Philips tda9178 DATASHEETS

INTEGRATED CIRCUITS

DATA SH EET

TDA9178

YUV one chip picture improvement

based on luminance vector-, colour

vector- and spectral processor

Preliminary specification

File under Integrated Circuits, IC02

1999 Sep 24

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

FEATURES

• Picture content dependent non-linear Y, U and V

processing by luminance histogram analysis

• Variable gamma control

• Adaptive black and white stretch control

• Skin tone correction

• Green enhancement

• Blue stretch

• Luminance Transient Improvement (LTI)

• Smart peaking for detail enhancement

• Colour Transient Improvement (CTI)

• SCAn VElocity Modulation (SCAVEM) output

• Line Width Control (LWC)

• Video Dependent Coring (VDC)

• Colour Dependent Sharpness (CDS)

• Noise measurement

• Feature Mode (FM) detector

• Cue Flash (CF) detector

• Three additional pins for access to 6-bit ADC and

I2C-bus

• Adjustable chrominance delay

• TV standard independent

• I2C-bus controlled

• 1fH and 2f

• DEmonstration MOde (DEMO).

GENERAL DESCRIPTION

The TDA9178 is a transparent analog video processor

with YUV input and output interfaces. It offers three main

functions: luminance vector processing, colour vector

processing and spectral processing. Beside these three

main functions, there are some additional functions.

In the luminancevector processor, the luminance transfer

function is controlled in a non-linear way by the

distribution, in 5 discrete histogram sections, of the

luminance values measured in a picture. As a result, the

contrast ratio of the most important parts of the scene will

be improved. Black restoration is available in the event of

a set-up in the luminance signal.

A variable gamma function, after the histogram

conversion,offersthepossibilitiesofalternativebrightness

control or factory adjustment of the picture tube.

H

The adaptive black stretch function of the TDA9178 offers

the possibility of having a larger ‘weight’ for the black parts

of the video signal; the white stretch function offers an

additional overall gain for increased light production.

To maintain a proper colour reproduction, the saturation of

theU- and V-colour difference signals is also controlledas

a function of the actual non-linearity in the luminance

channel.

In the colour vector processor, the dynamic skin tone

correction locally changes the hue of colours that match

skin tones to the correct hue. The green enhancement

circuit activates medium saturated green towards to more

saturated green. The blue stretch circuit can be activated

which shifts colours near white towards blue.

The spectral processor provides 1D luminance transient

improvement, luminance detail enhancement by smart

peaking and a 1 D colour transient improvement.

The TDA9178 can be used as a cost effective alternative

to (but also in combination with) scan velocity modulation.

In the spectral processor line width control (or aperture

control) can be user defined. The TDA9178 is capable of

adjusting the amount of coring according to the video level

with the video dependent coring. The TDA9178 is also

capable to give extra sharpness in the cases of saturated

red and magenta parts of the screen using the colour

dependent sharpness feature.

An embedded noise detector measures noise during the

field retrace in parts which are expected to be free from

video or text information. With the noise detector a variety

of ‘smart noise control’ architectures can be set up.

A feature mode detector is available for detecting signal

sources like VCR (in still picture mode) that re-insert the

levels of the retrace part. For this kind of signals the noise

measurement of the TDA9178 is not reliable.

An output signal (on the I2C-bus and on a separate pin) is

available that detects when the picture content has been

changed significantly, called cue flash.

An embedded 6-bit ADC can be used for interfacing three

analog low frequency voltage signals (e.g. ambient light

control or beam current voltage level) to the I2C-bus.

TDA9178

1999 Sep 24 2

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

TDA9178

vector-, colour vector- and spectral processor

In the demonstration mode all the features selected by the user are automatically toggled between on and off.

