Philips TDA9332H-N2, TDA9331H-N1, TDA9330H-N2, TDA9330H-N1 Datasheet

DATA SH EET

Preliminary specification

Supersedes data of 1998 Oct 22

File under Integrated Circuits, IC02

2000 May 08

INTEGRATED CIRCUITS

TDA933xH series

I

2

C-bus controlled TV display

processors

2000 May 08 2

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

FEATURES

Available in all ICs:

• Can be used in both single scan (50 or 60 Hz) and

double scan (100 or 120 Hz) applications

• YUV input and linear RGB input with fast blanking

• Separate OSD/text input with fast blanking or blending

• Black stretching of non-standard luminance signals

• Switchable matrix for the colour difference signals

• RGBcontrolcircuitwithContinuousCathodeCalibration

(CCC), plus white point and black level offset

adjustment

• Blue stretch circuit which offsets colours near white

towards blue

• Internal clock generation for the deflection processing,

which is synchronized by a 12 MHz ceramic resonator

oscillator

• Horizontal synchronization with two control loops and

alignment-free horizontal oscillator

• Slow start and slow stop of the horizontal drive pulses

• Low-power start-up option for the horizontal drive circuit

• Vertical count-down circuit

• Vertical driver optimized for DC-coupled vertical output

stages

• Vertical and horizontal geometry processing

• Horizontal and vertical zoom possibility and vertical

scroll function for application with 16 : 9 picture tubes

• Horizontal parallelogram and bow correction

• I2C-bus control of various functions

• Low dissipation.

GENERAL DESCRIPTION

The TDA933xH series are display processors for

‘High-end’ television receivers which contain the following

functions:

• RGB control processor with Y, U and V inputs, a linear

RGBinput for SCART orVGA signals with fastblanking,

a linear RGB input for OSD and text signals with a fast

blanking or blending option and an RGB output stage

withblack current stabilization, which isrealizedwith the

CCC (2-point black current measurement) system.

• Programmable deflection processor with internal clock

generation, which generates the drive signals for the

horizontal, East-West (E-W) and vertical deflection.

The circuithasvariousfeaturesthatareattractiveforthe

application of 16 : 9 picture tubes.

• Thecircuitcan be used in both singlescan(50 or 60 Hz)

and double scan (100 or 120 Hz) applications.

In addition to these functions, the TDA9331H and

TDA9332H have a multi-sync function for the horizontal

PLL, with a frequencyrange from 30 to 50 kHz(2fHmode)

or 15 to 25 kHz (1fHmode), so that the ICs can also be

used to display SVGA signals.

The supply voltage of the ICs is 8 V. They are each

contained in a 44-pin QFP package.

ORDERING INFORMATION

TYPE

NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TDA9330H QFP44 plastic quad flat package; 44 leads (lead length 1.3 mm);

