Page 1

INTEGRATED CIRCUITS

TDA5360

Pre–Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

Objective specification, Revision 2.2 1998 Jul 30

Page 2

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

1 FEATURES

2 APPLICATIONS

3 QUICK REFERENCE DATA

4 DESCRIPTION

5 ORDERING INFORMATION

6 BLOCK DIAGRAM

7 PINOUT DIAGRAM

8 PIN DESCRIPTIONS

9 FUNCTIONAL DESCRIPTION

9.1 ACTIVE READ MODE

9.2 ACTIVE WRITE MODE

9.3 ACTIVE STW MODE

9.4 STANDBY MODE

9.5 SLEEP MODE

10 BIASING OFTHE MR ELEMENT

10.1 MR HEAD RESISTANCE AND TEMPERATURE MEASUREMENT

10.2 FAULT MODE

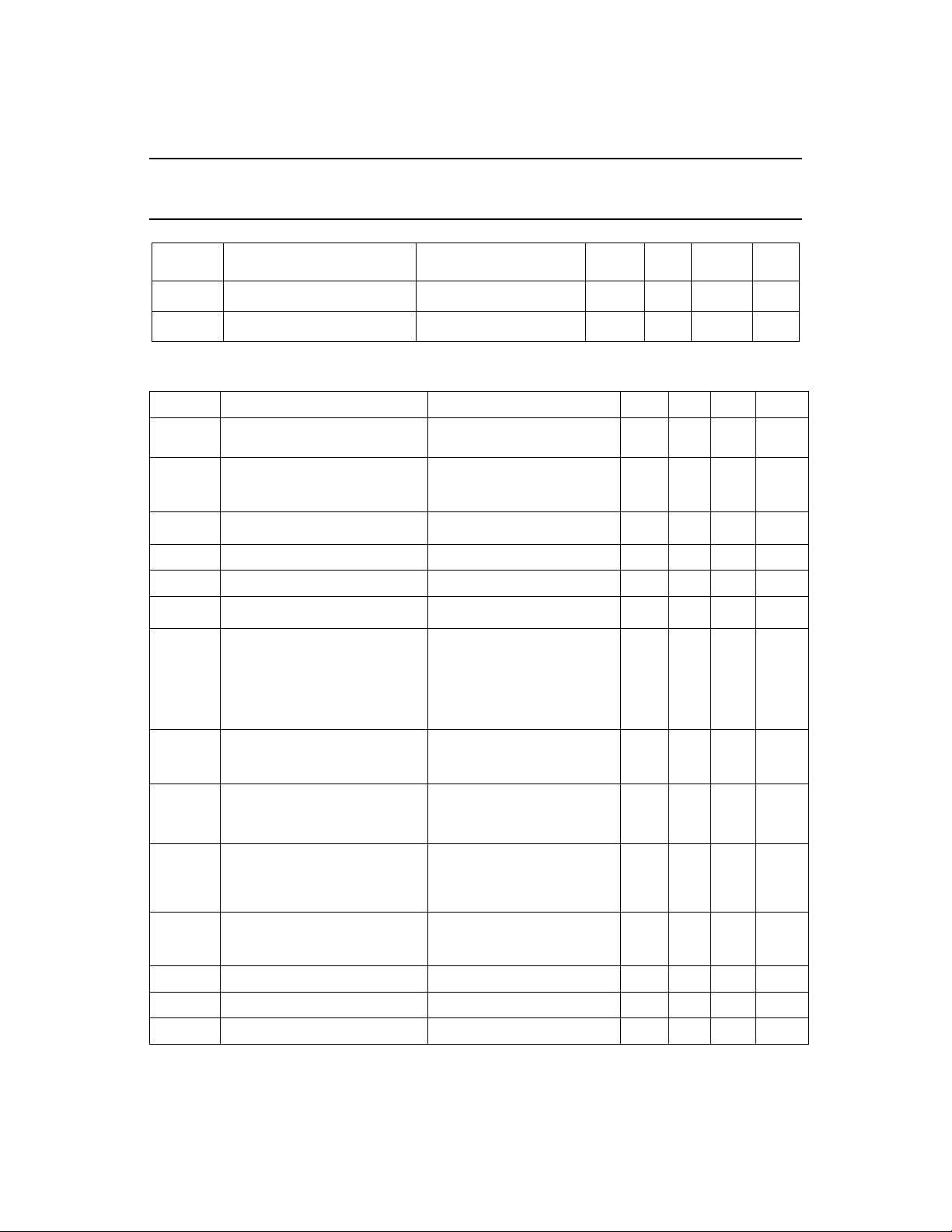

10.3 SERIAL INTERFACE ADDRESSING

10.4 SERIAL INTERFACE REGISTER BIT ALLOCATION

10.5 SERIAL INTERFACE OPERATIONS

10.6 REGISTERS DESCRIPTION

11 SERIAL INTERFACE TIMING

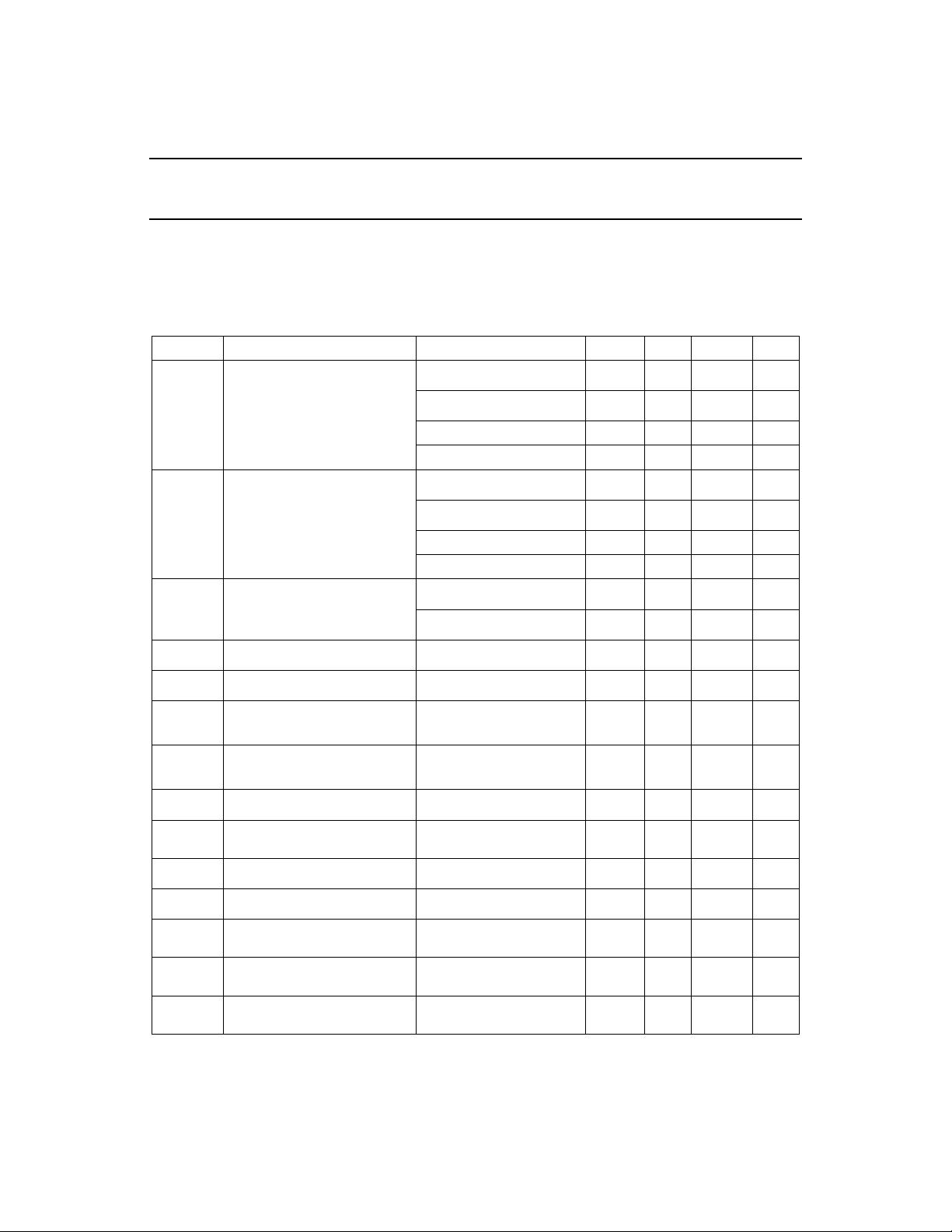

12 ELECTRICAL PARAMETERS

12.1 DC CHARACTERISTICS

12.2 READ CHARACTERISTICS

12.3 WRITE CHARATERISTICS

12.4 SWITCHING CHARACTERISTICS

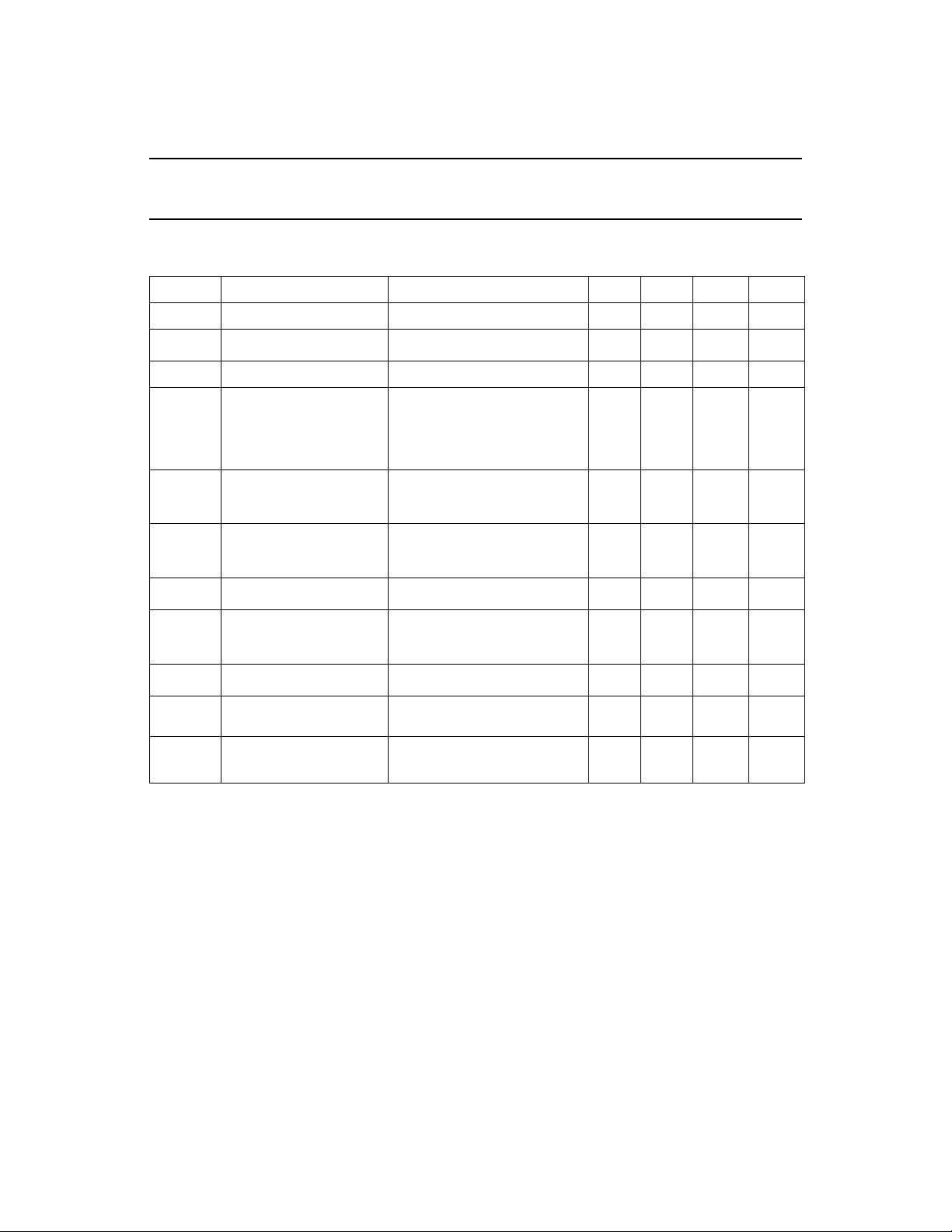

13 LIMITING VALUES / RECOMMENDED OPERATION CONDITIONS

14 ABSOLUTE MAXIMUM RATINGS

TDA5360

1998 July 30

2

Page 3

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

1 FEATURES

• 12 channels design for Single-stripe (SAL and GMR) Read / Thin-film Write heads.

• Design target 350 Mbps, for d=0 (16 / 17) rate code.

• Differential Hybrid sense Reader architecture.

• MR element biased by direct programmable constant Power or constant Current.

• Voltage driven Writer architecture.

• MR read / inductive write heads biased at ground level.

• Short rise and fall time with near rail to rail voltage swing.

• Dual power supplies : +5.0 V and -5.0 V.

• On-chip AC couplings eliminate MR head DC and DC offset voltage.

• Programmable 3-wire Serial Port Interface for programming (3.3 V and 5 V TTL / CMOS compatible).

• Extensive programmability of Write current wave overshoot.

• Programmable voltage / current mode write data input.

• Programmable voltage / current mode read data output.

• Programmable Read gain.

• Programmable Reader input impedance.

• Thermal asperity detection with programmable threshold.

• Thermal asperity compression with extensive programmability.

• High spurious-noise rejections.

• Internal Dummy Head available for MR heads protection during switchings.

• FAST mode available for short Write to Read mode transient.

• Sleep, Standby, Active, Servo Track Write, and Test modes available.

• Support servo writing.

• Write / Read Fault detection with fault code read back register and Fault masking capability.

• Low power-supplies fault protections.

• Short Write to Read Recovery, including DC settling.

• On-chip digitizing of Temperature and MR element Resistance value.

• Vendor ID and chip revision register.

• Illegal Multiple Device Selected detection.

• 2 pads CS0 and CS1, hard wired, for separate activation for multiple pre-amplifiers operation.

• Requires one external resistor.

TDA5360

2 APPLICATIONS

Hard Disk Drive (HDD).

1998 July 30

3

Page 4

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

TDA5360

3 QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

CC

V

EE

DC Supply voltage +4.5 +5 +5.5 V

-4.5 -5 -5.5 V

