Page 1

TDA8559T

Low-voltage stereo headphone amplifier

Rev. 03 — 15 May 2006 Product data sheets

1. General description

The TDA8559T is a stereo amplifier that operates over a wide supply voltage range from

1.9 V to 30 V and consumes a very low quiescent current. This makes it suitable for

battery fed applications (2 ×1.5 V cells). Because of an internal voltage buffer, this device

can be used with or without a capacitor connected in series with the load. It can be

applied as a headphone amplifier, but also as a mono amplifier with a small speaker

(25 Ω), or as a line driver in mains applications.

2. Features

n Operating voltage from 1.9 V to 30 V

n Very low quiescent current

n Low distortion

n Few external components

n Differential inputs

n Usable as a mono amplifier in Bridge-Tied Load (BTL) or stereo Single-Ended (SE)

n Single-ended mode without loudspeaker capacitor

n Mute and Standby mode

n Short-circuit proof to ground, to supply voltage (< 10 V) and across load

n No switch on or switch off clicks

n ESD protected on all pins

3. Applications

n Portable telephones

n MP3 players

n Portable audio

n Mains fed equipment

Page 2

Philips Semiconductors

4. Quick reference data

Table 1. Quick reference data

Symbol Parameter Conditions Min Typ Max Unit

Supplies

V

P

I

q(tot)

I

stb

Stereo application

P

o

THD total harmonic distortion P

G

v

f

ss

BTL application

P

o

THD total harmonic distortion P

G

v

[1] Measured with low-pass filter 30 kHz.

TDA8559T

Low-voltage stereo headphone amplifier

operating supply voltage 1.9 3 30 V

total quiescent current open load - 2.75 4 mA

standby supply current open load - - 10 µA

output power THD = 10 % 30 35 - mW

= 20 mW;

o

f

= 1 kHz

i

= 20 mW;

P

o

f

=10kHz

i

voltage gain 25 26 27 dB

small signal roll-off

−1 dB - 750 - kHz

frequency

output power THD = 10 % 125 140 - mW

= 70 mW;

o

f

= 1 kHz

i

= 70 mW;

P

o

f

=10kHz

i

voltage gain 31 32 33 dB

[1]

- 0.075 0.15 %

[1]

- 0.1 - %

- 0.05 0.1 %

- 0.1 - %

5. Ordering information

Table 2. Ordering information

Type number Package

Name Description Version

TDA8559T SO16 plastic small outline package; 16 leads; body width 3.9 mm; body thickness

