Page 1

TDA5051A

Home automation modem

Rev. 5 — 13 January 2011 Product data sheet

1. General description

The TDA5051A is a modem IC, specifically dedicated to ASK transmission by means of

the home power supply network, at 600 baud or 1200 baud data rate. It operates from a

single 5 V supply.

2. Features and benefits

Full digital carrier generation and shaping

Modulation/demodulation frequency set by clock adjustment, from microcontroller or

on-chip oscillator

High clock rate of 6-bit D/A (Digital to Analog) converter for rejection of aliasing

components

Fully integrated output power stage with overload protection

Automatic Gain Control (AGC) at receiver input

8-bit A/D (Analog to Digital) converter and narrow digital filtering

Digital demodulation delivering baseband data

Easy compliance with EN50065-1 with simple coupling network

Few external components for low cost applications

SO16 plastic package

3. Applications

Home appliance control (air conditioning, shutters, lighting, alarms and so on)

Energy/heating control

Amplitude Shift Keying (ASK) data transmission using the home power network

Page 2

NXP Semiconductors

4. Quick reference data

TDA5051A

Home automation modem

Table 1. Quick reference data

Symbol Parameter Conditions Min Typ Max Unit

V

DD

I

DD(tot)

supply voltage 4.75 5.0 5.25 V

total supply current f

=8.48MHz

osc

Reception mode - 28 38 mA

[1]

Transmission mode;

DATA_IN

=0; ZL=30Ω

-4768mA

Power-down mode - 19 25 mA

f

f

V

V

cr

osc

o(rms)

i(rms)

carrier frequency

oscillator frequency 6.08 - 9.504 MHz

output carrier signal (RMS value) DATA_IN = LOW;

input signal (RMS value)

THD total harmonic distortion on CISPR16 load

= CISPR16

Z

L

[2]

- 132.5 - kHz

120 - 122 dBμV

[3]

82 - 122 dBμV

- −55 - dB

with coupling network

T

amb

[1] The value of the total transmission mode current is the sum of I

[2] Frequency range corresponding to the EN50065-1 band. However, the modem can operate at any lower oscillator frequency.

[3] The minimum value can be improved by using an external amplifier; see application diagrams Figure 19

ambient temperature −50 - +100 °C

DD(RX/TX)(tot)

+ I

in the Table 5 “Characteristics”.

DD(PAMP)

and Figure 20.

5. Ordering information

Table 2. Ordering information

Type number Package

TDA5051AT SO16 plastic small outline package; 16 leads; body width 7.5 mm SOT162-1

