INTEGRATED CIRCUITS

DATA SH EET

TDA9177

YUV transient improvement

processor

Preliminary specification

File under Integrated Circuits, IC02

1996 Jun 28

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

FEATURES

• Can be used in 1fH and 2fH applications

• Luminance step improvement

• Line width control

• Smart peaking for detail enhancement

• Embedded feature reduction facility for smart noise

control

• Compensating chrominance delay

• YUV interface

• Two additional pins for access to 6-bit ADC and I2C-bus

2

• Versatile I

C-bus and pin control for user adjustments.

In combination with the TDA9170A, it builds a high

performance and intelligent picture improvement solution.

The sharpness processor provides 1D luminance step

improvement and detail enhancement by smart peaking,

suitable for both 1f

and 2fH applications. The TDA9177

H

can be used as a cost effective alternative to (but also in

combination with) Scan Velocity Modulation (SVM).

GENERAL DESCRIPTION

The TDA9177 is an I

2

C-bus controlled sharpness

An on-board 6-bit Analog-to-Digital Converter (ADC) can

be used for interfacing two analog, low frequency voltage

signals to the I2C-bus.

improvement IC with additional inputs for 6-bit

analog-to-digital conversion to facilitate additional

parameter measurement (e.g. ambient light control).

The supply voltage is 8 V. The TDA9177 is mounted in a

24-pin SDIP envelope.

It should preferably be used in front of an RGB video signal

processor with YUV interface.