The TDA9178 concept has a maximum flexibility which can be controlled by the embedded I2C-bus. The supply voltage

is 8 V. The device is mounted in a 24-lead SDIP package, or in a 24-lead SO package.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

V

i(Y)

V

i(UV)

V

FS(ADC)

ORDERING INFORMATION

TYPE

NUMBER

TDA9178 SDIP24 plastic shrink dual in-line package; 24 leads (400 mil) SOT234-1

TDA9178T SO24 plastic small outline package; 24 leads; body width 7.5 mm SOT137-1

supply voltage 7.2 8.0 8.8 V

luminance input voltage (excluding sync) AMS = 0 − 0.315 0.45 V

AMS = 1 − 1.0 1.41 V

UV input voltage −−1.9 V

full-scale ADC input voltage − 2.0 − V

PACKAGE

NAME DESCRIPTION VERSION

1999 Sep 24 3

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

1999 Sep 24 4

n.c.12n.c.

handbook, full pagewidth

BLOCK DIAGRAM

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

DEC

YIN

UIN

VIN

DIG

V

CC

V

EE

SC

TP

ADR

SDA

SCL

6

8

9

15

20

18

1

10

7

14

11

13

INPUT

ST A GE

SUPPL Y

WINDOW

GENERA TION

CALIBRATE

Y

U, V

LUMINANCE

PROCESSING

black stretch

histogram processing

gamma control

colour vector

processing

SATURATION

CORRECTION

skin tone correction

green enhancement

blue stretch

NOISE

MEASURING

FEA TURE

MODE

DETECTION

CONTROL

PROCESSING

cue flash

I2C-BUS CONTROL

spectral processingluminance vector processing

SMART PEAKING

LUMINANCE TRANSIENT

IMPROVEMENT

VIDEO DEPENDENT

CORING

COLOUR DEPENDENT

SHARPNESS

DELA Y

COLOUR

COLOUR TRANSIENT

IMPROVEMENT

+

ANALOG

TO

DIGIT AL

CONVERTER

OUTPUT

STAGE

21

SOUT

19

YOUT

17

UOUT

16

VOUT

24

n.c.

23

n.c.

22

CF

2

n.c.

3

ADEXT1

4

ADEXT2

5

ADEXT3

TDA9178

Fig.1 Block diagram.

MGR897

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

PINNING

SYMBOL PIN DESCRIPTION

SC 1 sandcastle input

n.c. 2 not connected

ADEXT1 3 ADC input 1

ADEXT2 4 ADC input 2

ADEXT3 5 ADC input 3

YIN 6 luminance input

ADR 7 address selection input

UIN 8 U signal input

VIN 9 V signal input

TP 10 test pin

SCL 11 serial clock input (I

2

C-bus)

n.c. 12 not connected

SYMBOL PIN DESCRIPTION

n.c. 13 not connected

SDA 14 serial data input/output (I

DEC

DIG

15 decoupling digital supply

VOUT 16 V signal output

UOUT 17 U signal output

V

EE

18 ground

YOUT 19 luminance output

V

CC

20 supply voltage

SOUT 21 SCAVEM output

CF 22 cue flash output

n.c. 23 not connected

n.c. 24 not connected

TDA9178

2

C-bus)

handbook, halfpage

SC

n.c.

ADEXT1

ADEXT2

ADEXT3

YIN

ADR

UIN

VIN

TP

SCL

n.c.

1

2

3

4

5

6

7

8

9

10

11

12

TDA9178

MGR898

n.c.

24

n.c.

23

CF

22

SOUT

21

V

20

CC

19

YOUT

V

18

EE

17

UOUT

VOUT

16

DEC

15

DIG

SDA

14

n.c.

13

handbook, halfpage

SC

n.c.

ADEXT1

ADEXT2

ADEXT3

YIN

ADR

UIN

VIN

TP

SCL

n.c.

1

2

3

4

5

6

TDA9178T

7

8

9

10

11

12

MGR899

n.c.

24

n.c.

23

CF

22

SOUT

21

V

20

CC

19

YOUT

V

18

EE

17

UOUT

VOUT

16

DEC

15

DIG

SDA

14

n.c.

13

Fig.2 Pin configuration (SOT234-1).

1999 Sep 24 5

Fig.3 Pin configuration (SOT137-1).

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

FUNCTIONAL DESCRIPTION

Y input selection and amplification

The gain of the luminance input amplifier and output

amplifier can be adjusted to signal amplitudes of

0.315 and 1.0 V typically (excluding sync) by I2C-bus

bit AMS. The sync part is processed transparently to the

output, independently of the feature settings.