1.47 mm

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 2 of 36

SOT109-1

Page 3

Philips Semiconductors

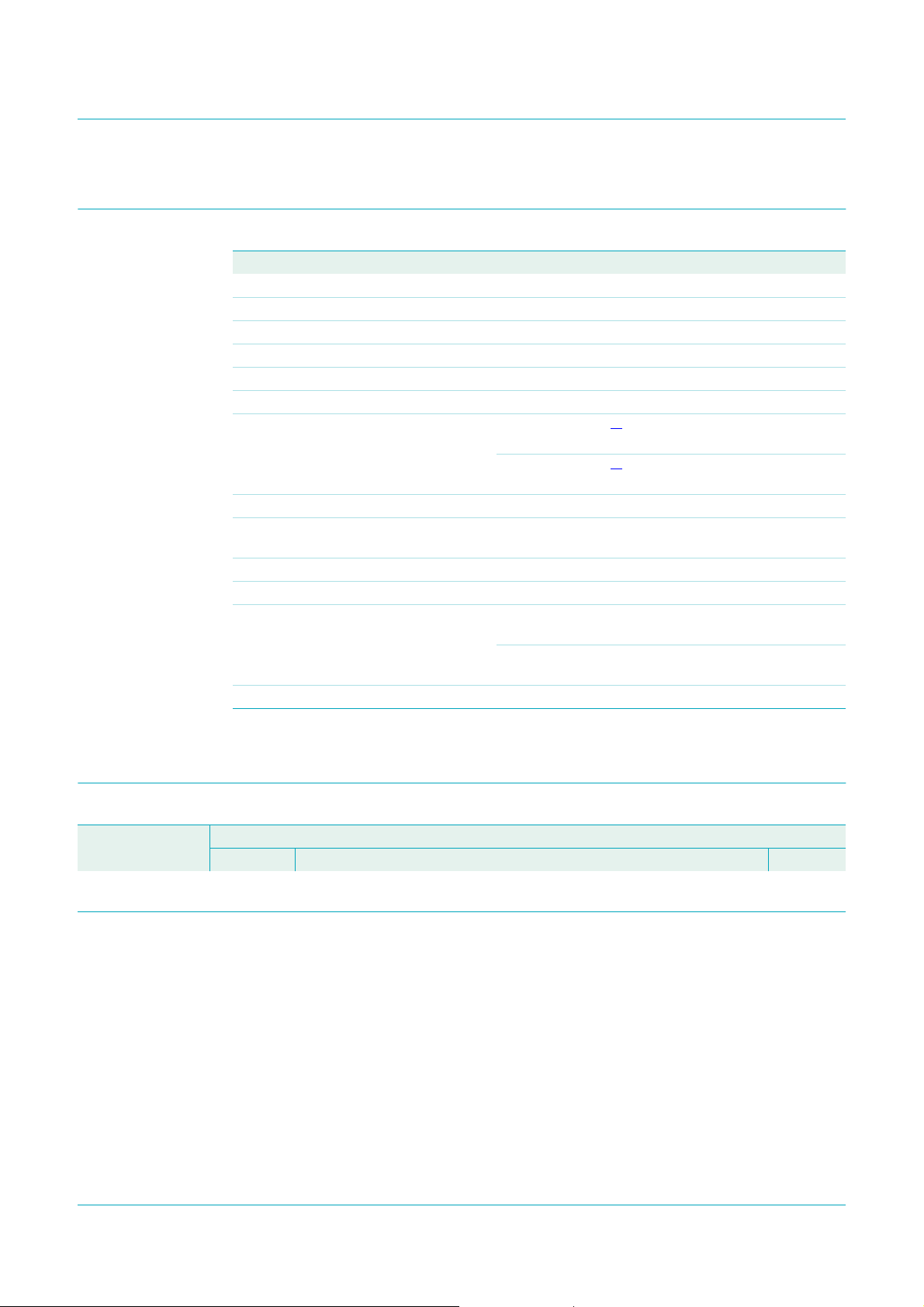

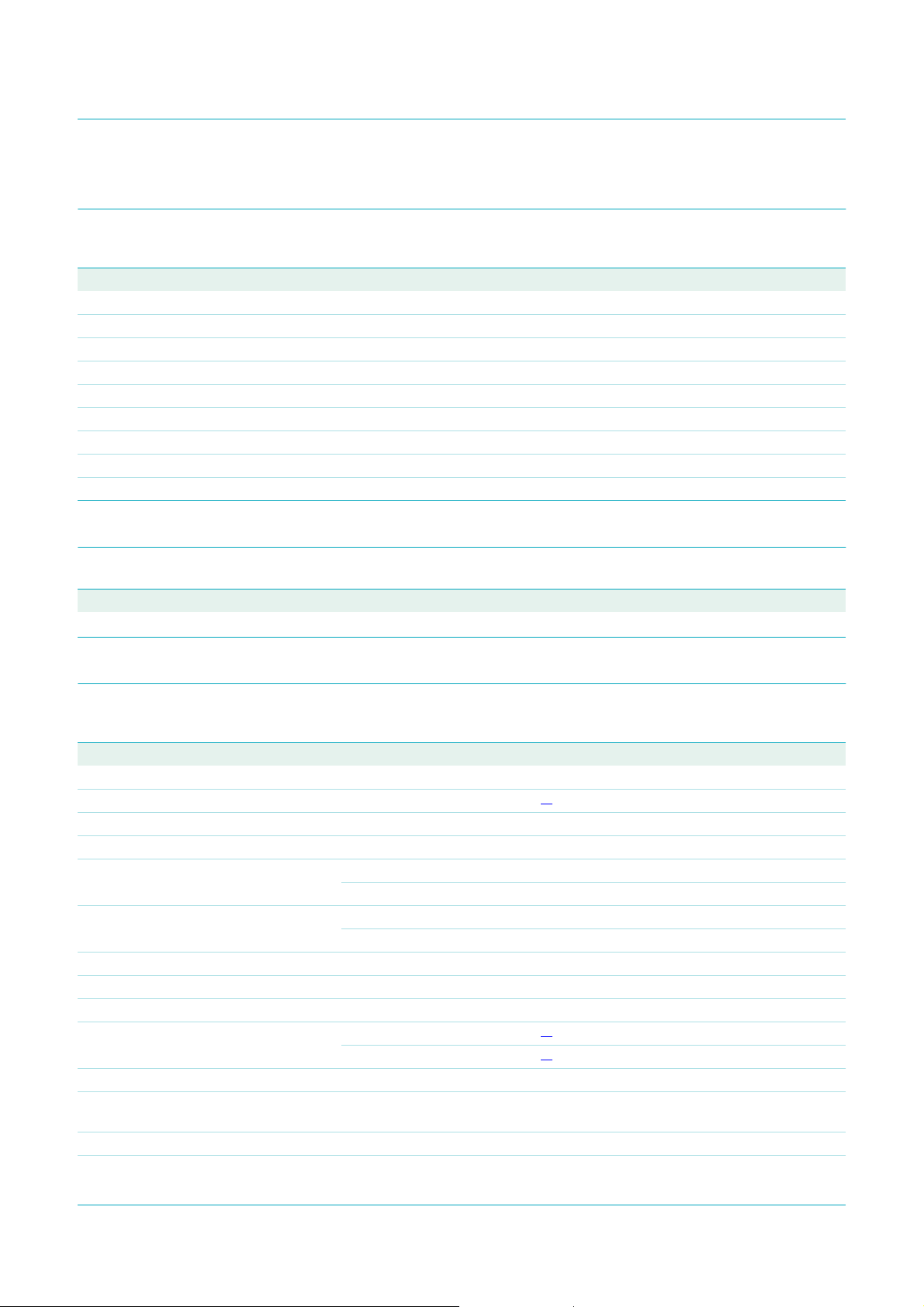

6. Block diagram

TDA8559T

Low-voltage stereo headphone amplifier

STANDBY

+IN1

−IN1

MUTE

MODE

+IN2

−IN2

SVRR

1

2

3

7

8

5

6

V

4

REFERENCE

50 kΩ

50

kΩ

P

100 kΩ

100

kΩ

+

V/I

−

50 kΩ

INPUT

LOGIC

+

V/I

−

50

kΩ

TDA8559T

V

P2

−

+

+

−

BUFFER

50 kΩ

OA

DQC

OA

50 kΩ

V

P1

1615

V

P

14

OUT1

11

OUT2

12

BUFFER

Fig 1. Block diagram

139,10

mgd115

n.c. GND

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 3 of 36

Page 4

Philips Semiconductors

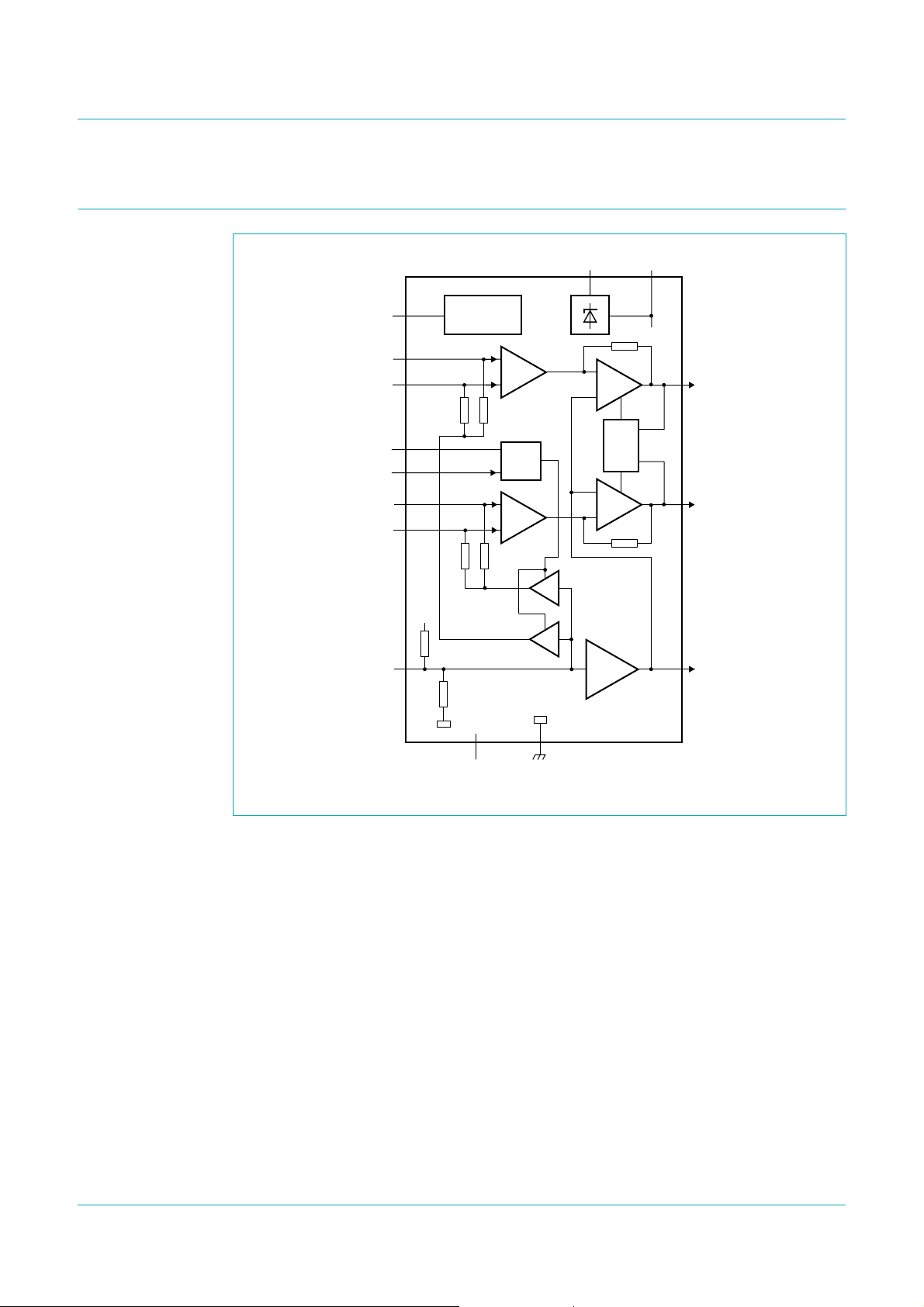

7. Pinning information

7.1 Pinning

TDA8559T

Low-voltage stereo headphone amplifier

STANDBY V

Top view

1

2

+IN1 V

3

−IN1 OUT1

4

SVRR GND

5

+IN2 BUFFER

6

−IN2 OUT2

7

MUTE n.c.

8

MODE n.c.

Fig 2. Pin configuration

7.2 Pin description

Table 3. Pin description

Symbol Pin Description

STANDBY 1 standby select

+IN1 2 non-inverting input 1

−IN1 3 inverting input 1

SVRR 4 supply voltage ripple rejection

+IN2 5 non-inverting input 2

−IN2 6 inverting input 2

MUTE 7 mute select

MODE 8 input mode select

n.c. 9 not connected

n.c. 10 not connected

OUT2 11 output 2

BUFFER 12 buffer output (0.5V

GND 13 ground

OUT1 14 output 1

V

P2

V

P1

15 high supply voltage

16 low supply voltage

TDA8559T

001aae802

)

P

16

P1

15

P2

14

13

12

11

10

9

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 4 of 36

Page 5

Philips Semiconductors

8. Functional description

The TDA8559T contains two amplifiers with differential inputs, a 0.5VPoutput buffer and a

high supply voltage stabilizer. Each amplifier consists of a voltage-to-current converter

(V/I), an output amplifier and a common dynamic quiescent current controller. The gain of

each amplifier is internally fixed at 26 dB (= 20 ×). The 0.5VP output can be used as a

replacement for the single-ended capacitors. The two amplifiers can also be used as a

mono amplifier in a BTL configuration thereby resulting in more output power.

With three mode select pins, the device can be switched into the following modes:

1. Standby mode (IP<10µA)

2. Mute mode

3. Operation mode, with two input selections (the input source is directly connected or

connected via coupling capacitors at the input).

The ripple rejection in the stereo application with a single-ended capacitor can be

improved by connecting a capacitor between the 0.5VP capacitor pin and ground.

TDA8559T

Low-voltage stereo headphone amplifier

The device is fully protected against short-circuiting of the output pins to ground, to the

low supply voltage pin and across the load.

8.1 V/I converters

The V/I converters have a transconductance of 400 µS. The inputs are completely

symmetrical and the two amplifiers can be used in opposite phase. The Mute mode

causes the V/I converters to block the input signal. The input mode pin selects two

applications in which the V/I converters can be used.

The first application (input mode pin floating) is used with a supply voltage below 6 V.The

input DC level is at ground level (the unused input pin connected to ground) and no input

coupling capacitors are necessary. The maximum converter output current is sufficient to

obtain an output swing of 3 V (peak).

In the second application with a supply voltage greater than 6 V (input mode pin HIGH),

the input mode pin is connected to VP. In this configuration (input DC level is

0.5VP+ 0.6 V) the input source must be coupled with a capacitor and the two unused

input pins must be connected via a capacitor to ground, to improve noise performance.

This application has a higher quiescent current, because the maximum output current of

the V/I converter is higher to obtain an output voltage swing of 9 V (peak).

8.2 Output amplifiers

The output amplifiers have a transresistance of 50 kΩ, a bandwidth of approximately

750 kHz and a maximum output current of 100 mA. The mid-tap output voltage equals the

voltage applied at the non-inverting pin of the output amplifier.This pin is connected to the

output of the 0.5VP buffer. This reduces the distortion when the load is connected

between an output amplifier and the buffer (because feedback is applied over the load).

8.3 Buffer

The buffer delivers 0.5VPto the output with a maximum output (sink and source) current of

200 mA (peak).

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 5 of 36

Page 6

Philips Semiconductors

8.4 Dynamic quiescent controller

The Dynamic Quiescent Current controller (DQC) gives the advantage of low quiescent

current and low distortion. When there are high frequencies in the output signal, the DQC

will increase the quiescent current of the two output amplifiers and the buffer. This will

reduce the crossover distortion that normally occurs at high frequencies and low

quiescent current. The DQC gives output currents that are linear with the amplitude and

the frequency of the output signals. These currents control the quiescent current.

8.5 Stabilizer

The TDA8559T has a voltage supply range from 1.9 V to 30 V. This range is divided over

two supply voltage pins. Pin 16 is 1.9 V to 18 V (breakdown voltage of the process); this

pin is preferred for supply voltages less than 18 V. Pin 15 is used for applications where

VPis approximately 6 V to 30 V. The stabilizer output is internally connected to the supply

voltage pin 16. In the range from 6 V to 18 V, the voltage drop to pin 16 is 1 V.In the range

from 18 V to 30 V the stabilizer output voltage (to pin 16) is approximately 17 V.

8.6 Input logic

TDA8559T

Low-voltage stereo headphone amplifier

The MUTE pin (pin 7) selects the Mute mode of the V/I converters. LOW (TTL/CMOS)

levelis mute. A voltage between 0.5 V (low level) and 1.5 V (high level) causes a soft mute

to operate (no plops). When pin 7 is floating or greater than 1.5 V it is in the operating

condition.

The input mode pin must be connected to VPwhen the supply voltage is greater than 6 V.

The input mode logic raises the tail current of the V/I converters and enables the two

buffers to bias the inputs of the V/I converters.

8.7 Reference

This circuit supplies all currents needed in this device. With the Standby mode pin 1

(TTL/CMOS), it is possible to switch to the Standby mode and reduce the total quiescent

current to below 10 µA.

