Philips TDA9150B Datasheet

INTEGRATED CIRCUITS

DATA SH EET

TDA9150B

Programmable deflection controller

Preliminary specification

File under Integrated Circuits, IC02

Philips Semiconductors

July 1994

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

FEATURES

General

• 6.75, 13.5 and 27 MHz clock frequency

• Few external components

• Synchronous logic

2

• I

C-bus controlled

• Easy interfacing

• Low power

• ESD protection

• Flash detection with restart

• Two-level sandcastle pulse.

Vertical deflection

Horizontal deflection

• Phase 2 loop with low jitter

• Internal loop filter

• Dual slicer horizontal flyback input

2

• Soft start by I

C-bus

• Over voltage protection/detection with selection and

status bit.

• Self adaptive 16-bit precision vertical scan

• DC coupled deflection to prevent picture bounce

• Programmable fixed compression to 75%

• S-correction can be preset

• S-correction setting independent of the field frequency

• Differential output for high DC stability

• Current source outputs for high EMC immunity

• Programmable de-interlace phase.

East-West correction

• DC coupled EW correction to prevent picture bounce

• 2nd and 4th order geometry correction can be preset

• Trapezium correction

• Geometry correction settings are independent of field

frequency

• Self adaptive Bult generator prevents ringing of the

horizontal deflection

• Current source output for high EMC immunity.

ORDERING INFORMATION

EHT correction

• Input selection between aquadag or EHT bleeder

• Internal filter.

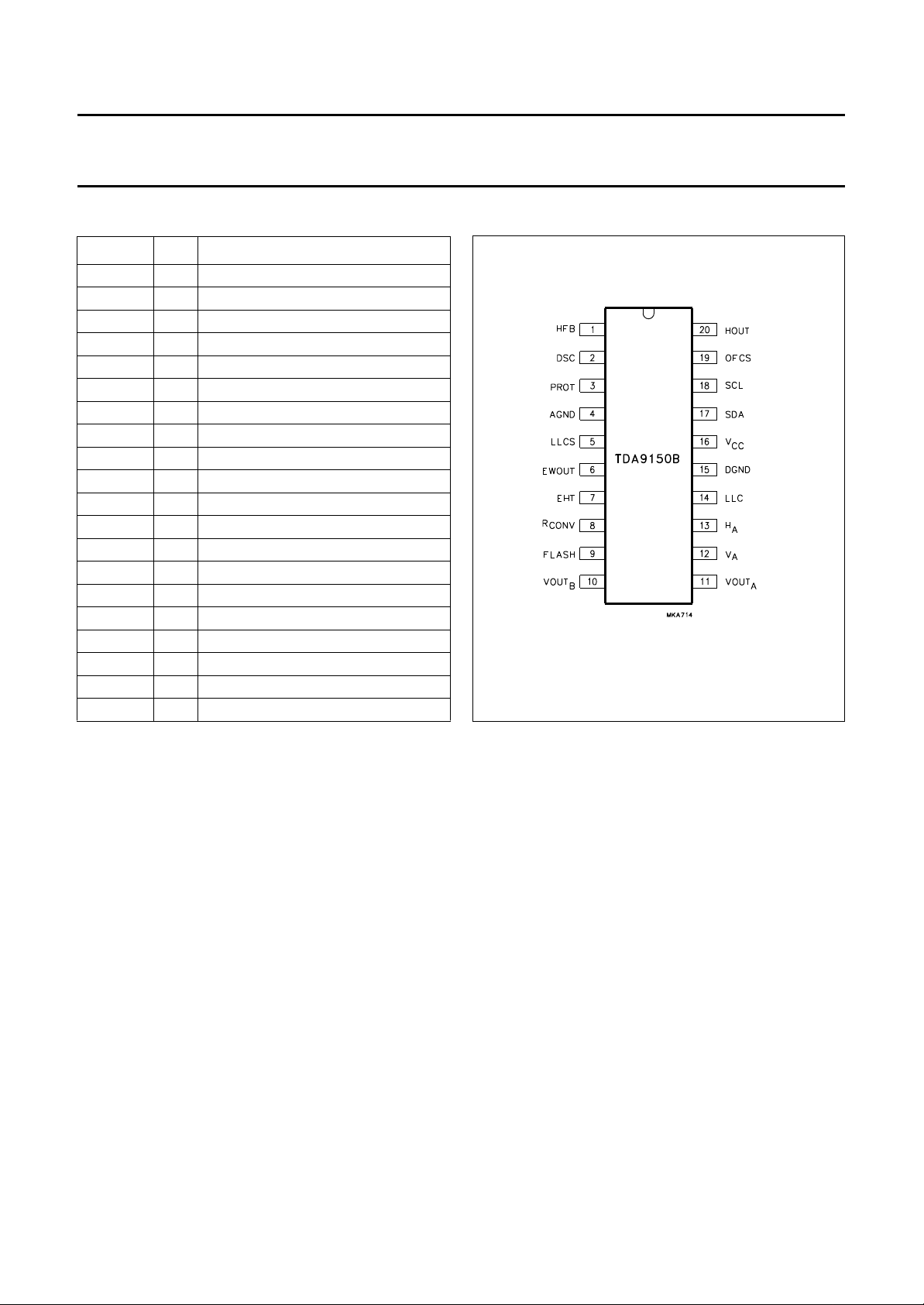

GENERAL DESCRIPTION

The TDA9150B is a programmable deflection controller

contained in a 20-pin DIP package and constructed using

BIMOS technology. This high performance

synchronization and DC deflection processor has been

especially designed for use in both digital and analog

based TV receivers and monitors, and serves horizontal

and vertical deflection functions for all TV standards. The

TDA9150B uses a line-locked clock at 6.75, 13.5 or

27 MHz, depending on the line frequency and application,

and requires only a few external components. The device

is self-adaptive for a number of functions and is fully

2

programmable via the I

C-bus.

