED6

BAV99

2

1

3

1

2

3

3

2

ED11

BAV99(NU)

1

1

R406

R410

MMBT3904

R415

R419

MMBT3904

2

BAV99

1

3

2

1

ED12

BAV99(NU)

3

2

82

82

1

Q25

82

82

1

Q27

ED8

BAV99

ESD5V

ED13

BAV99(NU)

C41

1nF

C42

1nF

AV_OUT 5

2

ED5

BAV99

1

3

B2

DVD & DTT INPUT

J4B UJB-04-13A

5

D D

C C

B B

3

J5A UJB-04-13A

3

J5B UJB-04-13A

3

J5C UJB-04-13A

6

J5D UJB-04-13A

6

J4A UJB-04-13A

3

J4C UJB-04-13A

6

J4D UJB-04-13A

6

2

C35

10pF

5

C40

10pF

1

4

BAV99

C50

+

220uF/16V

2

1

4

C32

10pF

R572

15K

R575

15K

A9V

ED15

M_L_OUT8

LINE_OUT_LA4

AV_OUT_L

AV_OUT_R

12

2

1

3

12

R37

75_1%

R40

75_1%

12

R41

75_1%

12

R45

220K

12

R46

220K

R53 75R

R428 0R ED68

R429 0R(NU)

PIP OPTION.

PIP OPTION.

M_R_OUT8

LINE_OUT_RA4

A A

R4300R

R431 0R(NU)

ED7

3

ED10

BAV99

3

2

1

MMBT3904

32

MMBT3904

32

1

Q24

R412

270

1

Q26

R421

270

4

MST_Y 4

MST_Pb/Cb 4

MST_Pr/Cr 4

DVD_L_IN 8

DVD_R_IN 8

32

R409

270

R411

470

32

R418

270

R420

470

HH1

MTHOLE

R408

470

1

2

C347

10uF_2012

1

2

R417

470

1

2

C350

10uF_2012

1

2

1

2

3

4

5

6

7

8

9

FM1

FM5

C346

10uF_2012

ED61

BAV99

ED63

BAV99

C349

10uF_2012

ED65

BAV99

ED67

BAV99

FM2

FM6

HH2

MTHOLE

FM3

FM7

1

3

1

3

1

3

1

3

FM4

FM8

3

3

3

3

3

HH4

HH3

1

2

3

4

5

6

7

8

9

MTHOLE

FM9

FM10

ED60

BAV99

2

ESD5V

ED62

BAV99

ESD5V

2

ED64

BAV99

2

ESD5V

ED66

BAV99

ESD5V

2

1

2

3

4

5

6

7

8

9

R413

1M

R422

1M

FM11

MTHOLE

FM12

C348

1nF

C351

1nF

1

2

3

4

5

6

7

8

9

HH5

HH6

12

R42 0R

R43 0R

R573

0(NU)

R574

0(NU)

VSS5

R484 470R(NU)

32

Q29

1

KSC1623

C452 10uF_2012

C453 10uF_2012

C454 10uF_2012

C455 10uF_2012

SPDIF_OPT

R482

4.7K

HS_L_OUT 5

AV_OUT_L

HS_R_OUT 5

AV_OUT_R

HDMI_SPDIF_OUT4

D_IR6

SVHS_YS8

SVHS_YD

SVHS_CS8

SVHS_CD

DVB_ SPDIF

R4810R

IR_MUTE4

R486 3.3K

SVHS_CS

C382 56pF

3

BAV99

R35

0R(NU)

R573, R574

Analog Tuner

only option.

1

2

2

2

3

5

6

11

10

12

12

SVHS_YSVHS_YS

SVHS_C

1

DVB_AUD_R4

DVB_AUD_L4

TV_MUTE4

SVHS_YD

SVHS_CD

14

13

R4800R

R483

100R(NU

32

Q28

KSC1623(NU)

R485

0R(NU)

R487

4.7K(NU)

DTT_CVBS4

TS5V330DR (SOIC-16)

