Page 1

TEA5880TS

Integrated FM stereo radio IC for host processor tuning in

handheld applications

Rev. 02 — 26 April 2004 Preliminary data sheet

1. General description

The TEA5880TS stereo FM radio IC dramatically reduces the printed-circuit board area

(only 100 mm2) needed to integrate FM radio functionality into portable devices. This

makes it invaluable for any application where space is at a premium.

Relying on a system host processor for radio tuning, the TEA5880TS is ideally suited for

powerful devices such as PDAs, notebooks, portable CD and MP3 players.

2. Features

■ No alignments necessary

■ Complete adjustment-free stereo decoder; no external crystal required

■ Fully integrated MPX VCO circuit

■ Fully integrated low IF selectivity and demodulation

■ The full integration level means no or few external components required

■ No external FM discriminator needed due to full integration

■ Built-in adjacent channel interference total reduction (no 114 kHz, no 190 kHz)

■ The leveloftheincomingsignalatwhichtheradiomust lock is software programmable

■ Due to new tuning concept, the tuning is independent of the channel spacing

■ Very high sensitivity due to integrated low noise RF input amplifier

■ RF Automatic Gain Control (AGC) circuit

■ Standby mode for power-down, no power switch circuitry required

■ 2.7 V minimum supply voltage

■ MPX output for RDS

■ 3-wire bus

■ In combination withthe host, fast, low power operation of preset mode, manual search,

automatic search and automatic store are possible

■ Host can be in Sleep mode after tuning; a minute retuning is recommended to

compensate for temperature and voltage fluctuations

■ Covers all Japanese, European and US bands.

Page 2

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

3. Quick reference data

Table 1: Quick reference data

V

= V

CCA

Symbol Parameter Conditions Min Typ Max Unit

V

V

I

CCA

I

CCD

I

LED

f

FM(ant)

T

FM overall system parameters

V

SUP

IP3

IP3

S

S

S

S

IR image rejection f

V

V

(S+N)/N maximum signal plus

α

CCA

CCD

amb

i(RF)

in

out

−300

+300

−200

+200

AUDL

AUDR

cs

CCD

analog supply voltage 2.7 3.0 5.0 V

digital supply voltage 2.7 3.0 5.0 V

analog supply current operating - 17 22 mA

standby - 1 100 µA

digital supply current operating - 250 500 mA

standby - 1 100 µA

optional stereo LED - 1 2 mA

FM input frequency 76 - 108 MHz

ambient temperature V

RF sensitivity input

voltage

V

CCA

CCA

= V

= V

CC(VCO)

CC(VCO)

= V

= V

= 3 V −10 - +75 °C

CCD

= 5 V −40 - +85 °C

CCD

fRF = 76 MHz to 108 MHz; ∆f = 22.5 kHz;

f

= 1 kHz; (S+N)/N = 26 dB;

mod

-13µV

de-emphasis = 75 us;

B

= 300 Hz to 15 kHz; left = right

AF

pilot suppression ∆f

pilot

in-band 3rd order

= 6.75 kHz; ∆f = 68.5 kHz 40 dB

pilot

-95-dBµV

intercept point at LNA

input

out-band 3rd order

-95-dBµV

intercept point at LNA

input

LOW side 300 kHz

∆f = −300 kHz; fRF= 76 MHz to 108 MHz - 40 - dB

selectivity

HIGH side 300 kHz

∆f = 300 kHz; fRF = 76 MHz to 108 MHz - 50 - dB

selectivity

LOW side 200 kHz

∆f = −200 kHz; fRF = 76 MHz to 108 MHz - 30 - dB

selectivity

HIGH side 200 kHz

∆f = 200 kHz; fRF = 76 MHz to 108 MHz - 40 - dB

selectivity

= 76 MHz to 108 MHz - 26 - dB

RF

;

left and right audio output

voltage

noise-to-noise ratio

stereo channel

separation

VRF = 1 mV; left = right; ∆f = 22.5 kHz;

f

= 1 kHz

mod

= 1 mV; left = right; ∆f = 22.5 kHz;

V

RF

f

= 1 kHz de-emphasis = 75 µs;

mod

B

= 300 Hz to 15 kHz

AF

VRF = 1 mV; right = 1 and left = 0 or

right = 0 and left = 1; f

∆f

= 6.75 kHz; ∆f

pilot

∆f

= 0 or ∆f

right

= 68.5 kHz and ∆f

right

= 1 kHz;

mod

= 68.5 kHz and

left

left

- 100 - mV

48 56 - dB

15 25 - dB

= 0

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 2 of 27

Page 3

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Table 1: Quick reference data

V

= V

CCA

Symbol Parameter Conditions Min Typ Max Unit

THD total harmonic distortion VRF = 1 mV; left = right; ∆f = 75 kHz;

DEEM

CCD

integrated de-emphasis - 50/75 - µs

…continued

f

= 1 kHz; BAF = 300 Hz to 15 kHz

mod

= 1 mV; left = right; ∆f = 22.5 kHz;

V

RF

f

= 1 kHz; BAF = 300 Hz to 15 kHz

mod

- 0.7 1.5 %

- 0.2 0.7 %

4. Ordering information

Table 2: Ordering information

Type number Package

Name Description Version

TEA5880TS SSOP24 plastic shrink small outline package; 24 leads; body width 5.3 mm SOT340-1

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 3 of 27

Page 4

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 4 of 27

xxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx x xxxxxxxxxxxxxx xxxxxxxxxx xxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx

xxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxxxx xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxx xxxxxxxxxxxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxx x x

