Philips TDA9112 Service Manual

TDA9112

LOW-COST I2C CONTROLLED DEFLECTION PROCESSOR

FOR MULTISYNC MONITOR

FEATURES

General

■ ADVANCED I

2

C BUS CONTROLLED

DEFLECTION PROCESSOR DEDICATED

FOR HIGH-END CRT MONITORS

■ SINGLE SUPPLY VOLTAGE 12V

■ VERY LOW JITTER

■ DC/DC CONVERTER CONTROLLER

■ ADVANCED EW DRIVE

■ ADVANCED ASYMMETRY CORRECTIONS

■ AUTOMATIC MULTISTANDARD

SYNCHRONIZATION

■ 2 DYNAMIC CORRECTION WAVEFORM

OUTPUTS

■ X-RAY PROTECTION AND SOFT-START &

STOP ON HORIZONTAL AND DC/DC DRIVE

OUTPUTS

2

■ I

C BUS STATUS REGISTER

Horizontal section

■ 150 kHz maximum frequency

■ Corrections of geometric asymmetry: Pin

cushion asymmetry, Parallelogram, separate

Top/Bottom corner asymmetry

■ Tracking of asymmetrycorrections with vertical

size and position

■ Fully integrated horizontal moiré cancellation

Vertical section

■ 200 Hz maximum frequency

■ Vertical ramp for DC-coupled output stage with

adjustments of: C-correction, S-correction for

super-flat CRT, Vertical size, Vertical position

■ Vertical moiré cancellation through vertical

ramp waveform

■ Compensation of vertical breathing with EHT

variation

EW section

■ Symmetricalgeometrycorrections:Pin cushion,

Keystone, Top/Bottom corners separately

■ Horizontal size adjustment

■ Tracking of EW waveform with Vertical sizeand

position and adaptation to frequency

■ Compensation of horizontal breathing through

EW waveform

Dynamic correction section

■ Generates waveforms for dynamic corrections

like focus, brightness uniformity, ...

■ 1 output with vertical dynamic correction

waveform

■ 1 output with composite HV dynamiccorrection

waveform

■ Fixed on screen by means of tracking system

DC/DC controller section

■ Step-up and step-down conversion modes

■ Internal and external sawtooth configurations

■ Bus-controlled output voltage

■ Synchronization on hor. frequency with phase

selection

■ Selectable polarity of drive signal

DESCRIPTION

The TDA9112 is a monolithic integrated circuit assembled in a 32-pin shrink dual-in-line plastic

package. This IC controls all the functions related

to horizontal and vertical deflection in multimode

or multi-frequency computer display monitors.

The internal sync processor, combined with the

powerful geometry correction block, makes the

TDA9112 suitable for very high performance monitors, using few external components.

Combined with other ST components dedicated

for CRTmonitors (microcontroller, video preamplifier, video amplifier, OSD controller) the TDA9112

allows fully I2C bus-controlled computer display

monitors to be built with a reduced number of external components.

SHRINK 32 (Plastic Package)

ORDER CODE: TDA9112

Version 4.0

May 2001 1/49

1

TABLE OF CONTENTS

1 -PIN CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

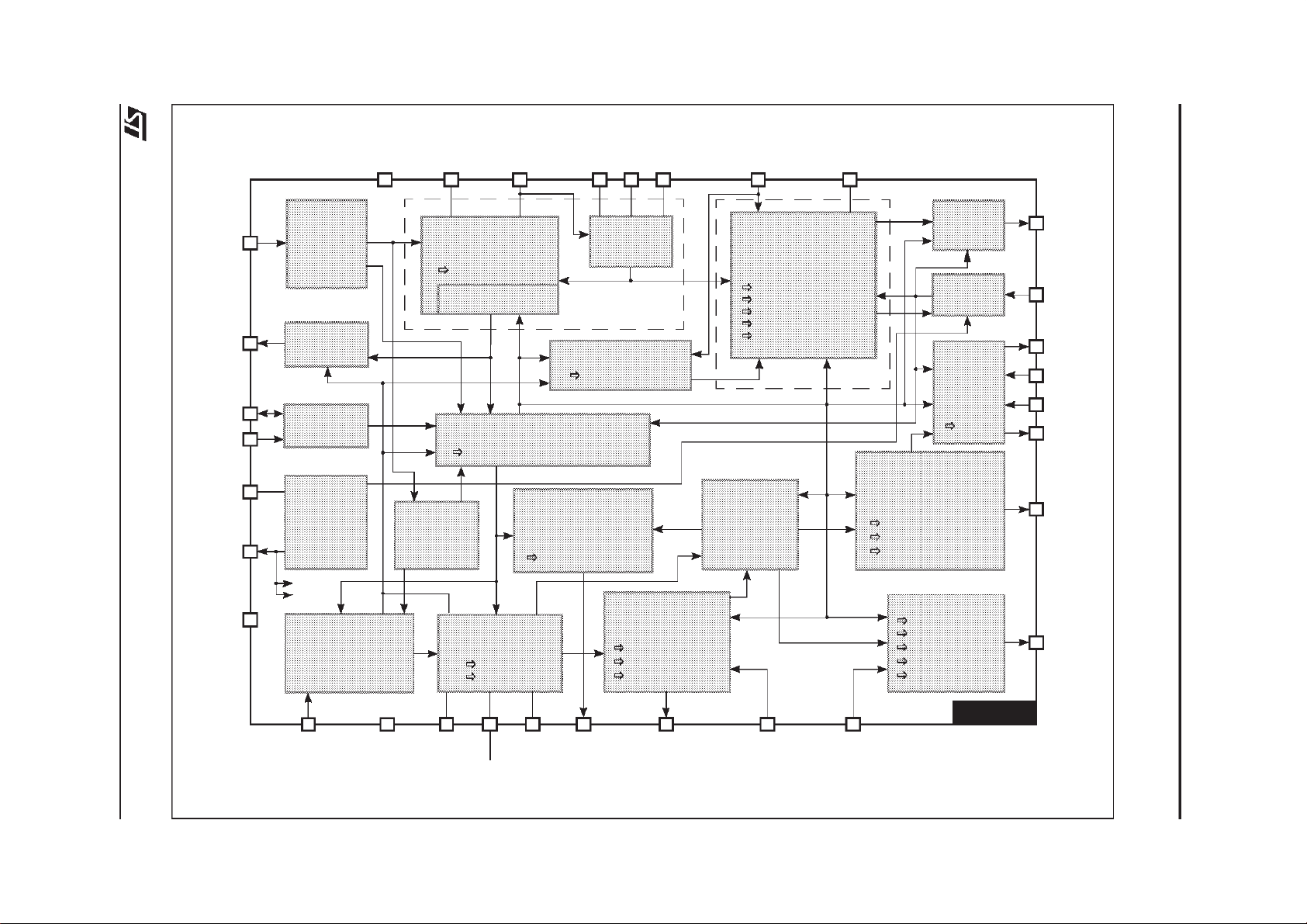

2 -BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 -PIN FUNCTION REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 -QUICK REFERENCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 -ABSOLUTE MAXIMUM RATINGS . . . . . . . ........................................ 8

6 -ELECTRICAL PARAMETERS AND OPERATING CONDITIONS . . . . . . ................. 9

6.1 -THERMAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 -SUPPLY AND REFERENCE VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.3 -SYNCHRONIZATION INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.4 -HORIZONTAL SECTION . . ................................................ 10

6.5 -VERTICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.6 -EW DRIVE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.7 -DYNAMIC CORRECTIONOUTPUTS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.8 -DC/DC CONTROLLER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . ................17

6.9 -MISCELLANEOUS . . . . . . . . . . . . . . . . . . . . ................................... 18

7 -TYPICAL OUTPUT WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8-I2C BUS CONTROL REGISTER MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9 -OPERATING DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1 -SUPPLY AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1.1 -Power supply and voltage references .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.1.2 -I2C Bus Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2 -SYNC. PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2.1 -Synchronization signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9.2.2 -Sync. presence detection flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.2.3 -MCU controlled sync. selection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.2.4 -Automatic sync. selection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.3 -HORIZONTAL SECTION . . ................................................ 28

9.3.1 -General . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9.3.2 -PLL1 . . . . . . . . . . . . . ................................................ 28

9.3.3 -Voltage controlled oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3.4 -PLL2 . . . . . . . . . . . . . ................................................ 30

9.3.5 -Dynamic PLL2 phase control . . . . . . . . . . ................................ 30

9.3.6 -Output Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................31

9.3.7 -Soft-start and soft-stop on H-drive . . . . . . . . . . . . . . . . . . . . . . ................31

9.3.8 -Horizontal moiré cancellation . . . ....................................... 31

9.4 -VERTICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.4.1 -General . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.4.2 -Vertical moiré . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.5 -EW DRIVE SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.6 -DYNAMIC CORRECTIONOUTPUTS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.6.1 -Composite horizontal and vertical dynamic correction output HVDyCor . . . . . . . . . 36

9.6.2 -Vertical dynamic correction output VDyCor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.7 -DC/DC CONTROLLER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . ................37