The Y, U and V input signals are clamped during the

burstkey period, defined by the sandcastle reference and

should be DC-coupled (the circuit uses internal clamp

capacitors). During the clamp pulse (see Figs 7, 8, 9

and 10) an artificial black level is inserted in the Y input

signal to correctly preset the internal circuitry.

Luminance vector processor

Intheluminancevectorprocessorthetransfer is controlled

bya black stretch, the histogramprocessing and a gamma

control circuit. The luminance vector processor also

creates the cue flash signal.

BLACK STRETCH

Ablack detector measures and stores thelevelof the most

black part of the scene within an internal defined fixed

window in each field into a time constant. The time

constant and the response time of the loop are internally

fixed. Any difference between this value and the value

measured during the clamp is regarded as black offset.

In a closed loop offsets until a predefined value of the fullscale value are fed back to the input stage for

compensation.The loop gain is afunction of the histogram

and variable gamma settings. The black offset correction

can be switched on and off by the I2C-bus bit BON.

Related to the corrected black offset the nominal signal

amplitude is set again to 100% full scale through an

amplitude stretch function. Luminance values beyond full

scale are unaffected. Additionally, the measured black

offset is also used to set the adaptive black stretch gain

(see also Section “Adaptive black stretch”).

HISTOGRAM PROCESSING

For the luminance signal the histogram distribution is

measured in real-time over five segments within an

internally defined fixed window in each field. During the

period that the luminance is in one segment, a

corresponding internal capacitor is loaded by a current

source. At the end of the field five segment voltages are

stored into on-board memories. The voltages stored in the

memories determine the non-linear processing of the

luminance signal to achieve a picture with a maximum of

information (visible details).

Each field the capacitors are discharged and the

measurement starts all over again.

Parts in the scene that do not contribute to the information

inthatscene,likesub or side titles,should be omitted from

the histogram measurement. No measurements are

performed outside the internal fixed window period.

Very rapid picture changes, also related to the field

interlace,canresultinflickereffects.The histogram values

are averaged at the field rate thus cancelling the flicker

effects.

Adaptive black stretch

The so-called adaptive black stretch gain is one of the

factors that control the gamma of the picture. This gain is

controlled by the measured black offset value in the black

stretch circuit and theI2C-bus adaptive black stretchDAC:

bits BT5 to BT0. For pictures with no black offset the black

stretchgainequalsunitysothegammaisnotchanged and

the DAC setting has no influence. In case of a black offset,

the black stretch gain is increased so the gamma of the

pictureis reduced. This procedure results in amaximumof

visible details over the whole range of luminances.

However, depending on personal taste, sometimes higher

values of gamma are preferred. Therefore the amount of

gamma reduction can be adjusted by the DAC.

Adaptive white-point stretching

Forpictureswithmany details in white parts, the histogram

conversion procedure makes a transfer with large gain in

the white parts. The amount of light coming out of the

scene is reduced accordingly. The white stretcher

introduces additional overall gain for increased light

production, and so violating the principle of having a

full-scale reference. The white-point stretching can be

switched on or off by means of the I2C-bus bit WPO.

Standard deviation

Forscenesinwhichsegmentsofthehistogramdistribution

areverydominantwithrespecttotheothers,thenon-linear

amplification should be reduced in comparison to scenes

with a flat histogram distribution. The standard deviation

detectormeasuresthe spread of the histogram distribution

and modulates the user setting of the non-linear amplifier.

Non-linear amplifier

Thestoredsegmentvoltagesdeterminetheindividualgain

of each segment in such a way that continuity is granted

for the complete luminance range.

TDA9178

1999 Sep 24 6

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

The maximum and minimum gain of each segment is

limited. Apart from the adaptive white-point stretching the

black and white references are not affected by the

non-linear processing. The amount of non-linearity can be

controlled by the I2C-bus non-linearity DAC:

bits NL5 to NL0.

VARIABLE GAMMA

On top of the histogram conversion a variable gamma

function is applied for an alternative brightness control, or

for factory adjustment. It is intended as an alternative for

the DC-offset of the classic brightness user control.