MICROCONTROLLER

LR1 V

CC1VCC1

LL1

reserved

2117 18 19 20

R/W CLOCK

68 7

DATA

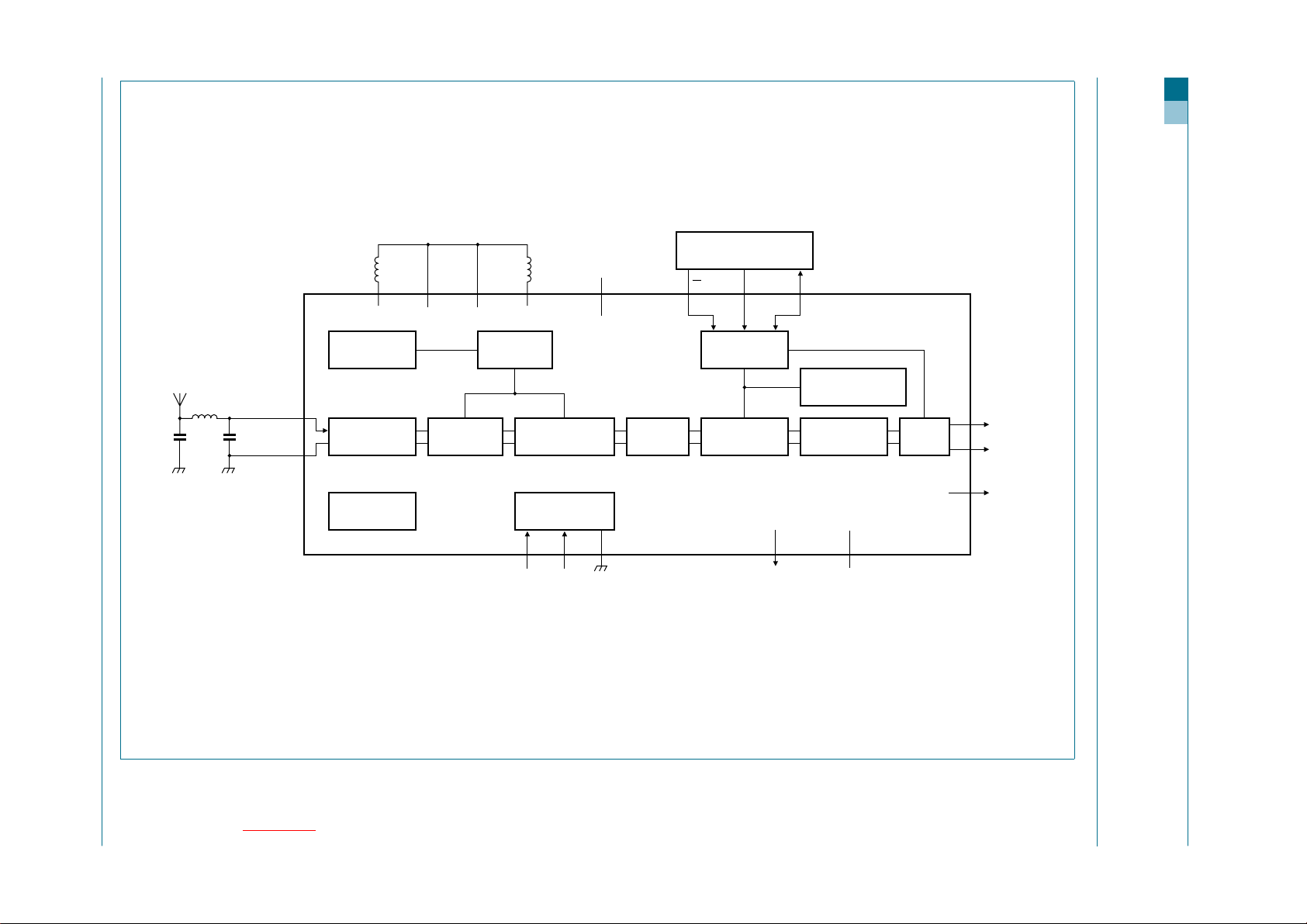

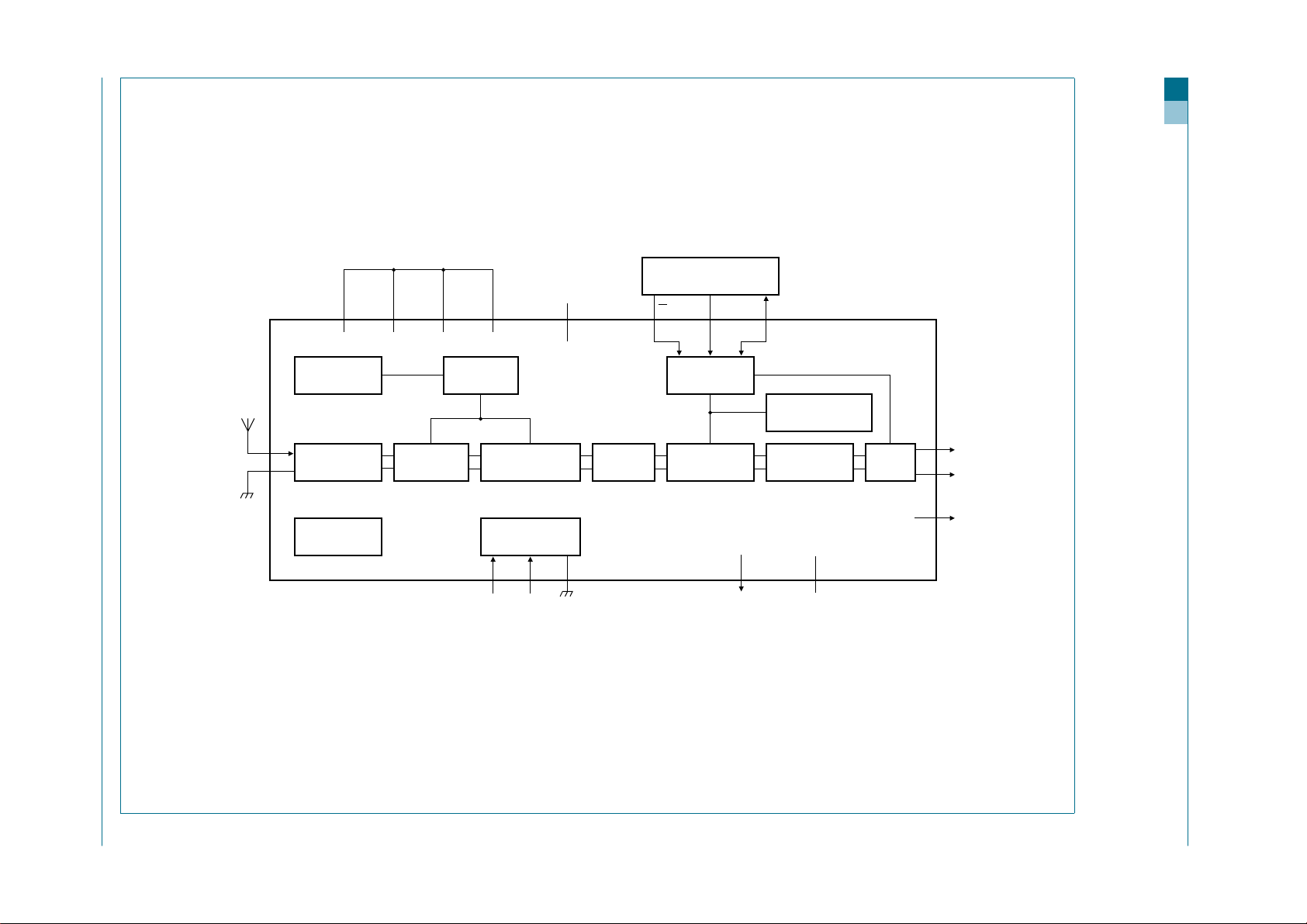

5. Block diagram

Philips Semiconductors

RFIN

RFGND

QUADRATURE

OSCILLATOR

1

QUADRATURE

2

STABILISATOR

MIXER

SELECTIVITY DEMODULATOR

TUNING

SYSTEM

V

CCA

POWER

SWITCH

5

V

CCD

DIGITAL

INTERFACE

STEREO

DECODER

DE-EMPHASIS

50/75 µs

TEA5880TS

4 3, 13, 24

GND LED n.c.

12 14, 15, 16, 22, 23

LEVEL VOLTAGE

GENERATOR

DE-EMPHASIS

15 kHz

MIXER

001aaa665

10

AUDL

11

AUDR

9

MPX

Fig 1. Block diagram.