body 10 × 10 × 1.75 mm

SOT307-2

TDA9331H

TDA9332H

2000 May 08 3

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

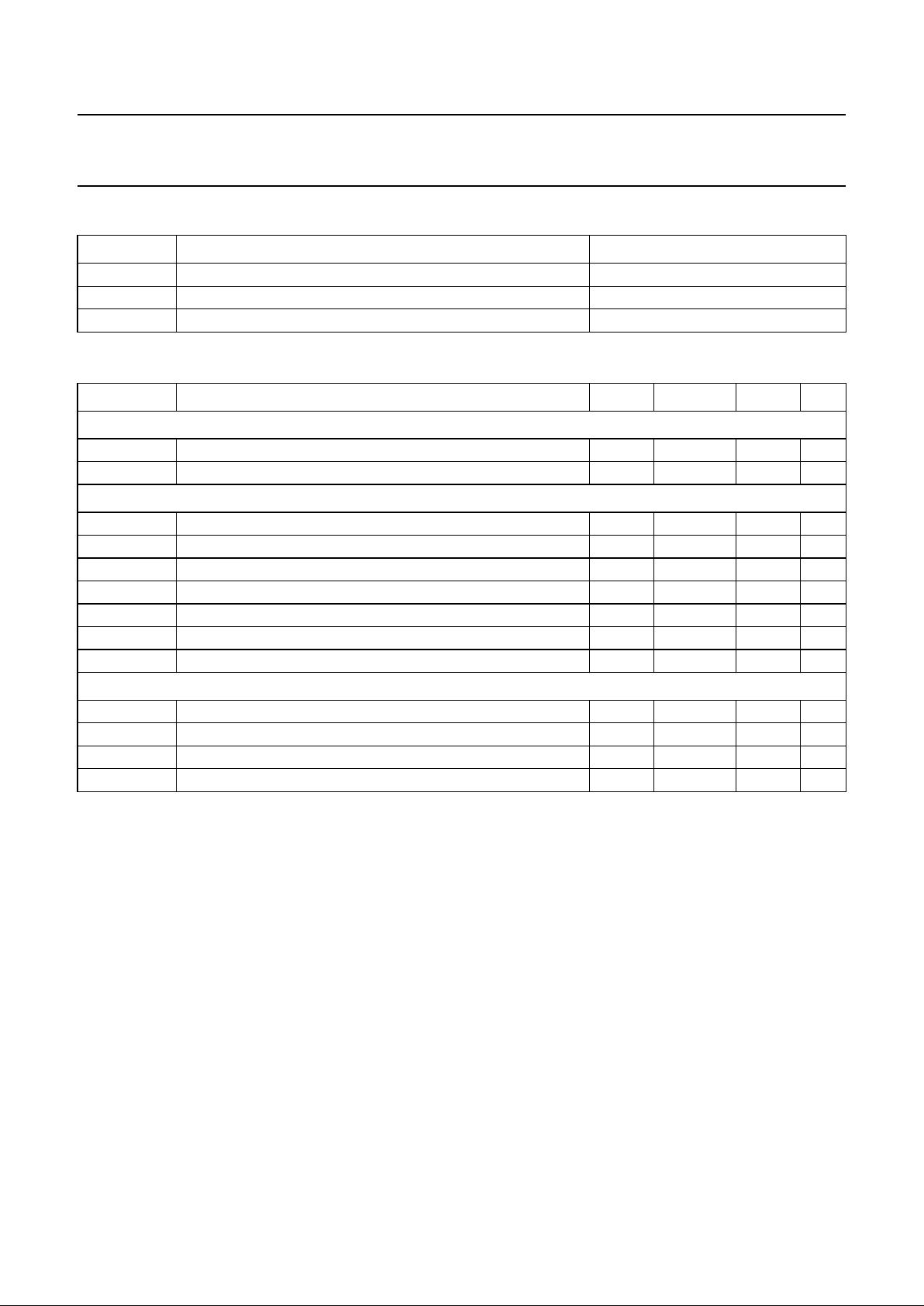

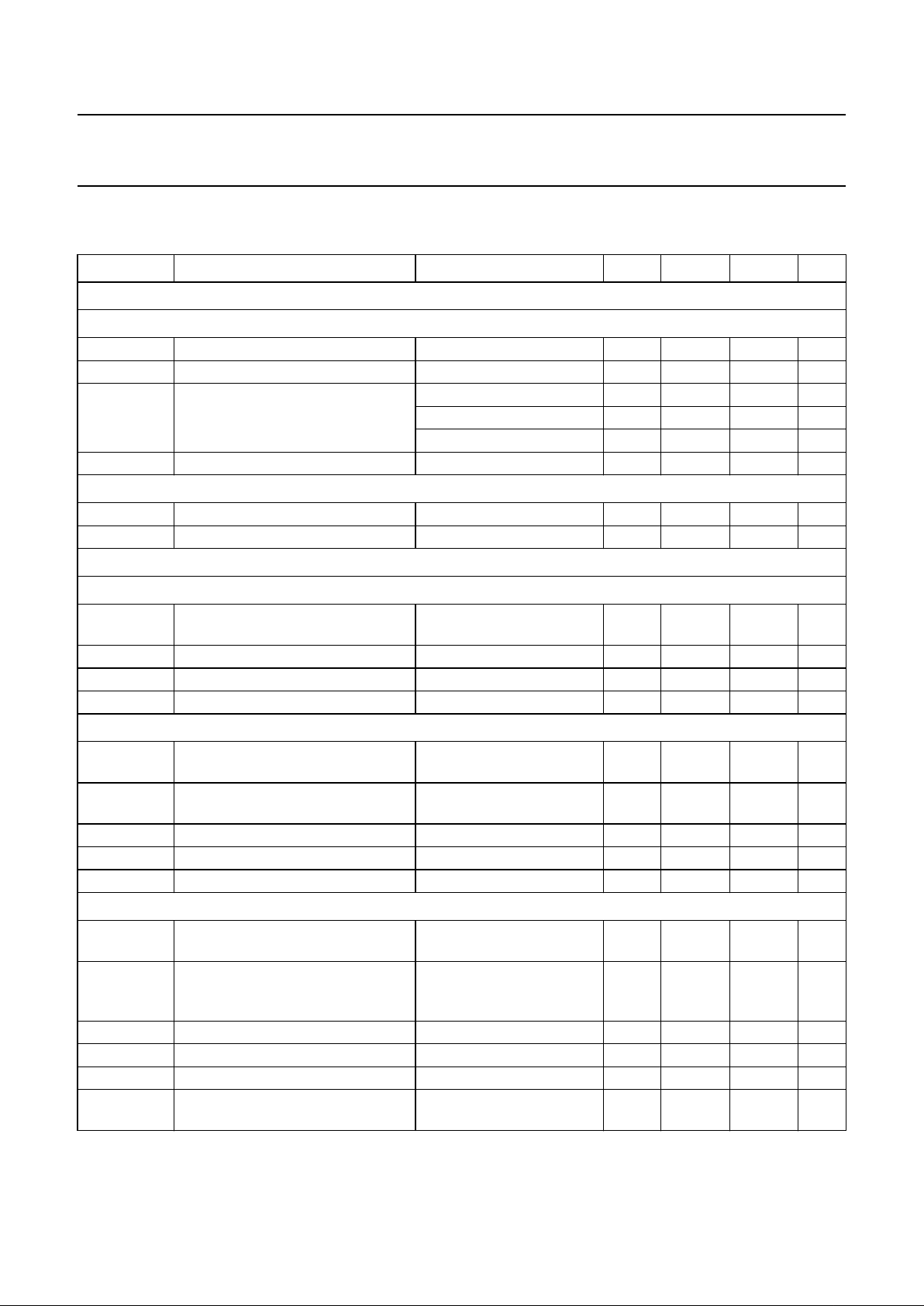

SURVEY OF IC TYPES

QUICK REFERENCE DATA

IC VERSION VGA MODE DAC OUTPUT

TDA9330H no I

2

C-bus controlled

TDA9331H yes proportional to VGA frequency

TDA9332H yes I

2

C-bus controlled

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Supply

V

P

supply voltage − 8.0 − V

I

P

supply current (VP1plus VP2) − 50 − mA

Input voltages

V

i(Y)(b-w)

luminance input signal (black-to-white value) − 1.0/0.315 − V

V

i(U)(p-p)

U input signal (peak-to-peak value) − 1.33 − V

V

i(V)(p-p)

V input signal (peak-to-peak value) − 1.05 − V

V

i(RGB)(b-w)

RGB input signal (black-to-white value) − 0.7 − V

V

i(Hsync)

horizontal sync input (HD) − TTL − V

V

i(Vsync)

vertical sync input (VD) − TTL − V

V

i(IIC)

I2C-bus inputs (SDA and SCL) − CMOS 5 V − V

Output signals

V

o(RGB)(b-w)

RGB output signal amplitude (black-to-whitevalue) − 2.0 − V

I

o(hor)

horizontal output current −− 10 mA

I

o(ver)(p-p)

vertical output current (peak-to-peak value) − 0.95 − mA

I

o(EW)