TYPE NUMBER

PINS PIN POSITION MATERIAL CODE

TDA9150B 20 DIP plastic SOT146-1

July 1994 2

PACKAGE

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

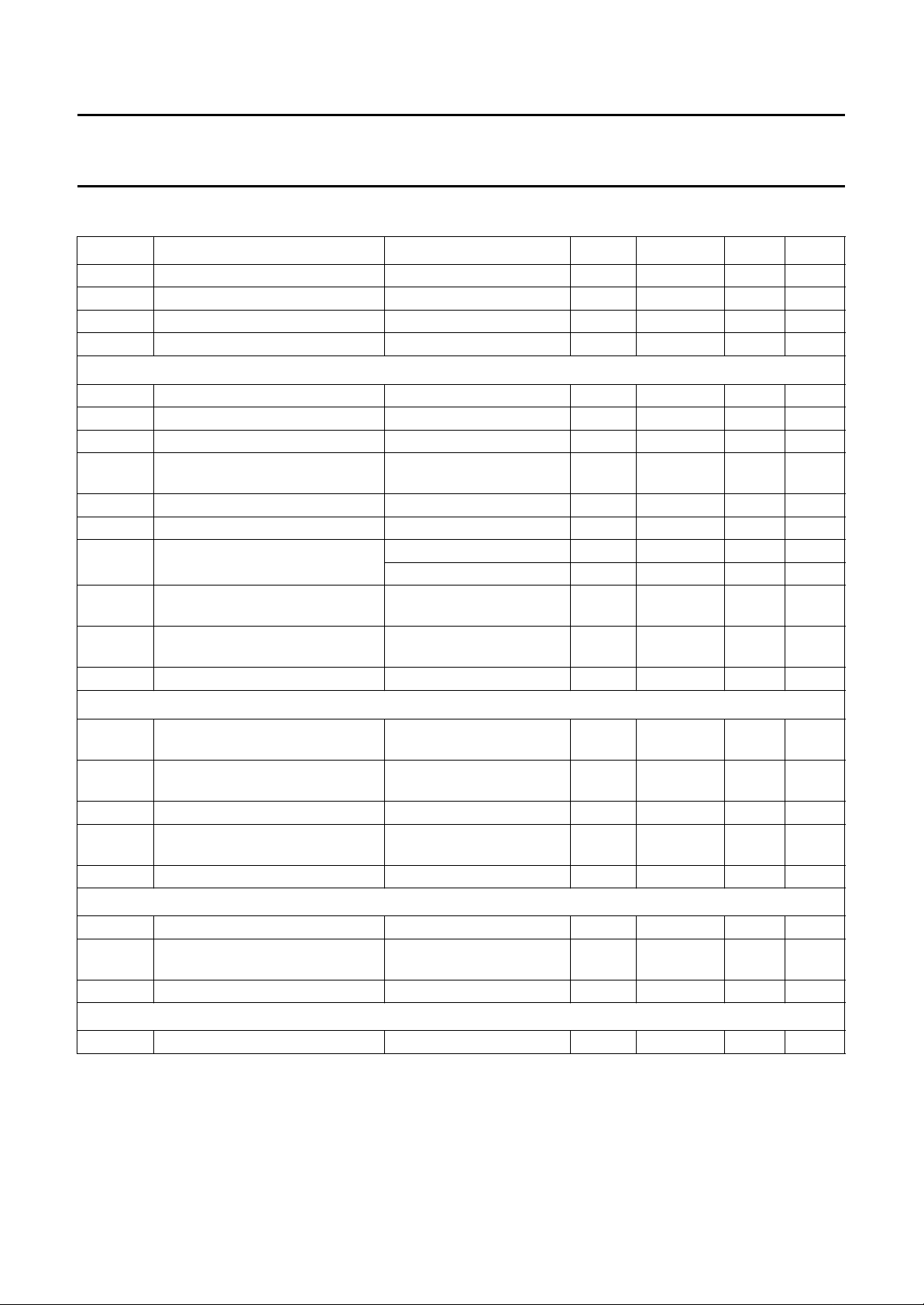

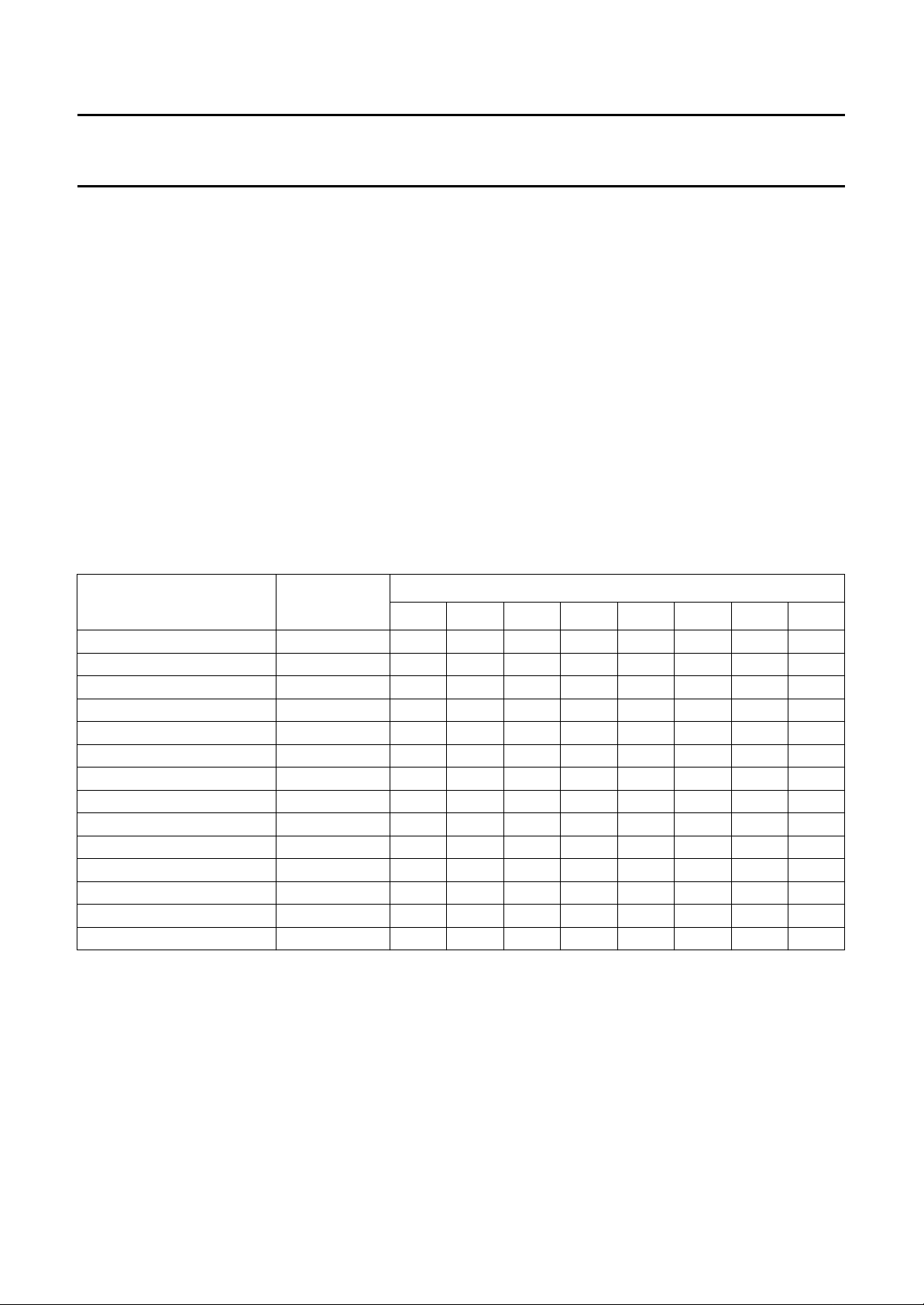

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

I

CC

P

tot

T

amb

Inputs

V

14

V

13

V

12

V

5

V

18

V

17

V

PSL

V

1

V

3

V

9

Outputs

V

20

I

11−I10(M)

V

10,11

I

6(M)

V

6

SANDCASTLE OUTPUT LEVELS (DSC)

V

2

V

2

V

2

HORIZONTAL OFF-CENTRE SHIFT (OFCS)

V

19

supply voltage 7.2 8.0 8.8 V

supply current f

= 6.75 MHz − 27 − mA

clk

total power dissipation − 220 − mW

operating ambient temperature −25 − +70 °C

line-locked clock (LLC) logic level − TTL −

horizontal sync (HA) logic level − TTL −

vertical sync (VA) logic level − TTL −

line-locked clock select (LLCS)

note 1 − CMOS 5 V −

logic level

serial clock (SCL) logic level − CMOS 5 V −

serial data input (SDA) logic level − CMOS 5 V −

horizontal flyback (HFB) phase

slicing level

horizontal flyback (HFB) blanking

FBL = logic 0 − 3.9 − V

FBL = logic 1 − 1.3 − V

− 100 − mV

slicing level

over voltage protection (PROT)

− 3.9 − V

level

EHT flash detection level − 1.5 − V

horizontal output (HOUT) voltage

I20 = 10 mA −− 0.5 V

(open drain)

vertical differential (VOUT

output current (peak value)

A, B

)

vertical amplitude = 100%;

I8 = −120 µA; note 2

440 475 510 µA

vertical output voltage 0 − 3.9 V

EW (EWOUT) total output current

I8 = −120 µA −− 930 µA

(peak value)

EW (EWOUT) output voltage 1.0 − 5.5 V

base voltage level − 0.5 − V

horizontal and vertical blanking

− 2.5 − V

voltage level

video clamping voltage level − 4.5 − V

output voltage I19 = 2 mA 0 − V

CC

V

Notes

1. Hard wired to ground or V

is highly recommended.