NF Noise Figure Note 3, Section 14 1.7 1.7 dB

IRNV Input Referred Noise

Voltage

Avd Differential gain VIN=1mVpp @ 20 MHz,

Rmr=66Ω; Imr=8mA;

10 MHz<f<100 MHz

R

=330Ω, Imr=8mA,

Loaddif

0.8 nV/

sqrtHz

50 dB

Rmr=66Ω,

GAIN0=0, GAIN1=1;

f

HR

-3dB frequency bandwidth Rmr=66Ω, Lmr=30 nH

-3dB: without Boost SAL

GMR

225

225

MHz

MHz

CMR Common Mode Rejection Imr=8mA, Rmr=66Ω,

10MHz<f<200MHz

1 MHz<f< 10MHz

f<100 kHz, 1mV input signal

20

40

60

dB

dB

dB

PSR Power Supply Rejection 200mVpp on Vcc or Vee,

Imr=8mA, Rmr=66Ω,

tr, t

f

I

MR(PR)

I

WR(b-p)

Write Current Rise/Fall times

(-0.8 * Iwr => +0.8 * Iwr)

Programming MR bias

current range

Programming Write current

10MHz<f<200MHz

1 MHz<f<10 MHz

f<100 kHz

Iwr=50mA; f=20 MHz;

LH=75nH, RH=10Ω 0.84 ns

SAL

GMR (see note section 10)43

Rext = 10 kΩ 10 50.3 mA

20

40

60

10.2

6 .1

dB

dB

dB

mA

mA

range (base-to-peak)

f

sclk

Serial interface clock rate 40 MHz

1998 July 30

4

Page 5

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

4 DESCRIPTION

The +/- 5.0 volt pre-amplifier for HDD described here has been designed for 12 terminals, comprised of a SAL or GMR

magneto-resistive reader and an inductive thin film writer. In read mode, the device operates as a low noise differential

preamplifier which senses resistance changes in the MR element that correspond to flux changes on the disk. In write

mode, the circuit operates as a thin film head current switch, driving the inductive element of the head.

The IC incorporates Read amplifiers with programmable gain and HF boosts, Write amplifiers, 3-wires Serial Interface,

Digital-to-Analog Converters, Thermal Asperity Detector and Programmable Thermal Asperity Compressor, reference

and control circuits which operate on a Dual Supply Voltage of +/-5V (+/-10%).

The Read amplifier has programmable medium input impedance. The DC offset between the two terminals of the MR

head is eliminated using on chip AC coupling. The bandwidth can be enhanced by using programmable high frequency

gain-boost. Fast settling features are used to keep the transients short. As an option, the Read amplifier may be left

biased during writing, so as to reduce the duration of these transients even further.

The Write amplifier has a programmable current overshoot which may be added to the programmable steady state write

current.

Fault protection is provided for a variety of read or write unsafe conditions. For added data protection, internal pull up

resistors are connected to RWN, CS0, CS1, STWN, WDP and WDN pins and pull down resistors are connected to SEN,

SDATA, SCLK, DRN and BFAST pins, to prevent accidental writing due to open lines and to ensure the device will power

up in a non-writing condition.

On-chip Digital to Analog converters for MR bias current or power and Write current are programmed via a 3 wire Serial

Interface. Head selection, Mode control, Testing and Servo Writing can also be programmed using the serial interface.

In Sleep mode, the CMOS serial interface is operationnal. Fig 2 shows the block diagram of the IC. Invalid head select

codes disable the writer, select the dummy head and trigger the FLT output.