E-W drive output current −− 1.2 mA

2000 May 08 4

Philips Semiconductors Preliminary specification

I

2

C-bus controlled TV display processors

TDA933xH series

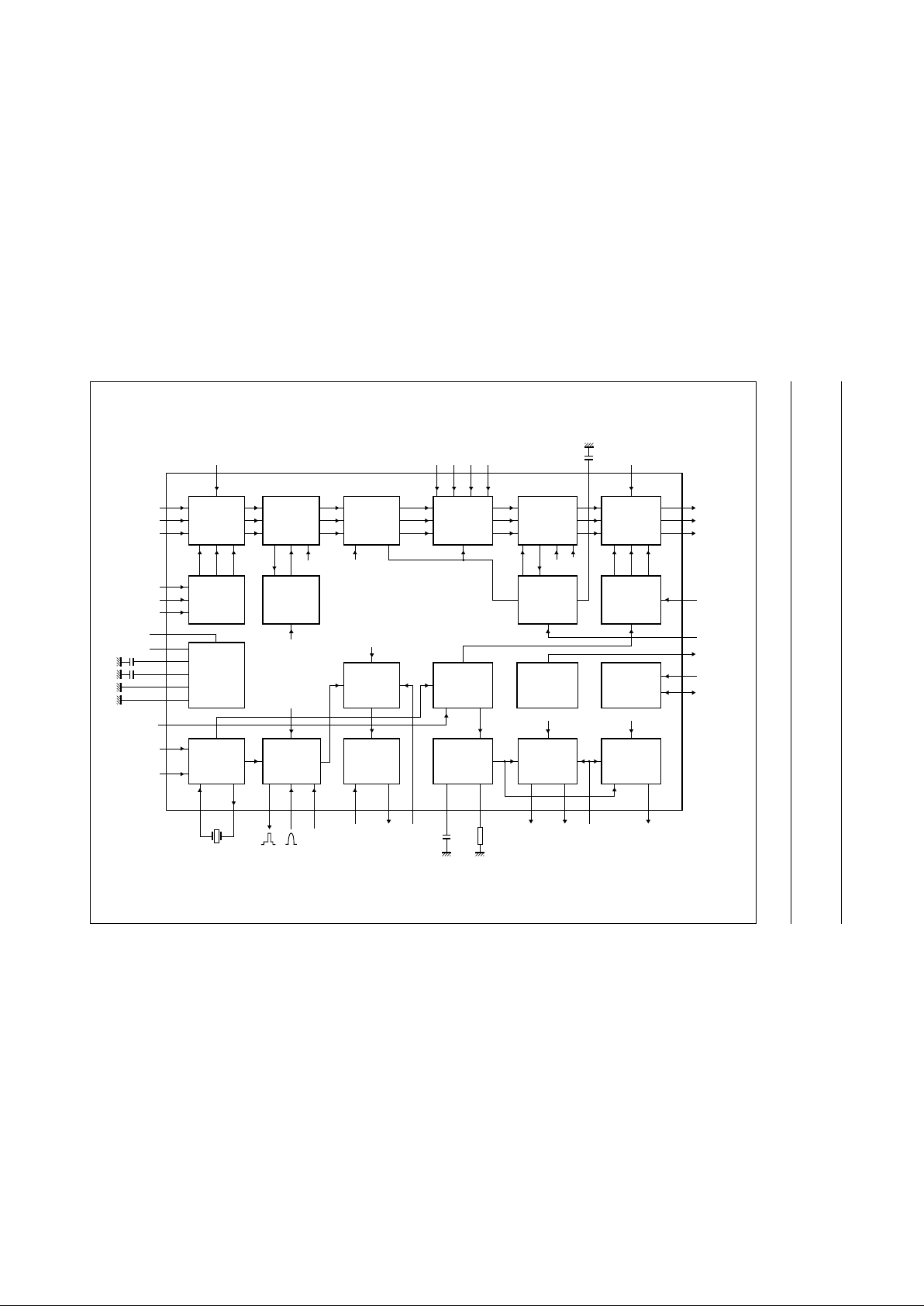

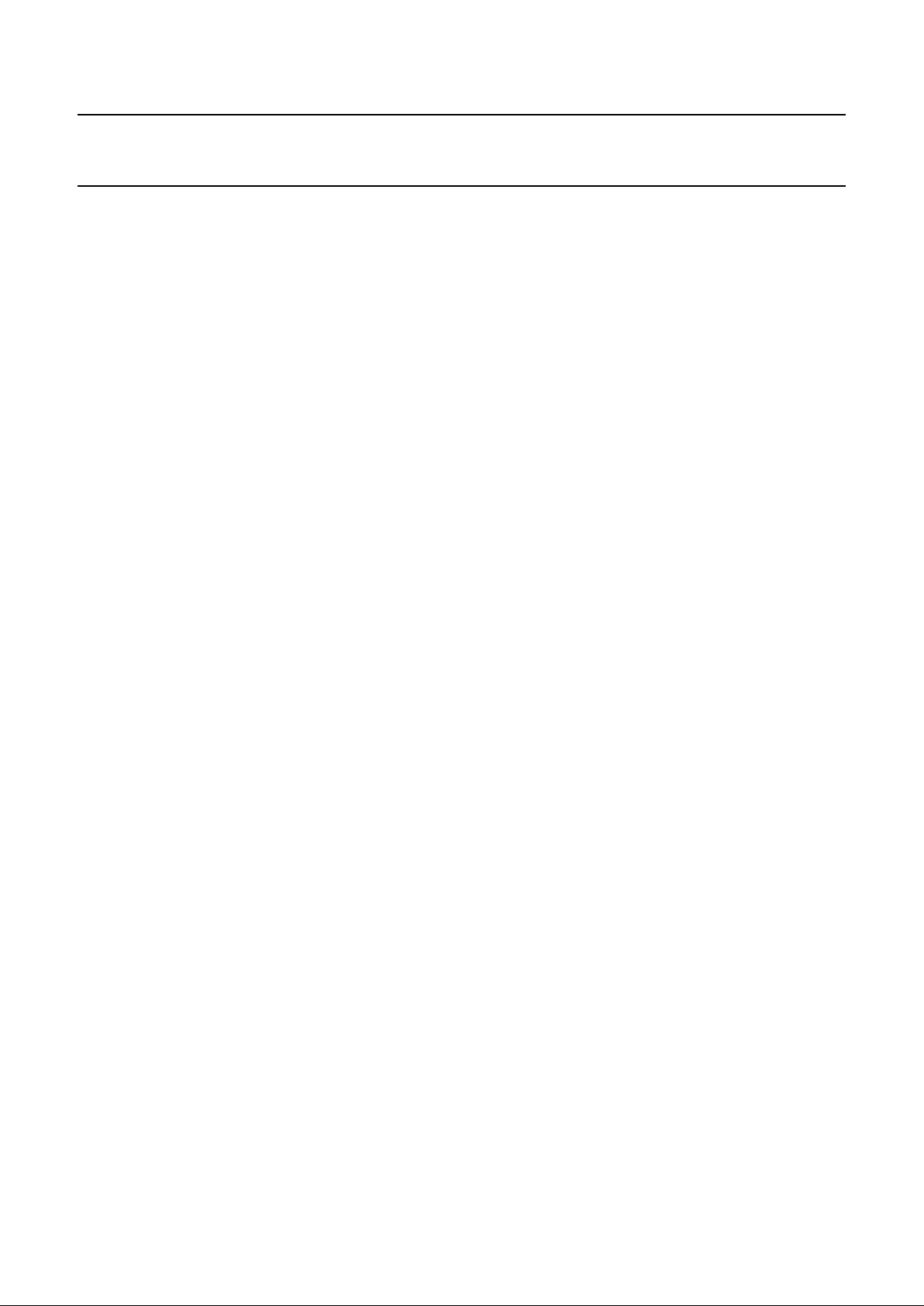

BLOCK DIAGRAM

handbook, full pagewidth

MGR445

SWITCH

Y

Y

U V

SAT

CONTR

U

V

SATURATION

CONTROL

COLOUR

DIFFERENCE

MATRIX

R

G

B

CONTRAST

CONTROL

R

G

B

RGB

INSERTION

R

GG

B

BRI

white

point

WHITE POINT

AND

BRIGHTNESS

CONTROL

R

B

OUTPUT

AMPLIFIER

AND

BUFFER

BLUE STRETCH

40

41

42

28

27

26

YIN

UIN

VIN

RGB-YUV

MATRIX

BLACK

STRETCH

PWL

AND

BEAM

CURRENT

LIMITER

CONTINUOUS

CATHODE

CALIBRATION

44

30

31

32

RI1

GI1

BI1

SUPPLY

H-SHIFT

SOFT

START/STOP

LOW-POWER

START-UP

H/V DIVIDER

19 × 6-BIT DACs

2 × 4-BIT DACs

I2C-BUS

TRANSCEIVER

10

43

11

25

18

6

19

17

7

39

DEC

BG

GND1

GND2

23

V

P1

DEC

VD

V

P2

CLOCK

GENERATION

AND

1st LOOP

20

21 13 14 22

PHASE-2

LOOP

HORIZONTAL

OUTPUT

15 16

VSC I

ref

RAMP

GENERATOR

1 24

VERTICAL

GEOMETRY

3

E-W

GEOMETRY

GEOMETRY CONTROL

24

12

HSEL

33

29

38373635

34

TDA933xH

BL1

FBCSO

BL2GI2RI2

PWL

BI2

BCL

BO

GO

RO

BLKIN

DACOUT

SDA

SCL

VDOA

589

VDOB EWOEHTIN

XTALI

XTALO

LPSU

FLASH

HOUT

SCO

HFB

DPC

H

D

V

D

Fig.1 Block diagram.

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to forcelandscapepagestobe rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2000 May 08 5