U6

S1A

S2A

S1B

S2B

S1C

S2C

S1D

S2D

16

VCC

SW

SW

SW

SW

SW

SW

SW

SW

GND

8

DTT_INTERFACE_OPTION

DTT_DL_RX5

DTT_DL_TX5

C461

C462

22pF

22pF

1 2

IR_DVB

DVB_ON4

DVB_ PIP4

DVB_MENU_OPEN4

TV_MENU_OPEN4

R488 15K

R489 15K

DVB_AUD_R

DVB_AUD_L

DVB_TV_MUTE

DVB_ SPDIF

DTT_CVBS

SVHS_YD

SVHS_CD

R490 15K

R491 15K

FB60 600 Ohm 0.5A 2012

1 2

FB61 600 Ohm 0.5A 2012

1 2

12

C30

100nF

4

DA

7

DB

9

DC

12

DD

1

IN

15

EN

DVBT Download(

1) SPEAKER : BLUE ==> CN4

2) IDTV POWER : RED ==> CN19

3) IR : WHITE ==> CN20

4) IDTV DOWNLOAD : BLACK ==> CN15

R478 0R

R479 0R

1 2

FB67 UPB201209T-500Y-S

FB71 UPB201209T-500Y-S

FB68 UPB201209T-500Y-S

FB69 UPB201209T-500Y-S

C385 22pF

C384 22pF

C383 22pF

5VD

12

FB2

600 Ohm 0.5A 2012

12

C31

10uF/10V(2012)

SVHS_Y 4

SVHS_C 4

SPDIF_OPT

R44 100R

SVHS==>HIGH

DVBT==>LOW

C464

22pF

C465

22pF

C388 22pF

C387 22pF

C386 22pF

1 2

C389 22pF

C463

22pF

1 2

C466

22pF

1

1 2

C471

22pF

1 2

COMP_SEL 4

CN15

1

NC

2

RXD_DVB

3

TXD_DVB

4

GND

JST250-4P

1 2

CN17

1

AUD_R

2

GND

3

AUD_L

4

TV_MUTE

5

SPDIF

6

GND

7

CVBS

8

GND

9

Y

10

GND

11

C

12

GND

FLEX 12Pin

J11

BS-V13040Y

2

)

R593

0R

B2

1

CN16

1

IR_DVB

2

GND

3

DVB_ON

4

NC

5

DVB_MENU

6

TV_MENU

JST200-6P (2mm)

H_17490_002.eps

5

4

3

2

1

011107

Page 20

Circuit Diagrams and PWB Layouts

EN 20TES2.0E LA 7.