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 6 of 36

Page 7

Philips Semiconductors

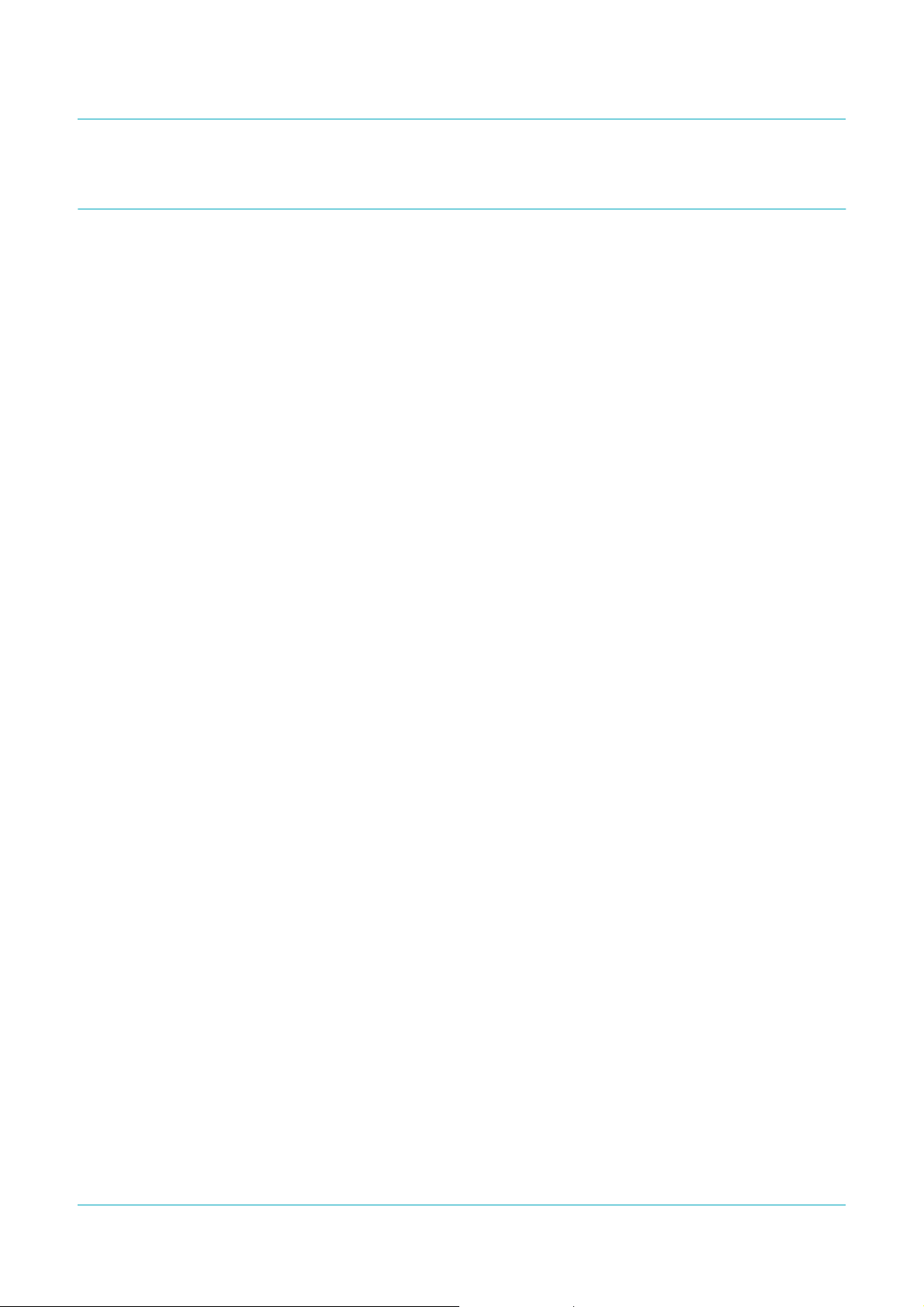

9. Internal circuitry

Table 4. Internal circuits

Symbol Pin Equivalent circuit

STANDBY 1

TDA8559T

Low-voltage stereo headphone amplifier

V

P1

10 kΩ

12

kΩ

mgd110

+IN1, −IN1, +IN2

and −IN2

SVRR 4

2, 3, 5 and 6

V

P1

mgd106

V

P1

50

kΩ

50

kΩ

50

kΩ

50

kΩ

mgd107

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 7 of 36

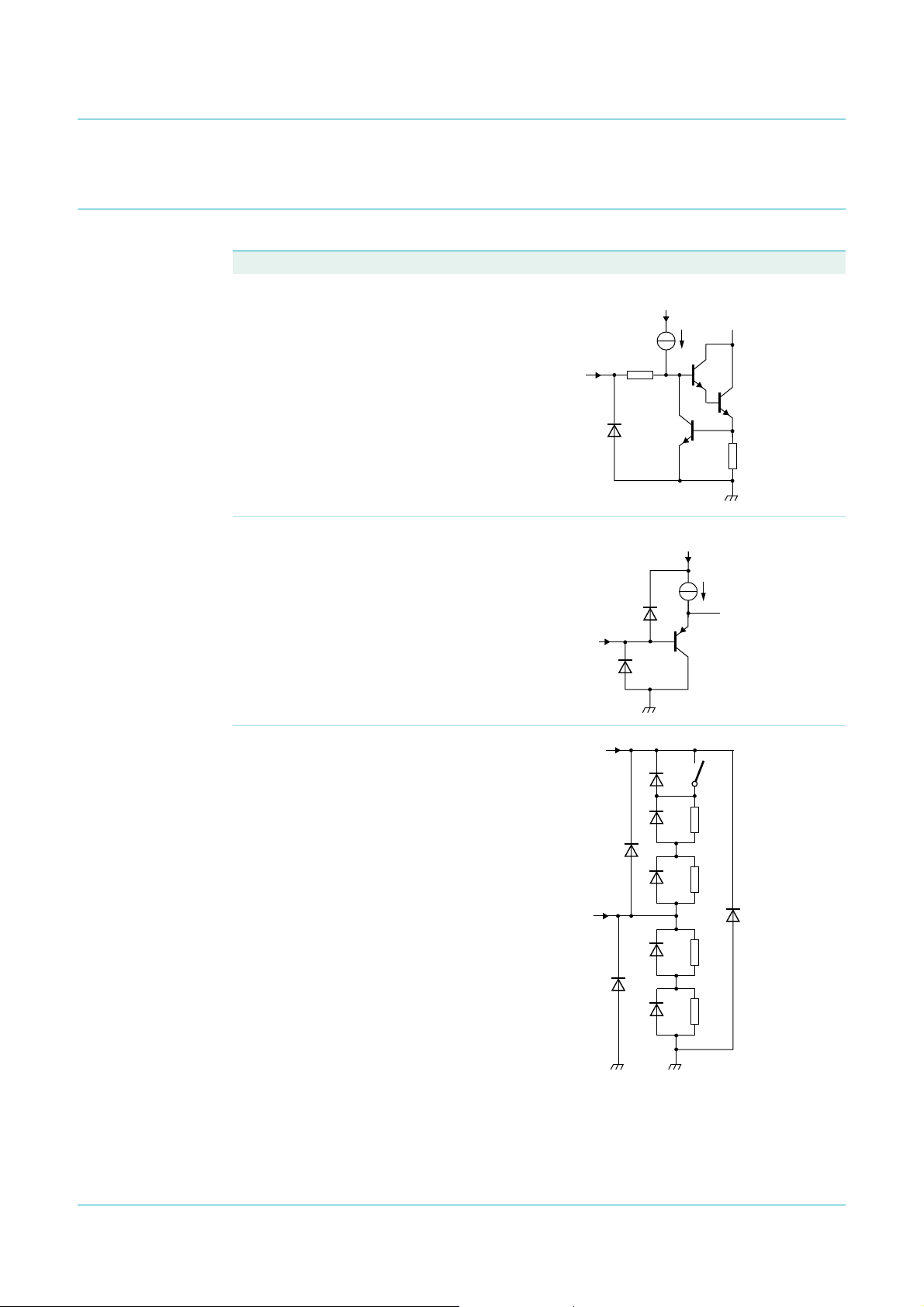

Page 8

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

Table 4. Internal circuits

…continued

Symbol Pin Equivalent circuit

MUTE 7

MODE 8

1 kΩ

V

P1

mgd112

V

P1

250

kΩ

5 kΩ

mgd113

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 8 of 36

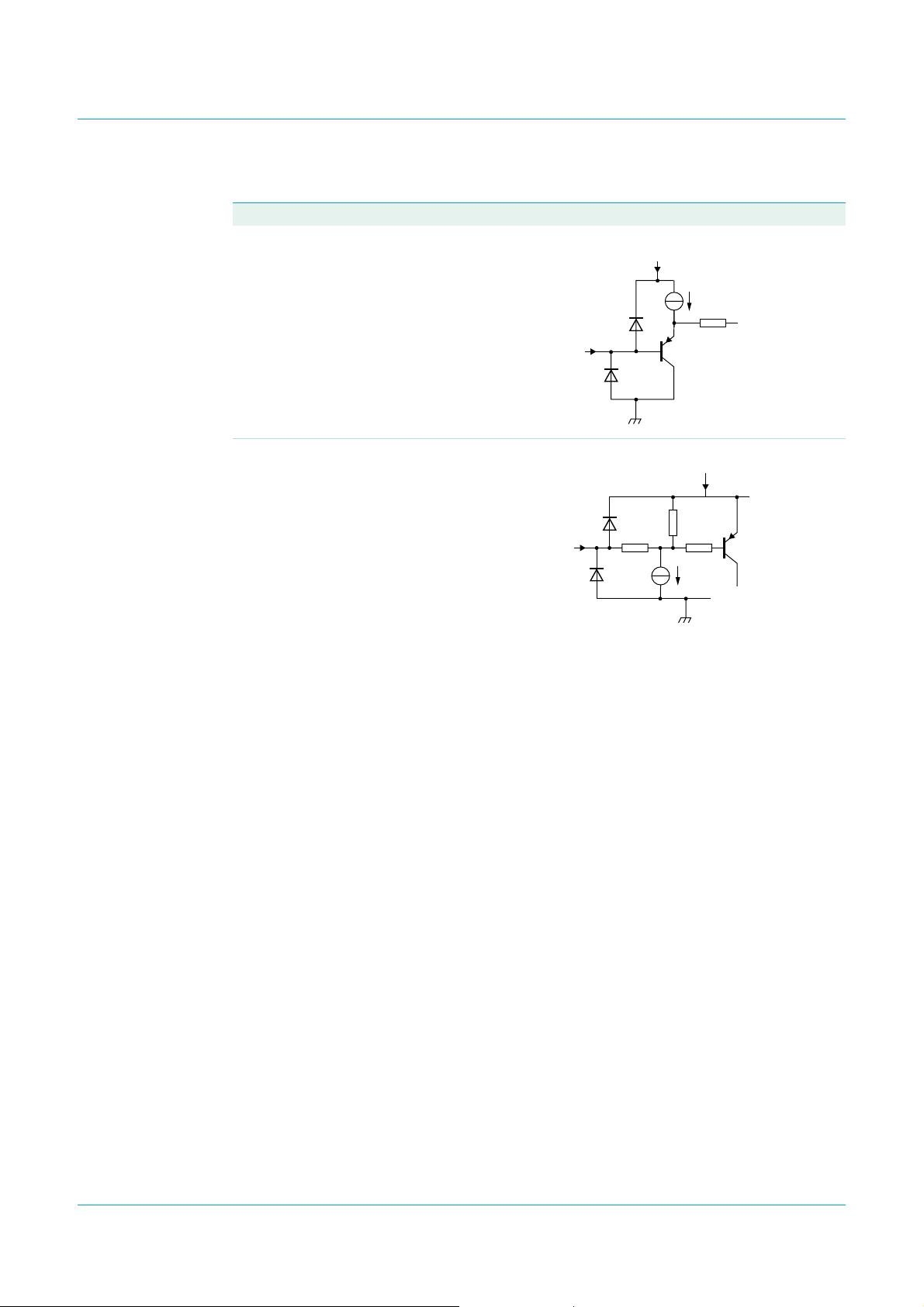

Page 9

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

Table 4. Internal circuits

…continued

Symbol Pin Equivalent circuit

OUT2 and OUT1 11 and 14

50 Ω

buffer output

BUFFER 12

V

P1

100 Ω

mgd108

V

P1

buffer output

V

and V

P2

P1

15 and 16

2 kΩ

mgd109

V

P2

V

P1

mgd111

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 9 of 36

Page 10

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

10. Limiting values

Table 5. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

P2(max)

