Page 1

Colour Television Chassis

TDVD3.1E

AA

F_15160_000.eps

Contents Page

1. Technical Specifications, Connections and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes and Fault Finding 9

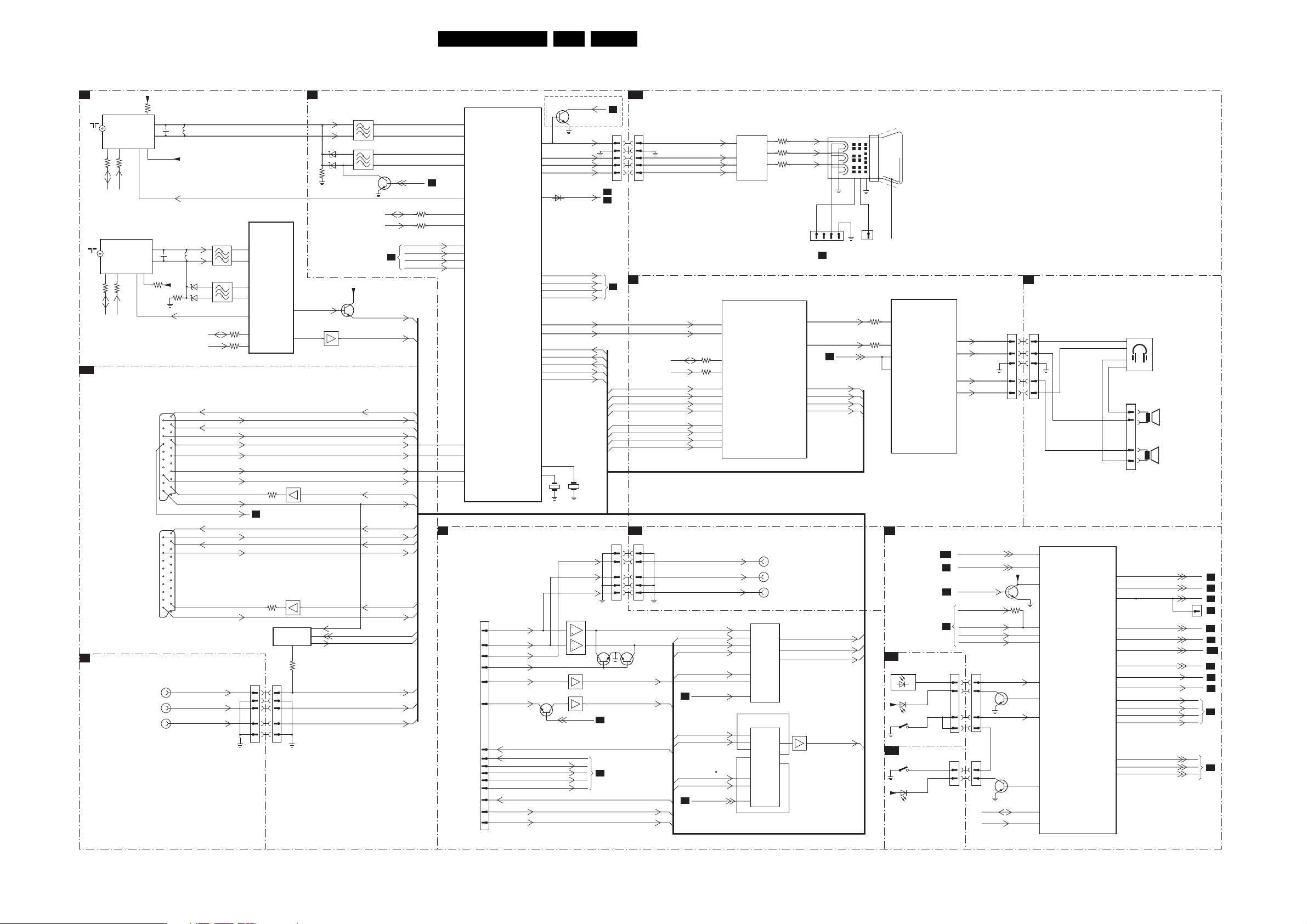

6. Block Diagrams and Test Point Overviews

Wiring Diagram 11

Block Diagram Video, Audio, and Control 13

Block Diagram Supply, Deflection, and I2C 12

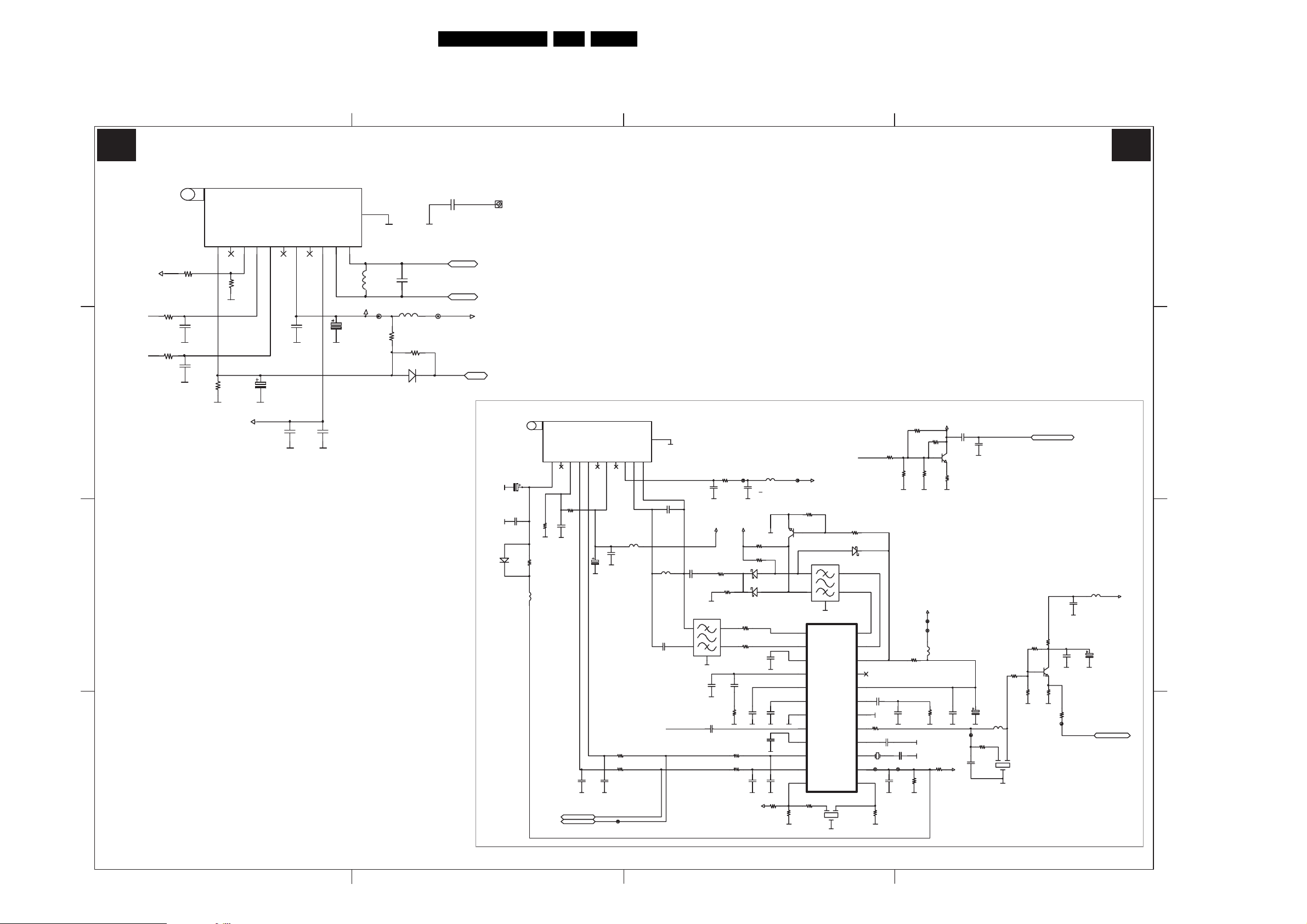

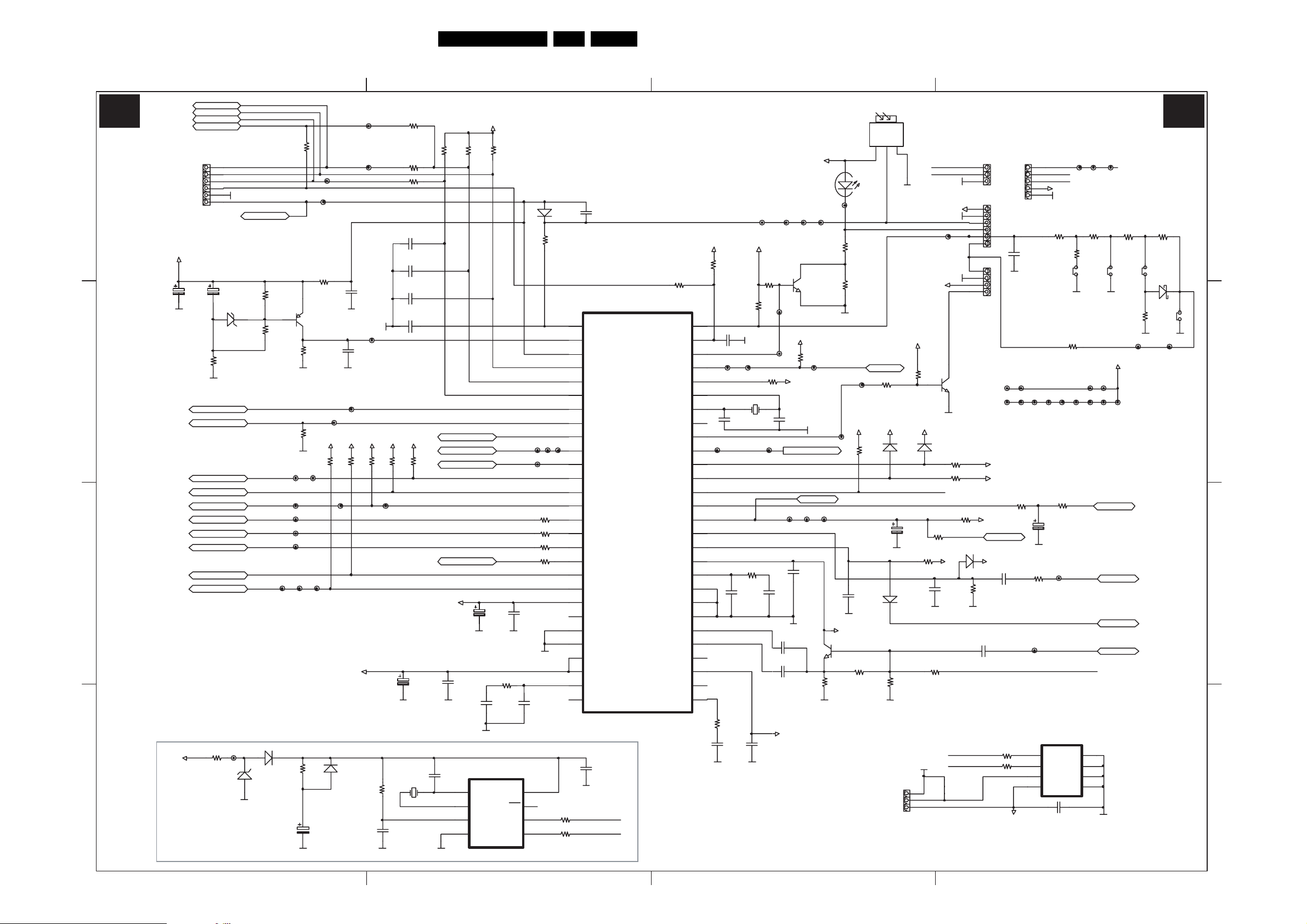

7. Circuit Diagrams and PWB Layouts Diagram PWB

Main Panel: Tuner (A1) 14 27-28

Main Panel: EEPROM (A2) 15 27-28

Main Panel: Sound (A3) 16 27-28

Main Panel: Vertical Deflection (A4) 17 27-28

Main Panel: Video (A5) 18 27-28

Main Panel: DVD + I/O Conn. (A6) 19 27-28

Main Panel: Side A/V (A8) 20 29

Main Panel: Power (A9) 21 27-28

Main Panel: SCART (A10) 22 27-28

Main Panel: Mains Switch + Keyb. + LED (A11) 23 29-30

Main Panel: CRT Panel (A13) 24 27-28

Main Panel: Eject (A14) 25 27-28

Main Panel: Line Out (A15) 26 29

8. Alignments 31

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 34

Abbreviation List 37

IC Data Sheets 40

10. Spare Parts List 44

11. Revision List 48

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JH 0569 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 15161

Page 2

EN 2 TDVD3.1E AA1.

