Page 1

Colour Television Chassis

TEH1.0E

LA

G_16500_000.eps

291106

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 5

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 10

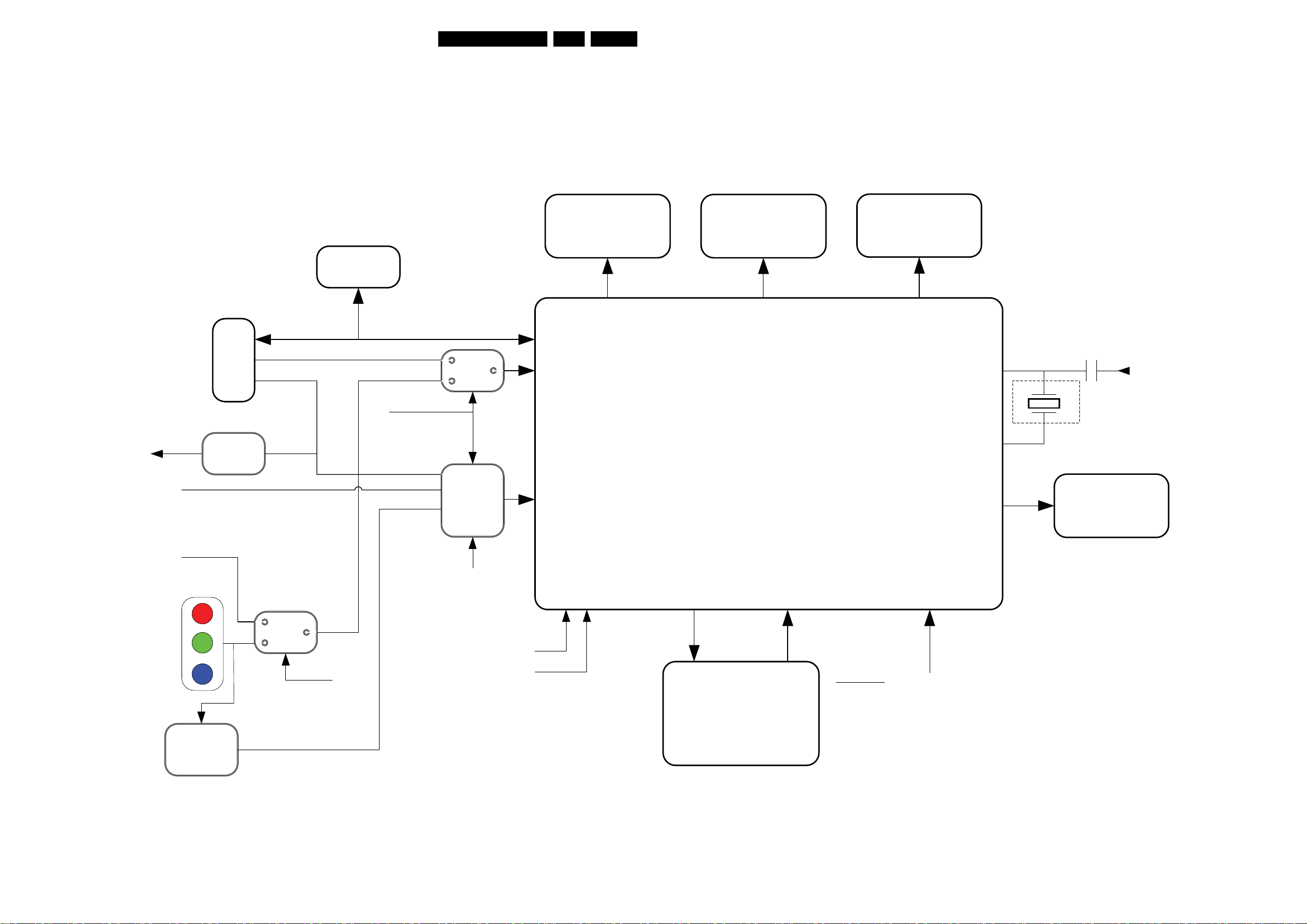

6. Block Diagrams, Test Point Overviews, and

Waveforms

Block Diagram Power Supply 11

Block Diagram SCALER 12

Block Diagram UOCIII 13

Block Diagram Sync Input Multiplexer 14

7. Circuit Diagrams and PWB Layouts Diagram PWB

Main Board Overview 15 20-21

Main Board Part 1 16 20-21

Main Board Part 2 17 20-21

Main Board Part 3 18 20-21

Main Board Part 4 18 20-21

Side I/O Board 22 22

Control Board 23 23

IR & LED Board 24 24

8. Alignments 25

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 30

Abbreviation List 31

IC Data Sheets 32

10. Exploded View 36

Spare Parts List 37

11. Revision List 42

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JH 0672 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 16500

Page 2

EN 2 TEH1.0E LA1.

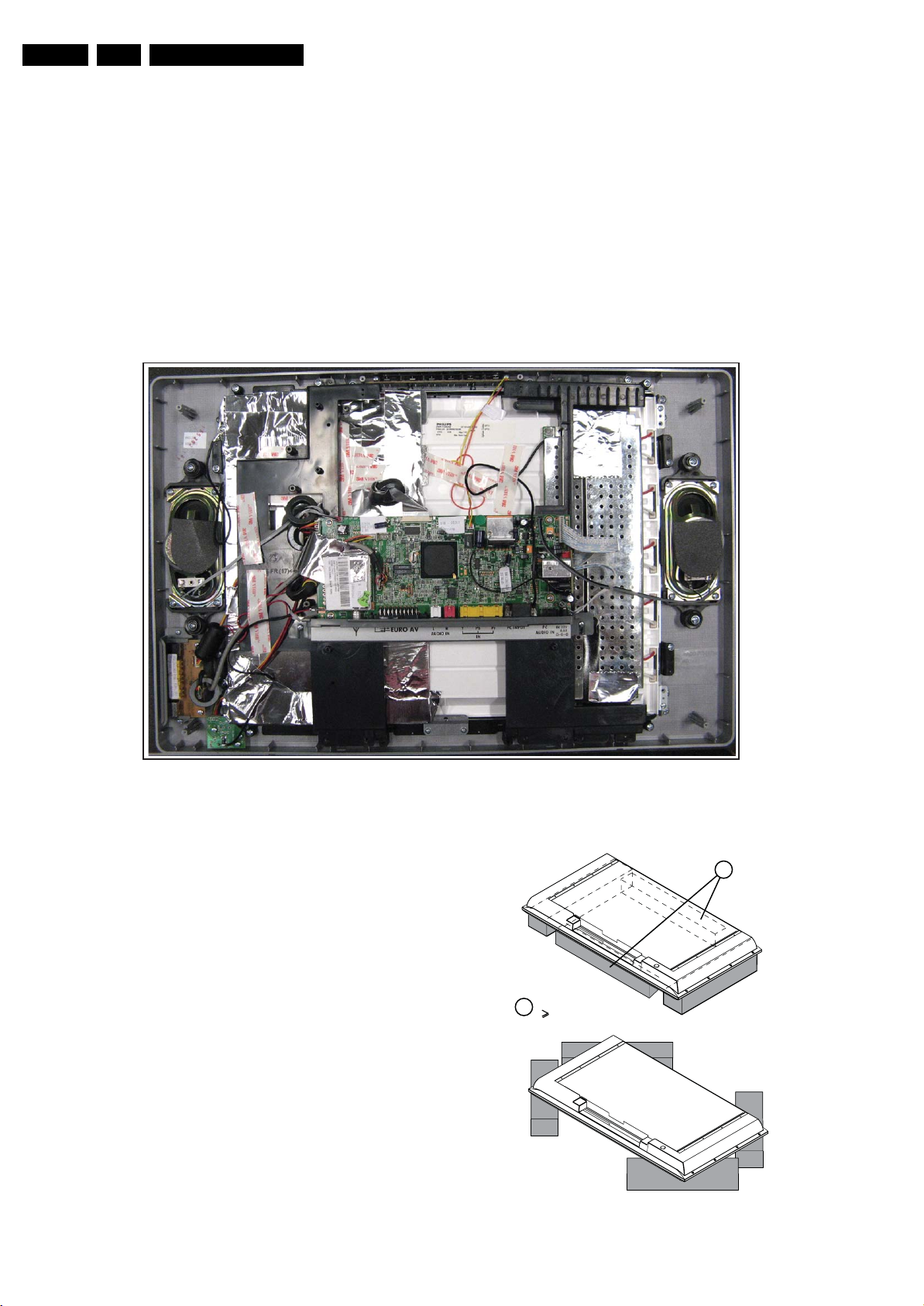

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 19.7” (50 cm), 4 : 3

Resolution : 640 x 480p

Viewing angle : 170 / 170

Brightness : 450 cd/m

Contrast ratio : 600 : 1

Response time : 20 ms

Tuning system : PLL

TV Colour systems : PAL B/G, D/K, I

: SECAM B/G, D/K, L/L’

Video playback : NTSC M/N 3.58, 4.43

Presets/channels : 100 presets

Tuner bands : VHF

: UHF

:CATV

: Hyper-band (S1-S41)

Picture preset modes : Movie / Sport / Game /

Weak signal /

Personal

Picture formats : Compressed (16 : 9) /

Normal (4 : 3) / Auto /

Expand

1.2 Connection Overview

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

G_16500_025.eps

291106

Figure 1-1 Connection overview

2

1.2.1 Side Connections

Mini Jack: Audio Head phone - Out

Bk - Head phone 32 - 600 ohm / 10 mW ot

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

1.2.2 Rear Connections

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm j

PP

P / 75 ohm j

PP

1.1.2 Sound

Sound systems : A2 + NICAM Stereo

Equalizer : 5-band graphic

equalizer

Preset equalizer modes : Personal / Music /

Theatre / Voice

Sound effects : Spatial stereo

Maximum power (W

):2 x 2

RMS

1.1.3 Miscellaneous

Power adapter:

- Mains voltage (V

) : 90 - 264

AC

- Mains frequency (Hz) : 47 - 63

- Output : 12 Vdc, 6.6 A

Ambient conditions:

- Temperature range (°C) : -25 to +70

- Maximum humidity : 5 - 95 % R.H.

