Page 1

查询TEA1541供应商

INTEGRATED CIRCUITS

DATA SH EET

TEA1541

SMPS control IC with

synchronization function

Product specification 2003 Aug 11

Page 2

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

CONTENTS

1 FEATURES

1.1 Distinctive features

1.2 Green features

1.3 Protection features

2 GENERAL DESCRIPTION

3 ORDERING INFORMATION

4 BLOCK DIAGRAM

5 PINNING

6 FUNCTIONAL DESCRIPTION

6.1 Start-up, mains voltage-dependent

operation-enabling level and undervoltage

lock-out

6.2 Supply management

6.3 Primary current regulation

6.4 Oscillator

6.5 Demagnetization

6.6 Minimum and maximum ‘on-time’

6.7 Overvoltage protection

6.8 Overcurrent protection and overpower

protection

6.9 Soft start

6.10 Winding short-circuit protection

6.11 Overtemperature protection

6.12 Burst standby mode

6.13 Driver

TEA1541

7 LIMITING VALUES

8 THERMAL CHARACTERISTICS

9 QUALITY SPECIFICATION

10 CHARACTERISTICS

11 APPLICATION INFORMATION

12 PACKAGE OUTLINE

13 SOLDERING

13.1 Introduction to soldering through-hole mount

packages

13.2 Soldering by dipping or by solder wave

13.3 Manual soldering

13.4 Suitability of through-hole mount IC packages

for dipping and wave soldering methods

14 DATA SHEET STATUS

15 DEFINITIONS

16 DISCLAIMERS

2003 Aug 11 2

Page 3

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

1 FEATURES

1.1 Distinctive features

• Universal mains supply operation (70 to 276 V AC)

• High-level of integration requiring few external

components

• Synchronization with internal frequency divider

• Frequency independent over-power protection.

1.2 Green features

• Frequency reductionat low power standby for improved

system efficiency (<3 W)

• Burst mode operation for very low power standby

levels (<1 W)

• On-chip start-up current source.

1.3 Protection features

• Safe restart mode for system fault conditions

• Continuous mode protection using demagnetization

detection (zero switch-on current)

• Accurate and adjustable overvoltage protection

• Winding short-circuit protection

• Undervoltage protection (foldback during overload)

• Overtemperature protection

• Adjustable low overcurrent protection (OCP) trip level

• Soft (re)start

• Mains voltage-dependent operation-enabling level.

TEA1541

2 GENERAL DESCRIPTION

The TEA1541 is a second generation GreenChip

Switched Mode Power Supply (SMPS) controller IC that

operates directly from the rectified universal mains.

A high-level of integration provides a cost-effective power

supply requiring only a few external components.

The TEA1541 controller enables easy design of highly

efficient, reliable switched mode power supplies.

Its internal oscillator can be synchronized to pulses from

an external signal source. External synchronizing pulses

whose frequency is above the SMPS switching frequency

range are divided by an internal divider.

Special built-in green functions ensure optimum efficiency

at all power levels. At low power (standby) levels, the

SMPS supply operates at a lower frequency. In burst

standbymode, power consumptioncan be reducedto less

than 1 W.

The proprietary EZ-HV SOI process allows start-up

directly from the rectified mains voltage,avoiding the need

for bleeder circuits, and also saves energy.

A low voltage BICMOS implements accurate control and

high speed protection functions.

(1) GreenChip is a trademark of Koninklijke Philips

Electronics N.V.

TM(1)