Depending on the antenna design the filter components at pins 1 and 2 may not be necessary.The only two remaining coils connected to pin

17 to 20 can be replaced by printed-circuit board traces that will fit underneath the TEA5880TS resulting in a design without any external

components; see Section 14 for details on the printed-circuit board coils.

Integrated FM stereo radio IC for host processor tuning

TEA5880TS

Page 5

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 5 of 27

xxxx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxx x xxxxxxxxxxxxxx xxxxxxxxxx xxx xxxxxx xxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx

xxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxxxx xxxxxxxxxxxxxxxxxxx

xxxxxxxxxxxxxxxx xxxxxxxxxxxxxx xxxxxx xx xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxxxxxx xxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxxxx x x

MICROCONTROLLER

LR1 V

CC1VCC1

LL1

reserved

2117 18 19 20

R/W CLOCK

68 7

DATA

Philips Semiconductors

QUADRATURE

OSCILLATOR

RFIN

RFGND

QUADRATURE

MIXER

STABILISATOR

SELECTIVITY DEMODULATOR

Fig 2. Block diagram (no external components).

TUNING

SYSTEM

V

CCA

POWER

SWITCH

5

V

CCD

DIGITAL

INTERFACE

STEREO

DECODER

DE-EMPHASIS

50/75 µs

TEA5880TS

4 3, 13, 24

GND LED n.c.

12 14, 15, 16, 22, 23

LEVEL VOLTAGE

GENERATOR

DE-EMPHASIS

15 kHz

MIXER

001aaa666

10

AUDL

11

AUDR

9

MPX

Integrated FM stereo radio IC for host processor tuning

TEA5880TS

Page 6

Philips Semiconductors

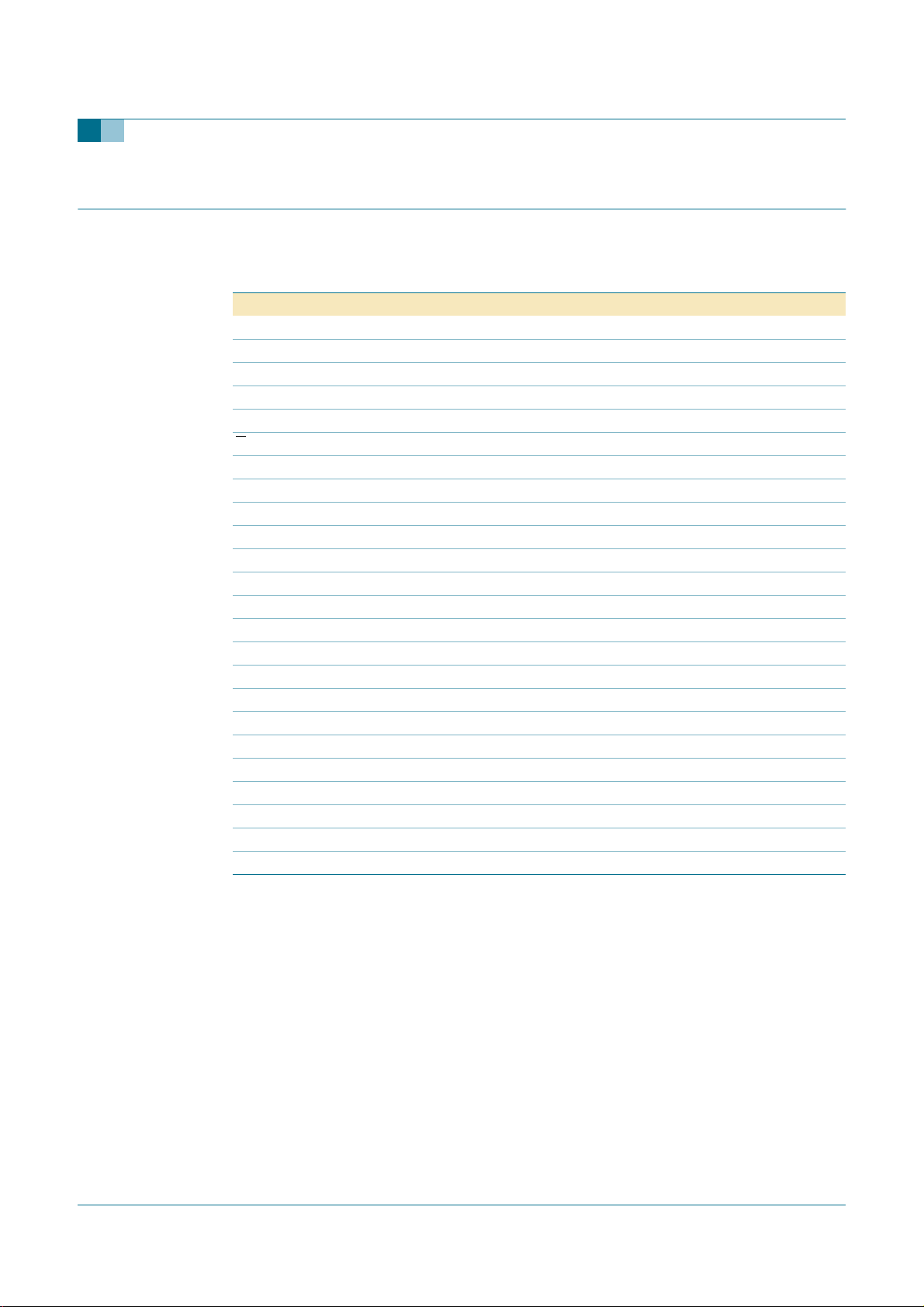

6. Pinning information

6.1 Pin description

Table 3: Pin description

Symbol Pin Description

RFIN 1 RF input

RFGND 2 RF ground

GND 3 ground

V

CCD

V

CCA

R/W 6 digital read/write command input

DATA 7 bidirectional digital data line

CLOCK 8 digital data clock line input

MPX 9 FM MPX signal output

AUDL 10 audio left channel output

AUDR 11 audio right channel output

LED 12 stereo LED output

GND 13 ground

n.c. 14 not connected

n.c. 15 not connected

n.c. 16 not connected

LR1 17 coil right

V

CC1

V

CC1

LL1 20 coil left

reserved 21 reserved for testing use

n.c. 22 not connected

n.c. 23 not connected

GND 24 ground

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

4 digital supply voltage

5 analog supply voltage

18 internal analog voltage

19 internal analog voltage

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 6 of 27

Page 7

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Fig 3. Pin configuration.

7. Functional description

7.1 FM quadrature mixer

The FM quadrature mixer converts FM RF (76 MHz to 108 MHz) to an IF of 110 kHz. The

FM quadrature mixer provides inherent image rejection.

RFIN GND

1

RFGND n.c.

CLOCK LR1

2

GND n.c.

3

V

4

CCD

V

5

CCA

R/W V

6

7

8

9

10

11

12

TEA5880TS

001aaa667

DATA V

MPX n.c.

AUDL n.c.

AUDR n.c.