V

P1(max)

V

i(max)

I

ORM

P

tot

T

amb

T

stg

T

vj

t

sc

maximum supply voltage (pin 15) - 30 V

maximum supply voltage (pin 16) - 18 V

maximum input voltage - 18 V

peak output current repetitive - 150 mA

total power dissipation - 1.19 W

ambient temperature −40 +85 °C

storage temperature −55 +150 °C

virtual junction temperature - 150 °C

short-circuiting time VP<10V - 1 h

11. Thermal characteristics

Table 6. Thermal characteristics

Symbol Parameter Conditions Typ Unit

R

th(j-a)

thermal resistance from junction to ambient in free air 105

K/W

12. Characteristics

Table 7. Characteristics

VP = 3 V; T

Symbol Parameter Conditions Min Typ Max Unit

DC characteristics

V

P

I

q(tot)

I

stb

V

1

V

7

I

bias

Single-ended stereo application (R

P

o

THD total harmonic distortion P

G

v

f

ss

α

cs

channel unbalance - - 1 dB

∆G

v

= 25°C; fi = 1 kHz; unless otherwise specified.

amb

operating supply voltage

[1]

1.9 3 30 V

total quiescent current open load - 2.75 4 mA

standby supply current open load - - 10 µA

Standby mode voltage standby 0 - 0.5 V

operating 1.5 - 18 V

Mute mode voltage mute 0 - 0.5 V

operating 1.5 - 18 V

input bias current - 100 300 nA

= 32 Ω)

L

output power THD = 10 % 30 35 - mW

= 20 mW; fi= 1 kHz

o

= 20 mW; fi=10kHz

P

o

[2]

- 0.075 0.15 %

[2]

- 0.1 - %

voltage gain 25 26 27 dB

small signal roll-off

−1 dB - 750 - kHz

frequency

channel separation Rs = 5 kΩ 40--dB

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 10 of 36

Page 11

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

Table 7. Characteristics

VP = 3 V; T

= 25°C; fi = 1 kHz; unless otherwise specified.

amb

…continued

Symbol Parameter Conditions Min Typ Max Unit

V

no

V

no(mute)

noise output voltage

noise output voltage in

[3]

-7085µV

[3]

-2030µV

mute

V

o(mute)

V

mt

Z

i

V

os

output voltage in mute

mid-tap voltage 1.4 1.5 1.6 V

input impedance 75 100 125 kΩ

DC output offset voltage

SVRR supply voltage ripple

[4]

--30µV

[5]

- - 100 mV

[6]

45 55 - dB

rejection

BTL application (R

P

o

THD total harmonic distortion P

G

v

f

ss

= 25 Ω)

L

output power THD = 10 % 125 140 - mW

= 70 mW; fi= 1 kHz - 0.05 0.1 %

o

= 70 mW; fi= 10 kHz - 0.1 - %

P

o

voltage gain 31 32 33 dB

small signal roll-off

−1 dB - 750 - kHz

frequency

V

no

V

no(mute)

noise output voltage

noise output voltage in

[3]

- 100 120 µV

[3]

-2540µV

mute

V

o(mute)

Z

i

V

os

output voltage in mute

input impedance 39 50 61 kΩ

DC output offset voltage

SVRR supply voltage ripple

[4]

--40µV

[7]

- - 150 mV

[6]

39 49 - dB

rejection

Line driver application (R

V

o

line output voltage 0.1 - 2.9 V

= 1 kΩ)

L

[1] The supply voltage range at pin VP1 is from 1.9 V to 18 V. Pin VP2 is used for the voltage range from 6 V to 30 V.

[2] Measured with low-pass filter 30 kHz.

[3] Noise output voltage measured with a bandwidth of 20 Hz to 20 kHz, unweighted. Rs=5kΩ.

[4] RMS output voltage in mute is measured with Vi= 200 mV (RMS); f = 1 kHz.

[5] DC output offset voltage is measured between the signal output and the 0.5VP output.

[6] The ripple rejection is measured with a ripple voltage of 200 mV (RMS) applied to the positive supply rail (Rs=0kΩ).

[7] DC output offset voltage is measured between the two signal outputs.

13. Application information

13.1 General

For applications with a maximum supply voltage of 6 V (input mode low) the input pins

need a DC path to ground (see Figure 3 and Figure 4). For applications with supply

voltages in the range from 6 V to 18 V (input mode HIGH) the input DC level is

0.5VP+ 0.6 V. In this situation the input configurations illustrated in Figure 5 and Figure 6

have to be used.

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 11 of 36

Page 12

Philips Semiconductors

The capacitor Cb is recommended for stability improvement.The value may vary between

10 nF and 100 nF. This capacitor should be placed close to the IC between pin 12 and

pin 13.

13.2 Heatsink design

The standard application is stereo headphone single-ended with a 32 Ω load impedance

to buffer (see Figure 9). The headphone amplifier can deliver a peak output current of

150 mA into the load.

TDA8559T

Low-voltage stereo headphone amplifier

For the SO16 envelope R

T

amb

For T

=25°C is:

=60°C the maximum total power dissipation is:

amb

1.2 W

13.3 Test conditions

T

=25°C; unless otherwise specified: VP= 3 V, f = 1 kHz, RL=32Ω, Gain = 26 dB,

amb

low input mode, band-pass filter: 22 Hz to 30 kHz. The total harmonic distortion as a

function of frequency was measured with low-pass filter of 80 kHz. The quiescent current

has been measured without any load impedance.

In applications with coupling capacitors towards the load, an electrolytic capacitor has to

be connected to pin 4 (SVRR).

1. The graphs for the single-ended application have been measured with the application

illustrated in Figure 9; input configuration for input mode low (Figure 4) and input

configuration for input mode high (Figure 6).

2. The graphs for the BTL application ‘input mode low’ have been measured with the

application circuit illustrated in Figure 11 and the input configuration illustrated in

Figure 4.

3. The graphs for the line-driver application have been measured with the application

circuit illustrated in Figure 13 and the input configuration illustrated in Figure 6; input

mode high.

th(j-a)

150 25–

=

-------------------- -

= 105 K/W; the maximum sinewave power dissipation for

105

0.85 W

150 60–

=

-------------------- -

105

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 12 of 36

Page 13

Philips Semiconductors

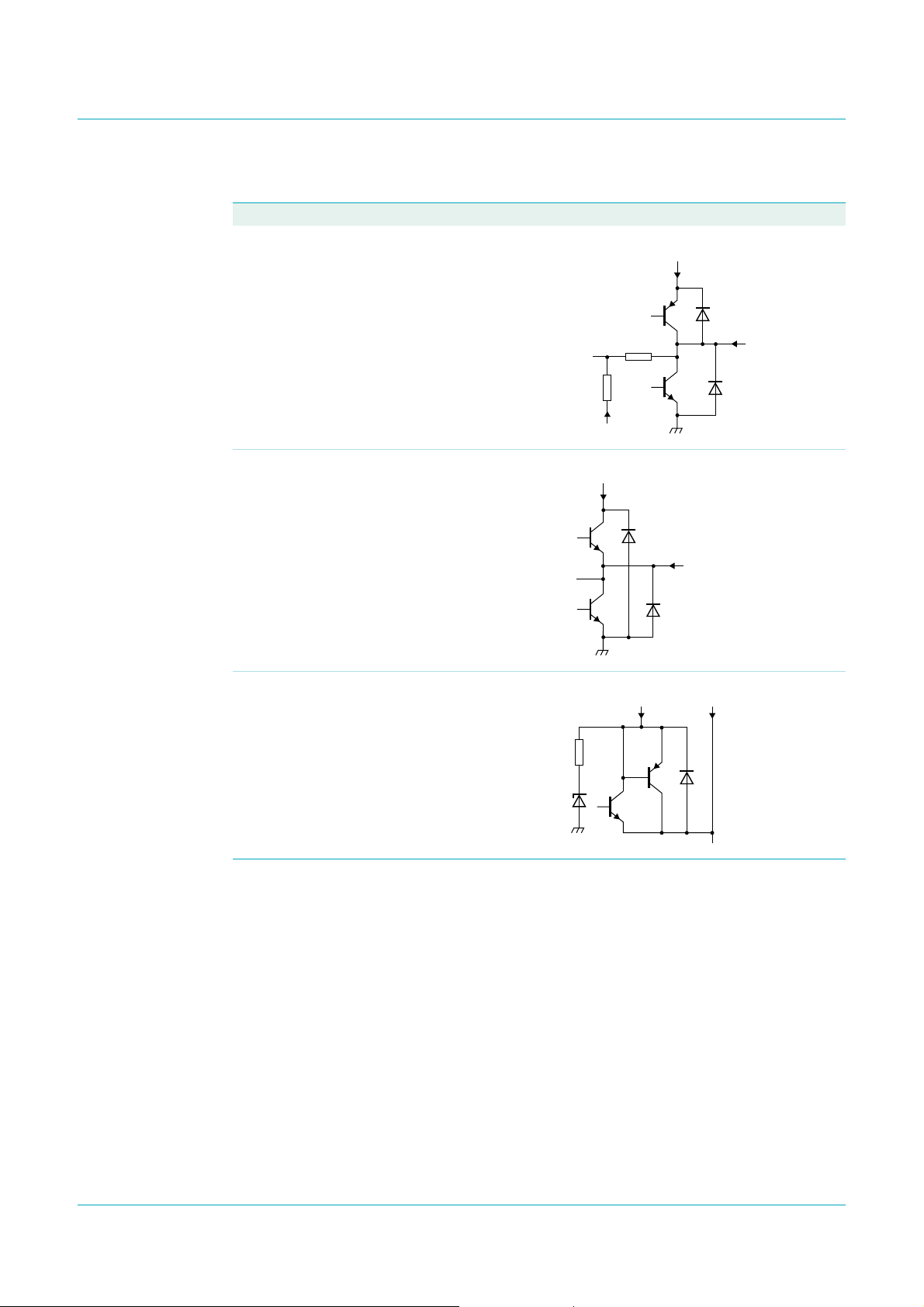

13.4 Input configurations

The IC can be applied in two ways, ‘input mode low’ and ‘input mode high’. This can be

selected by the input mode at pin 8:

1. Input mode low: pin 8 floating: The DC level of the input pins has to be between 0 V

and (VP− 1.8 V). A DC path to ground is needed. The maximum output voltage is

approximately 2.1 V (RMS). Input configurations illustrated in Figure 3 and Figure 4

should be used.