CC

2. DAC values: vertical amplitude = 31; EHT = 0; SHIFT = 3; SCOR = 0.

July 1994 3

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

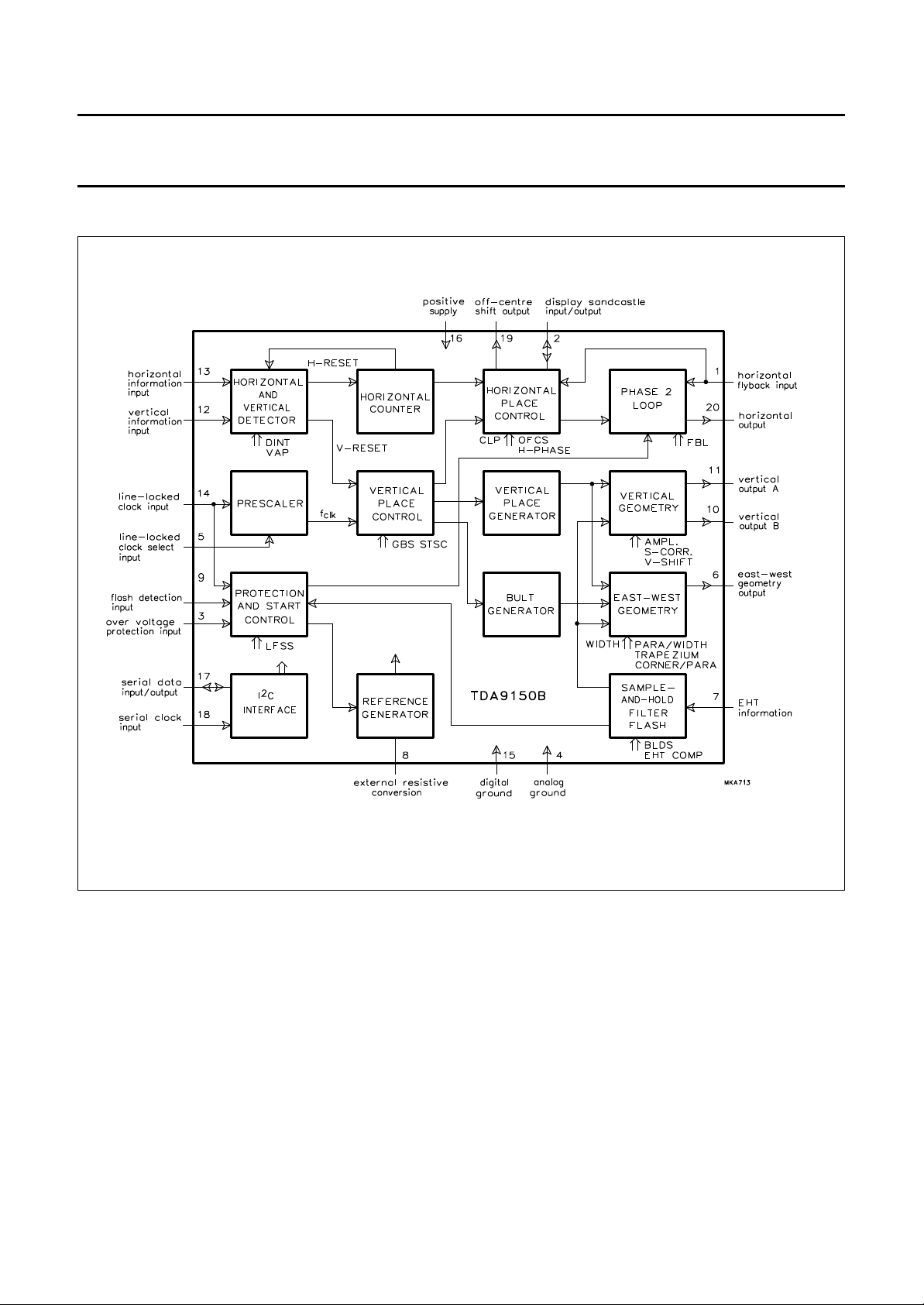

BLOCK DIAGRAM

Fig.1 Block diagram.

July 1994 4

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

PINNING

SYMBOL PIN DESCRIPTION

HFB 1 horizontal flyback input

DSC 2 display sandcastle input/output

PROT 3 over voltage protection input

AGND 4 analog ground

LLCS 5 line-locked clock selection input

EWOUT 6 east-west geometry output

EHT 7 EHT compensation

R

CONV

FLASH 9 flash detection input

VOUT

B

VOUT

A

V

A

H

A

LLC 14 line-locked clock input

DGND 15 digital ground

V

CC

SDA 17 serial data input/output

SCL 18 serial clock input

OFCS 19 off-centre shift output

HOUT 20 horizontal output

8 external resistive conversion

10 vertical output B

11 vertical output A

12 vertical information input

13 horizontal information input

16 supply input (+8 V)

Fig.2 Pin configuration.

FUNCTIONAL DESCRIPTION

Input signals (pins 12, 13, 14, 17 and 18)

The TDA9150B requires three signals for minimum

operation (apart from the supply). These signals are the

line-locked clock (LLC) and the two I

2

C-bus signals (SDA

and SCL). Without the LLC the device will not operate

because the internal synchronous logic uses the LLC as

the system clock.

I2C-bus transmissions are required to enable the device to

perform its required tasks. Once started the IC will use the

HA and/or VA inputs for synchronization. If the LLC is not

present the outputs will be switched off and all operations

discarded (if the LLC is not present the line drive will be

inhibited within 2 µs, the EW output current will drop to

zero and the vertical output current will drop to 20% of the

adjusted value within 100 µs). The SDA and SCL inputs

meet the I

2

C-bus specification, the other three inputs are

TTL compatible.

The LLC frequency can be divided-by-two internally by

connecting LLCS (pin 5) to ground thereby enabling the

prescaler.

The LLC timing is given in the Chapter “Characteristics”.

