Page 1

Colour Television Chassis

TDVD1.1E

AA

CL 26532120_000.eps

061202

Contents Page

1. Technical Specifications, Connections

and Chassis Overview 2

2. Safety & Maintenance Instructions,

Warnings and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 14

5. Service Modes, Error Codes and Faultfinding 15

6. Block Diagram, I2C Bus Interconnection Diagram

and Supply Voltage Diagram

Block Diagram 17

2

I

C-Bus Interconnection Diagram 18

Supply Voltage Diagram 19

7. Electrical Diagrams and PWB’s Diagram CBA

Main Panel: Tuner (Diagram A1) 20 26-27

Main Panel: Video Processor (Diagram A2) 20 26-27

Main Panel: SCART (Diagram A3) 21 26-27

Main Panel: EEPROM (Diagram A4) 21 26-27

Main Panel: Power Supply (Diagram A5) 22 26-27

Main Panel: Horizontal (Diagram A6) 23 26-27

Main Panel: u-Controller (Diagram A7) 21 26-27

Main Panel: Audio Amplifier (Diagram A8) 24 26-27

Main Panel: Vertical (Diagram A9) 24 26-27

Main Panel: Out (Diagram A10)25 26-27

Main Panel: Keyboard Panel (Diagram A11)25 26-27

CRT Panel (Diagram B) 28 28

RC Panel (Diagram C) 29 29

Front AV Module (Diagram D) 29 29

Line Out Panel (Diagram E) 30 30

8. Alignments 31

9. Circuit Description 34

Abbreviation List (Not Applicable yet) 34

IC Data Sheets 34

10 Spare Parts List 42

©

Copyright 2002 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 0271 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12970

Page 2

EN 2 TDVD1.1E1.

Technical Specifications, Connection Facilities, and Chassis Overview

1. Technical Specifications, Connection Facilities, and Chassis Overview

1.1 Technical Specifications

1.1.1 Reception

Tuning System : PLL

Colour Systems : PAL

: SECAM

:NTSC

Sound System : Mono

A/V Connections : SCART

: FRONT AV

Channel Selections : Air

: Cable

IF Frequency : B/G, D/K, L: 38.9 MHz

: L': 33.4 MHz

: I: 39.5 MHz

Aerial Input : 75 Ohm

1.1.2 DVD module

Disc formats : CD (R/RW)

:CVD

: (S) VCD

:DVCD

:DVD (+R/+RW)

Rotational speed : 4x CD

:2x DVD

Data transfer rate : 2760 kB/s for DVD

: 688 kB/s for VCD

Avg. access time : 250 ms typical

Data buffer capacity : 512 Kbytes

1.1.3 Miscellaneous

Audio Output (RMS) : 2 x 2.5 W

Mains Voltage : 220 - 240 V (± 10 %)

Mains Frequency : 50 / 60 Hz (± 5 %)

Power Consumption : 50 W

Standby Power Consumption : 4 W

1.2 Connection/Control Facilities

1.2.1 TV Side Connections and Front Control

FRONT CONTROL

PHILIPS

- VOLUME + - PROGRAM +

SIDE I/O

VIDEO

AUDIO R

AUDIO L

CL 26532120_001.eps

IR

Receiver

081102

3.5

Cinch (Input)

1 - CVBS 1 Vpp / 75 Ω

2 - Audio - L 0.5 Vrms / 10 kΩ

3 - Audio - R 0.5 Vrms / 10 kΩ

1.2.2 TV Rear Connections

REAR CONNECTIONS

PCMA/RA/L

EURO-AV

CL 26532120_002.eps

251002

Figure 1-2 Rear connections

Cinch (Output)

1 - Audio - L 0.5 Vrms / 1 kΩ

2 - Audio - R 0.5 Vrms / 1 kΩ

3 - S/PDIF (PCM)

Euro AV

121

CL96532137_056.eps

202

171199

Figure 1-3 SCART connector

1 - Audio - R 0.5 Vrms / 1 kOhm

2 - Audio - R 0.5 Vrms / 10 kOhm

3 - Audio - L 0.5 Vrms / 1 kOhm

4 - Audio Ground

5 - Blue Ground

6 - Audio - L 0.5 Vrms / 10 kOhm

7 - Blue 0.7 Vpp / 75 Ohm

8 - CVBS-status 0 - 1.3 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3

9 - Green Ground

10-

11-Green 0.7 Vpp / 75 Ohm

12-

13-Red Ground

14-CVBS status Ground

15-Red 0.7 Vpp / 75 Ohm

16-RGB status 0 - 0.4 V: INT

1 - 3 V: EXT / 75 Ohm

17-CVBS Ground

18-RGB status Ground

19-CVBS-o ut 1 Vpp / 75 Ohm

20-CVBS-in 1 Vpp / 75 Ohm

21-Shielding Ground

Figure 1-1 Side connections and Front control

Page 3

Technical Specifications, Connection Facilities, and Chassis Overview

EN 3TDVD1.1E 1.

1.2.3 DVD Module Connections

DC Power Connector (CN401)

1 - Supply voltage + 12 V

2 - Ground

(analogue) A-GND

3 - Ground

(digital) D-GND

4 - Supply voltage + 5 V

A/V and DAIO Output (CN403)

1-ML n.c.

2-MC n.c.

3 - R/R (MD) Rear Right Audio

4 - AGND Audio Ground

5 - R/L (PCM2) Rear Left Audio

6 - CEN (PCM1) Centre Audio

7 - A-GND Audio Ground

8 - S/W (PCM0) Sub Woofer

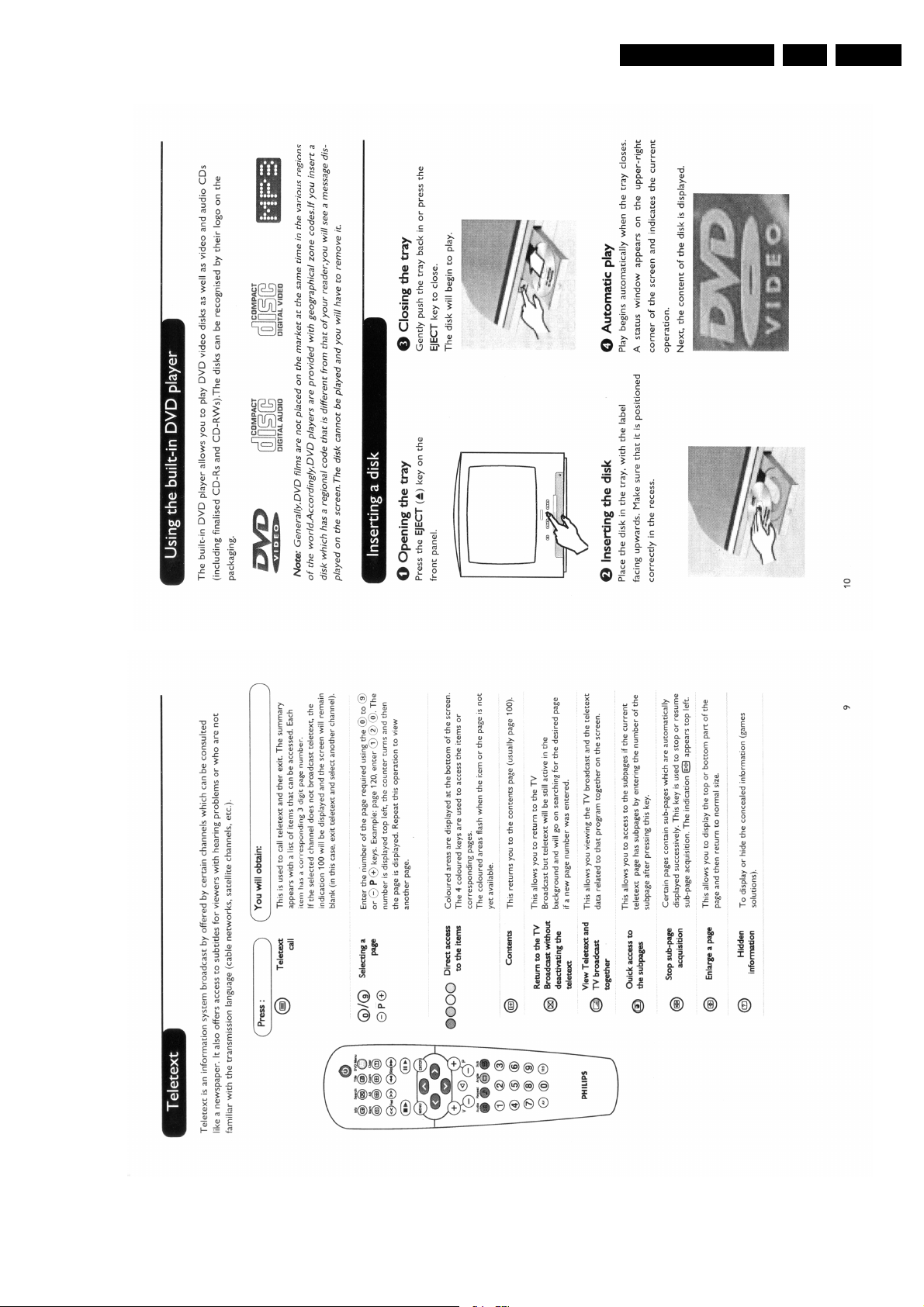

1.3 Chassis Overview

CRT PANEL

B

9 - F/R (SCK) Front Right Audio

10-A-GND Audio Ground

11-F/L (BCK) Front Left Audio

12-MUTE (LRCK) Mute for Audio

13-S/PDIF Digital Audio

14-D-GND Digital Ground

15-CVBS 1 Vpp / 75 Ohm

16-V-GND Video Ground

17-Y 1 Vpp / 75 Ohm

18-V-GND Video Ground

19-C 0.3 Vpp / 75 Ohm

20-V-GND Video Ground

21-G/Y 0.7 Vpp / 75 Ohm

22-B/Cb 0.7 Vpp / 75 Ohm

23-R/Cr 0.7 Vpp / 75 Ohm

24-V-GND Video Ground

25-VID_S/W Video switching

26-TV_S/W TV switching

DVD ENGINE

RC PANEL

C

FONT AV PANEL

D

LINE OUT PANEL

E

Figure 1-4 PWB location

MAIN

CHASSIS

PANEL

TUNER

VIDEO PROCESSOR

SCART

EEPROM

POWER SUPPLY

HORIZONTAL

µ-CONTROLLER

AUDIO AMPLIFIER

VERTICAL

AV INTERFACE CONN.