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

PINNING

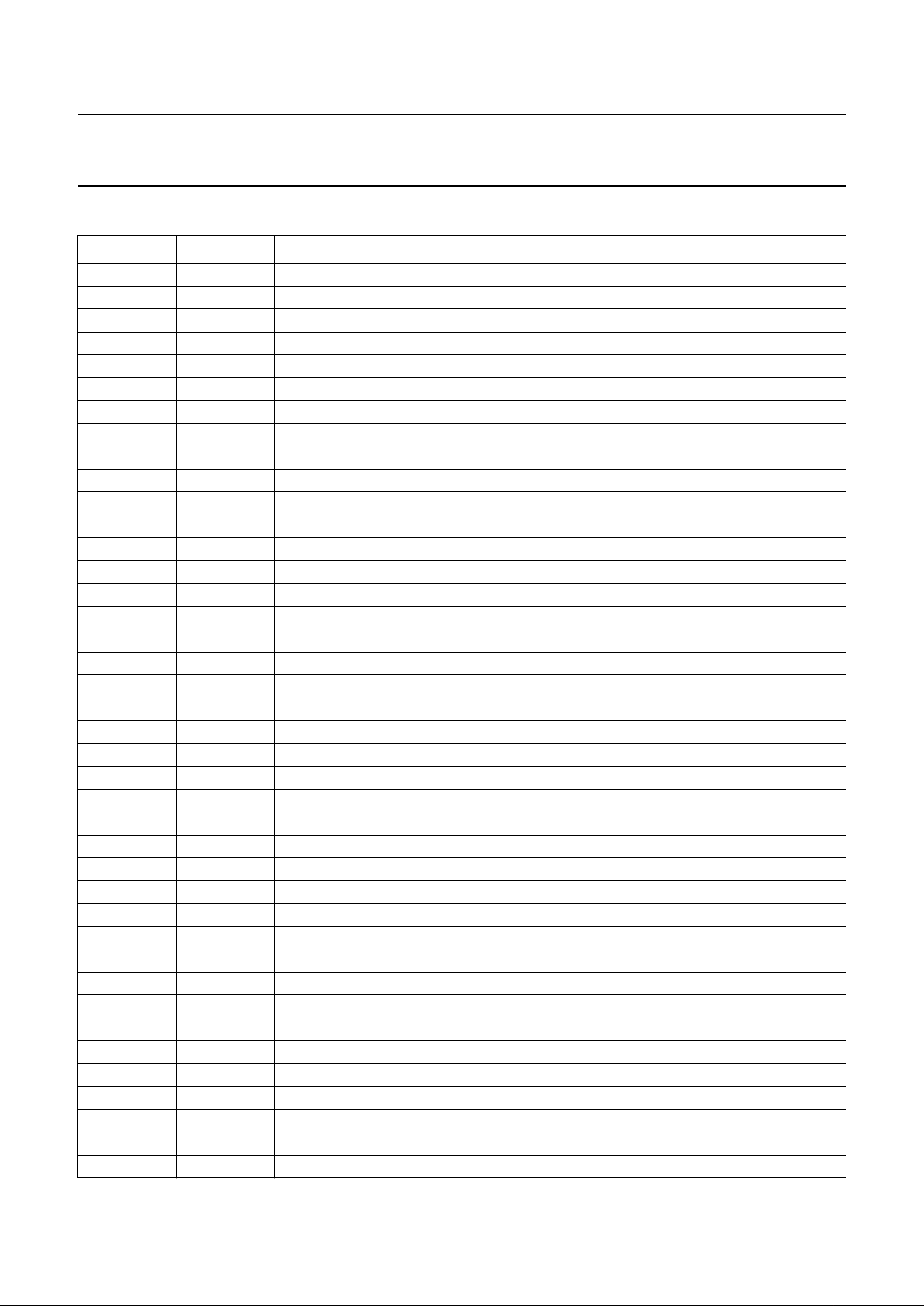

SYMBOL PIN DESCRIPTION

VDOA 1 vertical drive output A

VDOB 2 vertical drive output B

EWO 3 E-W output

EHTIN 4 EHT compensation input

FLASH 5 flash detection input

GND1 6 ground 1

DEC

VD

7 digital supply decoupling

HOUT 8 horizontal output

SCO 9 sandcastle pulse output

SCL 10 serial clock input

SDA 11 serial data input/output

HSEL 12 selection of horizontal frequency

HFB 13 horizontal flyback pulse input

DPC 14 dynamic phase compensation

VSC 15 vertical sawtooth capacitor

I

ref

16 reference current input

V

P1

17 positive supply 1 (+8 V)

DEC

BG

18 band gap decoupling

GND2 19 ground 2

XTALI 20 crystal input

XTALO 21 crystal output

LPSU 22 low-power start-up supply

V

D

23 vertical sync input

H

D

24 horizontal sync input

DACOUT 25 DAC output

VIN 26 V-signal input

UIN 27 U-signal input

YIN 28 luminance input

FBCSO 29 fixed beam current switch-off input

RI1 30 red 1 input for insertion

GI1 31 green 1 input for insertion

BI1 32 blue 1 input for insertion

BL1 33 fast blanking input for RGB-1

PWL 34 peak white limiting decoupling

RI2 35 red 2 input for insertion

GI2 36 green 2 input for insertion

BI2 37 blue 2 input for insertion

BL2 38 fast blanking/blending input for RGB-2

V

P2

39 positive supply 2 (+8 V)

RO 40 red output

2000 May 08 6

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

GO 41 green output

BO 42 blue output

BCL 43 beam current limiting input

BLKIN 44 black current input

SYMBOL PIN DESCRIPTION

handbook, full pagewidth

1

2

3

4

5

6

7

8

9

10

11

33

32

31

30

29

28

27

26

25

24

23

12

13

14

15

16

17

181920

21

22

44

43

42

41

40

39

38

37

36

35

34

TDA933xH

MGR446

BL1

BI1

GI1

RI1

YIN

UIN

VIN

DACOUT

H

D

V

D

VDOA

VDOB

EWO

EHTIN

FLASH

GND1

HOUT

SCO

SDA

FBCSO

BCL

BO

GO

RO

V

P2

BL2

GI2

RI2

PWL

BLKIN

BI2

HFB

DPC

VSC

I

ref

V

P1

DEC

BG

XTALI

XTALO

LPSU

HSEL

GND2

DEC

VD

SCL

Fig.2 Pin configuration.

2000 May 08 7

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

FUNCTIONAL DESCRIPTION

RGB control circuit

INPUT SIGNALS

The RGB control circuit of the TDA933xH contains three

sets of input signals:

• YUV input signals, which are supplied by the input

processor or the feature box. Bit GAI can be used to

switch the luminance input signal sensitivity between

0.45 V (p-p) and 1.0 V (b-w). The nominal input signals

for U and V are 1.33 V (p-p) and 1.05 V (p-p),

respectively. These input signals are controlled on

contrast, saturation and brightness.

• The first RGB input is intended for external signals

(SCARTin 1fHandVGA in 2fHapplications),which have

an amplitude of 0.7 V (p-p) typical. This input is also

controlled on contrast, saturation and brightness.

• The second RGB input is intended for OSD and teletext

signals. The required input signals havean amplitude of

0.7 V (p-p). The switching between the internal signal

and the OSD signal can be realized via a blending

function or via fast blanking. This input is only controlled

on brightness.

Switchingbetween the various sources canberealized via

the I2C-bus and by fast insertion switches. The fast

insertion switches can be enabled via the I2C-bus.

The circuit contains switchable matrix circuits for the

colour difference signals so that the colour reproduction

can be adapted for PAL/SECAM and NTSC. For NTSC,

two different matrices can be chosen. In addition, a matrix

for high-definition ATSC signals is available.

OUTPUT AMPLIFIER

The output signal has an amplitude of approximately

2 V (b-w) at nominal input signals and nominal settings of

the controls. The required ‘white point setting’ of the

picture tube can be realized by means of three separate

gain settings for the RGB channels.

To obtain an accurate biasing of the picture tube, a CCC

circuit has been developed. This function is realized by a

2-point black level stabilization circuit.

Byinsertingtwotestlevelsforeachgunandcomparing the

resulting cathode currents with two different reference

currents,the influence of thepicture tube parameters such

as the spread in cut-off voltage can be eliminated.

This 2-point stabilization is based on the principle that the

ratio between the cathode currents is coupled to the ratio

between the drive voltages according to:

The feedback loop makes the ratio between cathode

currents I

k1

and Ik2 equal to the ratio between the

reference currents (which are internally fixed)by changing

the (black) level and the amplitude of the RGB output

signals via two converging loops. The system operates in

such a way that the black level of the drive signal is

controlled to thecut-off point of the gun. In this way, a very

good grey scale tracking is obtained. The accuracy of the

adjustmentof the black level isonly dependent on the ratio

ofinternalcurrents and these can be madeveryaccurately

in integrated circuits. An additional advantage of the

2-point measurement is that the control system makes the

absolute value of Ik1 and Ik2 identical to the internal

reference currents. Because this adjustment is obtained

by adapting the gain of the RGB control stage, this control

stabilizes the gain of the complete channel (RGB output

stage and cathode characteristic). As a result, this 2-point

loop compensates for variations in the gain figures during

life.

An important property ofthe 2-point stabilizationis that the

offset and the gain of the RGB path are adjusted by the

feedback loop. Hence, the maximum drive voltage for the

cathode is fixed by the relationship between the test

pulses, the reference current and the relative gain setting

of the three channels. Consequently, the drive level of the

CRT cannot be adjusted by adapting the gain of the RGB

output stage. Because different picture tubes may require

different drive levels, the typical ‘cathode drive level’

amplitudecan be adjusted bymeans of an I2C-bussetting.

Depending on the selected cathode drive level, the typical

gain of the RGB output stages can be fixed, taking into

account the drive capability of the RGB outputs

(pins 40 to 42). More details about the design are given in

the application report (see also Chapter “Characteristics”;

note 11).

The measurement of the high and the low currents of the

2-point stabilization circuit isperformed in two consecutive

fields. The leakage current is measured in each field. The

maximum allowable leakage current is 100 µA.