Name Description Version

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 2 of 29

Page 3

NXP Semiconductors

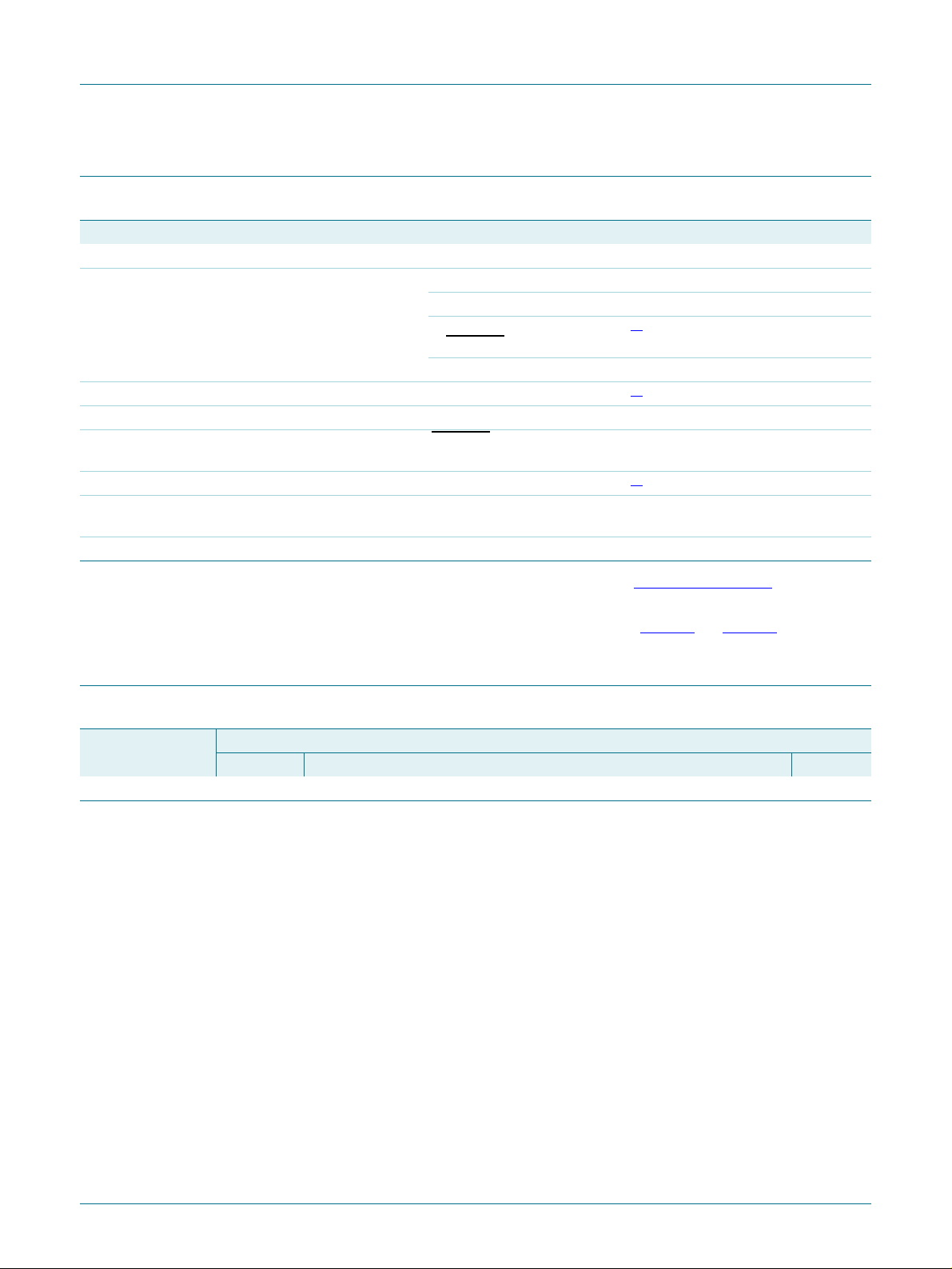

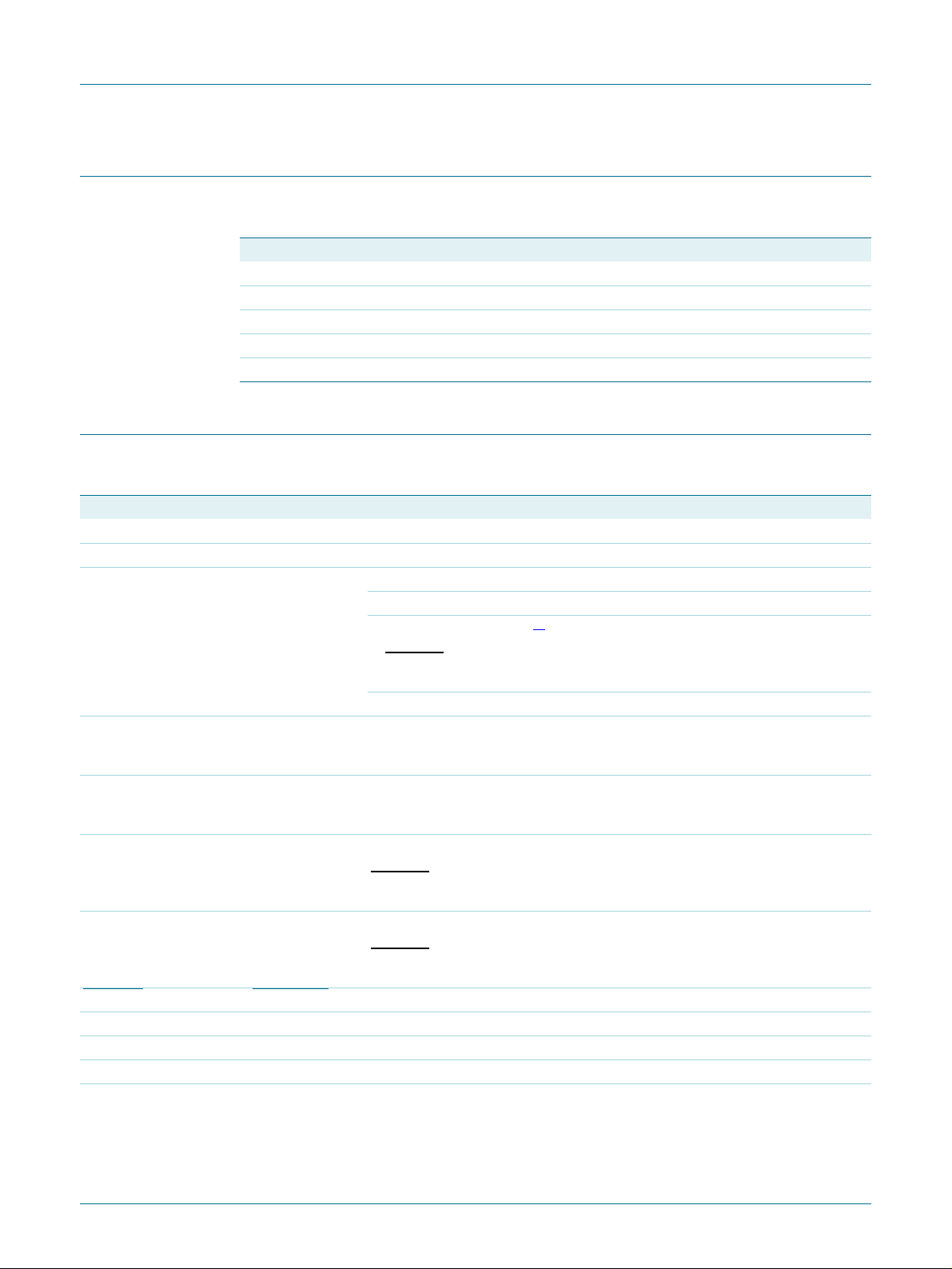

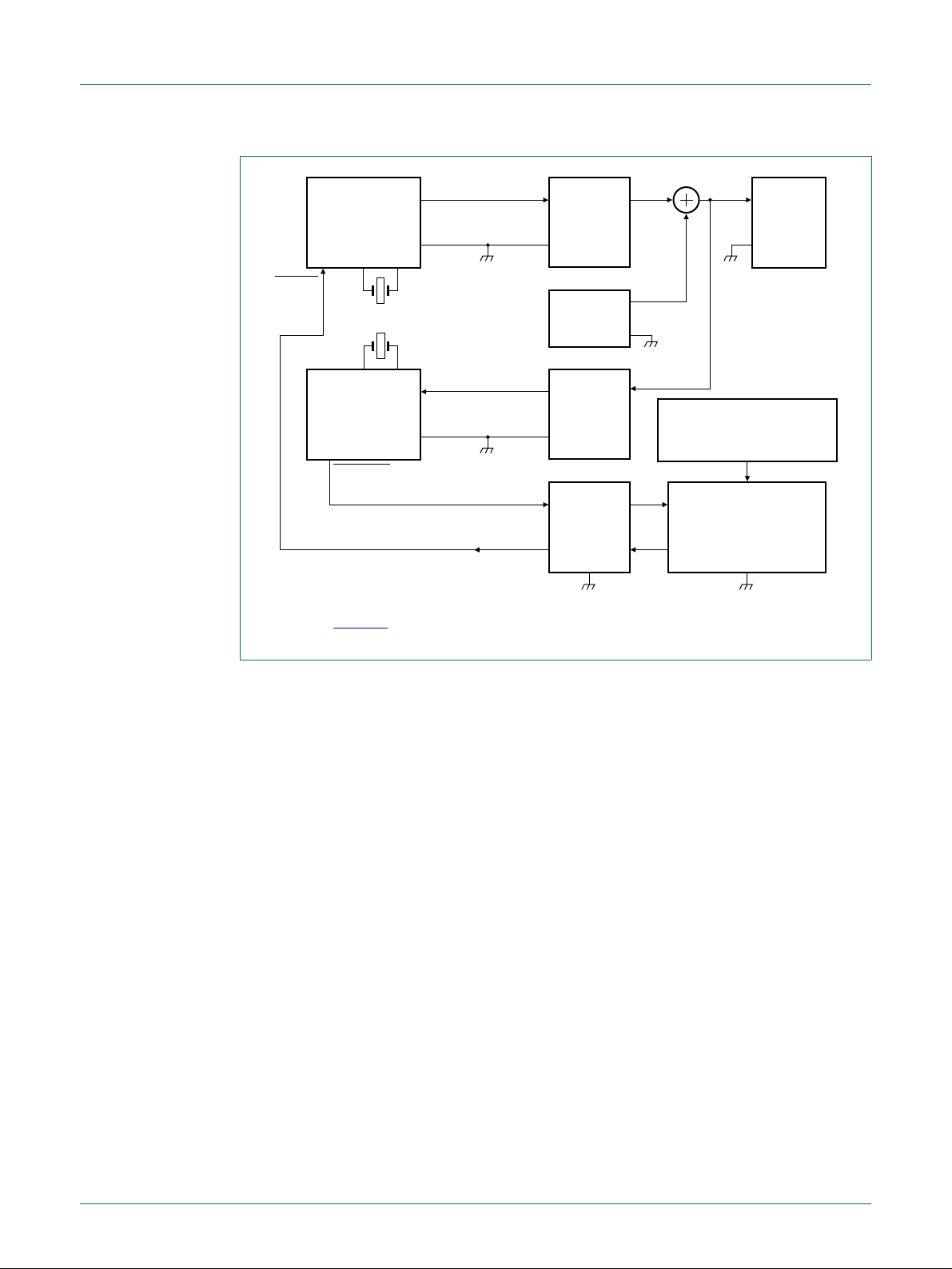

6. Block diagram

TDA5051A

Home automation modem

DATA_IN

CLK_OUT

OSC1

OSC2

DATA_OUT

DGND5AGND12V

1

4

7

OSCILLATOR

8

2

DIGITAL

DEMODULATOR

TEST1 SCANTEST

DDA

13

ROM

10

CONTROL LOGIC

16

6

V

DDD

311

6

D/A

DAC clock

modulated

carrier

V

DDAP

POWER

DRIVE

WITH

PROTECTION

10

9

TDA5051A

filter clock

÷ 2

DIGITAL

BAND-PASS

FILTER

8

PEAK

DETECT

A/D

H

L

U

U/D

D

COUNT

15

14

5

002aaf038

TX_OUT

APGND

PD

RX_IN

Fig 1. Block diagram

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 3 of 29

Page 4

NXP Semiconductors

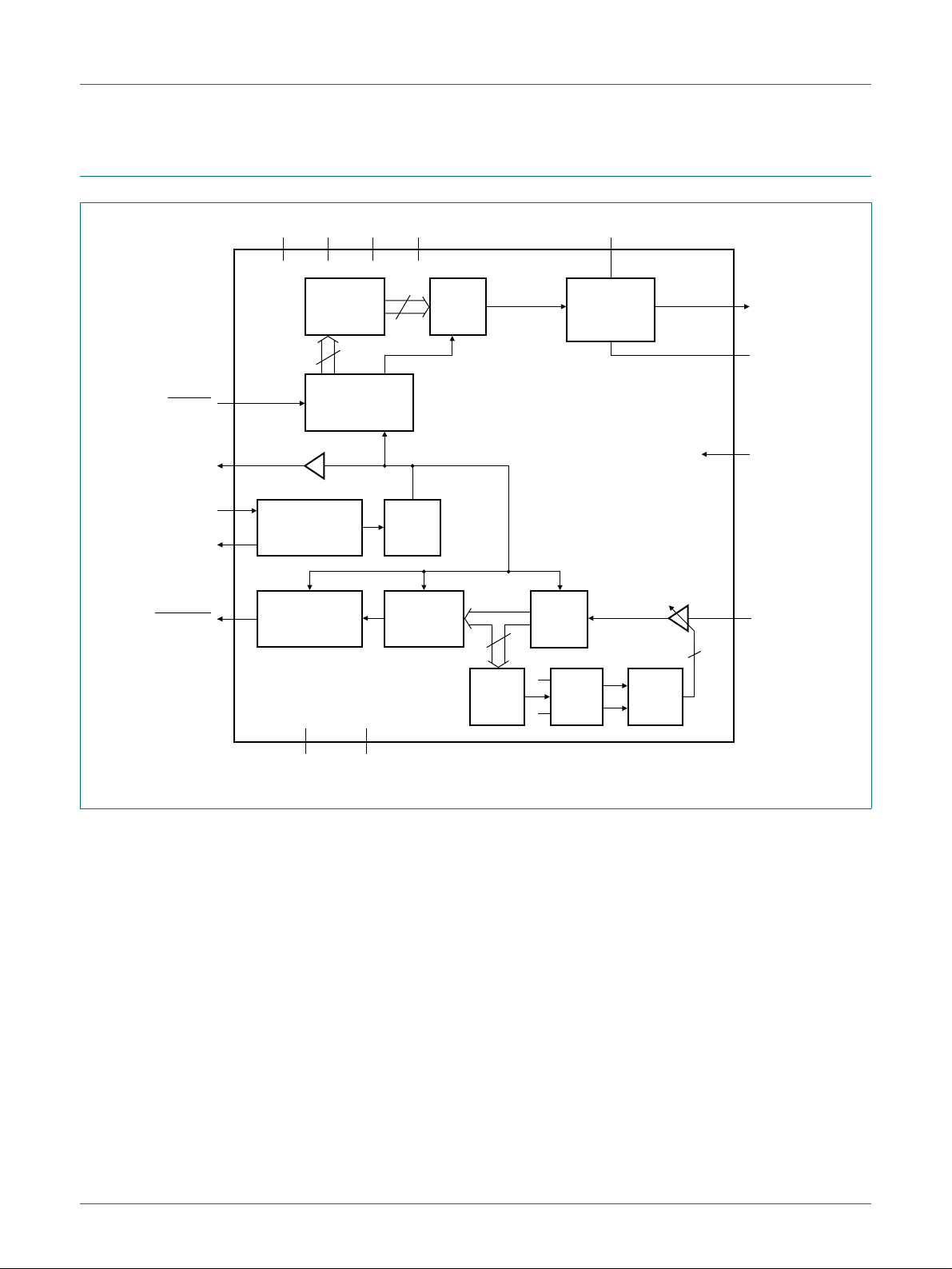

7. Pinning information

7.1 Pinning

TDA5051A

Home automation modem

DATA_IN TEST1

DATA_OUT PD

CLK_OUT V

SCANTEST V

1

2

3

V

DDD

4

TDA5051AT

5

DGND AGND

6

7

OSC1 TX_OUT

8

OSC2 APGND

Fig 2. Pin configuration for SO16

7.2 Pin description

Table 3. Pin description

Symbol Pin Description

DATA_IN

DATA_OUT

V

DDD

CLK_OUT 4 clock output

DGND 5 digital ground

SCANTEST 6 test input (LOW in application)

OSC1 7 oscillator input

OSC2 8 oscillator output

APGND 9 analog ground for power amplifier

TX_OUT 10 analog signal output

V

DDAP

AGND 12 analog ground

V

DDA

RX_IN 14 analog signal input

PD 15 power-down input (active HIGH)

TEST1 16 test input (HIGH in application)

1 digital data input (active LOW)

2 digital data ou tput (active LOW)

3 digital supply voltage

11 analog supply voltage for power amplifier

13 analog supply voltage

002aaf039

16

15

14

RX_IN

13

DDA

12

11

DDAP

10

9

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 4 of 29

Page 5

NXP Semiconductors

8. Functional description

Both transmission and reception stages are controlled either by the master clock of the