9.7.1 -External sawtooth configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.7.2 -Internal sawtooth configuration. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.8 -MISCELLANEOUS . . . . . . . . . . . . . . . . . . . . ................................... 39

9.8.1 -Safety functions . . . . ................................................ 39

9.8.2 -Soft start and soft stop functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3

2/49

9.8.3 -X-ray protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.8.4 -Composite output HLckVBk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10 -INTERNAL SCHEMATICS . . . . . . . . . . . . . ....................................... 43

11 -PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12 -GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3/49

TDA9112

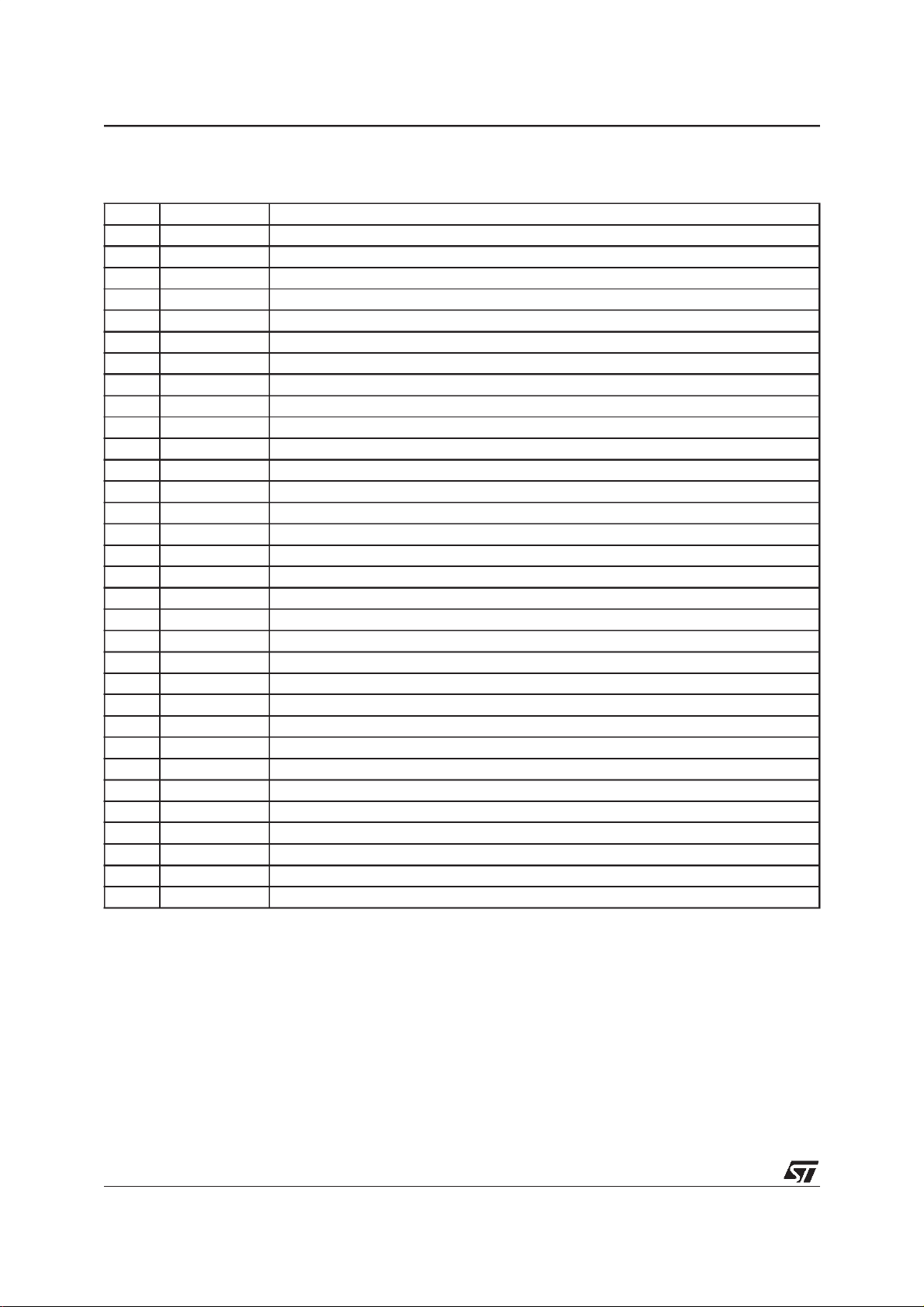

1 - PIN CONFIGURATION

H/HVSyn

VSyn

HLckVBk

HOscF

HPLL2C

CO

HGND

RO

HPLL1F

HPosF

HVDyCor

HFly

RefOut

BComp

BRegIn

BISense

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 17

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

VDyCor

SDA

SCL

Vcc

BOut

GND

HOut

XRay

EWOut

VOut

VCap

VGND

VAGCCap

VOscF

VEHTIn

HEHTIn

4/49

2 - BLOCK DIAGRAM

H/HVSyn

HLckVBk

SDA

SCL

Vcc

RefOut

GND

HGND

7

HPosF

10

HPLL1F

9

R0

HOscF

C0

4

6

8

HFly

12

H-sync

1

detection

Polarity

handling

Phase/frequency

comparator

Horizontal position

Lock detection

3

V-blank

H-lock

31

30

I2C Bus

interface

2

C Bus registers

I

: Functions controlled via I2C Bus

Horizontal

VCO

PLL1

H-moiré controller

H-moiré amplitude

Phase comparator

Phase shifter

H duty controller

Pin cushion asymm.

Parallelogram

Top corner asymm.

Bottom corner asymm.

Hor. duty cycle

HPLL2C

5

PLL2

H-drive

buffer

Safety

processor

B+

DC/DC

converter

controller

B+ ref.

26

25

28

16

15

14

HOut

XRay

BOut

BIsense

BRegIn

BComp

HV-dynamic

29

13

27

Supply

supervision

Reference

generation

Internal

ref.

V-sync detection

Input selection

Polarity handling

V-sync

extraction

& detection

Vertical oscillator

with AGC

S-correction

C-correction

V-dynamic

correction

(focus, bright.)

VDyCor amplitude

Geometry

tracking

V-ramp control

Tracking EHT

Vertical size

Vertical position

Vertical moiré

correction

(focus,brightness)