Power consumption (values are indicative):

- Normal operation (W) : 75

- Stand-by (W) : 1.8

Dimensions incl. stand (W x H x D, in mm):

- 26PF1000/62 : 610 x 436 x 150

Aerial - In

- - IEC-type Coax, 75 ohm D

EXT1: AV + RGB

21

20

E_06532_001.eps

2

1

050404

Figure 1-2 SCART connector EXT1

1 - Audio R 0.5 V

2 - Audio R 0.5 V

3 - Audio L 0.5 V

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

4 - Ground Gnd (audio) H

5 - Ground Gnd H

6 - Audio L 0.5 V

7 - RGB Blue 0.7 V

8 - Function Select 0 - 2 V: INT

/ 10 kohm j

RMS

/ 75 ohm j

PP

4.5 - 12 V: EXT 4:3 j

9 - Ground Gnd H

10 - Res. Clock signals

11 - RGB Green 0.7 V

/ 75 ohm j

PP

12 - Res. Remote control

13 - Ground Gnd H

14 - Ground Gnd (switch RGB) H

15 - RGB Red 0.7 V

16 - Switch RGB j

/ 75 ohm j

PP

17 - Ground Gnd (video) H

18 - Ground Gnd (video out) H

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3TEH1.0E LA 1.

19 - Video out 1 VPP / 75 ohm k

20 - Video in 1 V

/ 75 ohm j

PP

21 - Shield Gnd H

Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

VGA: Video RGB - In

1

5

6

11

10

15

E_06532_002.eps

050404

Figure 1-3 VGA Connector

1.3 Chassis Overview

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

4 - Self test.

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

5 - DDC return

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

10 - Ground Sync Gnd H

Supply of DDC circuit j

DC

11 - GND GND H

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

Mini Jack: PC Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

DC - In

1 - 12 V_dc / 6.6 A / 75 W jr

CONTROL BOARD

SIDE I/O BOARD

IR & LED BOARD

Figure 1-4 PWB locations

G_16500_019.eps

291106

MAIN BOARD

Page 4

EN 4 TEH1.0E LA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "ON" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "OFF" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

-9

), or pico-farads (p= x10

-12

-6

),

).

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "ON".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 2006

week 17).

MODEL :

PROD.NO:

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number example

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

BJ3.0E LA

S

128W

E_06532_024.eps

130606

P

b

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

Page 5

Directions for Use

EN 5TEH1.0E LA 3.

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

2.3.4 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-1) is

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering the

correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.3.5 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.6 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 6

EN 6 TEH1.0E LA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.3 Rear Cover Removal

4.6 Main Board Removal

4.5 IR & LED / Power Switch Board Removal

4.4 Side I/O Board Removal

4.8 LCD Display Panel Removal

4.7 Speaker Removal

4.9 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation.

• Follow the disassemble instructions in the described order.

• The presence of adhesive tape can interfere severely with

the described actions!

• The removal of adhesive aluminium tape can interfere

severely with the quality of the image!

4.2 Service Position

For easy servicing of flat TV sets, we have created foam bars,

which can be used as indicated in the following drawing.

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. By putting the TV

face down on the (ESD protective) foam bars, a stable situation

is created to perform measurements and alignments.

By placing a mirror under the TV, you can monitor the screen.

Figure 4-1 Cable Dressing

Required for sets

1

42”

G_16500_009.eps

281106

1

E_06532_018.eps

171106

Figure 4-2 Foam bars

Page 7

Mechanical Instructions

EN 7TEH1.0E LA 4.

4.3 Rear Cover Removal

1. Put the set face down on a table.

2. Remove cable cover [1].

3. Remove fixation screws [2] and the stand.

4. Remove fixation screws [3] and the rear cover.

1

Figure 4-3 Rear cover removal 1/2

G_16500_010.eps

281106

4.4 Side I/O Board Removal

1. Remove the rear cover, as described earlier.

2. Unplug connectors [1].

3. Remove screws [2].

4. Remove the side I/O board.

1

22

G_16500_014.eps

281106

3 3

2

G_16500_011.eps

281106

Figure 4-4 Rear cover removal 2/2

Before you assemble the rear cover:

1. Place all cables in their original position (see figure “Cable

dressing”).

Figure 4-5 Side I/O board removal

4.5 IR & LED / Power Switch Board Removal

1. Remove the rear cover, as described earlier.

2. De-solder wire [1].

3. Remove fixation screws [2].

4. Unplug connector [3].

5. Remove the IR & LED/ Power Switch board.

3

2

1

G_16500_013.eps

Figure 4-6 IR & LED / power switch board removal

281106

Page 8

EN 8 TEH1.0E LA4.

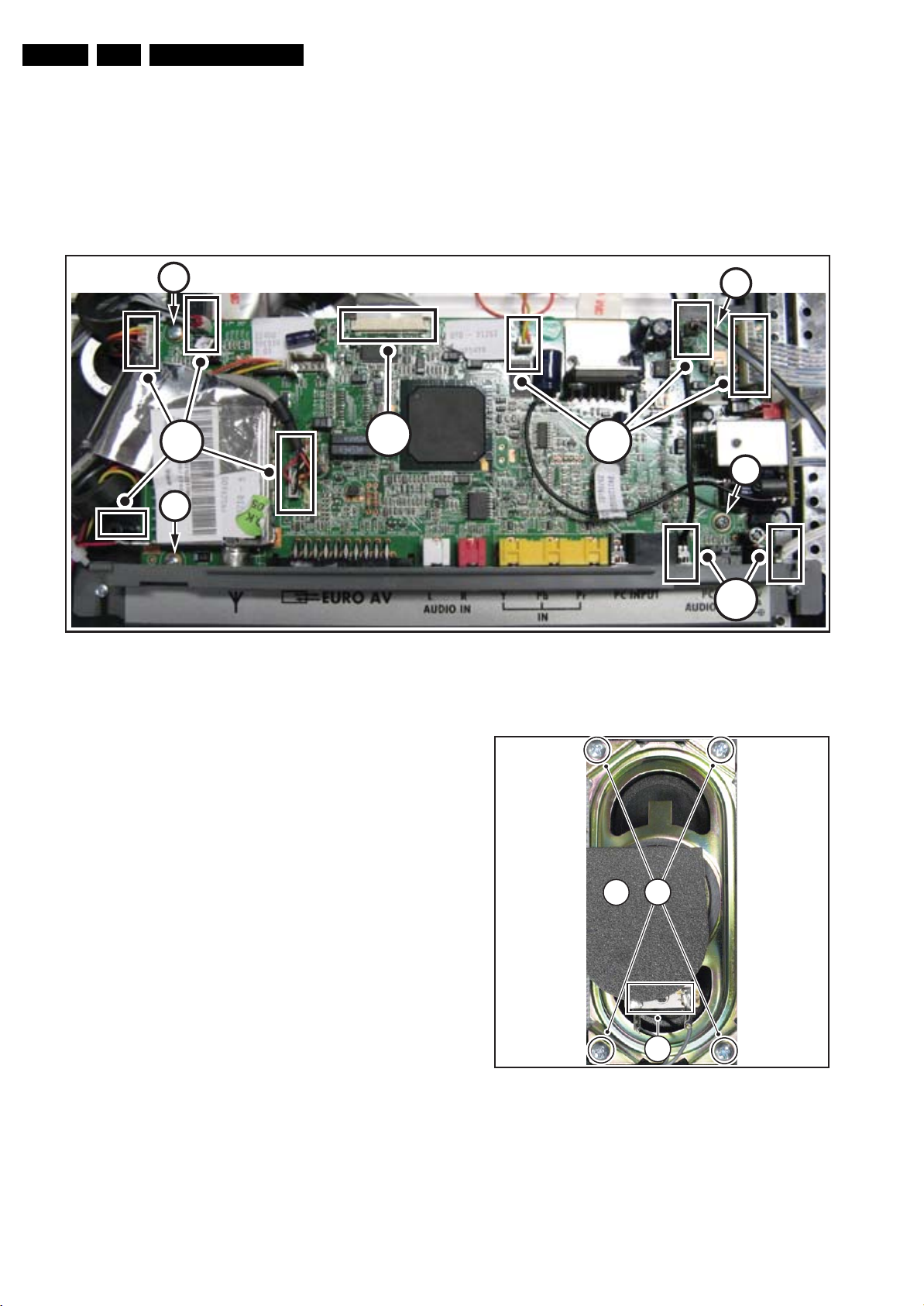

4.6 Main Board Removal

1. Remove the rear cover, as described earlier.

2. Remove the subframe, as described earlier.

3. Unplug connectors [1].

4. Carefully unplug the fragile LVDS connector [2].

5. De-solder wires [3].

6. Remove fixation screws [4].

7. Remove the main board.

Mechanical Instructions

4

1

4

4.7 Speaker Removal

2

Figure 4-7 Main board removal

4

1

4

3

G_16500_012.eps

011206

1. Remove the rear cover, as described earlier.

2. De-solder the wires [1] from the speaker contacts.

3. Remove screws [2].

4. Remove the speaker.

5. At installation of a new speaker, also glue a new piece of

foam [3] to the speaker.

22

3

1

Figure 4-8 Speaker removal

G_16500_015.eps

281106

Page 9

Mechanical Instructions

EN 9TEH1.0E LA 4.