microcontroller or by the on-chip reference oscillator connected to a crystal. This ensures

the accuracy of the transmission carrier and the exact trimming of the digital filter, thus

making the performance totally independent of application disturbances such as

component spread, temperature, supply drift and so on.

TDA5051A

Home automation modem

The interface with the power network is made by means of an LC network (see Figure 15

The device includes a power output stage that feeds a 120 dBμV (RMS) signal on a

typical 30 Ω load.

To reduce power consumption, the IC is disabled by a power-down input (pin PD): in this

mode, the on-chip oscillator remains active and the clock continues to be supplied at

pin CLK_OUT. For low-power operation in reception mode, this pin can be dynamically

controlled by the microcontroller, see Section 8.4 “

When the circuit is connected to an external clock generator (see Figure 6

signal must be applied at pin OSC1 (pin 7); OSC2 (pin 8) must be left open-circuit.

Figure 7

All logic inputs and outputs are compatible with TTL/CMOS levels, providing an easy

connection to a standard microcontroller I/O port.

The digital part of the IC is fully scan-testable. Two digital inputs, SCANTEST and TEST1,

are used for production test: these pins must be left open-circuit in functional mode

(correct levels are internally defined by pull-up or pull-down resistors).

shows the use of the on-chip clock circuit.

Power-down mode”.

), the clock

8.1 Transmission mode

To provide strict stability with respect to environmental conditions, the carrier frequency is

generated by scanning the ROM memory under t he con trol of the microcon troller clock or

the reference frequency provided by the on-chip oscillator. High frequency clocking rejects

the aliasing components to such an extent that they are filtered by the coupling

LC network and do not cause any significant disturbance. The data modulation is applied