TDA5360

5 ORDERING INFORMATION

EXTENDED TYPE NUMBER PACKAGE

TDA5360UH bare die

TDA5360UK bumped die

Fig.1 Type Number

1998 July 30

5

Page 6

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

6 BLOCK DIAGRAM

hybrid

sense

TA handling

Rin:2bits

RMR

RFE

hybrid

sense

TA handling

Rin:2bits

RMR

RFE

HEADMUX

Read Back End

MR BIAS

CURRENT

/ POWER

SETTING

TA CORRECTOR

5 bits

3bits

Av

1.5 bit

THERMAL

ASPERITY

DETECTOR

Rmr measure

temperatue

DIGITIZER

Av

On/Off

d/dt

4 bits

+

FAULT

DETECTION

CODING

SERIAL

INTERFACE

BUFFER

out

V / I

TDA5360

RDp

RDn

FLT

SDATA

SCLK

SEN

1998 July 30

voltage

driven

voltage

driven

WRITE

boost:1bit

pre-driver

CURRENT

5 bits

WDI

MUX

boost:2bits

boost 1 bit

pre-driver

6

BANDGAP

WDI

V/I

Interface

1 bit

Rext

WDp

WDn

Page 7

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

7 PAD ARRANGEMENT

DRN

BFAST

WP11

RP11

SDATA

SEN

WDP

RWN

RDN

SHIELDP

SCLK

FLT

WDN

SHIELDN

RDP

REXT

CS0

CS1

WN11

RN11

VCC

RP10

RN10

VCC

WP10

WN10

VCC

GND

TDA5360

WN7

RN9

WN9

RP9

WP9

GND

RP8

RN8

VCC

VCC

VEE

WP8

WN8

WP7

RP7

RN7

RN6

RP6

WP6

WN6

WN5

WP5

RP5

RN5

STWN

1998 July 30

RN4

RP4

WP4

RN0

WN0

RP0

WP0

RN1

RP1

WP1

WN1

RP2

WP2

WN2

RN3

RN2

RP3

VEE

WP3

WN3

WN4

Fig.2 TDA5360 pad arrangement pads up.

7

Page 8

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

8 PAD DESCRIPTION

SYMBOL Pin Description

VCC +5V supply

GND Ground

VEE -5V supply

RDP,RDN output Read Data, Differential read signal outputs

RWN logic input Read/Write : read = HIGH, write = LOW

WDP,WDN input Differential PECL or current mode write data input

FLT output

input

REXT a 10kΩ external resistor must be connected between REXT and GND

SEN logic input Serial Enable line. Active High

SCLK logic input Serial Clock line. 40 MHz max.

SDATA logic

input/output

BFAST logic input Controls reader passband or enables the Imr generator depending on the state

DRN logic input Selects the dummy head or performs a system reset depending on the state of

RP0...RP11 input MR head connections, positive end

RN0...RN11 input MR head connections, negative end

WP0...WP11 output Write head connections, positive end

WN0...WN11 output Write head connections, negative end

STWN logic input Set Low for Servo Track Write mode only

CS0 logic input Code for Chip ID

CS1 logic input Code for Chip ID

In Write mode, a fault is flagged when FLT is high.

In Read Mode, a fault is flagged when FLT is low.

a 5kΩ external resistor must be connected between FLT and VCC.

This pad is used as an input in MDS mode.

Serial Data line. Bi-directional interface

of BFCTL bit from Reg.01

RSTDMY bit from Reg.09

TDA5360

1998 July 30

8

Page 9

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

9 FUNCTIONAL DESCRIPTION

9.1 Active READ mode

Taking RWN high and programming bits MODE0 and MODE1 (see Reg.09) selects the read mode.

The Head select inputs, in serial register, select the appropriate head.

In read mode, the circuit provides either a constant power bias or a constant current bias that flows from the P to the N

side of the MR section of the head.

The value of the current/power is programmed in Reg. 02 and is referenced by the external resistor, REXT, which is

connected between the REXT pin and GND. The reference voltage on REXT pin is stable over the entire operating

temperature range and process.

The current or power in the MR element is constant over temperature.

The resistance of the MR element, RMR, changes in the presence of a magnetic field and causes a change in the MR

head voltage. The circuit acts as a low-noise differential amplifier to sense this voltage change. The read amplifier

outputs, RDP and RDN, are in phase with the MRP and MRN head ports.

The read data at pins RDP, RDN can output either voltage or current, depending on how the RVORI bit in Reg.01 is set:

LOW or HIGH respectively.

The polarity convention for current mode is :

“positive” => pin with least current flowing

“negative” => pin with most current flowing

Write current is not present in read mode under any circumstances; either transient or steady state.

The read path includes the following programmable features :

Gain programmation (Reg. 02 and Reg. 03) :

- gain only,

- a combination of gain plus differentiator (therefore HF-gain-boost),

- differentiator only.

The gain is programmable with step of 3dB between 44dB and 50dB.

Input impedance :

With bits RIN1, RIN0 (Reg.01), the input impedance of the readpath can be programmed from 15 to 30Ω.

Low Pole Frequency :

Bits LFP (Reg.03) allow the programmation of the Low Pole Frequency from 1 to 4 MHz.

Thermal Asperity Detection and Compression :

Thermal Asperity Detector flags an error on FLT line when a thermal disturbance is detected and load the

appropriate error code in Reg. 07. The threshold is programmable via Reg. 05.

Thermal Asperity Compressor extracts the signal from the disturbance. Its thresholds levels and frequency

response are also programmable with Reg.11.

TDA5360

1998 July 30

9

Page 10

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

9.2 Active WRITE mode

Taking RWN low from an Active READ mode selects the Active WRITE mode. The head select inputs, in a serial register,

select the appropriate head.

In write mode the circuit acts as a current switch with write current toggled between the P and N directions of the thinfilm section of the selected head x. The signal polarity is noninverting from WDP, WDN to WPx, WNx.

The write data at pins WDP, WDN could be driven by either a voltage or a current, according to the WVORI bit in Reg.01

(set LOW or HIGH respectively.)

The polarity convention for current mode is :

“positive” => input pin with minimum current flowing

“negative” => input pin with maximum current flowing

The writer terminal voltages are driven to GND during read mode to avoid accidental discharges to the disc.

Note that the write mode CAN NOT be selected directly from a sleep or standby condition.

The steady state value of the write current is programmed in Reg. 04 and is referenced by the external resistor, REXT,

which is connected between the REXT pin and GND. The reference voltage on REXT pin is stable over the entire

operating temperature range and process.

Internal compensation networks are optimized and provided to control the write current shape and settling characteristics

based on specified head loads. The value can be programmed in Reg. 04.

TDA5360

9.3 Active STW mode

In Active Read or Active Write mode, only one head in one preamp is selected.

A special programmation of Reg. 09, using (STWN = LOW) AND (CS0 = CS1 = HIGH) allows the user to either :

- select one head per preamp (if several preamps are adressed at the same time)

- select one head in one preamp when in read mode but two heads in one preamp when going to write mode.

In that case Head x and Head (x+6) will be selected, with x=0...5. Head x is selected via Reg. 00

9.4 STANDBY mode

The standby mode is selected by programming bits MODE0 and MODE1. (see Reg.09)

The internal write current source, and MR bias current source are deactivated while RDP, RDN and FLT outputs are in

a high-impedance state so that they can be OR’d in multiple preamplifiers applications. The device is specially designed

for reduced dissipation in this mode. Response time from Standby to Active Read mode is much shorter than from Sleep

mode to Active Read. The CMM of RDP and RDN is the same as in Sleep or Active mode. (see Note 2)

Internal fault detectors are powered off.

1998 July 30

10

Page 11

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

9.5 SLEEP mode

The sleep mode is selected by programming bits MODE0 and MODE1. (see Reg.09)

In Sleep Mode, the IC is accessible via the Serial Interface. All circuits, other than those of the CMOS Serial Interface

and the circuit which forces the data registers to their default values at power up and which fixes the DC level of RDpRDn (required when operating with more than one amplifier), are inactive. Typical static current consumption is less than

one mA, depending on the state of the logic pins where internal pull-up or pull-down resistors are connected. Dynamic

current consumption during operation of the Serial Interface in the Sleep mode and owing to external activity at the inputs

to the Serial Interface is not included. In all Modes including the Sleep mode, data registers can be

programmed. Sleep is the default Mode at power-up. Switching to other modes takes less than 0.1 ms.

The CMM of RDP and RDN is the same as in Standby or Active mode. (see Note)

Internal fault detectors are powered off.

Note 1 : At power-up, as long as DRN pin is LOW, a reset of the Serial Interface registers occurs. Before any register

programmation, the user should first force DRN pin to HIGH in order to exit the reset mode and enable a register

programmation. See description of DRN function in (10.6).

Note 2 : As a goal, the CMM of RDP and RDN is identical in all operating modes. The term “high-impedance” here means

at least 10 to 20 kOhm from RDP or RDN to an internal CMM voltage reference.

TDA5360

1998 July 30

11

Page 12

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

10 BIASING OF THE MR ELEMENT

This preamplifier has been designed for SAL and GMR elements. Programming bit GMR in Reg. 01 select either a SAL

range (LOW) or a GMR range (HIGH).

By programming bit PORI in Reg. 01, the user can program either a constant current bias (LOW) or a constant power

bias (HIGH) for the MR element. The value of the current/power is programmed on 5 bits via Reg. 02.

If bit PORI in Reg. 01 is HIGH, a constant power bias is maintained accross the MR element.

The power is defined as :

Pw = RMR * I

In power bias mode, two power ranges are possible :

For SAL heads 1.5mW to 9.25 mW in steps of 0.25mW

For GMR heads 375uW to 2.3 mW in steps of 0.0625mW

Note : whatever Power programmation is used, the IMR current flowing into the MR element will be within the min-

If bit PORI in Reg.01 is LOW, then the biasing scheme shall revert to constant current instead of constant power.

IMR is then constant over temperature and process.

In current bias mode, two current ranges are possible :

For SAL heads : 4 to 10.2 mA in steps of 0.2 mA

For GMR heads : 3 to 6.1 mA in steps of 0.1 mA

2

, where Pw is constant over temperature and process.

MR

max range given below.

TDA5360

Note : In GMR mode, IMR current is guaranted up to 5.1mA

6.1mA can be reached under certain supplies/Rmr conditions.