KEYBOARD

CL 26532120_003.eps

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

061202

Page 4

EN 4 TDVD1.1E2.

Safety and Maintenance Instructions, Warnings, and Notes

2. Safety and Maintenance Instructions, Warnings, and Notes

2.1 S af et y In st ruc tions

Safety regulations require that during a repair:

• Due to the chassis concept, a part of the circuitry is 'hot'.

Therefore, connect the set to the mains via an isolation

transformer.

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, you must return

the set in its original condition. Pay, in particular, attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current is flowing. In particular this is

valid for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the mains cord for external

damage.

• Check the strain relief of the mains cord for proper function,

to prevent the cord from touching the CRT, hot

components, or heat sinks.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets that have an isolated

power supply). Do this as follows:

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Turn on the main power switch (keep the mains cord

unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection of the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch the TV 'off' and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

,

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

2.3.1 General

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in Fig. 2-2, to

discharge the picture tube. Use a high voltage probe and a

multi-meter (position V

reading is 0 V (after approx. 30 s).

V

). Discharge until the meter

DC

2.1.1 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

CL96532156_040.eps

140501

Figure 2-2 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol w). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this

potential. Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and ground cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

Page 5

Safety and Maintenance Instructions, Warnings, and Notes

• Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. We do not recommend adjusting this unit during

repair.

• Be careful during measurements in the high voltage

section and on the picture tube.

• Never replace modules or other components while the unit

is 'on’.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYO NNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

EN 5TDVD1.1E 2.

Figure 2-3

2.4 Notes

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (), or hot ground (), depending

on the tested area of circuitry.

• The voltages and waveforms shown in the diagrams are

indicative. Measure them in the Service Default Mode (see

chapter 5) with a colour bar signal and stereo sound (L: 3

kHz, R: 1 kHz unless stated otherwise) and picture carrier

at 475.25 MHz (PAL) or 61.25 MHz (NTSC, channel 3).

• Where necessary, measure the waveforms and voltages

with () and without () aerial signal. Measure the

voltages in the power supply section both in normal

operation () and in standby (). These values are

indicated by means of the appropriate symbols.

• The picture tube panel has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

Page 6

EN 6 TDVD1.1E3.

3. Directions for Use

Directions for Use

Page 7

Directions for Use

EN 7TDVD1.1E 3.

Page 8

EN 8 TDVD1.1E3.

Directions for Use

Page 9

Directions for Use

EN 9TDVD1.1E 3.

Page 10

EN 10 TDVD1.1E3.

Directions for Use

Page 11

Directions for Use

EN 11TDVD1.1E 3.

Page 12

EN 12 TDVD1.1E3.

Directions for Use

Page 13

Directions for Use

EN 13TDVD1.1E 3.

Personal Notes:

Page 14

EN 14 TDVD1.1E4.

Mechanical instructions

4. Mechanical instructions

Index of this chapter:

1. Rear Cover Removal

2. Service Position Main Panel

3. DVD Module Removal

4. Side I/O Panel Removal

5. Rear I/O Panel Removal

6. Rear Cover Mounting

Note:

Figures can deviate slightly from the actual situation.

4.1 Rear Cover Removal

1. Remove all fixation screws (7x) of the rear cover.

2. Pull the rear cover a little backwards.

3. Disconnect the Rear I/O and Side I/O panel cables

4. Now pull the rear cover backwards to remove it.

4.2 Service Position Main Panel

1. Disconnect all cables of the DVD module.

2. Remove the main panel, by pushing the two centre clips

outward [1]. At the same time, pull the panel away from the

CRT [2].

3. Turn the panel 90 degrees clockwise [3].

4. Flip the panel 90 degrees [4], with the components towards

the CRT.

4.3 DVD Module Removal

Remove the complete DVD module after unscrewing the four

fixation screws [1].

CL 26532120_026.eps

Figure 4-2 Disassemble DVD module

311002

4.4 Side I/O Panel Removal

A

Remove the side I/O panel after unscrewing the screw from the

outside of the rear cover.

4.5 Rear I/O Panel Removal

1

1

Remove the rear I/O panel after unscrewing the two screws

from the inside of the rear cover.

4.6 Rear Cover Mounting

3

2

B

To reassemble the set, perform all described processes in

reverse order.

Be sure that, before the rear cover is mounted:

• The mains cord is mounted correctly in its guiding bracket.

• All wires/cables are returned in their original position.

4

CL 26532120_027.eps

311002

Figure 4-1 Service position Main panel

Page 15

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

EN 15TDVD1.1E 5.

Index of this chapter

1. Service Modes

2. Dealer Mode

3. Fault Finding

5.1 Service Modes

The Service Mode is a combination of the TV Service Mode

and the DVD Service Mode. You can enter the DVD Service

Mode via the TV Service Mode. The Service Mode offers

features, which the service technician can use to repair a set.

Any feature change, made via the Service Menu, will respond

at the same time (for example; if Hotel Mode is enabled, the

volume cannot be increased above max. volume displayed at

the Service Menu).

The Dealer Mode is a special DVD mode, to provide an auto

replay function for commercial purposes.

All displayed text strings in the Service Modes are in English.

5.1.1 TV Service Mode

Purpose

• To perform alignments (e.g. colour adjustment and

geometry alignments)

• To change option settings

• Hotel Mode operations

• DVD Service menu

5. G2ADJ. To align the G2 (see chapter 8.x for a detailed

description).

6. VIDEO. To adjust RGB, R_cut-off and G_cut-off.

7. TUNE/IF. To align the tuner.

8. DVD. To enter the DVD Service Mode.

9. HOTEL M. To switch the Hotel mode 'on/off'.

10. VOLUME. To adjust the volume when Hotel mode is 'off'.

How to navigate

• Select menu items with the CURSOR UP/DOWN keys.

• With the CURSOR LEFT/RIGHT keys, it is possible to

change the value of the last two menu items (Hotel mode

and Volume).

• With the CURSOR RIGHT and ENTER keys, activate the

selected menu item.

• When you press the MENU key in a sub menu, you will

return to the previous menu.

• When you press the MENU key in the Service Mode menu,

you will return to the Main menu.

How to exit

• With the STANDBY command, the set switches to

Standby.

• With the MENU key, the set returns to the Main menu.

• With the AV key, the service mode closes.

Switching the set 'off' and 'on' with the mains switch, brings the

set into normal operation again.

All changes in the Service Mode are stored immediately.

Specifications

All service unfriendly modes (if present) are disabled, like:

• Auto switch 'off' (when there is no 'ident' signal)

• Timer switch to a channel

• Automatic user menu time-out

• The NVM is unprotected

• AV functions are not working

How to enter the Service Mode

Screen menu's must be 'off', when you enter the Service Mode.

Use a standard customer RC-transmitter and key in the code

062596 directly followed by the MENU button.

The following screen is visible when you enter the Service

Mode:

LLLLLLLPAB#- XX

OPT I ONS

GEOME TRY

G2ADJ

VIDEO

TUNE/ I F

DVD

Ho t e l M OF F

V o l u m e ------ ------ ------ ------ ------ ------ ------ ---

CL 26532120_018.eps

311002

Figure 5-1 TV Service Mode menu

1. LLLLLLL. This is the used IC type.

2. PAB#-XX. This is the software identification.

– P = Philips.

– A = the region (W = West Europe, E = East Europe).

– B = sound specification (M = Mono, S = Stereo).

– # = number of TXT pages.

– XX = the software version number (the first X is the

main software version number and the second X is the

sub software version number).

3. OPTIONS. Three codes possible. (see chapter 8.x for a

detailed description).

4. GEOMETRY. To align the geometry (see chapter 8.x for a

detailed description).

5.1.2 Dealer Mode

Purpose

• To provide an auto replay function (commercial purpose).

• To ignore some features.

Pre-conditions to start the Dealer Mode are:

• Put the set in DVD Mode.

• Switch Teletext 'off' (if set is in TV Mode).

• Switch Childlock 'off'.

• No screen Menu's.

• A disc exists in the tray.

• Close disc tray.

• Switch the DVD in STOP condition.

Specifications

• The information line displays the current mode.

• The set starts to play the disc.

• The Disc Menu passes automatically.

• At the end of the disc, the set replays the disc from chapter

1 onwards.

In Dealer Mode, some restrictions and rules are defined:

• While the Dealer Mode is active, you cannot use the

STANDBY key (RC reception is blocked), so it is not

possible to go to standby. The only way to switch off the set

is to switch the Mains Power 'off'.

• When the mains Power is switched 'on', the set will go out

of standby (DVD Mode) automatically.

How to enter the Dealer Mode

Use a standard RC-transmitter and key in the code 9999

directly followed by the MENU button.

The set will now switch to Dealer Mode. The current mode is

written to the NVM.

The set switches to the DVD mode and informs the DVD about

the current mode.

Page 16

EN 16 TDVD1.1E5.

Service Modes, Error Codes, and Fault Finding

Dea l e r Mode ON

CL 26532120_019.eps

311002

Figure 5-2 Dealer Mode menu

How to exit

Use a standard RC-transmitter and key in the code 9999

directly followed by the MENU button.