through pin DATA_IN

(shaping). Harmonic components are limited in this process, thus avoiding unaccep table

disturbance of the transmission channel (according to CISPR16 and EN50065-1

recommendations). A −55 dB Tot al Harmonic Distortion ( THD) is reached when the typical

LC coupling network (or an equivalent filter) is used.

and smoothly applied by specific digital circuits to the carrier

).

The DAC and the power stage are set in order to provide a maximum signal level of

122 dBμV (RMS) at the output.

The output of the power stage (TX_OUT) must always be connected to a decoup ling

capacitor, because of a DC level of 0.5V

device is not transmitting. This pin must also be protected against overvoltage and

negative transient signals. The DC level of TX_OUT can be used to bias a unipolar

transient suppressor, as shown in the application diagram (see Figure 15

Direct connection to the mains is done through an LC network for low-cost applications.

However, an HF signal transformer could be used when power-line insulation has to be

performed.

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 5 of 29

at this pin, which is present even when the

DD

).

Page 6

NXP Semiconductors

Remark: In transmission mode, the receiving part of the circuit is not disabled and the

detection of the transmitted signal is normally performed. In this mode, the gain chosen

before the beginning of the transmission is stored, and the AGC is internally set to

−6dB as long as DATA_IN

8.2 Reception mode

The input signal received by the modem is applied to a wide range input amplifier with

AGC (−6 dB to +30 dB). This is basically for noise performance improvement and signal

level adjustment, which ensures a maximum sensitivity of the ADC. An 8-bit conversion is

then performed, followed by digital band-pass filtering, to meet the CISPR16

normalization and to comply with some additional limitations met in current applications.