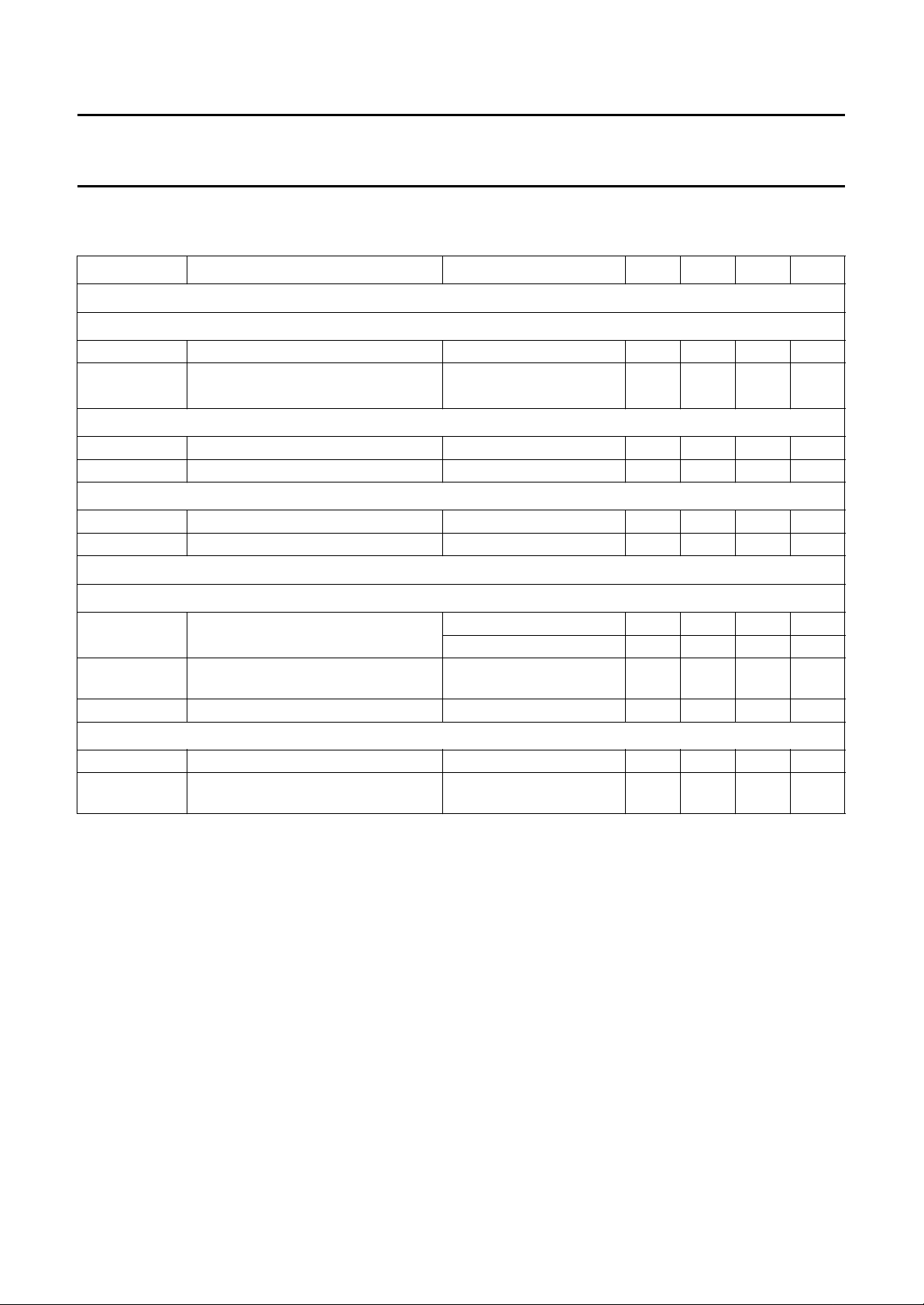

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

V

i(Y)

supply voltage 7.2 8.0 8.8 V

luminance input voltage AMS = LOW − 0.315 0.42 V

AMS = HIGH − 1.0 1.33 V

V

i(UV)

V

FS(ADC)