10.1 MR Head Resistance and Temperature Measurement

By programming RANGE0,RANGE1 bits in Reg. 08, the user can select either a Rmr measurement or a Temperature

measurement (junction temperature).

Setting DIGON bit HIGH launch a digitazation

The settling time of the digitization operation is less than TBD µs.

A 5 bit code is then available in Reg. 08, as long as DIGON stays HIGH,

Setting DIGON bit LOW, reset the 5 bit code.

In case of Rmr measurement, the user have access to two Rmr range by programming RANGE0 and RANGE1 bits.

In case of Temperature too high condition (T > 140oC), during a Temperature measurement, a Fault is triggered on FLT

line and a error code is available in Reg. 07.

1998 July 30

12

Page 13

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

10.2 Fault Mode

Fault conditions are indicated on the FLT pin (HIGH during write mode and LOW during read mode). The fault condition

is coded and stored in Reg. 07 for monitoring purposes. The fault code is cleared on power up, on system reset and on

writing to Reg.09

The FLT output is an open collector to an external resistor of 5Kohms connected to +5V.

Table 1: Fault Conditions

Mode Fault condition FCOD3 FCOD2 FCOD1 FCOD0

Both No fault 0 0 0 0

Read Write current present 0 0 0 1

Fault code not used 0 0 1 0

Thermal Asperity detected 0 0 1 1

Read head open 0 1 0 0

Write No write current 0 1 0 1

Write Data frequency to low 0 1 1 0

Write head open 0 1 1 1

Write head shorted to GND 1 0 0 0

Both Rext open or short 1 0 0 1

Write to read head short 1 0 1 0

Low Vcc or Low Vee 1 0 1 1

Fault code not used 1 1 0 0

Illegal head address 1 1 0 1

Fault code not used 1 1 1 0

Temperature too high 140 C 1 1 1 1

TDA5360

1998 July 30

13

Page 14

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

The following are valid READ fault conditions which set FLT=LOW

• Rext pin open or shorted to GND or Vcc

• Thermal Asperity detected

• Read Head open

• Power supplies too low (VCC and/or VEE)

• Write current present in read mode

• Illegal head address ( i.e. head 12, 13, 14 or 15)

In this case, besides asserting the fault flag, the MR bias current is diverted to the dummy head.

The following are valid WRITE fault conditions which set FLT=HIGH. An action can eventually be taken :

FAULT ACTION

• No write current in write mode Disable write current

• Rext pin open or shorted to GND or Vcc Disable write current

• Open write head or shorted to GND Do not disable write current

• Write data frequency too low Do not disable write current

• Power supplies too low Disable write current

• lllegal head address (i.e. HD 12, 13, 14, 15) Disable write current

TDA5360

If the write current is disabled, the writer is powered down. The only way to restart a write sequence is to switch R/W

high and then to switch R/W low again.

Trying to go in Write mode from a sleep or standby mode condition will disable the write current.

If two fault conditions occurs nearly at the same time, the first to occur will be loaded in Reg. 07.

1998 July 30

14

Page 15

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

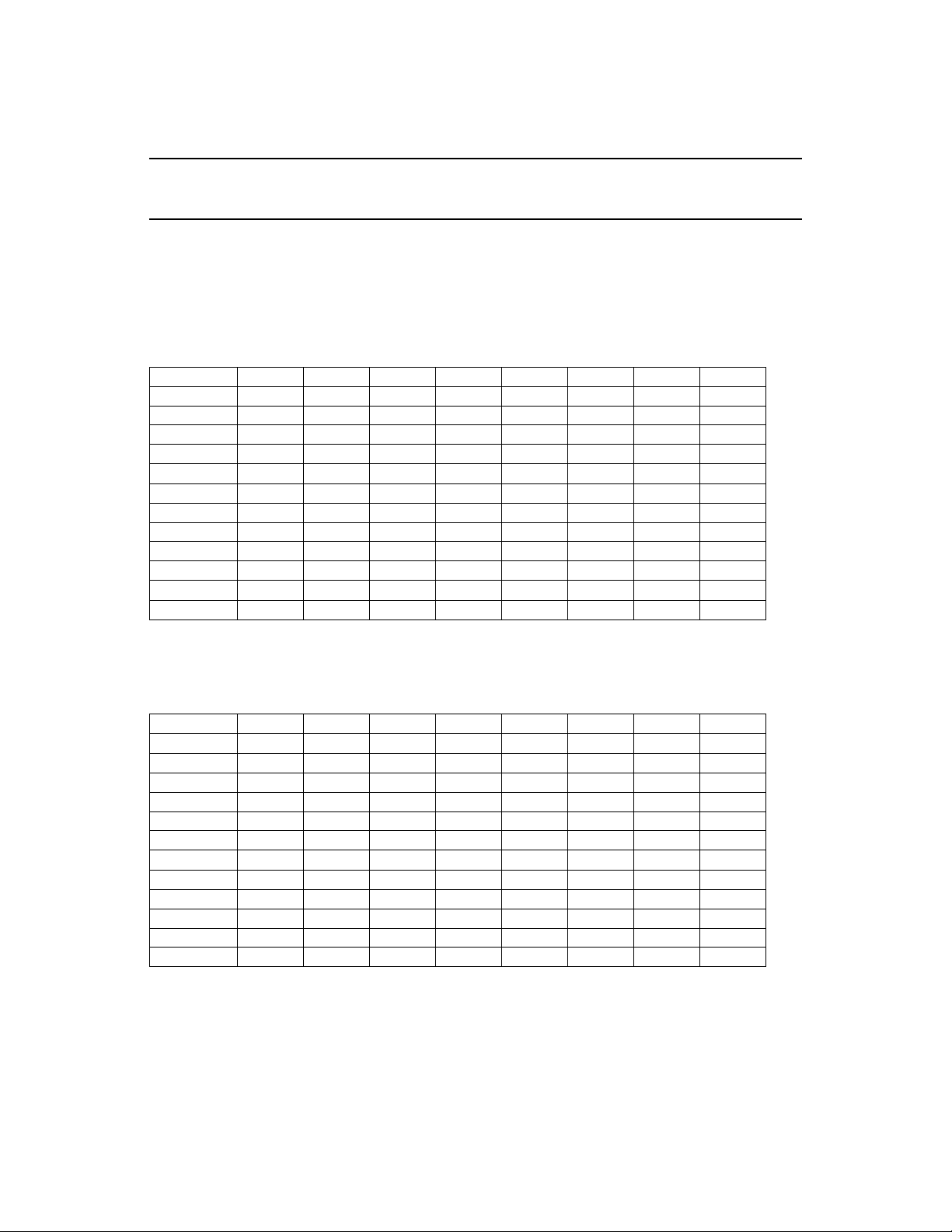

10.3 Serial Interface Address bit Allocation

Register A7 A6 A5 A4 A3 A2 A1 A0

0 X 0 0 0 0 CS1 CS0 RWN

1 X 0 0 0 1 CS1 CS0 RWN

2 X 0 0 1 0 CS1 CS0 RWN

3 X 0 0 1 1 CS1 CS0 RWN

4 X 0 1 0 0 CS1 CS0 RWN

5 X 0 1 0 1 CS1 CS0 RWN

6 X 0 1 1 0 CS1 CS0 RWN

7 X 0 1 1 1 CS1 CS0 RWN

8 X 1 0 0 0 CS1 CS0 RWN

9 X 1 0 0 1 CS1 CS0 RWN

10 X 1 0 1 0 CS1 CS0 RWN

11 X 1 0 1 1 CS1 CS0 RWN

TDA5360

10.4 Serial Interface Register bit Allocation

9

Register D7 D6 D5 D4 D3 D2 D1 D0

0 HS3 HS2 HS1 HS0 SELT SELF LCS1 LCS0

1 X PORI GMR RIN1 RIN0 RVORI WVORI BFCTL

2 DUMMY PWR4 PWR3 PWR2 PWR1 PWR0 GAIN1 GAIN0

3 HFZ3 HFZ2 HFZ1 HFZ0 X X LFP1 LFP0

4 IW4 IW3 IW2 IW1 IW0 WCP2 WCP1 WCP0

5 TRANGE TAD TAC TAD4 TAD3 TAD2 TAD1 TAD0

6 VEND7 VEND6 VEND5 VEND4 VEND3 VEND2 VEND1 VEND0

7 X FLT2 FLT1 FLT0 FCOD3 FCOD2 FCOD1 FCOD0

8 M4 M3 M2 M1 M0 RANGE1 RANGE0 DIGON

9 X X X X SIOLVL RSTDMY MODE1 MODE0

10 X X X X X X X X

11 X X X ENFST TAU TACT2 TACT1 TACT0

1998 July 30

15

Page 16

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

10.5 Serial Interface Operations

The serial interface communication consists of an adress word of 8 bits followed by a data word of 8 bits. See section

11, page 24 and 25 for timing diagrams.

10.5.1 SERIAL ADDRESSING

When SEN goes HIGH, bits are latched-in at rising edges of SCLK. The first eight bits a7-a0 starting with the LSB, are

shifted serially into an address register.

If SEN goes LOW before 16 bits have been found, then the operation is ignored.

When STWn is HIGH; if a1 does not match CS0 or a2 does not match CS1, then the operation is ignored.

When STWn is LOW; if a1 and a2 are not HIGH, then the operation is ignored.

Bits a3 to a6 constitute the register address. Bit a7 is an unused one.