For extra flexibility, it also possible to switch the CCC

circuit to 1-point stabilization with the OPC bit. In this

mode, only the blacklevel at theRGB outputs is controlled

by the loop. The cathode drive level setting has no

influence on the gain in thismode. This level should be set

to the nominal value to get the correct amplitude of the

measuring pulses.

I

k1

I

k2

------ -

V

dr1

V

dr1

-----------

γ

=

2000 May 08 8

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

Via the I2C-bus, an adjustable offset can be made on the

black level of red and green channels with respect to the

level that is generated by the black current control loop.

These controls can be used to adjust the colour

temperature of the dark part of the picture, independent of

the white point adjustment.

When the TV receiver is switched on, the black current

stabilization circuit is directly activated and the RGB

outputs are blanked. The blanking is switched off as soon

as the loop has stabilized (e.g. the first time that bit BCF

changes from 1 to 0, see also Chapter “Characteristics”;

note 15). This ensures that the switch-on time is reduced

to a minimum and is only dependent on the warm-up time

of the picture tube.

The black current stabilization system checks the output

levelof the three channels andindicateswhether the black

level of the lowest RGB output of the IC is in a certain

window (WBC bit), below or above this window (HBC bit).

This indication can be read from the I2C-bus and can be

used for automatic adjustment of voltage Vg2 during the

production of the TV receiver.

When a failure occurs in theblack current loop (e.g. due to

an open circuit), statusbit BCF is set.This information can

be used to blank the picture tube to avoid damage to the

screen.

The control circuit contains an average beam current

limiting circuit and a peak white level (PWL) circuit. The

PWL detects small white areas in the picture that are not

detected by the average beam current limiter. The PWL

can be adjusted via the I2C-bus. A low-pass filter is placed

in front of the peak detector to prevent it from reacting to

short transients in the video signal. The capacitor of the

low-pass filter is connected externally so that the set

maker can adapt the time constant as required. The IC

also contains a soft clipper that limits the amplitude of the

shorttransientsintheRGBoutputsignals.Inthisway,spot

blooming on, for instance, subtitles is prevented. The

differencebetween the PWL and thesoftclipping level can

be adjusted via the I2C-bus in a few steps.

The vertical blanking is adapted to the vertical frequency

of the incoming signal (50 or 100 Hz or, 60 or 120 Hz).

When the flyback time of the vertical output stage is

greater than the 60 Hz blanking time, the blanking can be

increased to the same value as that of the 50 Hz blanking.

This can be set by means of bit LBM.

When no video is available, it is possible to insert a blue

background. This feature can be activated via bit EBB.

Synchronization and deflection processing

HORIZONTAL SYNCHRONIZATION AND DRIVE CIRCUIT

The horizontal drive signal is obtained from an internal

VCO which runs at a frequency of 440 times (2fHmode) or

880 times (1fHmode) the frequency of the incoming H

D

signal. The free-running frequency of this VCO is

calibrated by a crystal oscillator which needs an external

12 MHz crystal or ceramic resonator as a reference. It is

also possible to supply an external reference signal to the

IC (in this case, the external resonator should be

removed).

The VCO is synchronized to the incoming horizontal H

D

pulse (applied from the feature box or the input processor)

by a PLL with an internal time constant. The frequency of

thehorizontaldrive signal (1fHor2fH)isselected by means

of a switching pin, which must be connected to ground or

left open circuit.

For HDTV applications, it is possible to change the

free-running frequency of the horizontal drive output from

31.2 kHz to 33.7 kHz by means of bit HDTV.

For safety reasons, switching between 1fH and 2f

H

modes is only possible when the IC is in the standby

mode.

For the TDA9331H and TDA9332H, it is also possible to

set the horizontal PLL to a ‘multi-sync’ mode by means of

bit VGA. In this mode, the circuit detects the frequency of

theincomingsyncpulses and adjusts the centre frequency

of the VCO accordingly by means of an internal

Digital-to-Analog-Converter (DAC). The frequency range

in this mode is 30 to 50 kHz at the output.

The polarities of the incoming HD and VD pulses are

detected internally. The detected polarity can be read out

via status bits HPOL and VPOL.

The horizontal drive signal is generated by a second

control loop which compares the phase of the reference

signal (applied from the internal VCO) with the flyback

pulse. The time constant of this loop is set internally. The

IC has a dynamic horizontal phase correction input, which

can be used to compensate phase shifts that are caused

by beam current variations. Additional settings of the

horizontal deflection (which are realized via the second

loop) are the horizontal shift and horizontal parallelogram

and bow corrections (see Chapter “Characteristics”;

Fig.16). The adjustments are realized via the I2C-bus.

When no horizontal flyback pulse is detected during three

consecutive line periods, status bit NHF is set (output

status byte 01-D3; see Table 3).

2000 May 08 9

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

The horizontal drive signal is switched on and off via the

so-called slow-start/slow-stop procedure. This function is

realizedby varying the tonof the horizontal drive pulse. For

EHT generators without a bleeder, the IC can be set to a

‘fixed beam current mode’ via bit FBC. In this case, the

picture tube capacitance is discharged with a current of

approximately 1 mA. The magnitude of the discharge

current is controlled via the black current feedback loop.

If necessary, the discharge current can be enlarged with

the aid of an external currentdivision circuit. With the fixed

beam current option activated, it is still possible to have a

black screen during switch-off. This can be realized by

placing the vertical deflectionin an overscan position. This

mode is activated via bit OSO.

An additional mode of the IC is the ‘low-power start-up’

mode.This mode is activated when asupplyvoltageof 5 V

is supplied to the start-up pin.

The required current for this mode is 3 mA (typ.). In this

condition, the horizontal drive signal has the nominal t

off

and the ton grows gradually from zero to approximately

30% of the nominal value. This results in a line frequency

of approximately 50 kHz (2fH) or 25 kHz (1fH). The output

signal remains unchanged until the main supply voltage is

switched on and the I2C-bus data has been received. The

horizontal drive then gradually changes to the nominal

frequency and duty cycle via the slow-start procedure.

TheICcanonlybeswitched on and to standby mode when

both standby bits (STB0 and STB1) are changed. The

circuit will not react when only one bit changes polarity.

The IC has a general purpose bus controlled DAC output

with a 6-bit resolution and with an output voltage range

between 0.2 to 4 V. In the TDA9331H, the DC voltage on

this output is proportional to the horizontal line frequency

(only in VGA mode). This voltage can be used to control

the supply voltage of the horizontal deflection stage, to

maintain constant picture width for higher line frequencies.

VERTICAL DEFLECTION AND GEOMETRY CONTROL

The drive signals for the vertical and E-W deflection

circuits are generated by a vertical divider, which derives

its clock signal from the line oscillator. The divider is

synchronized by the incoming VDpulse, generated by the

input processor or the feature box. The vertical ramp

generator requires an external resistor and capacitor; the

tolerances for these components must be small. In the

normal mode, the vertical deflection operates in constant

slope and adapts its amplitude, depending on the

frequency of the incoming signal (50 or 60 Hz, or

100 or 120 Hz). When the TDA933xH is switched to the

VGA mode, the amplitude of the vertical scan is stabilized

andindependent of the incomingvertical frequency. In this

mode, the E-W drive amplitude is proportional to the

horizontalfrequency so that the correctiononthe screen is

not affected.

The vertical drive is realized by a differential output

current. The outputs must be DC-coupled to the vertical

output stage (e.g. TDA8354).

The vertical geometry can be adjusted via the I2C-bus.

Controls are possible for the following parameters:

• Vertical amplitude

• S-correction

• Vertical slope

• Vertical shift (only for compensation of offsets in output

stage or picture tube)

• Vertical zoom

• Verticalscroll (shifting the picture inthevertical direction

when the vertical scan is expanded)

• Vertical wait, an adjustable delay for the start of the

vertical scan.