2. Input mode high: pin 8 is connected to VP: This mode is intended for supply voltages

> 6 V. It can deliver a maximum output voltage of approximately 6 V (RMS) at

THD = 0.5 %. The DC voltage level of the input pins is (0.5VP+ 0.6 V). Coupling

capacitors are necessary. Input configurations illustrated in Figure 5 and Figure 6

should be used.

TDA8559T

Low-voltage stereo headphone amplifier

2.2 µF

V

IN

5 kΩ INPUT

pins 2 and 5

pins 3 and 6

mgd123

pins 2 and 5

V

IN

INPUT

pins 3 and 6

mgd124

VP< 6 V. VP< 6 V.

Fig 3. Input configuration; with input capacitor Fig 4. Input configuration; without input capacitor

pin 2

V

220 nF

V

IN

220 nF

pins 2 and 5

INPUT

pins 3 and 6

mgd125

V

100 nF

IN

220

nF

IN

100 nF

pin 3

pin 6

pin 5

mgd126

VP< 6 V. At VP< 6 V, combined negative inputs.

Fig 5. Input configuration Fig 6. Input configuration

V

P

620 kΩ

47 kΩ

mute

7

220 nF

mgl135

Fig 7. Soft mute

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 13 of 36

Page 14

Philips Semiconductors

13.5 Standby/mute

1. The Standby mode (V1< 0.5 V) is intended for power saving purpose. Then the total

quiescent current is < 10 µA.

2. To avoid ‘pop-noise’ during switch-on or switch-off the IC can be muted (V7< 0.5 V).

This can be achieved by a ‘soft-mute’ circuit or by direct control from a microcontroller.

13.6 Application 1: SE with loudspeaker capacitor

The value of capacitor Cr influences the behavior of the Supply Voltage Ripple Rejection

(SVRR) at low frequencies; increasing the value of Cr increases the performance of the

SVRR; see Figure 8.

13.7 Application 2: SE to buffer (without loudspeaker capacitor)

This is the basic headphone application. The advantage of this application with respect to

application 1, is that it needs only one external component (Cb) in the event of stability

problems; see Figure 9.

TDA8559T

Low-voltage stereo headphone amplifier

13.8 Application 3: Improved SE to buffer (without loudspeaker capacitor)

This application is an improved configuration of application 2. The distinction between the

two is connecting the loads in opposite phase. This lowers the average current through

the SE buffer. It should be noted that a headphone cannot be used because the load

requires floating terminals; see Figure 10.

13.9 Application 4: Bridge tied load mono amplifier

This configuration delivers fourtimes the output power of the SE application with the same

supply and load conditions. The capacitor Cr is not required; see Figure 11.

13.10 Application 5: Line driver application

The TDA8559T delivers a virtual rail-to-rail output voltage and is also usable in a low

voltage environment, as a line driver. In this application the input needs a DC path to

ground, input configurations illustrated in Figure 3 and Figure 4 should be used. The value

of capacitor Cr influences the behavior of the SVRR at low frequencies; increasing the

value of Cr increases the performance of the SVRR; see Figure 12.

13.11 Application 6: Line driver application

The TDA8559T delivers a virtual rail-to-rail output voltage.Because the input mode has to

be high, the input configurations illustrated in Figure 5 and Figure 6 should be used. This

application can also be used for headphone application, however, due to the limited output

current and the limited output power at the headphone, series resistors have to be used

between the output pins and the load; see Figure 13.

The value of capacitor Cr influences the behavior of the SVRR at low frequencies;

increasing the value of Cr increases the performance of the SVRR.

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 14 of 36

Page 15

Philips Semiconductors

13.12 Application 7: Line driver application

With the supply voltage connected to pin 15 it is possible to use the head amplifier above

the maximum of 18 V to pin 16. The internal supply voltage will be reduced to a maximum

of approximately 17 V.

This will be convenient in applications where the supply voltage is higher than 18 V,

however an output voltage swing that reaches the higher supply voltage is not required.

the input configurations illustrated in Figure 5 and Figure 6 should be used. This

application can also be used for headphone applications. However, due to the limited

output current, series resistors have to be used between the output pins and the load; see

Figure 14.

13.13 Application diagrams

STANDBY

IN1

1

2

3

REFERENCE

50 kΩ

50 kΩ

TDA8559T

Low-voltage stereo headphone amplifier

+V

P

100 µF

+−

32 Ω

50 kΩ

V

P1

1615

V

P

14

OUT1

100

nF

220 µF

V

P2

+

V/I

−

−

OA

+

MUTE

MODE

IN2

22 µF

SVRR

Cr

7

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

INPUT

LOGIC

+

V/I

−

50

kΩ

TDA8559T

GND

13

DQC

+

OA

−

50 kΩ

BUFFER

Fig 8. Application 1; single-ended with loudspeaker capacitor

11

12

OUT2

BUFFER

220 µF

32 Ω

+−

Cb

mgd116

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 15 of 36

Page 16

Philips Semiconductors

STANDBY

IN1

1

2

3

REFERENCE

50 kΩ

+

−

50 kΩ

V/I

TDA8559T

Low-voltage stereo headphone amplifier

+V

V

P2

50 kΩ

−

OA

+

V

P1

1615

V

P

14

OUT1

100

nF

+−

32 Ω

P

100 µF

MUTE

MODE

IN2

SVRR

7

50

kΩ

INPUT

LOGIC

+

V/I

−

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

TDA8559T

DQC

+

OA

−

50 kΩ

BUFFER

11

12

OUT2

BUFFER

32 Ω

+−

13

GND

Fig 9. Application 2; single-ended to buffer (without loudspeaker capacitor)

Cb

mgd117

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 16 of 36

Page 17

Philips Semiconductors

STANDBY

IN1

1

2

3

REFERENCE

50 kΩ

+

−

50 kΩ

V/I

TDA8559T

Low-voltage stereo headphone amplifier

+V

P

100 µF

50 kΩ

V

P1

1615

V

P

14

OUT1

100

nF

32 Ω

+−

V

P2

−

OA

+

MUTE

MODE

IN2

SVRR

7

50

kΩ

INPUT

LOGIC

+

V/I

−

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

TDA8559T

DQC

+

OA

−

50 kΩ

BUFFER

11

12

32 Ω

OUT2

+−

BUFFER

Cb

13

mgd118

GND

Fig 10. Application 3; improved single-ended to buffer (without loudspeaker capacitor)

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 17 of 36

Page 18

Philips Semiconductors

STANDBY

IN1

1

2

3

REFERENCE

50 kΩ

50 kΩ

TDA8559T

Low-voltage stereo headphone amplifier

50 kΩ

V

P1

1615

V

P

100

nF

OUT1

14

V

P2

+

V/I

−

−

OA

+

100 µF

+V

P

MUTE

MODE

IN2

SVRR

7

8

5

6

100

kΩ

50

kΩ

TDA8559T

50

kΩ

V

P

100 kΩ

4

Fig 11. Application 4; BTL mono amplifier

INPUT

LOGIC

+

V/I

−

GND

11

12

25 Ω

OUT2

BUFFER

Cb

mgd119

DQC

+

OA

−

50 kΩ

BUFFER

13

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 18 of 36

Page 19

Philips Semiconductors

STANDBY

IN1

1

2

3

REFERENCE

50 kΩ

50 kΩ

TDA8559T

Low-voltage stereo headphone amplifier

+V

P

100 µF

1 kΩ

50 kΩ

V

P1

1615

V

P

14

OUT1

100

nF

10 µF

V

P2

+

V/I

−

−

OA

+

22 µF

MUTE

MODE

IN2

Cr

SVRR

7

50

kΩ

INPUT

LOGIC

+

V/I

−

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

TDA8559T

GND

VP = 1.9 V to 6 V.

Fig 12. Application 5; line driver application

DQC

+

OA

−

50 kΩ

BUFFER

11

12

OUT2

BUFFER

10 µF

1 kΩ

Cb

13

mgd120

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 19 of 36

Page 20

Philips Semiconductors

STANDBY

100 nF

IN1

1

2

3

REFERENCE

50 kΩ

50 kΩ

TDA8559T

Low-voltage stereo headphone amplifier

+V

P

100 µF

1 kΩ

50 kΩ

V

P1

1615

V

P

100

nF

OUT1

14

10 µF

V

P2

+

V/I

−

−

OA

+

220

nF

100 nF

IN2

22 µF

Cr

MUTE

MODE

SVRR

7

50

kΩ

INPUT

LOGIC

+

V/I

−

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

TDA8559T

VP = 6 V to 18 V.

Fig 13. Application 6; line driver application

GND

DQC

+

OA

−

50 kΩ

BUFFER

11

12

OUT2

BUFFER

10 µF

1 kΩ

Cb

13

mgd121

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 20 of 36

Page 21

Philips Semiconductors

STANDBY

100 nF

IN1

1

2

3

REFERENCE

50 kΩ

50 kΩ

TDA8559T

Low-voltage stereo headphone amplifier

+V

P

50 kΩ

V

P1

1615

V

P

100

100 µF

nF

OUT1

14

10 µF

+

−

V

P2

+

V/I

−

−

OA

+

220

nF

100 nF

IN2

SVRR

MUTE

MODE

7

50

kΩ

INPUT

LOGIC

+

V/I

−

8

5

6

50

kΩ

V

P

100 kΩ

4

100

kΩ

TDA8559T

13

GND

VP = 6 V to 30 V.