It maintains the black and white references. The gamma

ranges from 0.5 to 1.5. The gamma can be set by the

I2C-bus variable gamma DAC: bits VG5 to VG0.

CUE FLASH

In the present TV environment there is a lot of measured

information like ambient light and noise. This information

can be used to make an update of settings of the several

algorithms after a picture has changed. The cue flash

signal detects when a picture changes significantly. When

the picture content has changed, the I2C-bus bit CF is set

to logic 1 in the status register. After reading the status

register, bit CF is reset to logic 0. On the output pin CF the

cue flash information is present (active LOW) for only one

line in the vertical retrace part. This pin is configured as an

open drain output and therefore should be pulled up to the

5 V supply.

Spectral processor

In the spectral processor the luminance transfer is

controlled by smart peaking, colour dependent sharpness

and luminance transient improvement, defined by the

sharpness improvement processor. The colour transfer is

controlled by a colour transient improvement circuit; an

additional output is available to provide a SCAVEM circuit.

ADJUSTABLE CHROMINANCE DELAY

The colour vector processor drives a delay line for

correctingdelayerrors between the luminance input signal

and the chrominance input signals (U and V).

The chrominance delay can be adjusted in 6 steps of

12 ns (1fH) or 6 ns (2fH) by the I2C-bus bits CD2 to CD0.

It comprises three main processing units: the step

improvement processor, the contour processor and the

smart sharpness controller.

Transient improvement processor

The step improvement processor (see Fig.11) comprises

two main functions:

• MINMAX generator

• MINMAX fader.

The MINMAX generator utilizes all taps of an embedded

luminance delay line to calculate the minimum and

maximumenvelopeofallsignalsmomentarilystored in the

delay line. The MINMAX fader chooses between the

minimum and maximum envelopes, depending on the

polarity of a decision signal derived from the contour

processor. Figures 12, 13 and 14 show some waveforms

of the step improvement processor and illustrate that fast

transients result with this algorithm. The MINMAX

generator also outputs a signal that represents the

momentary envelope of the luminance input signal.

This envelope information is used by the smart sharpness

controller.

Line width control (also called aperture control) can be

performed by I2C-bus line width DAC: bits LW5 to LW0.

This control can be used to compensate for horizontal

geometryerrorscausedby the gamma, for blooming of the

spot of the CRT, or for compensating SCAVEM.

Contour processor

The contour processor comprises two contour generators

with different frequency characteristics. The contour

generator generates a second-order derivative of the

incoming luminance signal which is supplied to the smart

sharpness controller. In the smart sharpness controller,

this signal is added to the properly delayed original

luminance input signal, making up the peaking signal for

detail enhancement. The peaking path features a low

peaking frequency of 2 MHz (at 1fH), or a high peaking

frequency of 3 MHz (at 1fH), selectable by I2C-bus

bit CFS.

The contour generators utilize three taps of the embedded

luminance delay line. Figure 15 illustrates the normalized

frequency transfer of the filter.

TDA9178

SHARPNESS IMPROVEMENT PROCESSOR

The sharpness improvement processor increases the

slope of large luminance transients of vertical objects and

enhancestransientsofdetailsinnaturalscenesbycontour

correction.

1999 Sep 24 7

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

Smart sharpness controller

The smart sharpness controller (see Fig.16) is a fader

circuit that fades between peaked luminance and

step-improved luminance, controlled by the output of a

step discriminating device known as the step detector.

It also contains a variable coring level stage.

The step detector is basically a differentiator, so both

amplitude of the step and its slope add to the detection

criterion. The smart sharpness controller has four user

controls:

• Steepness control, performed by the I2C-bus DAC:

bits SP5 to SP0

• Peaking control, performed by the I2C-bus DAC:

bits PK5 to PK0

• Video dependent coring, switched on or switched off by

the I2C-bus bit VDC

• Coring level control, performed by the I2C-bus DAC:

bits CR5 to CR0.

Thesteepness setting controls the amountof steepness in

the edge-correction processing path.