V

ref

UV input voltage −−1.9 V

full scale ADC input voltage − 0.5V

− V

ref

reference voltage 3.90 4.00 4.10 V

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGE

TDA9177 SDIP24 plastic shrink dual in-line package; 24 leads (400 mil) SOT234-1

1996 Jun 28 2

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

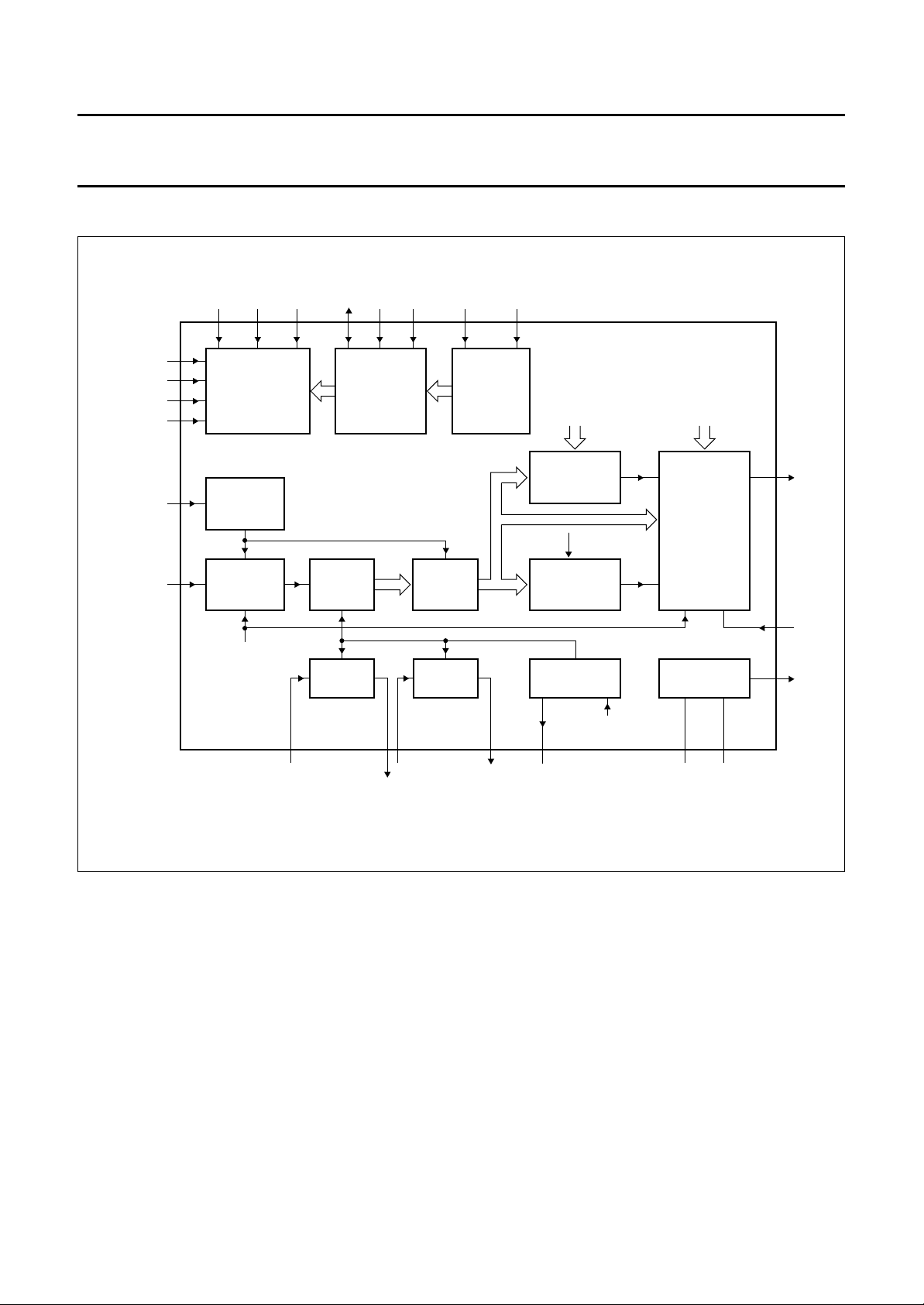

BLOCK DIAGRAM

handbook, full pagewidth

STEEP

LWC

COR

PEAK

SANDCASTLE

input

YIN

AMS CFS FHS

14 8 17

22

4

PIN-TO-I

2

INTERFACE

11

1

SANDCASTLE

DETECTOR

BLACK

5

INSERTION

CLAMP

amplitude

selection

2

C-BUS

SDA

13

CONTROLLER

DELAY

DELAY DELAY IPTAT

UIN

ADR

SCL

12

2

I

C-BUS

VIN VOUT R

UOUT

ADEXT1

6

CLAMPS

3

6-BIT

ADC

ADEXT2

10

line width

STEP

IMPROVEMENT

PROCESSOR

contour filter

selection

CONTOUR

PROCESSOR

line frequency

selection

24918 167

ext

TDA9177

steepness coring peaking

SMART

SHARPNESS

CONTROLLER

BANDGAP

21 19

VCCGND

20

YOUT

15

SNC

23

V

ref

MBH229

Fig.1 Block diagram.