The Play mode is stopped, the Dealer mode is deactivated, and

the TV menu returns.

Page 17

Wiring Diagram, Block Diagrams and Overviews

6. Wiring Diagram, Block Diagrams and Overviews

Block Diagram

BLOCK DIAGRAM

17TDVD1.1E 6.

A1 TUNER

IF1 A2-5

IF2 A2-4

SDA A4-1/A2-3

SCL A4-2/A2-2

AGC A2-1

SC_I A2-2

11

10

5

4

1

A3 SCART

2 3 4

AV_STATUS

A2-1

A11

KEYBOARD

KEYB A7-1

13

6 7 8

B A 2-8 CLI A7-1

11

17

12

21

10

G A2-7

A4 EEPROM

A7-1/A2-1/A1-1

A1-2/A2-2/A7-2

A5 POWER SUPPLY

AC IN

FBEXT A2-5

18

SDA

SCL

15

16

R A2- 6

CVBS A2-3

5

14

5

6

19

20

SCART1

IC02

24C08

9

SS01

2

3

A2 VIDEO PROCESSOR

L/L’ A7-8

IF1 A2-5/A1-5

IF1 A2-5/A1-5

IF2 A1-4

AGC A1-1

AV_STATUS A3-1

SC_IN A3-2

CVBS A3-3

CVBSEXT A3-4

B A3-8

G A3-7

R A3-6

FBEXT A3-5

IP01

TDA16846

14

11

STV2246/47/48

1

2

6

7

8

11

14

13

20

25

26

27

28

ICV1

WP02

AUDOUT A8-1

55

SDA A7-1/A4-1/A1-3

52

SCL A7-2/A1-2/A4-2

51

HEATER A6-1/A7-7

49

HOUT A6-2

48

VERT A9-1

47

BCL A6-3

46

CVBSOUT A7-6

44

V_AMP A9-2

42

FB_OSD A7-10

37

R_OSD A7-3

36

G_OSD A7-4

35

B_OSD A7-5

34

A7 µ-CONTROLLER A8 AUDIO AMPLIFIER

IA01

TDA7057

CLI A3-1

MUTE_DVD

A8-10/A8-1/A10-1

L/L’ A2-8

TV/DVD A8-2

B_ OSD A2-5

G_OSD A2-4

R_ OSD A2-3

FB_OSD

A2-10/A7-5

SDA

A2-1/A4-1/A1-1

SCL

A2-2/A4-2/A1-2

ST92195/92185

8

11

12

13

15

16

17

18

19

25

IC01

56

KEYBOARD A11-1

42

43

V_OSD A9-1

41

40

33

34

DVD SB

VOL A8-1

HEATER A2-7/A6-1

CVBSOUT

FB_OSD

A7-5/A2-10

A2-6

VOL A7-1

AUDIO OUT A2-1

MUTE_DVD

A8-10/A10-1/A7-1

L_DVD A10-2

A9 VERTICAL

18

ID41 TDA1771

2

34

3

1

12

1

2

VERT A2-1

V_OSD A7-1 V_AM P A2-2

.

110 V

A6 HORIZONTAL

A10 AV INTERFACE CONN.

16 V

5 VD

5 VA

HOUT A2-2

BCL A2-3

FBT

1

8

4

24 V

12 14 15 16 18

SS08

MN405

LM358

IA03

3B

I060

2

6

7

R_DVD

A10-3

12V

8 V

HEATER

9

3

12 V

CVBS_DVD DOUT _DVD A7-L_DVD R_DVD

MUTE

A8-5 A8-4 1/A8-1 A8-2 A8-3

CL 26532120_004.eps

251002

Page 18

Wiring Diagram, Block Diagrams and Overviews

I2C Bus Interconnection Diagram

I²C BUS INTERCONNECTION DIAGRAM

A1

A2

18TDVD1.1E 6.

A4

+5V

A7

TUNER

5

4

SDA

SCL

RT

RT

SDA

SCL

RV33

51

VIDEO

PROC.

52

RV34

SDA

SCL

R048

6 5

EEPROM

R049

SDA

SCL

R013

20 19

u-CONTROLLER

R012

SDA

SCL

CL 26532120_005.eps

251002

Page 19

Wiring Diagram, Block Diagrams and Overviews

Supply Voltage Diagram

SUPPLY VOLTAGE DIAGRAM

19TDVD1.1E 6.

A2

8V

A8

5V

LV01

LV03

DV23

DV22

DV21

DV20

IA03

MN4

053

SA02

1

2

STV2246/47/48

12

17

25

26

27

28

RA11

16

11

RS58

LV07

VIDEO

PROC.

+12V TO RA10

8V

5V

LV01

53

LV01

45

8V

8V

A6

110V

16V

A9

12

TV05

TV01

RV03

SS05

14

RV54

8V

A1

5V

5V

A4

5V

33V

LT01

RT03

RT01

9

7

3

1

TUNER

EEPROM

C011

A7

5V

5V

5VD

1 8

5VA

T003

R011

R010

R007

R032

R012

R013

2

3

12

13

14

19

20

21

25

26

ST92195/92185

56

54

46

45

41

40

39

34

33

31

55

43

D004

R052

D002

D001

R002

R008

R057

D005

R028 RA09

T001

R080

R081

5VA

5VA

5V

5V

5V

12VDVD

5VDVD

5V

5VA

5V

FBT

1

2

4

3

RD15 RD12

8

24V

12V

8V

A3

19

RV06

8V TO SS05/4

8V

24V

TDA1

771

9

8

7

4

1

RD45

RD44 RD56

RD28 RD40

12V

A10

SS08

DV10

5V

8V

RV57

CL 26532120_006.eps

251002

Page 20

Circuit Diagrams and PWB Layouts

20TDVD1.1E 7.

7. Circuit Diagrams and PWB Layouts

Main Panel: Tuner

A1

Main Panel: Video Processor

A2

D2

D1

CL 26532120_039.eps

021202

D1

D2

D3

D5

D4

D3

CL 26532120_042.eps

D4

021202

Page 21

Circuit Diagrams and PWB Layouts

21TDVD1.1E 7.

Main Panel: SCART

A3

Main Panel: u-Controller

A7

Main Panel: EEPROM

A4

CL 26532120_038.eps

021202

D2

D1

CL 26532120_029.eps

021202

CL 26532120_033.eps

021202

Page 22

Main Panel: Power Supply

A5

Circuit Diagrams and PWB Layouts

22TDVD1.1E 7.

D1

D1

CL 26532120_036.eps

021202

Page 23

Main Panel: Horizontal

A6

Circuit Diagrams and PWB Layouts

23TDVD1.1E 7.

D2

D1

CL 26532120_031.eps

021202

Page 24

Circuit Diagrams and PWB Layouts

24TDVD1.1E 7.

Main Panel: Audio Amplifier

A8

Main Panel: Vertical

A9

D1 D2

CL 26532120_028.eps

021202

D1 D2

CL 26532120_028.eps

281102

CL 26532120_041.eps

021202

Page 25

Circuit Diagrams and PWB Layouts

25TDVD1.1E 7.

Main Panel: Out

A10

CL 26532120_035.eps

021202

Personal Notes:

Main Panel: Keyboard Panel

A11

KEYBOARD PANEL

CL 26532120_034.eps

0212102

Page 26

Circuit Diagrams and PWB Layouts

Layout Main Panel (Top Side)

26TDVD1.1E 7.

CL 26532120_051.eps

281102

Page 27

Circuit Diagrams and PWB Layouts

Layout Main Panel (Bottom Side)

27TDVD1.1E 7.

CL 26532120_050.eps

281102

Page 28

Circuit Diagrams and PWB Layouts

28TDVD1.1E 7.

CRT Panel

B

Layout CRT Panel (Top Side)

CL 26532120_040.eps

021202

CL 26532120_046.eps

281102

Layout CRT Panel (Bottom Side)

CL 26532120_047.eps

281102

Page 29

Circuit Diagrams and PWB Layouts

29TDVD1.1E 7.

RC Panel

C

Front AV Module

D

Layout RC Panel (Top Side)

CL 26532120_045.eps

281102

CL 26532120_037.eps

021202

CL 26532120_030.eps

021202

Layout Front AV Module (Top Side)

CL 26532120_048.eps

281102

Page 30

Circuit Diagrams and PWB Layouts

30TDVD1.1E 7.

Line Out Module

E

Personal Notes:

Layout Line Out Module (Top Side)

CL 26532120_032.eps

021202

CL 26532120_049.eps

281102

Page 31

8. Alignments

Alignments

EN 31TDVD1.1E 8.

Index of this chapter

1. Hardware Alignments

2. Software Alignments/Settings

8.1 Hardware Alignments

8.1.1 System Voltage Adjustment

• Switch the TV in AV mode by pressing the AV button on the

remote control unit (minimum beam current condition).

• Adjust the VAP2 potentiometer until you measure 115 Vdc

on the cathode of diode DP08.

8.2 Software Alignments/Settings

Enter the TV Service Mode (see chapter 5). The Service Mode

menu will now appear on the screen.

LLLLLLLPAB#- XX

OPT IONS

GEOME TRY

G2ADJ

VIDEO

TUNE/ I F

DVD

Ho t e l M OFF

V o l u m e --- ------ ------ ------ ------ ------ ------ ------

Figure 8-1 Service mode menu

Select one of the following alignments:

1. OPTIONS.

2. GEOMETRY.

3. G2ADJ.

4. VIDEO.

5. TUNE/IF.

8.2.1 Options

Options are used to control the presence/absence of certain

features and hardware.

An Option byte represents a number of different options. All

options are controlled via three option bytes.

OPT IONS

O1 11111111

O2 01010000

O3 11100111

Figure 8-2 Option menu

How to change an Option byte

Select the option byte (01, 02 or 03) with the CURSOR UP/

DOWN keys.