The peaking setting controls the amount of contour

correction for proper detail enhancement. The envelope

signal generated by the step improvement processor

modulates the peaking setting in order to reduce the

amount of peaking for large sine wave excursions.

With video dependent coring, it is possible to have more

reduction of the peaking in the black parts of a scene than

inthewhiteparts,andthereforeautomaticallyreducing the

visibility of the background noise.

The coring setting controls the coring level in the peaking

path for rejection of high-frequency noise.

All four settings facilitate reduction of the impact of the

sharpness features, e.g. for noisy luminance signals.

COLOUR DEPENDENT SHARPNESS

The colour dependent sharpness circuit increases the

luminance sharpness in saturated red and magenta parts

of the screen. Because of the limited bandwidth of the

colour signals, there is no need to increase the high

frequenciesofthecolour signals. Instead, the details in the

luminance signal will be enhanced. In this circuit a limited

number of colours are enhanced (red and magenta).

Contrarytonormal peaking algorithm, extra gain is applied

for low frequencies (2 MHz at 1fH). This is needed,

because the information that is lacking below 2 MHz (at

1fH) is most important. In large coloured parts the normal

peaking is still active to enhance the fine details.

The smart peaking algorithm has been designed such that

the luminance output amplitude will never exceed 110% of

the luminance input signal amplitude. Therefore the

normal peaking range (12 dB) will be reduced at large

transients, and in case of colour dependent sharpness

there is even more reduction.

However, by setting bit OSP (Overrule Smart Peaking)

onecan undo the extra peaking reduction in case ofcolour

dependant sharpness. It must be emphasized that setting

OSP may lead to unwanted large luminance output

signals, for instance in details in red coloured objects.

COLOUR TRANSIENT IMPROVEMENT

The colour transient improvement circuit (see Fig.17)

increases the slope of the colour transients of vertical

objects. Each channel of the CTI circuit basically consists

oftwodelaycells:anelectronicpotentiometerandanedge

detector circuit that controls the wiper position of the

potentiometer.Normally the wiper of the potentiometerwill

be in position B (mid position), so passing the input

signal B to the output with a single delay. The control

signal is obtained by the signals A and C.

When an edge occurs the value of the control signal will

fade between +1 and −1 and finally will become zero

again. A control signal value of +1 fades the wiper in

position C, passing the two times delayed input signal to

the output. A control signal of −1 fades the wiper in

position A, so an undelayed input signal is passed to the

output. The result is an output signal which has steeper

edges than the input signal. Contrary to other existing

CTI algorithms, the transients remain time correct with

respect to the luminance signal, as the algorithm steepens

edges proportionally, without discontinuity.

SCAVEM

A luminance output is available for SCAVEM processing.

This luminance signal is not affected by the spectral

processing functions.

Colour vector processor

The colour processing part contains skin tone correction,

green enhancement and blue stretch. The colour vector

processing is dependent on the amplitude and sign of the

colour difference signals. Therefore, both the polarity and

the nominal amplitude of the colour difference signals are

relevant when using the colour vector processor facility.

TDA9178

1999 Sep 24 8

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

SKIN TONE CORRECTION

Skintones are very sensitive fortransmission (hue) errors,

because we have an absolute feeling for skin tones.

To make a picture look free of hue error, the goal is to

make sure that skin tones are put at a correct colour.

The dynamic skin tone correction circuit achieves this goal

by instantaneously and locally changing the hue of those

colours which are located in the area in the UV plane that

matches skin tones (see Fig.4).

The correction is dependent on luminance, saturation and

distance to the preferred axis and can be done towards

twodifferentangles.Thepreferredanglecanbechosenby

bit ASK in the I2C-bus settings. The settings are

123° (ASK = 0) and 117° (ASK = 1). The enclosed

correction area can be increasedto 140% with the I2C-bus

bit SSK(so-called:Size).Theencloseddetection‘angle’of

the correcting area can be increased to 160% with the

I2C-bus bit WSK (so-called: Width). The skin tone

correction can be switched on or off with the I2C-bus

bit DSK.