If (a0, a1, a2, STWn) = (0, CS0, CS1, 1)

or if (a0, a1, a2, STWn) = (0, 1, 1, 0)

then a PROGRAMMING sequence starts (see Reg. 09 description for details about preamp addressing)

If (a0, a1, a2, STWn) = (1, CS0, CS1, 1)

or if (a0, a1, a2, STWn) = (1, 1, 1, 0)

then READING data from the pre-amplifier can start. The data read back can be either 3.3V compatible or 5V

compatible depending on SIOLV bit in Reg. 09.

TDA5360

10.5.2 PROGRAMMING DATA

During a programming sequence, the last eight bits d0-d7, before SEN goes LOW, are shifted into an input register.

When SEN goes LOW, the communication sequence is ended and the data in the input register are copied in parallel to

the data register corresponding to the decoded address a6-a3. SEN should go LOW at least 5ns after the last rising

edge of SCLK.

10.5.3 READING DATA

Immediately after the IC detects a reading sequence, data from the data register (address a6-a3) are copied

in parallel to the input register. The LSB d0 is placed on SDATA line followed by d1 at the

next falling edge of SCLK, etc...

If SEN goes LOW before 8 address bits (a7-a0) have been detected, the communication is ignored. If SEN goes LOW

before the 8 data bits have been sent out of the IC, the reading sequence is immediately interrupted.

SEN must stay LOW at least 75ns between two adressings.

See Timing diagramms for Serial Adressing on section 11.

10.5.4 BROADCAST MODE

When A1=A2=1 and STWN=LOW, all the preamps will be adressed whatever their CS1/CS0 setup is.

This mode allows parallel programming of any register of the serial interface, and allows STW mode programming (See

Reg. 09 description).

1998 July 30

16

Page 17

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

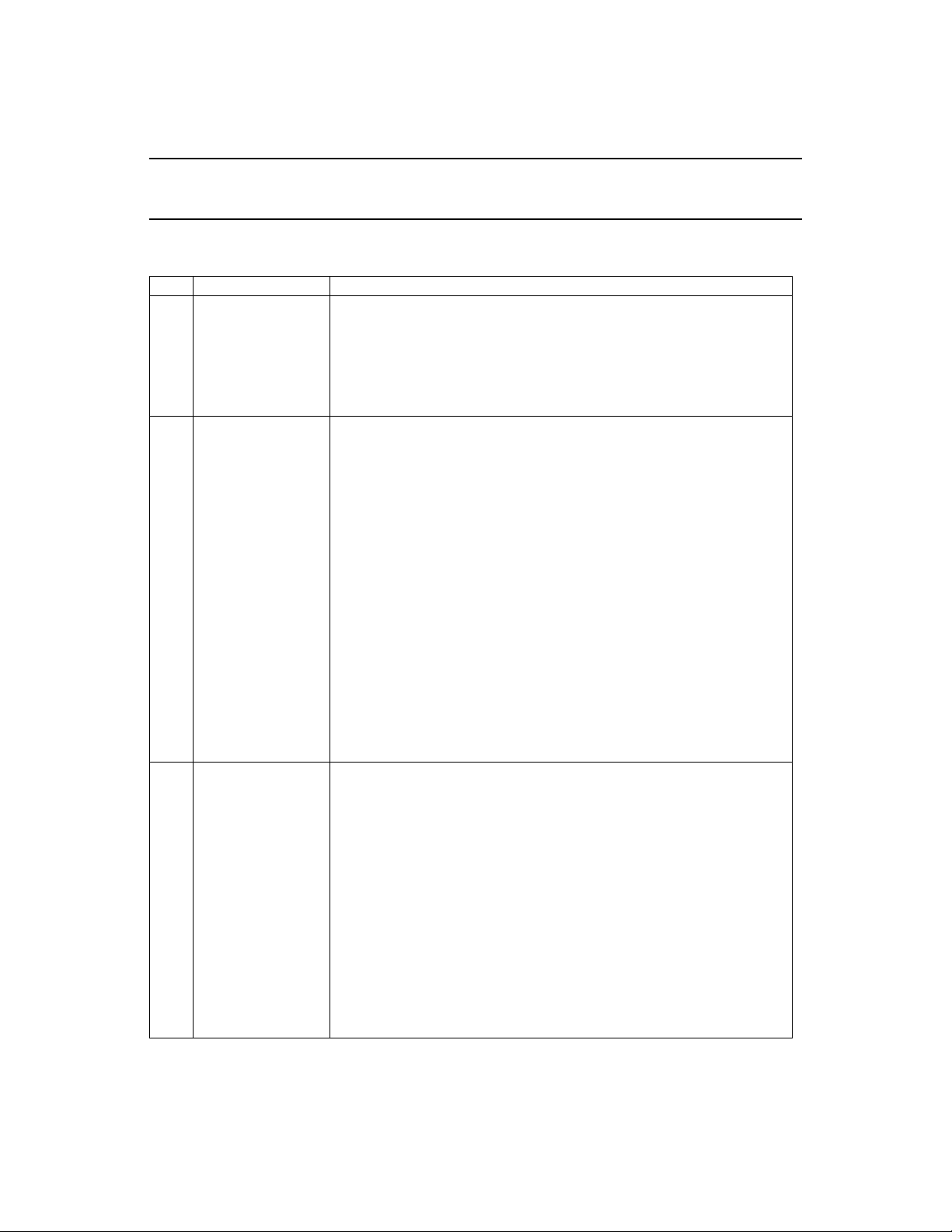

10.6 Registers description

Nb Register Name Contents

0 Head Select Register HS3..HS0 = 0,0,0,0 to 1,0,1,1 = H0 to H11

SELT : if HIGH, the multiple selection detector is enabled. Inactive in STW mode

SELF : is set HIGH if illegal MDS is detected (read back only bit)

( Note 0 )

LCS1,LCS0 : copy of CS1,CS0 pins state (read back only bits)

1 Control Register PORI : Select a MR Bias mode.

LOW = Current Bias

HIGH = Power Bias

GMR : select the range to be used in current or power

LOW = SAL range

HIGH = GMR range

RIN1,0 = define the input impedance of the reader.

(0,0) = 30Ω

(0,1) = 23Ω

(1,0) = 18Ω

(1,1) = 15Ω

RVORI = Reader output buffer mode.

LOW = Voltage mode

HIGH = Current mode

TDA5360

WVORI = Writer data inputs mode.

LOW = Voltage mode,

HIGH = Current mode

( Note 1a)

BFCTL = Control of BFAST pin functionality

( Note 1b)

2 Reader Bias Register DUMMY : Dummy head is selected in read mode if LOW

PWR4...PWR0 = define Imr current/power.

Range according to GMR bit setting

Rmr current bias mode :

SAL : Imr = 4mA+200uA*(pwr0 + 2 * pwr1 + 4 * pwr2 + 8 * pwr3 + 16 * pwr4)

GMR : Imr = 3mA+100uA*(pwr0 + 2 * pwr1 + 4 * pwr2 + 8 * pwr3 + 16 * pwr4)

Rmr power bias mode :

SAL : Pwr = 1.5mW+250uW*(pwr0 + 2 * pwr1 + 4 * pwr2 + 8 * pwr3 + 16 * pwr4)

GMR : Pwr = 375uW+62.5uW*(pwr0 + 2 * pwr1 + 4 * pwr2 + 8 * pwr3 + 16 * pwr4)

GAIN1, GAIN0 = read amplifier gain.

(0,0) = 44 dB

(0,1) = 47 dB

(1,0) = 50 dB

(1,1) = Differentiator only

1998 July 30

17

Page 18

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

3 Reader Bandwith

Register

4 Writer Bias Register IW4, IW3, IW2, IW1, IW0 = 5 bits to define Iwr current :

5 Thermal Asperity

Detection

6 Vendor Register VEND7...VEND0 = 8 bits for identification (read back only bits)

7 Fault Management

Register

HFZ3, HFZ2, HFZ1, HFZ0 = high frequency gain boost/ differentiator control

( Note 3 )

LFP1, LFP0 = low frequency pole.

(0,0) =1 MHz

(0,1) =2 MHz

(1,0) =3 MHz

(1,1) =4 MHz

Iwr = 10mA + 1.3mA*(IW0+2*IW1+4*IW2+8*IW3+16*IW4)

WCP2...WCP1 = 3 bits for the write current overshoot

(Note 4)

TRANGE = if HIGH, the TA detector range is shifted up 3.17mV

TAD = if HIGH, the TA detection circuits are enabled

TAC = if HIGH, the TA Compression circuits are enabled

TAD4..TAD0 = 5 bits for TAD threshold programmation (referred to the input)

Vth(mV) = 0.390

+ 3.170*TRANGE

+ 0.177*(TAD0 + 2*TAD1 + 4*TAD2+ 8*TAD3 + 16*TAD4)

(Note 5)

7 6 5 4 3 2 1 0

0 0 1 0 0 0 1 1 = rev1

0 1 0 0 0 0 1 1 = rev2

FLT2...FLT0 = 3 bits to set the reporting of a fault condition :

000 = report all fault detected

001 = Disable low supply fault

010 = Disable temperature too high fault

011 = Disable write head open/short fault

100 = Disable write data frequency too low fault

101 = disable MR power too high fault

110 = Disable TA Detected fault

111 = Disable all faults

TDA5360

1998 July 30

FCOD3...FCOD0 = 4 bits for encoding the fault conditions (read back only bits)

( Note 7 )

18

Page 19

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

8 Measurement Register M4...M0 = 5 bits for Rmr/Temperature digitazation (read back only bits)

RANGE1,RANGE0 = 2bits to define which measurement to be done

(0,0) RMR measurement for 15Ω < Rmr < 46Ω

Rmr = 698 / (15.5 + M0 + 2*M1 + 4*M2 + 8*M3 + 16*M4)

(0,1) and (1,0) : RMR measurement for 40Ω < Rmr < 90Ω

Rmr = 2094 / ( 21 + M0 + 2*M1 + 4*M2 + 8*M3 + 16*M4 )

9 Operating mode

Register

(1,1) = Temperature measurement

DIGON = is set HIGH to launch a digitazation

( Note 8 )

SIOLVL = level of SDATA when reading back a register

if LOW, 3.3V compatible.

if HIGH, 5.0V compatible.