Technical Specifications, Connections and Chassis Overview

1. Technical Specifications, Connections and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connections / Control Facilities

1.3 Chassis Overview

Video

Audio

L

R

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Reception

Tuning system : PLL

Colour systems : PAL B/G, D/K, I

: SECAM B/G, L/L’

Sound systems : FM/FM (5.5 - 5.74) (B/

G)

: NICAM B/G (5.5 -

5.85), NICAM D/K

: NICAM I (6.0 - 6.52),

NICAM L (6.5 (AM) -

5.85)

A/V connections : NTSC 3.58

: NTSC 4.43

Channel selections : 100 channels

: UVSH

IF frequency : 38.9 MHz

Aerial input : 75 Ω, Coax

1.1.2 DVD Module

Disc formats : CD Audio

: MP3 Audio

: DVD Audio

: CD (R/RW)

:CVD

: (S) VCD

:DVCD

:DVD (+R/RW)

: DVD (-R/RW)

Rotational speed : 3.9 - 5.5 x CD

: 1.6 - 2.4 x DVD

Data transfer rate : 2216 - 3324 kB/s for

DVD

: 672 - 947 kB/s for CD

Avg. access time : 320 ms (DVD). 420

: ms (CD) typical

Data buffer capacity : 256 Kbytes

1.1.3 Miscellaneous

Audio output (RMS) : 2 x 5 W stereo

Mains voltage : 220 - 240 V (± 10 %)

Mains frequency : 50 / 60 Hz (± 5 %)

Ambient temperature : + 5 to + 45 deg. C

Maximum humidity : 90%

Power consumption : 50 W

Standby Power consumption : < 3W

1.2 Connections / Control Facilities

1.2.1 Side Connections and Front Control

-

+

IR

Figure 1-1 Front Control

F_15160_001.eps

040705

F_15160_002.eps

040705

Figure 1-2 Side AV

Audio / Video In

1 -Video CVBS (1 Vpp / 75 Ω) jq

2 -Audio L (0.5 Vrms / 10 kΩ) jq

3 -Audio R (0.5 Vrms / 10 kΩ) jq

4 -Headphone 3.5 mm (8 - 600 Ω / 4 mW) rt

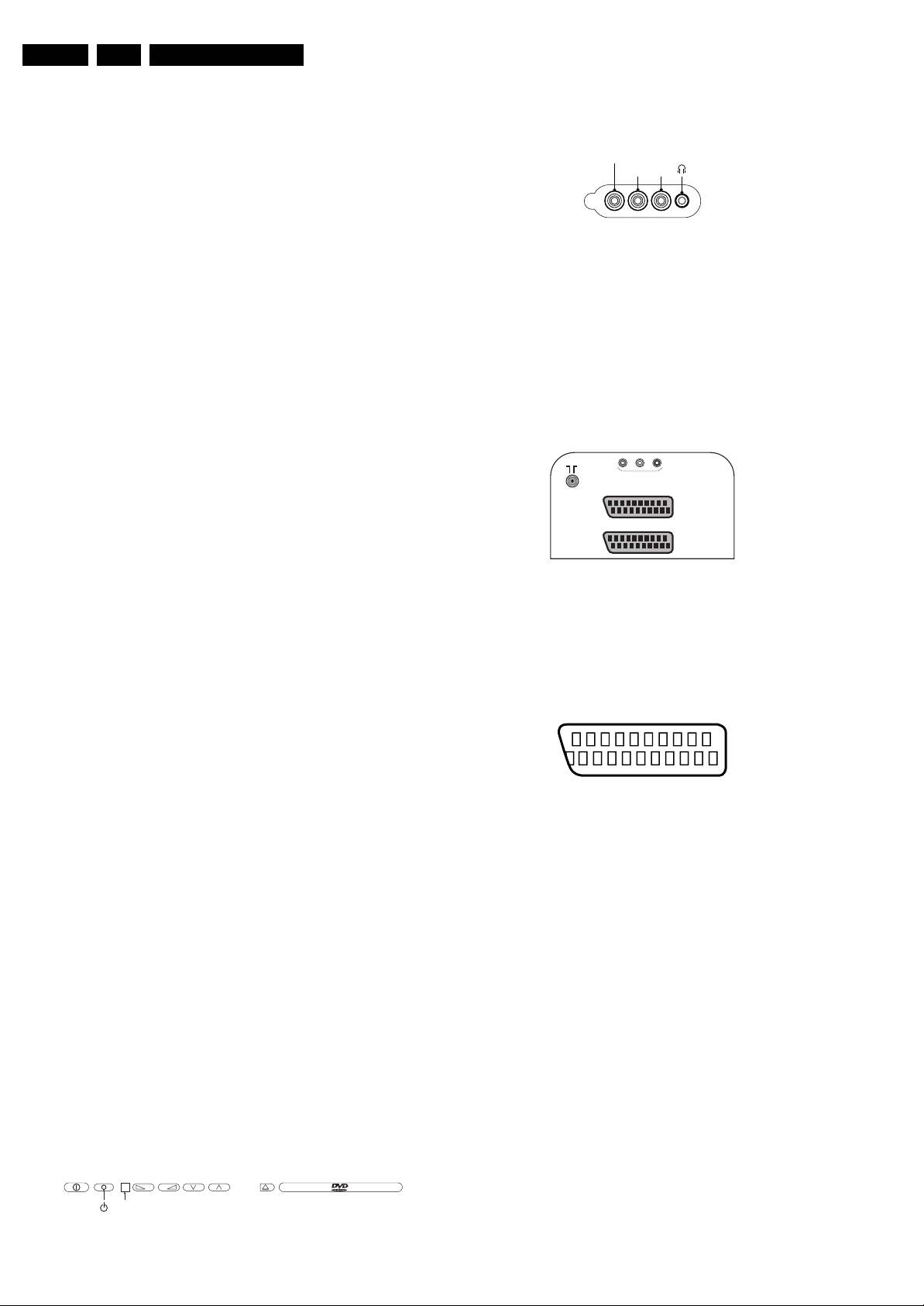

1.2.2 Rear Connections

AUDIO

LR

PCM

AV OUT

EXT2

EXT1

F_15160_003.eps

040705

Figure 1-3 Rear Connections

TV Aerial In

Aerial input : 75 Ω, Coax (IEC-type)

External 1: RGB in + CVBS in/out

21

20

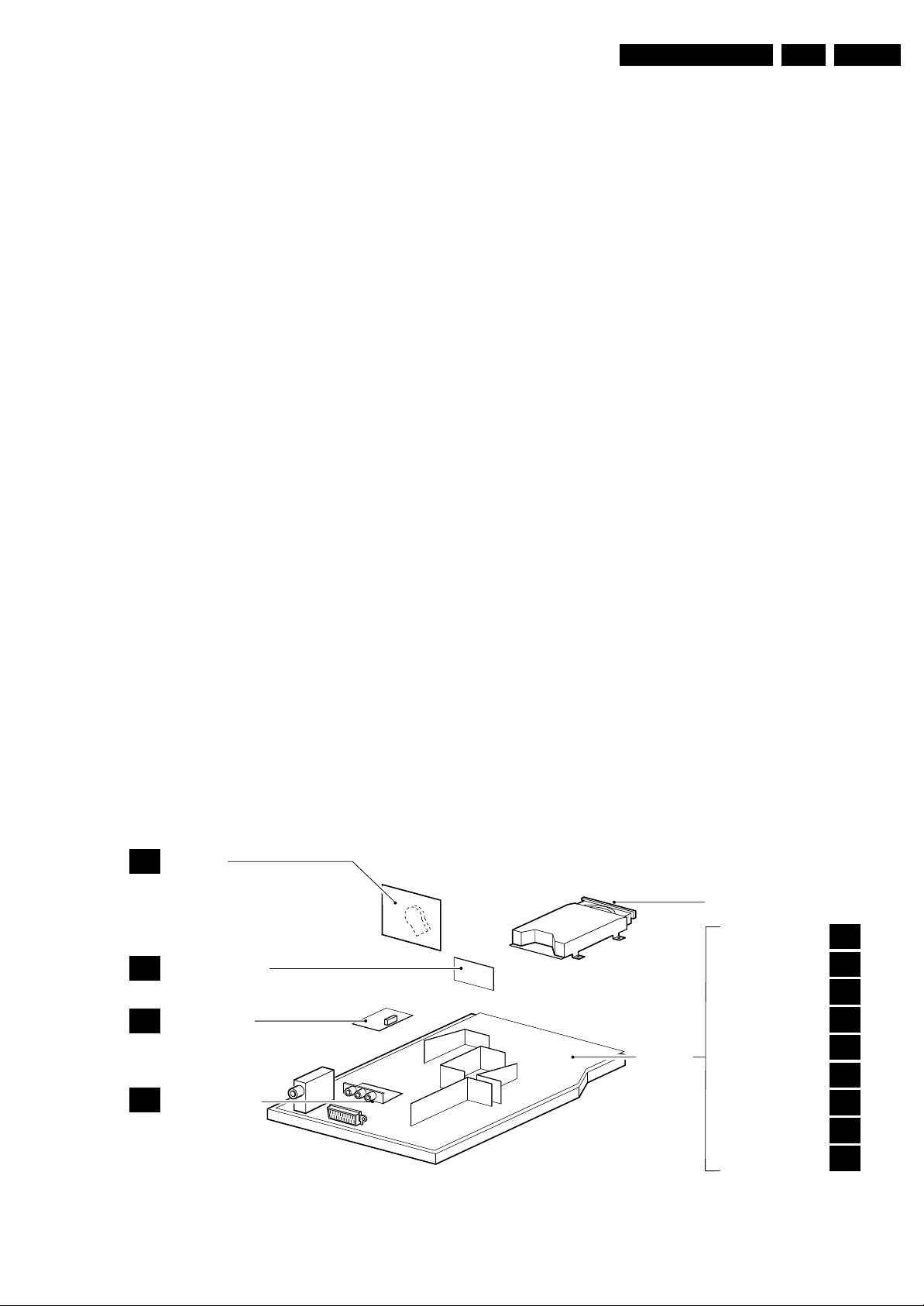

E_06532_001.eps

2

1

050404

Figure 1-4 SCART connector

1 -Audio R (0.5 Vrms 10 kΩ k

2 -Audio R (0.5 Vrms 10 kΩ j

3 - Audio L (0.5 Vrms 1 kΩ k

4 - GND H

5 - GND H

6 - Audio L (0.5 Vrms 10 kΩ j

7 - Blue (0.7 Vpp / 75 Ω) j

8 - CVBS-status 0 - 2.0 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3

9 - GND H

10 -

11 - Green (0.7 Vpp / 75 Ω) j

12 -

13 - GND H

14 - GND H

15 - Red (0.7 Vpp / 75 Ω) j

16 - RGB-status 0 - 0.4 V: INT

1 - 3 V: EXT / 75 Ω

17 - GND H

18 - GND H

19 - CVBS (1 Vpp / 75 Ω) k

20 - CVBS (1 Vpp / 75 Ω) j

21 - Earth GND vj

Page 3

Technical Specifications, Connections and Chassis Overview

EN 3TDVD3.1E AA 1.

External 2: CVBS in/out

1 - Audio R (0.5 Vrms 10 kΩ k

2 - Audio R (0.5 Vrms 10 kΩ j

3 - Audio L (0.5 Vrms 1 kΩ k

4- GND H

5- GND H

6 - Audio L (0.5 Vrms 10 kΩ j

7-

8 - CVBS-status 0 - 2.0 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3

9- GND H

10 -

11 -

12 -

13 - GND H

14 - GND H

15 -

16 -

17 - GND H

18 - GND H

19 - CVBS (1 Vpp / 75 Ω) k

20 - CVBS (1 Vpp / 75 Ω) j

21 - Earth GND j

1.2.3 DVD Module Connections

DC Power Connector (CN1)

1. Supply voltage + 12 V

2. Ground GND

3. Supply voltage + 3.3 V

4. Ground (analogue) A-GND

5. Ground (digital) D-GND

6. Supply voltage + 5 V

7. Power Control Active high

A/V and DAIC Output (CN6)

1. R/R (PCM3) Rear Right Audio (Audio Data 3)

2. AGND Audio Ground _

3. R/L (PCM2) Rear Left Audio (Audio Data 2)

4. CEN (PCM1) Centre Audio (Audio Data 1)

5. A-GND Audio Ground

6. S/W (PCM0) Sub Woofer (Audio Data 0)

7. F/R (SCK) Front Right Audio (System clock)

8. AGND Audio Ground

9. F/L (BCK) Front Left Audio (Audio bit clock)

10. MUTE (LRCK) Mute for Audio (Audio L/Rch clock)

11. SPDIF Digital Audio

12. D-GND Digital Ground

13. CVBS 1 Vpp / 75 Ohm

14. VGND Video Ground

15. Y 1 Vpp / 75 Ohm

16. VGND Video Ground

17. C 0.3 Vpp / 75 Ohm

18. VGND Video Ground

19. G(Y) 0.7 Vpp / 75 Ohm

20. B(Cb) 0.7 Vpp / 75 Ohm

21. R(Cr) 0.7 Vpp / 75 Ohm

22. VGND Video Ground

23. VID_S/W Video switching

24. TV_S/W TV switching

25. MODE1 SCL or TXD

26. MODE2 SDA or RXD

Slave Interface Connector (CN7)

1. INTOR

2. GND

3. VDATAIN

4. VDATAOUT

5. VCLK

6. VSTB

External A/V Interface Connector(CN8)