Use a digit key (0 to 7) to change the relevant option bit. The bit

values will change from 0 to 1 and from 1 to 0 on each pressing

of the relevant digit key.

CL 26532120_018.eps

CL 26532120_020.eps

311002

311002

Option bit definition

Option byte 1 (01): System configuration

Default setting is: 10111111 (b7.....b0)

b0

1: France and Europe available

0: Only Europe available

b1 (*)

1: not used

0: not used

b2

1: not used

0: not used

b3

1: not used

0: not used

b4

0: not used

1: not used

b5

0: not used

1: not used

b6-7

00: Alps tuner

10: Philips UV1316 tuner

01: Thomson/Orega tuner

Option byte 2 (02): Video configuration

Default setting is: 11011011 (b7.....b0)

b0

1: RGB Peak Lim. available

0: not available

b1

1: QSS application

0: Intercarrier application

b2

1: Coring available

0: not available

b3

1: Black Strecth available

0: not available

b4

1: Blue Screen disable

0: Enable

b5

1: OSD Contrast Control enable

0: Disable

b6-b7

00: APR OFF (Auto Peak Regulation 'off')

01: APR 50 IRE (Auto Peak Regulation 50)

10: APR 75 IRE (Auto Peak Regulation 75)

11: APR 100 IRE (Auto Peak Regulation 100)

Option byte 3 (03): Feature configuration

Default setting is: 01101111 (b7.....b0)

b0

1: CVBS output 2.3 V

0: CVBS output 2.0 V

b1

1: not used

0: not used

b2

1: DVD available

0: not available

b3

1: AFC open

0: AFC closed

b4

1: One Crystal apllied (4.43 MHz)

Page 32

EN 32 TDVD1.1E8.

Alignments

0: Two crystals applied (for NTSC playback)

b5

1: AVL Auto Volume Level (Mono 22XX)

0: not available

b6

1: 2248E (microprocessor)

0: 2248C (microprocessor)

b7

1: Standby after power 'on'

0: No Standby after power 'on'

Note:

• Reserved bits (*) must be set to 0.

• The 7th bit of Option byte 03 enables the 'no video ident'

timer.

8.2.2 Geometry

The Geometry Alignments menu contains several items to

align the set, in order to obtain a correct picture geometry.

1V.S4/350h0

Figure 8-3 Geometry alignment menu

How to align

Enter the Service Mode and select the GEOMETRY settings.

Standard geometry adjustments are carried out by VSIZE,

VPOS and HPOS settings.

VSIZE 16/9 50h setting has to be carried out until 3 cm distance

between upper and lower parts of the screen.

Same adjustments are valid for 60H 16/9 and 4/3.

• V.S4/3 50h Vertical size property of picture at 50 Hz 4/3

aspect ratio broadcast (default value -17).

• V.S16/9 50h Vertical size property of picture at 50 Hz 16/

9 aspect ratio broadcast (default value 16).

• V.S4/3 60h Vertical size property of picture at 60 Hz 4/3

aspect ratio broadcast (default value -32).

• V.S16/9 60h Vertical size property of picture at 60 Hz 16/

9 aspect ratio broadcast (default value 0).

• V.P To adjust the vertical position of the picture (default

value 7).

• H.P To adjust the horizontal position of the picture (default

value 3).

8.2.3 G2 Adjust menu

In this menu we will see a comparative display according to the

preset. To adjust the G2, turn the G2 potentiometer on the LOT

until you reach the ':' sign. If the colon is highlighted,

adjustment is achieved ('<' means you have to decrease and '>'

means you have to increase).

G2ADJ

>:<

Figure 8-4 G2 adjustment menu

CL 26532120_021.eps

CL 26532120_022.eps

311002

311002

8.2.4 Video

1R 0

Figure 8-5 Video alignment menu

1. Apply a 'white' pattern (at 100 IRE)

2. Set CONTRAST to 70% and BRIGHTNESS and COLOUR

SATURATION in the middle.

3. Place the colour analyser.

4. Via R, G, and B, it is possible to modify the 'peak white'.

5. Adjust to obtain the necessary values for x and y.

– R (default value = 20)

– G (default value = 16)

– B (default value = 12)

1. Apply a 'dark gray' pattern (at 10 IRE).

2. Set CONTRAST to 70% and BRIGHTNESS and COLOUR

SATURATION in the middle.

3. Adjust to obtain the necessary values for x and y by

changing the RED CFF and GREEN CFF

– R CFF (default value = 3)

– G CFF (default value = -7)

Remark:After the low light alignment it may be necessary to

check and to re-align the high light, and to repeat several times

the procedure to obtain a good alignment for both low and high

light.

8.2.5 Tune IF

1AGC 50

>:<

Figure 8-6 Tuner alignment menu

AGC adjustment (default value = 49):

Select AGC, and adjust the settings until the ':' indicator

(displayed as >:< ) turns into red by pressing < and > on the

remote control.

PIF adjustment for BG/DK/L systems:

1. Apply a 38.9 MHz PAL BG signal.

2. Enter the Service Mode.

3. Select TUNE IF.

4. Choose the PIF COARSE and PIF FINE items, and adjust

the settings until the ':' indicator (displayed as >:< ) turns

into red by pressing < and > on the remote control.

– PIF C (default value = -2)

– PIF F (default value = -12)

PIF adjustment for L' system:

1. Apply a 33.9 MHz SECAM L' signal.

2. Enter the Service Mode.

3. Select TUNE IF.

CL 26532120_023.eps

CL 26532120_024.eps

311002

311002

Page 33

4. Choose the PIF COARSE L’ and PIF FINE L’ items, and

adjust the settings until the ':' indicator (displayed as >:< )

turns into red by pressing < and > on the remote control.

– PIFCL’ (default value = -0)

– PIF FL’ (default value = -0)

8.2.6 DVD

Tel r A DVD-TV Ver 0 .000

Reg iOn Code 2

Alignments

EN 33TDVD1.1E 8.

Figure 8-7 DVD settings menu

In this menu the following selections are possible:

• Region Code 2

• Region Code All

8.2.7 Hotel Mode

Installation and Child Lock Menus are omitted in Hotel Mode.

You cannot search any channel when the Hotel Mode is

activated.

8.2.8 Volume

In Hotel Mode the volume level cannot be increased higher

then the level adjusted in the Service Mode.

CL 26532120_025.eps

311002

Page 34

EN 34 TDVD1.1E9.

Circuit Descriptions and Abbreviation List

9. Circuit Descriptions and Abbreviation List

9.1 List of Abbreviations (not applicable yet)

9.2 IC Data Sheets

In this paragraph, the internal block diagrams and pinning are

given of ICs that are drawn as a “black box” in the electrical

diagrams (with the exception of “memory” and “logic” ICs).

9.2.1 STV2248 Multi Standard TV Processor

CL 26532120_011.eps

251002

Figure 9-1 STV2248 internal block diagram

Page 35

Circuit Descriptions and Abbreviation List

EN 35TDVD1.1E 9.

CL 26532120_009.eps

251002

Figure 9-2 STV2248 pin definitions (1)

Page 36

EN 36 TDVD1.1E9.

Circuit Descriptions and Abbreviation List

Figure 9-3 STV2248 pin definitions (2)

CL 26532120_010.eps

251002

Figure 9-4 STV2248 pinning

CL 26532120_008.eps

251002

Page 37

9.2.2 ST92195 C/D

Circuit Descriptions and Abbreviation List

EN 37TDVD1.1E 9.

NMI

INT[7:4]

INT2

INT0

OSCIN

OSCOUT

RESET

RESETO

SDO/SDI

SCK

MCFM

STOUT

VSO[2:1]

Up to 64

Kbytes ROM

256 bytes

RAM

Up to 8

Kbytes

TDSRAM

TRI

256 bytes

Register File

8/16-bit

CPU

MMU

Interrupt

Management

ST9+ CORE

RCCU

16-BIT

TIMER/

WATCHDOG

SPI

TIMING AND

CLOCK CTRL

STANDARD

TIMER

VOLTAGE

SYNTHESIS

MEMORY BUS

REGISTER BUS

I/O

PORT 0

I/O

PORT 2

I/O

PORT 3

I/O

PORT 4

I/O

PORT 5

DATA

SLICER

& ACQUI-

SITION

UNIT

SYNC.

EXTRAC-

TION

VPS/WSS

DATA

SLICER

ADC

SYNC

CONTROL

ON

SCREEN

DISPLAY

PWM

D/A CON-

VERTER

8

6

4

8

2

FREQ.

MULTIP

P0[7:0]

P2[5:0]

P3[7:4]

P4[7:0]

P5[1:0]

TXCF

CVBS1

WSCR

WSCF

CVBS2

AIN[4:1]

EXTRG

VSYNC

HSYNC/CSYNC

CSO

PXFM

.

R/G/B/FB

TSLU

HT

PWM[7:0]

All alternate functions

Figure 9-5 ST92195 C/D internal block diagram

(Italic characters)

are mapped on Ports 0, 2, 3, 4 and 5

CL 26532120_012.eps

251002

Page 38

EN 38 TDVD1.1E9.