RSTDMY = define functionality of DRN pin

( Note 9a)

Temp = 473K - 4.6K * (M0 + 2*M1 + 4*M2 + 8*M3 + 16*M4)

TDA5360

11 Thermal Asperity

Compression

1998 July 30

MODE1,MODE0 = 2 power management control bits.

(0,0) Sleep Mode

(0,1) Standby Mode

(1,0) Active Mode or STW one head

(1,1) Test Mode or STW two heads

(Note 9b)

ENFST = when TAC is enable, this bit defines BFAST functionality

( Note 11a)

TAU = Low Pole Frequency time constant of the TAC

LOW = 700 ns

HIGH = 70 ns

TACT2,TACT1,TACT0 = 3 bits to determine the TAC threshold

(0,0,0) = 4.00 mV

(0,0,1) = 2.97 mV

(0,1,0) = 2.21 mV

(0,1,1) = 1.64 mV

(1,0,0) = 1.22 mV

(1,0,1) = 0.91 mV

(1,1,0) = 0.67 mV

(1,1,1) = 0.50 mV

( Note 11b )

19

Page 20

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

Note 0 : MDS (Multiple Device Selected) detector :

When several preamps are connected in parallel, this function allows the user detection of wrong adressing

withing the preamps.

When SELT is high, the selected preamp pull a precise current on FLT pin. If only one preamp has reacted,

SELF is LOW. If more than one preamp has reacted, the voltage on FLT pin is lower than a reference voltage

and thus SELF is HIGH.

Note 1a : The Write path can be controled by either a voltage or a current input signal.

The signal polarity is non inverted from WDP - WDN input to WPx - WNx output

Voltage mode : WDP-WDN > 0 => WPx-WNx > 0 (current flowing externally from WPx to WNx)

Current mode : current has to be pulled from WDP and WDN pins.

The positive side for signal, is the one where the least current is pulled

The negative side for signal, is the one where the most current is pulled

most current pulled from WDN => current flowing externally from WPx to WNx)

Note 1b : BFCTL define BFAST functionality :

BFCTL BFAST Function

LOW LOW IMR generator ON (Reader ON) during write

LOW HIGH IMR generator OFF (Reader OFF) during write

HIGH LOW Normal Reader PassBand

HIGH HIGH Low Frequency corner increased to 8 MHz

See ENFST bit in Reg. 11 for restrictions of BFAST functionality

Note 3 : For differentiator only (GAIN0 = GAIN1 = 1),

the midrange setting ( HFZ3 = 1, HFZ0 = HFZ1 = HFZ2 = 0 ) have a gain of 44dB at 100 Mhz.

i.e. gain (@100 Mhz)= 80 +10 * (HFZ0 + 2*HFZ1 + 4*HFZ2 + 8*HFZ3)

TDA5360

For gain plus differentiator (other GAIN0, GAIN1 programmation)

the midrange setting (HFZ3=1, HFZ0,1,2=0) create a zero at 300 Mhz independent of the gain bits.

HF Zero @ f = 2400 MHz / (HFZ0 +2*HFZ1 + 4*HFZ2 +8*HFZ3)

i.e. gain = 150 + 75 * ( GAIN0 + 2*GAIN1 - 5*GAIN0*GAIN1)

Note 4 : In order to increase performance for high data rate, 3 bits are available to tune the write current waveform.

WCP2 : this bit is used to add a capacitive boost during a transition of the write current.

WCP1,WCP0 : these bits are used to increase the internal swing on the write data signal.

when IW4 is HIGH ( Iwr > 30.8 mA), some capacitive compensation is also activated in the write driver.

Note 5 : The threshold range of the TAD can be shifted up by 50% by setting TRANGE HIGH.

1998 July 30

In that case the steps are still 177uV,

but the range is shifted from ( 0.390mV-5.877mV ) to ( 3.560mV-9.047mV )

The relation between the threshold of the TAD programmed in Reg. 05 and the real threshold is a function of

the input impedance of the reader and the low corner frequency of the reader.

20

Page 21

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

Formula to link real TAD threshold with LF pole of the reader and programmed input impedance :

VthVthprog

----------------------------------------------------------×=

K

where : fLFP is the low frequency pole of the read amplifer (1 to 4 MHz, programmable via Reg. 03)

and :

fTA is the frequency of the principal harmonic of the TA signal.

K

RINnom

-----------------------------------------=

RINnomRMR+

0.85

1

------------------------

+

KfTA×()

-------------------------------------------×

1

+

fLFP

fLFP

-------------

fTA

2

2

TDA5360

where : RINnom is the input impedance of the reader in mid-band (programmable via Reg. 01)

For RINnom = 18Ω, RMR = 66Ω, fTA = 2MHz, Tj = 70

and so, Vth( fLFP = 1MHz) = Vthprog * 1.747

Vth( fLFP = 4MHz) = Vthprog * 0.945

Note 7: FAULT code protocol.

When a fault occurs, the FAULT pin is set LOW (if read mode) or HIGH (if write mode) and a 4 bits code is

available in Reg. 07 (See Section 10.2 for details).

The FAULT pin is flagged as long as the error remains present. When the error condition is removed, the

FAULT pin toggles to a non-error state, but the 4 bits code still remains present in Reg. 07

To Reset the FAULT code, the user should reprogramm Reg. 09.

Some fault detections can be inhibited via FLT2,1,0 bits. If an action is linked to the inhibited detection (for

example inhibiting the write current when a low power supply condition occurs), then the action is still taken,

but no fault code and no FAULT pin toggling occurs.

Note 8 : RMR and Temperature Digitizer

- RMR digitizer

This measurement can only be done in Read mode, with the head to be measured selected.

the Digitazation is launched when DIGON toggles from LOW to HIGH,

after a maximum of TBD us, a 5 bits code is available in Reg. 08.

The 5 bits code will only be reseted by DIGON toggling from HIGH to LOW.

1998 July 30

o

C, we have K = 0.214

21

Page 22

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

- Temperature digitizer

This measurement can be done either in Active Read mode or in Active Write mode.

Note 9a : RSTDMY define DRN pin functionality

RSTDMY DRN Function

LOW LOW Serial Interface register reset

LOW HIGH No effect

HIGH LOW No effect

HIGH HIGH Dummy Head selected in read mode

Note 9b : MODE1,MODE0 power management control bits

A2 A1 Mode1 Mode0 STWN

CS1 CS0 0 0 x Sleep

CS1 CS0 0 1 x Standby

CS1 CS0 1 0 1 Active Read or Write

1 1 1 0 0 Active STW with one head

CS1 CS0 1 1 1 Test mode

1 1 1 1 0 Active STW with 2 heads in write mode

1 1 x x 1 Forbidden : no change in register

TDA5360

- Test mode is a state where both Reader and Writer are ON when R/W pin is LOW : in write mode, reader

signal is present at RDP-RDN output pins.

- (A2=A1=1 and STWN=0) is a broadcast mode condition, where all the preamps will treat the data arriving on

SDATA line.

- In order to get two write head selected, Head Hx should be programmed in Reg. 00 (x = 0 to 5). In that case

Head Hx and Head H(x+6) will be selected in STW (Servo Track Write) 2 heads.

Note 11a : ENFST define BFAST pin functionality when Thermal Asperity Compression is ON

Note 11b : Thermal Asperity Compression ( TAC ) functionality

ENFST BFAST functionality

LOW inhibit BFAST control of the passband

HIGH enable BFAST control of the passband

When a thermal asperity occurs at the reader input, the reader output signal get superposed with an amplified

signal corresponding, to a certain extent, to the thermal asperity.

1998 July 30

22

Page 23

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

The aim of the TAC is to limit the amplitude and the duration of the perturbation seen at the reader output.

Because thermal asperity amplitude is not constant, the TAC need some threshold programmation to define

the sharpness of the response.

note that reducing the TAC threshold also impact the Low corner frequency value of the read amplifier.