July 1994 5

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

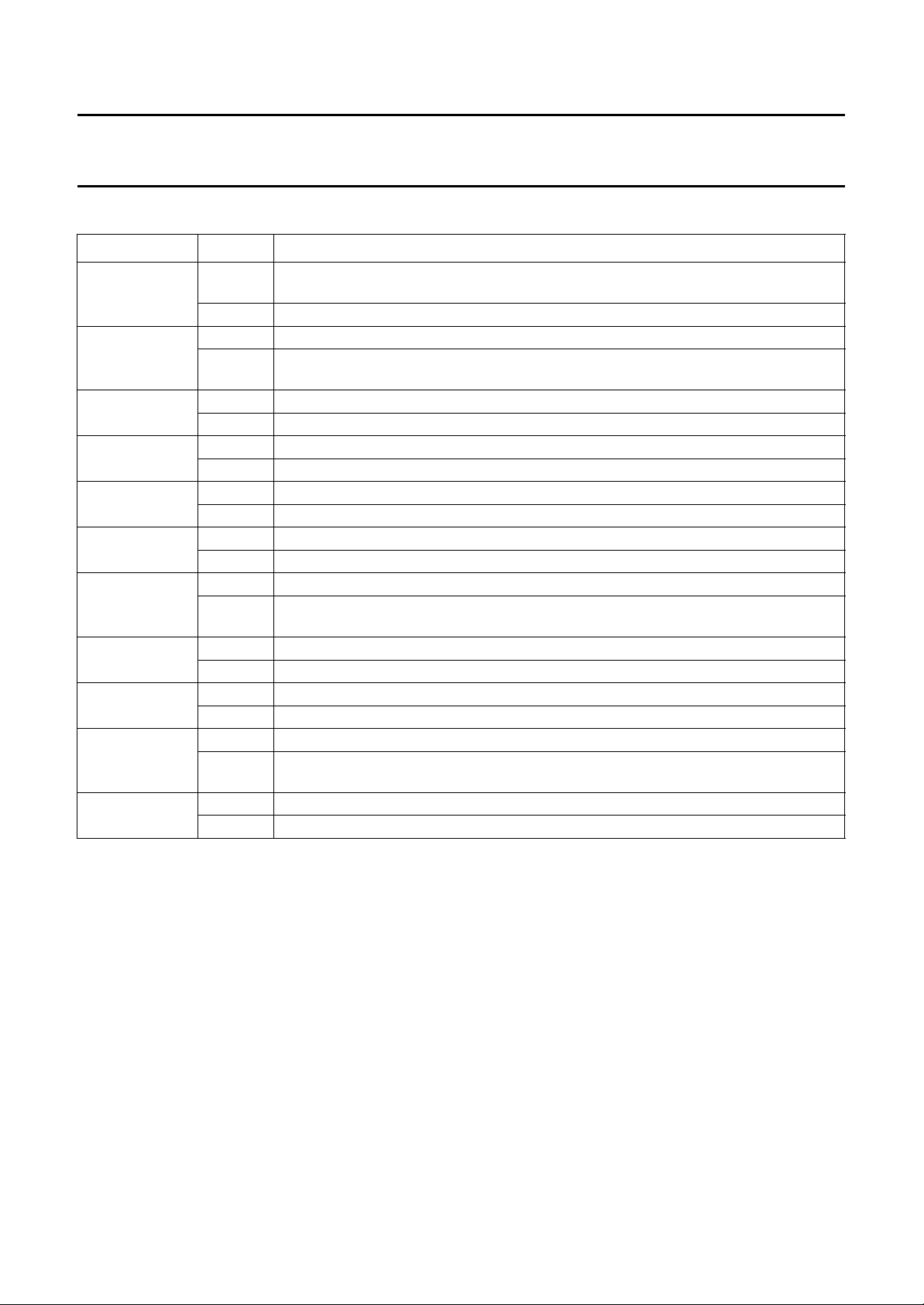

I2C-bus commands

Slave address: 8C HEX = 1000110X BIN

READ MODE

The format of the status byte is: PON PROT 000000

Where:

PON is the status bit for power-on reset (POR) and after

power failure:

• Logic 1:

– after the first POR and after power failure; also set to

1 after a severe voltage dip that may have disturbed

the various settings

– POR 1 to 0 transition, VCC = 6.25 V (typ.)

– POR 0 to 1 transition, VCC = 5.75 V (typ.)

Table 1 Write mode with auto increment; subaddress and data byte format.

FUNCTION SUBADDRESS

Vertical amplitude 00 X

Vertical S-correction 01 X X A5 A4 A3 A2 A1 A0

Vertical start scan 02 X X A5 A4 A3 A2 A1 A0

Vertical off-centre shift 03 X note 2 note 2 note 2 X A2 A1 A0

EW trapezium correction 03 X A6 A5 A4 X note2 note2 note2

EW width/width ratio 04 X X A5 A4 A3 A2 A1 A0

EW parabola/width ratio 05 X X A5 A4 A3 A2 A1 A0

EW corner/parabola ratio 06 X X A5 A4 A3 A2 A1 A0

EHT compensation 07 X X A5 A4 A3 A2 A1 A0

Horizontal phase 08 X X A5 A4 A3 A2 A1 A0

Horizontal off-centre shift 09 X X A5 A4 A3 A2 A1 A0

Clamp shift 0A X XXXXA2A1A0

Control 1 0B MS WS FBL VAP BLDS LFSS DINT GBS

Control 2 0F X X X VPR CPR DIP PRD CSU

D7 D6 D5 D4 D3 D2 D1 D0

(1)

• Logic 0:

– after a successful read of the status byte.

PROT is the over voltage detection for the scaled EHT

input:

• Logic 1:

– if the scaled EHT rises above the reference value of

3.9 V

• Logic 0:

– after a successful read of the status byte and EHT

<3.9 V.

Remark: a read action is considered successful when an

End Of Data signal has been detected (i.e. no master

acknowledge).