1. POWER

2. STOP

3. EJECT

4. LED1

5. NEXT

6. BACK

7. PLAY

8. LED2

9. EXT_IF_!

10. EXT_IN_2

11. Ground

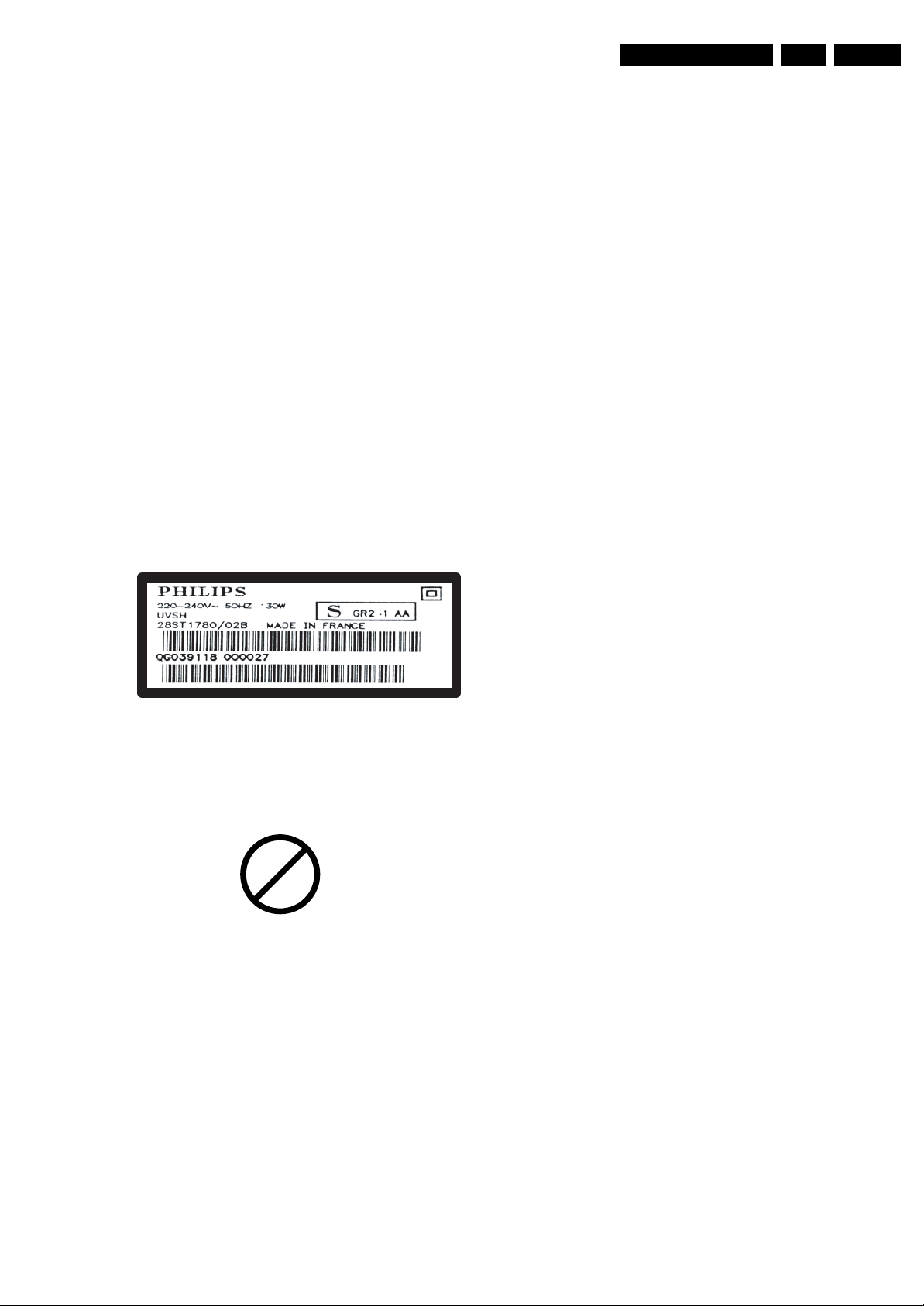

1.3 Chassis Overview

CRT PANEL

A13

KEYBOARD PANEL

A11

SIDE AV PANEL

A8

LINE OUT PANEL

A15

Figure 1-5 Chassis Overview

MAIN

CHASSIS

PANEL

DVD ENGINE

TUNER

MCU & EEPROM

SOUND

DEFLECTION

VIDEO

DVD AV

POWER SUPPLY

SCART

EJECT

A1

A2

A3

A4

A5

A6

A9

A10

A14

F_15160_054.eps

250805

Page 4

EN 4 TDVD3.1E AA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains (AC Power) via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains (AC Power) lead for

external damage.

• Check the strain relief of the Mains (AC Power) cord for

proper function.

• Check the electrical DC resistance between the Mains (AC

Power) plug and the secondary side (only for sets that have

a Mains (AC Power) isolated power supply):

1. Unplug the Mains (AC Power) cord and connect a wire

between the two pins of the Mains (AC Power) plug.

2. Set the Mains (AC Power) switch to the "on" position

(keep the Mains (AC Power) cord unplugged!).

3. Measure the resistance value between the pins of the

Mains (AC Power) plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains (AC Power) plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (µ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

-9

), or pico-farads (p= x10

-12

-6

),

).

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3.3 Rework on BGA (Ball Grid Array) ICs

General

Although (LF)BGA assembly yields are very high, there may

still be a requirement for component rework. By rework, we

mean the process of removing the component from the PWB

and replacing it with a new component. If an (LF)BGA is

removed from a PWB, the solder balls of the component are

deformed drastically so the removed (LF)BGA has to be

discarded.

Device Removal

As is the case with any component that, is being removed, it is

essential when removing an (LF)BGA, that the board, tracks,

solder lands, or surrounding components are not damaged. To

remove an (LF)BGA, the board must be uniformly heated to a

temperature close to the reflow soldering temperature.

A uniform temperature reduces the risk of warping the PWB. To

do this, we recommend that the board is heated until it is certain

that all the joints are molten. Then carefully pull the component

off the board with a vacuum nozzle. For the appropriate

temperature profiles, see the IC data sheet.

Area Preparation

When the component has been removed, the vacant IC area

must be cleaned before replacing the (LF)BGA.

Removing an IC often leaves varying amounts of solder on the

mounting lands. This excessive solder can be removed with

either a solder sucker or solder wick. The remaining flux can be

removed with a brush and cleaning agent.

Page 5

Safety Instructions, Warnings, and Notes

EN 5TDVD3.1E AA 2.

After the board is properly cleaned and inspected, apply flux on

the solder lands and on the connection balls of the (LF)BGA.

Note: Do not apply solder paste, as this has been shown to

result in problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new

component on the board. Ideally, the (LF)BGA should be

aligned under a microscope or magnifying glass. If this is not

possible, try to align the (LF)BGA with any board markers.

So as not to damage neighbouring components, it may be

necessary to reduce some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Workshop Information”. Here you will find

Information on how to deal with BGA-ICs.

2.3.4 Lead-free Solder

Philips CE is producing lead-free sets (PBF) from 1.1.2005

onwards.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 5 and 6 refer to the production year, digits

7 and 8 refer to production week (in example below it is 1991

week 18).

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

• Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

shortly before it is used (soldered). Otherwise the body of

the IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90°C) for drying (think of ESD-protection!).

Do not re-use BGAs at all!

• For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

In case of doubt whether the board is lead-free or not (or with

mixed technologies), you can use the following method:

• Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

• De-solder thoroughly (clean solder joints to avoid the

mixing of two alloys).

E_06532_024.eps

230205

Figure 2-1 Serial number example

Regardless of the special lead-free logo (which is not always

indicated), one must treat all sets from this date onwards

according to the rules as described below.

P

b

Figure 2-2 Lead-free logo

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilise the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

Caution: For BGA-ICs, you must use the correct temperature

profile, which is coupled to the 12NC. For an overview of these

profiles, visit the website www.atyourservice.ce.philips.com

(needs subscription, but is not available for all regions).

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repair help

desk.

2.3.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

Page 6

EN 6 TDVD3.1E AA3.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Directions for Use

Page 7

4. Mechanical Instructions

Index of this chapter:

4.1 Exploded View

4.2 Rear Cover Removal

4.3 Service Position Main Panel

4.4 DVD Module Removal

4.5 Side I/O Panel Removal

4.6 Rear I/O Panel Removal

4.7 Rear Cover Mounting

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

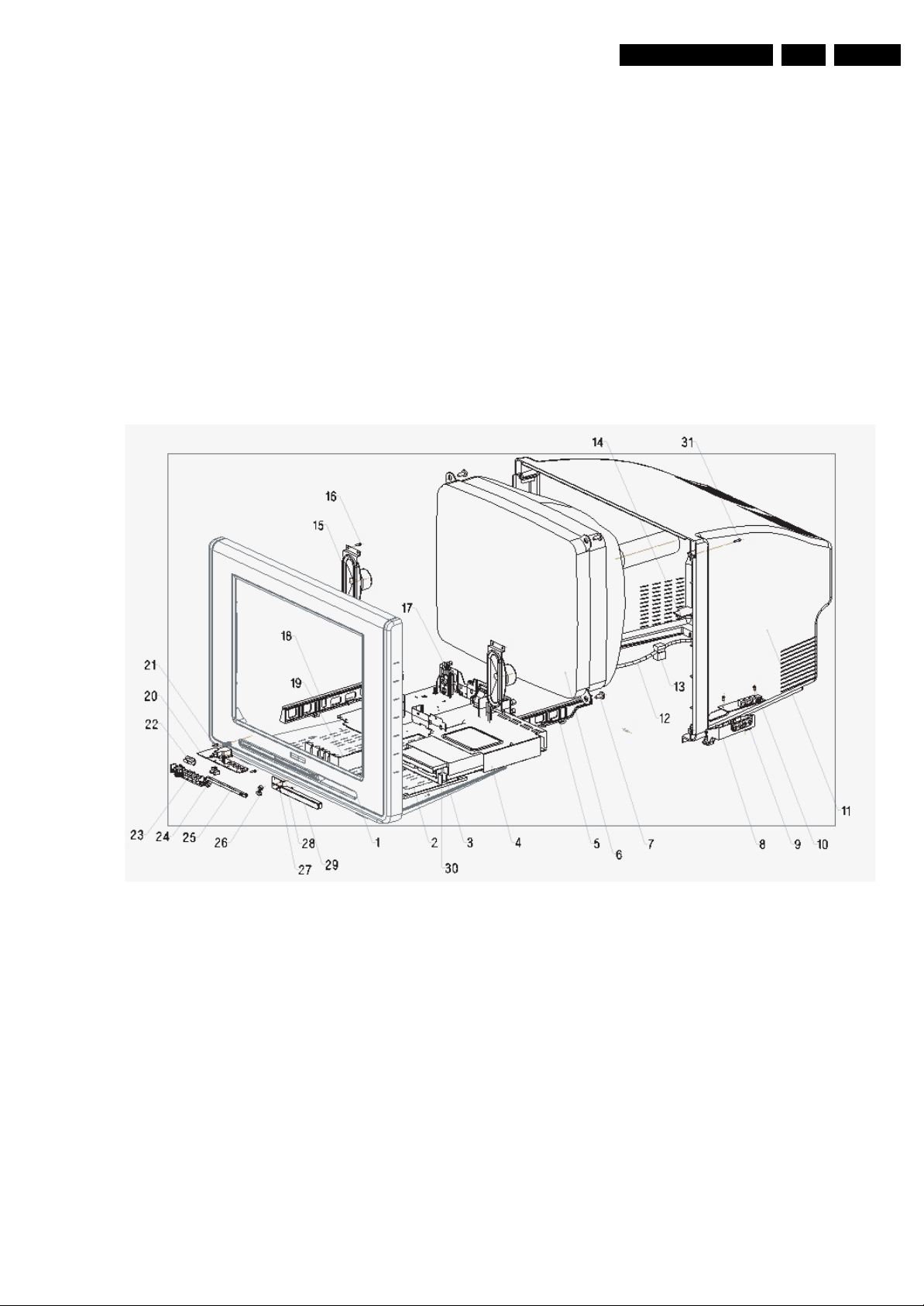

4.1 Exploded View

Mechanical Instructions

EN 7TDVD3.1E AA 4.

4.2 Rear Cover Removal

1. Remove all fixation screws (4x) of the rear cover.

2. Pull the rear cover a little backwards.

3. Disconnect the Rear I/O panel

4. Now pull the rear cover backwards to remove it.

4.3 Service Position Main Panel

1. Disconnect all cables of the DVD module

2. Remove the main panel [1]. At the same time, pull the

panel away from the

3. CRT [2].

4. Turn the panel 90 degrees clockwise [3].

5. Flip the panel 90 degrees [4], with the components towards

6. the CRT.

Figure 4-1 Exploded view

4.4 DVD Module Removal

4.5 Side I/O Panel Removal

4.6 Rear I/O Panel Removal

F_15160_013.eps

040705

Remove the complete DVD module after unscrewing the four

fixation screws [1].