Main Board: Scaler MST96889LD

5

SCALER MST96889LD

B3 B3

<< HDMI_INP UT >>

HDMI_DDC_DATA2

HDMI_DDC_CLK2

HDMI_RXC-2

HDMI_RXC+2

HDMI_RX0-2

HDMI_RX0+2

HDMI_RX1-2

HDMI_RX1+2

HDMI_RX2-2

D D

HDMI_RX2+2

VGA_R2

VGA_G2

VGA_B2

HS_MST2

VS_MST2

R73 0R

R74 0R

<< PC_INPUT >>

R100

R101

2.2K

2.2K

R88

47R

R89

47R

R91

47R

R92

470

R94

47R

R96

47R

R97

47R

R98 100R

R99 100R

HDMI_SDA

HDMI_SCL

HDMI_TXCLKHDMI_TXCLK+

HDMI_TX0-

HDMI_TX0+

HDMI_TX1-

HDMI_TX1+

HDMI_TX2-

HDMI_TX2+

C71 47nF

C73 47nF

C75 47nF

C76 1nF

C81 47nF

C82 47nF

C83 47nF

S_RGB

H

VS_RGB

RIN+

GIN+

BIN+

SOG

RIN-

GIN-

BIN-

<< DVD_INP UT >>

R108 47R

C89 47nF

MST_Pr/Cr3

MST_Y3

MST_Pb/Cb3

C C

R113 47R

R116 47R

R117 470

R118 47R

R120 47R

R121 47R

<< SCART_INP UT >>

R125 47R

HS_R_C5

SCART_R_C5

SCART_G5

SCART_B5

FS_FB5

FS_ID5

HS_ID5

HS_FB5

R396 75R

R13175R

R133 75R

R13275R

C101 47nF

R126 47R

C102 47nF

C103 47nF

R127 47R

C104 47nF

R128 47R

R129 47R

C105 47nF

R13047R

C106 47nF

R13447R

C115 47nF

C92 47nF

C93 47nF

C94 1nF

C95 47nF

C96 47nF

C97 47nF

SC_Chroma

SCR+

SCG+

SCB+

SCR-

SCG-

SCB-

FS_FB

FS_ID

HS_ID

HS_FB

PR+

Y+

PB+

SOY

PR-

Y-

PB-

SCART_INPUT

POWER_ON/OFF9

<< VIDEO_INP UT >>

C390 47nF

R170 75R

R169 75R

R493 75R

R172 75R

R171 75R

U10

1

2

3

4 5

PM25LV040

R174 75R

R173 75R

CE#

SO

HOLD#

WP#

VSS SI

R492 47R

R158 47R

R159 47R

R160 47R

R161 47R

R163 47R

R164 47R

R165 47R

R167 47R

R168 47R

VSS3V

8

VDD

7

6

SCK

CAP 02/14

R211 100R

R219 100R

C116 47nF

C117 47nF

C118 47nF

C119 47nF

C120 47nF

C121 47nF

C122 47nF

C123 47nF

C126 47nF

10uF_2012

1 2

B B

DTT_CVBS3

FS_CVBS_Y5

HS_CVBS_Y5

SVHS_Y3

SVHS_C3

AV3_CVBS8

TCVBS8

CVBS_OUT5

SPI_Serial_ Flash

VSS3V

A A

R217 10K

R209 100R

SPI_CZ

SPI_DO

R210 100R

R218 10K(NU)

SPI FLASH 9688 . 0214

CVBS3

FS_CVBS

HS_CVBS

SV_Y0

VCOM2

SV_C0

CVBS1

VCOM1

TUNER_CVBS

VCOM0

CVBS_OUT

Mode Selec tion.

VSS3V

INT/EXT u-COM _OPTION

C127

C128

100nF

SPI_CK

SPI_DI

R204

10K

R213

10K(NU)

EXT_u-COM.

PWM1,PWM2==>LOW

PWM0,PWM3==> HI

R205

10K(NU)

R214

10K

R206

10K(NU)

R215

10K

VDDP_3.3

SW1

3214

C68

10uF/16V

SW

D4

EDS914

132

HDMI_INPUT

PC_INPUT

DVD_INPUT

VIDEO_IN PUT

R143 100R

R146 100R

BLK_ON9

R148 100R

LCD_ON/OFF6

R150 100R

TV_MUTE3

R152 100R

SLEEP7

R154 100R

IR_MUTE3

R155 100R

ODSEL16

R207

R216

10K

PWM3PWM2PWM1PWM0

10K/NC

R156 100R

RPForEXT_Vbr6

R86

10K

SYS_RST

C84 100nF

C87 100nF

C88

100nF

C90

100nF

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1 2

VSS3V

RA9 4.7K

7

RA11 4.7K

7

.