Withregardtothevertical wait, the following conditions are

valid:

• In the 1fHTV mode, the start of the vertical scan is fixed

and cannot be adjusted with the vertical wait

• In the 2fH TV mode, the start of the vertical scan

depends on the value of the Vertical Scan Reference

(VSR) bus bit. If VSR = 0, the start of the vertical scan is

related to the end of the incoming VDpulse. If VSR = 1,

it is related to the start. In both cases, the start of the

scan can be adjusted with the vertical wait setting

• In the multi-sync mode (TDA9331H and TDA9332H

both in 1fHmode and 2fHmode), the start of the vertical

scan is related to the start of the incoming VDpulse and

can be adjusted with the vertical wait setting.

The minimum value for the vertical wait setting is 8 line

periods. If the setting is lower than 8, the wait period will

remain at 8 line periods.

The E-W drive circuit has a single-ended output. The E-W

geometry can be adjusted on the following parameters:

• Horizontal width with increased range because of the

‘zoom’ feature

• E-W parabola/width ratio

• E-W upper corner/parabola ratio

• E-W lower corner/parabola ratio

• E-W trapezium.

2000 May 08 10

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

The IC has an EHT compensation input which controls

both the vertical and the E-W output signals. The relative

control effect on both outputs can be adjusted via the

I2C-bus (sensitivity of vertical correction is fixed; E-W

correction variable).

Toavoiddamagetothe picture tube in the event of missing

or malfunctioning vertical deflection, a vertical guard

function is available at the sandcastle pin (pin SCO). The

vertical guard pulse from the vertical output stage

(TDA835x) should be connected to the sandcastle pin,

which acts as a current sense input. If the guard pulse is

missing or lasts too long, bit NDF is set in the status

register and the RGB outputs are blanked. If the guard

function is disabled via bit EVG, only NDF status bit NHF

is set.

TheICalsohasinputsforflashandovervoltageprotection.

More details about these functions are given in Chapter

“Characteristics”; note 43.

I

2

C-BUS SPECIFICATION

The slave address of the IC is given in Table 1. The circuit

operates up to clock frequencies of 400 kHz. Valid

subaddresses: 00 to 1F, subaddress FE is reserved for

test purposes. The auto-increment mode is available for

subaddresses.

Table 1 Slave address (8C)

A6 A5 A4 A3 A2 A1 A0 R/W

10001101/0

2000 May 08 11

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

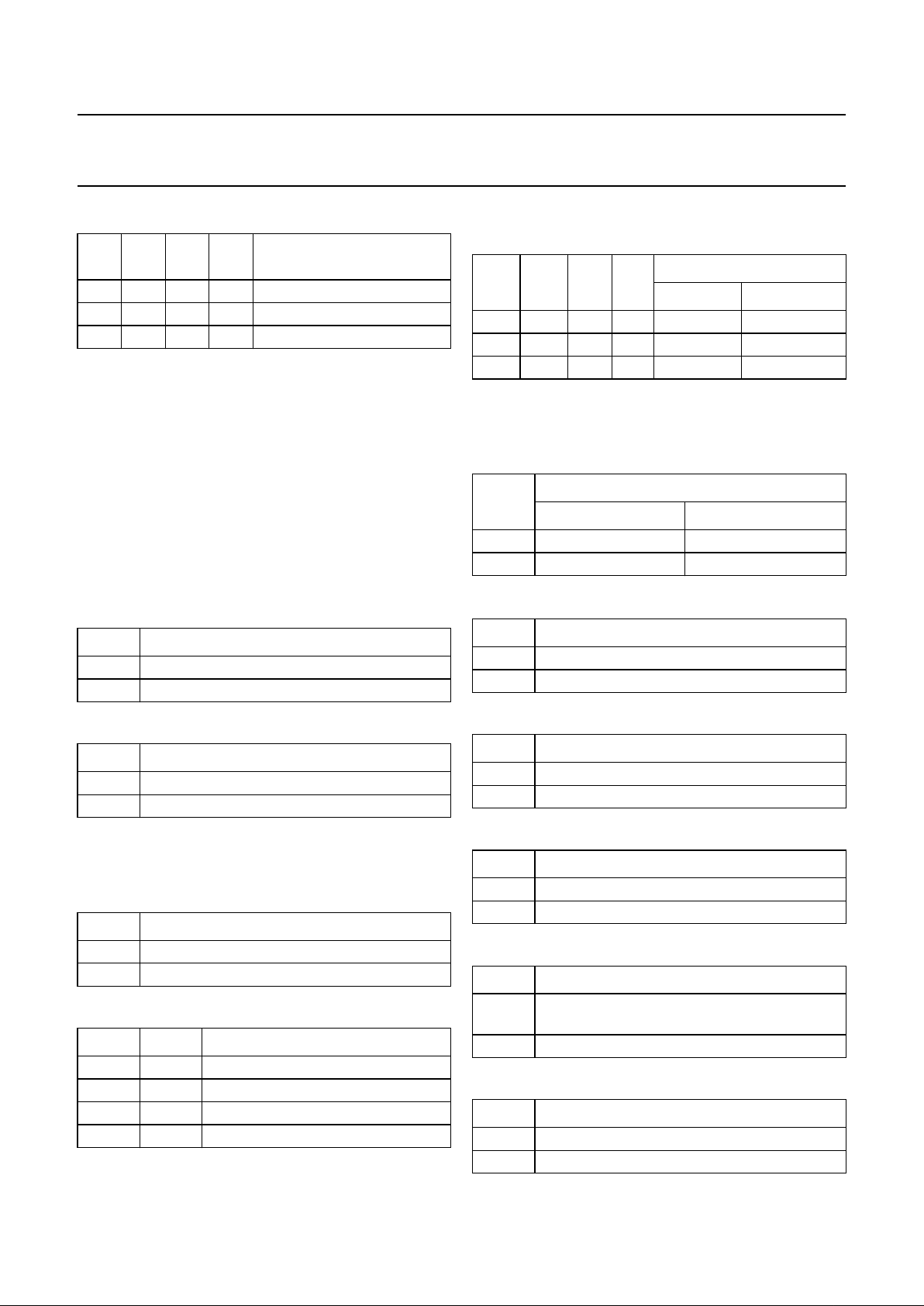

Table 2 Input control bits

Notes

1. For zero parallelogram and bow correction use register value 7 DEC.

2. See Chapter “Characteristics”; note 47.

3. Bit VGA is not available in the TDA9330H.

FUNCTION

SUBADDRESS

(HEX)

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

RGB processing-1 00 MAT EBB SBL RBL BLS BKS IE1 IE2

RGB processing-2 01 MUS FBC OBL AKB CL3 CL2 CL1 CL0

Wide horizontal blanking 02 HBL TFBC GAI STB0 HB3 HB2 HB1 HB0

Horizontal deflection 03 HDTV VSR 0 STB1 POC PRD VGA

(3)

ESS

Vertical deflection 04 OPC VFF LBM DIP OSO SVF EVG DL

Brightness 05 0 0 A5 A4 A3 A2 A1 A0

Saturation 06 0 0 A5 A4 A3 A2 A1 A0

Contrast 07 0 0 A5 A4 A3 A2 A1 A0

White point R 08 0 0 A5 A4 A3 A2 A1 A0

White point G 09 0 0 A5 A4 A3 A2 A1 A0

White point B 0A 0 0 A5 A4 A3 A2 A1 A0

Peak white limiting 0B 0 0 SC1 SC0 A3 A2 A1 A0

Horizontal shift 0C 0 0 A5 A4 A3 A2 A1 A0

Horizontal parallelogram

(1)

0D 0000A3A2A1A0

E-W width 0E 0 0 A5 A4 A3 A2 A1 A0

E-W parabola/width 0F 0 0 A5 A4 A3 A2 A1 A0

E-W upper corner/parabola 10 0 0 A5 A4 A3 A2 A1 A0

E-W trapezium 11 0 0 A5 A4 A3 A2 A1 A0

E-W EHT compensation sensitivity 12 0 0 A5 A4 A3 A2 A1 A0

Vertical slope 13 0 0 A5 A4 A3 A2 A1 A0

Vertical amplitude 14 0 0 A5 A4 A3 A2 A1 A0

S-correction 15 0 0 A5 A4 A3 A2 A1 A0

Vertical shift 16 0 0 A5 A4 A3 A2 A1 A0

Vertical zoom 17 0 0 A5 A4 A3 A2 A1 A0

Vertical scroll 18 0 0 A5 A4 A3 A2 A1 A0

Vertical wait 19 0 0 0 A4 A3 A2 A1 A0

DAC output

(2)