DATA BYTE

X A5A4A3A2A1A0

Notes

1. X = don’t care.

2. Data bit used in another function.

July 1994 6

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

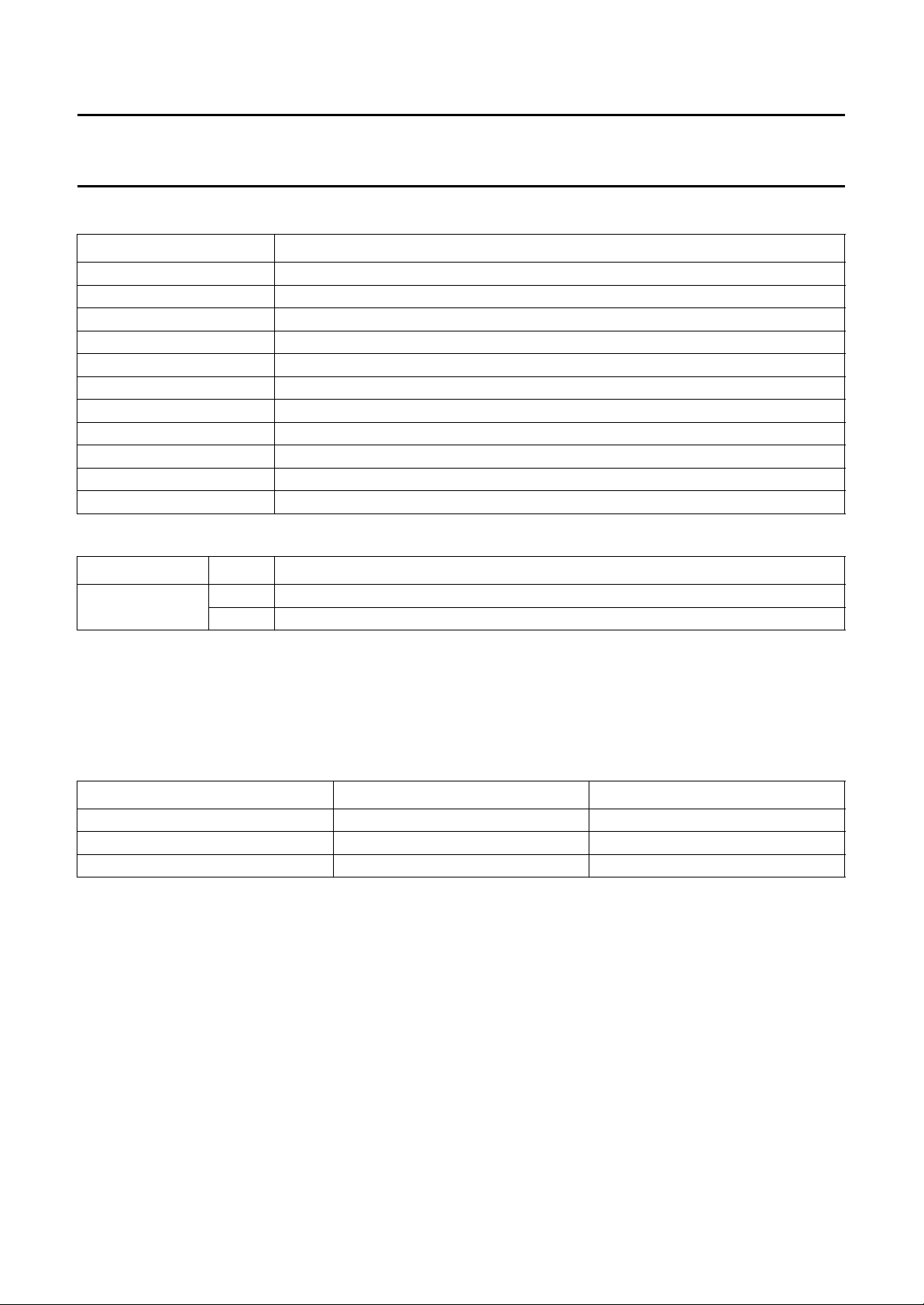

Table 2 Control bits.

CONTROL BIT LOGIC FUNCTION

LFSS 0 Line stop: EW output current becomes zero and the vertical output current is reduced

to 20% of the adjusted value. LFSS becomes logic 0 after a HIGH on PON.

1 Line start enabled: the soft start mechanism is now activated.

DINT 0 De-interlace on: the V

1 De-interlace off: the V

edge is used as vertical reset.

BLDS 0 Aquadag selected.

1 Bleeder selected.

GBS 0 Becomes logic 0 after power-on.

1 Guard band 48/12 lines.

VAP 0 Positive V

1 Negative V

edge detection.

A

edge detection.

A

FBL 0 Horizontal flyback slicing level = 3.9 V.

1 Horizontal flyback slicing level = 1.3 V.

CSU 0 No clamping suppression, standard mode of operation.

1 Clamping suppression in wait, stop and protection modes

(used in systems with e.g. TDA4680/81).

PRD 0 No defeat of HOUT, the over voltage information is only written in the PROT status bit.

1 HOUT is defeated and status bit PROT is set when over voltage is detected.

DIP 0 V

1V

is sampled 42 clock pulses after the leading edge of HA.

A

is sampled 258 clock pulses after the leading edge of HA.

A

CPR 0 Nominal amplitude.

1 Compression to 75% of adjusted amplitude, used for display of 16 : 9 standard pictures

on 4 : 3 displays.

VPR 0 Nominal amplitude (100%) during wait, stop and clipping.

1 Amplitude reduced to 20% during wait, stop and clipping.

pulse is sampled at a position selected with control bit DIP.

A

pulse is sampled with the system clock and the detected rising

A

July 1994 7

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

Table 3 Explanation of control bits shown in Table 2.

CONTROL BITS DESCRIPTION

LFSS line frame start/stop

DINT de-interlace

BLDS bleeder mode selection

GBS guard band selection

VAP polarity of V

FBL flyback slicing level

CSU clamping suppression mode

PRD protection/detection mode

DIP de-interlace phase

CPR compression on/off

VPR vertical power reduction mode

Table 4 Clock frequency control bit (pin 5; note 1).

edge detection

A

CONTROL BIT LOGIC FUNCTION

LLCS 0 prescaler on: the internal clock frequency f

1 prescaler off (default by internal pull-up resistor): the internal clock frequency f

clk

=1⁄2f

LLC

clk

= f

LLC

Note

1. Switching of the prescaler is only allowed when LFSS is LOW. It is highly recommended to hard wire LLCS to ground

. Active switching may damage the output power transistor due to the changing HOUT pulse. This may cause

or V

CC

very high currents and large flyback pulses. The permitted combinations of LLC and the prescaler are shown in

Table 5.

Table 5 Line duration with prescaler.