0214

4

R85 100R

C70 20pF

C74 20pF

C91

100nF

FS_CVBS

C100 1000pF

18

2

3456

18

2

3456

SDA18

SCL18

MST_TXD8

MST_RXD8

ADC-IN16

IR6

X1

14.318MHZ

HDMI_TXCLKHDMI_TXCLK+

HDMI_TX0HDMI_TX0+

HDMI_TX1HDMI_TX1+

HDMI_TX2HDMI_TX2+

HDMI_SDA

HDMI_SCL

SOGIN0

TUNER_CVBS

ADC-IN1

HS_RGB

VS_RGB

BIN+

BINSOG

GIN+

GINRIN+

RIN-

SCB-

SCB+

SCG-

SCG+

SCR-

SCR+

FS_ID

FS_FB

HS_FB

PB+

PBSOY

Y+

YPR+

PR-

SC_Chroma

FS_CVBS

SV_C0

SV_Y0

VCOM2

CVBS3

HS_CVBS

CVBS1

VCOM1

VCOM0

CVBS_OUT

SDA1

SCL1

HS_ID

R87

1M

1

RXCKN

2

RXCKP

4

RX0N

5

RX0P

7

RX1N

8

RX1P

10

RX2N

11

RX2P

14

DDCD_DA

15

DDCD_CK

18

RMID

19

VCLAMP

20

REFP

21

REFM

16

HSYNC1

17

VSYNC1

22

BIN1P

23

BIN1M

24

SOGIN1

25

GIN1P

26

GIN1M

27

RIN1P

28

RIN1M

29

BIN0M

30

BIN0P

31

GIN0M

32

GIN0P

33

SOGIN0

34

RIN0M

35

RIN0P

38

HSYNC0

39

VSYNC0

40

VSYNC2

41

BIN2P

42

BIN2M

43

SOGIN2

44

GIN2P

45

GIN2M

46

RIN2P

47

RIN2M

48

C1

49

Y1

50

C0

51

Y0

52

VCOM2

53

CVBS3

54

CVBS2

55

CVBS1

56

VCOM1

57

CVBS0

58

VCOM0

59

CVBSOUT

151

AD0

152

AD1

153

AD2

154

AD3

155

AD4

156

AD5

157

AD6

158

AD7

83

NC

84

NC

88

NC

89

NC

90

NC

91

NC

92

NC

93

NC

94

NC

95

NC

96

NC

R175 22R

R176 22R

R18122R

R183 22R

R186 100R

R188 100R

R189 100R

R190 100R

SPK_LA7

SPK_RA7

AVDD_DVI_3.3

AVDD_ADC_3.3 VDDP_3.3

R93390R_1%

6

254

255

13

12

253

36

XIN

REXT

XOUT

AVDD-DVI

AVDD_ DVI

HWRESET

AVDD_ADC

SAR0

SAR1

SAR2

SAR3

DDCR_DA

DDCR_CK

DDCA_DA

DDCA_CK

168

169

170

171

174

175

176

177

97

180

162

VDDP

VDDP

IRIN

172

179

C354 4.7uF_2012

C357 4.7uF_2012

AVDD_AU_3.3

252

196

209

223

237

VDDP

VDDP

VDDP

VDDP

VDDP

PWM2

PWM3

PWM0

PWM1

3

192

193

173

PWM0

PWM2

PWM1

PWM3

R191 10K(NU)

R192 10K(NU)

R193 10K(NU)

R194 10K

VDDP

GND

R72

22K

R82

22K

70

AVDD_AU

GND

GND

9

37

AVDD_MPLL_3.3

194

256

AVDD_ MP LL

AVDD_ MP LL

GND

GND

GND

98

6066131

R71 100R

C67

15nF

R78 100R

C69

15nF

VDDC_18/12

AVDD_MEMPLL_3.3

VDDM_2.5

99

195

106

117

242

182

146

112

132

VDDC

VDDC

VDDC

VDDC

VDDC

VDDM

VDDM

VDDM

U7

MST9688 LD

TP9

GND

GND

GND

GND

GND

GND

GND

GND

GND

210

164

111

103

181

224

243

145

163

SPI_CK

HDMI1_SEL2

HDMI2_SEL2

DVI_SEL2

Dimming_PWM

Dimming_PWM 9

AVDD_ SIF_3.3

144

133

63

VDDM

VDDM

AVDD_ SIF

AVDD_MEMPLL

SCK

SDI

CSZ

SDO

165

166

167

SPI_DI

SPI_DO

SPI_CZ

VSS3V

R195 4.7K

RA14 4.7K

RA15 4.7K

7

7

AUOUT S

225

R177 100R(NU)

858687

84

AUOUT L

AUOUT R

AUOUTR 2

GPIOE3

GPIOE2

GPIOE1

226

227

R179 100R

R178 100R

3

R432100R(NU)

R433 100R(NU)

R434100R(NU)

R435100R(NU)