Fig 14. Application 7; line driver application

DQC

+

OA

−

50 kΩ

BUFFER

11

12

OUT2

10 µF

BUFFER

POWER

AMPLIFIER

+

−

Cb

mgd122

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 21 of 36

Page 22

Philips Semiconductors

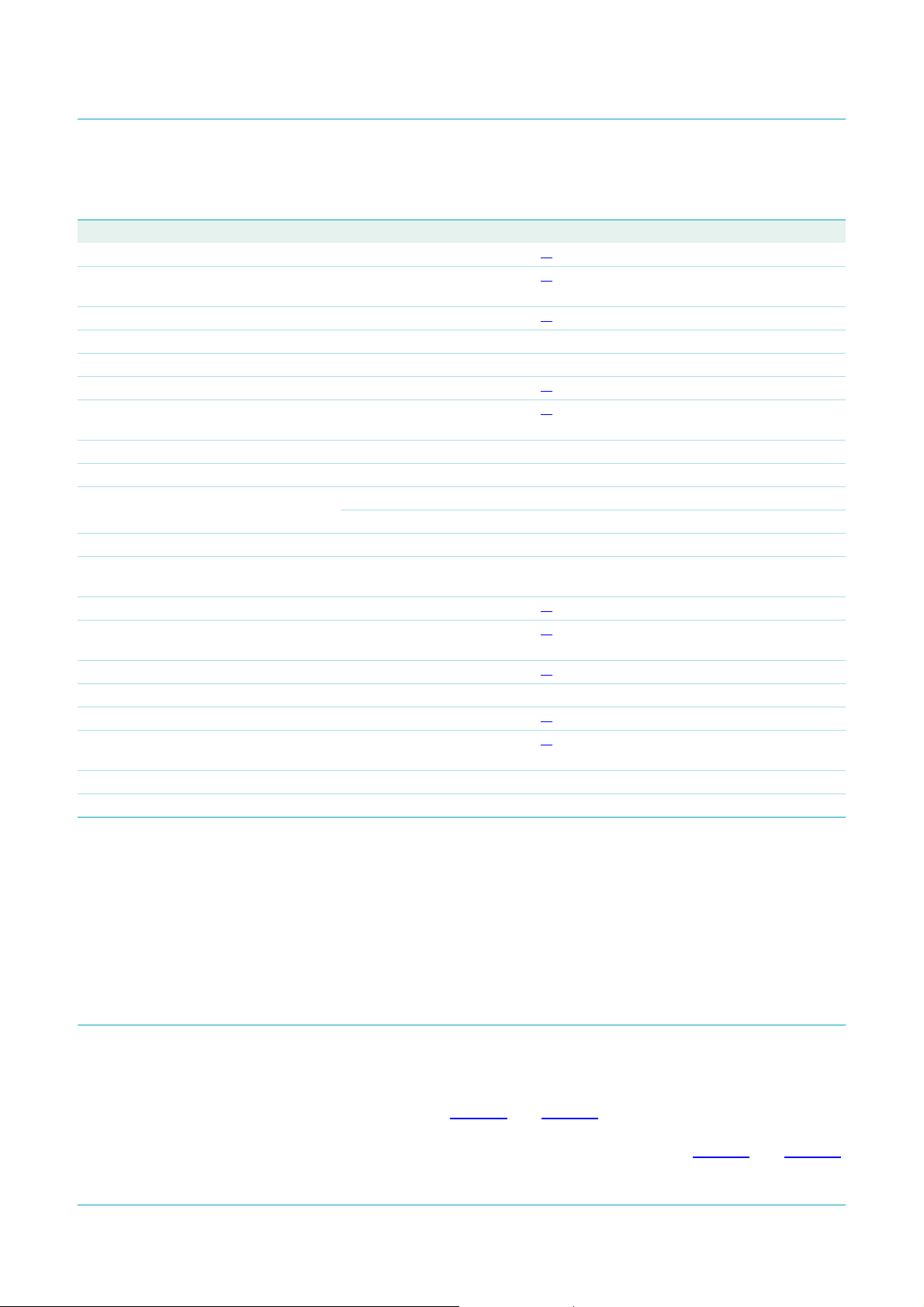

13.14 Printed-circuit board layout

TDA8559T

Low-voltage stereo headphone amplifier

INP2

INP1

220 nF

220 nF

MUTE

Std.

by

89

TDA8559T

1

100 nF

22 µF

5.1 kΩ

5.1 kΩ

Inp.

mode

220 µF

220 µF

Out2

Buf.

Out1

TDA8559T

100 µF

D&A AUDIO POWER

QC - NIJMEGEN

+Vp

HR

001aae801

Top view component side.

Fig 15. Printed-circuit board layout

The Printed-Circuit Board (PCB) layout supports all applications as illustrated in Figure 8

to Figure 14. The PCB layout has been assembled for input configuration as shown in

Figure 3, and output and supply configuration as shown in Figure 8 for a maximum supply

voltage of 6 V.

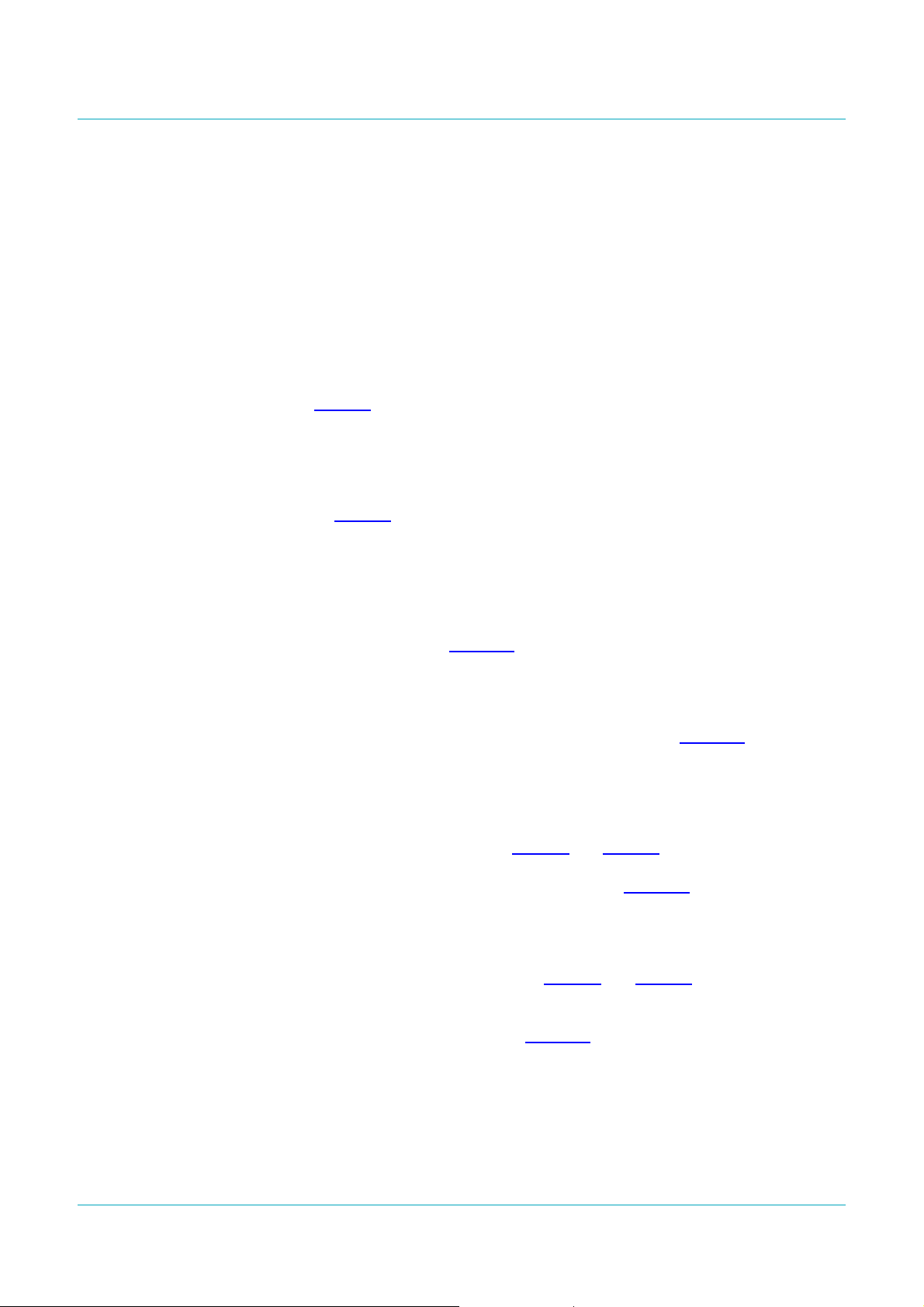

13.15 Response curves for low input mode

10

I

q

(mA)

8

6

4

2

0

020

48

(1)

(2)

12 16

mda089

VP (V)

20

V

P1

(V)

16

12

8

4

0

010 30

20

(1) High mode.

(2) Low mode.

Fig 16. Iq as a function of VP (stereo headphone) Fig 17. VP1 as a function of VP2 (stereo headphone)

mda090

V

(V)

P2

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 22 of 36

Page 23

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

2

10

mda091

1

mda092

THD

(%)

10

1

−

1

10

−2

10

−

3

10

−2

10

f = 1 kHz.

(1) VP = 3 V, RL = 32 Ω.

(2) VP = 5 V, RL = 32 Ω.

(2) (1)

−

1

10

P

o

(W)

1

THD

(%)

−1

10

−2

10

10 10

2

RL = 32 Ω.

(1) VP = 5 V, THD = 50 mW.

(2) VP = 3 V, THD = 20 mW.

(1)

(2)

3

10

4

10

f (Hz)

Fig 18. THD as a function of Po (stereo headphone) Fig 19. THD as a function of frequency (stereo

headphone)

5

10

−2

10

I

q

(A)

−3

10

−4

10

−5

10

−6

10

−7

10

0

(1) (2) (3)

(1) VP = 12 V.

(2) VP = 3 V and 6 V.

(3) VP = 3 V, 6 V and 12 V.

Fig 20. Iq as a function of V

mda093

V

stb

321

(V)

1

V

o

(V)

−1

10

−2

10

−3

10

−4

10

−5

10

(1) VP = 3 V.

(2) VP = 12 V.

(stereo headphone) Fig 21. Vo as a function of V

stb

mda094

(2) (1)

2.50 0.5 1 1.5 2

V

(V)

mute

(stereo headphone)

mute

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 23 of 36

Page 24

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

mda095

4

10

f (Hz)

5

10

α

(dB)

−20

−40

−60

−80

0

cs

10

2

10

3

10

VP = 3 V, Vi = 20 mV. VP = 3 V, Vi = 20 mV.

Fig 22. Channel separation as a function of frequency

(stereo headphone)

0

SVRR

(dB)

−20

mda097

mda096

4

10

f (Hz)

5

10

∆Gr

(dB)

0.5

−0.5

1

0

−1

10

2

10

3

10

Fig 23. Channel unbalance as a function of frequency

(stereo headphone)

0.4

P

(W)

0.3

o

mda098

−40

−60

−80

10

2

10

3

10

4

10

f (Hz)

5

10

0.2

(1)

(2)

0.1

0

04 12

8

VP (V)

VP = 3 V, Rs = 0 Ω, Vr = 0.2 V (RMS). (1) RL = 32 Ω, THD = 10 %.