LLC (MHz) ON (µs) OFF (µs)

6.75 note 1 64

13.5 64 32

27 32 note 1

Note

1. Combination not allowed.

July 1994 8

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

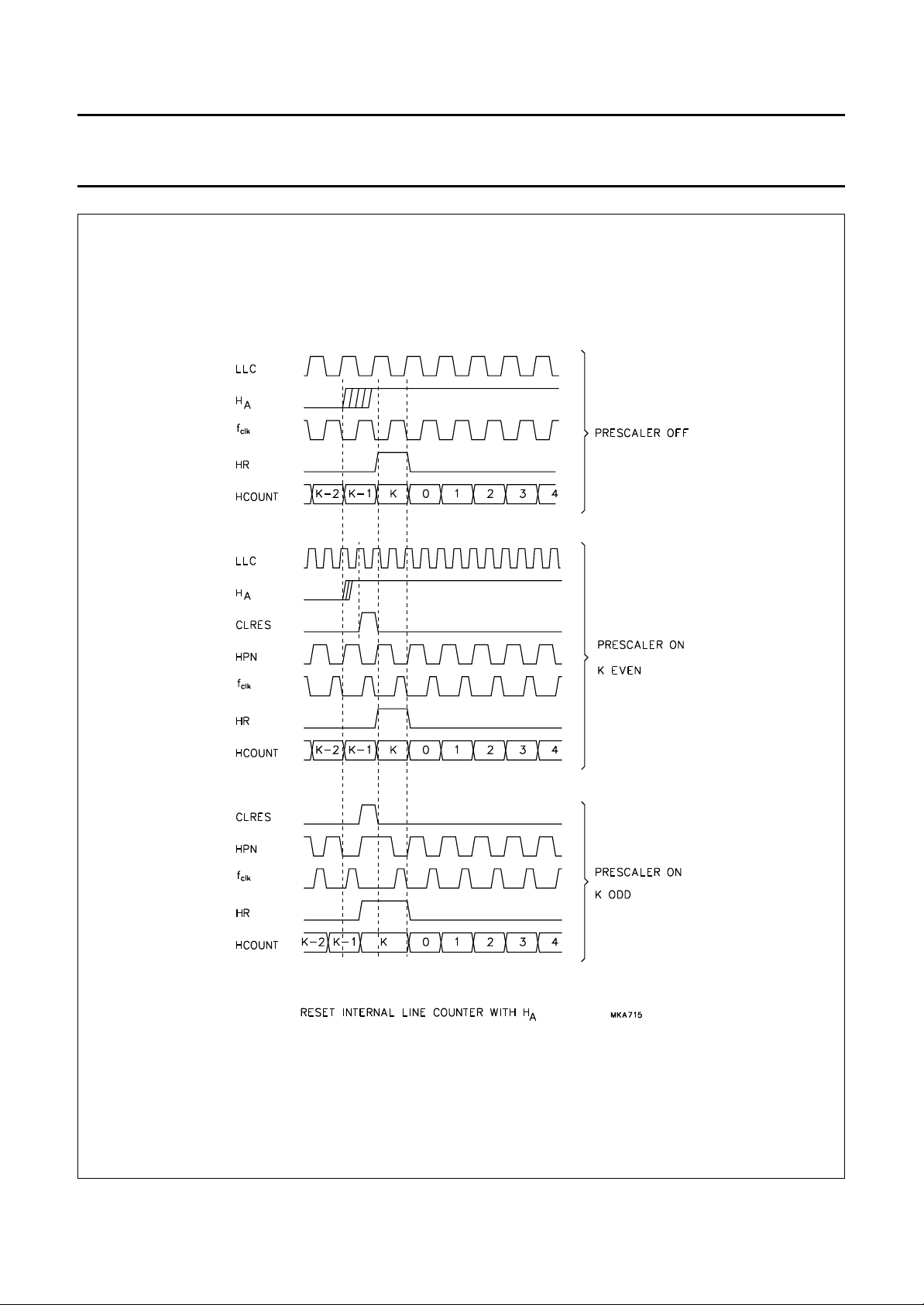

Fig.3 Timing relations between LLC, HA and line counter.

July 1994 9

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

Horizontal part (pins 1, 2, 13, 19 and 20)

S

YNCHRONIZATION PULSE

The HA input (pin 13) is a TTL-compatible CMOS input.

Pulses on this input have to fulfil the timing requirements

as illustrated in Fig.6. For correct detection the minimum

pulse width for both the HIGH and LOW periods is 2

internal clock periods.

F

LYBACK INPUT PULSE

The HFB input (pin 1) is a CMOS input. The delay of the

centre of the flyback pulse to the leading edge of the H

A

pulse can be set via the I2C-bus with the horizontal phase

byte (subaddress 08), as illustrated in Fig.7. The

resolution is 6-bit.

UTPUT PULSE

O

The HOUT pulse (pin 20) is an open-drain NMOS output.

The duty factor for this output is typically52⁄

48

(conducting/non-conducting) during normal operation. A

soft start causes the duty factor to increase linearly from 5

to 52% over a minimum period of 2000 lines in 2000 steps.

FF-CENTRE SHIFT

O

The OFCS output (pin 19) is a push-pull CMOS output

which is driven by a pulse-width modulated DAC.

By using a suitable interface, the output signal can be used

for off-centre shift correction in the horizontal output stage.

This correction is required for HDTV tubes with a 16 × 9

aspect ratio and is useful for high performance flat square

tubes to obtain the required horizontal linearity. For

applications where off-centre correction is not required,

the output can be used as an auxiliary DAC. The OFCS

signal is phase-locked with the line frequency. The

off-centre shift can be set via the I2C-bus, subaddress 09,

with a 6-bit resolution as illustrated in Fig.8.

S

ANDCASTLE

The DSC input/output (pin 2) acts as a sandcastle

generating output and a guard sensing input. As an output

it provides 2 levels (apart from the base level), one for the

horizontal and vertical blanking and the other for the video

clamping. As an input it acts as a current sensor during the

vertical blanking interval for guard detection.