1996 Jun 28 3

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

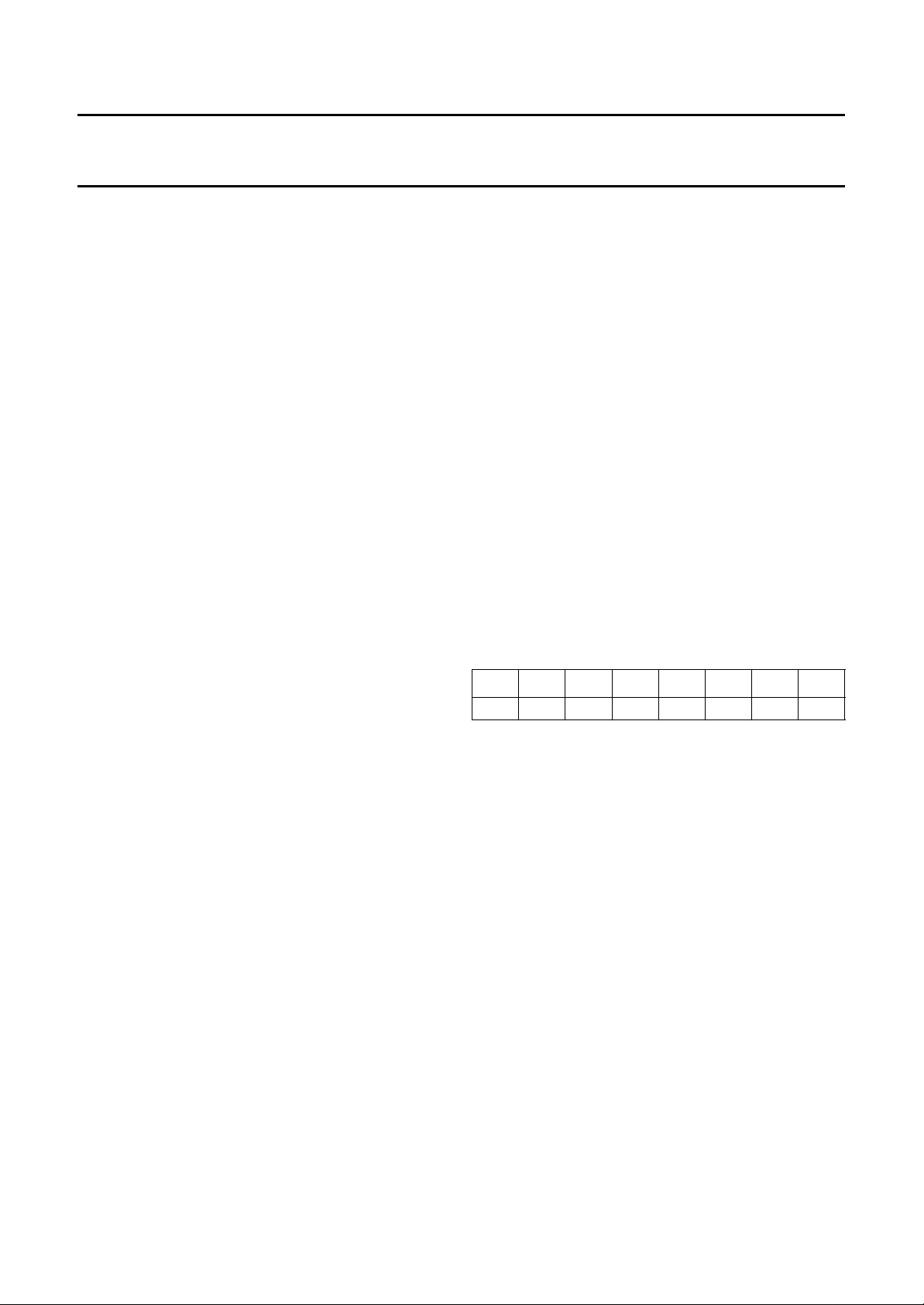

PINNING

SYMBOL PIN DESCRIPTION

SANDCASTLE 1 sandcastle input

COR 2 coring level input

ADEXT1 3 ADC input 1

LWC 4 line width control input

YIN 5 luminance input

2

ADR 6 I

C-bus address input

UIN 7 colour U input

CFS 8 contour filter select input

VIN 9 colour V input

ADEXT2 10 ADC input 2

PEAK 11 peaking amplitude input

2

SCL 12 serial clock input (I

C-bus)

SDA 13 serial data input/output

2

C-bus)

(I

AMS 14 amplitude select input

SNC 15 smart noise control input

VOUT 16 colour V output

FHS 17 line frequency select input

UOUT 18 colour U output

GND 19 system ground

YOUT 20 luminance output

V

CC

21 supply voltage

STEEP 22 steepness control input

V

ref

R

ext

23 reference voltage output

24 resistor reference

handbook, halfpage

SANDCASTLE

1

COR

2

ADEXT1

LWC

YIN

ADR

3

4

5

6

TDA9177

UIN

7

8

CFS

VIN

9

PEAK

SCL

10

11

12

ADEXT2

Fig.2 Pin configuration.