4.8 LCD Display Panel Removal

1. Remove the rear cover, as described earlier.

2. Unplug connectors [1].

3. De-solder wire [2] from the backlight inverter board.

4. Remove fixation screws [3].

1

3

5. Move the plastic subframe with the main board to the left,

just far enough to have access to connector [4]. Unplug

connector [4].

6. Remove fixation screws [5] and bracket [6]

7. Lift the display panel from the front cover, and put it on an

appropriate surface (e.g. foam bars).

3

2

1

4

Figure 4-10 Display panel removal 2/3

3 3 3

Figure 4-9 Display panel removal 1/3

5

5

G_16500_017.eps

291106

G_16500_016.eps

6

5

Figure 4-11 Display panel removal 3/3

5

011206

5

5

G_16500_018.eps

291106

4.9 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Note:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure "Cable

dressing".

• As the adhesive aluminium tape is crucial for a correct

shielding of the set, make sure it is replaced if necessary.

Page 10

EN 10 TEH1.0E LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Service Mode

5.2 Error Codes

5.3 Fault Finding and Repair Tips

5.1 Service Mode

The Service Mode is activated by pressing ‘1147’ on the

Remote Control, while the set is in the Main User Menu.

The software provides menu flexibility and full control to the

software. Service persons can adjust the TV in all manners. In

the Service Menu, you find a list of parameters.

All functions of the Service Mode, and the default parameter

settings, are listed in Chapter “Alignments”.

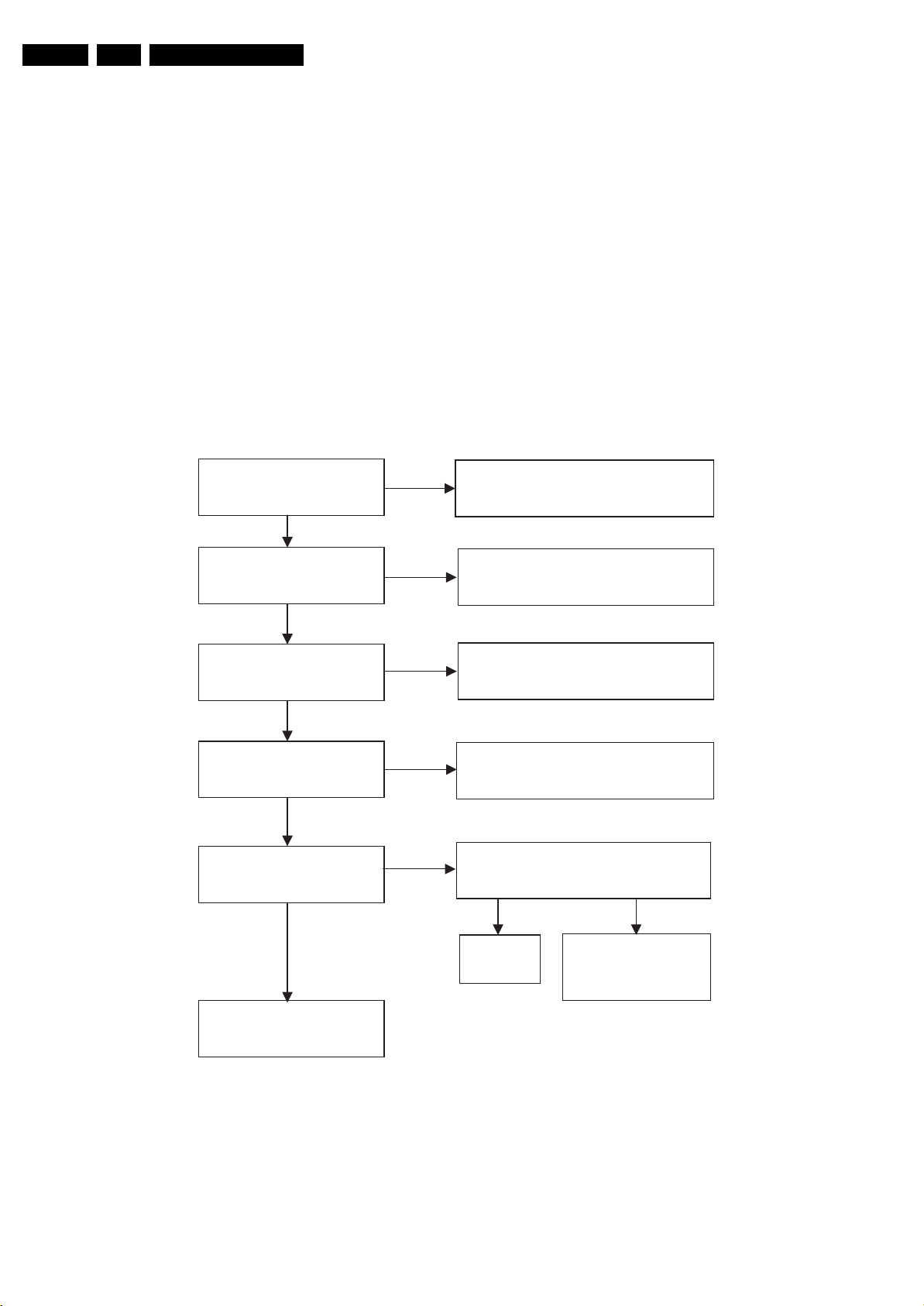

FAULT TRACING DIAGRAM FOR POWER SUPPLY

Check 12 V DC

Adapter Out

YES

Check 12 V on s401

NO

NO

5.2 Error Codes

This set does not generate Error Codes

5.3 Fault Finding and Repair Tips

Notes:

• It is assumed that the components are mounted correctly

with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options

are set.

Check AC Power Cable

If AC is OK Change Adapter

Check Cable

YES

Check +5V

YES

Check 3.3 V STB

YES

Check 3.3 V S_SW

& 1V8_SW

YES

POWER IS OK

NO

NO

NO

Check IC U403 and Peripheral

Components

Check U500 and and Peripheral

Components

Check StandBy Pin, Q400A and

and Peripheral Components

LOW HIGH

StandBy

Mode

Normal Mode

Check Components

For 5V

G_16500_028.eps

291106

Figure 5-1 Fault finding power supply

Page 11

Block Diagrams, Test Point Overviews, and Waveforms

EN 11TEH1.0E LA 6.

6. Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram Power Supply

Power supply

+12V

SMPS

+5V

+5V_SW

On/Off

Linear

regulator

+3V3

Linear

regulator

+3V3

Personal Notes:

+5V

+5V_SW

+3Vstb

+3V3s_SW

+5V_SW

+12V_SW

SMPS

+1V8

Linear

regulator

+8V

On/Off

+1V8s_SW

+8V

+12V_SW

G_16500_021.eps

291106

E_06532_012.eps

131004

Page 12

Block Diagrams, Test Point Overviews, and Waveforms

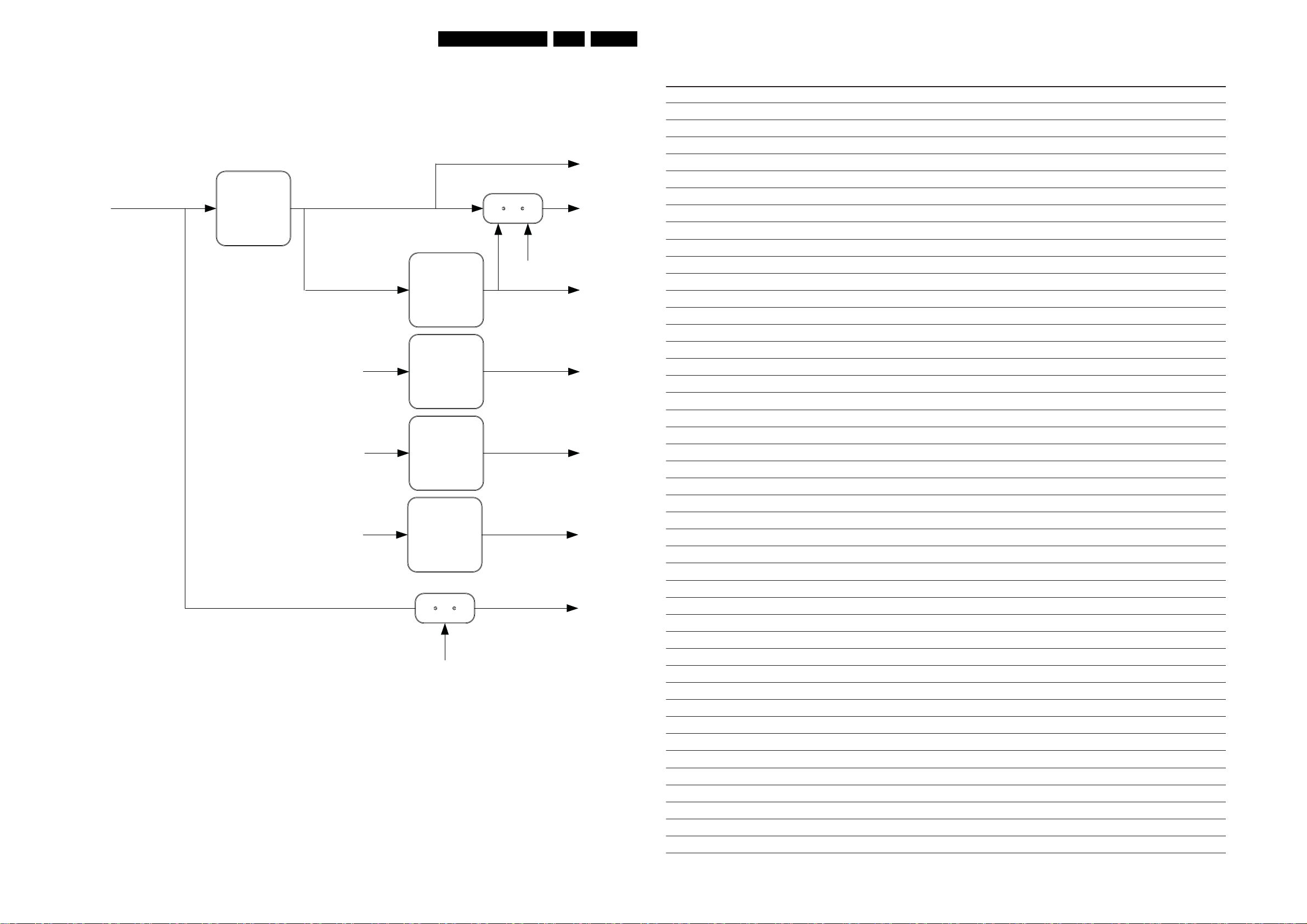

Block Diagram SCALER

Scaler Block Diagram

EN 12TEH1.0E LA 6.