HVDyCor V-amplitude

HVDyCor H-amplitude

HVDyCor H-symmetry

EW generator

H size

Pin cushion

Keystone

Top corners

Bottom corners

11

HVDyCor

24

EWOut

5/49

2

VSyn

21

VGND

19

VOscF

20 22

VAGCCap

VCap

32

VDyCor

23

VOut

18

VEHTIn

17

HEHTIn

TDA9112

TDA9112

TDA9112

3 - PIN FUNCTION REFERENCE

Pin Name Function

1 H/HVSyn TTL compatible Horizontal /Horizontal and Vertical Sync. input

2 VSyn TTL compatible Vertical Sync. input

3 HLckVBk Horizontal PLL1 Lock detection and Vertical early Blanking composite output

4 HOscF High Horizontal Oscillator sawtooth threshold level Filter input

5 HPLL2C Horizontal PLL2 loop Capacitive filter input

6 CO Horizontal Oscillator Capacitor input

7 HGND Horizontal section GrouND

8 RO Horizontal Oscillator Resistor input

9 HPLL1F Horizontal PLL1 loop Filter input

10 HPosF Horizontal Position Filter and soft-start time constant capacitor input

11 HVDyCor Horizontal and Vertical Dynamic Correction output

12 HFly Horizontal Flyback input

13 RefOut Reference voltage Output

14 BComp B+ DC/DC error amplifier (Comparator) output

15 BRegIn Regulation feedback Input of the B+ DC/DC converter controller

16 BISense B+ DC/DC converter current (I) Sense input

17 HEHTIn Input for compensation of Horizontal amplitude versus EHT variation

18 VEHTIn Input for compensation of Vertical amplitude versus EHT variation

19 VOscF Vertical Oscillator sawtooth low threshold Filter (capacitor to be connected to VGND)

20 VAGCCap Input for storage Capacitor for Automatic Gain Control loop in Vertical oscillator

21 VGND Vertical section GrouND

22 VCap Vertical sawtooth generator Capacitor

23 VOut Vertical deflection drive Output for a DC-coupled output stage

24 EWOut E/WOutput

25 XRay X-Ray protection input

26 HOut Horizontal drive Output

27 GND Main GrouND

28 BOut B+ DC/DC converter controller Output

29 Vcc Supply voltage

30 SCL I

31 SDA I

32 VDyCor Vertical Dynamic Correction output

2

C bus Serial CLock Input

2

C bus Serial DAta input/output

6/49

TDA9112

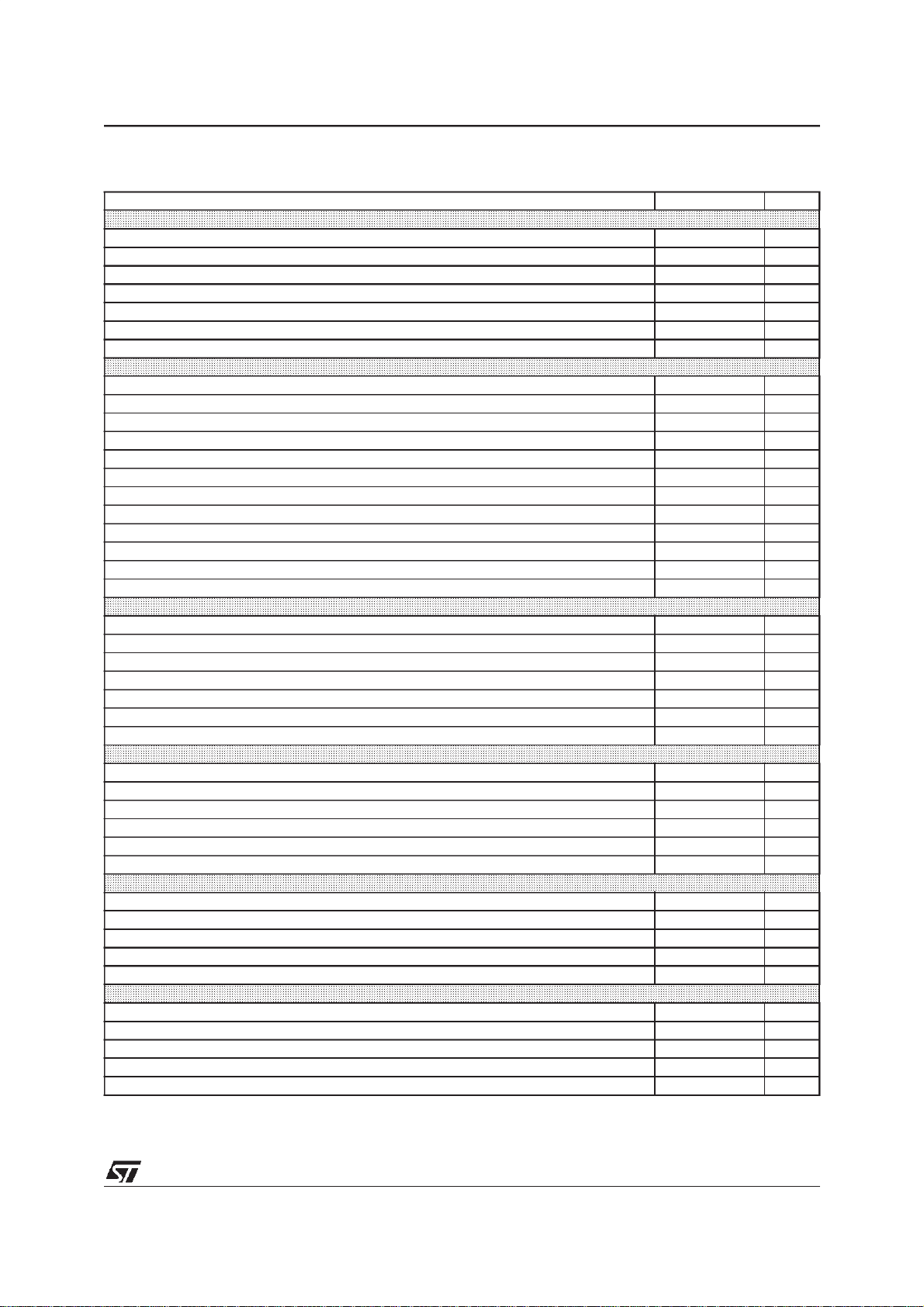

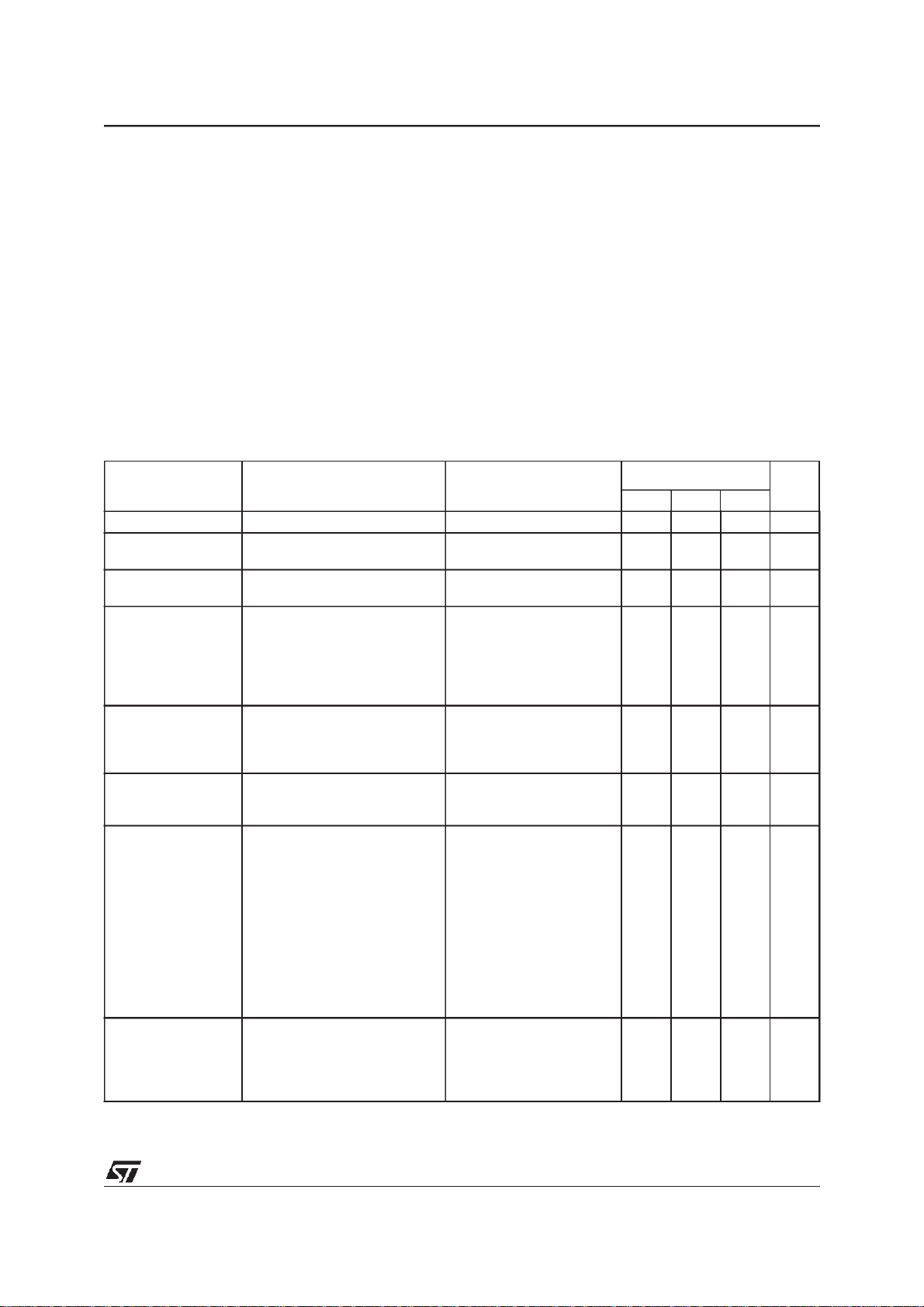

4 - QUICK REFERENCE DATA

Characteristic Value Unit

General

Package SDIP 32

Supply voltage 12 V

Supply current 65 mA

Application category High-end

Means of control/Maximum clock frequency I

EW drive Yes

DC/DC converter controller Yes

Horizontal section

Frequency range 15 to 150 kHz

Autosync frequency ratio (can be enlarged in application) 4.28

Positive/Negative polarity of horizontal sync signal/Automatic adaptation Yes/Yes/Yes

Duty cycle range of the drive signal 30 to 65 %

Position adjustment range with respect to H period ±10 %

Soft start/Soft stop feature Yes/Yes

Hardware/Software PLL lock indication Yes/Yes

Parrallelogram Yes

Pin cushion asymmetry correction (also called Side pin balance) Yes

Top/Bottom/Common corner asymmetry correction Yes/Yes/No

Tracking of asymmetry corrections with vertical size & position Yes

Horizontal moiré cancellation (int.) for Combined/Separated architecture Yes/Yes

Vertical section

Frequency range 35 to 200 Hz

Autosync frequency range (150nF at VCap and 470nF at VAGCCap) 50 to 180 Hz

Positive/Negative polarity of vertical sync signal/Automatic adaptation Yes/Yes/Yes

S-correction/C-correction/Super-flat tube characteristic Yes/Yes/Yes

Vertical size/Vertical position adjustment Yes/Yes

Vertical moiré cancellation (internal) Yes

Vertical breathing compensation Yes

EW section

Pin cushion correction Yes

Keystone correction Yes

Top/Bottom/Common corner correction Yes/Yes/No

Horizontal size adjustment Yes

Tracking of EW waveform with Frequency/Vertical size & position Yes/Yes

Breathing compensation on EW waveform Yes

Dynamic correction section (dyn. focus, dyn. brightness,...)