MBH228

24

23

22

21

20

19

18

17

16

15

14

13

R

ext

V

ref

STEEP

V

CC

YOUT

GND

UOUT

FHS

VOUT

SNC

AMS

SDA

1996 Jun 28 4

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

FUNCTIONAL DESCRIPTION

Y-input selection and amplification

The dynamic range of the luminance input amplifier and

output amplifier can be switched between 0.315 V and

1.0 V typically (excluding sync), either externally

(pin AMS) or by I

2

C-bus (bit AMS of the control register).

Amplitudes outside the corresponding maximum specified

range will be clipped smoothly. The sync part is processed

transparently to the output, independently of the feature

settings. The input is clamped during the HIGH period of

the CLP, defined by the sandcastle reference, and should

be DC-decoupled with an external capacitor. During the

clamp pulse, an artificial black level is inserted in the input

signal to correctly preset the internal circuitry.

The input amplifier drives a delay line of four delay

sections, which form the core of the sharpness

improvement processor.

Sharpness improvement processor

The sharpness improvement processor increases the

slope of large luminance transients of vertical objects and

enhances transients of details in natural scenes by contour

correction. It comprises three main processing units, these

being the step improvement processor, the contour

processor and the smart sharpness controller.

TEP IMPROVEMENT PROCESSOR

S

The step improvement processor (see Fig.9) comprises

two main functions:

1. the MINMAX generator

2. the MINMAX fader.

The MINMAX generator utilizes 5 taps of an embedded

luminance delay line to calculate the minimum and

maximum envelope of all signals momentarily stored in the

delay line. The MINMAX fader chooses between the

minimum and maximum envelopes, depending on the

polarity of a decision signal derived from the contour

processor. Figures 4, 5 and 6 show some waveforms of

the step improvement processor and illustrate that fast

transients result with this algorithm. The MINMAX

generator also outputs a signal that represents the

momentary envelope of the luminance input signal.

This envelope information is used by the smart sharpness

controller.

Limited line width control (also called aperture control) can

be performed externally (pin 4, LWC) or by I2C-bus

(LW-DAC). Line width control can be used to compensate

for horizontal geometry because of the gamma or

blooming of the spot of the CRT.

HE CONTOUR PROCESSOR

T

The contour processor comprises two contour generators

with different frequency characteristics. The contour

generator generates a second-order derivative of the

incoming luminance signal and is used both as a decision

signal for the step improvement processor and as a

luminance correction signal for the smart sharpness

controller. In the smart sharpness controller, this

correction signal is added to the proper delayed original

luminance input signal, making up the peaking signal for

detail enhancement. The peaking path is allowed to select

either the narrow- or wide-peaked contour generators

2

either externally (pin 8, CFS) or by I

C-bus (bit CFS in the

control register). The step improvement circuitry always

selects the wide-peaked contour filter.

The contour generators utilize 3 taps (narrow band) or

5 taps (broad band) of the embedded luminance delay

lines. Figures 11 and 12 illustrate the normalized

frequency transfer of both the narrow and wide contour

filters.

MART SHARPNESS CONTROLLER

S

The smart sharpness controller (see Fig.10) is a fader

circuit that fades between peaked luminance and

step-improved luminance, defined by the output of a step

discriminating device known as the step detector. It also

contains a variable coring level stage.

The step detector behaves like a band-pass filter, so both

amplitude of the step and its slope add to the detection

criterion. The smart sharpness controller has four user

controls:

1. Steepness control

2. Peaking control

3. Coring level control

4. Smart Noise control.

Control settings can be performed either by the I2C-bus or

externally by pin, depending on the status of the I2C-bus

bit STB.