LED GND

24

23

22

21

20

19

18

17

16

15

14

13

reserved

LL1

CC1

CC1

7.2 Quadrature oscillator

The internally tuned LC VCO provides the Local Oscillator (LO) signal for the FM

quadrature mixer. The VCO frequency range is 150 MHz to 217 MHz.

7.3 Selectivity

Fully integrated I and Q channel IF filter.

7.4 Demodulator

The FM quadrature demodulator is an integrated PLL demodulator.

7.5 Level voltage generator and analog-to-digital converter

The level voltage is analog-to-digital converted with 3 bits and output via the data line.

7.6 IF counter

The IF counter outputs a 16-bit count result via the data line.

7.7 Mute

The digital interface controls the audio mute and output level.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 7 of 27

Page 8

Philips Semiconductors

7.8 Stereo decoder

The PLL stereo decoder is adjustment free. The stereo decoder can be switched to mono

via the digital interface.

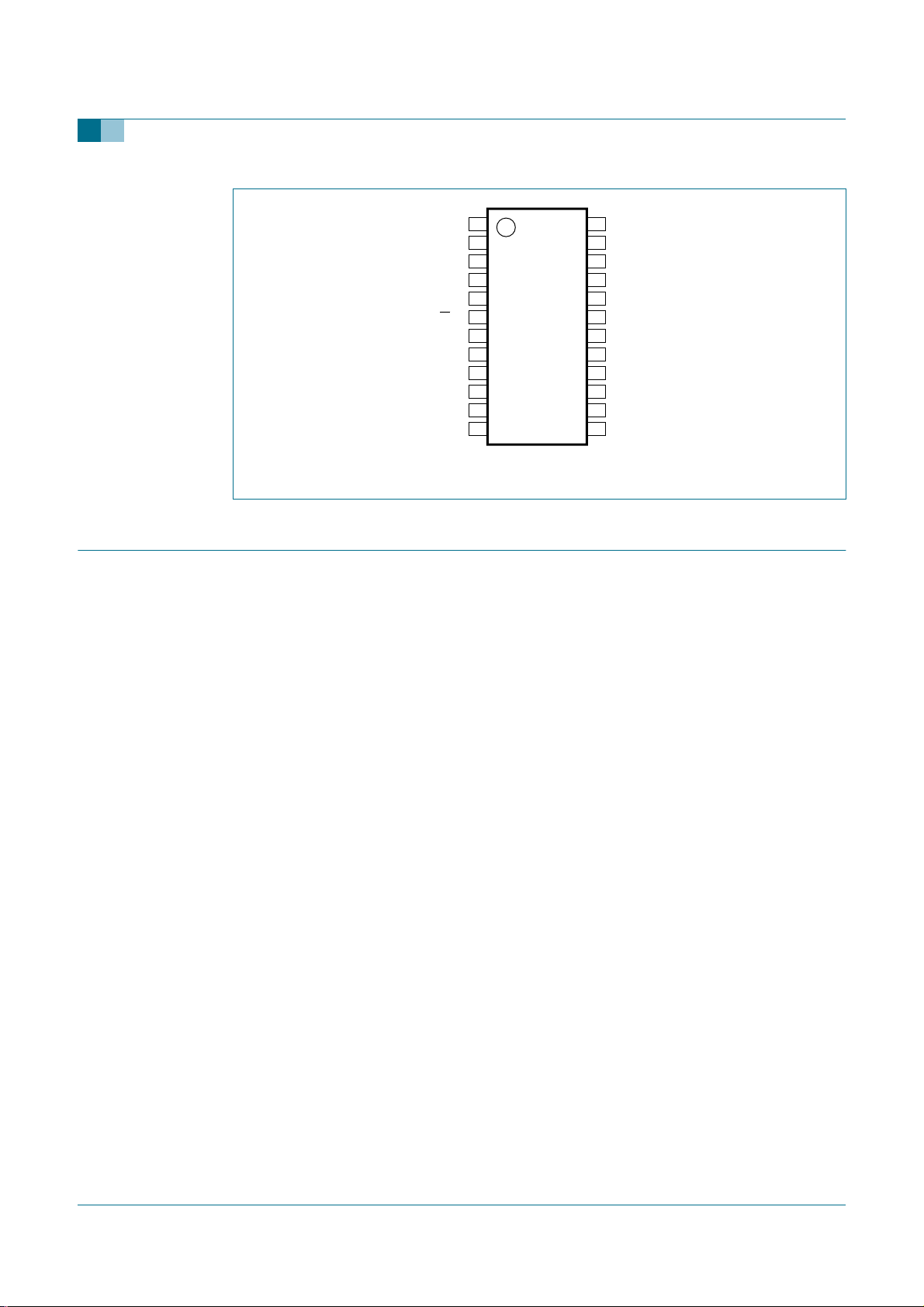

8. Digital interface (3-wire bus)

The TEA5880TS has a 3-wire bus with read/write, clock and data line.

The register set of the TEA5880TS can be accessed via the digital interface.

The pins given in Table 4 are defined for the digital interface of the TEA5880TS.

Table 4: Digital interface pins

Pin number Name Type Description Remark

Pin 6

Pin 8 CLOCK input clock rising edge

Pin 7 DATA input/output bidirectional data

R/W input LOW is read from TEA5880TS;

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

HIGH is write to TEA5880TS

DATA

R/W

enable

counter 1

R/W

OUTPUT

SOURCE

SELECTOR

CLOCK

15 BITS SIPO (SERIAL IN PARALLEL OUT)

4 bits data

ADDRESS

DECODER

COUNTER 1 (16 bits)

16 bits data 16 bits data

16 BITS PISO (PARALLEL IN SERIAL OUT)

CLOCK R/W

stereo LED

stereo clock

IF OSC

FM OSC

REGISTER A

REGISTER B

REGISTER C

REST OF THE

REGISTERS

STATUS REGISTER

R/W

11 bits data

CONTROL

CONTROL

CONTROL

control bits

control bits

control bits

control bits

1-bit data

001aaa668

Fig 4. Digital interface block diagram.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 8 of 27

Page 9

Philips Semiconductors

8.1 Register description

Table 5: TEA5880TS registers description

Address Register name Access Operation Data width Clocks

0000b VADC write only VADC register 11 bits 15

0001b CTRL_C write only control register C 11 bits 15

0010b CTRL_A write only control register A 11 bits 15

0011b OSC_STEREO write only oscillator stereo

0100b CTRL_B write only control register B 11 bits 15

0101b CAP_FM write only capacitor bank FM 11 bits 15

0110b OSC_IF write only oscillator IF 11 bits 15

0111b OSC_FM write only oscillator FM 11 bits 15

- STATUS read only status register 16 bits 15

- COUNTER read only counter register 16 bits 15

Table 6: VADC - (address 0h) bit description

Bit Symbol Description

14 to 11 - address bits

10 to 6 VADC2[4:0] controls the width filter

5 - not applicable; should be written to logic 0

4 to 0 VADC1[4:0] controls the center filter

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

11 bits 15

decoder clock

Table 7: CTRL_C - (address 1h) bit description

Bit Symbol Description

14 to 11 - address bits

10 and 9 - reserved for production test; should be written to logic 0

8 - reserved for swapping counters1 and 2; should be written to logic 0

7 to 4 - not applicable; should be written to logic 0

3 to 1 - reserved for time delay selection (counter 2); application should keep

bits 3 to 1 at logic 0; see

0 - reserved for enable counter 2; should be written to logic 0

[1] The application should write logic 0 to this register at start-up to ensure that the device functions correctly.