(2) RL = 32 Ω, THD = 0.5 %.

Fig 24. SVRR as a function of frequency (stereo

Fig 25. Po as a function of VP (stereo headphone)

headphone)

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 24 of 36

Page 25

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

1.5

P

(W)

1

0.5

0

04

(2) (1)

812

mda099

VP (V)

(1) RL = 25 Ω.

(2) RL = 32 Ω.

Fig 26. Total worst case power dissipation as a

function of supply voltage (SE) (stereo

headphone)

10

THD

(%)

10

10

2

10

1

−1

−2

−3

10

−2

10

−1

10

mda130

(2) (1)

Po (W)

f = 1 kHz.

(1) VP = 3 V, RL = 25 Ω.

(2) VP = 5 V, RL = 25 Ω.

Fig 27. THD as a function of Po (BTL mono)

1

1

THD

(%)

−1

10

(1)

(2)

−2

10

10 10

2

3

10

(1) VP = 3 V, RL = 25 Ω, THD = 70 mW.

mda131

4

10

f (Hz)

5

10

SVRR

(dB)

−20

−40

−60

−80

0

10

2

10

3

10

VP = 3 V, Rs = 0 Ω, Vr = 0.2 V (RMS).

mda132

4

10

f (Hz)

5

10

(2) VP = 5 V, RL = 25 Ω, THD = 150 mW.

Fig 28. THD as a function of frequency (BTL mono) Fig 29. SVRR as a function of frequency (BTL mono)

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 25 of 36

Page 26

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

1

P

o

(W)

0.75

(2) (1)

0.5

0.25

0

04 12

8

mda133

VP (V)

(1) THD = 10 %, RL = 25 Ω.

(2) THD = 0.5 %, RL = 25 Ω.

1.6

P

(W)

1.2

0.8

0.4

0

04

(1) RL = 25 Ω.

(2) RL = 32 Ω

812

mda134

(2) (1)

VP (V)

Fig 30. Po as a function of supply voltage (BTL mono) Fig 31. Total worst case power dissipation as a

function of supply voltage (BTL mono)

13.16 Response curves for high input mode

0.8

P

o

(W)

0.6

0.4

0.2

0

048

(1) RL = 32 Ω, THD = 10 %.

(2) RL = 32 Ω, THD = 0.5 %.

mda119

(2) (1)

12

VP (V)

16

2

P

(W)

1.6

1.2

0.8

0.4

0

048

(2) (1)

(1) RL = 25 Ω.

(2) RL = 32 Ω.

mda120

12

VP (V)

Fig 32. Po as a function of VP (SE) (BTL mono) Fig 33. Total worst case power dissipation as a

function of supply voltage (SE) (stereo

headphone)

16

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 26 of 36

Page 27

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

10

THD

(%)

10

10

2

10

1

−1

−2

−3

10

−2

10

−1

10

mda121

Po (W)

1

THD

(%)

−1

10

−2

10

1

10 10

(1)

(2)

2

3

10

mda122

4

10

f (Hz)

VP = 10 V, RL = 32 Ω, f = 1 kHz. VP = 10 V, RL = 32 Ω.

(1) Po = 100 mW.

(2) Po = 50 mW.

Fig 34. THD as a function of Po (stereo headphone) Fig 35. THD as a function of frequency (stereo

headphone)

5

10

mda123

4

10

f (Hz)

5

10

α

(dB)

−20

−40

−60

−80

0

cs

10

2

10

3

10

VP = 10 V, Vi = 20 mV. VP = 10 V, Rs = 0 Ω, Vr = 0.2 V (RMS).

Fig 36. Channel separation as a function of frequency

(stereo headphone)

0

mda124

SVRR

(dB)

−20

−40

−60

−80

10

2

10

3

10

4

10

f (Hz)

10

Fig 37. SVRR as a function of frequency (stereo

headphone)

5

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 27 of 36

Page 28

Philips Semiconductors

TDA8559T

Low-voltage stereo headphone amplifier

2

10

THD

(%)

10

1

−1

10

−2

10

−2

10

−1

10

(1) VP = 12 V, RL = 1 kΩ.

mda125

(2)

(1)

110

Vo (V)

1

THD

(%)

−1

10

−2

10

10 10

VP = 12 V, Vo = 1 V.

2

3

10

mda126

4

10

f (Hz)

5

10

(2) VP = 18 V, RL = 1 kΩ.

Fig 38. THD as a function of Vo (stereo line driver) Fig 39. THD as a function of frequency (stereo line

driver)

α

(dB)

−20

0

mda127

0

SVRR

(dB)

−20

mda128

−40

−60

−80

10

2

10

3

10

4

10

f (Hz)

5

10

−40

−60

−80

10

2

10

3

10

4

10

f (Hz)

5

10

VP = 12 V, Vi = 20 mV. VP = 12 V, Rs = 0 Ω, Vr = 0.2 V (RMS).

Fig 40. Channel separation as a function of frequency

(stereo line driver)

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Fig 41. SVRR as a function of frequency (stereo line

driver)

Product data sheets Rev. 03 — 15 May 2006 28 of 36

Page 29

Philips Semiconductors

TDA8559T

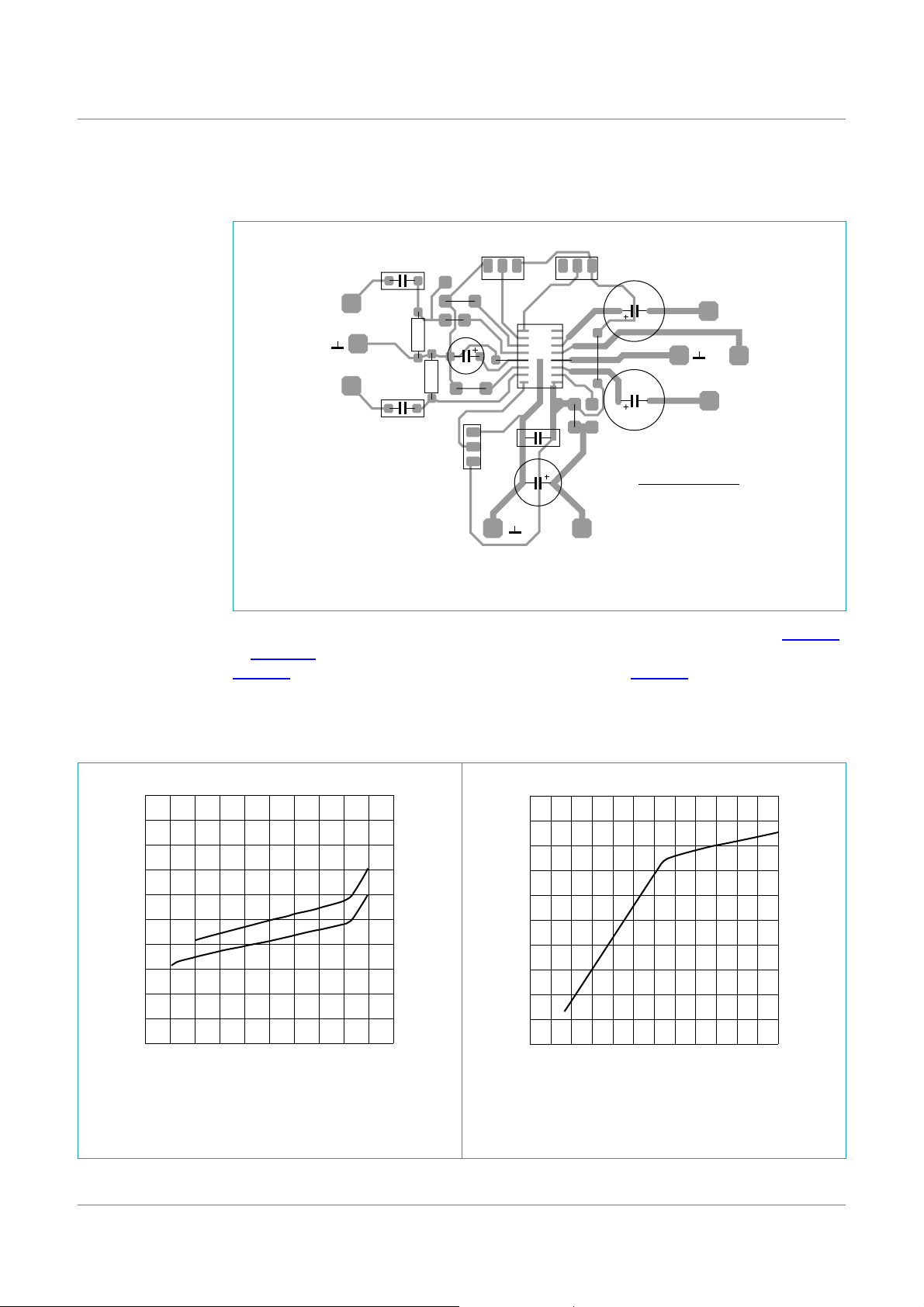

Low-voltage stereo headphone amplifier

(1) THD = 10 %, RL = 1 kΩ.

(2) THD = 0.5 %, RL = 1 kΩ.

Fig 42. Vo as a function of VP (stereo line driver)

14. Test information

10

V

o

(V)

8

6

(1)

4

2

0

020

48

(2)

12 16

mda129

VP (V)

14.1 Quality information

The

General Quality Specification for Integrated Circuits, SNW-FQ-611

is applicable.

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 29 of 36

Page 30

Philips Semiconductors

15. Package outline

TDA8559T

Low-voltage stereo headphone amplifier

SO16: plastic small outline package; 16 leads; body width 3.9 mm

D

c

y

Z

16

pin 1 index

1

e

9

8

w M

b

p

SOT109-1

E

H

E

A

2

A

1

detail X

A

X

v M

A

Q

(A )

L

p

L

A

3

θ

0 2.5 5 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT109-1

A

A1A2A3b

max.

0.25

1.75

0.10

0.010

0.069

0.004

p

1.45

1.25

0.057

0.049

IEC JEDEC JEITA

076E07 MS-012

0.25

0.01

0.49

0.36

0.019

0.014

0.25

0.19

0.0100

0.0075

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

(1)E(1) (1)

cD

10.0

9.8

0.39

0.38

REFERENCES

eHELLpQZywv θ

4.0

3.8

0.16

0.15

1.27

0.05

6.2

5.8

0.244

0.228

1.05

0.041

1.0

0.4

0.039

0.016

0.7

0.25

0.6

0.028

0.01 0.004

0.020

EUROPEAN

PROJECTION

0.25 0.1

0.01

0.7

0.3

0.028

0.012

ISSUE DATE

99-12-27

03-02-19

o

8

o

0

Fig 43. Package outline SOT109-1 (SO16)

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 30 of 36

Page 31

Philips Semiconductors

16. Soldering

16.1 Introduction to soldering surface mount packages

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering can still be used for certain surface mount ICs, but it is not suitable for fine pitch

SMDs. In these situations reflow soldering is recommended.