After digital demodulation, the baseband data signal is made available after pulse

shaping.

The signal pin (RX_IN) is a high-impedance input which has to be protected and

DC decoupled for the same reasons as with pin TX_OUT. The high sensitivity (82 dBμV)

of this input requires an efficient 50 Hz rejection filter (realized by the LC coupling

network), which also acts as an anti-aliasing filter for the internal digital processing;

(see Figure 15

TDA5051A

Home automation modem

is LOW. Then, the old gain setting is automatically restored.

).

8.3 Data format

8.3.1 Transmission mode

The data input (DATA_IN) is active LOW: this means that a burst is generated on the line

(pin TX_OUT) when DATA_IN

Pin TX_OUT is in a high-impedance state as long as the device is not transmitting.

Successive logic 1s are treated in a Non-Return-to-Zero (NRZ) mode, see pulse shapes

in Figure 8

and Figure 9.

8.3.2 Reception mode

The data output (pin DATA_OUT) is active LOW; this means that the data output is LOW

when a burst is received. Pin DATA_OUT

8.4 Power-down mode

Power-down input (pin PD) is active HIGH; this means that the power consumption is

minimum when pin PD is HIGH. Now, all functions are disabled, except clock generation.

pin is LOW.

remains LOW as long as a burst is received.

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 6 of 29

Page 7

NXP Semiconductors

9. Limiting values

Table 4. Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

DD

f

osc

T

stg

T

amb

T

j

10. Characteristics

TDA5051A

Home automation modem

supply voltage 4.5 5.5 V

oscillator frequency - 12 MHz

storage temperature −50 +150 °C

ambient temperature −50 +100 °C

junction temperature - 125 °C

Table 5. Characteristics

V

DDD=VDDA

=5V±5%; T

=−40°C to +85°C; V

amb

connected to V

DDD

; DGND connected to AGND.

DDA

Symbol Parameter Conditions Min Typ Max Unit

Supply

V

DD

I

DD(tot)

supply voltage 4.75 5 5.25 V

total supply current f

=8.48MHz

osc

Reception mode - 28 38 mA

[1]

Transmission

-4768mA

mode;

DATA_IN

=0;

ZL=30Ω

Power-down mode - 19 25 mA

I

DD(RX/TX)(tot)

total analog + digital

supply current

VDD=5V± 5%;

Transmission or

-2838mA

Reception mode

I

DD(PD)(tot)

total analog + digital

supply current

VDD=5V± 5%;

PD = HIGH;

-1925mA

Power-down mode

I

DD(PAMP)

power amplifier

supply current

VDD=5V± 5%;

=30Ω;

Z

L

DATA_IN

= LOW in

-1930mA

Transmission mode

I

DD(PAMP)(max)

maximum power amplifier

supply current

VDD=5V± 5%;

=1Ω;

Z

L

DATA_IN

= LOW in

-76-mA

Transmission mode

DATA_IN

V

IH

V

IL

V

OH

V

OL

and PD inputs; DATA_OUT and CLK_OUT outputs

HIGH-level input voltage 0.2VDD+0.9 - VDD+0.5 V

LOW-level input voltage −0.5 - 0.2VDD− 0.1 V

HIGH-level output voltage IOH= −1.6 mA 2.4 - - V

LOW-level output voltage IOL= 1.6 mA - - 0.45 V

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 7 of 29

Page 8

NXP Semiconductors

TDA5051A

Home automation modem

Table 5. Characteristics …continued

V

DDD=VDDA

Symbol Parameter Conditions Min Typ Max Unit

OSC1 input and OSC2 output (OSC2 only used for driving external quartz crystal; must be left open-circuit when

using an external clock generator)

V

IH

V

IL

V

OH

V

OL

Clock

f

osc

f

osc/fcr

f

osc/fCLKOUT

Transmission mode

f

cr

t

su

t

h

t

W(DI)(min)

V

o(rms)

I

o(max)

Z

o

V

O

THD total harmonic distortion on

B

−20dB

=5V±5%; T

HIGH-level input voltage 0.7V

=−40°C to +85°C; V

amb

connected to V

DDD

; DGND connected to AGND.

DDA

DD

-V

+0.5 V

DD

LOW-level input voltage −0.5 - 0.2VDD− 0.1 V

HIGH-level output voltage IOH= −1.6 mA 2.4 - - V

LOW-level output voltage IOL= 1.6 mA - - 0.45 V

oscillator frequency 6.080 - 9.504 MHz

ratio between oscillator and

-64-

carrier frequency

ratio between oscillator and

-2-

clock output frequency

carrier frequency f

set-up time of the shaped

burst

hold time of the shaped

burst

minimum pulse width of

DATA_IN

signal

output carrier signal

(RMS value)

power amplifier maximum

output current (peak value)

output impedance of the

=8.48MHz

osc

f

= 8.48 MHz;

osc

see Figure 8

f

= 8.48 MHz;

osc

see Figure 8

f

= 8.48 MHz;

osc

see Figure 8

DATA_IN = LOW;

ZL= CISPR16

DATA_IN = LOW;

=1Ω

Z

L

[2]

- 132.5 - kHz

- 170 - μs

- 170 - μs

- 190 - μs

120 - 122 dBμV

- 160 - mA

-5-Ω

power amplifier

output DC level at

-2.5-V

pin TX_OUT

CISPR16 load with the

coupling network (measured

on the first ten harmonics)

= 121 dBμV on

V

o(rms)

CISPR16 load;

= 8.48 MHz;

f

osc

DATA_IN

=LOW

- −55 - dB

(no modulation);

see Figure 3

and

Figure 22

bandwidth of the shaped

output signal (at −20 dB)

on CISPR16 load with the

coupling network

V

= 121 dBμV on

o(rms)

CISPR16 load;

= 8.48 MHz;

f

osc

DATA_IN = 300 Hz;

- 3000 - Hz

duty factor = 50 %;

see Figure 4

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 8 of 29

Page 9

NXP Semiconductors

TDA5051A

Home automation modem

Table 5. Characteristics

V

DDD=VDDA

=5V±5%; T

…continued

=−40°C to +85°C; V

amb

connected to V

DDD

; DGND connected to AGND.