1A 0 0 A5 A4 A3 A2 A1 A0

Black level offset R 1B 0000A3A2A1A0

Black level offset G 1C 0000A3A2A1A0

Horizontal timing 1D 0 0 0 HDCL LBL3 LBL2 LBL1 LBL0

E-W lower corner/parabola 1E 0 0 A5 A4 A3 A2 A1 A0

Horizontal bow

(1)

1F 0000A3A2A1A0

2000 May 08 12

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

Table 3 Output status bits

FUNCTION

SUBADDRESS

(HEX)

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

Output status bytes 00 POR FSI SL XPR NDF IN1 IN2 WBC

01 N2 ID2 ID1 ID0 NHF BCF FLS NRF

02 X X X X X HPOL VPOL HBC

Input control bits

Table 4 Colour difference matrix

Table 5 Enable ‘blue-back’

Table 6 Service blanking

Table 7 RGB blanking

Table 8 Blue stretch

Table 9 Black stretch

Table 10 Enable fast blanking RGB-1

Table 11 Enable fast blanking RGB-2

Table 12 Fixed beam current switch-off

Table 13 Blending function on OSD; note 1

Note

1. When bit OBL is set to 1, the blending function is

always activated, independent of the setting of bit IE2.

Table 14 Black current stabilization

MAT MUS MATRIX POSITION

00 PAL

0 1 ATSC

1 0 NTSC Japan

1 1 NTSC USA

EBB MODE

0 blue-black switched off

1 blue-black switched on

SBL SERVICE BLANKING MODE

0 off

1on

RBL RGB BLANKING

0 not active

1 active

BLS BLUE STRETCH MODE

0 off

1on

BKS BLACK STRETCH MODE

0 off

1on

IE1 FAST BLANKING

0 not active

1 active

IE2 FAST BLANKING

0 not active

1 active

FBC MODE

0 switch-off with blanked RGB outputs

1 switch-off with fixed beam current

OBL MODE

0 OSD via fast blanking

1 OSD via blending function

AKB OPC MODE

0 0 2-point control

0 1 1-point control

1 − not active

2000 May 08 13

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

Table 15 Cathode drive level (15 steps; 3.6 V/step)

Note

1. The given values are valid for the following conditions:

a) Nominal CVBS input signal.

b) Settings for contrast and white point nominal.

c) Black and blue stretch switched off.

d) Gain of output stage such that no clipping occurs.

e) Beam current limiting not active.

f) Gamma of picture tube is 2.25.

g) The tolerance on these values is approximately

±3V.

Table 16 RGB blanking mode

Table 17 Picture tube discharge time

Note

1. See Chapter “Characteristics”; Fig.15

Table 18 Gain of luminance channel

Table 19 Standby

Table 20 Position of wide blanking (14 steps; 1f

H

mode

0.29 µs/step; 2f

H

mode 0.145 µs/step)

Note

1. See Chapter “Characteristics”; note 13.

Table 21 Horizontal free-running frequency in TV mode

Table 22 Vertical scan reference in 2f

H

TV mode

Table 23 Synchronization mode

Table 24 Overvoltage input mode

Table 25 Multi-sync mode

Table 26 Extended slow start mode

CL3 CL2 CL1 CL0

SETTING OF CATHODE

DRIVE AMPLITUDE

(1)

0000 41V(b-w)

1000 70V(b-w)

1111 95V(b-w)

HBL MODE

0 normal blanking (horizontal flyback)

1 wide blanking

TFBC MODE

0 18.6 ms

1 25 ms

GAI MODE

0 normal gain [V

28

= 1 V (b-w)]

1 high gain [V

28

= 0.45 V (p-p)]

STB0 STB1 CONDITION

0 0 horizontal drive off

0 1 no action

1 0 no action

1 1 horizontal drive on

HB3 HB2 HB1 HB0

TIMING OF BLANKING

(1)

1fH MODE 2fH MODE

0000−2.03 µs −1.015 µs

0111 0µs0µs

111−2.03 µs 1.015 µs

HDTV

FREQUENCY

1f

H

MODE 2fH MODE

0 15.65 kHz 31.3 kHz

1 16.85 kHz 33.7 kHz

VSR VERTICAL SCAN REFERENCE

0 end of V

D

pulse

1 start of V

D

pulse

POC MODE

0 synchronization active

1 synchronization not active

PRD OVERVOLTAGE MODE

0 detection mode

1 protection mode

VGA MODE

0

horizontal frequency fixed by internal

reference

1 multi-sync function switched on

ESS EXTENDED SLOW START MODE

0 not active

1 active

2000 May 08 14

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

Table 27 Long blanking mode

Table 28 Vertical free-running frequency in TV mode

Table 29 De-interlace phase

Table 30 Switch-off in vertical overscan

Table 31 Select vertical frequency

Table 32 Enable vertical guard (RGB blanking)

Table 33 Interlace

Table 34 Soft clipping level

Table 35 Clamp pulse timing

Note

1. See Chapter “Characteristics”; note 13.

Table 36 Start line blanking (15 steps; 2 line locked clock

period per step; 1 line period is 440 LLC pulses)

Note

1. See Chapter “Characteristics”; note 13.

Output status bits

Table 37 Power-on reset

Table 38 Field frequency indication

Table 39 Phase 1 (ϕ

1

) lock indication

LBM BLANKING MODE

0 adapted to standard (50 or 60 Hz)

1 fixed in accordance with 50 Hz standard

VFF FREQUENCY

0 50 Hz (SVF = 0) or 100 Hz (SVF = 1)

1 60 Hz (SVF = 0) or 120 Hz (SVF = 1)

DIP PHASE

0

delay of 1st field (start of synchronized V

D

pulse coincides with H-flyback) with 0.5 H

1 delay of 2nd field with 0.5 H

OSO MODE

0 switch-off undefined

1 switch-off in vertical overscan

SVF MODE

0 vertical frequency is 50 or 60 Hz

1 vertical frequency is 100 or 120 Hz

EVG VERTICAL GUARD MODE

0 not active

1 active

DL STATUS

0 interlace

1 de-interlace

SC1 SC0

VOLTAGE DIFFERENCE

BETWEEN SOFT CLIPPING AND

PWL

0 0 0% above PWL

0 1 5% above PWL

1 0 10% above PWL

1 1 soft clipping off

HDCL MODE

(1)

0 normal timing

1 HDTV timing

LBL3 LBL2 LBL1 LBL0

START LINE

BLANKING

(1)

0000 +14 LLC

0111 normal

1111 −16 LLC

POR MODE

0 normal

1 power-down

FSI FREQUENCY

0 50 or 100 Hz

1 60 or 120 Hz

SL INDICATION

0 not locked

1 locked

2000 May 08 15

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

Table 40 X-ray protection

Table 41 Output of vertical guard

Table 42 Indication of RGB-1 insertion

Table 43 Indication of RGB-2 insertion

Table 44 Indication of output black level inside/outside

Vg2 alignment window

Note

1. See Chapter “Characteristics”; note 16.

Table 45 IC identification

Table 46 Mask version indication

Table 47 Condition of horizontal flyback

Table 48 Indication of failure in black current circuit

Table 49 Indication of flash detection

Table 50 Locking of reference oscillator to crystal

oscillator

Table 51 Indication of output black level below or above

the middle of Vg2 alignment window

Note

1. See Chapter “Characteristics”; note 16.

Table 52 Polarity of H

D

input pulse

Table 53 Polarity of V

D

input pulse

XPR OVERVOLTAGE

0 no overvoltage detected

1 overvoltage detected

NDF VERTICAL OUTPUT STAGE

0OK

1 failure

IN1 RGB INSERTION

0no

1yes

IN2 RGB INSERTION

0no

1yes

WBC CONDITION

(1)