LAMPING PULSE

C

The clamping pulse width is 21 internal clock periods. The

shift, with respect to HA can be varied from 35 to 49 clock

periods in 7 steps via the I2C-bus, clamp shift byte

subaddress 0A, as illustrated in Fig.9. It is possible to

suppress the clamping pulse during wait, stop and

protection modes with control bit CSU. This will avoid

unwanted reset of the TDA4680/81 (only used in those

circuits).

H

ORIZONTAL BLANKING

The start of the horizontal blanking pulse is minimum 38

and maximum 41 clock periods before the centre of the

flyback pulse, depending on the f

clk/fH

ratio K in

accordance with 41 − (432 − K).

Stop of the horizontal blanking pulse is determined by the

trailing edge of the HFB pulse at the horizontal blanking

slicing level crossing as illustrated in Fig.10.

ERTICAL BLANKING

V

The vertical blanking pulse starts two internal clock pulses

after the rising edge of the VA pulse. During this interval a

small guard pulse, generated during flyback by the vertical

power output stage, must be inserted. Stop vertical

blanking is effected at the end of the blanking interval only

when the guard pulse is present (see Section “Vertical

guard”).

The start scan setting determines the end of vertical

blanking with a 6-bit resolution in steps of one line via the

I2C-bus subaddress 02 (see Figs 11 and 12).

ERTICAL GUARD

V

In the vertical blanking interval a small unblanking pulse is

inserted. This pulse must be filled-in by a blanking pulse or

guard pulse from the vertical power output stage which

was generated during the flyback period. In this condition

the sandcastle output acts as guard detection input and

requires a minimum 800 µA input current. This current is

sensed during the unblanking period. Vertical blanking is

only stopped at the end of the blanking interval when the

inserted pulse is present. In this way the picture tube is

protected against damage in the event of missing or

malfunctioning vertical deflection (see Figs 11 and 12).

July 1994 10

Philips Semiconductors Preliminary specification

Programmable deflection controller TDA9150B

Vertical part (pins 6, 8, 10, 11 and 12)

S

YNCHRONIZATION PULSE

The VA input (pin 12) is a TTL-compatible CMOS input.

Pulses at this input have to fulfil the timing requirements as

illustrated in Fig.6. For correct detection the minimum

pulse width for both the HIGH and LOW period is 2 internal

clock periods. For further requirements on minimum pulse

width see also Section “De-interlace”.

ERTICAL PLACE GENERATOR

V

With control bit CPR a compress to 75% of the adjusted

values is possible in all modes of operation. This control bit

is used to display 16 : 9 standard pictures on 4 : 3

displays. No new adjustment of other corrections, such as

corner and S-correction, is required.

With control bit VPR a reduction of the current during

clipping, wait and stop modes to 20% of the nominal value

can be selected, which will reduce the dissipation in the

vertical drive circuits.

The vertical start-scan data (subaddress 02) determines

the vertical placement in the total range of 64 × 432 clock

periods in 63 steps. The maximum number of

synchronized lines per scan is 910 with an equivalent field

frequency of 17.2 or 34.4 Hz for fH = 15625 or 31250 Hz

respectively.

The minimum number of synchronized lines per scan is

200 with an equivalent field frequency of 78 or 156 Hz for

fH= 15 625 or 31250 Hz respectively.

D

E-INTERLACE

With de-interlace on (DINT = logic 0), the VA pulse is

sampled with LLC at a position supplied by control bit DIP

(de-interlace phase).

When DIP = logic 0 sampling takes place 42 clock pulses

after the leading edge of HA (T = T

× 42/432).

line

When DIP = logic 1 sampling takes place 258 clock pulses

after the leading edge of HA (T = T

× 258/432).

line

The distance between the two selectable sampling points

is (T

× (258 − 42)/432) which is exactly half a line, thus

line

de-interlace is possible in two directions.

The duration of the V

pulse must, therefore, be sufficient

A

to enable the HA pulse to caught, in this event an active

time of minimum of half a line (see Fig.13 which has an

integration time of T

×1⁄4 for the VA pulse).

line

With de-interlace off, the VA pulse is sampled with the

system clock. The leading edge is detected and used as

the vertical reset. Selection of the positive or negative

leading edge is achieved by the control bit VAP.

ERTICAL GEOMETRY PROCESSING

V

The vertical geometry processing is DC-coupled and

therefore independent of field frequency. The external

resistive conversion (R

) at pin 8 sets the reference

CONV

current for both the vertical and EW geometry processing.

A useful range is 100 to 150 µA, the recommended value

is 120 µA.

If the VA pulse is not present, the number of lines per scan

will increase to 910.2. If the LLC is not present the vertical

blanking will start within 2 µs.

Amplitude control is automatic, with a settling time of 1 to

2 new fields and an accuracy of either 16/12 or 48/12 lines

depending on the value of the GBS bit.

Differences in the number of lines per field, as can occur in

TXT or in multi-head VTR, will not affect the amplitude

setting providing the differences are less than the value

selected with GBS. This is called amplitude control

guardband. The difference sequence and the difference

sequence length are not important.

July 1994 11

VERTICAL OUTPUTS

The vertical outputs VOUTA and VOUTB on pins 10 and 11

together form a differential current output. The vertical

amplitude can be varied over the range 80 to 120% in

63 steps via the I2C-bus (subaddress 00). Vertical

S-correction is also applied to these outputs and can be

set from 0 to 16% by subaddress 01 with a 6-bit resolution.

The vertical off-centre shift (OFCS) shifts the vertical

deflection current zero crossing with respect to the EW

parabola bottom. The control range is −1.5 to +1.5%

(±1⁄8× I8) in 7 steps set by the least significant nibble at

subaddress 03.

Loading...

Loading...