DDA

Symbol Parameter Conditions Min Typ Max Unit

Reception mode

V

i(rms)

analog input signal

[3]

82 - 122 dBμV

(RMS value)

V

I

Z

i

R

AGC

t

c(AGC)

DC level at pin RX_IN - 2.5 - V

RX_IN input impedance - 50 - kΩ

AGC range - 36 - dB

AGC time constant f

= 8.48 MHz;

osc

- 296 - μs

see Figure 5

t

d(dem)(su)

demodulation delay

set-up time

t

d(dem)(h)

demodulation delay

hold time

B

det

detection bandwidth f

BER bit error rate f

f

= 8.48 MHz;

osc

- 350 400 μs

see Figure 21

f

= 8.48 MHz;

osc

- 420 470 μs

see Figure 21

=8.48MHz-3-kHz

osc

= 8.48 MHz;

osc

-1-1× 10

600 baud;

S/N = 35 dB;

signal 76 dBμV;

see Figure 23

Power-up timing

t

d(pu)(TX)

delay between power-up

and DATA_IN

in

transmission mode

XTAL = 8.48 MHz;

C1 = C2 = 27 pF;

Rp=2.2MΩ;

-1-μs

see Figure 10

t

d(pu)(RX)

delay between power-up

and DATA_OUT in

reception mode

XTAL = 8.48 MHz;

C1 = C2 = 27 pF;

Rp=2.2MΩ;

= 132.5 kHz;

f

RXIN

-1-μs

120 dBμV sine wave;

see Figure 11

Power-down timing

t

d(pd)(TX)

delay between PD = 0 and

DATA_IN

in transmission

f

= 8.48 MHz;

osc

see Figure 12

-10-μs

mode

t

d(pd)(RX)

delay between PD = 0 and

DATA_OUT

in reception

mode

= 8.48 MHz;

f

osc

f

= 132.5 kHz;

RXIN

120 dBμV sine wave;

- 500 - μs

see Figure 13

t

active(min)

minimum active time with

T = 10 ms power-down

period in reception mode

f

= 8.48 MHz;

osc

f

= 132.5 kHz;

RXIN

120 dBμV sine wave;

-1-μs

see Figure 14

−4

[1] The value of the total transmission mode current is the sum of I

[2] Frequency range corresponding to the EN50065-1 band. However, the modem can operate at any lower oscillator frequency.

[3] The minimum value can be improved by using an external amplifier; see application diagrams Figure 19

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 9 of 29

DD(RX/TX)(tot)

+ I

DD(PAMP)

.

and Figure 20.