The steepness setting controls the amount of steepness in

the edge-correction processing path. The peaking setting

controls the amount of contour correction for proper detail

enhancement.

The envelope signal generated by the step improvement

processor modulates the peaking setting in order to

reduce the amount of peaking for large sine excursions.

1996 Jun 28 5

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

The coring setting controls the coring level in the peaking

path for rejection of high-frequency noise. All three

settings facilitate reduction of the impact of the sharpness

features, e.g. for noisy luminance signals.

An external noise detector and a user-preferred noise

algorithm are needed to make a fully automatic I2C-bus

controlled smart sharpness control.

An on-board, hard-wired smart sharpness algorithm can

be executed by driving pin SNC with the output of an

external noise detector. This pin, however, is active both in

I2C-bus and pin mode. Figures 13 and 14 illustrate the

impact of the noise control voltage at pin SNC on the user

settings.

Figure 15 shows the relationship between the feature

settings STEEP, COR, PEAK, LWC and their

corresponding pin voltages.

Chrominance compensation

The chrominance delay lines compensate for the delay of

the luminance signal in the step improvement processor,

to ensure a correct colour fit. No delay compensation will

be performed in the chrominance path for line-width

corrections in the luminance path.

Successive approximation ADC

Pins ADEXT1 and ADEXT2 are connected to a 6-bit

successive approximation ADC, via a multiplexer.

The multiplexer toggles between the inputs with each field.

2

I

C-bus

At power up, the bit STB (standby) in the control register is

reset, to leave control to the pins. However, the I2C-bus is

at standby and responds if properly addressed. By setting

STB to logic 1, the control of all features is instead left to

the I2C-bus registers. The PDD bit (Power Down Detected)

in the status register is set each time an interruption of the

supply power occurs and is reset only by reading the

status register. A 3-bit identification code can also be read

from the status register, which can be used to

automatically configure the application by software.

The input control registers can be written sequentially by

the I2C-bus by the embedded automatic subaddress

increment feature or by addressing it directly. The output

control functions cannot be addressed separately.

Reading out the output control functions always starts at

subaddress 00 and all subsequent words are read out by

the automatic subaddress increment procedure. The I2C

address is 40H if pin 6 (ADR) is connected to ground and

E0H if pin 6 (ADR) is connected to pin 23 (V

2

C-bus specification

I

ref

).

Slave address

A6 A5 A4 A3 A2 A1 A0 R/W

ADR1ADR0000X

Auto-increment mode available for subaddresses.

For each field flyback, a conversion is started for either of

the two inputs and the result is stored in the corresponding

bus register, ADEXT1 or ADEXT2.

In this way, any analog, slowly varying signal can be given

2

access to the I

C-bus. If a register access conflict occurs,

the data of that register is made invalid by setting the flag

bit DV (Data Valid) to zero.