Table 8: Time delay selection

Value Decimal Stop value

000b 0 count 2

001b 1 count 8

010b 2 count 32

011b 3 count 128

100b 4 count 512

101b 5 count 2048

110b 6 count 8192

111b 7 count 32768

[1]

Table 8

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 9 of 27

Page 10

Philips Semiconductors

Table 9: CTRL_A - (address 2h) bit description

Bit Symbol Description

14 to 11 - address bits

10 to 7 OUTPUT_

6 STE_PMUTE mutes the stereo PLL when set to logic 1; this bit should be

5 DEM_PMUTE mutes the demodulator PLL when set to logic 1; this bit

4 STE_INT_OFF# turns off the stereo integrator loop when set to logic 0

3 EN_MEAS# enables measurement when set to logic 0

2 AMUTE mutes the audio when set to logic 1

1 FM enables the FM circuitry when set to logic 1

0 - reserved for AM circuitry; should be written to logic 0

Table 10: Description of OUTPUT_SELECT bits

Symbol Value Decimal Output selected

OS-NONE 0000b 0 no output selected

OS_FM_OSC 0001b 1 FM oscillator

OS_NA2 0010b 2 not defined

OS_CNT2_RDY_NA 0011b 3 reserved for counter 2 ready output

OS_NA4 0100b 4 not defined

OS_STEREO_DEC 0101b 5 stereo decoder clock

OS_NA6 0110b 6 not defined

OS_STEREO_LED 0111b 7 stereo LED

OS_NA8 1000b 8 not defined

OS_IF_OSC 1001b 9 IF oscillator

OS_INTERRUPT_NA 1010b 10 reserved for interrupt output

OS_PISO 1011b 11 PISO output (reading STATUS / COUNTER

OS_NA12 1100b 12 not defined

OS_RDS_NA 1101b 13 reserved for RDS output

OS_NA14 1110b 14 not defined

OS_NA15 1111b 15 not defined

SELECT[3:0]

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

selects an internal circuit as output for measurement purpose;

Table 10

see

set during calibration of the stereo decoder clock and should be

cleared during normal operation

should be set during calibration of the IF frequency and should

be cleared during normal operation

register)

Table 11: OSC_STEREO - (address 3h) bit description

Bit Symbol Description

14 to 11 - address bits

10 to 0 SO[10:0] 11-bit digital-to-analog converter for adjusting the stereo decoder clock

[1] The frequency is decreased when increasing the content of this register.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 10 of 27

[1]

Page 11

Philips Semiconductors

Table 12: CTRL_B - (address 4h) bit description

Bit Symbol Description

14 to 11 - address bits

10 L_CNT latch counter: a transition from logic 1 to logic 0 will latch the

9 L_STS latch status: a transition from logic 1 to logic 0 will latch the STATUS

8 to 6 - reserved for output level control; should be written with 4 (100b);

5 DEEMP de-emphasis: logic 1 is 75 µs (USA), logic 0 is 50 µs (Europe, Japan)

4 PISO_CLR a transition from logic 1 to logic 0 will clear the PISO; the PISO should

3 CNT_RST a transition from logic 1 to logic 0 will clear both counter 1 and counter 2

2 CNT1_EN counter 1 enabled (counting mode) when set to logic 1

1 - should be written to logic 0

0 MONO mono mode when set to logic 1, stereo mode when set to logic 0

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

COUNTER register into the PISO (reading the PISO hereafter will read

the COUNTER register)

register into the PISO (reading the PISO hereafter will read the STATUS

register)

Table 13

see

be clear before reading the STATUS/COUNTER register

Table 13: Description of output level control register bits

Value Decimal Output level

0000b 0 12 mV

0001b 1 20 mV

0010b 2 35 mV

0011b 3 60 mV

0100b 4 100 mV

0101b 5 170 mV

0110b 6 200 mV

Table 14: CAP_FM - (address 5h) bit description

Bit Symbol Description

14 to 11 - address bits

10 - reserved for capacitor extra current; this bit should be written to logic 1

by any access to the CAP_FM to ensure that the device functions

properly

9 to 8 - reserved, should be written to logic 0

7 to 0 FC[7:0] FM capacitor bank switches for adjusting the FM (RF) frequency in big

steps. Every bit, when set, will switch on a capacitor with a weight

according to its position i.e. bit 0 has weight 1, bit 1 has weight 2, bit 2

has weight 4 etc, bit 6 has weight 64, exceptforbit 7, which also has the

same weight as bit 6; there is thus only 71⁄2 effective bits; this means

that the value range 0 to 127 will switch on different capacitors the value

range 128 to 191 switches on the same capacitors as range 64 to 127,

the value range 192 to 255 will switch on different capacitors (an

overlapped range of 64 values caused when FC[7:6] = 01b or 10b)

[1]

[1] The frequency is decreased when increasing the content of this register (more capacitors).

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 11 of 27

Page 12

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Table 15: OSC_IF - (address 6h) bit description

[1]

Bit Symbol Description

14 to 11 - address bits

10 to 0 IFO[10:0] 11-bit digital-to-analog converter for adjusting the IF frequency

[1] The frequency is decreased when increasing the content of this register.

Table 16: OSC_FM - (address 7h) bit description

[1]

Bit Symbol Description

14 to 11 - address bits

10 to 0 FO[10:0] 11-bit digital-to-analog converter for adjusting the FM frequency in fine steps;

this register is used in combination with the CAP_FM register to set a FM

frequency

[1] The frequency is increased when increasing the content of this register.

Table 17: STATUS - bit description

[1]

Bit Symbol Description

15 to 9 FS[6:0] field strength, indicated by the amount of bits set:

0 bits set = < 10 dBµV

1 bit set = 10 dBµV to 20 dBµV

2 bits set = 20 dBµV to 30 dBµV

3 bits set = 30 dBµV to 40 dBµV

4 bits set = 40 dBµV to 50 dBµV

5 bits set = 50 dBµV to 60 dBµV

6 bits set = 60 dBµV to 70 dBµV

7 bits set = > 70 dBµV

8 - not applicable; always read as logic 1

7 to 5 R[2:0] chip revision; the revision for TEA5880TS is 100b

4 to 3 - not applicable; always read as logic 1

2 - reserved for production test

1 - not applicable; always read as logic 1

0 - reserved for production test

[1] This register does not have an address. To read the status register, latch its content into the PISO (using

L_STS bit in control register B) then read out the PISO.