Remove the side I/O panel after unscrewing the screws (2x) at

the bottom of the set.

Remove the rear I/O panel after unscrewing the two screws

from the inside of the rear cover.

Page 8

EN 8 TDVD3.1E AA4.

4.7 Rear Cover Mounting

To reassemble the set, perform all described processes in

reverse order.

Be sure that, before the rear cover is mounted:

• The mains cord is mounted correctly in its guiding bracket.

• All wires/cables are returned in their original position

Mechanical Instructions

Page 9

Service Modes, Error Codes and Fault Finding

5. Service Modes, Error Codes and Fault Finding

EN 9TDVD3.1E AA 5.

Index of this chapter

5.1 Service Modes

5.2 Fault Finding and Repair Tips

5.1 Service Modes

The Service Mode is a combination of the TV Service Mode

and the DVD Service Mode. You can enter the DVD Service

Mode via the TV Service Mode. The Service Mode offers

features, which the service technician can use to repair a set.

Any feature change, made via the Service Menu, will respond

at the same time The Dealer Mode is a special DVD mode, to

provide an auto replay function for commercial purposes. All

displayed text strings in the Service Modes are in English.

5.1.1 TV Service Mode

Purpose

• To perform alignments (e.g. colour adjustment and

geometry alignments)

• To change option settings

• DVD Service menu

Specifications

All service unfriendly modes (if present) are disabled, like:

• Auto switch 'off' (when there is no 'ident' signal)

• Timer switch to a channel

• Automatic user menu time-out

• The NVM is unprotected

• AV functions are not working

How to Enter the Service Mode

Screen menu's must be 'off', when you enter the Service Mode.

Use a standard customer RC transmitter and key in the code

062596 directly followed by the MENU button in 10 seconds.

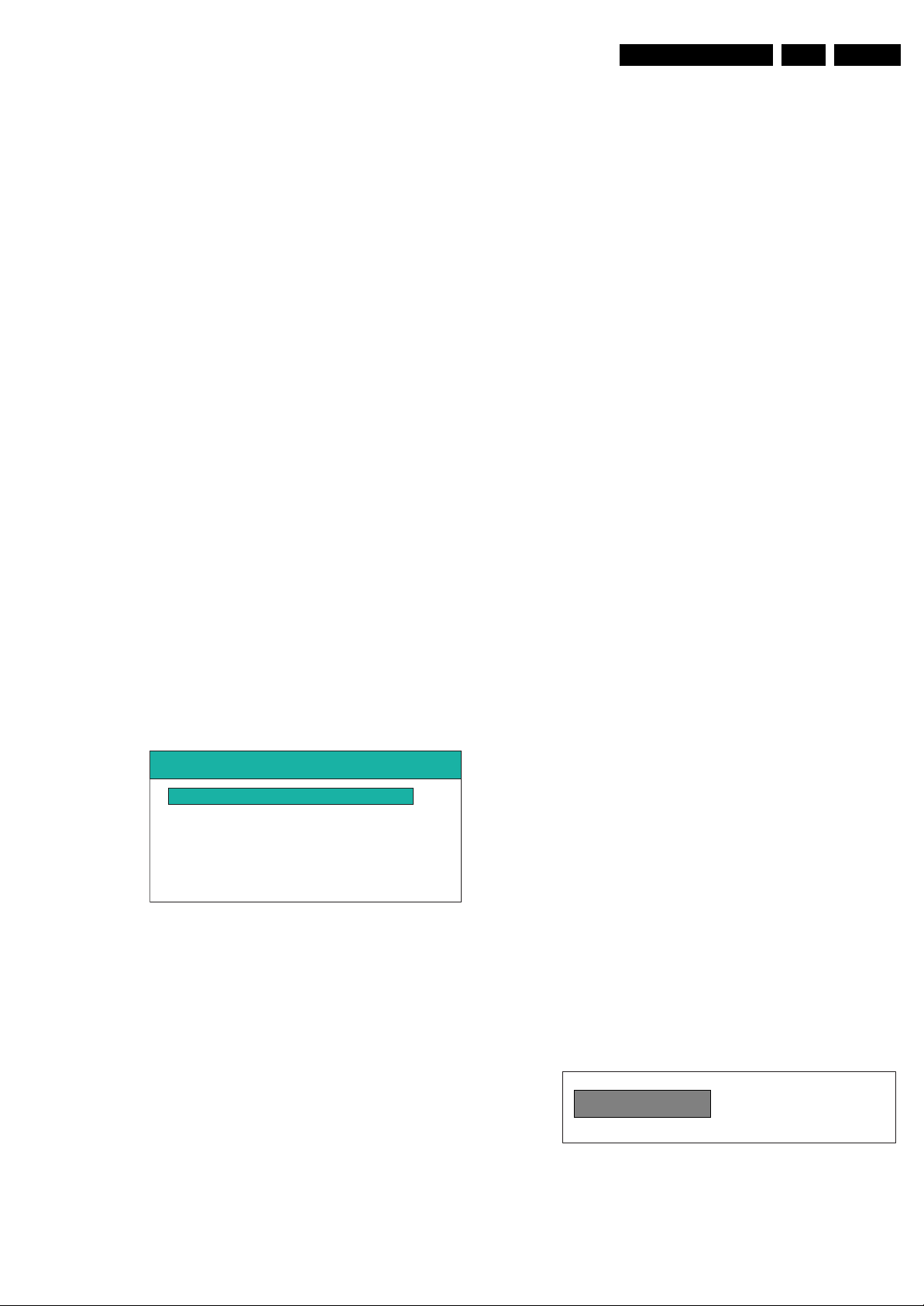

The following screen is visible when you enter the Service

Mode:

ST92195PWS7-V3 06.06.05

Program 06

OPTIONS

GEOMETRY

G2A

VIDEO

TUNER/IF

DVD

F_15160_005.eps

Figure 5-1 Figure 5.1 TV Service Mode Menu.pdf

• LLLLLLL. This is the used IC type.

• PAB#-XX. This is the software identification.

– P = Philips.

– A = the region (W = West Europe, E = East Europe).

– B = sound specification (M = Mono, S = Stereo).

– # = number of TXT pages.

– XX = the software version number (the first X is the

main software version number and the second X is the

sub software version number).

• PROGRAM. .......

• OPTIONS. Three codes possible.

• GEOMETRY. To align the geometry (see chapter 8.x for a

detailed description).

• G2A. To align the G2 (see chapter 8.x for a detailed

description).

• VIDEO. To adjust RGB, R_cut-off and G_cut-off.

• TUNER/IF. To align the tuner.

• DVD. To enter the DVD Service Mode.

How to Navigate

• Select menu items with the CURSOR UP/DOWN keys.

• With the CURSOR LEFT/RIGHT keys, it is possible to

change the value of the first item (Program)

• With the CURSOR RIGHT and OK keys, activate the

selected menu item.

• When you press the MENU key in a sub menu, you will

return to the previous menu.

• When you press the MENU key in the Service Mode menu,

you will return to the Main menu.

How to Exit

• With the STANDBY command, the set switches to

Standby.

• With the MENU key, the set returns to the Main menu.

Switching the set 'off' and 'on' with the mains switch, brings

the set into normal operation again. All changes in the

Service Mode are stored immediately.

5.1.2 Dealer Mode

Purpose

• To provide an auto replay function (commercial purpose).

• To ignore some features.

Pre-conditions to Start the Dealer Mode are:

• Put the set in DVD Mode (not necessary but is better).

• Switch Teletext 'off' (if set is in TV Mode).

• Switch Childlock 'off'.

• No screen Menu's.

• A DVD disc is present in the tray.

• Close disc tray.

• Switch the DVD in PLAY condition.

Specifications

• The information line displays the current mode.

• The set starts to play the disc.

• The Disc Menu passes automatically.

• At the end of the disc, the set replays the disc from chapter

1 onwards.

In Dealer Mode, some restrictions and rules are defined:

• While the Dealer Mode is active, you cannot use the

STANDBY key (RC reception is blocked), so it is not

possible to go to standby. The only way to switch off

the set is to switch the Mains Power 'off'.

• When the mains Power is switched 'on', the set will go out

of standby (DVD Mode) automatically.

250805

How to Enter the Dealer Mode

Use a standard RC-transmitter and key in the code 9999

directly followed by the MENU button.

The set will now switch to Dealer Mode. The current mode is

written to the

NVM.

The set switches to the DVD mode and informs the DVD about

the current mode

Dealer Mode ON

F_15160_006.eps

040705

Figure 5-2 Figure 5.2 Dealer Mode menu

Page 10

EN 10 TDVD3.1E AA5.

Service Modes, Error Codes and Fault Finding

How to Exit

Use a standard RC-transmitter and key in the code 9999

directly followed by the MENU button.