TP33

TP32

TP34

TP35

79

808182

83

AUR3

AUMON O

AUOUTL3

AUOUT L2

AUOUTR 3

DIGO0

GPIOE0

183

184

228

R180100R

DIGO1

DIGO0

18

2

3456

18

2

3456

TP36

AUL3

DIGO1

185

DIGO2

AUR2

DIGO2

186

DIGO3

AUL2

DIGO3

187

DIGO4

AUCOM

DIGO4

AUR1

DIGO5

188

DIGO5

DIGO6

72737475767778

AUL1

AUR0

DIGO6

DIGO7

189

190

DIGO7

C358

R436

22K

15nF

AUVREFAUVREF

AUVRADP

AUVRADNAUVRADN

AUL0

SIF1P

SIF1M

AUVREF

AUVRAN P

AUVRAD N

IVSYNC/TX1

IHSYNC/RX1

DIGO8

WRZ

RDZ

ALE

INT

191

159

160

161

178

R187 100R

R196 100R

R197 100R

R198 100R

R199 100R

R200 100R

R201 100R

R202 100R

R203 100R

R208

R437

C359

22K

15nF

DVB_AUD_R 3

DVB_AUD_L 3

R_M

SP 8

L_MSP 8

SIFP 8

SIFM 8

62646567716869

61

SIF0P

SIF0M

251

DI15

250

DI14

249

DI13

248

DI12

247

DI11

246

DI10

245

DI9

244

DI8

241

DI7

240

DI6

239

DI5

238

DI4

236

DI3

235

DI2

234

DI1

233

DI0

232

231

230

IDE/TX0

229

ICLK/RX0

222

LB0M

221

LB0P

220

LB1M

219

LB1P

218

LB2M

217

LB2P

216

LBCKM

215

LBCKP

214

LB3M

213

LB3P

212

LB4M

211

LB4P

208

LA0M

207

LA0P

206

LA1M

205

LA1P

204

LA2M

203

LA2P

202

LACKM

201

LACKP

200

LA3M

199

LA3P

198

LA4M

197

LA4P

121

MDATA 0

120

MDATA 1

119

MDATA 2

118

MDATA 3

116

MDATA 4

115

MDATA 5

114

MDATA 6

113

MDATA 7

110

MDATA 8

109

MDATA 9

108

MDATA 1 0

107

MDATA 1 1

105

MDATA 1 2

104

MDATA 1 3

102

MDATA 1 4

101

MDATA 1 5

135

WEZ

134

CASZ

130

RASZ

129

BADR0

128

BADR1

127

MCLK

126

MCLKZ

125

MCLKF

124

MVREF

123

DQM

122

DQS0

100

DQS1

150

MADR11

149

MADR10

148

MADR9

147

MADR8

143

MADR7

142

MADR6

141

MADR5

140

MADR4

139

MADR3

138

MADR2

137

MADR1

136

MADR0

VSS3V

6

7

RA13

4.7K

1 823

4 5

R182100R

R184100R

R185100R

1 2

1 2

1 2

1 2

1 2

1 2

100R

1 2

R438

C360

R439

22K

22K

15nF

C72 100nF

AUCOM

C77

10uF_2012

R109 100R

R111 100R

R114 0R(NU)

R115 0R(NU)

RA16 22

1 8

2

3

4 5

RA17 22

1 8

2

3

4 5

RA18 22

1 8

2

3

4 5

RA1 22

1 8

2

3

4 5

RA2 22

1 8

2

3

4 5

RA3 22

1 8

2

3

4 5

RA4 100

7

RA5 100

7

RA6 100

1 8

2

3

4 5

RA7 100

1 8

2

3

4 5

RA19 33

1 8

2

3

4 5

RA20 33

1 8

2

3

4 5

RA21 33

1 8

2

3

4 5

R600 4.7K

R601 4.7K(NU)

DVB_MENU_OPEN 3

SRS_SDA3 7

AUDIO_MUTE 7

SRS_SCL3 7

DVB_ON 3

COMP_S

EL 3

HPD_SINK 2

TV_MENU_OPEN 3

LED_R 6

C355 4.7uF_2012

C356 4.7uF_2012

C361

15nF

C78

100nF

TP20

TP21

TP22

TP23

TP24

TP25

TP26

TP27

TP28

TP29

7

6

7

6

7

6

7

6

7

6

7

6

3456

2

18

3456

2

18

7

6

7

6

7

6

7

6

7

6

DVB_PIP 3

5VD_1 9

ACD 9

C79

1uF

AUSD

AUSCK

AUWS

AUMUTE

AUMCK

MDATA 0

MDATA 1

MDATA 2

MDATA 3

MDATA 4

MDATA 5

MDATA 6

MDATA 7

MDATA 8

MDATA 9

MDATA 1 0

MDATA 1 1

MDATA 1 2

MDATA 1 3

MDATA 1 4

MDATA 1 5

WE_DDR

CAS_DDR

RAS_DDR

SBA0

SBA1

MCLK+

MCLKCKE_DDR

MVREF_1

DQM_DDR

DQS0_DDR

DQS

1_DDR

AR11

AR10

AR9

AR8

AR7

AR6

AR5

AR4

AR3

AR2

AR1

AR0

MVREF_1

VSS3V S5V

LG_SEL_DCR 6

TV_OUT_RA 5

TV_OUT_LA 5

LINE_OUT_RA 3

LINE_OUT_LA 3

R90 6.5M (NU)