3 ORDERING INFORMATION

TYPE

NUMBER

TEA1541P DIP8 plastic dual-in-line package; 8 leads (300 mil) SOT97-1

2003 Aug 11 3

NAME DESCRIPTION VERSION

PACKAGE

Page 4

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

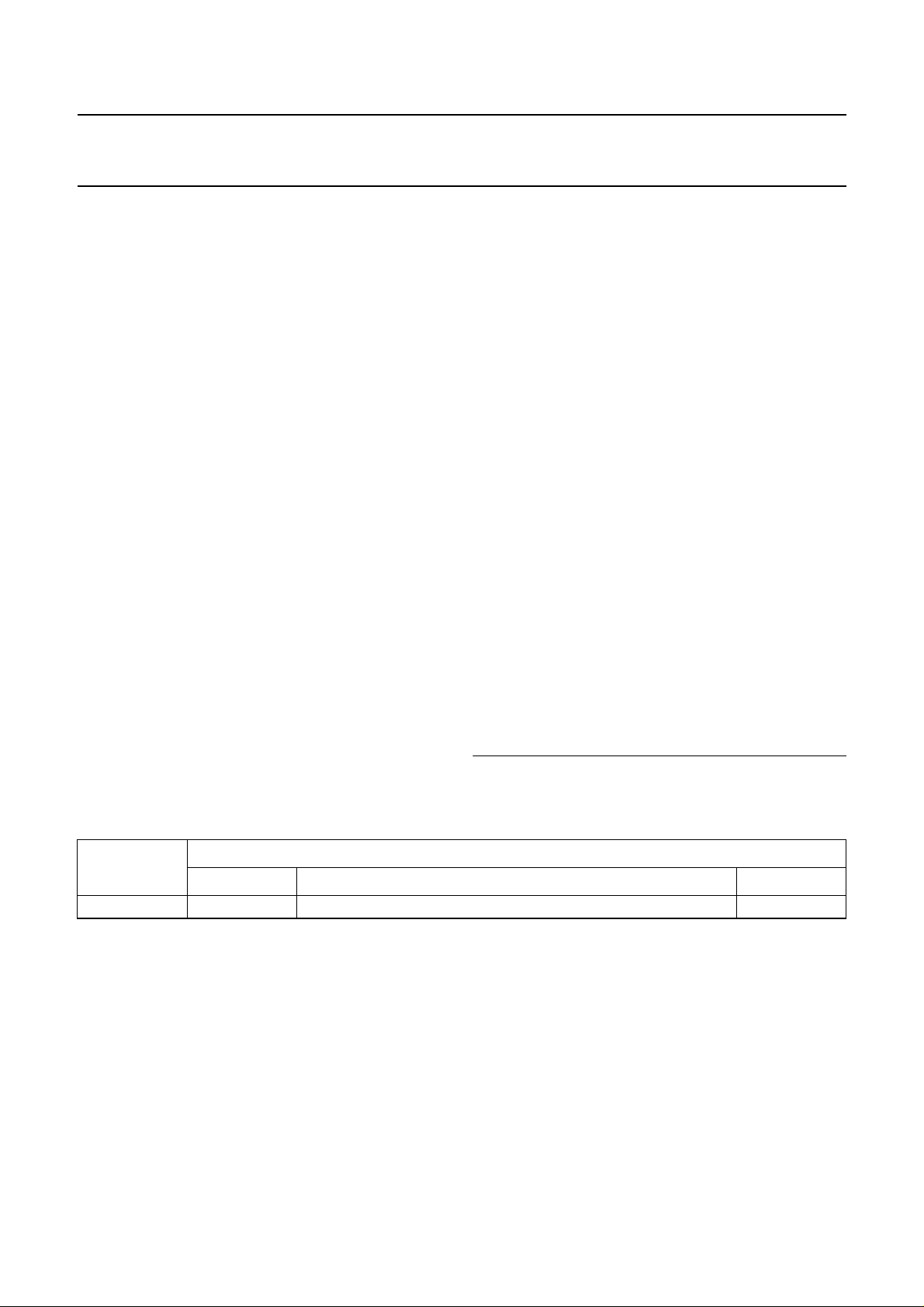

handbook, full pagewidth

V

mains

Sync

pulses

C

VCC

1

2

TEA1541P

3

4

R

DEM

TEA1541

C

VIN

8

n.c.

7

6

5

MDB082

Fig.1 Basic application.

2003 Aug 11 4

Page 5

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

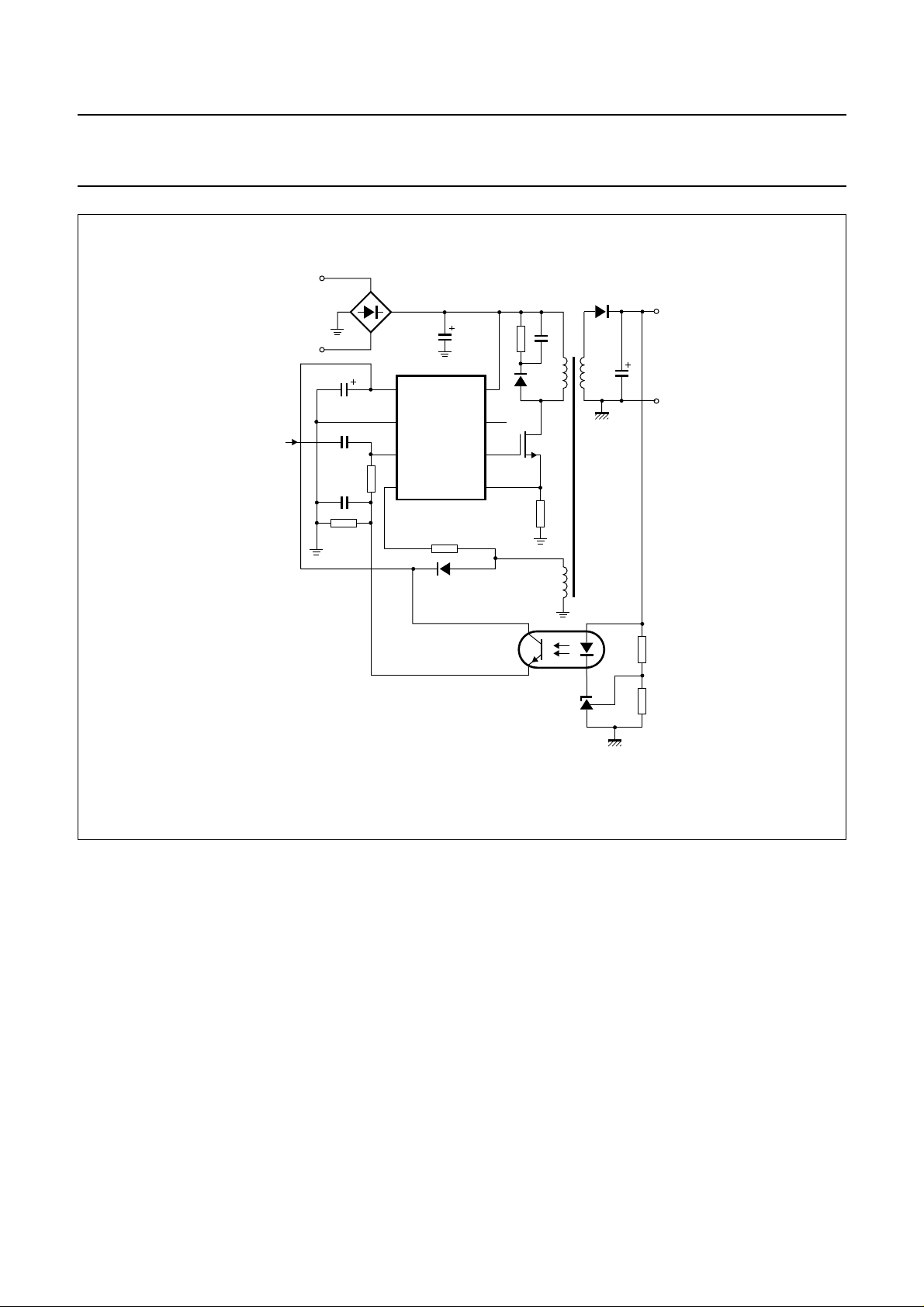

4 BLOCK DIAGRAM

(internal

control)

PRIMARY

CURRENT

PCS

HVS

7

SIMULATION

VIN

8

SOURCE

CURRENT

START-UP

Clamp

DEM

I

−50 mV

4

DEM

100 mV

PROTECTION

OVERVOLTAGE

DRIVER

6

DRIVER

TEA1541

sense

I

5

MDB083

SS

I

soft

start

S2

PROTECTION

OVERPOWER

(frequency

880 mV

information)

LEB

blank

short-

circuit

winding

OCP

700 mV

SUPPLY

MANAGEMENT

1

mains ok

DEM

SHORT-CIRCUIT

UVLO start

supply

internal

S1

OCP

PROTECTION

2

MODE

PROTECTION

CONTINUOUS

(frequency

VOLTAGE

OSCILLATOR

CONTROLLED

CTRL

I

information)

CONTROL

FREQUENCY

SYNC.