PC input

UOC P1_2/INT2

(PC auto detect)

From

H,V sync

Sync

detect

I2C

R,G,B

H,V sync

NVM

(DDC)

VGA_TV_SW

Sync input mux

(see separate page)

3x15pin emulator

connectors

VGA I2C

R,G,B

H, V sync

Keyboard

Backlight on/off

interface

KBD[1..0]

6745 “Lithium-C”

brightness

control

GPIO(3), GPIO(4)

LVDS outputs

XTL

Xtal input from UOC

Xtal not mounted on

PCB

Panel interface

connector

UOCIII

HD video

input

External

H-sync

input

connector

R,G,B

HD_Y

YUV_TV_SW

Ext_Hsync

Ext_Hsync_Sel

+3V3s_SW

+1V8s_SW

Scaler power

supply voltages

A[17..0]

Flash Rom

D[7..0]

I2C

From UOCIII

G_16500_022.eps

301106

Page 13

Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram UOCIII

EN 13TEH1.0E LA 6.

UOCIII

Scart

From Sync Detection

(auto PC mode detect)

HD audio in

Xtal output to scaler

Audin5, AudOut5,

R,G,B, STATAV1,

FBLin

P1_2/INT2

Aud2in

Keyboard interface

XTALin, XTALout

connector

I2SWS, I2SCLK, I2SDO2,

UOCIII

I2S output

connectors

I2SDO1,I2SDI1/O

P1_6, P1_7

YUVin, YUVout

DECDIG

I2C interface

connector

NVM

I2C to scaler

TDA9178

picture booster

(optional)

+5V_SW

+3Vstb

1V8 supply

PC audio in

AV front PCB

CVBS

Y/C

Headphones

Aud3in

Aud4in

y3,c3

Headphone

amplifiers

AudoutHP

Line out

AudoutLS

P2_4

Mute

Speaker

amplifiers

TDA1517

P3_1

Astb

Refo/Refin

FM-

radio

filter

Rout, Gout, Bout

Hout, VDRB Hsync, Vsync

SAW

filter

Tuner

UV1316 mk4

UR1316 mk3

P2_0

P1_3

P2_1

P2_2

VIFinSIFin

SAW

filter

Reset

On/Off (to power supply)

YUV_TV_SW

VGA_TV_SW

R,G,B

Ext_Hsync_selP1_1

Reset circuit not mounted on

the PCB, P2_0 reserved

Speaker

connectors

G_16500_023.eps

291106

Page 14

Block Diagrams, Test Point Overviews, and Waveforms

Block Diagram Sync Input Multiplexer

Sync input multiplexer

EN 14TEH1.0E LA 6.

TV_VS

PC_VS

Ext_Hsync

TV_HS

PC_HS

VGA_TV_SW,

Ext_Hsync_sel

Vsync

Hsync

Function

On/Off EXT_Hsync_Sel VGA_TV_SWH-sync V-sync

0x x OffOff

10 0ExternalOff

10 1 OffOff

11 0 TVTV

11 1 PCPC

G_16500_024.eps

291106

Page 15

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

EN 15TEH1.0E LA 7.

Main Board Overview

1

EEPROM INTERFACE

U700

1

A0

2

A1

3

A2

VSS4SDA

D

C715

C709

100nF

47uF/10V

C

B

+5V_SW

L200

BEAD

C200

ROUT

10uF/10V

C201

GOUT

TP185

10uF/10V

C202

BOUT

TP267

10uF/10V

+5V_SW

L201

BEAD

TP265

C205

TP266

PR_CR

4.7uF/6.3V

S201

R251

R246

75R

NS

4

1

5

A

C209

2

PB_CB

TP264

4.7uF/6.3V

R247

R252

75R

NS

6

3

CHINC3

C218

HD_Y

TP263

4.7uF/6.3V

R248

R253

NS

75R

05TA065H

1

VDD

PTC

24C32

SCL

TUN1

TUNER

SECAM L

R734

R733

27K

27K

SANDC

YOUT

UOUT

VOUT

SCL

MISC

R200

4.7K

TP187

R213

10K

R201

4.7K

TP186

R214

10K

R203

4.7K

TP268

R215

10K

TP269

R209

4.7K

TP270

R243

10K

R222

4.7K

TP271

R244

10K

TP275

R242

4.7K

TP272

R245

10K

+3VSTB

TP100

L700

8

FB

C700

C701

R700

R701

100nF

220nF

7

3.3K

3.3K

SCL

6

TP188

SDA

5

TP105

AGC/AGC1TUN/TUN2AS/UHF3SCL/UHF34SDA/UHF15NC/+5V6+5V/AFT7ADC/NC8+33V/NC9IF2/IF210IF1/IF1

R705

TP18

TP53

NS

TP27

5V_T

TP160

L704

47uH

TP26

TP25

TP24

TP23

R735

R729

6.8K

NS

ADR. SEL.

R738

22R

L710

47uH

TP161

C717

4.7nF

C203

100nF

R219

75R

R220

75R

R221

75R

C219

100nF

C222

R267

100R

33pF

C220

100nF

C223

33pF

C221

100nF

C224

R269

100R

33pF

R730

0R

TP45

TP46

R719

R720

C876NSC877

100R

100R

TP34

TP33

SCL

SDA

+5V_SW

TP38

L706

10uH

TP163

R739

33K

Q701

BC847

C718

4.7nF

U701

R708

1

0R

2

R721

3

100R

R722

4

100R

R723

5

100R

6

7

8

9

10

R724

11

100R

12

TDA9178T

R

TP7

C214

270pF

G

TP8

C215

270pF

B

TP122

C216

270pF

TP276

PR

TP124

PB

TP125

R268

100R

Y

TP123

TP56TP55

TP35

NS

FM-OPT.

PLACE CLOSE

TO TUNER

L711 47uH

L705

47uH

C719

220pF/50V

SC

GND

ADEXT1

ADEXT2

ADEXT3

YIN

ADR

UIN

VIN

GND

SCL

GND

D700

1N4148

L703

12uH

TP32

AGC

C716

4.7nF

Q200

BC847B

R216

120R

TP189

Q201

BC847B

R217

120R

Q202

BC847B

R218

120R

Q205

BC847B

R254

0R

Q206

BC847B

R255

0R

TP274

Q207

BC847B

R256

0R

C723

10uF/10V

33V

TP101

C720

C712

1nF

100nF

R706

0R

TP83

10.7

C727

10uF/10V

C724

TP164TP162

33nF/50V

GND

GND

CF

SOUT

VCC

YOUT

VEE

UOUT

VOUT

DECDIG

SDA

GND

+3V3S_SW

SECONDPANEL

2

+5V_SW

L701

FB

TP206

C900

R702

10.7

330R

1nF

R704

0R

NM

GND

5V_T

11

C713

100nF

L709

1uH

C729

8.2pF

SYMMETRIC

TUNER OPT.