C80

4.7uF_2012

R95 0_2012

AUSD

AUSCK

AUWS

AUMUTE

AUMCK

HDMI_SPDIF_OUT 3

TXO0- 6

TXO0+ 6

TXO1- 6

TXO1+ 6

TXO2- 6

TXO2+ 6

TXOC- 6

TXOC+ 6

TXO3-6

TXO3+6

TXO4- 6

TXO4+ 6

TXE0- 6

TXE0+ 6

TXE1- 6

TXE1+ 6

TXE2- 6

TXE2+ 6

TXEC- 6

TXEC+ 6

TXE3-6

TXE3+6

TXE4- 6

TXE4+ 6

C124

1000pF

2

VSS5

CN23

1

VSS

2

SCL

3

SDA

4

GND

SMW250-04/NC

VSS3V

SCL18

SDA18

R106 4.7K

R107 4.7K

PANEL_SYNC 6

RLY_ON 9

<< DDR_MEMORY_BLOCK >>

+2.5V_DMC +2.5V_DMQ

U9

DDR_128Mb_TSOP66

1

MDATA 8

MDATA 9

MDATA 1 0

MDATA 1 1

MDATA 1 3

MDATA 1 4

MDATA 1 5

DQS1_DDR

R135 100R

DQM_DDR

R137 100R

WE_DDR

R590 0R

CAS_DDR

R591 0R

RAS_DDR

R592 0R

R145 0R

SBA0

SBA1

AR10

AR0

AR1

AR2

AR3 AR4

MVDD_2.5

R162

1K

C125

R166

1K

100nF

AUMCK

AUMCK

AUSCK

AUSCK

AUWS

AUWS

AUSD

AUSD

AUMUTE

AUMUTE

A3.3V

R328 10K(NU)

R331 10K(NU)

R332 10K

BOM .

PCS : L .

SFOR1 : L .

SFOR0 : L .

DEEM : H .

MVDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13 54

DQ7 DQ8

14

NC

15

VDDQ

16 51

LDQS UDQS

17

NC

18

MVDD

19

NC

20 47

LDM UDM

21

WE

22

CAS

23

RAS

24

CS

25

NC

26

BA0

27

BA1

28

A10/AP

29

A0

30

A1

31

A2

32 35

A3 A4

33

MVDD

2M X 16bit X 4BK

HYNIX HY5DU281622ET-5-20 0MHz 8x16-2.5V

EtronTech EM6A9160TS-5G-2 00MHz 8x16-2.5V

MIRA P2S28D40DCTP-G5-200 MHz 8x16X2-2.5V

NANYA NT5DS8M16FS-5T-200 MHz 8x16X2-2.5V

U14

R311 47

6

R315 47

R316 47

R319 47

R323 47

R324 0R

R3350R

SYSCLK

1

BCK

2

WS

3

DATA_IN

8

MUTE

10

PCS

7

SFOR1

11

SFOR0

9

DEEM

R3370R(NU)

R3360R

NON_PIP_TV-OUT

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

NC

VSSQ

NC

VREF

VSS

CLK

CLK

CKE

NC

A12

A11

A9

A8

A7

A6

A5

VSS

15

VSSA

UDA1334BTS

R576

4.7K

I2C address at A0.

Main EEP ROM

66

65

64

63

62

61

60

59

58

57

56

55

53

52

R136 100R

50

49

48

MCLK-

46

MCLK+

45

44

43

256M

42

41

40

39

38

37

36

34

22R(NU)

A3.3V

4

13

VDD

VDDA

I2C address at A1.