DETECTOR

LOGIC

PCS

control)

(internal

OCP

OVER-

PROTECTION

TEMPERATURE

control)

(internal

SAMPLE-

AND-HOLD

3

Q

S

R

UVLO

RESET

POWER-ON

3.5 V

BURST

CONTROL

burst

detect

ON-TIME

MAXIMUM

PROTECTION

(frequency

information)

TEA1541

handbook, full pagewidth

Fig.2 Block diagram.

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2003 Aug 11 5

CC

V

GND

CTRL

Page 6

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

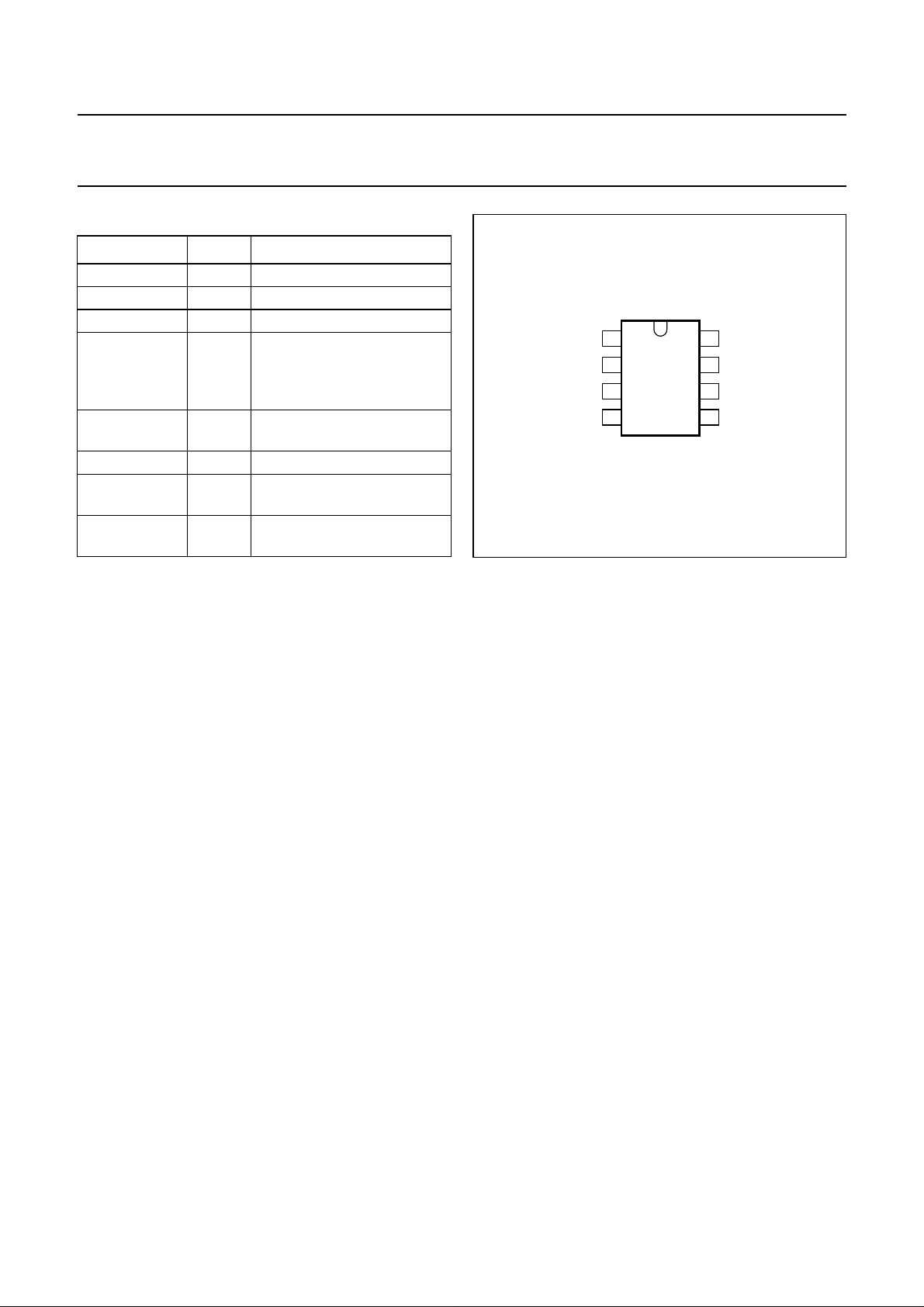

5 PINNING

SYMBOL PIN DESCRIPTION

V

CC

GND 2 ground

CTRL 3 control input

DEM 4 input from auxiliary winding

I

sense

DRIVER 6 gate driver output

HVS 7 high voltage safety spacer,

VIN 8 input for start-up current and

6 FUNCTIONAL DESCRIPTION

The TEA1541 is intended as the controller for a compact

flyback converter for CRT monitor applications. The IC is

situated on the primary side of the output transformer.

Output power is determined by the current in the primary

winding. The voltage across an auxiliary winding in the

transformer is converted to a current by resistor R

used by theIC to derive the current in theprimary winding.

This winding is also used for continuous mode protection,

overvoltage protection, and to power the IC after start-up.

The IC can operate in either synchronized or

unsynchronized mode. In synchronized mode, the IC

synchronizes the converter switching frequency to the

monitor line frequency to prevent interference.

Line synchronizing pulses are applied to pin CTRL.

1 supply voltage

for demagnetization timing,

OVP and overpower

protection (OPP)

5 programmablecurrent sense

input

not connected

mains voltage recognition

and

DEM

TEA1541

handbook, halfpage

The IC has an internal frequency divider which allows it to

operate in synchronized mode at a lower frequency than

the synchronizing pulses supplied to pin CTRL by the

application. The limited frequency range allows an

economical design of the transformer.

In unsynchronized mode, when the power that is drawn

from the converter decreases, the converter switching

frequency also decreases. At very low power (standby)

levels, the frequency of the VCO decreases from 25 kHz

to the minimumvalue of approximately 6 kHz as shown by

the slope of Fig.4. In a typical application it is possible to

obtain an input power of less than 3 W with an output

power of 100 mW.

1

V

CC

2

GND

CTRL

DEM

TEA1541P

3

4

MDB084

Fig.3 Pin configuration.

8

7

6

5

VIN

HVS

DRIVER

I

sense

Each operating cycle of the convertercomprises a primary

stroke followed by a secondary stroke. During the primary

stroke, current flows in the primary winding.