Vertical dynamic correction output VDyCor Yes

Horizontal dynamic correction output HDyCor No

Composite HV dynamic correction output HVDyCor Yes

Tracking of horizontal waveform component with Horizontal size/EHT Yes/Yes

Tracking of vertical waveforms (component) with V. size & position Yes

DC/DC controller section

Step-up/Step-down conversion mode Yes/Yes

Internal/External sawtooth configuration Yes/Yes

Bus-controlled output voltage Yes

Soft start/Soft stop feature Yes/Yes

Positive (N-MOS)/Negative(P-MOS) polarity of BOut signal Yes/Yes

2

C Bus/400 kHz

7/49

TDA9112

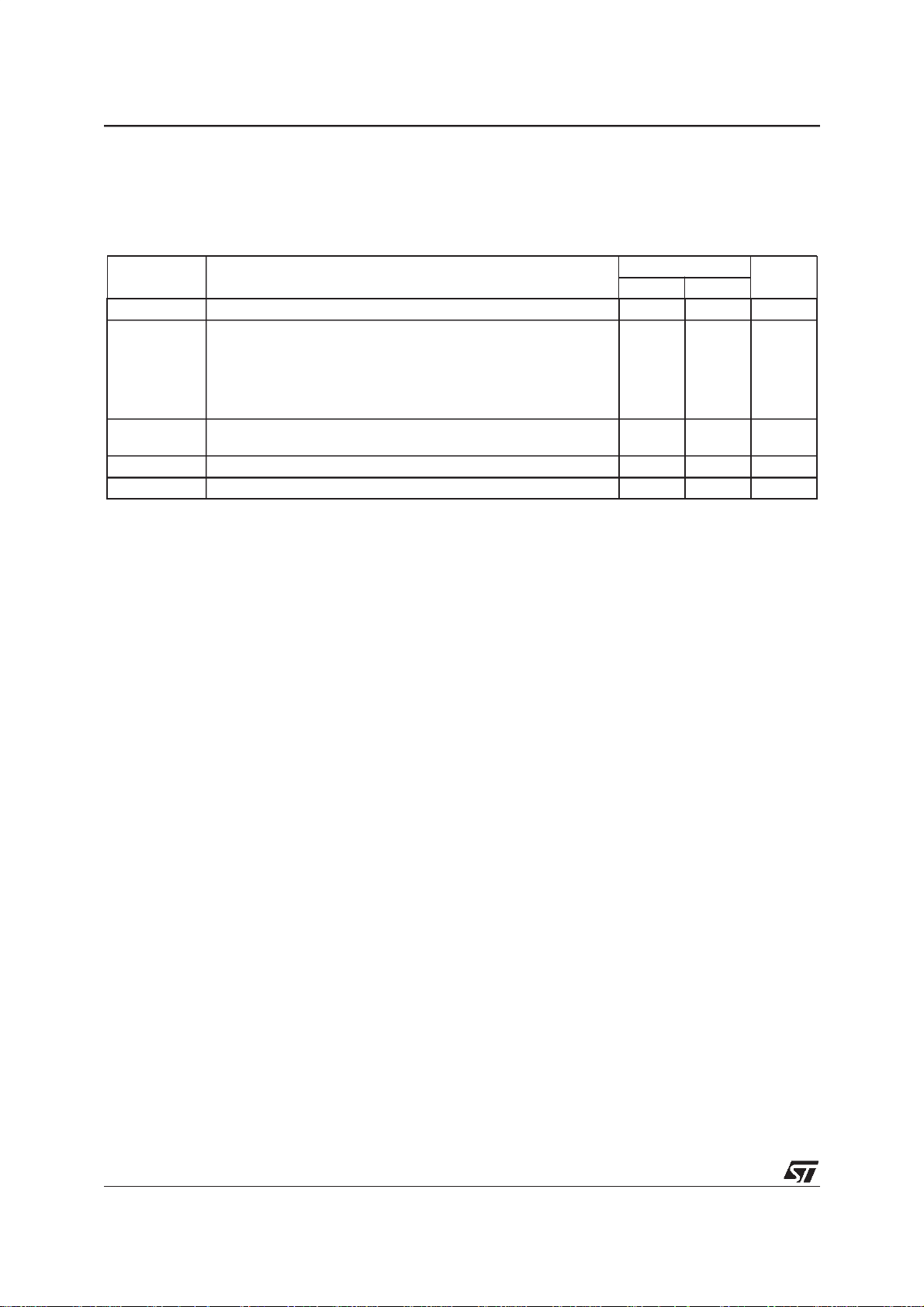

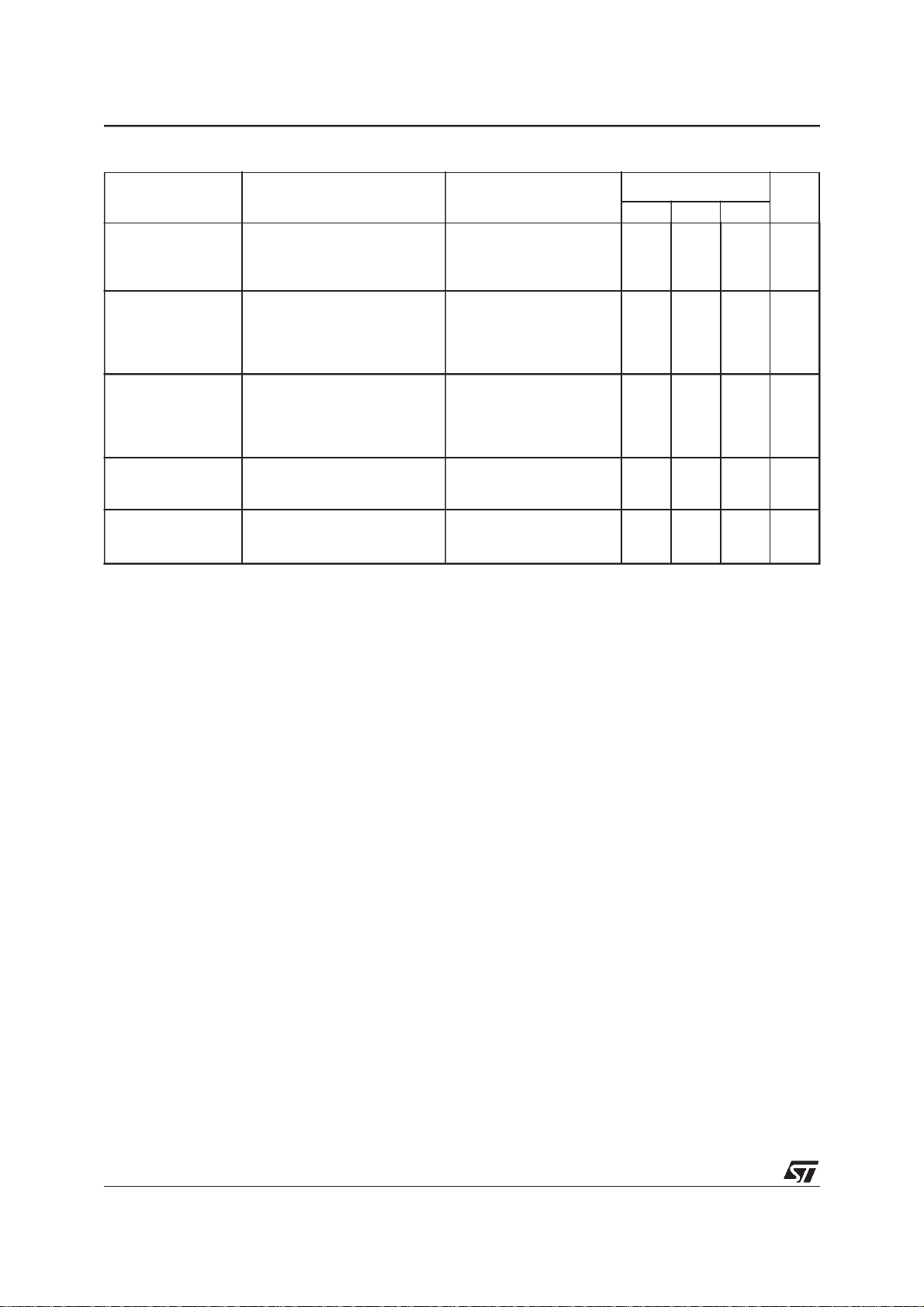

5 - ABSOLUTE MAXIMUM RATINGS

All voltages are given with respect to ground.

Currents flowing from the device (sourced)are signed negative. Currents flowing tothe device aresigned

positive.