5.2 Fault Finding and Repair Tips

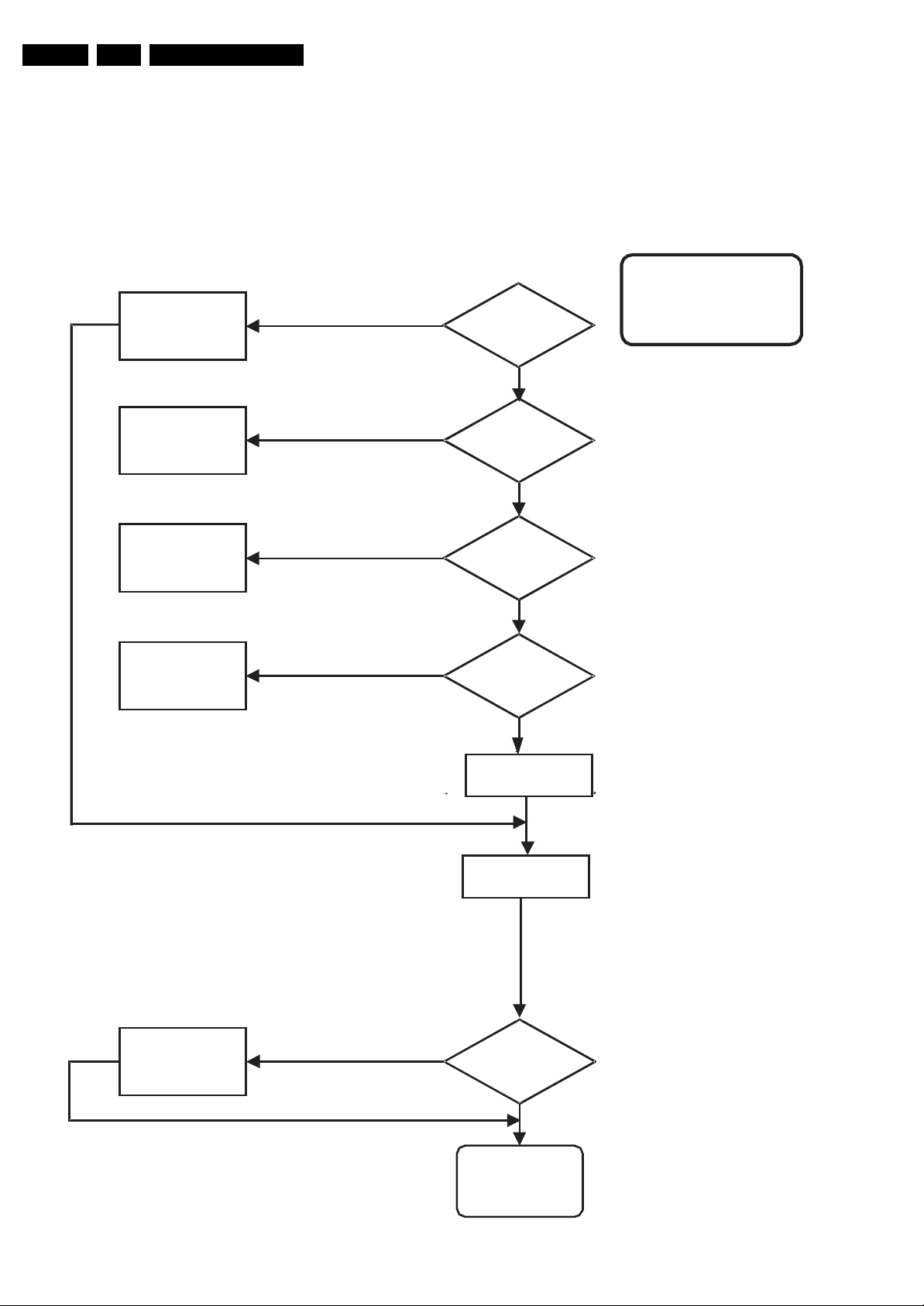

5.2.1 Fault Tracing Diagram for Power Supply

D101-04

C101-04

C106, T101

R107, R105

open

circuit

YES

NO

The Play mode is stopped, the Dealer mode is deactivated, and

the TV menu -Returns

Switched mode

Power Supply defective,

Fuse

F1

Defective

+123V is missing or

level is wrong

NO

Voltag e at

drain of

T101

YES

R104

R111, D107

D116,

YES

YES

Voltag e at

I101 pin 3

< 1V

NO

start-up

voltage pin

8

< 8V

NO

I101

NO

Measure

V102, R159

NO

adjustable with

Control range of

switched-mode

Power Supply

Figure 5-3 Fault Tracing

+123V

V101

YES

F_15160_007.eps

040705

Page 11

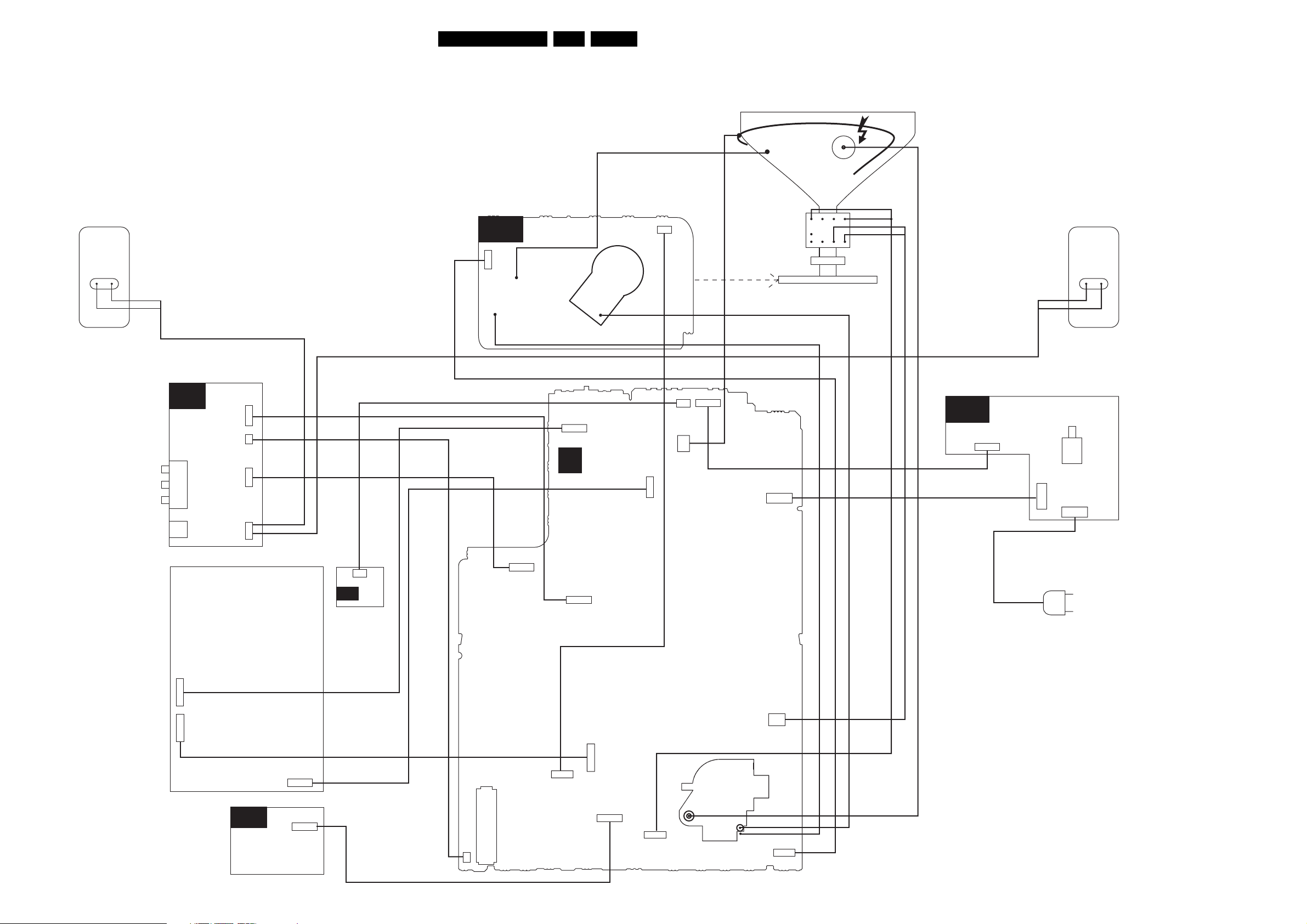

Block Diagrams and Test Point Overviews

6. Block Diagrams and Test Point Overviews

Wiring Diagram

11TDVD3.1E AA 6.

DEGAUSSING COIL

AQUADAG

CRT

EHT

CRT

RIGHT

SPEAKER

VIDEO (YELLOW)

AUDIO LEFT (WHITE)

AUDIO RIGHT (RED)

HEADPHONE

A8

SIDE A/V

K901

K1

K907

K905

S104

4P

S501

5P

S003

2P

S102

2P3

S001

6P

S101

2P3

CRT PANEL

A11

MAINS SWITCH +

KEYBOARD + LED

0214

6P

O212

2P3

LEFT

SPEAKER

MAINS

SWITCH

O211

2P3

A13

S502

4P3

S505

5P

1P

5P

4P

CRT PANEL

S507

S002

A

S506

6P

CRT

SOCKET

MONO

CARRIER

6P

12P

DVD PLAYER

A14

LINE OUT

4P

5P

KS01

A14

2P

0220

EJECT

S202

5P

S302

5P

S403

2P3

JP01

12P

5P

S301

LOT

S303

5P

TUNER

K1

1P

2P

S421

4P3

S401

MAINS

CORD

F_15160_055.eps

290905

Page 12

Block Diagrams and Test Point Overviews

Block Diagram Video, Audio, and Control

Video Audio Control

A1

TUNER

X101

UV1316

SDA

54 1

R614

SDA

TT01

UV1316

SDA

54 1

RT09

SDA

A10

SCART

A8

SIDE A/V

MAIN

TUNER

SCL

R613

SCL

TUNER - II

SCL

RT07

SCL

SCART II

AUDIO IN L

AUDIO IN R

AGC

SCART I

VIDEO IN

5VM

RT03

11

1F1

C605

L602

10

1F2

AGC

NC

9

1F1

1F2

9

11

10

RES

RT17

S306A

2

6

8

16

20

S306B

2

6

20

K904

K903

K902

CT13

1

3

7

11

15

19

1

3

19

33V

RT40

33V

AGC

LT04

DT02

DT03

AGC

FRONT_CVBS

FT02

125

FT01

125

SDA

SCL

R1OUT

R1IN

L1OUT

L1IN

FBEXT

EXT1IN

AV_STATUS

R2OUT

SC2_R

L2OUT

SC2_L

EX2_IN

L2IN

R2IN

B

G

R

4

4

RT08

RT10

1T01

TDA9886

DEMODULATOR

6

PIFIN1

7

PIFIN2

1

NC/SIF1

2

NC/SIF2

8

AGCTU

52

SDA

51

SCL

A4

K

901

11

22

33

44

55

IF-PLL

R380

RE11

S302

AUD

CVBS

RES

T310

EF

Q029

EF

CONTROL

R351

8

17

A5

VIDEO PROCESSOR

IF1

1

IF2

2

D307

D308

R345

+5V

Q027

Q030

EF

EXT1IN

AV1/AV2

CVBSEXT

MONO-IN

F301

F302

124

AUDIO_TUNER2

CVBS_TUNER2

FRONT_CVBS

5

4

5

T303

SDA

SCL

A2

R1OUT

R1IN

L1IN

FBEXT

CVBSOUT

EXT1IN

R2OUT

SC2_R

L2OUT

SC2_L

CVBS_TXT

EX2_IN

L2IN

R2IN

12TDVD3.1E AA 6.

A13

S501

55

44

33

22

11

A3

sound

A15

KS01

11

22

33

44

55

T202T201

Y_DVD

CHR_DVD

AV2_ AUD L

AV2_AUDR

CRT

AM_MONO

LDVD/SC2L

RDVD/SC2R

AV2_ AUD L

AV2_ AUD R

LINE OUT

A10

A10

A10

A10

A10

A10

A1

SDA

SCL

R1IN

L1IN

L2IN

R2IN

SC

A5

A1

A3

A3

ICATH

RED

GREEN

BLEU

R208

R207

RDVD_GAIN

LDVD_GAIN

DVD/SC2-SEL

A2

FRONT_CVBS

CVBS_TUNER2

S_SEL_1,2,3

A2

47

44

42

41

39

40

37

38

22

21

SC2_R

SC2_L

EXT2_IN

EXT1_IN

EXT2_IN

I202

MSP3411G

ANA_IN1+

MONO_IN

8

I2C_DA

7

I2C_CL

SC1_IN_R

SC1_IN_L

SC2_IN_L

SC2_IN_R

SC3_IN_L

SC3_IN_R

DACM_R

DACM_L

DOUT

LOUT

ROUT

CONTROL

9,10,11

SOUND

PROCESSOR

KC01

KC02

KC03

U001

74VHC4053M

1

Y1

2

Y0

13

X1

12

X0

5

Z0

3

Z1

A,B,C

U002

74VHC4053M

1

Y1

2

Y0

13

X1

12

X0

5

Z0

3

Z1

9

A,B,C

R519

R518

R517

DACM_L

DACM_R

SC1_OUT_R

SC1_OUT_L

SC2_OUT_R

SC3_OUT_L

SPDIF

AUDIO OUT L

AUDIO OUT R

14

X

15

Y

4

Z

Q007

14

X

15

Y

4

Z

BLU

GRN

RED

+175V

123

S502

TO S401

DEFLECTION

25

24

30

31

27

28

DVD_Y/SC2_V

EF

CVBS_COMM_IN

S506

CRT

HT1

HEATER

A4

TV S/L

TV S/R

A4

R1OUT

L1OUT

R2OUT

L2OUT

LDVD/SC2L

RDVD/SC2R

4

VOL

G1

G3

G2

1

EHT

S505

A8

S301

11

22

33

44

55

SIDE A/V

K907

K906

HEADPHONE

K905

1

2

3

4

SPEAKER

RIGHT

SPEAKER

LEFT

I201

TDA7057Q

AUDI O

R203

R202

A10

A10

A10

A10

AMPLIFIER

3

VIN1

8

5

VIN2

1

7

OUT2+

OUT2-

OUT1-

OUT1+

10

11

13

Control

A2

A3

A3

A5

MCU & EEPROM

A11

KEYBOARD +LED

1002

IR

1008

+5V

LED

4x Switch

Keyboard

A14

EJECT

1010

EJECT

1008

+5V

RES

A10

A6

A5

A6

0214

0220

AV_STATUS

DVD/SC2-SEL

CVBS_TXT

VDATAOUT

VDATAOUT

S001

33

44

55

66

S003

44

11

VSTB

VCLK

SDA

SCL

T002

T005

Q030

IR_TV

KEYB

R179

DVD

Opt.