Table 18: COUNTER - bit description

[1]

Bit Symbol Description

15 to 0 CNT[15:0] pulses counted during the period that the counter is enabled and the NR/W

line the 3 wire bus is low

[1] This register does not have an address. To read the counter register, latch its content into the PISO (using

L_CNT bit in control register B) then read out the PISO.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 12 of 27

Page 13

Philips Semiconductors

8.2 Accessing the TEA5880TS

Access to the TEA5880TS can be achieved via the 3-wire bus. At the host side, the R/W

and CLOCK are output signals, while the DATA signal is bidirectional.

When powered up, the host should initialize the 3-wire bus in the host read mode as

follows:

1. Set (at host side) the DATA line into input mode

2. R/W set to LOW

3. CLOCK set to LOW.

Note: Use the following sequence for changing read/write mode:

1. To change from host read mode to host write mode proceed as follows:

a. Keep the CLOCK signal LOW

b. Set the R/W signal to HIGH (write mode)

c. Set the DATA pin (of the application controller) into output mode.

2. To change from host write mode to host read mode proceed as follows:

a. Keep the CLOCK signal LOW

b. Set the DATA pin (of the application controller) into input mode

c. Set R/W to LOW (input mode).

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

8.3 Writing to the TEA5880TS

Writing to the TEA5880TS is achieved with a 15-bit data pattern:

• D[14:11]: 4-bit register address

• D[10:0]: 11-bit register data.

The data pattern is sent serially to the TEA5880TS as follows:

1. Drive R/W pin HIGH to set the TEA5880TS in input mode

2. Drive the DATA pin to correct level

3. Generate positive edge of CLOCK (driving CLOCK into LOW-to-HIGH transition)

4. Delay some time to meet the data hold time requirement

5. Driving CLOCK into HIGH-to-LOW transition

6. Repeat step (2) to (5) 15 times to shift the 15-bit data pattern into the TEA5880TS

7. Drive R/W pin LOW; this signals the TEA5880TS to latch the data into the correct

register.

Note: The application should shift the LSB out first.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 13 of 27

Page 14

Philips Semiconductors

8.4 Reading from the TEA5880TS

Only the status or the counter register can be read from the TEA5880TS.

These are 16-bit registers and can be read serially as follow:

1. Select OS_PISO (parallel in, serial out) as output (control register A,

OUTPUT_SELECT bits)

2. Clear the PISO (control register B, PISO_CLR bit, pulse HIGH-to-LOW transition)

3. Latch the counter register (control register B, L_CNT bit, pulse HIGH-to-LOW

transition) or the status register (control register B, L_STS bit, pulse HIGH-to-LOW

transition) into the PISO

4. Drive R/W pin LOW to set the TEA5880TS in output mode

5. Read the first bit at pin DATA

6. Generate positive CLOCK pulse (LOW-to-HIGH transition)

7. Delay for a period of time to meet the data set-up time requirement

8. Read the data bit at pin DATA

9. Drive CLOCK into HIGH-to-LOW transition

10.Repeat step (6) to (9) 15 times to shift the remaining 15 bits of data out of the chip

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Note: The TEA5880TS will shift the MSB out first.

8.5 Measuring frequency with the TEA5880TS

The three frequencies: IF, stereo decoder clock and FM can be measured by using the

counter register and a software timing window. This is achieved as follows:

1. Select the output to be measured (control register A, OUTPUT_SELECT bits, select

OS_STEREO_DEC, OS_IF_OSC or OS_FM_OSC output)

2. Enable measure mode (clear EN_MEAS# bit of control register A)

3. Reset the counter (control register B, CNT_RST bit, pulse HIGH-to-LOW transition)

4. Start the counter on the TEA5880TS (control register B, set CNT1_EN bit); at the

moment the R/W signal goes LOW the counter starts

5. Wait time t

6. To stop the counter, first set the R/W signal HIGH, then disable the counter in the

TEA5880TS (control register B, clear CNT1_EN bit)

7. Read the pulse count n from the counter register of the TEA5880TS

8. Restore the measure mode

9. Restore the output select bits.

Note: The measuring window begins at the moment the R/W signal is driven LOW (point

4) and ends when the R/W signal is driven HIGH (point 6).

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 14 of 27

Page 15

Philips Semiconductors

The IF and stereo decoder frequency can be calculated using the equation f = n/t, and the

FM frequency can be calculated using the equation f = (n/t) x 256.

Note: The precision of ‘f’ depends on the following:

• The duration of t. 1 pulse wrong at t = 1 ms results in more deviation than at t = 32 ms

• The precision of the measuring window: calculate with t = 32 ms gives other ‘f’ values

than with t = 32 ms. In the application care should be taken to have an accurate

measuring window t.

8.6 Initialize the TEA5880TS

After power-up, the TEA5880TS needs to be initialized as follows:

• Control register A: STE_PMUTE = 1; DEM_PMUTE = 1; AMUTE = 1; FM = 1; other

bits = 0

• Control register B: CNT_RST = 1; PISO_CLR = 1; MONO = 1; DEEMP = 1 (for

Europe); Bit [8:6] = 100b; other bits = 0

• Control register C: All bits = 0

• VADC register: VADC1 = 26 (decimal), this value should not be changed hereafter;

VADC2 = 18 (decimal), this value should not be changed hereafter

• Calibrate the IF frequency at 110 kHz

• Calibrate the stereo decoder clock at 37.5 kHz (to reduce the initialization time,

calibration of the stereo decoder clock can be postponed until the stereo mode is

selected).

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

9. Timing diagrams

R/W

CLOCK

1 1511

LSB MSB MSBLSB

DATA

Fig 5. Writing data.

11-bit data 4-bit address

001aaa669

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 15 of 27

Page 16

Philips Semiconductors

R/W

CLOCK

0 15

LSB

DATA

Fig 6. Reading data.

enable FM OSC at output source selector

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

MSB

16-bit data

001aaa670

enable internet clock

set 16-bit counter clear

reset 16-bit counter clear

enable 16-bit counter to count

timing width 8 ms to 100 ms

disable 16-bit counter

enable PISO at output source

Fig 7. Measuring sequence.

001aaa671

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 16 of 27

Page 17

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

10. Limiting values

Table 19: Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

CCD

V

CCA

T

stg

T

amb

V

esd

[1] Machine model (R = 10 Ω, C = 200 pF, 75 µH).

[2] Human body model (R = 1.5 kΩ, C = 100 pF).

digital supply voltage −0.3 +5 V

analog supply voltage −0.3 +8 V

storage temperature −55 +150 °C

ambient temperature V

electrostatic discharge voltage

for all pins

V

CCA

CCA

= V

= V

CC(VCO)

CC(VCO)

= V

= V

= 3 V −10 +75 °C

CCD

= 5 V −40 +85 °C

CCD

[1]

−200 +200 V

[2]

−2000 +2000 V

11. Thermal characteristics

Table 20: Thermal characteristics

Symbol Parameter Conditions Typ Unit

R

th(j-a)

thermal resistance from junction to ambient in free air <tbd> K/W

12. Characteristics

Table 21: Digital input AC values

Symbol Parameter Conditions Min Typ Max Unit

Digital inputs

V

IH

V

IL

Digital outputs

I

sink (L)

V

OL

Timing

f

clk

t

CLK(H)

t

CLK(L)

HIGH-level input voltage IOH = 500 µA 1.4 - - V

LOW-level input voltage - - 0.6 V

LOW-level sink current 500 - - µA

LOW-level output voltage IOL = 500 µA - - 0.6 V

clock input - - 1 MHz

clock HIGH time 495 - - ns

clock LOW time 495 - - ns

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 17 of 27

Page 18

Philips Semiconductors

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

20

dB

(1)

0

−20

−40

−60

−10 1107030

(1) Mono signal.