Symbol Parameter

V

CC

Supply voltage (pin Vcc) -0.4 13.5 V

Pins HEHTIn, VEHTIn, XRay, HOut, BOut

Pins H/HVSyn, VSyn, SCL, SDA

V

(pin)

Pins HLckVBk, CO, RO, HPLL1F, HPosF, HVDyCor, BRegIn,

BISense, VAGCCap, VCap, VDyCor, HOscF, VOscF

Pin HPLL2C

Pin HFly

V

T

ESD

stg

T

j

ESD susceptibility

(human body model: discharge of 100pF through 1.5kΩ) -2000 2000 V

Storage temperature -40 150 °C

Junction temperature 150 °C

Value

Min Max

V

V

5.5

V

RefO

RefO

V

RefO

CC

-0.4

-0.4

-0.4

-0.4

-0.4

Unit

V

V

V

/2

V

V

8/49

TDA9112

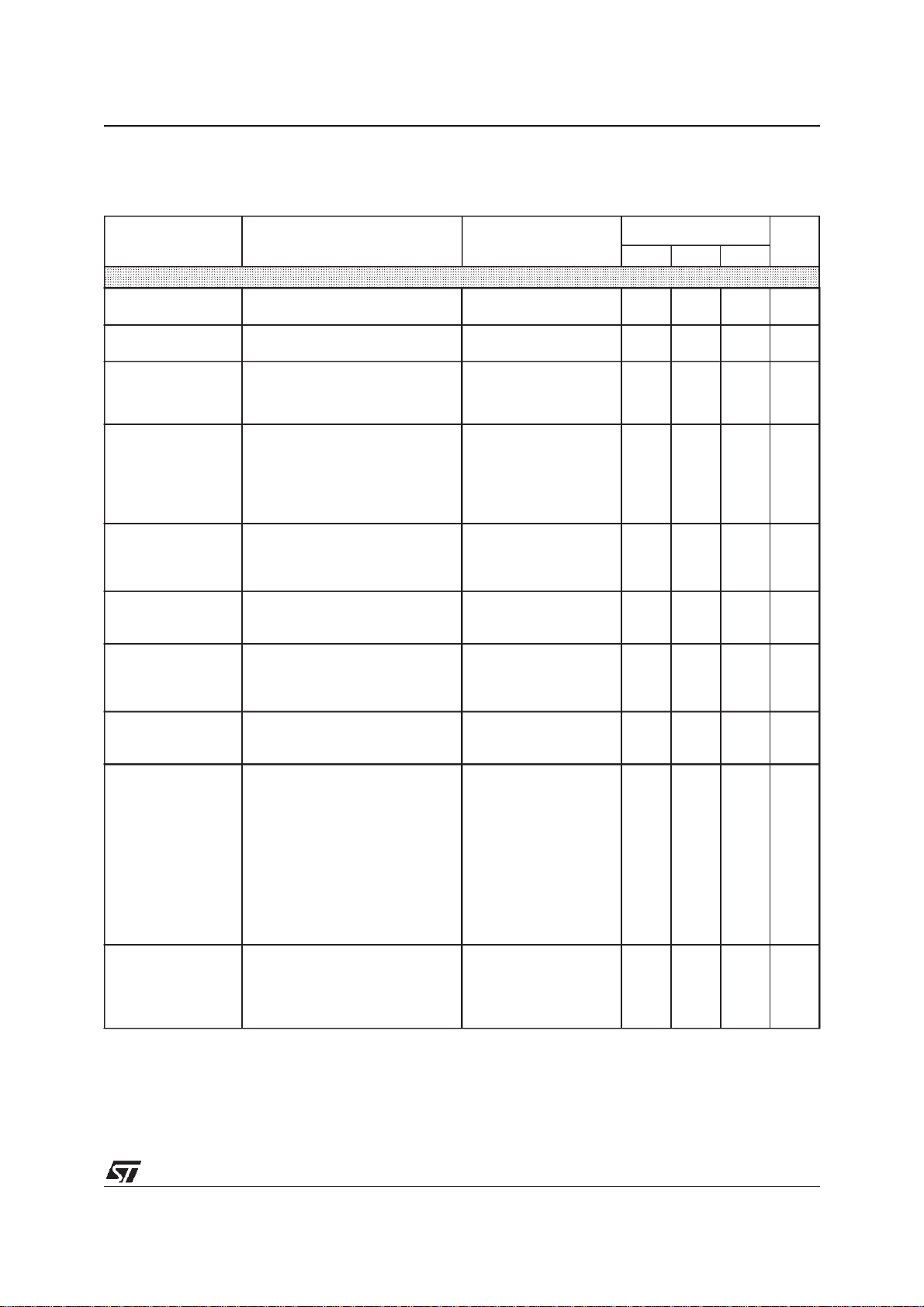

6 - ELECTRICAL PARAMETERS AND OPERATING CONDITIONS

Medium (middle) value of an I2C Bus control or adjustment register composed of bits D0, D1,...,Dn is the

one having Dn at ”1” and all other bits at ”0”. Minimum value is the one with all bits at 0, maximum value

is the one with all at ”1”.

Currents flowing from the device (sourced)are signed negative. Currents flowing tothe device aresigned

positive.

THis period of horizontal deflection.

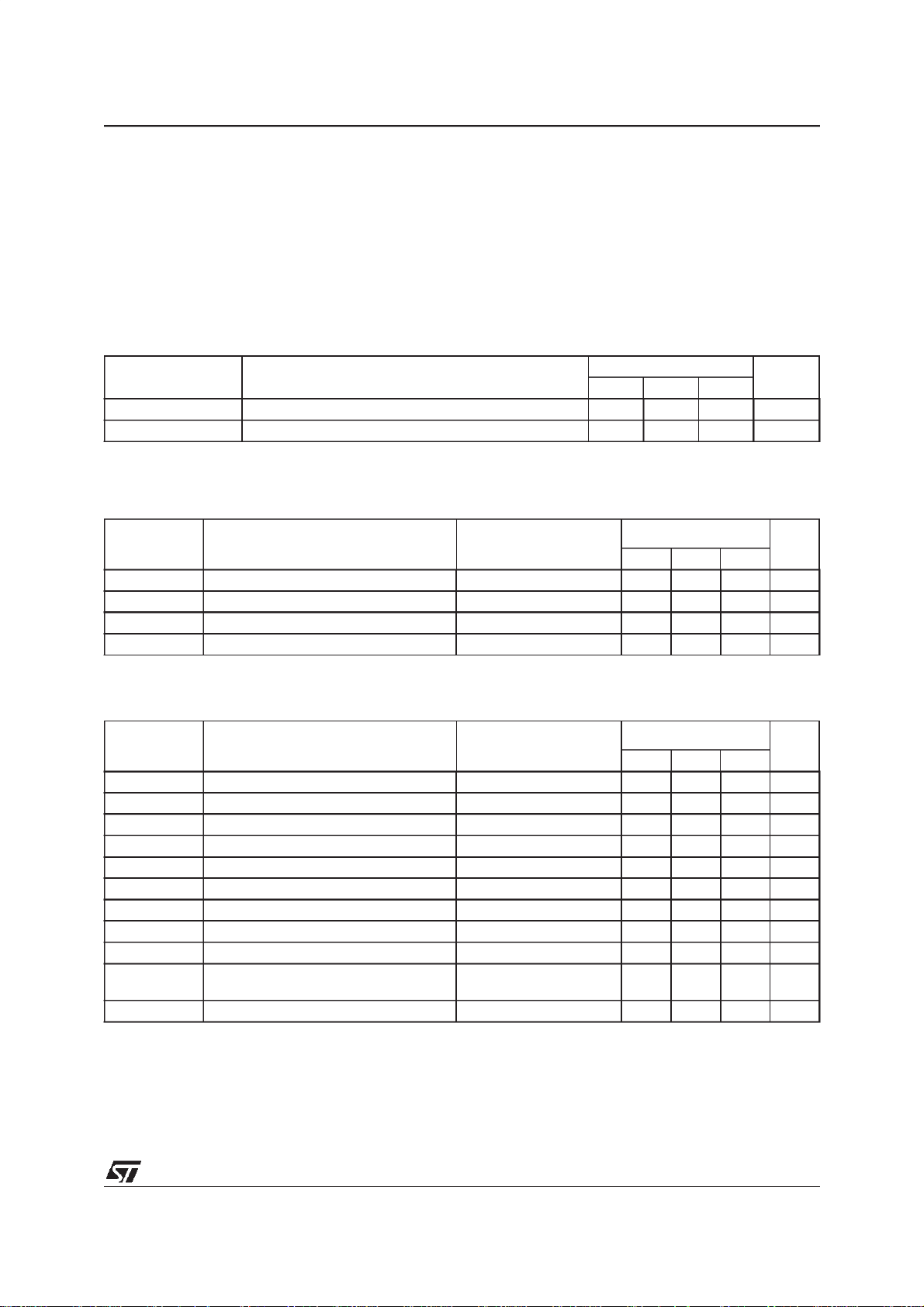

6.1 - THERMAL DATA

Symbol Parameter

T

R

amb

th(j-a)