GREEN ENHANCEMENT

The green enhancement circuit (see Fig.5) is intended to

shift low saturated green colours towards more saturated

green colours. This shift is achieved by instantaneously

andlocallychangingthosecolourswhicharelocatedinthe

area in the UV plane that matches low saturated green.

The saturation shift is dependent on the luminance,

saturation and distance to the detection axis of 208°.

The direction of shift in the colour is fixed by hardware.

The amount of green enhancement can be increased to

160% by the I2C-bus bit GGR. The enclosed detection

‘angle’ of the correcting area can be increased to 160%

withthe I2C-busbit WGR (so-called: Width). The enclosed

correction area can be increasedto 140% with the I2C-bus

bit SGR (so-called: Size). The green enhancement can be

switched on or switched off with the I2C-bus bit DGR.

BLUE STRETCH

The blue stretch circuit (see Fig.6) is intended to shift

colours near white towards more blueish coloured white to

give a brighter impression. This shift is achieved by

instantaneously and locally changing those colours which

are located in the area in the UV plane that matches

colours near white. The shift is dependent on the

luminance and saturation. The direction of shift (towards

an angle of 330°) in the colour is fixed by hardware.

The amount of blue stretch can be increased to 160% by

the I2C-bus bit GBL.

Theenclosedcorrectionareacanbeincreasedto140%by

the I2C-bus bit SBL (so-called: Size). The blue stretch can

be switched on or off by the I2C-bus bit DBL.

SATURATION CORRECTION

The non-linear luminance processing done by the

histogram modification and variable gamma, influences

the colour reproduction; mainly the colour saturation.

Therefore, the U and V signals are linear processed for

saturation compensation.

Noise measuring

A video line which is supposed to be free from video

information(‘emptyline’)is used to measure the amount of

noise. The measured RMS value of the noise can be used

for reducing several features, by the I

such as luminance vector processing and spectral

processing. For the TDA9178 the empty line is chosen

three lines after recognition of the vertical blanking from

the sandcastle pulse input. Figures 7, 8, 9 and 10 show

the measurement locations for different broadcast norms.

The noise detector is capable of measuring the

signal-to-noise ratio between −45 and −20 dB. The output

scale runs linearly with dB. The noise samples are

averagedforover20 fields to reduce the fluctuations in the

measurement process. It is obvious, that for signal

sources (like VCR in still picture mode) that re-insert the

levels of the retrace part, the measurement is not reliable

(see Section “Feature mode detector”). The result of the

averaging process will update the contents of the I

register: bits ND5 to ND0 at a rate of

frequency. If a register access conflict occurs, the data of

the noise register is made invalid by setting the flag bit DV

(Data Valid) to zero.

Feature mode detector

A detector is available for detecting signal sources (like

VCR in still picture mode) that re-inserted the levels of the

retrace part. For this kind of signals the noise

measurement of the TDA9178 is not reliable, but this

detector sets bit FM in the ND-register to logic 1.

For normal video signals bit FM is set to logic 0.

This circuit measures transients (like synchronization

pulses) on the luminance input during the internal V-pulse.

Thefeaturemodedetector is setting bit FM to logic 1 when

no transients are present during 2 lines in the vertical

retrace part over 3 fields (like the synchronization pulses).

TDA9178

2

C-bus interface,

2

1

⁄32 of the field

C-bus

1999 Sep 24 9

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

vector-, colour vector- and spectral processor

Successive approximation ADC

Pins ADEXT1, ADEXT2 and ADEXT3 are connected to a

6-bit successive approximation ADC via a multiplexer.

The multiplexertogglesbetweentheinputswitheachfield.

At each field flyback, a conversion is started for two of the

three inputs and the result is stored in the corresponding

bus register ADEXT1, ADEXT2 or ADEXT3. The input pin

ADEXT1 is updated every field, while input fields

ADEXT2 and ADEXT3 are updated once in two

consecutive fields (see Figs 7, 8, 9 and 10). Once in

32 fields the ADEXT2 input is not updated, because then

the noise measurement is updated.

In this way, any slow varying analog signal can be given

access to the I2C-bus. If a register access conflict occurs,

the data of that register is made invalid by setting the flag

bit DV (Data Valid) to zero.