(2) Mono noise.

(3) Stereo left.

(4) Stereo right.

(5) Stereo noise.

Fig 8. Signal characteristics.

001aaa673

(2)

(3)

(4)

(5)

RFIN (dBµV)

Fig 9. Total harmonic distortion.

13. Components list

No external components necessary.

THD = 30 %.

5

THD

(%)

4

3

2

1

0

−10 1107030

001aaa674

RFIN (dBµV)

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 18 of 27

Page 19

Philips Semiconductors

Integrated FM stereo radio IC for host processor tuning

14. Printed-circuit board layout for SSOP24 package

TEA5880TS

The printed-circuit board traces from LL1 to V

and from V

CC1

to LR1 as shown in

CC1

Figure 10, are to create two inductors, each of approximately 38 nH. These inductors,

together with internal capacitors, form part of the LC oscillator to determine the FM tuning

band. If the value of the inductors becomes much greater than 38 nH, the whole FM

tuning band (normally from 76 MHz to 108 MHz) will be shifted lower. If the value of the

inductors becomes much smaller than 38 nH, the whole FM tuning band (normally from

76 MHz to 108 MHz) will be shifted higher.

If the layout of the two inductance traces is not preferred, two SMD inductors can be used

to replace the two printed-circuit board inductance traces as an alternative. The layout of

the two SMD inductors should be as close to the pins as possible.

RFIN

RFGND

GND

V

CCD

V

CCA

R/W

DATA

CLOCK

MPX

AUDL

AUDR

LED

GND

n.c.

n.c.

reserved

LL1

LR1

n.c.

n.c.

n.c.

GND

V

CC1

V

CC1

3.5 mm

3.5 mm

(1) Width of printed-circuit board trace = 0.15 mm; spacing between printed-circuit board

trace = 0.15 mm.

(2) Pins 14, 15, 16, 21, 22 and 23 are not connected.

001aaa675

Fig 10. Printed-circuit board layout.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 19 of 27

Page 20

Philips Semiconductors

15. Application information

V

CCD

100 nF

FM antenna

(1)

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

RFIN

V

CCA

R/W

DATA

CLOCK

MPX

AUDL

AUDR

LED

1

2

3

4

5

6

7

8

9

10

11

12

TEA5880FM

24

23

22

21

20

19

18

17

16

15

14

13

001aaa672

LL1

V

CC1

LR1

V

CC1

100 nF

(1)

(1) optional.

Fig 11. Application diagram.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 20 of 27

Page 21

Philips Semiconductors

16. Package outline

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

SSOP24: plastic shrink small outline package; 24 leads; body width 5.3 mm

D

c

y

Z

24 13

A

2

A

pin 1 index

1

SOT340-1

E

H

E

Q

L

p

L

(A )

A

X

v M

A

A

3

θ

112

w M

b

e

DIMENSIONS (mm are the original dimensions)

UNIT A1A2A

Note

1. Plastic or metal protrusions of 0.2 mm maximum per side are not included.

A

max.

0.21

mm

2

OUTLINE

VERSION

SOT340-1 MO-150

0.05

1.80

1.65

IEC JEDEC JEITA

0.25

b

3

p

0.38

0.25

p

cD

0.20

8.4

0.09

8.0

REFERENCES

0 2.5 5 mm

scale

(1)E(1) (1)

5.4

0.65 1.25

5.2

eHELLpQZywv θ

7.9

7.6

1.03

0.63

detail X

0.9

0.7

EUROPEAN

PROJECTION

0.13 0.10.2

0.8

0.4

ISSUE DATE

99-12-27

03-02-19

o

8

o

0

Fig 12. Package outline.

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 21 of 27

Page 22

Philips Semiconductors

17. Soldering

17.1 Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology. A more in-depth account of

soldering ICs can be found in our

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering can still be used for certain surface mount ICs, but it is not suitable for fine pitch

SMDs. In these situations reflow soldering is recommended.

17.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement. Driven by legislation and

environmental forces the worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example, convection or convection/infrared

heating in a conveyor type oven. Throughput times (preheating, soldering and cooling)

vary between 100 and 200 seconds depending on heating method.

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Data Handbook IC26; Integrated Circuit Packages

Typical reflow peak temperatures range from 215 to 270 °C depending on solder paste

material. The top-surface temperature of the packages should preferably be kept:

• below 225 °C (SnPb process) or below 245 °C (Pb-free process)

– for all BGA, HTSSON..T and SSOP..T packages

– for packages with a thickness ≥ 2.5 mm

– for packages with a thickness < 2.5 mm and a volume ≥ 350 mm3 so called

thick/large packages.

• below 240 °C (SnPb process) or below 260 °C (Pb-free process) for packages with a

thickness < 2.5 mm and a volume < 350 mm3 so called small/thin packages.

Moisture sensitivity precautions, as indicated on packing, must be respected at all times.

17.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering method was specifically

developed.

If wave soldering is used the following conditions must be observed for optimal results:

• Use a double-wave soldering method comprising a turbulent wave with high upward

pressure followed by a smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

parallel to the transport direction of the printed-circuit board;

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 22 of 27

Page 23

Philips Semiconductors

– smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

The footprint must incorporate solder thieves at the downstream end.

• For packages with leads on four sides, the footprint must be placed at a 45° angle to

the transport direction of the printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time of the leads in the wave ranges from 3 to 4 seconds at 250 °C or

265 °C, depending on solder material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal of corrosive residues in most

applications.

17.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low voltage

(24 V or less) soldering iron applied to the flat part of the lead. Contact time must be

limited to 10 seconds at up to 300 °C.

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

transport direction of the printed-circuit board.

When using a dedicated tool, all other leads can be soldered in one operation within

2 to 5 seconds between 270 and 320 °C.

17.5 Package related soldering information

Table 22: Suitability of surface mount IC packages for wave and reflow soldering methods

Package

BGA, HTSSON..T

SSOP..T

DHVQFN, HBCC, HBGA, HLQFP, HSO, HSOP,

HSQFP, HSSON, HTQFP, HTSSOP, HVQFN,

HVSON, SMS

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO, VSSOP not recommended

CWQCCN..L

[1] For more detailed information on the BGA packages refer to the

[2] All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

[3] These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no

[1]

Soldering method

Wave Reflow

[3]

[3]

, LBGA, LFBGA, SQFP,

, TFBGA, USON, VFBGA

not suitable suitable

not suitable

[5]

, SO, SOJ suitable suitable

[8]

, PMFP

order a copy from your Philips Semiconductors sales office.

maximum temperature (with respect to time) and body size of the package, there is a risk that internal or

external package cracks may occur due to vaporization of the moisture in them (the so called popcorn

effect). For details, refer to the Drypack information in the

Packages; Section: Packing Methods

account be processed through more than one soldering cycle or subjected to infrared reflow soldering with

peak temperature exceeding 217 °C ± 10 °C measured in the atmosphere of the reflow oven. The package

body peak temperature must be kept as low as possible.