Operating ambient temperature 0 70 °C

Junction-ambience thermal resistance 65 °C/W

6.2 - SUPPLY AND REFERENCE VOLTAGES

T

=25°C

amb

Symbol Parameter Test Conditions

V

V

I

RefO

CC

I

CC

RefO

Supply voltage at Vcc pin 10.8 12 13.2 V

Supply current to Vcc pin VCC=12V 65 mA

Reference output voltage at RefOut pin VCC=12V,I

Current sourced by RefOutoutput -5 0 mA

6.3 - SYNCHRONIZATION INPUTS

Vcc = 12V, T

Symbol Parameter Test Conditions

V

LoH/HVSyn

V

HiH/HVSyn

V

LoVSyn

V

HiVSyn

R

PdSyn

t

PulseHSyn

t

PulseHSyn/TH

t

PulseVSyn

t

PulseVSyn/TV

t

extrV/TH

t

HPolDet

=25°C

amb

LOW level voltage on H/HVSyn 0 0.8 V

HIGH level voltage on H/HVSyn 2.2 5 V

LOW level voltage on VSyn 0 0.8 V

HIGH level voltage on VSyn 2.2 5 V

Internal pull-down on H/HVSyn, VSyn 100 175 250 kΩ

H sync. pulse duration on H/HVSyn pin 0.5 µs

Proportion of H sync pulse to H period Pin H/HVSyn 0.2

V sync. pulse duration Pins H/HVSyn, VSyn 0.5 750 µs

Proportion of V sync pulse to V period Pins H/HVSyn, VSyn 0.15

Proportion of sync pulse length to H peri-

od for extraction as V sync pulse

Pin H/HVSyn,

cap. on pin CO = 820pF

Polarity detection time (after change) Pin H/HVSyn 0.75 ms

Value

Value

Min. Typ. Max.

= -2mA 7.65 8.0 8.2 V

RefO

Value

Min. Typ. Max.

0.21 0.3

Unit

Units

Units

9/49

TDA9112

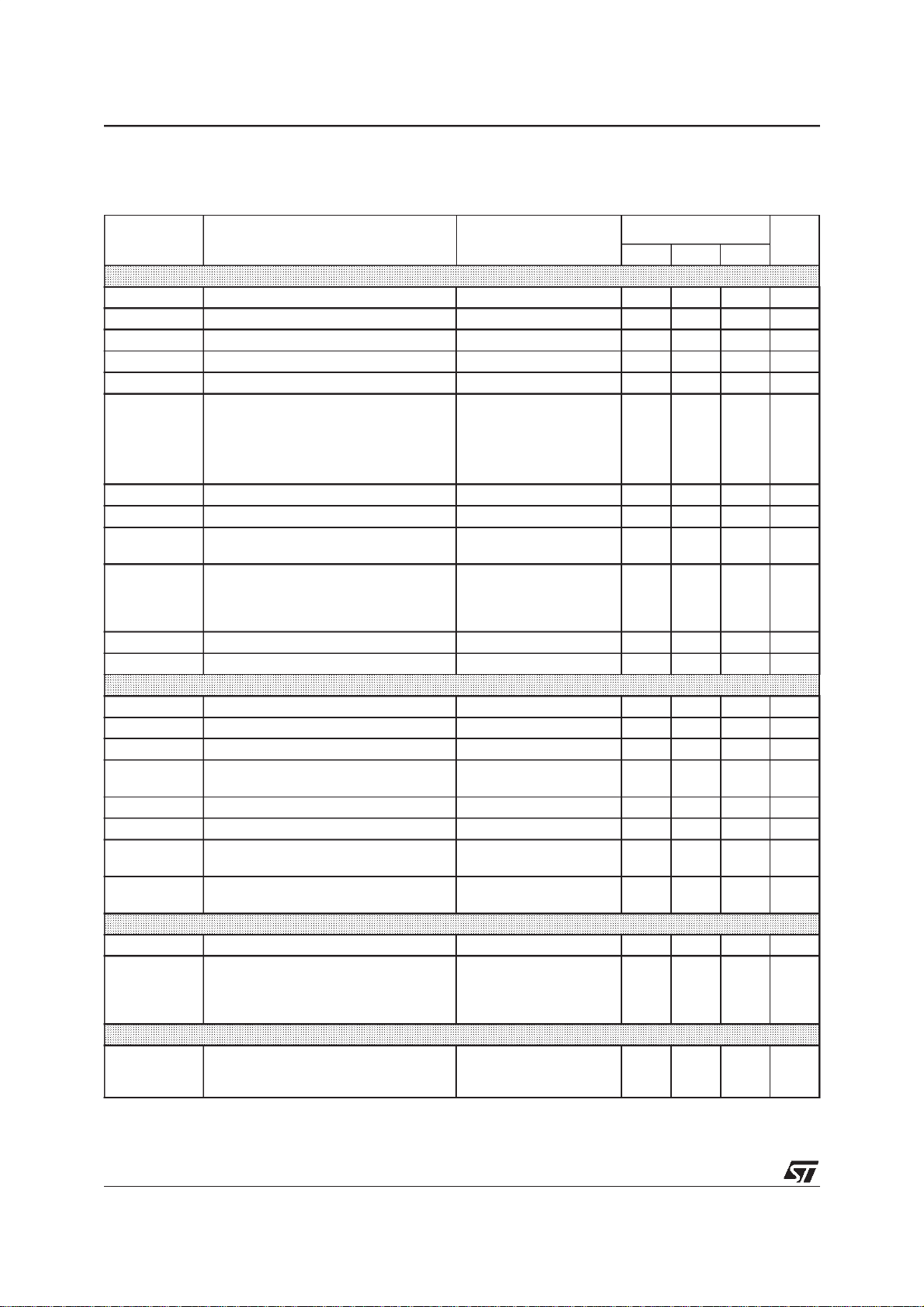

6.4 - HORIZONTAL SECTION

Vcc = 12V, T

amb

=25°C

Symbol Parameter Test Conditions

PLL1

I

RO

C

CO

f

HO

f

HO(0)

f

HOCapt

f

∆

HO 0()

-----------------------------

f

HO 0()

∆f

/∆V

HO

V

HO

V

HOThrfr

V

HPosF

Current load on RO pin 1.5 mA

Capacitance on CO pin 390 pF

Frequency of hor. oscillator 150 kHz

Free-running frequency of hor. oscill.

Hor. PLL1 capture frequency

(4)

Temperature drift of free-running freq.

(1)

RRO=5.23kΩ,CCO=820pF 27 28.5 29.9 kHz

f

= 28.5kHz 29 122 kHz

HO(0)

(3)

T∆⋅

Average horizontal oscillator sensitivity f

HO

H. oscill. control voltage on pin HPLL1F V

Threshold on H. oscill. control voltage on

HPLL1F pin for tracking of EW with freq.

Control voltage on HPosF pin

= 28.5kHz 19.6 kHz/V

HO(0)

=8V 1.4 6.0 V

RefO

V

=8V 5.0 V

RefO

HPOS

(Sad01):

11111111b

10000000b

00000000b

V

HOThrLo

V

HOThrHi

Bottom of hor. oscillator sawtooth

Top of hor. oscillator sawtooth

(6)

(6)

PLL2

R

In(HFly)

I

InHFly

V

ThrHFly

V

S(0)

V

BotHPLL2C

V

TopHPLL2C

(min)/T

t

ph

(max)/T

t

ph

Input impedance on HFly input V

(HFly)>VThrHFly

Current into HFly input At top of H flyback pulse 5 mA

Voltage threshold on HFly input 0.6 0.7 V

H flyback lock middle point

Low clamping voltage on HPLL2C pin

High clamping voltage on HPLL2C pin

Min. advance of H-drive OFF before

H

middle of H flyback

Max. advance of H-drive OFF before

H

middle of H flyback

(7)

(8)

(6)

No PLL2 phase modulation

(5)

(5)

Null asym. correction 0 %

Null asym. correction 44 %

H-drive output on pin HOut

I

HOut

t

Hoff/TH

Current into HOut output Output driven LOW 30 mA

HDUTY

Duty cycle of H-drive signal

(Sad00):

x1111111b

x0000000b

Soft-start/Soft-stopvalue

Picture geometry corrections through PLL1 & PLL2

HPOS

(Sad01):

11111111b

00000000b

t

Hph/TH

H-flyback (centre) static phase vs. sync

signal (via PLL1), see Figure 7

(2)

Value

Units

Min. Typ. Max.

-150 ppm/°C

2.6

3.2

3.8

2.8

3.4

4.0

3.0

3.6

4.2

1.6 V

6.4 V

300 500 700 Ω

4.0 V

1.6 V

3.9 4.05 4.2 V

27

65

85

+11

-11

V

V

V

%

%

%

%

%

10/49

TDA9112

Symbol Parameter Test Conditions

Value

Units

Min. Typ. Max.