The secondary stroke transfers the energy stored in the

transformer core to the secondary winding. In either

synchronized or unsynchronized mode, the primary stroke

only starts at the end of the secondary stroke when the

transformer is demagnetized to ensure zero switching

primary current. If no synchronizing pulses are present

(unsynchronized mode), the IC will operate at its minimum

switching frequency.

2003 Aug 11 6

Page 7

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

f

handbook, halfpage

(kHz)

50

synchronized operation

25

6

VCO

variable

unsynchronized operation

VCO

fixed

Fig.4 Multi mode operation.

P(W)

MDB085

handbook, halfpage

M-level

V

CC(start)

V

CC(trip)(VIN)

I

VIN(max)

I

VIN(min)

V

I

VIN

CC

VIN

I

CC

TEA1541

6.1 Start-up, mains voltage-dependent

operation-enabling level and undervoltage

lock-out

Initially, the IC is supplied by the rectified mains voltage at

pin VIN. When the voltage at pin VCC is below the V

voltage for VIN current trip level V

current drawn from pin VIN, (I

I

. When VCC rises to the V

VIN(min)

VIN

CC(trip)(VIN)

) is at the low value

CC(trip)(VIN)

, the supply

level, the

current at pin VIN changes to the high value I

VIN(max)

CC

.

When the voltage at pin VIN is below the mains

voltage-dependent operation-enabling level (M-level), the

IC supply capacitor C

is charged by the internal

VCC

start-up current source to approximately 5 V. When the

voltage at pin VIN exceeds the M-level, the start-up

current source continuesto charge C

(switch S1 open;

VCC

see Fig.2).

When VCCreaches the start-up voltage level V

CC(start)

, the

ICswitches to high efficiency(green function) operation by

no longer drawing current from pin VIN (see Fig.5).

At V

the IC activates the external MOSFET. When

CC(start)

the voltage across the auxiliary winding rises above the

voltage across C

, the IC supply current will be supplied

VCC

by the auxiliary winding via pin VCC.

If the voltage on pin VCCfalls below the VCCundervoltage

lock-out level V

CC(UVLO)

, the IC stops switching and enters

a safe restart mode in which current to the IC is supplied

by the rectified mains voltage via pin VIN, and C

VCC

is

re-charged by the internal start-up current source to

V

CC(start)

.

MDB087

Fig.5 Start-up sequence.

Inhibiting the auxiliary supply by external means causes

the converter to operate in a stable, well-defined burst

mode. This is a burst standby mode that is less efficient

than the normal burst standby mode described in

section 6.12.

Ifthe voltage at pin VINfallsbelow the mains undervoltage

lock-out level M

, a safe restart mode is activated, and

UVLO

the IC stops switching.

During normal operation (non-burst standby mode), the

duty cycle of the IC, and thus the output power of the

supply, is regulated by a control voltage at pin CTRL.

If pin VCC is connected to ground, the IC switches to low

power standby operation and the start-up current drawn

via pin VIN reduces to 400 µA (typical). When the voltage

on pin VCC rises above 700 mV (typical), the start-up

current increases to 1 mA (typical).

6.2 Supply management

All internal reference voltages are derived from a

temperature compensated, on-chip bandgap.

2003 Aug 11 7

Page 8

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

6.3 Primary current regulation

The IC uses current mode control for its good line

regulation behaviour. The primary current is sensed

indirectly via the voltage at pin DEM.

The ‘on-time’ of the external MOSFET is controlled by the

voltage on pin CTRL which is compared with the internal

simulated primary current information. For pin CTRL

voltages (V

calculated by the equation:

t

α

on

PCS

where:

• t

: the on-time

on

•α

: an internal constant which is approximately 0.9.

PCS

• V

• I

: the voltage on pin CTRL

CTRL

:thecurrent drawn from pin DEM during theprimary

DEM

cycle.

) between 1 and 1.6 V, the on-time is

CTRL

1.6 V

–

× ns[]=

CTRL

------------------------------I

DEM

TEA1541

handbook, halfpage

Fig.6 Switching frequency as a function of the

f

(kHz)

f

smps(max)

f

osc

f

sync

(min)

synchronizing frequency.

f

sync

(max)

2 × f

(max)

sync

f

(kHz)

MDB086

6.4 Oscillator

In synchronized mode, the switching frequency of the

SMPS f

is controlled by the synchronizing pulses f

smps

sync

at pin CTRL. Synchronized mode prevents noise

disturbance on the CRT monitor screen. Synchronizing

pulseswhose frequency isoutside of the f

osc

andf

smps(max)

window of 26 to 54 kHz are divided by an internal

frequency divider. A small frequency hysteresis exists to

ensure a stable frequency switch-over. In unsynchronized

mode, the system runs at f

(26 kHz). In unsynchronized

osc

mode, at verylow power (standby)levels, the frequency of

theVCO and consequentlythe SMPS switching frequency

is reduced linearly to its low value of approximately 6 kHz

(see Figs 4 and 6).

6.5 Demagnetization

The system always operates in discontinuous conduction

modeto ensure demagnetizationof the output transformer

core.A primary cycleonlystarts when thesecondary cycle

has ended.

Pin DEM protects against an output short-circuit on a

cycle-by-cycle basis, by immediately lowering the

switching frequency to give a longer off-time and a lower

operating power.

Demagnetization detection is suppressed automatically at

the start of each secondary cycle for a period t

suppr

.

Suppressionofdemagnetizationdetectionisnecessaryfor

applications where the transformer has a large leakage

inductance, at low output voltages and at start-up.

If, due to a fault condition, pin DEM is left open circuit,

operation of the flyback converter supply immediately

stops, and restartswhen the faultsituation is removedand

pin DEM is reconnected.

If, during start-up, a fault condition causes pin DEM to be

shorted to ground, operation of the flyback converter

supply stops after the first cycle, and the IC then begins a

restart cycle. This situation continues until the short-circuit

is removed. Short-circuit protection is also active at full

power to ensure limitation of peak current.

2003 Aug 11 8

Page 9

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

6.6 Minimum and maximum ‘on-time’

The minimum on-time of the converter is notlimited by the

leading edge blanking time, and therefore can be zero.