VIF_2

D701

BAV99W

24

23

22

21

20

R725

19

100R

18

R726

17

100R

R727

16

100R

15

C706

100n

R728

14

100R

13

DECDIG

S200

1

2

TP191

3

4

5

6

7

BACKLIGHT

8

9

10

11

12

13

14

15

+12V_SW

TP352 TP353 TP354

R227

R226

0R

NS

TP58

2

TP208

R714

820R

R712

100K

TP210

Q700

BC847

R713

150K

R715

560R

12

+5V_SW

L707

10uH

TP36

TP37

C722

1nF

TP126

L708

NS

TP127

VIF_1

+5V_SW

TP165

C725

33nF/50V

TP30

TP29

TP28

C732

C731

C730

22pF

22pF

22pF

PICTURE IMPROVEMENT

+3Vstb

R745

4.7K

R746

4.7K

TP22

C728

10uF/6.3V

POWER SW PART

DIM

R231

0R

TP192

R205

BL_EN1

10R

TP115

TP277

100uF/16V

+5V_SW

R228

NS

C213

47uF/16V

TP219

R718

1K

R740

22K

R742

47R

TP19

C204

100nF

C948

+5VWD

R929

0R

C211

100nF

C702

100nF

C704

1nF

C714

100nF

R741

NS

TP128

C703

100nF

+3Vstb

R2040RR206

TP193

FM OPTION PART

C705

F700

SFE10.7MS3A

1n

R717

1K

TUNER PART

R736

6.8K

R737

6.8K

TP129

BA591

D702

D703

BA591

R743

220K

SAW_SW

D705

BZX284-C33

+8V_SW

TP31

L702

FB

TP166

C733

10uF/10V

YIN

UIN

VIN

SDA

C707

220n

Q702

BC847

C708

220n

BACKLIGHT

TP194

C212

22uF/6.3V

+5V

TP116

R229

0R

C207

+12V +12V_SW

100nF

TP117

C217

100uF/16V

R411

0R

TFT_ON/OFF

TP220

SSIF

123

R703

330R

TP130

SIF_1

D704

SIF_2

TP131

BA591

T700

BC847B

R744

680K

33V

TP168

C726

33nF/50V

R748

R749

R731

2.2R

2.2R

10K

TP167

Q703

BC557

TP20

+1V8_2

TP195

R750

R732

R747

2.2R

10K

2.2R

Q704

BC557

Q705

BC847

+1V8_1

TP21

+5V_SW +3V3S_SW

TP17

R208

R207

NS

NS

NS

R212

NS

TP121

Q203

BC848/NS

+5V_SW

+3V3S_SW

TP120

TP119

R211

R210

R250

NS

1K

NS

R225

TP196

NS

R202

4.7K

TP197

Q204

TP118

BC848

R223

R249

NS

0R

C206

100nF

R239

0R

R224

0R

R230

8

RSN4

1

TP273

RSP4

2

7

TP301

3

6

RSN3

TP310

4

RSP3

5

TP345

47R

R235

1

8

RSN2

TP346

RSP2

7

2

TP347

6

RSN1

3

TP348

RSP1

45

TP349

47R

R234

RSN0

1

8

TP243

2

7

RSP0

TP261

3

6

4

5

47R

8

5

Q406

D6D7D

D

SI4431

R412

S1S2S

G

1K

3

4

R413

10K

R410

Q405

BC848B

3.3K

R414

NS

3 4

PART 1

G_16500_001a.eps

L800

+1V8_1

FB

C803

100nF

L809

+3Vstb

FB

TP39

C804

100nF

L810

+3Vstb

FB

TP40

C805

100nF

XTAL2LI

L811

DECDIG

FB

C806

100nF

L808

+5V_SW

FB

C849

C818

C817

100n

220uF/16V

100n

R854

10R

VDRB

R807

10K

F800

????

VIF_1

5

1

VIF_2

4

2

R803

FM OPT.

0R

3

R864

F801

J2

????

5

1

SIF_1

2

4

SIF_2

3

C800

220nF

C903

220nF

T23

R23

C807

100nF

C854

R24

100uF/6.3V

P23

P24

P25

R802

N23

22R

TP41

N25

N24

C856

NS

N26

C802

220nF

M26

M23

C857

X800

NS

M25

24.576MHz

M24

L23

R806 1K

L26

L25

C855 6.8nF

R862

L24

C853

12K

1.5u/16V

K26

K25

C860

C846

J26

R865

C826

47K

10uF/10V

220n

J25

100n

H26

K24

K23

G26

R868

C882

H25

R800

39K

NS

J24

330N

J23

H23

G25

H24

R866

AGC

C883

680R

R804

100K

10n

C866

C865

47p

47p

R828

C892

C891

100R

470n

470n

C889

2.2u/20V

R845

R842

R844

R843

0R

10K

10K

0R

TP43

TP42

TP44 TP47

SCIR1

SCIL1

SSIF

+5V_SW

R86710K

C867

47p

SCOL1

PART 3

G_16500_001c.eps

S801

1

TP199

2

3

BL_ADJ

4

TP198

5

TP201

6

BACKLIGHT

7

TP200

8

9

10

TP202

11

12

BL_EN

TP15

SECONDPANEL

S204

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CON20

R270

0R

+1V8_1

TP11 TP12

R87110K

R820 100R

VSSP2

VSSC4

VDDC4

VVDA3

VREF_POS_ LSL

VREF_NEG_LSR+HPR

VREF_POS_ LSR +H P R

VREF_NEG_LSR+HPR

VREF_POS_ H PR

XTALIN

XTALOUT

GND4

VGUARD/SWI O

DECDIG

VP1

PH2LF

PH1LF

GND1

SECPLL

DECBG

EWD/AVL

VDRB

VDRA

VIFIN1

VIFIN2

VSC

IREF

GNDIF

SIFIN1/DVBIN1

SIFIN2/DVBIN2

AGCOUT

EHTO

C868

47p

R829

100R

C890

2.2u/20V

S301

CON15

C6

A5

NC36B5NC37D5NC38C5NC39A4NC40B4NC41

VSS_CORE5

VDD_CORE5

A8/CFG8/CLKOUT

A9/CFG9/PWM2

A10/CFG10

AF6

AE8

AD7

A8A9A10

PSEN_6745 FLASH_OE

WR_6745 F LA SH _WR

6745_RST

15

+3V3_IO

+1V8_CORE

D7

B7

A6

B6

D6

VSS_IO3

VDD_IO3

VSS_CORE4

VDD_CORE4

A11/CFG11

VDD_CORE1

VSS_CORE1

A12/CFG12

A13/CFG13

A14/CFG14

A15/CFG15

AF7

AF8

AE7

AC8

AD8

AC9

AD9

A12

A13

A14

A15

A11

R517

0R

TP404

R518

0R

TP405

R534

FLASH_RST

100R

+3V3S_SW

R511

WR_6745

4.7K

R512

PSEN_6745

4.7K

L13

B10

M14

L14

NC23

NC24

NC25B9NC26A9NC27

NC28

NC29A8NC30B8NC31A7NC32C8NC33D8NC34C7NC35

A16/GPIO(10)

VSS_CORE41H2NC4

VSS_IO1

VDD_IO2

NC5

VSS_CORE21

NC6

NC7

VSS_IO01

AE9

AF10

AF11

AC10

AE10

AC11

AE11

AD10

AD11

A16

TP254

R232

DVD_Y/Y4IN

9

0R

TP247

Y2IN

8

TP248

R936

U59

7

100R

C2IN

6

TP251

R937

5

+8V_SW

0R

SCIR2

4

TP252

3

SCIL2

2

TP253

1

+3V3S_SW

TP249

R237

1.2KK

TP250

R855

Q208

LED_BLNG

BC857B

10K

TP246

R238

4.7K

+3V3_IO

TP358

+3V3S_SW +3V3_LVDS

L507

TP182

BEAD

L508

BEAD

R907

5

6

7

8

0R

R910

6

7

8

0R

R911

5

6

7

8

0R

SECONDPANEL

R506

BL_ADJ

4.7K

TP355

R507

BL_EN

4.7K

TP356

R513

82K

TP359

R508

INTX

4.7K

TP360

R509

IAPMUTE

4.7K

TP357

R510

TCB_EN

4.7K

OPTIONAL

C544

TP158

NS

X500

NS

C545

TP159

C554

NS

100pF

TP184

C522

C523

100nF

100nF

TP183

C542

C524

100nF

22uF/6.3V

TP407

R913

PCLK

100R

R908

5

6

7

8

4

0R

3

2

1

R909

5

6

7

8

45

0R

3

2

1

R912

7

8

4

0R

3

2

1

R928

R927

47R

47R

R923

47R

R925

47R

R926

R924

NS

NS

12

+1V8_CORE

+3V3_IO

KBD0

TP2

KBD1

6745_RST

C537

10uF/10V

TP3

F029

TP4

A17

XTLOUT

XTLIN

XTAL2LI

C525

100nF

C527

C526

100nF

100nF

C942

47uF/6.3V

C943

47uF/6.3V

TP408

26

4

27

3

29

2

30

1

32

33

34

35

37

4

38

3

39

2

41

1

42

43

45

46

47

49

3456

50

2

51

1

53

54

55

1

2

3

5

6

7

+3V3_IO

RXCLKOUT

RXOUT0

RXOUT1

RXOUT2

RXOUT3

RXOUT4

RXOUT5

RXOUT6

RXOUT7

RXOUT8

RXOUT9

RXOUT10

RXOUT11

RXOUT12

RXOUT13

RXOUT14

RXOUT15

RXOUT16

RXOUT17

RXOUT18

RXOUT19

RXOUT20

RXOUT21

RXOUT22

RXOUT23

RXOUT24

RXOUT25

RXOUT26

RXOUT27

C529

C528

100nF

100nF

+3V3S_SW

L900

10uH

C939

100n

C940

100n

13

+1V8_ADC

L500

BEAD

C509

22uF/6.3V

IN_SOG

SCALER_R

FER_R

+1V8_PLL

+3V3S_SW

TP81

L901

10uH

TP242

TP241

TP244

23

VCC

VCC31VCC40VCC

PLL-VCC

D S 9 0 C 3 8 6

PLLGND

PLLGND22LVDS-GND21LVDS-GND14LVDS-GND8GND52GND44GND36GND28GND

24

LED_R_O

+3V3_AVI

SCALER_B

FER_B

F001

TP1

SCALER_G

FER_G

DIFFGND

R519

12K

+3V3_PLL

AHSYNC

AVSYNC

VSCL

L902

10uH

TP245

C906

100n

C907

100n

48

56

VCC

RXIN0-

RXIN0+

RXIN1-

RXIN1+

RXIN2-

RXIN2+

RXCLKIN-

RXCLKIN+

RXIN3-

RXIN3+

PWRDWN

4

12 13

1413

+1V8_XTL

VDDA_PP LL

INTX

6745_RST

U59

IIC_SDA

IIC_SCL

BL_ADJ

BL_EN

XTLOUT

XTLIN

PNL_PWRN

U20

AVI_DET

TCB_EN

TP5

G1

J3

G3

F2

G2

H3

J4

AF9

F1

NC2

NC43

RST_N

VSSA_PPL

VDDA_PPLL

INT_N/GPIO7

SDA/GPIO(13)

C908

100n

C909

100n

VSS_CORE3

VDD_IO0

VDD_IO01

KDB0

KBD1

PWM0

A17/GPIO(11)