Circuit Descriptions and Abbreviation List

INT7/P2.0

RESET

P0.7

P0.6

P0.5

P0.4

P0.3

AIN4/P0.2

P0.1

CSO/RESET0/P3.7

P0.0

P3.6

P3.5

P3.4

FB

SDI/SDO/P5.1

SCK/INT2/P5.0

V

JTDO

WSCF

V

/WSCR

PP

AVDD3

TEST0

MCFM

JTCK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

B

16

G

17

R

18

19

20

21

DD

22

23

24

25

26

27

28

P2.1/INT5/AIN1

56

P2.2/INT0/AIN2

55

P2.3/INT6/VS01

54

P2.4/NMI

53

P2.5/AIN3/INT4/VS02

52

OSCIN

51

OSCOUT

50

P4.7/PWM7/EXTRG/STOUT

49

P4.6/PWM6

48

P4.5/PWM5

47

P4.4/PWM4

46

P4.3/PWM3/TSLU/HT

45

P4.2/PWM2

44

P4.1/PWM1

43

P4.0/PWM0

42

VSYNC

41

HSYNC/CSYNC

40

AVDD1

39

PXFM

38

37

JTRSTO

36

GND

AGND

35

CVBS1

34

CVBS2

33

JTMS

32

AVDD2

31

CVBSO

30

29

TXCF

CL 26532120_013.eps

251002

Figure 9-6 ST92195 C/D pinning

Table 9-1 ST92195 C/D pin definitions

Pin No. Pin Name I/O Function

1 INT7/P2.0 IR INT. IN

3 P0.7 DVDDATAOUT

4P0.6 STOP

5P0.5 N.C.

6P0.4 N.C.

7P0.3 N.C.

8 AIN4 AV.STATUS

9P0.1 N.C.

10 P0.0 N.C.

11 CSO/RESET0/P3.7 MUTE_DVD

12 P3.6 L/L'

13 P3.5 TV/DVD

14 P3.4 STDBY

28 JTCK N.C.

30 CVBSO N.C.

32 JTMS N.C.

42 P4.0/PWMO DVD_STD_BY

43 P4.1/PWM1 VOL

44 P4.2/PWM2 N.C.

45 P4.3/PWM3 DVD POWER +5V

46 P4.4/PWM4 DVD POWER +12V

47 P4.5/PWM5 N.C.

48 P4.6/PWM6 N.C.

49 P4.7/PWM7/EXTRG/STOUT N.C.

53 P2.4/NMI N.C.

54 P2.3/INT6/VS01 LED CONTROL

55 P2.2/INT0/AIN2 DVDDATAIN

56 P2.1/INT5 /AIN1 KEYBOARD INPUT

Page 39

Circuit Descriptions and Abbreviation List

9.2.3 TDA1771 Vertical Deflection Circuit

EN 39TDVD1.1E 9.

TRIGGER IN

9

VOLTAGE

REGULATOR

2

FLYBACK

GENERATOR

R3

3

RAMP

GENERATOR

BUFFER

STAGE

CLOCK

PULSE

POWER

AMP.

THERMAL

PROTECTION

467 85

CL 26532120_015.eps

Figure 9-7 TDA 1771 internal block diagram

10

1

251002

10

9

8

7

6

5

4

3

2

1

FLYBACK GENERATOR

V

S

INVERTING INPUT

BUFFER OUTPUT

RAMP GENERATOR

GROUND

HEIGHT ADJUSTMENT

TRIGGER INPUT

OUTPUT STAGE V

POWER OUTPUT

CL 26532120_014.eps

Figure 9-8 TDA 1771 pinning

S

251002

Page 40

EN 40 TDVD1.1E9.

9.2.4 TDA 16846

SYN

OTC

RZI

SRC

OCI

7

5 V

1

3

4

5

3.5 V

R

7

30 k

R

8

75 k

Control Voltage

Limit

2 V

CS1

5 V

D3

Circuit Descriptions and Abbreviation List

R

D4

4

KSY

+

R

3

15 k

Off Time

Comparator

+

-

RSTC/RSTF

Error

Amplifier

Control Voltage

+

-

Buffer for

+

+

-

D2

PVC

Fold Back Point Correction

R

x 1/3

6

11

Primary

Voltage

G1

1.5 V

PVA

+

D5

-

+

1 V

3.5 V

R

6

Check

+

V

CC

1

+

-

1.2 V

9

REF

8

N.C.

6

FC2

ED2

G4

1

R

2

Error-

Flipflop

S

R

FC2

Q

R

PCS

1

20 k

5 V

2

On Time

Comparator

+

ED1

1.5 V

D1

Startup

Diode

< 25 mV

Overvoltage

Comparator

14

V

CC

12

GND

1)

The input with the lower voltage becomes operative

16 V

+

-

Figure 9-9 TDA 16846 internal block diagram

1

OTC

PCS

2

3

RZI

4

SRC

5

OCI

6

FC2

7

SYN N.C./PMO

AEP02647

VCC

14

OUT

13

GND

12

PVC

11

FC1

10

REF

9

8

CL 26532120_016.eps

251002

Figure 9-10 TDA 16846 pinning

I

1

15/8 V

&

G2

Zero Crossing

Signal

Supply

Voltage

Comparator

+

-

On Time

Flipflop

S

Q

R

G3

&

Output

Driver

13

OUT

FC1

1 V

+

10

FC1

AEB02648

CL 26532120_017.eps

251002

Table 9-2 TDA 16846 pin definitions

Pin Symbol Function

1 OTC Off Time Circuit

2 PCS Primary Current Simulation

3 RZI Regulation and Zero Crossing Input

4 SRC Soft-Start and Regulation Capacitor

5 OCI Opto Coupler Input

6 FC2 Fault Comparator 2

7 SYN Synchronization Input

8 N.C./PMO Not Connected (TDA16846)/

PMO (TDA16847)

9 REF Reference Voltage and Current

10 FC1 Fault Comparator 1

11 PVC Primary Voltage Check

12 GND Ground

13 OUT Output

14 VCC Supply Voltage

Page 41

9.2.5 TDA7057AQ

Circuit Descriptions and Abbreviation List

EN 41TDVD1.1E 9.

Figure 9-11

CL 26532120_052.eps

051202

Page 42

EN 42 TDVD1.1E10.

10. Spare Parts List

Spare Parts List

14PT6107

Various

0020 210 10300 Cable 4P 30cm

AC01 0750 302 61010 2P vert.

0020 272 32230 Cable 30cm

0023 443 50221 Cable 2P 35cm

0050 510 84620 Insulation plate 13X23

3990 000 02201 DVS combo loader DSL-760

1FRN 9965 000 15464 Side I/O panel

1LED 9965 000 15465 LED panel

1TUP 8411 400 10395 CRT panel

0673 100 01831 Fuse 2.5A 250V 5X20mm

FP01

FP01

0751 102 11040 Fuse holder 2.5A

FV02 4822 242 10254 Filter TPWA02B-TF21

HL01 0750 164 20211 Socket headphone

HS02 0751 004 11000 4P vert.

HS04 0750 305 11001 5P in-line vert. mini

KC01 0750 128 80021 Socket cinch rear BK

KC02 0750 128 80051 Socket cinch rear RD

KC03 0750 128 80061 Socket cinch rear WH

KD01 0751 002 01010 4P hor. male

KD02 0020 220 00030 4P (3P) 22cm mini

KD02 0750 304 11001 4P in-line vert. mini

KF01 0751 009 11001 9P in-line vert. mini

KF02 0750 164 44131 Socket cinch side YE.

KF03 0750 164 44121 Socket cinch side WH.

KF04 0750 164 44111 Socket cinch side RD

KL01 0020 920 00320 Cable 5P 25cm mini

KL02 0020 995 04450 Cable 4P 45cm

KP02 0751 002 11781 2P 7.5mm

KS01 0020 520 00401 Cable 5P 40cm mini

KS01 0750 305 11001 5P in-line vert. mini

POW1 0810 000 00141 Mains switch

S001 0020 720 00211 Cable 6P 20cm

SA01 0377 300 07991 Filter K2977M B/GD/K

SA02 0377 300 07771 Filter K9453M B/GD/KL/L'

SC01 0751 007 11041 5P straight flat

SD21 0750 302 11001 2P

SS01 0750 402 10051 Socket scart

SS03 0020 320 00040 Cable 4P 30cm

SS03 0750 304 11001 4P in-line vert. mini

SS05 0020 999 02311 Cable 9P 30cm mini

SS05 0751 009 11001 9P in-line vert. mini

SS07 0751 004 11000 4P vert.

SS08 0021 630 18230 Cable 12P FFC 30cm

SS08 0751 010 11061 12P FFC vert.