Smart noise control

With the help of the internal noise detector and a

user-preferred noise algorithm, the user can make a fully

automatic I2C-bus feature reduction, briefly called ‘Smart

Noise Control’.

I2C-bus

The I2C-bus is always instandby mode and responds on a

properly addressed command. Bit PDD (Power-Down

Detected) in the status register is set each time an

interruptionofthe power supply occurs and is reset only by

reading the status register. A 3-bit identification code can

also be read from the status register, which code can be

used to automatically configure the application by

software.

The input control registers can be written sequentially by

the I2C-bus by the embedded automatic subaddress

increment feature or by addressing them directly.

The output control functions cannot be addressed

separately. Reading out the output control functions

always starts at subaddress 00H and all subsequent

words are read out by the automatic subaddress

increment procedure.

The bits in the I2C-bus are preset to logic 0 at power-on

except for bits AMS and VG5: therefore the TDA9178 is in

1.0 V luminance signal range and the variable gamma is

set to 20H (gamma correction 0%).

TDA9178

Demonstration mode

By the I2C-bus bit DEM all the picture improvement

features can be demonstrated in one picture. By setting

bit DEM to logic 1, all the features selected bythe user are

active for 5 s in 1fH mode (in 2fH mode: 2.5 s), and for

another 5 s in 1fH mode (in 2fH mode: 2.5 s) all features

selected are turned off (then the TDA9178 is ‘transparent’

to the incoming signal).

Internal window

To determine the histogram levels and the black offset the

TDA9178 performs several measurements. An internally

defined window serves to exclude parts in the scene like

‘subtitling’ or ‘logos’. The internal window can be regarded

as a weighting function which has a value of one within a

square near the centre of the screen and which gradually

decreases to zero towards the edges.

When bit WLB (Window Letter Box) is made logic 1, the

2

height of the window is reduced by a factor of

This prevents the contribution of the black bars above and

below a 16 : 9 scene to the measurements.

⁄3.

2

I

C-BUS SPECIFICATION

The slave address of the IC is given in Table “Slave

address”. If pin ADR of the TDA9178 is connected to

ground, the I2C-bus address is 40H; if pin ADR is

connected to pin DEC

The circuit operates on clock frequencies up to 400 kHz.

Slave address

A6 A5 A4 A3 A2 A1 A0 R/W

ADR 1 ADR 0 0 0 0 X

Auto-increment mode is available for subaddresses.

, the I2C-bus address is E0H.