NC45

NC46

VDD_CORE11

NC47

NC48

VSS_CORE11

NC49

NC50

VSS_CORE01

NC51

NC52

TXD/GPIO(6)

NC53

VSS_IO31

VDD3V3_RGB2

VSSA_RGB2

IN_B

REF_B

VSSA_ADC_B

VDDA1V8_ADC_B

AVI_TEST

VDD3V3_RGB1

VSSA_RGB1

IN_G

REF_G

VSSA_ADC_G

VDDA1V8_ADC_G

VDD3V3_IN

VSSA_CLEAN

VDD_CORE2

RBIAS

SOGIN

VDD3V3_RGB0

VSSA_RGB0

IN_R

REF_R

VSSA_ADC_R

VDD1V8_ADC_R

VDD3V3_LPLL

VDD1V8_LP LL

VSSA_CLEAN _LP LL

VSSA_LPLL

AHS

AVS

ASCL(GPIO14)

GPIO(9)/ACLK

ASDA(GPIO15)

RXDGPIO(5)D1NC57

VDD_CORE12

NC3

APMUTE

AE1

AA2

AB1

AB2

AC1

AC2D7AD1D6AC3

LED_G_O

VSDA

C944

47uF/6.3V

R914

R918

RSN9

45

100R

RSP9

3

6

RSN8

7

2

RSP8

1

8

R915

68R

100R

R920

R919

45

RSN7

100R

6

3

RSP7

7

RSN6

2

1

RSP6

8

R921

68R

150R

R916

RSN5

1

8

2

7

RSP5

R922

3

6

4

5

100R

68R

R931

+3V3S_SW

10K

R904

NS

K4

J2

H1

J1

K2

L4

K1

A1

A2

L3

A10

A17

M2

A18

A19

M3

A21

A22

L1

A24

L2

M1

N4

N3

P4

N2

N1

P3

P2

P1

R3

R4

R2

R1

T1

T2

U1

T3

T4

V1

U2

U3

U4

V4

V2

V3

W1

W2

W3

Y1

Y2

AA1

U900

9

10

11

12

15

16

17

18

19

20

25

DS90C386

TP16

TP6

C4

AE14

B3

E4

D4

F4

D3

E3

G4

F3

E2

AA3

E1

H4

SCL/GPIO(12)

GPIO(4)/PWM1/TCP_TDO

D5

D4

AE2

AB4

FLASH_RST

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

NC55

XTAL0D2XTAL1

VDD_IO1

VSS_CORE7

GPIO(3)/TRST

D3

D2

VSS_IO0

AD3

AC4

+3V3S_SW

R514

10K

9

TP378

10

TP368

11

TP369

12

TP370

13

TP371

14

TP367

15

TP372

16

TP373

17

TP374

18

TP375

19

TP376

20

TP377

T_ENABLE

VDD_XTAL

VSS_CORE6

GPIO(0)/TMS

GPIO(2)/TCK

VSSA_XTAL

GPIO(1)/T1/TDI

7103

NC54

D0

VDD_CORE0

VSS_CORE0

A0/CFG0

A1/CFG1

A2/CFG2

A3/CFG3

A4/CFG4

A5/CFG5

A6/CFG6

A7/CFG7/RSTOUT

WR_NGPIO(8)