+5V

8

7

39

5

4

6

1

54

56

48

19

20

I001

ST92195

P02

P03

AVCC

P05

P06

P04

P20

P23

P21

P46

SDA

SCL

MICRO

CONTROLLER

P24

P45

P40

P41

P34

P35

P36

VSYNC

HSYNC

BLUE

GREEN

RED

P01

P00

P37

15

16

17

9

CHR-SW

BRST_ON/0FF

DVD_ STB

VOL

STDBY

AV1/ AV2

L/LA

V_OSD

H_OSD

B_OSD

G_OSD

R_OSD

FB_OSD

S_SEL_1

S_SEL_2

S_SEL_4

S104

A6

A9

A9

1

A9

A3

A9

A10

A5

A4

A4

A5

A6

53

47

42

43

14

13

12

41

40

18

FB

10

11

F_15160_057.eps

290905

1301

STV2246C

PIFIN1

PIFIN2

NC/SIF1

NC/SIF2

AGCTU

SDA

SCL

BOSD

GOSD

ROSD

FBOSD

BEXT

GEXT

REXT

FBEXT

JP01

1

3

24

13

10

11

6

15

16

17

18

22

26

27

28

PROCESSOR

VIDEO

LFB/SSC

CVBSOUT

AUDOUT

CVBS3

CVBS2

NTBC/CVBSOUT1

CVBSOUT1

R_DVD

L_DVD

COAX

MUTE_DVD

Y.D V D

C_DVD

AUDIO_TUNER2

VDATAOUT

CVBS_COMM_IN

AV2_AUDL

AV2_AUDR

ICATH

ROUT

GOUT

BOUT

HOUT

VERT

VAMP

CHR

XTAL2

XTAL1

BCL

T315

VDATAIN

6

7

1

2

L/LA

A2

8

R334

R333

B_OSD

G_OSD

R_OSD

FB_OSD

A6

A6

A3

A3

A3

A3

B

G

R

A5

A6

A3

A6

A3

A6

A5

A6

A5

A5

A6

A3

A3

52

51

34

35

36

37

25

26

27

28

A6

DVD + I/O CONNECTIONS

33

32

31

30

46

49

48

47

42

13

55

22

23

20

29

44

39

40

X301

VSTB

VCLK

IR_DVD

D302

BCLG

T314

ICATH

RED

GREEN

BLEU

BCLG

HOSD

HOUT

VERT

V_AMP

AM_MONO

DVD_Y/SC2_V

CHR_DVD

CVBSEXT

CVBS_TXT

CVBSOUT

X302

COAX

L_DVD

R_DVD

I203

LM358N

2

6

T311

EF

T312

EF

CHR_SW

A5

S301

A5

A4

A4

SC

A6

A6

A10

A10,A2

A10

A10

A10

A10

A10

A6

A6

A6

A6

S303

1

7

A2

A2

Page 13

Block Diagrams and Test Point Overviews

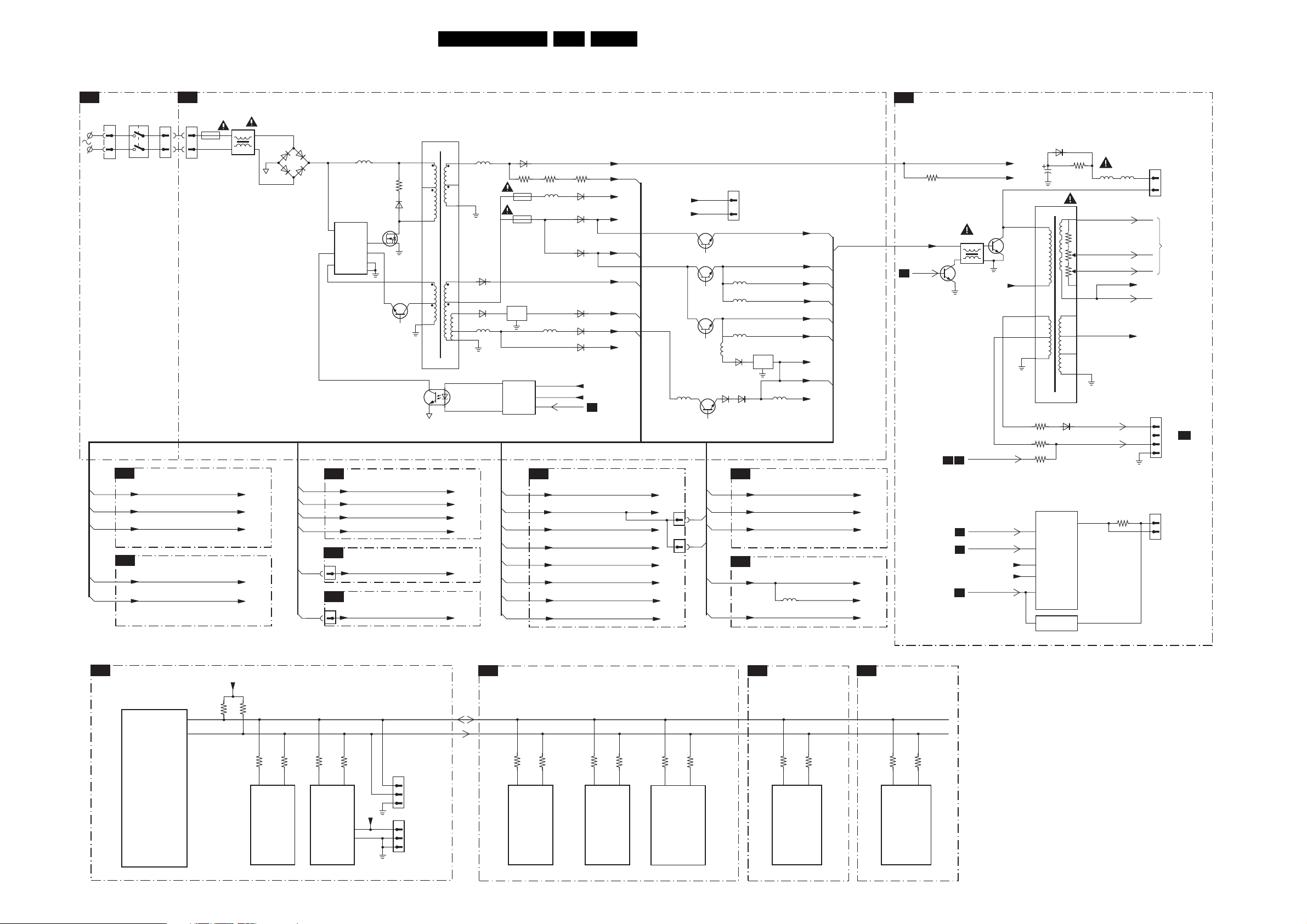

Block Diagram Supply, Deflection, and I2C

SUPPLY AND DEFLECTION + I²C

MAIN SWITCH

A11

0211

9002

0212

11

22

DVD + I/O CONNECTIONS

A6

A10

5V

+5V

8V

SCART

+5V

8V

A9

A9

A9

A9

A9

A9

S101

POWER

F101

T2.5A

L101

MAINS

FILTER

5V

+5V

8V

+5V

8V

D102

D103D104

+

-

D101

A9

A9

A9

A9

A2

A2

L111

R110

I101

ICE1QSO1

2

PCS

OUT

4

VCC

SRC

3

GND

RZI

OFC

TUNER

A1

5V

+5V

5VTM

33V

MAIN SWITCH KEYBOARD + LED

A11

0214

+5V

1

EJECT

A14

020

5V

2

D106

T101

7

8

6

5

T115

13TDVD3.1E AA 6.

DEFLECTION

A4

HORIZONTAL DEFLECTION

L110

A9

A9

A9

A9

A9

A9

A9

A9

D108

R115

R167

F3A

R132

F3A

1I02

LM317

IN OUT

ADJ

CONTROL

R135 R136

L114

L006

MCU & EEPROM

A2

5V

+5V

+5VA

+5VD

+5VS

6V5

12(3V3)V

+5VDVDRW

D128

D010

D010

D009

D112

D012

125V

6V5

STDBY

125V

33V

4V5

6V5M

6V5

+16V

8V

+12V

+12VA

A1

+5VDVDRW

A2

A4

A1,A2,A5,A6

A3

4V5

R148

Q001

T105

T108

T110

L117

D122

S104

2

DVD PLAYER

4

L106

L103

L117

D115

D123

To

I105

LF33CV

IN OUT

ADJ

L116

5V

+5V

5VD

5VA

+5VS

+5VDVDRW

+12VDVDRW

+12(3V3)V

+12VDVDRW

A1,A2,A3,A5,A6

A9

A1,A2,A6,A10

A2

A2

A2

A2

A2

R160

16V

T401

HOUT

A5

L401

125V

125VOUT

T402

125VOUT

A4

HOSD

VERTICAL DEFLECTION

V_AMP

V_OSD

VC

+24V_VERT

VERT

5V

+5V

+5VA

+5VD

+5VS

6V5

12(3V3)V

+5VDVDRW

S003

S001

A5

A2

SOUND

A3

A9

A9

2

A14

A9

1

A11

A9

A9

5V

8V

+12V

VIDEO PROCESSOR

A5

5V

8V

L304

5V

8V

+12V

5V

5VC

8V

A5

A2

A5

1

3

11

7

9

5

3

5VTM

2

12

10

4

14

8

16

6

14

I104

TCDT1101G

2

5V

+5V

33V

+5V

5V

L113

D110

D120

L115

C414

L404

HORZ

1

+B

2

5

9

6

R409

R409

R332

I401

TDA1771

4

HEIGHT

2

OSVS

6

RAMPGEN

9

VS

3

TRIGIN

CONTROL

D012

ABL

E/W

12V

D012

OUT

24V

R409

14

13

12

11

8

10

+24V_VERT

4

3

7

HEATER

1

L403

+175V

EHT

FOCUS

BCLG

G2

VC

R428

L402

S403

S401

S421

2

1

1

2

3

4

A

B

TO

HORIZONTOL

DEFLECTION

COIL

TO

CRT

TO S502

A13

CRT BOARD

TO

VERTICAL

DEFLECTION

COIL

I²C

A2

MCU & EEPROM

I001

ST92195

MICRO

CONTROLLER

SDA

SCL

B4D

+5V

R013

R012

19

20

R122

R121

56

U004

PCF8593

LOW POWER

CLOCK

CALENDAR

RES

R049

5

1CO2

24C16

EEPROM

R048

S004

JC01

3

2

1

1

2

3

COMPAIR

SERVICE

CONNECTOR

EXTERNAL

INFRARED

6

+5V

8

7

SDA

SCL

A1

TUNER

R614

54

UV1316

TUNER

X101

MAIN

R613

RT07

RT09

54

TT01

UV1316

TUNER

II

RES

RT08

RT10

11

10

1T01

TDA9886

IF-PLL

DEMODULATOR

RES

A3

SOUND

R208

87

I202

MSP3410G

SOUND

PROCESSOR

R207

VIDEO PROCESSOR

A5

R334

52 51

STV2246C/48C

PROCESSOR

I301

VIDEO

R333

F_15160_056.eps

290905

Page 14

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Main Panel: Tuner

14TDVD3.1E AA 7.

321

4

A1 A1

TUNER

X101

UV1316

D

C

NUT

GA

2

1

RT04

0R

5VM

RT03

0R

GND-PWR

R613

SCL

100R

C607

100P

GND-PWR

R614

SDA

100R

C608

100P

GND-PWR

C

R602

27K

GND-PWR

B

A

MAIN TUNER

3

1

FHU

FHV

FHV

V5

V5

3

4

5

6

6

GND-PWR

C601

47U25

GND-PWR

33V

GND-PWR

TFA

7

C606

100N

C603

100N

GND-PWR

CN8CN

9

GND-PWR

C627

10N

GND

2FI011FI

C602

100U16

0

GND-PWR

11

L602

1uH

5VM

J995 J257

GND-PWR

C605

8P2

L601

10uH

R601

4K7

R606

15K

D601

LL4148

FOR SECAM L

ELSE D601 JUMPER

IF1

IF2

C260

10N100V

IF1

IF2

AGC

K100

A

5V

AGC

RESERVED

GND-PWR

GND-PWR

D027

LL4148

CT17

47U50

C076

10N

1

R755

10K

GND-PWR

RT22

CHR0805-1R00

LT05

IND500-1U0H

TT01

UV1316

CG

NUT

A

2

GND-PWR

R701

10K

C079

47N

SCL

SDA

II - TUNER

0

GND

LT02

10uH

2FI011FI

11

GND-PWR

CT13

10P

LT04

IND500-1U0H

CT09

1N

MONO-IN

CT08

1N

2

1

GND-PWR

GND-PWR

FT02 K3953M

3

GND-PWR

GND-PWR

CT25

100N

SDA

SCL

RT17

22K

CT01

100N

100N

5V 5V

RT06

1K

RT40

22K

5

4

CT20

390P

RT23

5K6

GND-PWR

RT08

100R

RT10

100R

LT01

J207

10uH

CT02

IND500-10UH

GND-PWR

GND-PWR

RT12

6K8

RT13

6K8

DT02

BA582

DT03

BA582

RT15

0R

RT16

CT11

10N

0R

CT04

100N

GND-PWR

CT12

CT22

10N

470N

GND-PWRGND-PWRGND-PWR

CT10

1N

GND-PWR

CT29

CT28

22P

22P

GND-PWRGND-PWR

RT02

+5V

10K

MONO-IN

33V

J107

RT20

680K

TT02

BC847

FT01 K9453M

1

2

GND-PWR

IT01

1

IF1

2

IF2

3

OP1

4

FMPLL

5

DEEM

6

AFD

7

DGND

8

AUD

9

TOP

10

10

SDA

SDA

11

SCL

12

SIOMAD

TDA9886

RT11

RT39

100R

10K

GND-PWR GND-PWR

3

1

2

GND-PWR

RT21

220K

DT01

BA582

5

4

24

SIF2

23

SIF1

22

DELEAT

21

AFC

20

VP

CT21

19

VPLL

220N

18

AGND

GND-PWR

RT18

17

CVBS

100R

16

VAGC

XT01

15

REF

4MHZ HC49

14

TAGC

13

NC

3

TPW02B

FT03

RT26

12K

RT34

0R

GND-PWR

CT23

470N

GND-PWR

CT06

100N

CT15

10P

J071J070

RT35

0R

CT24

1N5

GND-PWR

RT05

22K

3FHV

1FHV

FHU

3

TFA

C

CN

V5

N

6

4

5V56

7

8

9

CT03

100N

GND-PWR

GND-PWR

CT07

100U50

RT07

100R

RT09

100R

CT27

CT26

47P

47P

GND-PWRGND-PWR

SCL

SDA

J027

RT33

0R

J067

GND-PWR

GND-PWR

RT01

100K

RT28

10K

RT29

10K

+5V

J073

LT03

10uH

GND-PWR

RT14

330R

RT25

12K

GND-PWRGND-PWRGND-PWR

+5V

Q030

BC547B

RT38

390R

GND-PWR

CT33

470N

CT05

100N

5V

GND-PWR

CT34

220N

AUDIO_TUNER2

AUDIO_TUNER2

II - TUNER AUDIO AMPLIFIER

RT32

10K

Q027

RT36

100R

RT30

1K

GND-PWR

FT04

TPW02B

GND-PWR

GND-PWR

J239

CT14

10P

RT24

620R

CT16

10U25

LT07

4.7uH

123

GND-PWR

GND-PWR

RT27

10R

CT30

100N

GND-PWR GND-PWR

BC848BLT1

RT37

220R

RT31

75R

J080

CVBS_TUNER2

CT31

100N

LT06

10uH

IND500-10UH

CT32

10U25

CVBS_TUNER2

D

C

+5V

B

A

1 2 3 4

F_15160_052.eps

250805

Page 15

Circuit Diagrams and PWB Layouts

15TDVD3.1E AA 7.