DIG

1999 Sep 24 10

Philips Semiconductors Preliminary specification

YUV one chip picture improvement based on luminance

TDA9178

vector-, colour vector- and spectral processor

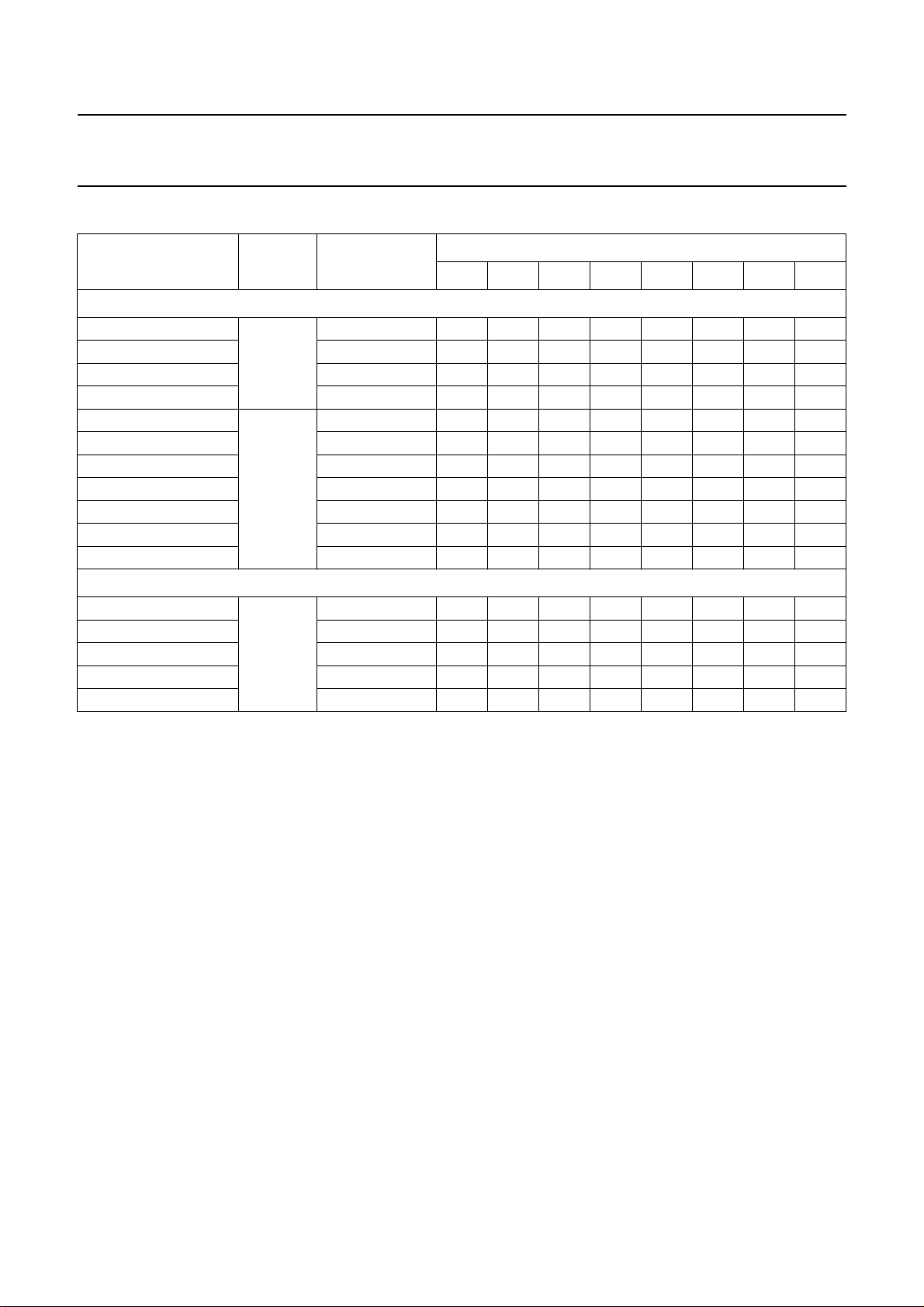

Control functions

FUNCTIONS TYPE SUBADDRESS

D7 D6 D5 D4 D3 D2 D1 D0

Inputs

Control 1 REG 00 DEM VDC WLB FHS CFS LDH 0 AMS

Control 2 01 0 0 OSP WPO 0 CD2 CD1 CD0

Control 3 02 SGR WGR GGR DGR SSK WSK ASK DSK

Control 4 03 0 0 BON CTI CDS SBL GBL DBL

Adaptive black stretch DAC 04 0 0 BT5 BT4 BT3 BT2 BT1 BT0

Non-linearity amplifier 05 0 0 NL5 NL4 NL3 NL2 NL1 NL0

Variable gamma 06 0 0 VG5 VG4 VG3 VG2 VG1 VG0

Peaking 07 0 0 PK5 PK4 PK3 PK2 PK1 PK0

Steepness 08 0 0 SP5 SP4 SP3 SP2 SP1 SP0

Coring 09 0 0 CR5 CR4 CR3 CR2 CR1 CR0

Line width 0A 0 0 LW5 LW4 LW3 LW2 LW1 LW0

Outputs

Status REG 00 X X X CF ID2 ID1 ID0 PDD

Noise detection 01 FM DV ND5 ND4 ND3 ND2 ND1 ND0

ADEXT1 (output) 02 X DV AD5 AD4 AD3 AD2 AD1 AD0

ADEXT2 (output) 03 X DV AD5 AD4 AD3 AD2 AD1 AD0

ADEXT3 (output) 04 X DV AD5 AD4 AD3 AD2 AD1 AD0

DATA BYTE

1999 Sep 24 11

Loading...

Loading...