16.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement. Driven by legislation and

environmental forces the worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example, convection or convection/infrared

heating in a conveyor type oven. Throughput times (preheating, soldering and cooling)

vary between 100 seconds and 200 seconds depending on heating method.

Typical reflow temperatures range from 215 °Cto260°C depending on solder paste

material. The peak top-surface temperature of the packages should be kept below:

TDA8559T

Low-voltage stereo headphone amplifier

Table 8. SnPb eutectic process - package peak reflow temperatures (from

July 2004)

Package thickness Volume mm3 < 350 Volume mm3≥ 350

< 2.5 mm 240 °C+0/−5 °C 225 °C+0/−5 °C

≥ 2.5 mm 225 °C+0/−5 °C 225 °C+0/−5 °C

Table 9. Pb-free process - package peak reflow temperatures (from

2004)

Package thickness Volume mm3 < 350 Volume mm3 350 to

< 1.6 mm 260 °C + 0 °C 260 °C + 0 °C 260 °C + 0 °C

1.6 mm to 2.5 mm 260 °C + 0 °C 250 °C + 0 °C 245 °C + 0 °C

≥ 2.5 mm 250 °C + 0 °C 245 °C + 0 °C 245 °C + 0 °C

Moisture sensitivity precautions, as indicated on packing, must be respected at all times.

16.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering method was specifically

developed.

2000

J-STD-020C

J-STD-020C

Volume mm3 > 2000

July

If wave soldering is used the following conditions must be observed for optimal results:

• Use a double-wave soldering method comprising a turbulent wave with high upward

pressure followed by a smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 31 of 36

Page 32

Philips Semiconductors

– larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

– smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

The footprint must incorporate solder thieves at the downstream end.

• For packages with leads on four sides, the footprint must be placed at a 45° angle to

the transport direction of the printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time of the leads in the wave ranges from 3 seconds to 4 seconds at 250 °C

or 265 °C, depending on solder material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal of corrosive residues in most

applications.

TDA8559T

Low-voltage stereo headphone amplifier

parallel to the transport direction of the printed-circuit board;

transport direction of the printed-circuit board.

16.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low voltage

(24 V or less) soldering iron applied to the flat part of the lead. Contact time must be

limited to 10 seconds at up to 300 °C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 seconds to 5 seconds between 270 °C and 320 °C.

16.5 Package related soldering information

Table 10. Suitability of surface mount IC packages for wave and reflow soldering methods

Package

BGA, HTSSON..T

SSOP..T

DHVQFN, HBCC, HBGA, HLQFP, HSO, HSOP,

HSQFP, HSSON, HTQFP, HTSSOP, HVQFN,

HVSON, SMS

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO, VSSOP not recommended

CWQCCN..L

[1]

[3]

[3]

, TFBGA, VFBGA, XSON

[5]

, SO, SOJ suitable suitable

, LBGA, LFBGA, SQFP,

[8]

, PMFP

[9]

, WQCCN..L

[8]

Soldering method

Wave Reflow

not suitable suitable

not suitable

not suitable not suitable

[2]

[4]

[5][6]

[7]

suitable

suitable

suitable

[1] For more detailed information on the BGA packages refer to the

order a copy from your Philips Semiconductors sales office.

[2] All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal or

external package cracks may occur due to vaporization of the moisture in them (the so called popcorn

effect). For details, refer to the Drypack information in the

Packages; Section: Packing Methods

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 32 of 36

.

(LF)BGA Application Note

Data Handbook IC26; Integrated Circuit

(AN01026);

Page 33

Philips Semiconductors

[3] These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no

account be processed through more than one soldering cycle or subjected to infrared reflow soldering with

peak temperature exceeding 217 °C ± 10 °C measured in the atmosphere of the reflow oven. The package

body peak temperature must be kept as low as possible.

[4] These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the

solder cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink

on the top side, the solder might be deposited on the heatsink surface.

[5] If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[6] Wave soldering is suitable for LQFP, QFP and TQFP packages with a pitch (e) larger than 0.8 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65mm.

[7] Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger

than 0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

[8] Image sensor packages in principle should not be soldered. They are mounted in sockets or delivered

pre-mounted on flex foil. However, the image sensor package can be mounted by the client on a flex foil by

using a hot bar soldering process. The appropriate soldering profile can be provided on request.

[9] Hot bar soldering or manual soldering is suitable for PMFP packages.

TDA8559T

Low-voltage stereo headphone amplifier

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 33 of 36

Page 34

Philips Semiconductors

Low-voltage stereo headphone amplifier

TDA8559T

17. Revision history

Table 11. Revision history

Document ID Release date Data sheet status Change notice Supersedes

TDA8559_3 20060515 Product data sheet - TDA8559_2

Modifications:

TDA8559_2

(9397 750 02066)

TDA8559_1

(9397 750 00546)

• Theformatof this data sheet has been redesigned to comply with the new presentation and

information standard of Philips Semiconductors.

• DIP16 (SOT39-1) package removed

19970627 Product specification - TDA8559_1

19960102 Preliminary specification - -

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 34 of 36

Page 35

Philips Semiconductors

18. Legal information

18.1 Data sheet status

TDA8559T

Low-voltage stereo headphone amplifier

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product status of device(s)described inthis document may havechanged since this document waspublished andmay differin case of multiple devices. Thelatest product status

information is available on the Internet at URL

[1][2]

Product status

18.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. Philips Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information includedherein and shallhave no liabilityfor the consequencesof

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with thesame product typenumber(s) and title.A short data sheet is intended

for quickreference only and shouldnot be relied upon tocontain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local Philips Semiconductors

sales office. In case of any inconsistency orconflict with the short data sheet,

the full data sheet shall prevail.

18.3 Disclaimers

General — Information in this document is believed to be accurate and

reliable. However, Philips Semiconductors does not give any representations

or warranties, expressed or implied, as to the accuracy or completeness of

such information and shall have no liability for the consequences of use of

such information.

Right to make changes — Philips Semiconductors reserves the right to

make changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all informationsupplied prior

to the publication hereof.

Suitability for use — Philips Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

[3]

http://www.semiconductors.philips.com.

Definition

malfunction of a Philips Semiconductors product canreasonably be expected

to result in personal injury, death or severe property or environmental

damage. Philips Semiconductors accepts no liability for inclusion and/or use

of Philips Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is for the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. Philips Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute MaximumRatings System of IEC 60134)may cause permanent

damage tothe device. Limitingvalues are stress ratingsonly and operation of

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale — Philips Semiconductors products are sold

subject to the general terms and conditions of commercialsale, as published

at

http://www.semiconductors.philips.com/profile/terms, including those

pertaining to warranty, intellectual property rights infringement and limitation

of liability, unless explicitly otherwise agreed to in writing by Philips

Semiconductors. Incase of any inconsistency orconflict between information

in this document and such terms and conditions, the latter will prevail.

No offer to sell or license — Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implication ofany license under any copyrights,patents

or other industrial or intellectual property rights.

18.4 Trademarks

Notice: Allreferenced brands,product names, servicenames and trademarks

are the property of their respective owners.

19. Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, send an email to: sales.addresses@www.semiconductors.philips.com

TDA8559_3 © Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheets Rev. 03 — 15 May 2006 35 of 36

Page 36

Philips Semiconductors

20. Contents

TDA8559T

Low-voltage stereo headphone amplifier

1 General description . . . . . . . . . . . . . . . . . . . . . . 1

2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Quick reference data . . . . . . . . . . . . . . . . . . . . . 2

5 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

6 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Pinning information. . . . . . . . . . . . . . . . . . . . . . 4

7.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 4

8 Functional description . . . . . . . . . . . . . . . . . . . 5

8.1 V/I converters . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8.2 Output amplifiers. . . . . . . . . . . . . . . . . . . . . . . . 5

8.3 Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8.4 Dynamic quiescent controller . . . . . . . . . . . . . . 6

8.5 Stabilizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8.6 Input logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8.7 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

9 Internal circuitry. . . . . . . . . . . . . . . . . . . . . . . . . 7

10 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 10

11 Thermal characteristics. . . . . . . . . . . . . . . . . . 10

12 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . 10

13 Application information. . . . . . . . . . . . . . . . . . 11

13.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

13.2 Heatsink design . . . . . . . . . . . . . . . . . . . . . . . 12

13.3 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . 12

13.4 Input configurations . . . . . . . . . . . . . . . . . . . . 13

13.5 Standby/mute . . . . . . . . . . . . . . . . . . . . . . . . . 14

13.6 Application 1: SE with loudspeaker capacitor. 14

13.7 Application 2: SE to buffer (without

loudspeaker capacitor) . . . . . . . . . . . . . . . . . 14

13.8 Application 3: Improved SE to buffer (without

loudspeaker capacitor) . . . . . . . . . . . . . . . . . . 14

13.9 Application 4: Bridge tied load mono amplifier 14

13.10 Application 5: Line driver application . . . . . . . 14

13.11 Application 6: Line driver application . . . . . . . 14

13.12 Application 7: Line driver application . . . . . . . 15

13.13 Application diagrams . . . . . . . . . . . . . . . . . . . 15

13.14 Printed-circuit board layout. . . . . . . . . . . . . . . 22

13.15 Response curves for low input mode . . . . . . . 22

13.16 Response curves for high input mode . . . . . . 26

14 Test information. . . . . . . . . . . . . . . . . . . . . . . . 29

14.1 Quality information . . . . . . . . . . . . . . . . . . . . . 29

15 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 30

16 Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

16.1 Introduction to soldering surface mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

16.2 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 31

16.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 31

16.4 Manual soldering . . . . . . . . . . . . . . . . . . . . . . 32

16.5 Package related soldering information. . . . . . 32

17 Revision history . . . . . . . . . . . . . . . . . . . . . . . 34

18 Legal information . . . . . . . . . . . . . . . . . . . . . . 35

18.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 35

18.2 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

18.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 35

18.4 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 35

19 Contact information . . . . . . . . . . . . . . . . . . . . 35

20 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

For more information, please visit: http://www.semiconductors.philips.com.

For sales office addresses, email to: sales.addresses@www.semiconductors.philips.com.

Date of release: 15 May 2006

Document identifier: TDA8559_3

Loading...

Loading...