HDCP KEY

VSS3V

TP30

TP31

U8

1

A0

VCC

2

A1

WP

3

A2

SCL

4 5

GND SDA

24C64

MDATA 7

MDATA 6

MDATA 5

MDATA 4

MDATA 3MDATA 1 2

MDATA 2

MDATA 1

MDATA 0

DQS0_DDR

MVREF

R138 100R

R140 150R_1%

AR11

AR9

AR8

AR7

AR6

AR5

R157

5

VSSD

14

VOUT_L

16

VOUT_R

12

Vref

U31

1

A0

2

A1

3

A2

4 5

GND SDA

VSS3V VSS3V

C85

100nF

8

7

6

DQM_DDR

CKE_DDR

C188

C189

10uF_2012

100nF

C197 10uF_2012

C201 10uF_2012

C212

100nF

24C08

R103

4.7K

R110 0R

R112 0R

C209

10uF_2012

VCC

WP

SCL

R104

4.7K

C86

100nF

C190

100nF

VSS3V VSS3V

C458

100nF

8

7

6

R309 100R

R320 100R

R325

220K

R577

4.7K

R579 0R

R5800R

SCL1

SDA1

1 2

R102 0R

1 2

R105 0R

MVREF

C107

100nF

R312

220K

1

R578

4.7K

SCL1 8

SDA1 8

C108

C109

100nF

100nF

C196

10nF

C206

10nF

C98

1000pF

+2.5V_DMQ+2.5V_DMC

C110

100nF

SCL1

SDA1

MVDD_2.5

C99

100nF

C111

100nF

TV_OUT_L 8

TV_OUT_R 8

SCL1 8

SDA1 8

+2.5V_DMQ+2.5V_DMCMVDD_2.5

R119

1K

R122

1K

C112

C113

100nF

100nF

C114

100nF

H_17490_003.eps

5

4

3

2

1

011107

Page 21

Circuit Diagrams and PWB Layouts

EN 21TES2.0E LA 7.

Main Board: SCART Input

5

B4 B4

D D

C C

5VD ESD5V

FB3

600 Ohm 0.5A 2012

HS_CVBS_Y4

HS_FB4

HS_ID4

HS_L_IN8

HS_R_IN8

C133

NU

R239

1K

ED26

BAV99

ESD5V

C131

100nF

1 2

C134

10pF

1 2

12

C137

1nF

1 2

2

ED27

3

BAV99

D6

2.4V_ZENER

R238

220K

2

3

1

2

1 2

C141

1nF

R235

75

1

ED28

3

BAV99(NU)

1 2

12

R242

220K

1

12

SCART INPUT

ED24

BAV99(NU)

2

3

1

2

1

ED29

3

BAV99(NU)

DTT_DL_TX3

DTT_DL_RX3

R236 5.6K

1 2

1 2

R581 15K

1 2

R582 15K

2

3

1

ED30

3

BAV99(NU)

HS_L_IN_CON_S

HS_R_IN_CON_S

4

ED25

BAV99(NU)

2

1

HS_CVBS_Y_CON

SCRT2

20

18

16

14

12

10

UPJ-R1-029

3

ED33

ESD5V

ED31

BAV99

21

19

17

15

13

11

8

6

4

2

9

7

5

3

1

24

25

ED32

BAV99

BAV99

2

2

2

1

3

3

C136

220uF/16V

+

C138

1nF

1

1

3

12

R240

1M

A9V

C142

1nF

2

1

ED34

3

BAV99

1 2

R229 75R

R243

1M

SC_OUT

MONITOR-OUT

HS_R_C 4

HS_L_OUT 3

HS_R_OUT 3

2

C132

47uF/25V

+

1 2

12

R223

22K

12

SC_OUT

R227

22K

C140

100nF

R224 100

1 2

C135

+

47uF/16V

12

+

C139

10uF/16V

12

5VD

1

3 2

MMBT3906

12

R244

75R

R241

470

Q9

R226 22K

1 2

R228 100

1 2

R231 22K

1 2

12

32

MMBT3904

1

A9VA9VA9V

32

Q7

1

32

Q8

1

MMBT3904

R233

0

1 2

R237

100

1 2

1

Q10

MMBT3904

R230

0

1 2

R234

100

1 2

CVBS_OUT 4

MONITOR-OUT

AV_O UT 3

12

R245

75R

ED35

ED37

BAV99

2

3

1

C147

1nF

1

ED40

BAV99(NU)

D8

2.4V_ZENER

R252

220K

2

ED41

BAV99(NU)

1 2

R254

220K

1

ED42

BAV99(NU)

3

12

2

1

3

R248

75

1 2

12

C149

1nF

ESD5V

2

ED39

BAV99

3

B B

FS_CVBS_Y4

FS_ID4

FS_L_IN8

FS_R_IN8

A A

FS_CVBS_Y

FS_FB4

C143

C144

NU

10pF

1 2

1 2

FS_L_IN_CON

FS_R_IN_CON

12

R250

1K

ED38

BAV99(NU)

3

2

1

3

R249 5.6K

1 2

1 2

R583 15K

1 2

R584 15K

ED43

BAV99(NU)

FS_CVBS_Y_CON

FS_L_IN_CON_S

FS_R_IN_CON_S

BAV99(NU)