The IC limits the maximum on-time to

where f

is the converter switching frequency in either

smps

synchronized or unsynchronized mode. If the system

requires a longer on-time, a fault condition is assumed, for

example, if C

is removed, the IC willstop switching and

VIN

enter the safe restart mode.

6.7 Overvoltage protection

The TEA1541 allows OVP to be set accurately.

The flyback converter output voltage is accurately

represented by the voltage across the auxiliary winding.

The auxiliary winding voltage is monitored by the current

flowinginto pin DEM during the demagnetizingcycleof the

transformer. The inevitable voltage spikes at pin DEM are

reduced using an internal filter.

1

------------f

smps

TEA1541

prematurely due to the false sensing of an overcurrent

condition caused by current spikes produced by the

discharge of primary-side snubber and parasitic

capacitances.

The OCP level is adjusted proportionally to the switching

frequency such that the product of (I

stays constant. This arrangement also implements OPP,

ensuringthatthemaximum output power is independentof

theswitchingfrequency, otherwise the output powerwould

increase in direct proportion to the switching frequency.

6.9 Soft start

The soft start function allows the transformer peak current

to slowly increase at every start-up and restart, to prevent

transformer rattle.

The soft start function requires a resistor RSS and

capacitor CSSto be connected between pin I

sense resistor R

(see Fig.7). CSS is charged by an

sense

internal current source ISSto V = ISS× RSS, to a maximum

of approximately 0.5 V.

)2× frequency

peak

sense

and the

If the output voltage causes the current into pin DEM to

exceed the OVP level l

OVP(DEM)

, the OVP circuit turns off

the power MOSFET. The controller then waits until the

V

CC(UVLO)

condition is reached. This is followed by a safe

restart cycle, before switching recommences.

This process is repeated until the OVP condition ends.

Theoutputvoltage at which OVPactivates,V

the value of resistor, R

N

V

o(ovp)

----------N

aux

s

I

, (see Fig.8) using the equation:

DEM

R

OVP DEM()

+×()×=

DEMVclamp DEM()pos()

o(ovp)

issetby

where N is the number of turns on the transformer

windings; V

clamp(DEM)(pos)

pin DEM; reference current I

is the positive clamp voltage on

OVP(DEM)

is set internally.

6.8 Overcurrent protection and overpower

protection

The current in the transformer primary is measured

accurately by the internal cycle-by-cycle source current

limit circuit using the external sense resistor R

sense

.

The accuracy of the current limit circuit allows the

transformer core to have a minimum specification for the

output power required. The OCP circuit limits the ‘sense’

voltage to an internal level, and is activated after the

leading edge blanking period, t

generated by the

leb

Leading Edge Blanking circuit (LEB shown in Fig.2).

Leading edge blanking is required to inhibit OCP for a

short period when the power MOSFET turns on.

This ensures that the MOSFET is not turned off

handbook, halfpage

I

SS

0.5 V

start-up

V

ocp

5

I

sense

R

SS

C

SS

R

sense

MBL503

Fig.7 Soft start.

The rate at which the primary current increases can be

adjustedby changing thevalues of RSSandCSStochange

the circuit time constant:

τ RSSCSS×=

The maximum primary current is calculated by the

equation:

I

primary max()

V

sense max()

=

------------------------------------------------------------------

ISSRSS×()–

R

sense

2003 Aug 11 9

Page 10

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

where V

sense(max)

ISS flows when the voltage on pin I

approximately 0.5 V. If this voltage exceeds 0.5 V, the

soft-start current source starts to limit ISS and completely

switches ISS off at V

Note that ISS is derived from the internal current source

supplying charging current to pin VCC. During soft-start,

the charging current to pin VCC will be reduced by up to

60 µA depending on the value of RSS.

6.10 Winding short-circuit protection

Thewindingshort-circuitprotectioncircuit is activated after

the leading edge blanking period. A short-circuit in the

transformer winding is detected when the voltage at

pin I

voltage V

exceeds the winding short-circuit protection

sense

swp

converter supply will stop switching. When the voltage at

pin VCC falls below V

mode, and capacitor C

start-up current source supplied from pin VIN until the

flyback converter supply restarts at V

detection and restart cycle will be repeated until the

short-circuit is removed. The winding short-circuit

protection circuit also provides protection if a diode in the

transformer secondary circuit goes short-circuit.

is the maximum source voltage for OCP.

is less than

sense

.

CC(start)

. When a short-circuit is detected, the flyback

CC(UVLO)

, the IC enters safe restart

will recharge via the internal

VCC

. The fault

CC(start)

TEA1541

period that is longer than the burst standby mode blanking

period t

blank(burst)

Duringa burst standbymode cycle, thesoft-start capacitor

CSS, (see Fig.8) is charged to 1.25 V and then discharged

via the soft-start resistor R

0.5 V, a soft-restart is initiated. The frequency of a typical

burst standby mode cycle is approximately:

If, during a burst standby mode cycle, the voltage at

pin V

falls below the trip level voltage V

CC

willbe supplied againfrom pin VIN. IfV

within the burst cycle period due to an external load on

pin V

, a restart cycle begins. If during a burst standby

CC

mode cycle, the voltage on pin V

level voltage V

obtained because the IC is being consistently powered by

the auxiliary winding.

6.13 Driver

The Gate of the external power MOSFET is driven from a

driver circuit having a current sourcing capability of

typically 100 mA, and a current sink capability of typically

500 mA.This permits fastturn-onand turn-off ofthe power

MOSFET for efficient operation.

.

CC(burst)

. When CSS is discharged to

SS

1

--------------------------- -

×

R

SSCSS

CC(burst)

CC(UVLO)

stays above the trip

CC

, the IC

isreached

, a maximum burst efficiency is

6.11 Overtemperature protection

An accurate temperature protection circuit stops the

converter from switching if the IC junction temperature

exceeds the maximum temperature protection level

T

prot(max)

V

CC(UVLO)

C

VCC

. When the voltage at pin VCC falls below

, the IC enters safe restart mode, and capacitor

will recharge to V

via the internal start-up

CC(start)

current source derived from pin VIN. If the temperature is

still too high, the voltage at pin VCC will fall again to

V

CC(UVLO)

temperature falls 8 degrees (typical) below T

. This cycle is repeated until the junction

prot(max)

.