SS09 0750 305 11001 5P in-line vert. mini

SS11 0020 205 11130 Cable 2P 15cm mini

SS11 0750 302 11011 2P in-line vert. mini

SS12 0750 302 11011 2P in-line vert. mini

SS13 0020 720 00201 Cable 6P 40cm 2mm

SS13 0750 303 11061 6P in-line vert. 2mm

SV01 0020 720 00211 Cable 6P 20cm

SV01 0750 306 11061 6P in-line vert. mini

SW01 0811 011 11601 Tact switch

SW02 0811 011 11601 Tact switch

SW03 0811 011 11601 Tact switch

SW04 0811 011 11601 Tact switch

SW05 0811 011 11601 Tact switch

SY02 0750 304 11011 4P (3P) in-line vert. mini

SY03 0750 306 11061 6P in-line vert. mini

SY04 0750 208 00031 Picture tube socket

TU01 6168 000 20001 Tuner PLL CTT5020E/

X001 0490 300 00461 Crystal 4 MHz HC49U

XV01 0490 300 00501 Crystal 4.433619 MHz

XV02 0490 300 00511 Crystal 3.579545 MHz

C001 0424 465 01061 10µF 50V 20%

C002 0400 310 42261 22pF 50V 5% 0603

C003 0424 465 01061 10µF 50V 20%

C004 0421 401 61071 100µF 16V 20%

C005 5322 126 11578 1nF 10% 50V 0603

C008 0400 670 41081 100nF 50V 20%

C009 0400 310 42261 22pF 50V 5% 0603

C010 4822 126 14238 2.2nF 50V 0603

C011 0400 440 81861 470nF 16V 10% 0603

CTF5510

HC49U

HC49U

C013 4822 126 14238 2.2nF 50V 0603

C014 0400 670 41081 100nF 50V 20%

C015 4822 122 33753 150pF 5% 50V

C016 0400 440 81861 CER 470nF 16V 10% 0603

C019 4822 126 13193 4,7nF 10% 63V

C020 5322 126 11583 10nF 10% 50V 0603

C022 0400 310 42261 CER 22pF 50V 5% COG

C023 0400 310 42261 CER 22pF 50V 5% COG

C024 4822 126 14238 2.2nF 50V 0603

C025 0424 165 01051 1µF 50V 20%

C030 0400 310 42261 22pF 50V 5% 0603

C031 4822 126 13883 220pF 5% 50V

C040 0400 440 81861 470nF 16V 10% 0603

C041 0400 400 42261 22nF 50V 20% 0603

C061 4822 126 14238 2.2nF 50V 0603

C062 0424 465 01061 10µF 50V 20%

C063 0424 465 01061 10µF 50V 20%

C064 0424 465 01061 10µF 50V 20%

C065 4822 122 33753 150pF 5% 50V

C066 0424 465 01061 10µF 50V 20%

C067 4822 122 33753 150pF 5% 50V

C068 0424 465 01061 10µF 50V 20%

C069 4822 126 14238 2.2nF 50V 0603

C070 0424 465 01061 10µF 50V 20%

CA01 0424 465 01061 10µF 50V 20%

CA02 5322 126 11583 10nF 10% 50V 0603

CA03 5322 126 11579 3,3nF 10% 63V

CA05 0424 142 54761 47µF 25V 20%

CA06 4822 051 30008 Jumper 0603

CA07 4822 051 30008 Jumper 0603

CA08 0400 440 81861 470nF 16V 10% 0603

CA10 0424 492 52271 220µF 25V 20%

CA11 0424 142 54761 47µF 25V 20%

CA12 0421 945 04751 4.7µF 50V 20%

CA13 0421 945 04751 4.7µF 50V 20%

CA14 0400 670 41081 100nF 50V 20%

CA17 0400 670 41081 100nF 50V 20%

CD02 6200 040 71031 10nF 50V 10%

CD04 6193 237 76221 6.2nF 1.6kV 2.5%

CD07 0400 670 41081 100nF 50V 20%

CD08 0424 161 60001 22µF 160V 20%

CD09 0424 408 61061 10µF 250V 20%

CD11 0400 670 41081 100nF 50V 20%

CD12 0424 403 54771 470µF 35V 20%

CD13 0400 461 51021 1nF 1kV 10%

CD14 0424 148 61051 1µF 250V 20%

CD15 6200 130 54741 470nF 250V 5%

CD15 6210 030 03351 330nF 250VC 5%

CD16 6190 050 64741 470nF 63V 10%

CD17 6180 140 11041 100nF 63V 10%

CD18 0407 320 41081 100pF 50V 5%

CD25 0407 430 22261 220nF 50V 20-80% 0603

CD28 0400 440 81861 470nF 16V 10% 0603

CD41 6200 040 72241 220nF 63V 10%

CD42 6210 030 04731 47nF 50V 5%

CD43 0424 165 02261 22µF 50V 20%

CD44 0424 102 52281 2200µF 25V 20%

CD45 0424 146 31071 100µF 63V 20%

CD47 4822 051 30184 180K 5% 0,062W

CD62 0400 401 54711 470pF 1kV 10%

CF01 0400 320 41001 10pF 50V 5%

CF02 0400 320 41001 10pF 50V 5%

CF03 0400 400 41011 100pF 50V 10%

CF04 0400 400 41011 100pF 50V 10%

CF05 0400 400 41011 100pF 50V 10%

CF06 0400 400 41011 100pF 50V 10%

CL01 0424 142 54761 47µF 25V 20%

CP01 6200 040 62241 220nF 275V 20%

CP02 6200 040 62241 220nF 275V 20%

0400 401 52211 2.2nF 1kV 10%

CP03

0400 401 52211 2.2nF 1kV 10%

CP04

CP05 6200 041 33331 33nF 630V 5%

CP06 0427 199 01071 100µF 400V 20%

CP08 0400 401 56811 680pF 1kV 10%

CP09 0424 165 02261 22µF 50V 20%

CP10 5322 126 11583 10nF 10% 50V 0603

CP11 0400 430 45661 56pF 50V 5% 0603

CP12 0400 500 56861 680pF 50V 5% 0603

CP13 4822 126 14238 2.2nF 50V 0603

CP14 0400 402 02221 0.2nF 400V 20%

CP15 5322 126 11583 10nF 10% 50V 0603

CP16 0400 402 02221 0.2nF 400V 20%

CP18 0424 198 34761 47µF 160V 20%

CP21 0424 401 62281 2200µF 16V 20%

CP22 0400 670 41081 100nF 50V 20%

CP24 0424 142 51071 100µF 25V 20%

CP25 0400 670 41081 100nF 50V 20%

0603

0603

CP26 0424 165 02261 22µF 50V 20%

CP27 5322 126 11583 10nF 10% 50V 0603

CP29 0424 485 04761 47µF 50V 20%

CP30 0400 670 41081 100nF 50V 20%

CP31 0421 401 61071 100µF 16V 20%

CP32 0400 670 41081 100nF 50V 20%

CP33 0424 165 01051 1µF 50V 20%

CP34 2222 586 18812 100nF 10% 50V 0603

CP35 0400 670 41081 100nF 50V 20%

CP36 0400 401 54711 470pF 1KV 10%

CP37 6200 050 76831 68nF 275V 20%

CP38 0424 402 51081 1000µF 25V 20%

CP40 0421 401 64771 470µF 16V 20%

CP41 0400 670 41081 100nF 50V 20%

CP42 0400 670 41081 100nF 50V 20%

CP44 0421 401 61071 100µF 16V 20%

CP45 0424 165 02261 22µF 50V 20%

CP47 0424 121 61081 1000µF 16V 20%

CP48 2222 586 18812 100nF 10% 50V 0603

CP50 0400 401 41011 100pF 500V 10%

CS01 0400 400 41011 100pF 10% 50V

CS02 0400 400 41011 100pF 10% 50V

CS02 0400 402 53361 330pF 50V 10% 0603

CS03 0400 320 41001 10pF 50V 5%

CS03 0400 402 53361 330pF 50V 10% 0603

CS04 0400 400 41011 100pF 10% 50V

CS04 0400 402 53361 330pF 50V 10% 0603

CS05 0400 400 41011 100pF 10% 50V

CS05 0400 402 53361 330pF 50V 10% 0603

CS06 0400 320 41001 10pF 50V 5%

CS06 0400 402 53361 330pF 50V 10% 0603

CS07 0424 465 01061 10µF 50V 20%

CS51 4822 051 30008 Jumper 0603

CS53 4822 051 30008 Jumper 0603

CS54 0400 310 42261 22pF 50V 5% 0603

CT01 0424 142 54761 47µF 25V 20%

CT02 0424 465 01061 10µF 50V 20%

CT03 0400 670 41081 100nF 50V 20%

CT05 0400 320 48301 8.2pF 50V +-0.5pF

CT06 0400 130 81041 100nF 63V 10%

CT09 6200 130 81041 100nF 63V 5%

CV01 0424 165 01051 1µF 50V 20%

CV02 0424 465 01061 10µF 50V 20%

CV03 0400 400 42261 22nF 50V 20% 0603

CV04 0424 165 01051 1µF 50V 20%

CV05 5322 126 11578 1nF 10% 50V 0603

CV06 0400 520 43381 330nF 50V 20-80%

CV07 0424 142 54761 47µF 25V 20%

CV08 0400 670 41081 100nF 50V 20%

CV09 0424 165 02261 22µF 50V 20%

CV10 0421 401 61071 100µF 16V 20%

CV11 0400 670 41081 100nF 50V 20%

CV12 0424 165 01051 1µF 50V 20%

CV13 0424 165 01051 1µF 50V 20%

CV14 0424 165 01051 1µF 50V 20%

CV15 0424 165 01051 1µF 50V 20%

CV16 0400 310 42261 22pF 50V 5% 0603

CV17 0424 165 01051 1µF 50V 20%

CV18 0400 670 41081 100nF 50V 20%

CV19 0400 670 41081 100nF 50V 20%

CV20 0400 670 41081 100nF 50V 20%

CV21 0400 670 41081 100nF 50V 20%

CV22 0400 670 41081 100nF 50V 20%

CV23 0400 670 41081 100nF 50V 20%

CV24 0400 670 41081 100nF 50V 20%

CV25 4822 126 13193 4,7nF 10% 63V

CV26 6200 130 81041 100nF 63V 5%

CV27 0421 401 61071 100µF 16V 20%

CV28 0400 670 41081 100nF 50V 20%

CV30 4822 126 13193 4,7nF 10% 63V

CV31 0424 465 02251 2.2µF 50V 20%

CV32 0421 401 61071 100µF 16V 20%

CV33 0400 670 41081 100nF 50V 20%

CV34 0424 165 02261 22µF 50V 20%

CV35 0424 465 01061 10µF 50V 20%

CV36 0424 165 01051 1µF 50V 20%

CV39 2222 586 18812 100nF 10% 50V 0603

CV40 0400 670 41081 100nF 50V 20%

CV41 0400 670 41081 100nF 50V 20%

CV42 5322 126 11578 1nF 10% 50V 0603

CV44 4822 126 13193 4,7nF 10% 63V

CV48 0424 165 01051 1µF 50V 20%

CV49 0424 465 01061 10µF 50V 20%

CV50 0400 670 41081 100nF 50V 20%

CV51 0400 130 81041 100nF 63V 10%

CV52 4822 126 14507 18pF 5% 50V 0603

CV53 0400 670 41081 100nF 50V 20%

CV55 5322 126 11583 10nF 10% 50V 0603

CV56 0400 310 42261 22pF 50V 5% 0603

Page 43

Spare Parts List

EN 43TDVD1.1E 10.