1996 Jun 28 6

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

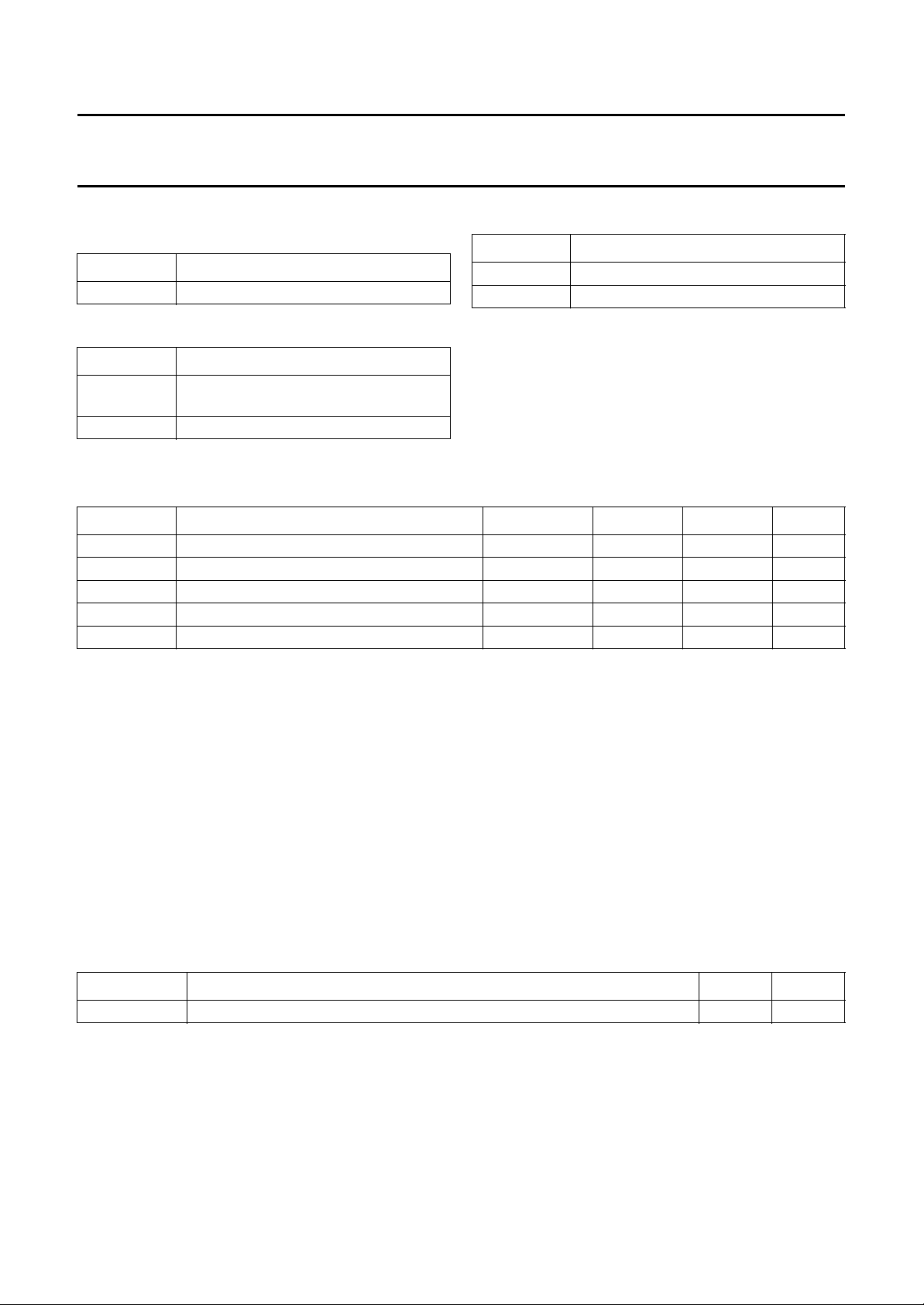

Control functions

FUNCTIONS TYPE SUBADDRESS

DATA BYTE

D7 D6 D5 D4 D3 D2 D1 D0

Inputs

Control REG 00 XXXXCFSFHSAMSSTB

Peaking DAC 01 X X PK5 PK4 PK3 PK2 PK1 PK0

Steepness DAC 02 X X SP5 SP4 SP3 SP2 SP1 SP0

Coring DAC 03 X X CR5 CR4 CR3 CR2 CR1 CR0

Line width DAC 04 X X LW5 LW4 LW3 LW2 LW1 LW0

Outputs

Status REG 00 0000ID2ID1ID0PDD

ADEXT1 (output) REG 01 0 DV AD5 AD4 AD3 AD2 AD1 AD0

ADEXT2 (output) REG 02 0 DV AD5 AD4 AD3 AD2 AD1 AD0

INPUT SIGNALS

Table 1 Address selection

ADR FUNCTION

2

0I

1I

C address is 40H

2

C address is E0H

Table 6 Peaking amplitude

PK5 to PK0 FUNCTION

000000 0%

111111 100%

Table 7 Steepness correction

Table 2 Standby

STB FUNCTION

0 pin mode

2

1I

C-bus mode

Table 3 Amplitude selection

AMS FUNCTION

0 0.315 V luminance

1 1.0 V luminance

Table 4 Line frequency selection

FHS FUNCTION

01f

12f

H

H

Table 5 Contour filter selection

CFS FUNCTION

0 narrow contour filter

1 wide contour filter

SP5 to SP0 FUNCTION

000000 0%

111111 100%

Table 8 Coring level

CR5 to CR0 FUNCTION

000000 0%

111111 100%

Table 9 Line width correction

LW5 to LW0 FUNCTION

000000 0%

111111 100%

O

UTPUT SIGNALS

Table 10 Power Down Detection (PDD)

PDD FUNCTION

0 no power down detected since last read

action

1 power down detected

1996 Jun 28 7

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

Table 11 Identification

(version number or derivative type)

ID2 to ID0 FUNCTION

000 TDA9177/N1

Table 13 Bits AD5 to AD0

AD5 to AD0 FUNCTION

000000B 0 V

111111B 0.5V

ref

Table 12 Data valid of ADC registers

DV FUNCTION

0 data not valid because of possible

register access collision

1 data valid

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

V

i

V

o

T

stg

T

amb

supply voltage −0.5 +8.8 V

input voltage on any input −0.5 VCC+ 0.5 V

output voltage of any output −0.5 VCC+ 0.5 V