Main Panel: EEPROM

4321

VSTB

A2 A2

MCU & EEPROM

D

VCLK

VDATAOUT

VDATAIN

S002

1

2

3

4

5

6

DVD TV

VDATAIN

GND-PWR

IR_DVD

RW OPT.

R178

0R

J148

J100

J149

VSTB

VCLK

VDATAOUT

IR_DVD

J147

+5V

R011

C006

47U25

GND-PWR

C

B

C001

10U50

R001

220R

GND-PWR

DVD/SC2-SEL

AV_STATUS

L/LA

AV1/AV2

STDBY

B_OSD

G_OSD

R_OSD

SDA

SCL

D003

2.7V ZENER

R055

220R

R064

220R

DVD/SC2-SEL

AV_STATUS

L/LA

AV1/AV2

STDBY

B_OSD

G_OSD

R_OSD

SDA

SCL

J078 J087 J106

100R

GND-PWR

T003

BC858BLT1

R056

4K7

GND-PWR GND-PWR

J998

J112

R043

4K7

GND-PWR

R013

4K7

+5V+5V

R012

4K7

J134 J173

J019 J029J058

J009

J008

J007

C032

22P

GND-PWR

C033

4N7

5VA

D050

6V5

RTC

R120 1K

J241

D052

1N5226B 3.3 V ZENER

LL4148

R124

2K2

D051

LL4148

A

GND-PWR

C045

470U16

SUPERCAP 0.1F

RESERVED

1 2 3 4

J098

R015

4K7

DVD OPT.

R179

0R

R063 0R

R062 0R

C026

22P

C028

22P

C027

22P

C002

22P

R007

4K7

GND-PWR

R123

10K

32.768KHZ HC49S

C043

100N

+5V+5V+5V

R010

4K7

C003

10U50

Y002

GND-PWR

C123

GND-PWRGND-PWRGND-PWR

R035

4K7

S_SEL_1

S_SEL_2

S_SEL_3

FB_OSD

5VD

C008

100N

22P

1

2

3

4

+5VDVDRW

R033

4K7

GND-PWR

GND-PWR

U004

XTAL1

XTAL2

RST

VSS

PCF8593

R034

4K7

C004

100U16

C010

2N2

S_SEL_1

S_SEL_2

S_SEL_3

FB_OSD

GND-PWR

R022

5K6

VDD

INT

SCL

SDA

C005

100N

C009

22P

D006

LL4148

R009

220R

J092 J093

J094

J090

R016

1K

R017

1K

R018

1K

R019

470R

GND-PWR

8

7

R121 100R

6

R122 100R

5

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

10

10

10

11

11

11

12

12

12

13

13

13

14

14

14

15

15

15

16

16

16

17

17

17

18

18

18

19

19

19

20

20

20

21

21

21

22

22

22

23

23

23

24

24

24

25

25

25

26

26

26

27

27

27

28

28

28

GND-PWR

C034

56P

I001

P20

P20

P20

RESET

RESET

RESET

P07

P07

P07

P06

P06

P06

P05

P05

P05

P04

P04

P04

P03

P03

P03

P02

P02

P02

P01

P01

P01

P00

P00

P00

P37

P37

P37

P36

P36

P36

P35

P35

P35

P34

P34

P34

BLUE

BLUE

BLUE

GREEN

GREEN

GREEN

RED

RED

RED

FB

FB

FB

SDA

SDA

SDA

SCL

SCL

SCL

VCC

VCC

VCC

JTDO

JTDO

JTDO

WSCF

WSCF

WSCF

WSCR

WSCR

WSCR

AVDD3

AVDD3

AVDD3

TEST

TEST

TEST

MCFM

MCFM

MCFM

JTCK

JTCK

JTCK

ST92195

C042

100N

SCL

SDA

MCU

R061

0R

P21

P21

P21

P22

P22

P22

P23

P23

P23

P24

P24

P24

P25

P25

P25

OSCIN

OSCIN

OSCIN

OSCOUT

OSCOUT

OSCOUT

P47

P47

P47

P46

P46

P46

P45

P45

P45

P44

P44

P44

P43

P43

P43

P42

P42

P42

P41

P41

P41

P40

P40

P40

VSYNC

VSYNC

VSYNC

HSYNC

HSYNC

HSYNC

AVCC

AVCC

AVCC

PLLR

PLLR

PLLR

PLLF

PLLF

PLLF

VSS

VSS

VSS

AGND

AGND

AGND

CVBS1

CVBS1

CVBS1

CVBS2

CVBS2

CVBS2

JTMS

JTMS

JTMS

AVDD2

AVDD2

AVDD2

CVBS0

CVBS0

CVBS0

TXCF

TXCF

TXCF

+5VDVDRW

R008

4K7

56

56

56

55

55

55

54

54

54

53

53

53

52

52

52

51

51

51

50

50

50

49

49

49

48

48

48

47

47

47

46

46

46

45

45

45

44

44

44

43

43

43

42

42

42

41

41

41

40

40

40

39

39

39

38

38

38

37

37

37

36

36

36

35

35

35

34

34

34

33

33

33

32

32

32

31

31

31

30

30

30

29

29

29

R023

15K

GND-PWR

C029

GND-PWR

22P

J102 J103

X001

4MHZ

C022

22P

BRST_ON/OFF

R025

5K6

C030

22P

C013

2N2

GND-PWR

+5V

C014

470N

R057

10K

R002

2K2

R030

10K

DVD_STB

J626J627

T002

BC848BLT1

J127

+5V

J125

+5V

C023

22P

BRST_ON/OFF

J129 J130 J131

C020

100N

C019

4N7

GND-PWR

C016

470N

C015

100P

5VA

+5V

R065

10K

J066

GND-PWR

DVD_STB

GND-PWR

J116J117J118J121

IR01

34836

GND-PWR

CHR-SW

J126

GND-PWR

5VA

BC848BLT1

R047

4K7

T001

J122

R059

220R

R040

1K5

JS01

0R

+5V

C031

100P

D013

STDBY

J124

R054

4K7

CCV

CHR-SW

R072

10K

+5V

GND-PWR

GND-PWR

DNG

RI

GND-PWR

D004

LL4148

TXT-SW

D001

LL4148

R058

47K

SDA

SCL

GND-PWR

GND-PWR

IR_TV

KEYB

GND-PWR

+5V

+5V

R024

10K

GND-PWR

+5V

D005

LL4148

R080 10K

R081 10K

C041

R060

10U

4K7

R044

10K

C024

GND-PWR GND-PWR

R053

47K

GND-PWR

3

2

1

JC01

EXT INFRARED

+5V

J164

REC_LED&EJECT

T005

BC848BLT1

R032

4K7

DVD_SB

+5V

470P

SDA

SCL

J291

3

2

1

1

2

3

4

5

6

4

3

2

1

D002

LL4148

S004

COMPAIR

S001

IR&LED

S003

C080

10N

SC01

1

2

3

4

5

SERVICE

GND-PWR

J074J082 J175J176

J182J183 J184J185J186J274J275

J181

12(3V3)V

5VS

R052

10K

+5V

DVD_SB

C025

1U50

GND-PWR

+5V

R045

CD28

470N16V

10K

J011

R027

4K7

C040

470N

EEPROM

+5V

IC02 24C16

5

6

7

8

SDA

SCL

PTC

VDD

R049

100RR048

100R

KEYB

SCL

SDA

5VM

GND-PWR

R003

220R

R028

0R

J075

HOSD

CVBS_TXT

TXT-SW

C011

100N

J114J115

R051

470R

SW01 SW02

CH+ CH-

GND-PWR

R077

5K6

VOL

V_OSD

USS

A2

A1

A0

R004

820R

GND-PWR

VOL

4

3

2

1

GND-PWR

J119

R005

560R

R076

5V

J177

V_OSD

HOSD

CVBS_TXT

1K5

GND-PWR

R006

SW04

VOL+

SW03

F_15160_015.eps

D

1K5

D030

BAT85

VOL-

GND-PWR

J300J301

C

B

A

040705

Page 16

Main Panel: Sound

Circuit Diagrams and PWB Layouts

16TDVD3.1E AA 7.