Page 10

NXP Semiconductors

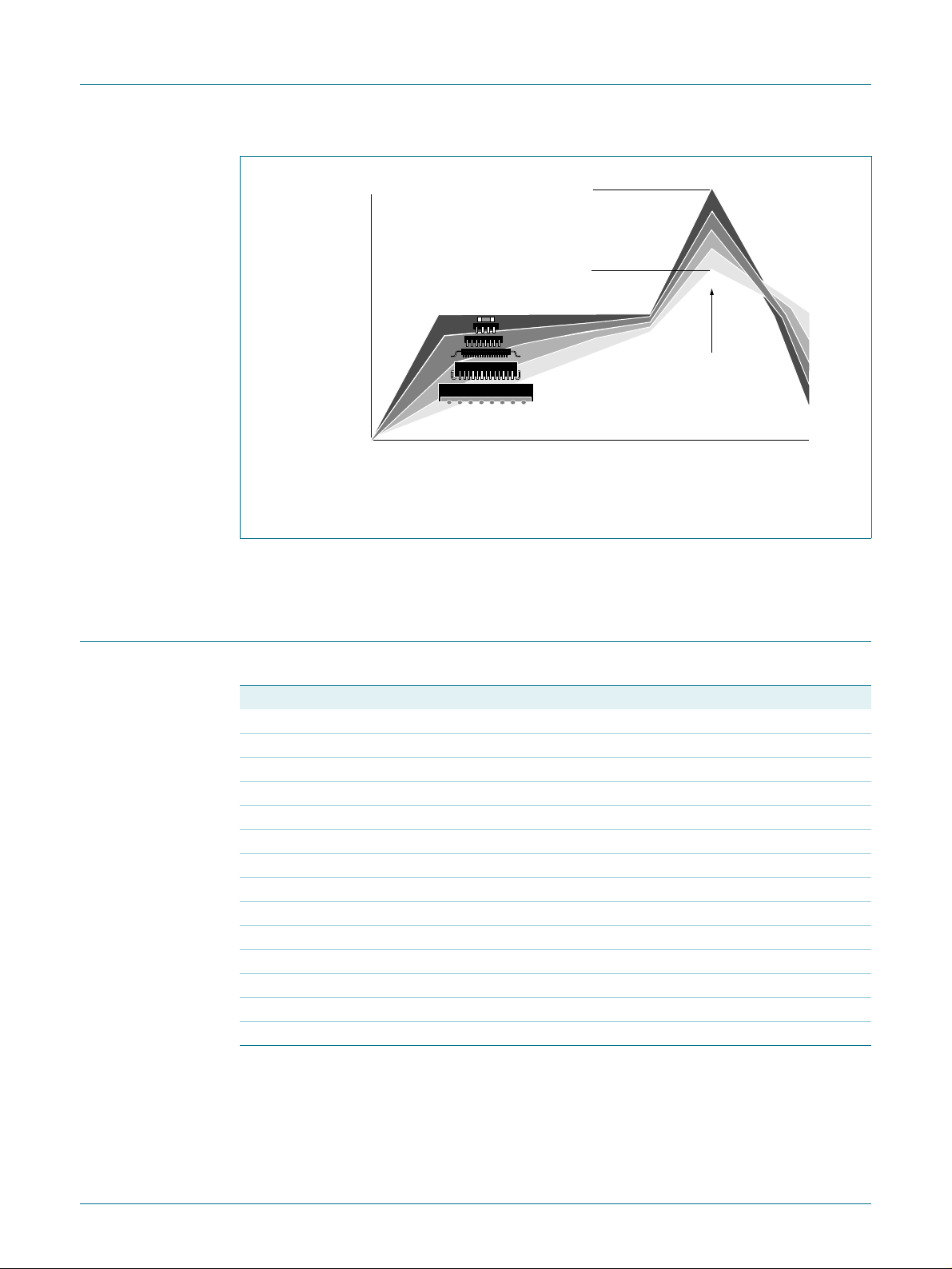

002aaf054

8

TDA5051A

Home automation modem

0

V

o(rms)

(dBV)

−20

−40

−60

−80

−100

5

10

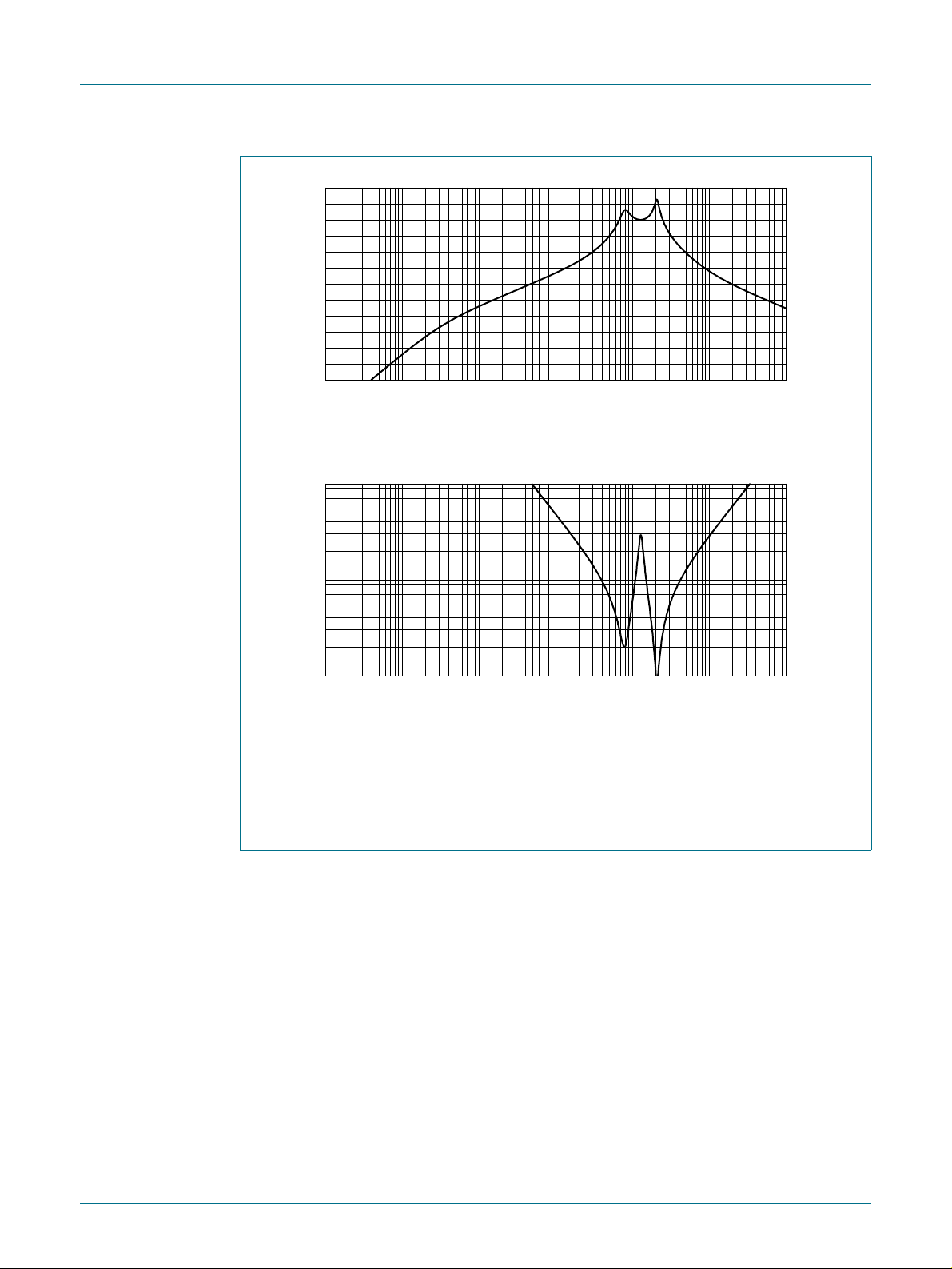

Resolution bandwidth = 9 kHz; top: 0 dBV (RMS) = 120 dBμV (RMS); marker at

−5dBV(RMS)=115dBμV (RMS); the CISPR16 network provides an attenuation of 6 dB,

so the signal amplitude is 121 dBμV (RMS).

Fig 3. Carrier spectrum

−10

dBV

(RMS)

−20

−30

132.5 kHz

1500 Hz

20 dB

f (Hz)

002aaf057

6

10

−40

−50

−60

117.5 147.5

Resolution bandwidth = 100 Hz; B

Fig 4. Shaped signal spectrum

V

RXIN

V

(I)

0

G

AGC

+30 dB

−6 dB

(AGC time constant)

132.5

= 3000 Hz (2 × 1500 Hz).