AF4

AE4

AE5

AC5

AD5

A0A1A2A3A4A5A6

A14

TP395

TP394

U501

4

A145A17

A13

TP382

3

A8

TP383

2

A9

TP384

1

A11

TP385

32

OE

TP386

31

A10

TP387

30

CE

29

D7

TP388

28

D6

TP389

27

D5

TP390

26

D4

TP391

25

D3

TP392

TP406

24

TP381

RDPSEN_N

AF5

AE6

AC6

AD6

AC7

A7

PSEN_6745

WR_6745

A13

A8

+3V3S_SW

A9

R521

A11

10K

FLASH_OE

A10

D7

D6

D5

D4

D3

A25D1AF2

AF3

AE3

AD4

D0D1D2D3D4D5D6D7IAPMUTE

A17

FLASH_WR

R520

10K

TP393

C536

100nF

6WE7

8

RST

VCC

A16

A15

A12

A7

A6

A5

A4

SST39VF020B/PLCC32

A3

A2

A1

A0

D021D122D223GND

TP379

D0D1D2

TP380

14 15 16

543

L802

+1V8_1

FB

L801

FB

C809

C839

220n

100n

MUTE

R808 100R

C810

PORT_C

100n

PORT_A

VDDA1

PC_DET

TP91

R821 100R

R822 100R

SAW_SW

AE23

AC23

AD23

AF24

AE24

M15

AE25

VSSC3

VDDC3

VDDA4

P1_4/RX

P1_5/TX

P1_2/INT2

P2_5/PWM4

REFO/REFIN

AUDIO/N5L

AUDIO/NR

AUDOUTSL

AUDOUTSR

F25

F24

F23

E25

G24

C885

4.7uF/10V

C905

C827

100n

100n

L816

FB

C861

C873

L817

10uF/10V

FB

47P

R870

R830

390R

100R

C835

C836

100n

100n

+8V_SW

+5V_SW

SCOR1

+5V

D300

BAV99W

PC_VS

PC_HS

+5V

TP59

D301

BAV99W

1

VRIN

VGIN

2

VBIN

3

4

5

6

7

8

9

10

R331

11

100R

TP281

12

13

TP280

TP279

14

TP278

15

R319NSR318NSR317NSR320

D304

BAV99W

L803

C840

C847

220n

100uF/6.3V

KEYB

+3Vstb

PWM1

TP90

TP14

R848

1.2K

R839NS

R84910R

R809100R

R840NS

AF23

AD22

AC22

AF22

AE22

VSSC/P

DECV1V8

P3_2/ADC2

P3_3/ADC3

P2_4/PWM3

DECSDEM

QSSO/AMOUT/AUDEEM

GND2

PLLIF

SIFAGC

E24

E23

D24

C24

B24

C886

C887

2.2uF/20V

3.9n

R900

R901

15K

15K

C875

C874

47pF

47pF

C893

C894

470n

470n

R847

R846

10K

10K

TP92

CVBSO2

SCIR2

SCIL2

VGA_TV_SW

+3VSTB

R352

4.7K

R300

VDRB

TP62

10R

TP60

R301

HOUT

10R

TP61

AVI_DET

R315

D302

NS

BAV99W

R335

220R

R332

100R

TP282

R351

NS

R336

220R

VSCL

TP283

NS

+5V

+1V8_1+3Vstb

FB

C841

+5V_SW

220n

R87210K

SCL

SDA

ASTB

ON_OFF

PORT_B

STATAV1

AMPLVOLUME

TP13

VGA_TV_SW

YUV_TV_SW

TP89

R8010R

R805NS

R811100R

R813100R

R815100R

R816100R

R810100R

R812100R

R8141K

AE19

AD19

AC19

AC20

AF20

AE20

AD20

AF21

AE21

AD21

AC21

VDDC1

DVBO/IFVO/FMRO

DVBO/FMRO

D23

C23

C902

100p

C901

100n

TP48

DVD_Y/Y4IN

R303

0R

R302

0R

TV_VS

R305

0R

R304

0R

TV_HS

TP284

TP285

P1_3/T1

P1_6/SCL

P1_7/SDA

P3_0/ADC0

P3_1/ADC1

P2_2/PWM1

P2_3/PWM2

P2_0/TPWM

VDDP_B183

P2_1/PWMO

C4

AUDION2L

VCC8V

AGC2SIF

VP2

IFVO/SVO/CVBS1

AUDION4L

AUDION4R

CVBS4/Y4

C20

B20

A20

D22

C22

D21

B23

A23

C21

B21

C888

2.2uF/20V

C899

C896

C895

C871

100p

47p

47p

47p

C872

10n

C897

C801

C837

C904

470n

100n

470n

470n

R833

R831

R832

100R

100R

100R

TP51

TP52

TP49

Y1SCART

DVD_C

PCIL

HDIR

HDIL

L300

TP351

BEAD

16

C300

U300

100nF

10

0

VDD

TP350

9

1

6

G4

12

0

14

TP64

1

R308

13

15

75R

2

11

74HC4052D

3

1

0

5

TP63

1

R309

3

2

75R

2

4

3

VEE7VSS

8

TP289

R329

100R

R330

100R

TP286

TP287

R333

100R

+3VSTB

R311

R312

R310

R337

75R

75R

75R

47K

+5V

D306

TP288

LL4148

R316

VSDA

NS

VSCL

8

R339

R3070RR340

U302

3.3K

3.3K

7

E0

WC

VCC

6

SCL

E1

24LC21A

5

SDA

E2

VSS

+5V

4

D305

BAV99W

5

6

L804

FB

C842

C811

220n

100n

+3V3S_SW

+3V3S_SW

R850

R858

DVD/PC

+3Vstb

NS

NS

REMOTE

TP88

IR_MUTE

+5V_SW

TP86

TP87

R838

R857220R

NS

R83710K

R82610K

R86110K

R817100R

R818100R

R819100R

MUTE_IN

LED_BLNG

TFT_ON/OFF

AA25

AA24

AA23

AC17

AD17

AE18

AD18

AC18

AF18

AF19

VSSC2

VDDC2

P1_1/TO

P1_0/INT1

INTO/P0_5

P0_4/I2SWS

P0_3/I2SCLK

P0_2/I2SDO2

P0_1/I2SDO1

P0_0/I2SDI1/O

VREFAD_POS

VREFAD_NEG

AUDION2R

CVBS2/Y2

AUDIOIN3L

AUDIOIN3R

CVBS3/Y3

C2/C3

AUDOUTLSL

AUDOUTLSR

AUDOUTHPL

AUDOUTHPR

B19

C878

47p

PCIR

CVBSO/PIP

D19

C19

D18

C18

C17

D17

D16

C16

B18

C870

C869

47p

47p

R835

R836

100R

100R

C881

C880

C879

47p

47p

47p

C884

C838

100n

10n

C898

470n

R834

100R

TP54

TP57

TP50

MOL

MOR

C2IN

Y2IN

L806

FB

C812

100n

L807

PORT_D

FB

C813

+5V_SW

100n

C848

100uF/6.3V

R863

R87310K

R85915K

L805

100R

FB

C843

220n

U500A

T16

VDD_ADC

T15

VSS_ADC

R16

VDDA2

C821

R15

VDDA

P16

100n

GNDA

C850

P15

VREFAD

N15

100uF/10V

N16

M16

VDDA1

R823

100R

Y25

BO

R824

100R

Y23

GO

R825

100R

Y24

RO

W23

C808

BLKIN

1n

W24

C858

BCLIN

47uF/10V

L16

VP3

L15

GND3

C819

V23

B/PBIN3

C820

V24

100n

G/YIN3

C828

U23

100n

R/PRIN3

R827 100R

U24

100n

INSSW3

T26

VOUT

T25

UOUT

F26

YOUT

C830

E26

YSYNC

C831

B14

100n

YIN

C829

A15

100n

UIN

C832

B15

100n

VIN

D15

100n

VDD_COM B

C15

C852

VSSCOMB

100uF/10V

A16

HOUT

B16

FBISO/CSY

B17

SVM

R869

7103

2.2K

R856

R841

R860

10K

27K

+5V

R528

LED_R_O

TP9

2.2K

R529

LED_G_O

2.2K

AVSYNC

C306

27pF

AHSYNC

C307

27pF

TV_R

TV_G

TP291

TV_B

TP292

VGA_TV_SW

C310

C308

C309

12pF

12pF

12pF

+5V_SW

D307

TP290

L302

BEAD

LL4148

S302

C303

100nF

L

C302

100nF

1

2

S303

3

R

TP10

+5V_SW

TP203

L301

BEAD

TP204

16

16

C301

100nF

U301

U306

VCC

VCC

2

2

S1A

S1A

4

4

DA

DA

3

3

S2A

S2A

5

5

S1B

S1B

RAIN

7

7

DB

DB

6

6

S2B

S2B

11

11

S1C

S1C

9

9

GAIN

DC

DC

10

10

S2C

S2C

14

14

S1D

S1D

12

12

BAIN

DD

DD

13

13

S2D

S2D

1

1

PI5V330W

IN

IN

PI5V330W_SOIC16

15

15

EN

EN

GND

GND

8

8

TP365

R347

1

2

1

2

S300

1

2

3

PC AUDIO

R306NSR349

TP363

R346

NS

TP366

R313NSR323

TP364

R314

NS

HDIL

10K

TP66

C315

15K

100pF

R348

HDIR

10K

TP65

R350

C316

15K

100pF

R321

PCL

10K

TP67

C304

15K

100pF

R322

PCR

10K

TP68

R324

C305

15K

100pF

6

7

+1V8_2

C815

100n

+3Vstb

C816

100n

+1V8_2

C814

100n

L812

+3Vstb

FB

C823

C844

100n

220n

VDDA1

L813

+3Vstb

100uF/6.3V

FB

C824

C845

100n

C851

220n

BOUT

C862

GOUT

47p

C863

ROUT

47p

C864

47p

L814

+5V_SW

FB

C825

C859

C822

100n

10uF/10V

100n

BIN

GIN

RIN

FBLIN

VOUT

UOUT

YOUT

YIN

UIN

VIN

L815

+5V_SW

FB

C833

C834

100n

100n

HOUT

TP94

10R

SANDC

TP93

+5V_SW

TP212

L303

BEAD

16

16

C317

100nF

U303

U305

VCC

VCC

2

2

S1A

S1A

4

4

DA

DA

3

3

S2A

S2A

R

5

5

S1B

S1B

TV_R

7

7

DB

DB

PR

6

6

TP213

S2B

S2B

TP207

B

11

11

S1C

S1C

TV_B

9

9

DC

DC

10

10

PB

TP209

G

Y

TP211

YUV_TV_SW

TP205

D303

BAV99W

AVI_DET

TP295

TP293

PC_HS

R342

1K

TP294

PC_VS

R343

1K

TP214

S2C

S2C

14

14

S1D

S1D

TV_G

12

12

DD

DD

13

13

TP215

S2D

S2D

1

1

PI5V330W

IN

IN

PI5V330W_SOIC16

15

15

EN

EN

GND

GND

8

8

TP296

C313

R341

100K

C314

1u0

TP300

R334

100R

1u0

C311

TP297

R325

Q300

BC847B

1K

1u0

R338

47K

C312

TP298

R326

Q301

BC847B

1K

1u0

R344

100K

TP299

R328

Q302

BC847B

1K

R345

100K

7

8

S304

1

2

DVD_C

TP396

3

R353

4

NS

TP398

5

R851

DVD_Y/Y4IN

6

DVD_CVBS

NS

TP399

7

8

COAX

S800

TP401

MUTE_IN

9

1

R852

10

2

DVDL

TP403

1K

TP400

11

3

+5V_SW

12

13

2

1

5

3

C913

10pF

TP132

TP133

C324

47uF/10V

U304

X0

X1

Y0

Y1

Z0

Z1

4

LINE OUT

16

8

VSS

VDD

MX/DEMX

INH6A11B10C

R600

SCOL1

300R

TP95

R601

SCOR1

TP96

300R

TP97

BIN

C600

100pF

GIN

TP98

C606

100pF

RIN

TP99

C607

100pF

R634

1K

Q600

BC847B

R635

1K

DVD IDTV WIRELESS IN TERFACE

C319

100nF

7

VEE

X

Y

Z

9

C601

100pF

C602

100pF

R604

100R

R609

75R

R605

100R

R610

75R

R607

100R

R612

75R

R611

75R

C613

47pF

+5V_SW

R636

22R

C612

10uF/10V

TP402

R853

12

DVDR

1K

TP397

DVD IN

C912

10pF

R356

R3540RR355

PCR

DVDR

PCL

TP82

DVDL

C320

1nF

R357

L304

0R

0R

0R

BEAD

C318

100nF

TP85

TP84

R934

R

R933

R

C321

R932

R935

C322

C323

R

R

1nF

1nF

1nF

MOL

MOR

FD2

FD3FDFD4

FD1

FD

C947

47uF/16V

TP302 TP305

10

11

12

FD

+5V_DVD

TP306

C911

C910

100uF/10V

100nF

U404

78M08

3

1

IN

OUT

C423

C420

GND

100nF

47uF/10V

2

+12V

TP77

L400

BEAD

R403

C405

10K

100nF

TP304

TP76

R404

ON_OFF

3.3K

C416

470uF/25V

330pF

S209

TP307

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

11

12

CON12

R406

0R

TP216

+12V

S400

1

2

3

4

5VSTB

5

POWER IN

6

7

BL_EN1

8

ON_OFF

+12V_SW

TP79

C422

47uF/16V

TP236

j001

1

2

+3VSTB

+12V_SW'