CV57 0400 402 53361 330pF 50V 10% 0603

CV58 4822 126 13883 220pF 5% 50V

CV59 4822 126 13883 220pF 5% 50V

CV60 4822 126 13883 220pF 5% 50V

CV61 0400 420 41021 1nF 50V 10%

CY01 0400 401 71021 1nF 2kV 10%

CY03 6200 031 34731 47nF 630V 5%

CY04 4822 126 13883 220pF 5% 50V

CY05 4822 126 13883 220pF 5% 50V

CY06 4822 126 13883 220pF 5% 50V

PTC1 0347 103 03631 PTC 18Ω 30%

R001 4822 051 30221 220Ω 5% 0,062W

R002 4822 051 30222 2k2 5% 0,062W

R003 4822 051 30221 220Ω 5% 0,062W

R004 0300 106 82161 820Ω 5% 1/10W 0603

R005 4822 051 30561 560Ω 5% 0,062W

R006 4822 051 30152 1k5 5% 0,062W

R007 4822 117 13632 100k 1% 0603 0.62W

R009 4822 051 30221 220Ω 5% 0,062W

R010 4822 051 30472 4k7 5% 0,062W

R012 4822 051 30472 4k7 5% 0,062W

R013 4822 051 30472 4k7 5% 0,062W

R016 0300 106 12261 1.2k 5% 1/10W 0603

R017 0300 106 12261 1.2k 5% 1/10W 0603

R018 0300 106 12261 1.2k 5% 1/10W 0603

R019 4822 051 30471 470Ω 5% 0,062W

R022 4822 051 30562 5k6 5% 0,063W 0603

R023 4822 051 30153 15k 5% 0,062W

R025 4822 051 30562 5k6 5% 0,063W 0603

R026 4822 051 30472 4k7 5% 0,062W

R027 4822 051 30223 22k 5% 0,062W

R028 4822 051 30472 4k7 5% 0,062W

R030 4822 051 30472 4k7 5% 0,062W

R032 4822 051 30472 4k7 5% 0,062W

R040 4822 051 30152 1k5 5% 0,062W

R042 4822 051 30103 10k 5% 0,062W

R043 4822 051 30472 4k7 5% 0,062W

R044 4822 051 30472 4k7 5% 0,062W

0300 206 10331 10k 1/4W 5%

R045

R047 4822 051 30472 4k7 5% 0,062W

R048 4822 051 30101 100Ω 5% 0,062W

R049 4822 051 30101 100Ω 5% 0,062W

R050 4822 051 30562 5k6 5% 0,063W 0603

R051 4822 051 30471 470Ω 5% 0,062W

R052 4822 051 30103 10k 5% 0,062W

R053 4822 117 12925 47k 1% 0.063W 0603

R054 4822 051 30472 4k7 5% 0,062W

R055 4822 051 30221 220Ω 5% 0,062W

R056 4822 051 30472 4k7 5% 0,062W

R057 4822 051 30103 10k 5% 0,062W

R059 0300 106 15161 150Ω 5% 1/10W 0603

R060 4822 117 13632 100k 1% 0603 0.62W

R061 4822 117 13632 100k 1% 0603 0.62W

R062 4822 051 30222 2k2 5% 0,062W

R063 4822 051 30103 10k 5% 0,062W

R064 4822 051 30223 22k 5% 0,062W

R065 4822 051 30332 3k3 5% 0,062W

R066 4822 051 30103 10k 5% 0,062W

R067 4822 051 30103 10k 5% 0,062W

R068 4822 051 30103 10k 5% 0,062W

R069 4822 051 30223 22k 5% 0,062W

R070 4822 051 30332 3k3 5% 0,062W

R071 4822 051 30222 2k2 5% 0,062W

R080 4822 051 30103 10k 5% 0,062W

R081 4822 051 30103 10k 5% 0,062W

RA01 0300 106 83061 2k 5% 1/10W 0603

RA02 0300 106 83061 2k 5% 1/10W 0603

RA03 4822 051 30221 220Ω 5% 0,062W

RA04 4822 051 30221 220Ω 5% 0,062W

RA05 5322 117 13052 2k7 1% 0.063W 0603

RA07 5322 117 13052 2k7 1% 0.063W 0603

RA08 2322 702 81828 8Ω2 5% 0603

RA09 4822 051 30683 68k 5% 0,062W

RA10 0301 056 47811 0.47Ω 1W 5%

RA11 0300 106 47961 4.7Ω 5% 1/10W 0603

RA13 4822 051 30562 5k6 5% 0,063W 0603

RD01 0300 256 10011 10Ω 1/4W 5%

RD02 0300 206 10131 100Ω 1/4W 5%

RD04 4822 117 12925 47k 1% 0.063W 0603

RD05 0301 406 39021 39Ω 1/2W 5%

RD07 0301 086 15511 0.22Ω 1W 5%

RD08 0300 556 10011 10Ω 1/2W 5%

RD09 0301 056 47811 0.47Ω 1W 5%

RD10 0300 557 22811 0.22Ω 1/2W 5%

RD12 4822 051 30472 4k7 5% 0,062W

RD13 0300 106 56221 5.6k 1W 5%

RD14 0300 506 10211 1k 1/2W 5%

RD15 0300 506 10211 1k 1/2W 5%

RD28 0300 596 22111 220Ω 1/2W 5%

RD40 0300 206 47131 470Ω 1/4W 5%

RD41 0300 206 22911 2.2Ω 1/4W 5%

RD43 0300 106 75461 750k 5% 1/10W 0603

RD44 0300 106 39461 390k 5% 1/10W 0603

RD45 4822 117 12902 8k2 1% 0.063W 0603

RD46 0300 106 83061 2k 5% 1/10W 0603

RD47 0300 106 24261 2.4k 1/10W5% 0603

RD48 0300 106 83061 2k 5% 1/10W 0603

RD49 4822 051 30221 220Ω 5% 0,062W

RD50 0300 206 10911 1Ω 1/4W 5%

RD51 4822 051 30682 6k8 5% 0,062W

RD52 4822 051 30332 3k3 5% 0,062W

RD53 4822 051 30332 3k3 5% 0,062W

RD54 0300 106 39381 39k 1/8W 5% 0805

RD55 4822 051 30102 1k 5% 0,062W

RL01 0300 206 10131 100Ω 1/4W 5%

0320 405 55211 5.6Ω 5W 10%

RP01

RP02 4822 051 30333 33k 5% 0,062W

RP04 4822 051 30103 10k 5% 0,062W

RP05 0300 106 11221 1M 1/4W 2%

0300 106 39221 3.9M 1/4W 2%

RP06

RP07 4822 051 30479 47Ω 5% 0,062W

RP08 4822 051 30333 33k 5% 0,062W

0300 506 47511 4.7M 1/2W 5%

RP09

RP10 0305 086 33311 33k 5W 5%

RP11 0300 206 15011 15Ω 1/4W 5%

RP12 4822 051 30472 4k7 5% 0,062W

RP13 0300 106 11221 1M 1/4W 2%

RP14 4822 051 30124 120k 5% 0,062W

0300 206 10331 10k 1/4W 5%

RP15

RP17 4822 051 30331 330Ω 5% 0,062W

RP18 4822 117 12903 1k8 1% 0.063W 0603

RP19 4822 051 30103 10k 5% 0,062W

RP30 0300 106 47961 4.7Ω 5% 1/10W 0603

RP31 4822 051 30101 100Ω 5% 0,062W

RP32 0673 100 01851 Fuse 5A 32V 0603

RP35

0300 206 10331 10k 1/4W 5% SFTY

0300 206 10331 10k 1/4W 5% SFTY

RP36

RP40 4822 051 30223 22k 5% 0,062W

RP41 0300 206 10131 100Ω 1/4W 5%

RP42 0300 106 15161 150Ω 5% 1/10W 0603

RP43 4822 051 30152 1k5 5% 0,062W

RP44 4822 051 30102 1k 5% 0,062W

RP45 0300 106 12261 1.2k 5% 1/10W 0603

RP46 4822 051 30103 10k 5% 0,062W

RP47 4822 051 30102 1k 5% 0,062W

RP48 6080 000 11011 10µH 1.4A 10%

RP49 4822 051 30101 100Ω 5% 0,062W

RP50 4822 051 30103 10k 5% 0,062W

RP51 4822 051 30008 Jumper 0603

0300 506 47511 4.7M 1/2W 5%

RP52

RP54 4822 051 30273 27k 5% 0,062W

RP55 0300 206 10131 100Ω 1/4W 5%

RS01 4822 051 30123 12k 5% 0,062W

RS02 4822 051 30123 12k 5% 0,062W

RS03 4822 051 30221 220Ω 5% 0,062W

RS04 4822 051 30683 68k 5% 0,062W

RS05 4822 051 30153 15k 5% 0,062W

RS06 4822 051 30681 680Ω 5% 0,062W

RS07 4822 051 30759 75Ω 5% 0,062W

RS09 4822 117 13632 100k 1% 0603 0.62W

RS10 4822 117 13632 100k 1% 0603 0.62W

RS11 4822 051 30223 22k 5% 0,062W

RS12 4822 117 12925 47k 1% 0.063W 0603

RS13 4822 051 30101 100Ω 5% 0,062W

RS51 4822 051 30102 1k 5% 0,062W

RS53 4822 051 30102 1k 5% 0,062W

RS58 0300 206 33331 33k 1/4W 5%

RS59 4822 051 30103 10k 5% 0,062W

RT01 4822 051 30472 4k7 5% 0,062W

RT02 4822 051 30273 27k 5% 0,062W

RT06 4822 051 30153 15k 5% 0,062W

RT13 4822 051 30101 100Ω 5% 0,062W

RT14 4822 051 30101 100Ω 5% 0,062W

RV01 0300 106 15161 150Ω 5% 1/10W 0603

RV02 4822 117 13632 100k 1% 0603 0.62W

RV03 0300 106 22261 22Ω 5% 1/10W 0603

RV04 4822 051 30101 100Ω 5% 0,062W