TDA5360

1998 July 30

23

Page 24

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

11 SERIAL INTERFACE TIMING

t > 5ns

1 Tclk

a0=1 a2a1 a3 a4 a5 a6 a7

Address

When Fclk > 20 MHz and a register reading is performed, it is necessary to extend the clock period as above

When Fclk < 20 MHz, this is not necessary

READ

2 Tclk

1.5 Tclk

WRITE

d0

d1 d2 d3

Data

d4

d5

t > 5ns

d6 d7

TDA5360

SEN

SCLK

SDATA

a0=0

0...Reg.00H

1998 July 30

a2a1 a3 a4 a5 a6 a7

Address

1 Tclk

0.5 Tclk

24

d0

d1 d2 d3

Data

d4

d5

SEN

SCLK

SDATA

d5 d7

Page 25

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

t_sen_sen

SEN

tr

trsen_sclk

SCLK

tr

tclkperiod tf_sclk_sen

tsetup

tclkwidth

thold

TDA5360

tf

tclklow

SDATA

SEN timing Description Min Nom Max Unit

tr_sen_sclk 90% of SEN to 10% of SCLK 5 ns

tf_sclk_sen last SCLK to 90% of SEN 5 ns

tr,tf rise/fall time 10%-90% 2 Tclk/4 ns

t_sen_sen delay between 2 SEN 75 ns

SCLK timing

frequency 40 MHz

tr , tf rise/fall time 10%-90% 2 Tclk/4 ns

tclklow 10% of SEN to CLK state change 5(*) ns

tclkwidth TBD ns

SDATA timing

tsetup data setup time before 10% of SCLK 5 Tclk/2 ns

thold data hold time after 90% of SCLK 5 Tclk/2 ns

1998 July 30

(*) either positive or negative, but ABS (tclklow) > 5ns

25

Page 26

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

12 ELECTRICAL PARAMETERS

12.1 DC Characteristics

Unless otherwise specified, recommended operating conditions apply

CS0=CS1=LOW, DRN=HIGH, BFAST=LOW, STWn=HIGH, RIN=18 Ohm, LFP = 1MHz, Imr = 8mA, Rmr = 66 Ohm

Iwr = 30.8mA.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

I

CC

I

EE

Pw (TJ=105°C) Write Mode IWR = 30.8 mA 800 1050 1625 mW

VCC Supply Current

VEE Supply Current

Power Dissipation Read Mode, IMR = 8mA 365 435 525 mW

Read Mode, IMR = 8mA 65 75 85 mA

Write Mode, IWR = 30.8 mA 100 130 175 mA

Standby Mode 200 1400 2500 uA

Sleep Mode 200 700 2000 uA

Read Mode, IMR = 8mA -20 -12 -8 mA

Write Mode, IWR = 30.8 mA -150 -80 -60 mA

Standby Mode -200 -5 0 uA

Sleep Mode -200 -5 0 uA

TDA5360

V

IL

V

IH

I

IL

I

IH

V

OL

V

OH

I

OH

V

OL

1998 July 30

Input Low Voltage TTL 0 0.8 V

Input High Voltage TTL 2.4 5 V

Input Low Current

VIL = 0.8 V

Input High Current

VIH = 2.4V

Output Low voltage SDATA IOL = 4mA 0.4 V

Output High voltage SDATA 5V mode

Output High Current FLT VOH = 5.0V 50 uA

Output Low Voltage FLT IOL = 4mA 0.4 V

High level WDP and WDN PECL (Note 1)

Low level WDP and WDN PECL (Note 1)

|WDP-WDN| PECL swing Voltage mode selected

PECL

TTL -160

PECL

TTL

SDATA 3.3V mode

Current mode (Note2) -0.25

Current mode (Note 2)

peak to peak (Note 1) 0.4 1.5 V

26

3.6

2.4

2.4

- 4 -1

50 uA

50

80

Vcc

3.6

Vcc

0

uA

uA

uA

V

V

V

mA

V

mA

Page 27

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

Voltage compliance for WDP

and WDN in current mode

V

CCTL

V

EETL

12.2 Read Characteristics

Unless otherwise specified, recommended operating conditions apply.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNIT

I

MR

Pwr MR Power Range SAL

V

Rext

A

Vd

f

HR

VCC Fault Threshold Hysteresis=100mV +/- 10% 3.80 4.00 4.20 V

VEE Fault Threshold Hysteresis=100mV +/- 10% -4.20 -4.00 -3.80 V

MR Current Range SAL

MR Power Tolerance 3 < IMR < 10mA -5 +5 %

MR Bias Current Overshoot 0 %

RMR Digitizer Accuracy 5 %

Rext Reference Voltage 1.31 V

Differential Voltage Gain VIN = 1mVPP @ 20MHz,

Passband Upper -3dB

Frequency

CMM of the inputs

in current mode

GMR

GMR

(Note 3)

R

dif = 330 Ohm,IMR=8mA,

Load

R

= 66 Ohm,

MR

RIN = 18 Ohm,

GAIN0=0, GAIN1=1,GMR=0

RMR = 66Ω;LMR=30nH

- 3dB. Without boost.

1.5 Vcc -1.7 V

4

3

1.500

0.375

48 50 52 dB

225

TDA5360

8 10.26mA

4.219.25

2.30mWmW

MHz

f

LR

IRNV Input referenced noise voltage

NF Noise figure (Note 5) 1.7 dB

1998 July 30

Passband Lower -3dB

Frequency

(including MR bias current noise,

excluding Rmr noise)

MR bias current noise IMR=8mA 10 MHz<f<100MHz

HF noise +3dB frequency Preamp noise=head noise 350 MHz

LF noise +3dB frequency Preamp noise=head noise 3 MHz

RMR = 66Ω; LMR = 30nH;

LPF0=0

LPF1=1

RMR = 66Ω; IMR=8mA

10 MHz<f<100 MHz, GMR=0

(Note 4)

IMR=5mA 10 MHz<f<130MHz

27

3 MHz

0.8 nV/

8

5.7

÷sqrt

Hz

pA/

sqrt÷

Hz

Page 28

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

C

IN

R

IN

DR Dynamic Range AC input where AVd falls to

CMR Common Mode Rejection IMR = 8mA, RMR = 66Ω,

PSR Power Supply Rejection

CS Channel Separation Unselected Channels:

VOS Output Offset Voltage IMR=8mA, RMR=66Ω,

V

OCM

R

SEO

Differential Input

Capacitance

Differential Input

Resistance

from a signal on VCC, VEE or any

logic pin, to RDP, R

Common Mode Output Voltage 2.45 V

Single-Ended Output

Resistance

DN

RIN0=0, RIN1=1 18 Ohm

90% of its value at@f = 20MHz TBD

10 Mhz < f < 200 Mhz

1 Mhz < f < 10 Mhz

f < 100 KHz, GMR=0,

1mV input signal

300mV

IMR = 8mA, RMR =66Ω,

10 Mhz < f < 200 Mhz

1 Mhz < f < 10 Mhz

f < 100 KHz, GMR=0

VIN = 1mV

1 < f < 200 MHz

GAIN0=GAIN1=0, GMR=0

on VCC or VEE,

P-P

PP

50

TDA5360

10 pF

mV

20

40

60

20

40

60

17.5 Ohm

dB

dB

dB

100 mV

PP

I

O

THD Total Harmonic Distortion First 10 harmonics 0.5 %

I

DISK

DV

OCM

1998 July 30

Output Current AC Coupled Load, RDP to RDN

MR head potential From any point to GND -500 +500 mV

MR Head-to-Disc Contact Current Extended contact

Common Mode Output Voltage

Change

TA Detection Response Time TA occurred to FLT active 20 40 nS

RVORI = HIGH

RVORI = LOW

Maximum Peak Discharge for

<20ns

C

=300pF,R

DISK

V

(READ) - V

OCM

(WRITE)

28

DISK

=10MΩ

OCM

TBD

4 mA

100

20uAmA

100 mV

Page 29

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

12.3 Write Charateristics

Unless otherwise specified, recommended operating conditions apply,

IW=50mA, LH=75nH, RH = 10Ω, f

SYMBOL PARAMETERS CONDITIONS MIN TYP MAX UNIT

I

WR

∆I

WR

I

UH

f

DATA

R

O

Write Current Range 10 30.8 50.3 mA

/ I

Write Current Tolerance -7 7 %

WR

Differential Head Voltage

Swing

Unselected Head Current

Glitch

Write Data Frequency for

Safe Condition

Differential Output

Resistance

=5MHz, Ambient temperature.

DATA

Iwr = 50mA TBD 16 V

IW = 50mA 1 mA

FLT = Low 1 MHz

30 60 Ohm

TDA5360

PK

PP

PK

C

O

A

SYM

tr , t

f

T

WSET

W

COV

1998 July 30

Differential Output

Capacitance

Asymmetry

(A

= |tr-tf| )

SYM

Rise/Fall Time

(-0.8 * IWR => +0.8 * IWR)

Write Current Settling Time IWR = 50mA,

Write Current Overshoot IW = 50mA,

6 pF

Write Data has 50% duty cycle &

0.5ns rise/fall time, load=short

10-90%; IW = 50mA

LH=75nH, RH=10Ω

LH=75nH, RH=10Ω

LH = 75 nH, RH = 10Ω

WCP0,1,2 = 000

0.1 ns

0.84 ns

2.5 ns

20 %

29

Page 30

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

12.4 Switching Characteristics

Unless otherwise specified, recommended operating conditions apply

PARAMETER CONDITIONS MIN TYP MAX UNIT

SI Serial Interface timing (Note 6)

t

RW

t

WR

t

CS

t

HS

t

RI

t

D1

t

D2

t

D3

T

RSET

R/WN to Write Mode To 90% of write current 50 ns

SEN to Write Mode To 90% of write current 50 ns

R/WN to Read Mode Reader outputs loaded with high-

CS to Read Mode Reader outputs loaded with high-

Head Switching Reader outputs loaded with high-

CS to Unselect To 10% write current 50 ns

Safe to Unsafe 50% WDP to 50% FLT

Unsafe to Safe 50% WDP to 50% FLT 20 ns

Head Current Propagation

Delay

MR Bias Current Settling

Time

pass single ended filters :

R=165Ω, C=270pF

Writer output shorted

(Note 7)

pass single ended filters :

R=165Ω, C=270pF

pass single ended filters :

R=165Ω, C=270pF

when a low frequency condition

occurs.