6.12 Burst standby mode

Pin CTRL and pin I

are also used to implement the

sense

burst standby mode feature. In burst standby mode, the

converter consumes lessthan 1 W (typical)of input power

at a maximum output power of 100 mW. This power is

sufficient to supply a low power device such as a

microcontroller. Burst standby mode is entered when a

current larger than the burst standby mode active current

I

is forced into pin CTRL, via the opto-coupler, for a

burst

A low driver source current has been chosen in order to

limit the ∆V/∆t at switch-on. Thisreduces Electro Magnetic

Interference (EMI) and also limits the voltage spikes

across the current sense resistor R

sense

.

2003 Aug 11 10

Page 11

Philips Semiconductors Product specification

SMPS control IC with

TEA1541

synchronization function

7 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134). All voltages are measured with respect to

ground (pin 2); positive currents flow into the chip; pin 1 is not allowed to be current driven. The voltage ratings are valid

provided other ratings are not being violated; current ratings are valid provided the maximum power rating is not

violated.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

V

CTRL

V

DEM

V

sense

V

VIN

I

CTRL

I

DEM

I

sense

I

DRIVER

I

VIN

P

tot

T

stg

T

j

V

esd

voltage on pin V

CC

voltage on pin CTRL −0.4 +5V

voltage on pin DEM current limited −0.4 − V

voltage on pin I

sense

voltage on pin VIN −0.4 +550 V

current on pin CTRL δ < 10% − 50 mA

current on pin DEM −250 +250 µA

current on pin I

sense

current on pin DRIVER δ < 10% −0.8 +2A

current pin VIN −+5mA

total power dissipation T

storage temperature −55 +150 °C

junction temperature −20 +145 °C

electrostatic discharge;

human body model; note 1 pins 1 to 6 (class II) − 2000 V

machine model; note 2 − 200 V

continuous −0.4 +40 V

current limited −0.4 − V

−1 +10 mA

<70°C − 0.75 W

amb

pin 8 (Vin) (class I) − 1250 V

Notes

1. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

2. Equivalent to discharging a 200 pF capacitor through a 0.75 µH coil and a 10 Ω resistor.

8 THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in free air 100 K/W

9 QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part D”

.

2003 Aug 11 11

Page 12

Philips Semiconductors Product specification

SMPS control IC with

TEA1541

synchronization function

10 CHARACTERISTICS

T

=25°C; VCC= 15 V; all voltages are measured with respect to ground (pin 2); currents are positive when flowing

amb

into the IC.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Start-up current source (pin VIN)

I

VIN(min)

V

CC(VIN)trip

I

VIN(max)

I

VIN

V

bd

M-level mains-dependentoperation-enabling

M

UVLO

VCC management (pin VCC)

minimum supply current drawn from

pin VIN

supply voltage for pin VIN current trip

VCC<V

V

V

CC(trip)(VIN)

> 100 V

VIN

> 100 V 0.5 0.75 1.0 V

VIN

,

300 400 500 µA

level

maximum supply current drawn from

pin VIN

supply current drawn from pin VIN after start-up;

VCC=10V;

V

> 100 V

VIN

V

CC>VCC(start)

V

> 100 V

VIN

1.25 1.6 1.95 mA

− 100 300 µA

;

breakdown voltage 550 −−V

33 37 40 V

level

mains undervoltage lock-out level 25 28.5 33 V

V

CC(start)

V

CC(UVLO)

V

CC(hys)

I

CC(h)

I

CC(l)

I

CC(restart)

I

CC(oper)

start-up voltage 10.8 11.4 12 V

undervoltage lock-out 8.5 9.0 9.5 V

hysteresis voltage V

charging current (high) V

charging current (low) V

restart current V

supply current under normal

operation

Primary current simulation

α

PCS

primary current simulation factor − 0.9 − A.s/V

Demagnetization management (pin DEM)

V

th(DEM)

demagnetization comparator

threshold voltage

I

prot(DEM)

V

clamp(DEM)(neg)

V

clamp(DEM)(pos)

t

suppr

demagnetization current −50 −−10 nA

negative clamp voltage I

positive clamp voltage I

suppression time of transformer

ringing at start of secondary stroke

V

sc(prot)(DEM)

short-circuit protection voltage −90 −50 −10 mV

CC(start)

VIN

VCC<V

VIN

V

CC(trip)(VIN)<VCC

<V

VIN

<VCC<V

− V

> 100 V;

CC(trip)(VIN)

> 100 V;

CC(UVLO)

> 100 V;V

CC(start)

CC(UVLO)

CC(UVLO)

2.1 2.4 2.7 V

−−0.25 − mA

−1.6 −1.2 −0.75 mA

−1.25 −1.0 −0.75 mA

no load on pin DRIVER − 1.6 − mA

70 100 130 mV

= −150 µA −0.5 −0.25 −0.05 V

(DEM)

= 250 µA 0.55 0.7 0.85 V

(DEM)

1.1 1.5 1.9 µs

2003 Aug 11 12

Page 13

Philips Semiconductors Product specification

SMPS control IC with

TEA1541

synchronization function

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Pulse width modulator

t

on(min)

t

on(max)

Oscillator

f

osc(min)

f

osc

f

smps(max)

f

smps(hys)

V

vco(start)

V

vco(max)

Duty cycle control (pin CTRL)

V

CTRL(min)

V

CTRL(max)

I

prot(CTRL)

Burst standby mode (pin CTRL)

V

th(burst)(on)

I

burst

t

blank(burst)

V

ch(sense)(burst)

V

dis(sense)(burst)

I

ch(sense)(burst)

V

CC(burst)

I

CC(burst)

Synchronization (pin CTRL)

V

sync

∆V/∆t

sync

minimum on-time − 0 −

maximum on-time latched − 1/f

minimum oscillator frequency V

oscillator frequency V

> 1.5 V; no sync − 6 − kHz

CTRL

< 1.5 V; no sync;