4321

A3 A3

D

C

SOUND

AV2_AUDR

AV2_AUDL

SCL

SDA

SCL

SDA

AV2_AUDR

AV2_AUDL

J085 J105 J108

5V

J160 J136

TV_S/R

TV_S/L

GND-PWR

R209

47K

J135

C216

470N

5V

R207

R208

C208

10U50

C075

22U50

GND-PWR

100R

100R

C215

470N

C218

1N

GND-PWR

GND-PWR

GND-PWR

C077

22U50

GND-PWR

C207

100N

C209

100N

GND-PWR

C210

100N

GND-PWR

C217

1N

SOUND PROCESSOR

I202 MSP 3411G

1

1

1

NC

NC

NC

2

2

2

AUD_OL_OUT

AUD_OL_OUT

AUD_OL_OUT

3

3

3

D_CTH_OUT_1

D_CTH_OUT_1

D_CTH_OUT_1

4

4

4

D_CTR_OUT_0

D_CTR_OUT_0

D_CTR_OUT_0

5

5

5

ADR_SEL

ADR_SEL

ADR_SEL

6

6

6

STANDBYQ

STANDBYQ

STANDBYQ

7

7

7

I2C_CL

I2C_CL

I2C_CL

8

8

8

I2C_DA

I2C_DA

I2C_DA

9

9

9

I2S_CL

I2S_CL

I2S_CL

10

10

10

I2S_WS

I2S_WS

I2S_WS

11

11

11

I2S_DA_OUT

I2S_DA_OUT

I2S_DA_OUT

12

12

12

I2S_DA_IN1

I2S_DA_IN1

I2S_DA_IN1

13

13

13

ADR_DA

ADR_DA

ADR_DA

14

14

14

ADR_WS

ADR_WS

ADR_WS

15

15

15

ADR_CL

ADR_CL

ADR_CL

16

16

16

DVSUP

DVSUP

DVSUP

17

17

17

DVSS

DVSS

DVSS

18

18

18

I2S_DA_IN2

I2S_DA_IN2

I2S_DA_IN2

19

19

19

NC

NC

NC

20

20

20

RESETQ

RESETQ

RESETQ

21

21

21

DACA_R

DACA_R

DACA_R

22

22

22

DACA_L

DACA_L

23

23

23

24

24

24

25

25

25

26

26

26

DACA_L

VREF2

VREF2

VREF2

DACM_R

DACM_R

DACM_R

DACM_L

DACM_L

DACM_L

DACM_SUB

DACM_SUB

DACM_SUB

J153J139

XTAL_OUT

XTAL_OUT

XTAL_OUT

XTAL_IN

XTAL_IN

XTAL_IN

TESTEN

TESTEN

TESTEN

ANA_IN2+

ANA_IN2+

ANA_IN2+

ANA_IN-

ANA_IN-

ANA_IN-

ANA_IN1+

ANA_IN1+

ANA_IN1+

AVSUP

AVSUP

AVSUP

AVSS

AVSS

AVSS

MONO_IN

MONO_IN

MONO_IN

VREFTOP

VREFTOP

VREFTOP

SC1_IN_R

SC1_IN_R

SC1_IN_R

SC1_IN_L

SC1_IN_L

SC1_IN_L

SC2_IN_R

SC2_IN_R

SC2_IN_R

SC2_IN_L

SC2_IN_L

SC2_IN_L

SC3_IN_R

SC3_IN_R

SC3_IN_R

SC3_IN_L

SC3_IN_L

SC3_IN_L

AGNDC

AGNDC

AGNDC

AHVSS

AHVSS

AHVSS

CAPL_M

CAPL_M

CAPL_M

AHVSUP

AHVSUP

AHVSUP

CAPL_A

CAPL_A

CAPL_A

SC1_OUT_L

SC1_OUT_L

SC1_OUT_L

SC1_OUT_R

SC1_OUT_R

SC1_OUT_R

VREF1

VREF1

VREF1

SC2_OUT_L

SC2_OUT_L

SC2_OUT_L

SC2_OUT_R

SC2_OUT_R

SC2_OUT_R

C245

GND-PWR

C236

3.3U50

C235

100N

C227

100N

C241

56P

C222

22U50

C220

22U50

2P2

C244

2P2

GND-PWR

GND-PWR

GND-PWR

GND-PWR

GND-PWR

GND-PWR

J111

C228

3.3U50

C226

10U50

C223

10U50

L2OUT

R2OUT

GND-PWR

C257

330N

C233

330N

C231

330N

C229

330N

F201

TPSRD 4.43

GND-PWR

L2OUT

R2OUT

R212

75R

R211

0R

C239

10U50

C234

330N

C232

330N

C230

330N

R210

0R

GND-PWR

C238

100N

C224

10U50

R224

100R

AM_MONO

R1IN

L1IN

R2IN

L2IN

RDVD/SC2R

LDVD/SC2L

C225

100N

L1OUT

R1OUT

5V

SC

J077J109 J110

GND-PWR

AM_MONO

R1IN

L1IN

R2IN

L2IN

RDVD/SC2R

LDVD/SC2L

8V

GND-PWR

L1OUT

R1OUT

SC

X201

52

52

52

18.432MHZ

51

51

51

50

50

50

GND-PWR

GND-PWR

GND-PWR

GND-PWR

J234

J233

C242

56P

C240

56P

C221

22U50

C219

22U50

49

49

49

48

48

48

47

47

47

46

46

46

45

45

45

44

44

44

43

43

43

42

42

42

41

41

41

40

40

40

39

39

39

38

38

38

37

37

37

36

36

36

35

35

35

34

34

34

33

33

33

32

32

32

31

31

31

30

30

30

29

29

29

28

28

28

27

27

27

D

C

AUDIO AMPLIFIER

R201

1R

I201

TDA7057Q

GND-PWR

D507

LL4148

1NC.V

1NIV

1CN2

3

C201

1000U25

C206

10U50

GND-PWR

C202

4.7U50

R204

R203

4K7

GND-PWR GND-PWR

L/S_VT

1K

C204

10N

GND-PWR

PUSV

DNGS

2NIV

4

5

6

GND-PWR GND-PWR GND-PWR

GND-PWR

C203

4.7U50

R205

1K

GND-PWR

B

+12VA

C258

R228

22k

T151

BC847B

100uf

A

6V5

R229

100k

1 2 3 4

J200 J201 J202 J203

R227

1K2

16V

VOL

T150

BC847B

VOL

J293 J294 J295

R226

2k

JUMPER

J083 J084

R225

D508

2k

1N4148

GND-PWRGND-PWR GND-PWR

2DNGP

+2TUO

2NC.V

7

8

9

R206

4K7

R202

4K7

C205

10N

R/S_VT

1DNGP

+1TUO

-1TUO

-2TUO

31

21

11

01

S202

5

4

3

2

1

GND-PWR

H.P.

F_15160_016.eps

B

A

040705

Page 17

Circuit Diagrams and PWB Layouts

Main Panel: Vertical Deflection

17TDVD3.1E AA 7.

4321

A4 A4

D

C

DEFLECTION

16V

HOUT

HOUT

C407

100N

GND-PWR GND-PWR

R401

4R7

C401

100U25

GND-PWR

D402

LL4148

C414

1U250

T401

BC639

R402

47K

D406

BYV36C

R413

5K6 3W

R403

100R

C402

10N

GND-PWRGND-PWRGND-PWRGND-PWR

!

C515

270N400V

!

1

2

3

602300033071

C405

100N

C413

1N2KV

L401

L403

150uH

125VOUT

R414

1K

5

0.22R 1/2W

4

125V

D401

BYV36C

R404

L402

56uH

R405

39R

GND-PWR

R160

10R 7W

2

1

GND-PWR

S403

HDY

!

T402

BU508DF

S401

CRT BRD

C403

OPT.

GND-PWR GND-PWR

C419

1U160V

GND-PWR

R407

470K

321

4

GND-PWR

RETAEH

ADNG

V571+

GND-PWR

GND-PWRGND-PWR

C404

6N8 2KV

C408

22U160

C409

10U250

D405

BYV36C

HORIZONTAL DEFLECTION

L404 604200000391

ABL

14

EHT

13

FOCUS

12

G2

11

8

10

4

3

76

GND-PWRGND-PWR

125VOUT

R406

JUMPER

R409

JMP

R332

560R

HORZ

+B

VID

H

GND

1

2

5

E/W

24V

9

12V

GND

!

J218

J292

R410

0.22R

D407

BYV36C

GND-PWR GND-PWR

GND-PWR

C462

100P500V

C411

100N

R421

GND-PWR

1M

R429

2K

R415

2K

C417

100N

GND-PWR GND-PWR

C412

1000U35

R425

750K

C418

100N

R422

1M

J205

R423

1M5

R424

1M5

VC

8V

R412

2K4

R411

7K5

R325

22K

J016

BCLG

BCLG

+24V_VERT

J051

J054

VERTICAL DEFLECTION

J060

HOSD

HOSD

I401 TDA1771

D

C

NEGPMAR

5

C444

TUO.FUB

DNG

6

7

R445

8K2

R446

3K3

R449

4R7

C443

22U50

NI.VNI

8SV9

R448

2K0

R450

0.82R

NEG.BF

01

D441

1N4007

C445

100U50

VC

+24V_VERT

B

VC

GND-PWR

A

F_15160_017.eps

250805

THGIEH

NIGIRT

SVSO

TUO

2

3

C442

4

47N

1

GND-PWR

R428

470R

R447

2K4

J240

2200U25

A

R452 3K3

R457

10K

GND-PWR

R456

180K

Q442

BC337-16

Q443

BC327-16

240J

J047J041

+24V_VERT

R440

220R

R441

2R2

GND-PWR

R444 120KR455 100R

C441

220N

B

VERT

S421

B

V_AMP

V_OSD

VERT

V_AMP

V_OSD

VERT

J043

J046

R454

R453

33K

4K7

T441

BC848BLT1

R458

R451

820R

0R

A

GND-PWRGND-PWR GND-PWR

1 2 3 4

Page 18

Main Panel: Video

Circuit Diagrams and PWB Layouts

18TDVD3.1E AA 7.

4321

A5 A5

D

C

B

VIDEO PROCESSOR

D311

ICATH

7.5V ZENER

AGC

SC

SC

T301

3

42

44MH39PF

1HM

GND-PWR

DVD_Y/SC2_V

DVD_Y/SC2_V

B

G

R

FBEXT

LL 4148

0R OPTIONAL

AGC

J061 J069

1

LC1

LC2

CVBSEXT

CHR_DVD

B

G

R

FBEXT

D310

IF1

IF2

R387

10K

R388

47K

GND-PWR

IF1

IF2

C348

10N

C350

R335

220P

100R

GND-PWR GND-PWR

CVBSEXT

8V

J235

J065

CHR_DVD

L302 8u2

123

C353

22N

1

2

J044

GND-PWR

R361

680R

5V

C343

100P

F303

TPW02B

R389

390K

BCLG

T314

BC848BLT1

F301

K3953

3

GND-PWR

L301

10uH

R307

1K5

BCLG

(PAL I--J1981m)

5

4

C344

4N7

J006

L303

8V

10uH

R308

1K5

J158

R303

120R

GND-PWR

GND-PWR

GND-PWR

GND-PWR

C306

330N

GND-PWR

J045

C307

100U16

C308

100N

GND-PWRGND-PWR

J247

C310

100U16

GND-PWR GND-PWR

C314

1U50

GND-PWR

C301

1U16

C302

10U50

C303

22N

C304

1U50

C349

100N

GND-PWR

C305

1N

C309

100N

C311

100N

C313

1U50

C315

1U50

C345

100N

C318

22N

C319

22N

C320

22N

C312

1U50

J015

R301

150R

J024

5

4

GND-PWR

LC1

LC2

J246

J226

GND-PWR

GND-PWR

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

10

10

10

11

11

11

12

12

12

13

13

13

14

14

14

15

15

15

16

16

16

17

17

17

18

18

18

19

19

19

20

20

20

21

21

21

22

22

22

23

23

23

24

24

24

25

25

25

26

26

26

27

27

27

28

28

28

3

I301

NC/SIF1

NC/SIF1

NC/SIF1

NC/SIF2

NC/SIF2

NC/SIF2

NC/AGCSIF

NC/AGCSIF

NC/AGCSIF

VREF

VREF

VREF

AGCIF

AGCIF

AGCIF

PIFIN1

PIFIN1

PIFIN1

PIFIN2

PIFIN2

PIFIN2

AGCTU

AGCTU

AGCTU

IFPLL

IFPLL

IFPLL

GNDIF

GNDIF

GNDIF

FMOUT

FMOUT

FMOUT

VCCIF

VCCIF

VCCIF

CVBSOUT

CVBSOUT

CVBSOUT

EXTAUD

EXTAUD

EXTAUD

LC1

LC1

LC1

LC2

LC2

LC2

VCC2

VCC2

VCC2

CVBS1

CVBS1

CVBS1

GND

GND

GND

CVBS2

CVBS2

CVBS2

BS

BS

BS

CVBS3

CVBS3

CVBS3

CHR

CHR

CHR

APR

APR

APR

BEXT

BEXT

BEXT

GEXT

GEXT

GEXT

REXT

REXT

REXT

FBEXT

FBEXT

FBEXT

F302

K9453

1

2

STV2246C/48E

T302

R344

68K

BC848BLT1

NTBC/CVBSOUT1

NTBC/CVBSOUT1

NTBC/CVBSOUT1

R341

10K

FMCAP

FMCAP

FMCAP

AUDOUT

AUDOUT

AUDOUT

GND

GND

GND

VCC

VCC

VCC

SDA

SDA

SDA

SCL

SCL

SCL

SLPF

SLPF

SLPF

LFB/SSC

LFB/SSC

LFB/SSC

HOUT

HOUT

HOUT

VERT

VERT

VERT

BCL

BCL

BCL

VCC1

VCC1

VCC1

CVBSOUT1

CVBSOUT1

CVBSOUT1

GND1

GND1

GND1

VAMP

VAMP

VAMP

CLPF

CLPF

CLPF

XTAL1

XTAL1

XTAL1

XTAL2

XTAL2

XTAL2

XTAL3

XTAL3

XTAL3

FBOSD

FBOSD

FBOSD

ROSD

ROSD

ROSD

GOSD

GOSD

GOSD

BOSD

BOSD

BOSD

ICATH

ICATH

ICATH

ROUT

ROUT

ROUT

GOUT

GOUT

GOUT

BOUT

BOUT

BOUT

R342

10K

GND-PWRGND-PWR

56

56

56

55

55

55

54

54

54

GND-PWR

53

53

53

52

52

52

51

51

51

50

50

50

49

49

49

48

48

48

47

47

47

46

46

46

45

45

45

44

44

44

43

43

43

42

42

42

41

41

41

40

40

40

39

39

39

38

38

38

37

37

37

36

36

36

35

35

35

34

34

34

33

33

33

32

32

32

31

31

31

30

30

30

29

29

29

D307

BA282

D308

BA282

T303

BC848BLT1

R346

22K

J022

J209

J195

R334

100R

R333

100R

J039 J040

GND-PWR

C356

0R

C323

100N

C321

100N

AM_MONO

J023

J026

VERT

R343

10K

GND-PWR

J079J091

SDA

SCL

VERT

X302

GND-PWR

3.579MHZ HC49

J018

C322

100N

R314

47K

8V

R345

2K2

L/LA

J168

AM_MONO

GND-PWR

SDA

SCL

C352

22P

C324

100N

R393

1.2K

C342

1N

L/LA

C336

1U50

R320

1K

IF1

X301

XTAL4.43MHZ

J017

C332

100U16

GND-PWR GND-PWR

GND-PWR

C328

100N

C327

GND-PWR

100U16

GND-PWR

GND-PWR

FB_OSD

J188

R_OSD

G_OSD

B_OSD

R315

1K

R317

150R

R391

1.2K

R322

5K6

R340

10K

R331

2K2

GND-PWR

FB_OSD

R_OSD

G_OSD

B_OSD

R316

150R

R318

150R

C333

100N

R329

8K2

L305

10uH

CVBSOUT

R324

10K

GND-PWR

CVBS_TXT

L304

10uH

D304

LL4148

8V

R330

2K2

C358

470P

GND-PWR

CVBS_TXT

R327

470R

CVBSOUT

V_AMP

C325

4N7

5VC

5V

GND-PWR

GND-PWR

C330

4N7

GND-PWR

D303

LL4148

GND-PWR

J048 J049

C335

4.7U50

GND-PWR

V_AMP

D305

R323

LL4148

27K

C326

1U50

ICATH

GND-PWR

RED

GREEN

BLUE

R328

15K

HOSD

C361

470P

R326

56K

8V

R337

330K

GND-PWR

5

4

3

2

1

HOUT

S301

RGB

GND-PWR

HOSD

D302

LL4148

R336

330K

C331

2.2U50

HOUT

5VC

BCLG

GND-PWR

R312

75R

A

75R

75R

D320

5V1 ZENER

D321

5V1 ZENER

D322

5V1 ZENER

D323

5V1 ZENER

C317

1U50

R310

R311

R309

330K

GND-PWR

D

C

B

A

1 2 3 4

F_15160_018.eps

250805

Page 19

Circuit Diagrams and PWB Layouts

Main Panel: DVD + I/O Conn.

19TDVD3.1E AA 7.

4321

A6 A6

DVD + I/O CONN.

S303

LINE_OUT

21345

S_SEL_1

S_SEL_2

S_SEL_3

DVD VIDEO BUFFER

L309

D

R036

L_DVD

L_DVD

R_DVD

R_DVD

J305

100R

R066

100R

R067

2K2

GND-PWR

GND-PWR

GND-PWR

C383

8.2P

C046

10P

C047

10P

T004

BC848BLT1