RV05 4822 051 30102 1k 5% 0,062W

RV06 4822 051 30759 75Ω 5% 0,062W

RV07 4822 051 30102 1k 5% 0,062W

RV08 4822 051 30102 1k 5% 0,062W

RV09 4822 051 30334 330k 5% 0,062W

RV10 4822 051 30759 75Ω 5% 0,062W

RV11 4822 051 30759 75Ω 5% 0,062W

RV12 4822 051 30759 75Ω 5% 0,062W

RV13 4822 051 30759 75Ω 5% 0,062W

RV14 4822 117 12925 47k 1% 0.063W 0603

RV15 4822 051 30102 1k 5% 0,062W

RV16 4822 051 30271 270Ω 5% 0,062W

RV17 4822 051 30271 270Ω 5% 0,062W

RV18 4822 051 30271 270Ω 5% 0,062W

RV19 4822 051 30102 1k 5% 0,062W

RV20 4822 051 30102 1k 5% 0,062W

RV21 4822 051 30102 1k 5% 0,062W

RV22 4822 051 30562 5k6 5% 0,063W 0603

RV23 4822 051 30183 18k 5% 0,062W

RV24 4822 051 30103 10k 5% 0,062W

RV25 4822 051 30223 22k 5% 0,062W

RV26 4822 051 30563 56k 5% 0,062W

RV27 4822 051 30471 470Ω 5% 0,062W

RV28 4822 051 30153 15k 5% 0,062W

RV29 4822 117 12902 8k2 1% 0.063W 0603

RV30 4822 051 30222 2k2 5% 0,062W

RV31 4822 051 30222 2k2 5% 0,062W

RV32 0300 206 56131 560Ω 1/4W 5%

RV33 4822 051 30101 100Ω 5% 0,062W

RV34 4822 051 30101 100Ω 5% 0,062W

RV35 0300 106 15161 150Ω 5% 1/10W 0603

RV41 4822 051 30103 10k 5% 0,062W

RV42 4822 051 30103 10k 5% 0,062W

RV43 4822 051 30682 6k8 5% 0,062W

RV44 4822 051 30683 68k 5% 0,062W

RV45 4822 051 30222 2k2 5% 0,062W

RV46 4822 051 30223 22k 5% 0,062W

RV48 4822 051 30759 75Ω 5% 0,062W

RV49 4822 051 30759 75Ω 5% 0,062W

RV50 4822 051 30221 220Ω 5% 0,062W

RV53 0301 406 33061 33Ω 5% 1/10W 0603

RV54 4822 051 30479 47Ω 5% 0,062W

RV55 0300 106 15161 150Ω 5% 1/10W 0603

RV56 4822 051 30101 100Ω 5% 0,062W

RV57 4822 051 30103 10k 5% 0,062W

RV61 4822 051 30681 680Ω 5% 0,062W

RV62 4822 051 30479 47Ω 5% 0,062W

RV63 4822 051 30479 47Ω 5% 0,062W

RY01 0300 506 15211 1.5k 1/2W 5%

RY05 0300 106 82161 820Ω 1/10W 5% 0603

RY06 4822 051 30471 470Ω 5% 0,062W

RY08 0301 406 33061 33Ω 1/10W 5% 0603

RY09 0302 086 27311 27k 2W 5%

RY11 4822 051 30471 470Ω 5% 0,062W

RY12 0301 406 33061 33Ω 1/10W 5% 0603

RY13 0300 106 82161 820Ω 1/10W 5% 0603

RY14 0302 086 27311 27k 2W 5%

RY17 4822 051 30471 470Ω 5% 0,062W

RY18 0301 406 33061 33Ω 1/10W 5% 0603

RY19 0300 106 82161 820Ω 1/10W 5% 0603

RY20 0300 506 15211 1.5k 1/2W 5%

RY21 0302 086 27311 27k 2W 5%

VAP1 6113 800 12021 Potmeter 2K 0.1W 30%

FBT1 6042 000 00371 LOT AC40SFT

LD02 6083 800 00101 Coil choke 110µH 15% 0.5A

LD03 6089 800 04051 Coil linearity 50µH

LF01 6089 800 00111 1µH 5% 0.27A

LF02 6080 000 00221 10µH 5% 0.41A

LF03 6080 000 00221 10µH 5% 0.41A

6089 800 03151 Line ter. 2*27mH 1.5A

LFP1

LH01 6089 800 00111 1µH 5% 0.27A

LH02 6080 000 00021 10µH 5% 0.16A

LH03 6080 000 00021 10µH 5% 0.16A

LP01 6080 000 00221 10µH 5% 0.41A

LP02 0320 405 55211 5.6Ω 5W 10%

LP03 6080 000 00221 10µH 5% 0.41A

LP04 6087 800 02411 Ferrite bead 3.5*9*0.8

LP05 6080 000 00261 6µH 1.5A 5%

LS01 6089 800 00101 12µH 5% 0.15A

LS02 6089 800 00101 12µH 5% 0.15A

LS03 6089 800 00101 12µH 5% 0.15A

LS09 6087 800 02411 Ferrite bead 3.5*9*0.8

LT01 6080 000 00221 10µH 5% 0.41A

LT02 6089 800 00111 1µH 5% 0.27A

LV01 6080 000 00221 10µH 5% 0.41A

LV02 6080 800 00191 8.2µH 5% 0.165A

LV03 6080 000 00221 10µH 5% 0.41A

LV04 6080 000 00221 10µH 5% 0.41A

LV05 6080 000 00221 10µH 5% 0.41A

LV06 6089 800 00101 12µH 5% 0.15A

LV07 6080 000 00221 10µH 5% 0.41A

LV09 6089 800 00111 1µH 5% 0.27A

6021 900 00321 Transf. SMPS

SMT1

TC01 6082 800 01981 Coil trim. 44MHz 39pF

WD01 6023 000 33071 Transf.hor.drive

D001 4822 130 30621 1N4148

D002 4822 130 30621 1N4148

D003 0481 000 00041 BZX55C-B2V7

D004 4822 130 30621 1N4148

D005 4822 130 30621 1N4148

D006 4822 130 30621 1N4148

D010 4822 130 30621 1N4148

D022 0483 214 23201 1N4007

Page 44

EN 44 TDVD1.1E10.

DD01 4822 130 42606 BYD33J

DD02 4822 130 30621 1N4148

DD05 4822 130 42606 BYD33J

DD06 4822 130 42606 BYD33J

DD07 4822 130 42606 BYD33J

DD41 0483 214 23201 1N4007

DL01 0487 738 09001 Led KLR114L red

DP01 4822 130 80858 1N5062

DP02 4822 130 80858 1N5062

DP03 4822 130 80858 1N5062

DP04 4822 130 80858 1N5062

DP06 0480 000 00021 Diode rect.600V 1.5A SOD-

DP07 4822 130 30621 1N4148

DP08 4822 130 41602 BYW95C

DP09 4822 130 30959 ZTK33B

DP10 4822 130 42606 BYD33J

DP11 0483 270 28221 Diode rect.schottky 5A 40V

DP12 0480 000 00021 Diode rect.600V 1.5A SOD-

DP13 4822 130 30621 1N4148

DP14 4822 130 34233 BZX79-B5V1

DP17 4822 130 30621 1N4148

DP18 0300 206 68111 680Ω 5% 1/4W

DP20 4822 130 42606 BYD33J

DP22 0483 214 23201 1N4007

DT01 4822 130 30621 1N4148

DV01 4822 130 30621 1N4148

DV02 4822 130 30621 1N4148

DV03 4822 130 30621 1N4148

DV04 4822 130 30621 1N4148

DV07 0483 221 07001 BA282

DV08 0483 221 07001 BA282

DV24 4822 130 34233 BZX79-B5V1

DY01 4822 130 30621 1N4148

DY02 4822 130 34382 BZX79-B8V2

DY03 4822 130 30842 BAV21

DY04 4822 130 30842 BAV21

DY05 4822 130 30842 BAV21

DY06 4822 130 30842 BAV21

57

57

Spare Parts List

I060 4822 209 70672 LM358N sel.

IA01 0450 000 00981 TDA7057AQ

IA03 0450 000 01121 74HC4053

IC01 0450 000 91171 ST92T195D7B1

IC02 0450 000 01041 PCF8598C-2 / ST24C08

ICV1 0450 000 02141 STV2248C

ID41 0450 000 01971 TDA1771

IL01 6093 300 01241 RPM7138

IP01 0451 900 00021 TDA16846

IP02 0452 381 03051 LM317

IP03 0452 381 03081 LM7805

T001 4822 130 40959 BC547B

T002 4822 130 40959 BC547B

T003 4822 130 44568 BC557B

T060 4822 130 40959 BC547B

T061 4822 130 40959 BC547B

TD01 4822 130 41053 BC639

TD02 0460 000 00141 Transistor.hor.out.

TD41 4822 130 40959 BC547B

TD42 4822 130 40855 BC337

TD43 0469 862 94161 2SA720 & BC327

TP01 0467 110 00001 SPP03N60S5

TP02 4822 130 40959 BC547B

TP05 4822 130 41053 BC639

TP07 4822 130 44568 BC557B

TP08 0460 015 37001 BD537

TP09 4822 130 40959 BC547B

TP10 5322 130 41888 BD140-16

TS01 4822 130 40959 BC547B

TS02 4822 130 44568 BC557B

TS03 4822 130 40959 BC547B

TS52 4822 130 40959 BC547B

TV01 4822 130 40959 BC547B

TV02 4822 130 44503 BC547C

TV03 4822 130 44503 BC547C

TV04 4822 130 40959 BC547B

TV05 4822 130 44568 BC557B

ZP01 4822 209 81397 TL431CLPST

Loading...

Loading...