CTRL

24 26 28 kHz

smps

− s

note 2

maximum SMPS switching

sync. on; note 3 − 54 − kHz

frequency before frequency division

frequency hysteresis for division sync. on − 4 − kHz

voltage on pin CTRL where

sync off 1.38 1.46 1.54 V

frequency reduction starts

peak voltage on pin CTRL where

frequency is equal to f

osc(min)

minimum voltage on pin CTRL for

sync off − 1.58 − V

− 1.0 − V

maximum duty cycle

maximum voltage on pin CTRL for

− 1.6 − V

minimum duty cycle

current on pin CTRL −0.6 −0.8 −1.0 µA

burst standby mode active threshold

I

=4mA − 3.6 − V

burst

voltage

burst standby mode active current 4 7 11 mA

burst standby mode blanking time 25 32 40 µs

charge voltage on pin I

sense

in burst

− 1.25 − V

standby mode

discharge voltage level on pin I

sense

− 0.5 − V

in burst standby mode

charging current into pin I

sense

in

− 100 −µA

burst standby mode

supply voltage trip level for supply

− 11.2 − V

from pin VIN during burst standby

mode

supply current during burst standby

− 600 −µA

mode

synchronization recognition voltage 0.37 0.52 0.65 V

synchronization recognition − 0.5

(1)

− V/µs

2003 Aug 11 13

Page 14

Philips Semiconductors Product specification

SMPS control IC with

TEA1541

synchronization function

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Overcurrent and winding short-circuit protection (pin I

V

sense(max)

t

PD

V

swp

maximum source voltage for OCP f

propagation delay from detecting

V

sense(max)

to switch-off

winding short-circuit protection

voltage

t

leb

blanking time forcurrent and winding

short-circuit protection

I

ss

V

ss(max)

soft start current V

soft start maximum sense voltage 0.45 0.50 0.55 V

Overvoltage protection (pin DEM)

I

OVP(DEM)

OVP trigger current see Section

Driver (pin DRIVER)

I

source

I

sink

V

o(driver)(max)

source current capability of driver VCC= 9.5 V;

sink current capability of driver VCC= 9.5 V;

maximum output voltage of driver VCC>12V − 11.5 12 V

Temperature protection

T

prot(max)

maximum temperature protection

level

T

prot(hys)

hysteresis for the temperature

protection level

)

sense

smps(min)

;

0.48 0.52 0.56 V

∆V/∆t = 0.1 V/µs

f

smps(max)

;

0.33 0.37 0.41 V

∆V/∆t = 0.1 V/µs

∆V/∆t = 0.5 V/µs − 140 185 ns

∆V/∆t = 0.5 V/µs 0.83 0.88 0.96 V

320 380 480 ns

< 0.5 V 45 60 75 µA

sense

54 60 66 µA

“Overvoltage protection”

−−100 −75 mA

V

DRIVER

=5V

− 500 − mA

V

V

V

DRIVER

= 9.5 V;

CC

DRIVER

=5V

400 700 − mA

= 9.5 V

130 140 150 °C

− 8 −°C

Notes

1. Guaranteed by design.

2. This is also the minimum SMPS switching frequency in synchronized mode.

3. This is also the maximum oscillator frequency in synchronized mode.

2003 Aug 11 14

Page 15

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

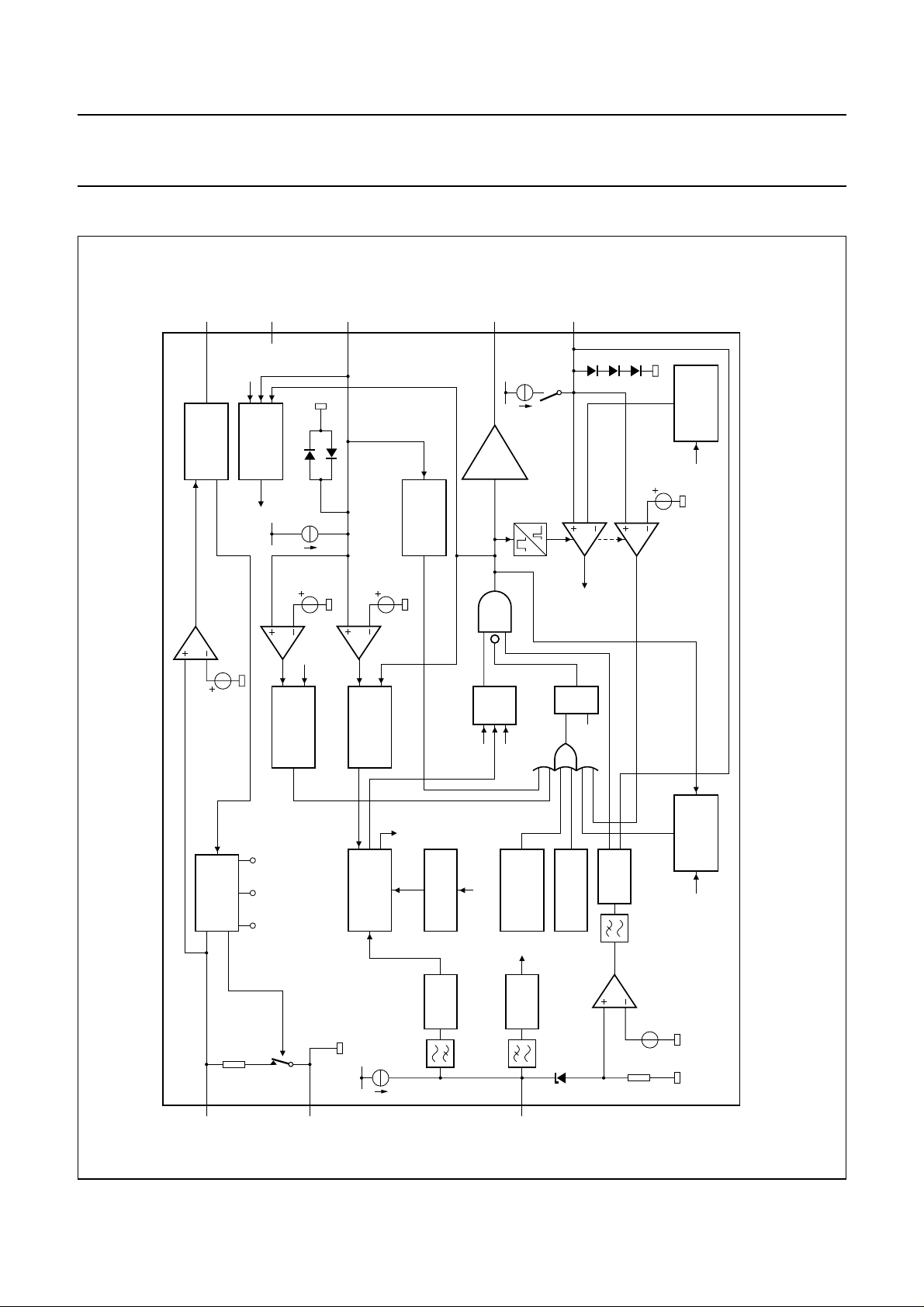

11 APPLICATION INFORMATION

Atypical flyback converter that usestheTEA1541 consists

of an input filter, a transformer with a third (auxiliary)

winding, and an output stage with a feedback circuit.