From 50% of WDP to 50% of write

current, load=short

IMR = 8mA, RMR =66Ω

(Note 8)

TDA5360

175 ns

1 us

1 us

1 us

5 ns

1 us

Notes:

1. The differential peak to peak voltage swing could be from 0.4V to 1.5V and the common mode should be such that

for any of the two states the maximum High shall be less than Vcc and the minimum LOW shall be more than 2.4V.

2. In current mode, a ratio of at least 5 sould exist between the HIGH and LOW level currents.

3. Whatever constant power is programmed, the value of the Imr current can not exceed the limits given in the constant

current mode.

4. The input referred noise voltage, excluding the noise of the MR resistor iis defined as follows :

2

4 kTRMR×××–=

Av

30

1998 July 30

vn

2

vnout

--------------

Page 31

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

5. The noise figure is defined as :

NF[dB] = 10xlog[(Vnout/Av)2 / (4kTxRMR)]

where Av is the gain and Vnout is the noise voltage at the output of the amplifier

6. See Section 11 for Serial Interface timing diagrams

7. This tWR is defined for a specific load on RDP,RDN reader outputs :

RDP

R

MR

tWR is the time between R/Wn going HIGH and the time when :

AND the differential DC decaying at RDPch-RDNch is below 10mV :

90% of the signal envelop is present at RDPch-RDNch

A

v

RDN

270pF

270pF

TDA5360

RDPch

330 Ohm

RDNch

RDPch-RDNch

10mV

R/Wn

Changing the load of the preamp will change tWR according to the new RC time constant.

8. When changing MR bias current, from SEN to 90% of IMR bias current.

1998 July 30

tWR

31

Page 32

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

TDA5360

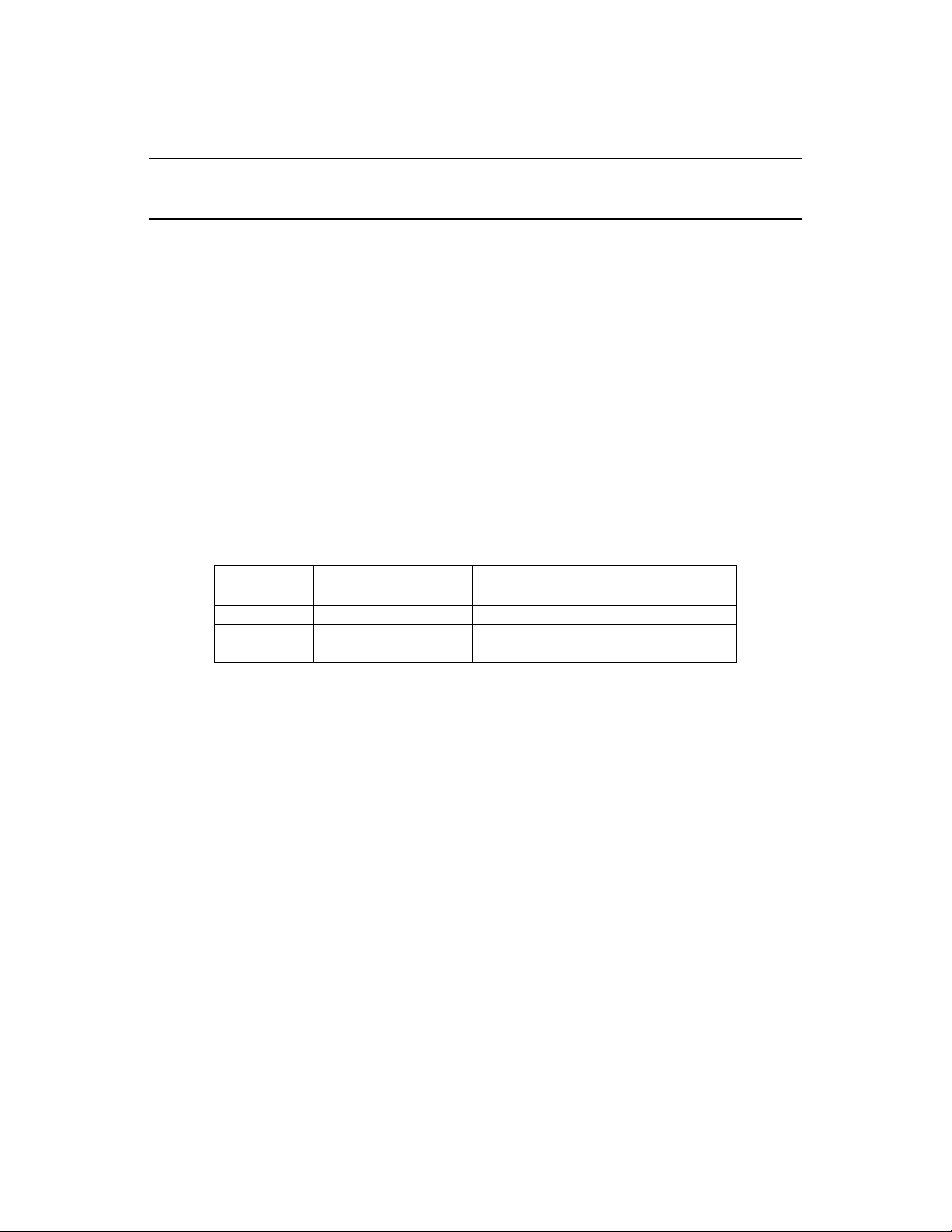

13 LIMITING VALUES / RECOMMENDED OPERATION CONDITIONS

In accordance with the Absolute Maximum System (IEC 134)

SYMBOL PARAMETER CONDITIONS MIN. TYP MAX. UNIT

V

CC

Positive Supply voltage

note1 4.5 5.0 5.5 V

range

V

EE

Negative Supply voltage

note 2 -4.5 - 5.0 -5.5 V

range

V

IH

High level CMOS input

2.4 V

CC

voltage

V

IL

Low level CMOS input

0 0.8 V

voltage

V

i(dif)(p-p)

Differential Peak to Peak

0.4

0.7

1.5

input voltage

(Writer input)

High level PECL input

voltage

Low level PECL input

2.4

3.2

2.8

V

CC

voltage

Imode

(Writer input)

T

amb

T

j

R

MR

L

l(tot)

Differential Peak to Peak

0.4

0.8

1.0

input current

High level input current

Low level input current

-1.4

-1.2

-0.4

-0.1

Ambient temperature 0 55 70 °C

Junction temperature when reading

when writing

70 110

130

MR element resistance 46 66 86 Ohm

Total lead inductance to

in each lead - 17 nH

the head

V

V

V

V

mA

mA

mA

°C

R

l(tot)

V

MR

V

sig(dif)(p-p)

L

wh

R

wh

C

wh

R

ext

1998 July 30

Total lead resistance to the

in each lead - 1.5 Ohm

head

Voltage accross MR

1 V

element (RPx-RNx)

MR head input signal peak

differential 0.4 1 3 mVpp

to peak voltage

Write Head inductance including lead 75 nH

Write Head resistance including lead - 10 Ohm

Write head capacitance including lead - TBD pF

Reference resistor Iref=Vref/Rext 9.9 10 10.1 k Ω

32

Page 33

Philips Semiconductors Objective Specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

TDA5360

Notes

1. A supply by-pass capacitor from VCC to ground or a low pass filter may be used to optimize the PSRR.

2. A supply by-pass capacitor from VEE to ground or a low pass filter may be used to optimize the PSRR

14 ABSOLUTE MAXIMUM RATINGS

SYMBOL PARAMETER MIN. MAX. UNIT

V

CC

V

EE

V

IN

V

n1

Positive supply voltage -0.5 6.0 V

Negative supply voltage -6.0 0.5 V

Digital input voltage -0.5 VCC+0.3V V

Voltage on all pins except VCC, read inputs RPx, RNx, write

-0.5 5.5

outputs WPx, WNx (x=0 to 11) and the ones mentionned in

this table

but not higher than

V

n2

V

n3

T

stg

T

j

Voltage on write driver outputs WPx, WNx

but not larger than

V

EE

VEE-0.5

Read inputs RPx, RNx -1 1 V

IC Storage temperature range -65 150 °C

Junction temperature range 150 °C

VCC+0.5

V

CC

VCC+0.5

V

V

V

V

1998 July 30

33

Page 34

Philips Semiconductors Objective specification, Revision 2.2

Pre-Amplifier for Hard Disk Drive with

MR-Read / Inductive Write Heads

Data sheet status

Data sheet

status

Objective

specification

Preliminary

specification

Product

specification

Product

status

Development

Qualification

Production

Definition

This data sheet contains the design target or goal specifications for product development.

Specification may change in any manner without notice.

This data sheet contains preliminary data, and supplementary data will be published at a later date.

Philips Semiconductors reserves the right to make chages at any time without notice in order to

improve design and supply the best possible product.

This data sheet contains final specifications. Philips Semiconductors reserves the right to make

changes at any time without notice in order to improve design and supply the best possible product.

[1]

TDA5360

[1] Please consult the most recently issued datasheet before initiating or completing a design.

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Philips Semiconductors

811 East Arques Avenue

P.O. Box 3409

Sunnyvale, California 94088–3409

Telephone 800-234-7381

Copyright Philips Electronics North America Corporation 1998

All rights reserved. Printed in U.S.A.

Date of release: 09-98

Document order number: 9397 750 04468

Loading...

Loading...