PCAC

(Sad11h) full span

(9)

VPOS

VSIZE

VSIZE

VSIZE

PARAL

(9)

VPOS

VSIZE

VSIZE

VSIZE

VPOS

VSIZE

TCAC

(9)

span

VPOS

VSIZE

VSIZE

VSIZE

BCAC

(9)

span

VPOS

VSIZE

VSIZE

VSIZE

at medium

at minimum

at medium

at maximum

(Sad12h) fullspan

at medium

at minimum

at medium

at maximum

at max. or min.

at minimum

(Sad13h) full

at medium

at minimum

at medium

at maximum

(Sad14h) full

at medium

at minimum

at medium

at maximum

±1.0

±1.8

±2.8

±1.75

±2.2

±2.8

±1.75

±0.8

±2.0

±4.4

±0.8

±2.0

±4.4

%

%

%

%

%

%

%

%

%

%

%

%

%

t

PCAC/TH

t

ParalC/TH

t

TCAC/TH

t

BCAC/TH

Contribution of pin cushion asymmetry

correction to phase of H-drive vs. static

phase (via PLL2), measured in corners

Contribution of parallelogram correction

to phase of H-drive vs. static phase (via

PLL2), measured in corners

Contribution of top corner asymmetry

correction to phase of H-drive vs. static

phase (via PLL2), measured in corners

Contribution of bottom corner asymmetry

correction to phase of H-drive vs. static

phase (via PLL2), measured in corners

Note 1: Frequency at no sync signal condition. For correct operation, the frequency of the sync signal applied must

always be higher than the free-running frequency. The application must consider the spread of values of real

electrical components in R

the free-running frequency is f

and CCOpositions so as to always meet this condition. The formula to calculate

RO

=0.12125/(RROCCO)

HO(0)

Note 2: Base of NPN transistor with emitter to ground is internally connected on pin HFly through a series resistance of

about 500Ω and a resistance to ground of about 20kΩ.

Note 3: Evaluated and figured out during the device qualification phase. Informative. Not tested on every single unit.

Note 4: This capture range can be enlarged by external circuitry.

Note 5: The voltage on HPLL2C pin corresponds to immediate phase of leading edge of H-drive signal on HOut pin with

respect to internal horizontal oscillator sawtooth. It must be between the two clamping levels given. Voltage

equal to one of the clamping values indicates a marginal operation of PLL2 or non-locked state.

Note 6: Internal threshold. See Figure 6.

Note 7: Thet

(min)/THparameter is fixed by the application. For correct operation of asymmetry corrections through

ph

dynamic phase modulation, this minimum must be increased by maximum of the total dynamic phase required

in the direction leading to bending of corners to the left. Marginal situation is indicated by reach of V

TopHPLL2C

high clamping level by waveform on pin HPLL2C. Also refer to Note 5 and Figure 6.

Note 8: Thet

(max)/THparameter is fixed by the application. For correct operation of asymmetry corrections through

ph

dynamic phase modulation, this maximum must be reduced by maximum of thetotal dynamic phase required in

the direction leading to bending of corners to the right. Marginal situation is indicated by reach of V

BotHPLL2C

low clamping level by waveform on pin HPLL2C. Also refer to Note 5 and Figure 6.

Note 9: All other dynamic phase corrections of picture asymmetry set to their neutral (medium) positions.

11/49

TDA9112

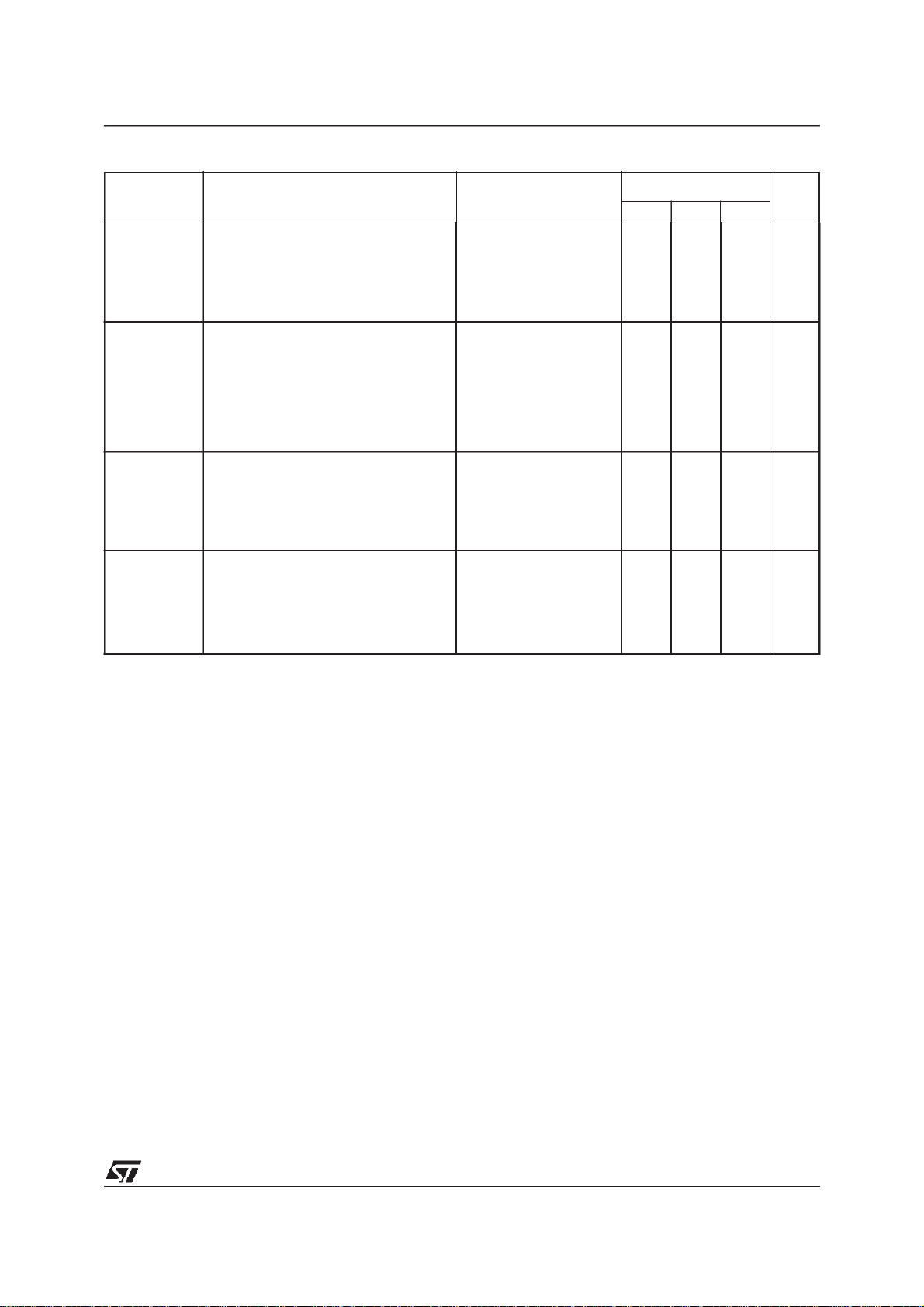

6.5 - VERTICAL SECTION

VCC= 12V,T

Symbol Parameter Test Conditions

amb

=25°C

Value

Units

Min. Typ. Max.

AGC-controlled vertical oscillator sawtooth; V

R

L(VAGCCap)

V

VOB

V

VOT

t

VODis

f

VO(0)

f

VOCapt

∆

V

VOdev

---------------------------------

V

VOamp

V

∆

--------------------------------

∆

V

--------------------------------

∆

---------------------------------------- -

V

VOampfVO

VOS cor–

V

VOamp

VOC cor–

V

VOamp

V

VOamp

16()

∆⋅

Ext. load resistance on

VAGCCap pin

Sawtooth bottom voltage on

VCap pin

(10)

(11)

Sawtooth top voltage on VCap

pin

Sawtooth Discharge time C

Free-running frequency C

AGC loop capture frequency C

Sawtooth non-linearity

(12)

S-correction range

C-correction range

Frequency drift of sawtooth

amplitude

(17)(18)

Vertical output drive signal (on pin VOut);V

V

mid(VOut)

V

amp

V

offVOut

I

VOut

V

VEHT

V

∆

amp

------------------------------------------

∆⋅

V

ampVVEHT

Middle point on VOut sawtooth

Amplitude of VOut sawtooth

(peak-to-peak voltage)

Level on VOut pin at V-drive ”off” I2Cbit VOutEn at 0 3.8 V

Current delivered by VOut out-

put

Control input voltage range on

VEHTIn pin

Breathing compensation

RefO

=8V

RefO

∆V

amp/Vamp

No load on VOscF pin

AGC loop stabilized

V sync present

No V sync

VCap

VCap

VCap

AGC loop stabilized,

AGC loop stabilized,

tVR=1/4 T

tVR=3/4 T

AGC loop stabilized,

tVR=1/2 T

CCOR

x0000000b

x1000000b

x1111111b

AGC loop stabilized

f

VOCapt

=8V

VPOS

x0000000b

x1000000b

x1111111b 3.65

VSIZE

x0000000b

x1000000b

x1111111b 3.5

V

VEHT>VRefO

V

VEHT

(R=∞) ≤1% 65 MΩ

(11)

1.85 1.95 2.1 V

5

4.9

V

V

=150nF 80 µs

=150nF 100 Hz

=150nF 50 185 Hz

(15)

VR

VR

(15)

VR

(Sad0A):

(min)≤f

VO≤fVOCapt

(12)

(13)

(14)

(max) 200

0.5 %

-5

+5

-3

0

+3

ppm/Hz

%

%

%

%

%

(Sad08):

3.2

3.5

3.8

3.3 V

V

V

(Sad07):

2.25

3.0

3.75

2.5 V

V

V

-5 5 mA

(min)≤V

VEHT≤VRefO

1 V

0

2.5

RefO

V

%/V

%/V

Note 10: Value of acceptable cumulated parasitic load resistance due to humidity, AGC storage capacitor leakage, etc.,

for less than 1% of V

amp

change.