CapacitorC

voltage from the rectified high voltage (AC) mains during

start-up, or from the auxiliary winding during operation.

Resistor R

at pin I

sense

primary peak current. Resistor RSS and capacitor C

enable soft start and burst standby mode operation.

handbook, full pagewidth

Sync

connectedto pin VCCbuffersthe IC supply

VCC

converts the primary current into a voltage

sense

. The resistor value defines the maximum

V

mains

C

C

R

SYNC

C

R

VCC

SYNC

REG

REG

V

CC

GND

CTRL

DEM

1

2

3

4

TEA1541P

SS

C

8

7

6

5

VIN

VIN

HV

DRIVER

I

TEA1541

A resistor and a series diode can be placed inparallel with

resistor R

and out of the IC, allowing the valuesof theOVP leveland

primary current simulation to be defined independently.

More details are available in

R

SNUB

D

SNUB

R

C

R

SS

SS

DEM

sense

to control the amount of current flowing into,

DEM

Application note AN10205

D

OUT

C

SNUB

OUTPUT

power

MOSFET

R

sense

C

OUT

.

MDB081

Fig.8 Flyback configuration with synchronization and soft start.

2003 Aug 11 15

D

VCC

OPTO

R

REG1

R

REG2

Page 16

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

12 PACKAGE OUTLINE

DIP8: plastic dual in-line package; 8 leads (300 mil)

D

seating plane

A

L

Z

e

b

8

1

w M

b

1

b

2

5

TEA1541

SOT97-1

M

E

A

2

A

c

(e )

1

M

H

pin 1 index

E

1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

A

A

A

UNIT

max.

mm

inches

Note

1. Plastic or metal protrusions of 0.25 mm (0.01 inch) maximum per side are not included.

OUTLINE

VERSION

SOT97-1

12

min.

max.

050G01 MO-001 SC-504-8

b

1.73

1.14

0.068

0.021

0.045

0.015

IEC JEDEC JEITA

b

1

0.53

0.38

4

0 5 10 mm

scale

b

2

0.36

1.07

0.23

0.89

0.014

0.042

0.009

0.035

REFERENCES

(1) (1)

cD E e M

9.8

6.48

9.2

6.20

0.39

0.26

0.36

0.24

L

e

1

M

3.60

8.25

3.05

7.80

0.14

0.32

0.12

0.31

EUROPEAN

PROJECTION

E

10.0

8.3

0.39

0.33

H

0.2542.54 7.62

ISSUE DATE

w

0.010.1 0.3

99-12-27

03-02-13

max.

1.154.2 0.51 3.2

0.0450.17 0.02 0.13

(1)

Z

2003 Aug 11 16

Page 17

Philips Semiconductors Product specification

SMPS control IC with

synchronization function

13 SOLDERING

13.1 Introduction to soldering through-hole mount

packages

This text gives a brief insight to wave, dip and manual

soldering.A more in-depth accountofsoldering ICs can be

found in our

Packages”

Wave soldering is the preferred method for mounting of

through-hole mount IC packages on a printed-circuit

board.

13.2 Soldering by dipping or by solder wave

Driven by legislation and environmental forces the

worldwide use of lead-free solder pastes is increasing.

Typical dwell time of the leads in the wave ranges from

3 to 4 seconds at 250 °C or 265 °C, depending on solder

material applied, SnPb or Pb-free respectively.

Thetotalcontact time of successive solderwavesmustnot

exceed 5 seconds.

“Data Handbook IC26; Integrated Circuit

(document order number 9398 652 90011).

TEA1541

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

13.3 Manual soldering

Apply the soldering iron (24 V or less) to the lead(s) of the

package, either below the seating plane or not more than

2 mm above it. If the temperature of the soldering iron bit

is less than 300 °C it may remain in contact for up to

10 seconds. If the bit temperature is between

300 and 400 °C, contact may be up to 5 seconds.

stg(max)

). If the

13.4 Suitability of through-hole mount IC packages for dipping and wave soldering methods

PACKAGE

DBS, DIP, HDIP, SDIP, SIL suitable suitable

(2)

PMFP

Notes

1. For SDIP packages, the longitudinal axis must be parallel to the transport direction of the printed-circuit board.

2. For PMFP packages hot bar soldering or manual soldering is suitable.

− not suitable

DIPPING WAVE

SOLDERING METHOD

(1)

2003 Aug 11 17

Page 18

Philips Semiconductors Product specification

SMPS control IC with

TEA1541

synchronization function

14 DATA SHEET STATUS

LEVEL

I Objective data Development This data sheet contains data from the objective specification for product

II Preliminary data Qualification This data sheet contains data from the preliminary specification.

III Product data Production This data sheet contains data from the product specification. Philips

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

3. For data sheets describing multiple type numbers,the highest-levelproduct statusdetermines thedata sheet status.

DATA SHEET

STATUS

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

(1)

PRODUCT

STATUS

(2)(3)

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Relevant changes will

be communicated via a Customer Product/Process Change Notification

(CPCN).

DEFINITION

15 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese or at anyotherconditionsabove those given inthe

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentationorwarranty that such applications willbe

suitable for the specified use without further testing or

modification.

16 DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result inpersonal injury. Philips

Semiconductorscustomersusingor selling these products

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes in the products including circuits, standard cells, and/or software described or contained herein in order to improve design

and/or performance. Whenthe product is in full production

(status ‘Production’), relevant changes will be

communicated via a Customer Product/Process Change

Notification (CPCN). Philips Semiconductors assumes no

responsibility or liability for the use of any of these

products, conveys no licence or title under any patent,

copyright, or mask work right to these products, and

makes no representations or warranties that these

products are free from patent, copyright, or mask work

right infringement, unless otherwise specified.

2003 Aug 11 18

Page 19

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2003

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 403502/01/pp19 Date of release: 2003 Aug 11 Document order number: 9397 750 10696

SCA75

Loading...

Loading...