3

1

3

SCRT1

UPJ-R1-029

ED44

BAV99

20

18

16

14

12

10

8

6

4

2

2

1

2

2

1

ED45

BAV99

3

21

19

17

15

13

11

9

7

5

3

1

24

25

1

3

C146

1nF

ED46

BAV99

R251

1M

2

1

3

C148

1nF

ED47

BAV99

2

220uF/16V

R253

1M

1

ED48

BAV99

3

C145

12

+

2

1

2

ED36

BAV99

2

3

1

2

1

3

A9V

2

ED49

BAV99

3

R440 470

R441 470

R442 470(NU)

R443 470(NU)

NTSC OPTION

BOM OPTION

21

5

13

J8A

2

20

J8C

8

2

J9B

5

6

UJB0617D_RCA Triple_top(NT) (NU)

FS_CVBS_Y_CON

UJB0617D_RCA Triple_top(NT) (NU)

FS_R_IN_CON_S

UJB0617D_RCA Triple_top(NT) (NU)

1

FS_TVOUT 8

SCART_R_C 4

SCART_G 4

SCART_B 4

FS_L_OUT 8

FS_R_OUT 8

TV_OUT_LA 4

TV_OUT_RA 4

UJB0617D_RCA Triple_top(NT) (NU)

UJB0617D_RCA Triple_top(NT) (NU)

UJB0617D_RCA Triple_top(NT) (NU)

J8B

13

J9A

21

5

5

6

2

20

J9C

8

2

FS_L_IN_CON_S

HS_CVBS_Y_CON

HS_R_IN_CON_SHS_L_IN_CON_S

H_17490_004.eps

5

4

3

2

1

311007

Page 22

Circuit Diagrams and PWB Layouts

EN 22TES2.0E LA 7.

Main Board: LVDS Output

5

4

3

2

1

LVDS OUTPUT

B5 B5

DUAL_LVDS_OPTION

D D

JTP63

1

JTP64

TXE0-4

TXE0+4

TXE1-4

TXE1+4

TXE2-4

TXE2+4

TXEC-4

TXEC+4

TXE3-4

TXE3+4

TXE4-4

TXE4+4

TXO0-4

TXO0+4

TXO1-4

TXO1+4

TXO2-4

TXO2+4

TXOC-4

TXOC+4

TXO3-4

TXO3+4

TXO4-4

TXO4+4

TXE0TXE0+

TXE1TXE1+

TXE2TXE2+

TXECTXEC+

TXE3-

TXE3+

TXE4TXE4+

TXO0TXO0+

TXO1TXO1+

TXO2TXO2+

TXOCTXOC+

TXO3-

TXO3+

TXO4TXO4+

INTERNAL SINGLE

LV DS_OUT

5V/12V_MOD

ODSEL14

INTERNAL DUAL LVDS_OUT

TP18

1

TP19

1

C C

FSCLK+, FSCLKdifferentail

routing

pair

JTP65

JTP66

JTP67

JTP68

JTP69

JTP70

JTP71

JTP72

R444 100(NU)

TXO0TXO0+

TXO1TXO1+

TXO2TXO2+

TXOCTXOC+

TXO3-

TXO3+

TXE0TXE0+

TXE1TXE1+

TXE2TXE2+

TXECTXEC+

TXE3-

TXE3+

JTP73

JTP74

JTP75

JTP76

JTP77

JTP78

JTP79

JTP80

JTP82

JTP83

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

J10

30

32

29

31

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

12507WR-30A01(NU)

CN24

Vbr_Out

GND

JST250-2P

PANEL_SYNC4

Vbr_Out

2

1

VSS3V

12

R553

1K(NU)

12

R558

0R

SINGLE_LVDS_OPTION

R551 0R(NU)

LG_SEL_DCR4

RPForEXT_Vbr4

ODSEL14

RPForEXT_Vbr4

TXE4TXE4+

5V/12V_MOD

JTP32

JTP28

JTP29

JTP30

JTP31

1 2

R550 0R(NU)

1 2

R552 0R(NU)

1 2

R603 0R(NU)

TXE0TXE0+

TXE1TXE1+

TXE2TXE2+

TXECTXEC+

TXE3-

1 2

1 2

1 2

1 2

R604 0R(NU)

TXE3+

R554 0R

R555 0R

R556 0R(NU)

R557 0R(NU)

1

1

R605 0R

1

1

1

R602 0R(NU)

R611 0R(NU)

J7

30

32

29

31

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8