[9]

, WQCCN..L

[8]

.

not suitable not suitable

[4]

[5] [6]

[7]

(LF)BGA Application Note

Data Handbook IC26; Integrated Circuit

suitable

suitable

suitable

(AN01026);

[2]

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 23 of 27

Page 24

Philips Semiconductors

[4] These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the

solder cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink

on the top side, the solder might be deposited on the heatsink surface.

[5] If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[6] Wave soldering is suitable for LQFP, QFP and TQFP packages with a pitch (e) larger than 0.8 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65mm.

[7] Wave soldering is suitable for SSOP, TSSOP, VSO and VSOP packages with a pitch (e) equal to or larger

than 0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5mm.

[8] Image sensor packages in principle should not be soldered. They are mounted in sockets or delivered

pre-mounted on flex foil. However, the image sensor package can be mounted by the client on a flex foil by

using a hot bar soldering process. The appropriate soldering profile can be provided on request.

[9] Hot bar soldering or manual soldering is suitable for PMFP packages.

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 24 of 27

Page 25

Philips Semiconductors

Integrated FM stereo radio IC for host processor tuning

TEA5880TS

18. Revision history

Table 23: Revision history

Document ID Release date Data sheet status Change notice Order number Supersedes

TEA5880_2 20040426 Preliminary data sheet - 9397 750 13022 -

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 25 of 27

Page 26

Philips Semiconductors

19. Data sheet status

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

Level Data sheet status

I Objective data Development This data sheet contains data from the objective specification for product development. Philips

II Preliminary data Qualification Thisdata sheet contains data fromthe preliminary specification. Supplementary data will bepublished

III Product data Production This data sheet contains data from the product specification. Philips Semiconductors reserves the

[1] Please consult the most recently issued data sheet before initiating or completing a design.

[2] The product status of the device(s) described in this data sheet may have changed since this data sheet was published. The latest information is available on the Internet at

URL http://www.semiconductors.philips.com.

[3] For data sheets describing multiple type numbers, the highest-level product status determines the data sheet status.

[1]

Product status

20. Definitions

Short-form specification — The data in a short-form specification is

extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with

the Absolute Maximum Rating System (IEC 60134). Stress above one or

more of the limiting values may cause permanent damage to the device.

These are stress ratings only and operation of the device at these or at any

other conditions above those given in the Characteristics sections of the

specification is not implied. Exposure to limiting values for extended periods

may affect device reliability.

Application information — Applications that are described herein for any

of these products are for illustrative purposes only. Philips Semiconductors

make no representation or warranty that such applications will be suitable for

the specified use without further testing or modification.

[2] [3]

Definition

Semiconductors reserves the right to change the specification in any manner without notice.

at a later date.Philips Semiconductors reserves theright to change thespecificationwithout notice, in

order to improve the design and supply the best possible product.

right to make changes at any time in order toimprove the design, manufacturing and supply. Relevant

changes will be communicated via a Customer Product/Process Change Notification (CPCN).

21. Disclaimers

Life support — These products are not designed for use in life support

appliances, devices, or systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips Semiconductors

customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to

make changes in the products - including circuits, standard cells, and/or

software - described or contained herein in order to improve design and/or

performance. When the product is in full production (status ‘Production’),

relevant changes will be communicated via a Customer Product/Process

Change Notification (CPCN). Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no

license or title under any patent, copyright, or mask work right to these

products, andmakes no representationsor warranties thatthese products are

free from patent,copyright, or mask workrightinfringement, unlessotherwise

specified.

22. Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, send an email to: sales.addresses@www.semiconductors.philips.com

9397 750 13022 © Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Preliminary data sheet Rev. 02 — 26 April 2004 26 of 27

Page 27

Philips Semiconductors

23. Contents

TEA5880TS

Integrated FM stereo radio IC for host processor tuning

1 General description . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Quick reference data . . . . . . . . . . . . . . . . . . . . . 2

4 Ordering information . . . . . . . . . . . . . . . . . . . . . 3

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 Pinning information. . . . . . . . . . . . . . . . . . . . . . 6

6.1 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 6

7 Functional description . . . . . . . . . . . . . . . . . . . 7

7.1 FM quadrature mixer . . . . . . . . . . . . . . . . . . . . 7

7.2 Quadrature oscillator . . . . . . . . . . . . . . . . . . . . 7

7.3 Selectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.4 Demodulator. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.5 Level voltage generator and analog-to-digital

converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.6 IF counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.7 Mute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.8 Stereo decoder. . . . . . . . . . . . . . . . . . . . . . . . . 8

8 Digital interface (3-wire bus). . . . . . . . . . . . . . . 8

8.1 Register description . . . . . . . . . . . . . . . . . . . . . 9

8.2 Accessing the TEA5880TS. . . . . . . . . . . . . . . 13

8.3 Writing to the TEA5880TS . . . . . . . . . . . . . . . 13

8.4 Reading from the TEA5880TS . . . . . . . . . . . . 14

8.5 Measuring frequency with the TEA5880TS . . 14

8.6 Initialize the TEA5880TS . . . . . . . . . . . . . . . . 15

9 Timing diagrams . . . . . . . . . . . . . . . . . . . . . . . 15

10 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 17

11 Thermal characteristics. . . . . . . . . . . . . . . . . . 17

12 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . 17

13 Components list. . . . . . . . . . . . . . . . . . . . . . . . 18

14 Printed-circuit board layout for SSOP24

package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

15 Application information. . . . . . . . . . . . . . . . . . 20

16 Package outline. . . . . . . . . . . . . . . . . . . . . . . . 21

17 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

17.1 Introduction to soldering surface mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

17.2 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 22

17.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 22

17.4 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 23

17.5 Package related soldering information. . . . . . 23

18 Revision history . . . . . . . . . . . . . . . . . . . . . . . 25

19 Data sheet status. . . . . . . . . . . . . . . . . . . . . . . 26

20 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

21 Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

22 Contact information . . . . . . . . . . . . . . . . . . . . 26

© Koninklijke Philips Electronics N.V. 2004

All rights are reserved. Reproduction in whole or in part is prohibited without the prior

written consent of the copyright owner. The information presented in this document does

not form part of any quotation or contract, is believed to be accurate and reliable and may

be changed without notice. No liability will be accepted by the publisher for any

consequence of its use. Publication thereof does not convey nor imply any license under

patent- or other industrial or intellectual property rights.

Document order number: 9397 750 13022

Published in The Netherlands

Date of release: 26 April 2004

Loading...

Loading...