storage temperature −55 +150 °C

operating ambient temperature −10 +70 °C

QUALITY SPECIFICATION

Quality level in accordance with

“Quality reference Handbook”

“SNW-FQ-611 part E”

. The numbers of the quality specification can be found in the

. The handbook can be ordered using the code 9397 750 00192.

All pins are protected against ESD by means of internal clamping diodes. The protection circuit meets the specification:

Human body model (100 pF,1500 Ω): All pins >3000 V.

Machine model (200 pF, 0 Ω): All pins >300 V.

Latch-up:

At an ambient temperature of 70 °C, all pins meet the specification:

I

> 100 mA or V

trigger

I

< −100 mA or V

trigger

pin

pin

> 1.5V

< −0.5V

CC(max)

CC(max)

THERMAL CHARACTERISTICS

SYMBOL PARAMETER VALUE UNIT

R

th j-a

thermal resistance from junction to ambient in free air <59 K/W

1996 Jun 28 8

Philips Semiconductors Preliminary specification

YUV transient improvement processor TDA9177

CHARACTERISTICS

V

=8V; R

CC

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supplies

M

AIN SUPPLY V

V

CC

I

CC

REFERENCE SUPPLY V

V

ref

I

L(max)

RESISTOR REFERENCE R

V

Rref

R

ref

Luminance input/output selection

=10kΩ±2%; T

ref

(PIN 21)

CC

=25°C; unless otherwise specified.

amb

supply voltage 7.2 8.0 8.8 V

supply current 1fH mode − 40 − mA

mode − 45 − mA

2f

H

(PIN 23)

ref

reference supply voltage 3.90 4.00 4.10 V

maximum load current 1.0 −−mA

(PIN 24)

ext

resistor supply voltage − 2 − V

resistor value − 10 − kΩ

L

UMINANCE INPUT YIN (PIN 5)

V

i(Y)

luminance input voltage AMS = LOW − 0.315 0.42 V

AMS = HIGH − 1.0 1.33 V

V

i(Yclamp)

luminance input voltage level during

clamping

I

ib(Y)

luminance input bias current no clamp −−0.1 µA

LUMINANCE INPUT VOLTAGE RANGE SELECTION AMS (PIN 14); note 1

V

AMSL

V

AMSH

input voltage for low luminance range −−0.5 V

input voltage for high luminance

range

− 4.0 − V

3.5 − 5.5 V

1996 Jun 28 9

Loading...

Loading...