0 black current stabilization outside window

1 black current stabilization inside window

ID2 ID1 ID0 IC VERSION

0 0 0 TDA9330H

0 0 1 TDA9332H

0 1 1 TDA9331H

N2 MASK VERSION

0 N1 version

1 N2 version

NHF CONDITION

0 flyback pulse present

1 flyback pulse not present

BCF CONDITION

0 normal operation

1 failure in black current stabilization circuit

FLS CONDITION

0 no flash-over detected

1 flash-over detected

NRF CONDITION

0 reference oscillator is locked

1 reference oscillator is not locked

HBC CONDITION

(1)

0 black current stabilization below window

1 black current stabilization above window

HPOL POLARITY

0 positive

1 negative

VPOL POLARITY

0 positive

1 negative

2000 May 08 16

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

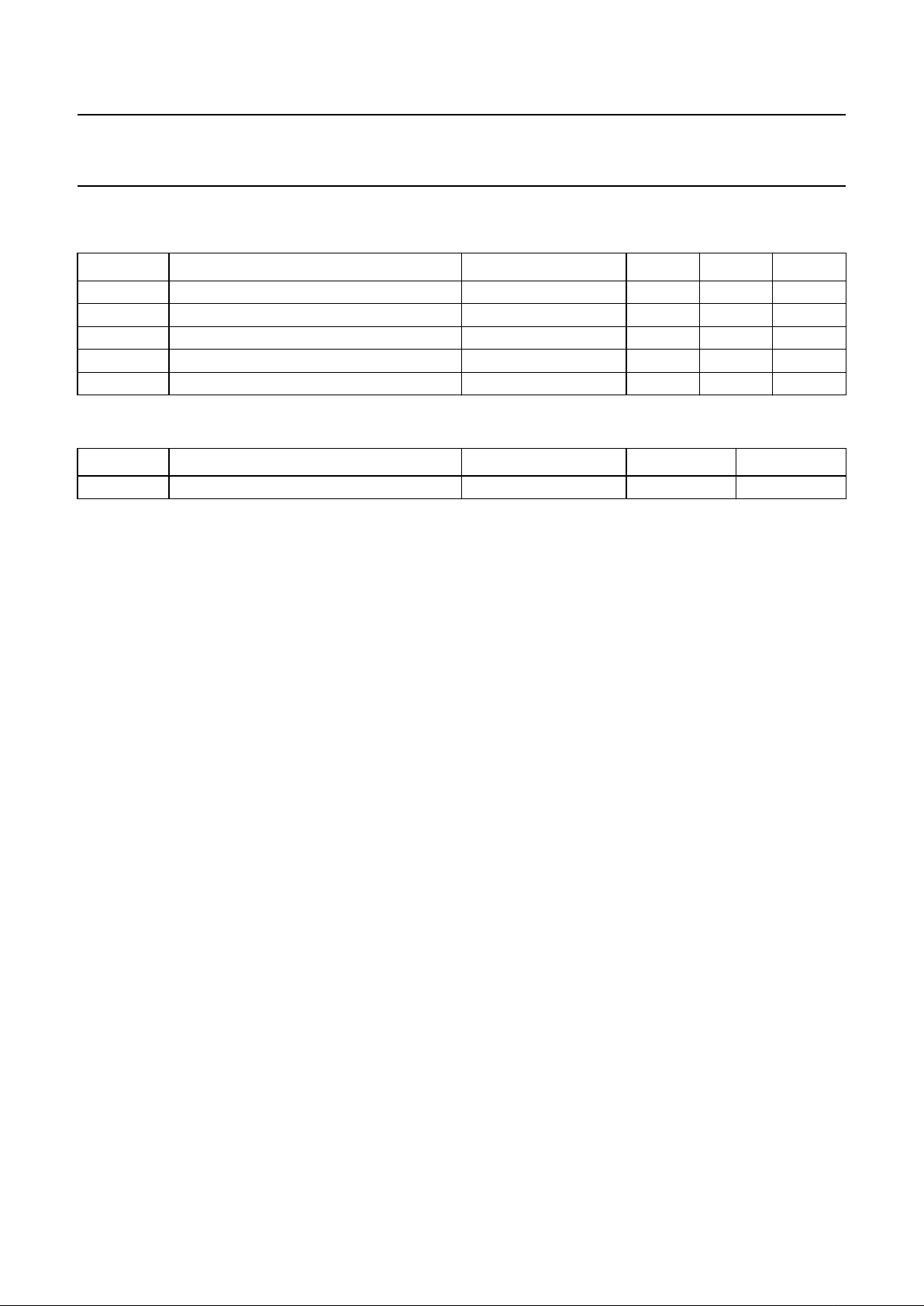

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

P

supply voltage − 9.0 V

T

stg

storage temperature −25 +150 °C

T

amb

ambient temperature 0 70 °C

T

sol

soldering temperature for 5 s − 260 °C

T

j

junction temperature − 150 °C

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in free air 60 K/W

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611E-part E”

.

ESD protection

All pins are protected against ESD by internal protection

diodes, and meet the following specification:

• Human body model (R = 1.5 kΩ; C = 100 pF):

all pins > ±3000 V

• Machine model (R = 0 Ω; C = 200 pF):

all pins > ±300V.

Latch-up performance

At an ambient temperature of 50 °C all pins meet the

following specification:

• Positive stress test: I

trigger

≥ 100 mA

or V

pin

≥ 1.5 × V

CC(max)

• Negative stress test: I

trigger

≤−100 mA

or V

pin

≤−0.5 × V

CC(max)

.

At an ambient temperature of 70 °C, all pins meet the

specification as mentioned above, with the exception of

pin 32, which can withstand a negative stress current of at

least 50 mA.

2000 May 08 17

Philips Semiconductors Preliminary specification

I2C-bus controlled TV display processors

TDA933xH series

CHARACTERISTICS

VP=8V; T

amb

=25°C; unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

M

AIN SUPPLY; PINS 17 AND 39

V

P1

supply voltage 7.2 8.0 8.8 V

V

POR

power-on reset voltage level note 1 5.8 6.1 6.5 V

I

P1

supply current pin 17 plus pin 39 44 50 58 mA

pin 17 − 22 − mA

pin 39 − 28 − mA

P

tot

total power dissipation − 400 − mW

L

OW-POWER START-UP; PIN 22

V

P2

supply voltage note 2 4.5 5.0 5.5 V

I

P2

supply current − 3.0 4.5 mA

RGB control circuit

LUMINANCE INPUT; PIN 28

V

i(Y)(b-w)

luminance input voltage

(black-to-white value)

GAI = 0 − 1.0 1.5 V

Z

i

input impedance 10 −−MΩ

C

i

input capacitance −− 5pF

I

i(Y)(clamp)

input current during clamping −25 0 +25 µA

U/V INPUTS; PINS 27 AND 26

V

i(U)(p-p)

U input signal amplitude

(peak-to-peak value)

− 1.33 2.0 V

V

i(V)(p-p)

V input signal amplitude

(peak-to-peak value)

− 1.05 1.6 V

Z

i

input impedance 10 −−MΩ

C

i

input capacitance −− 5pF

I

i(UV)(clamp)

input current during clamping −20 0 +25 µA

RGB-1 INPUT (SCART/VGA);PINS 30 TO 32; note 3

V

i(b-w)

input signal amplitude

(black-to-white value)

− 0.7 1.0 V

∆V

o

difference between black level of

YUV and RGB-1 signals at the

outputs

−− 10 mV

Z

i

input impedance 10 −−MΩ

C

i

input capacitance −− 5pF

I

i(clamp)

input current during clamping −25 0 +25 µA

∆t

d

delay difference for the three

channels

note 5 − 0 − ns

Loading...

Loading...