12/49

TDA9112

Note 11: The threshold for V

influence the value of V

is generated internally and routed to VOscF pin. Any DC current on this pin will

VOB

VOB

.

Note 12: Maximum of deviation from an ideally linear sawtooth ramp at null

CCOR

(Sad0A at x1000000b). The same rate applies to V-drive signal on VOut pin.

SCOR

Note 13: Maximum

Note 14: Null

Note 15: ”t

SCOR

” is time from the beginning ofvertical ramp of V-drive signal on VOut pin. ”TVR” is the duration ofthis ramp,

VR

(Sad09 at x1111111b), null

(Sad09 at x0000000b).

CCOR

(Sad0A at x1000000b).

see chapter TYPICAL OUTPUT WAVEFORMS and Figure 16.

Note 16: V

VOamp

= V

VOT-VVOB

Note 17: The same rate applies to V-drive signal on VOut pin.

Note 18: Informative, not tested on each unit.

6.6 - EW DRIVE SECTION

VCC= 12V, T

Symbol Parameter Test Conditions

V

EW

I

EWOut

V

HEHT

V

EW-DC

V

∆

EW DC–

-----------------------------

∆

V

HEH T

V

∆

EW DC–

-------------------------------------

V

EW DC–

V

EW-PCC

V

EW PCC–

--------------------------------------------------------

EW PC C–

tvrTVR=[]

=25°C

amb

Output voltage on EWOut pin 1.8 6.5 V

Current sourced by EWOut out-

put

Control voltage range on HEH-

TIn pin

DC component of the EW-drive

signal on EWOut pin

Breathing compensation on

V

Temperature drift of DC component of the EW-drive signal on

T∆⋅

EWOut pin

Pin cushion correction component of the EW-drive signal on

EWOut pin

tvr0=[]

Tracking of PCC component of

the EW-drive signalwith vertical

position adjustment

EW-DC

(19)(22)(23)(30)

tVR=1/2 T

HSIZE

VR

(Sad10h):

00000000b

10000000b

11111111b

(19)(20)(21)(22)

tVR=1/2 T

V

HEHT>VRefO

V

HEHT

(18)(19)(21)(23)(30)

tVR=1/2 T

(19)(20)(21)(23)(24)(25)

(26)(30)

VSIZE

PCC

(15)

VR

(min)≤V

VR

at maximum

(Sad0C):

x0000000b

x1000000b

x1111111b

Tracking with

PCC

at x1000000b

VSIZE

(Sad07):

x0000000b

x1000000b

(19)(20)(21)(24)(27)(29)(30)

PCC

at x1111111b

VPOS

(Sad08):

x0000000b

x1111111b

SCOR

(15)

HEHT≤VRefO

(15)

VSIZE

:

(Sad09 at x0000000b) and null

Value

Min. Typ. Max.

-1.5 0 mA

1 V

RefO

2

3.25

4.5

0

-0.125

100 ppm/°C

0

0.7

1.5

0.25

0.5

0.52

1.92

Units

V

V

V

V

V/V

V/V

V

V

V

V

V

13/49

TDA9112

Symbol Parameter Test Conditions

Value

Units

Min. Typ. Max.

Keystone correction component

V

EW-Key

of the EW-drive signal on

EWOut pin

Top corner correction compo-

V

EW-TCor

nent of the EW-drive signal on

EWOut pin

Bottom corner correction compo-

V

EW-BCor

V

∆

EW

---------------------------------

∆⋅

V

EWVHO

V

∆

EW AC–

-----------------------------------------------------

V

EW AC–

Note 19:

Note 20:

Note 21:

Note 22:

Note 23:

Note 24:

V

∆⋅

KEYST

TCC

at medium (neutral) value.

BCC

at medium (neutral) value.

PCC

at minimum value.

VPOS

HSIZE

HEH T

nent of the EW-drive signal on

EWOut pin

Tracking of EW-drive signal with

horizontal frequency

Breathing compensation on

(31)

V

EW-AC

at medium (neutral) value.

at medium (neutral) value.

at minimum value.

Note 25: Defined as difference of (voltage at t

Note 26: Defined as difference of (voltage at t

Note 27:

Note 28: Difference (voltage at t

VSIZE

at maximum value.

=0) minus (voltage at tVR=TVR).

VR

(32)

=0) minus (voltage at tVR=1/2 TVR).

VR

VR=TVR

(20)(21)(22)(23)(24)(27)(28)(30)

KEYST

(Sad0D):

x0000000b

x1111111b

(19)(21)(22)(23)(24)(25)(27)(30)

TCC

(Sad0E):

x0000000b

x1000000b

x1111111b

(19)(20)(22)(23)(24)(26)(27)(30)

BCC

(Sad0F):

x0000000b

x1000000b

x1111111b

VHO>V

HOThrfr

VHO(min)≤VHO≤V

(25)(26)

V

HEHT>VRefO

V

(min)≤V

HEHT

HOThrfr

HEHT≤VRefO

) minus (voltage at tVR=1/2 TVR).

0.4

-0.4

-1.25

0

+1.25

-1.25

0

+1.25

0

-27

0

1.75

Note 29: Ratio ”A/B”of parabola component voltage at tVR=0 versus parabola component voltage at tVR=TVR.

See Figure 2.

Note 30: V

Note 31: V

HEHT>VRefO

EW-AC

, V

VEHT>VRefO

is sum of all components other than V

(contribution of PCC, keystone correction and corner

EW-DC

corrections).

Note 32: More precisely tracking with voltage on HPLL1F pin which itself depends on frequency at a rate given by

external components on PLL1 pins.

V

V

V

V

V

V

V

V

%/V

%/V

%/V

%/V

14/49

6.7 - DYNAMIC CORRECTION OUTPUTS SECTION

TDA9112

VCC= 12V, T

amb

=25°C

Symbol Parameter Test Conditions

Composite Horizontal and Vertical Dynamic Correction output HVDyCor

I

HVDyCor

V

HVD-DC

V

∆

HVD DC–

--------------------------------------- -

V

HVD DC–

V

HVD-H

Current delivered by HVDyCor

output

DC component of the drive signal

on HVDyCor output

Temperature drift of DCcomponent

of the drive signal on HVDyCor

T∆⋅

Amplitude of H-parabola component of the drive signal on HVDyCor output

R

L(HVDyCor)

(18)

(33)(34)

=10kΩ 2.1 V

HDyCorTr Off

HVDC-HAMP

x0000000b

x1000000b

x1111111b

V

constant

V

HVD H–

------------------------------------------------------

V

HVD H–

V

HVD H–

---------------------------------------------------------- -

V

HVD H–

TrHSOn[]

TrHSOff[]

TrEHTOn[]

TrEHTOff[]

t

HVD-Hoffset/TH

Impact of horizontal size adjustment on HVDyCor H-parabola

component (tracking)

(35)

Impact of voltage on HEHTIninput

on HVDyCor H-parabola compo-

(36)

nent

Offset (phase) of H-parabola com-

ponent of the drive signal on HVDyCor output

(38)

HEHT

HSIZE

(Sad10h):

00000000b

11111111b

HSIZE

constant

V

HEHT>VRefO

V

HEHT=VRefO

HVDC-HSYM

x0000000b

x1000000b

x1111111b

-4V

(39)

Duration of the flat part at the start

t

HVD-Hflat

of H-parabola component of the

drive signal on HVDyCor output

fHO=31kHz 500 ns

(38)

(23)

VSIZE

at x1000000b

HVDC-VAMP

x0000000b

V

HVD-V

Amplitude of V-parabola component of the drive signal on HVDyCor output

x1000000b

x1111111b

HVDC-VAMP

mum

VSIZE

(Sad07):

x0000000b

x1111111b

HVDC-VAMP

V

HVD V–tvr

------------------------------------------------------

V

HVD V–tvrTVR

0=[]

=[]

Tracking of V-parabola component

of thedrive signal on HVDyCor output with vertical position

(37)

mum

VPOS

(Sad08):

x0000000b

x1111111b

(Sad04):

(Sad05):

(Sad06):

at maxi-

at maxi-

Value

Min. Typ. Max.

-2 0 mA

200 ppm/°C

3.7

1.5

0.9

2

(1.34)

1

1

2

(1.07)

+24.5

0

-24.5

0

0.5

1

0.5

1.6

0.52

1.92

Units

V

V

V

%

%

%

V

V

V

V

V

15/49

Loading...

Loading...