JUMPER

R327

10K

PC_DET

+12V_SW

R416

NS

3

5

6

Q400B

IRF7316

4

Q402

BC847B

+12V

+12V

S401

1

TP303

2

TP78

3

POWER IN

+5V

DIM

BL_EN1

8

+5V_SW

TP137

R627

NS

S306

1

TP134

2

PORT_A

3

PORT_B

4

PORT_C

5

PORT_D

6

PCIR

14

TP135

PCIL

15

TP136

4

DVD/PC

TP169

R615

NS

R616

S600

NS

2

4

R617

NS

6

8

10

R618

12

NS

14

16

R622

NS

18

20

R623

NS

SCART

Q601

CVBSO2

BC857B

R602

3.3K

TP107

R603

3.3K

TP106

FD5

FD

FD

R417

NS

1

8

7

Q404A

IRF7316

2

+8V_SW

TP80

C421

100nF

ON_OFF

C418

U403

1

IN

5

ON/OFF

C408

100nF

C325

R365

REMOTE

56pF

220R

TP138

TP142

D308 LL4148

Q304

R363

IR_MUTE

10K

TP141

TP140

BC848B

TP139

R364

220R

C503

R500

SCALER_R

RAIN

TP145

TP147

10R

TP143

33nF

C500

10pF

C504

FER_R

TP150

33nF

R503

47R

C505

R501

SCALER_G

GAIN

10R

TP146

TP148

TP144

33nF

C538

IN_SOG

TP149

22nF

C501

10pF

C506

FER_G

TP174

33nF

R504

47R

C507

R502

BAIN

SCALER_B

10R

TP170

TP173

TP171

33nF

C502

10pF

C508

FER_B

TP175

TP172

33nF

R505

47R

R628

SCIR1

15K

R619

R631

C603

15K

NS

100pF

R629

TP104

SCIL1

15K

R632

R620

C604

NS

15K

100pF

1

3

R630

TP103

STATAV1

10K

R621

R633

5

C605

NS

3.3K

100pF

7

9

TP102

R606

11

13

15

17

19

21

TP217

TP218

FD6

FD

TP75

MIC4576

FBLIN

100R

R613

R624

C608

75R

NS

100pF

R608

Y1SCART

100R

R614

R625

C609

75R

NS

100pF

AUDIO AMPLIFIERS

TP223

R645

Q602

MUTE

BC847B

6.8K

+5V_SW

R637

18K

R409

NS

C616

4.7uF/10V

C617

4.7uF/10V

+3VSTB

R400

10K

TP74

R401

10K

TP309

C410

100uF/6.3V

R407

NS

R408

NS

2

C619

22uF/6V

TP108

1

2

+

S601

SPEAKER L

+5V +5V_SW

C400

100nF

R402

10K

R405

3.3K

220uF/16V

L401

33uH

TP311

D400

SL44

R626

1K

R640

C618

6.8K

220nF

TP221

TP222

HPLIN

HPRIN

TP224

TP226

TP225

12345

S604

HEADCON

S602

TP227

L600

1

L601

2

BEAD

TP228

3

TP229

4

HEADCON

5

TP230

TP73

R415

NS

1

8

C425

7

220uF/16V

Q400A

IRF7316

2

Q401

BC847B

Q403

BC847B

TP72

C419

C406

C424

100nF

220uF/16V

AMPLVOLUME

C610

3.3nF

C611

3.3nF

HPLOUT

TP308

+3VSTB

4

OUT

FB

GND

3

9

+5V_DVD

S307

1

TP151

2

3

+12V_SW

TP152

DVD POWER

4

+1V8_XTL

+1V8S_SW

TP157

L501

TP153

BEAD

C511

C514

100nF

100nF

+3V3_PLL

+3V3S_SW

L502

TP156

TP154

BEAD

C539

C515

22uF/6.3V

100nF

TP155

L503

BEAD

C540

C516

47uF/6.3V

100nF

+1V8S_SW VDDA_P P LL

L504

TP176 TP178

BEAD

C512

100nF

+1V8_PLL

L505

TP179

BEAD

C513

100nF

DIFFGND

TP181

L506

BEAD

C541

C517

100nF

22uF/6.3V

+1V8S_SW

TP180

L509

BEAD

TP177

C543

C530

100nF

22uF/6.3V

STOCKO

R240

SDA

S202

47R

4

IIC_SDA

+5V

TP361

3

C210

2

NS

TP362

1

IIC_SCL

R241

SCL

STOCKO

47R

R639

4.7K

1uF/16V

C225

C946

C945

+12V_SW'

100uF/16V

100uF/16V

C615

C620

100uF/16V

100uF/16V

TP232

U600

1

V.CN1

2

MH2

NC

3

VIN1

4

VSUP

5

VIN2

6

SGND

7

V.CN2

8

OUT2+

9

PGND2

10

OUT2-

11

OUT1-

12

PGND1

MH1

13

OUT1+

TDA7057AQ

HPROUT

TP235

TP233

TP231

TP234

1

2

--

+

S603

SPEAKER R

HPLOUT

BEAD

TP112

HPLIN

TP111

L602

HPRIN

BEAD

TP110

L603

HPROUT

BEAD

TP109

U400

TP312

3

OUT

IN

LM1117MP

C409

C401

100nF

220uF/16V

VOUT

GND

1

U402

LF18

3

1

IN

OUT

C403

C411

GND

100uF/6.3V

100nF

2

D309 5L40

+5VWD

5VSTB

+5V

U401

TP313

L402

3

IN

OUT

BEAD

LM1117MP

C417

C414

330pF

NS

VOUT

GND

1

10

DIFFGND

+3V3_AVI

C518

C520

100nF

100nF

DIFFGND

+1V8_ADC

C519

C521

100nF

100nF

DIFFGND

+1V8_CORE

C531

C532

C533

100nF

100nF

100nF

C614

C621

100nF

220uF/16V

+3V3S_SW

2

TP69

C412

C402

100nF

47uF/6.3V

4

+1V8S_SW

TP70

C413

C404

47uF/6.3V

100nF

+3VSTB

2

TP71

C415

C407

47uF/6.3V

100nF

4

11109

PART 2

G_16500_001b.eps

C534

C535

100nF

100nF

PART 4

G_16500_001d.eps

S900

1

DGEF(7)

26

TP238 TP239

2

PCLK

27

TP237

3

DBEF(0)

28

TP240

4

DBEF(1)

29

HSYNC

TP334

TP330

30

5

VSYNC

DBEF(2)

TP331

TP335

DREF(0)

6

DE_TTL

DBEF(3)

31

DREF(1)

TP336

TP332

TP314

DREF(0)

TP315

DREF(1)

TP316

DREF(2)

TP317

DREF(3)

TP318

DREF(4)

TP319

DREF(5)

TP320

DREF(6)

TP321

DREF(7)

TP322

DGEF(0)

TP323

DGEF(1)

TP324

DGEF(2)

TP325

DGEF(3)

TP326

DGEF(4)

TP327

DGEF(5)

TP328

DGEF(6)

TP329

11

32

7

8

33

9

34

10

35

36

11

12

37

13

38

14

39

15

40

16

41

17

42

43

18

19

44

20

45

21

46

22

47

TP333 TP344

23

48

49

24

50

25

CON50

TP341

DREF(2)

DREF(3)

DREF(4)

DBEF(4)

DREF(7)

TP337

DREF(5)

DBEF(5)

DGEF(0)

TP338

DGEF(1)

DBEF(6)

DGEF(2)

TP339

DGEF(6)

DBEF(7)

DGEF(7)

TP340

DGEF(3)

DGEF(4)

DGEF(5)

DBEF(0)

DBEF(6)

DBEF(7)

DBEF(1)

DBEF(2)

DBEF(3)

DBEF(4)

DBEF(5)

HSYNC

VSYNC

DE_TTL

DREF(6)

TP343

L903

R906

10uH

0R

C938

100uF/16V

R902

+5V_SW

TP342

NS

R903

+5V_SW

NS

R917

R905

0R

0R

C11

B11

A11

C10

U500B

NC19

NC20

NC21

NC22

+3V3_LVDS

L12

VSS_LVDS3

L11

RSN7

D10

RSN8

C9

RSN9

M13

NC14

D12

VSS_LVDS21

C12

VSS_LVDS11

B12

VDD_LVD3

D11

RSP8

A12

NC59

A13

NC58

D13

NC56

D14

NC60

C13

VDD_LVDS2

M12

NC44

M11

RSP7

B13

VSS_LVDS2

D9

RSP9

C14

VDD_LVDS1

N13

RSN6

N14

RSP6

A14

VSS_LVDS1

N12

RSN5

N11

RSP5

P12

RSN4

P11

RSP4

P13

VDD_LVDS0

R11

RSN3

R12

RSP3

R13

RSN2

R14

RSP2

P14

VSS_LVDS0

T14

RSN1

T13

RSP1

T11

RSN0

T12

RSP0

AE17

VDD_CORE2

AC16

NC12

AD16

NC11

AE16

NC10

AF16

NC9

AC15

VDD_CORE5 1

AD15

VDD_CORE4 1

AE15

VDD_CORE3 1

AF15

VDD_CORE2 1

AF14

VSS_CORE71

A3

VSS_CORE51

AC14

VDD_CORE3

AD14

VSS_CORE31

AD13

NC8

AE13

VDD_IO11

AF13

VDD_IO21

Y4

VDD_CORE0 1

VSS_IO11

VSS_IO21

VSS_CORE2

VSS_IO2

AF12

AC12

AE12

AD12

S203

KEYB

1

TP257

2

5

A/V FRONT

4

TP258

REMOTE

3

+3VSTB

2

TP259

R516

1

KEYB

0R

TP256

5

TP260

4

R236

3.3K

3

REMOTE

2

+3VSTB

TP262

R233

KEYB

1

TP255

0R

G_16500_001.eps

16

S206

CON2

S207

CON5

S208

CON5

RSN7

RSN8

RSN9

RSP8

RSP7

RSP9

RSN6

RSP6

RSN5

RSP5

RSN4

RSP4

RSN3

RSP3

RSN2

RSP2

RSN1

RSP1

RSN0

RSP0

+1V8_CORE

231106

D

C

+3V3_IO

B

A

Page 16

Main Board Part 1

A0

A1

24C32

A2

VSS4SDA

C715

R733

27K

SANDC

YOUT

UOUT

VOUT

SCL

VDD

PTC

SCL

TUN1

TUNER

SECAM L

EEPROM INTERFACE

TP100

8

R700

7

3.3K

6

TP188

5

TP105

AGC/AGC1TUN/TUN2AS/UHF

TP18

D700

R734

R735

R729

1N4148

27K

6.8K

NS

5V_T

ADR. SEL.

L703

12uH

TP32

AGC

TP160

R738

22R

L710

L704

C716

47uH

47uH

4.7nF

TP27

TP26

TP25

TP24

TP23

TP161

C717

4.7nF

R701

3.3K

3

R730

0R

C876

NS

TP33

SCL

TP38

Q701

BC847

R708

0R

R721

100R

R722

100R

R723

100R

R724

100R

1

2

3

C709

100nF

U700

47uF/10V

Circuit Diagrams and PWB Layouts

+5V_SW

+3VSTB

L700

FB

C700

C701

100nF

220nF

SCL

SDA

SCL/UHF34SDA/UHF15NC/+5V6+5V/AFT7ADC/NC8+33V/NC9IF2/IF210IF1/IF1

R705

TP53

NS

TP56TP55

TP45

TP46

SDA

L706

10uH

R720

100R

TP34

TP35

C877

NS

FM-OPT.

PLACE CLOSE

TO TUNER

R719

100R

+5V_SW

TP163

R739

L711 47uH

33K

L705

47uH

C719

220pF/50V

C718

4.7nF

U701

1

SC

2

GND

3

ADEXT1

4

ADEXT2

5

ADEXT3

6

YIN

7

ADR

8

UIN

9

VIN

10

GND

11

SCL

12

GND

TDA9178T

33V

TP164TP162

C720

1nF

SOUT

YOUT

UOUT

VOUT

DECDIG

TP83

10.7

GND

GND

VCC

VEE

SDA

GND

C723

10uF/10V