−20dB

modulated sine wave 122 dBμV amplitude

t

c(AGC)

8.68 dB

f (kHz)

t

AGC range

002aaf05

Fig 5. AGC time constant definition (not to scale)

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 10 of 29

Page 11

NXP Semiconductors

2

3

11. Timing

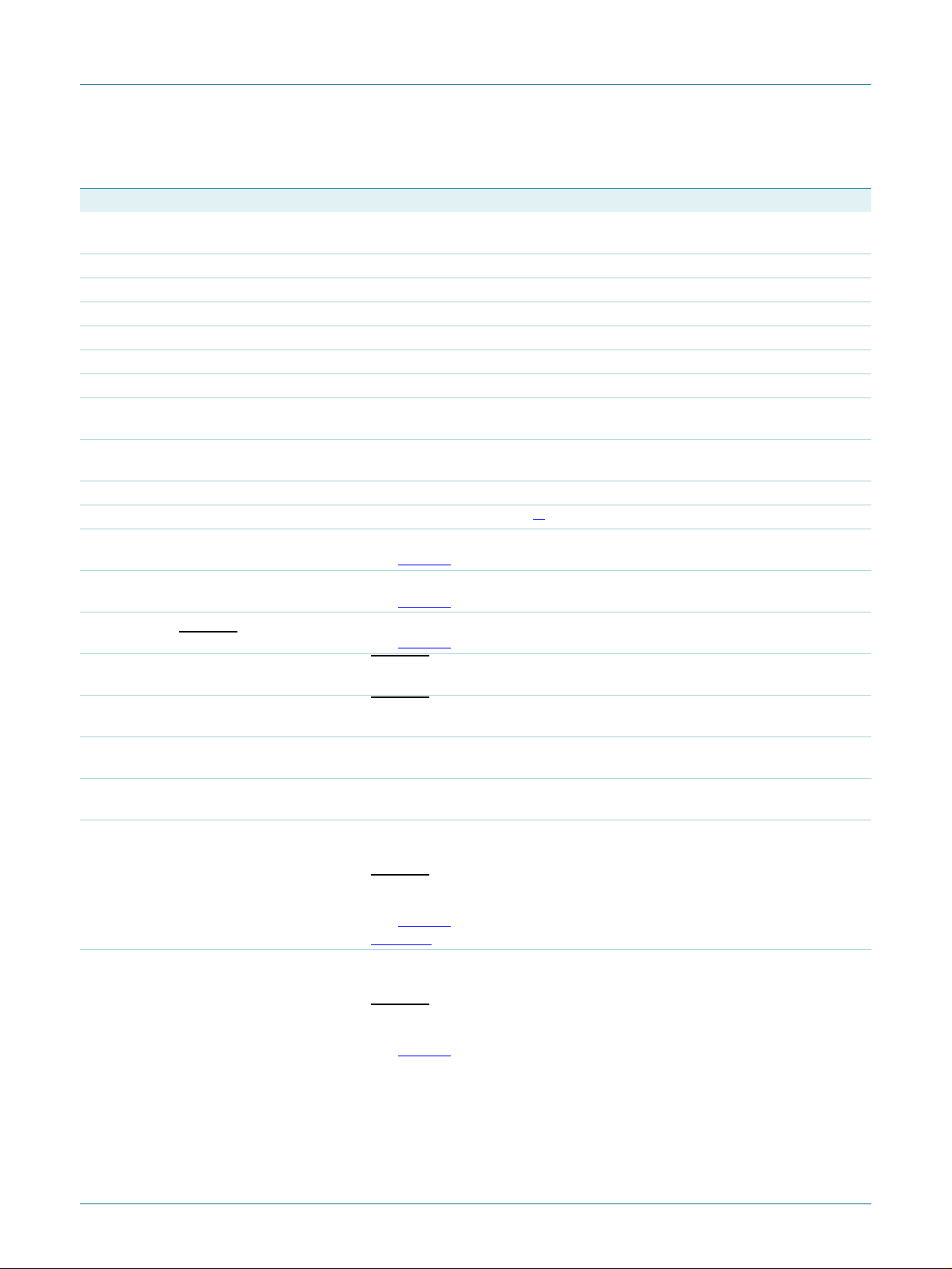

11.1 Configuration for clock

Fig 6. External clock

CLK_OUT

XTAL

MICROCONTROLLER

For parameter description, see Table 6.

GND

TDA5051A

Home automation modem

OSC1

DGND

7

TDA5051A

5

002aaf04

f

osc

CLK_OUT

MICROCONTROLLER

GND

CLK_OUT

1

/2 f

osc

DGND

4

TDA5051A

5

8

7

OSC2

OSC1

R

p

C1

XTAL

C2

002aaf04

For parameter description, see Table 6.

Fig 7. Typical configuration for on-chip clock circuit

Table 6. Clock oscillator parameters

Oscillator

frequency f

6.080 MHz to

9.504 MHz

osc

Carrier

frequency f

95 kHz to

148.5 kHz

Clock output frequency

1

cr

⁄

2fosc

External components

3.040 MHz to 4.752 MHz C1 = C2 = 27 pF to 47 pF;

R

=2.2MΩ to 4.7 MΩ;

p

XTAL= standard quartz crystal

Table 7. Calculation of parameters depending on the clock frequency

Symbol Parameter Conditions Unit

f

osc

oscillator frequency with on-chip oscillator: frequency of

Hz

the crystal quartz

with external clock: frequency of the

Hz

signal applied at OSC1

f

CLKOUT

f

cr

clock output frequency

carrier frequency/digital filter tuning

1

⁄

2fosc

1

⁄

64fosc

Hz

Hz

frequency

t

su

t

h

t

W(DI)(min)

set-up time of the shaped burst 23/fcr or 1472/f

hold time of the shaped burst 23/fcr or 1472/f

minimum pulse width of DATA_IN

tsu + 1/f

cr

osc

osc

s

s

s

signal

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 11 of 29

Page 12

NXP Semiconductors

4

5

TDA5051A

Home automation modem

Table 7. Calculation of parameters depending on the clock frequency

…continued

Symbol Parameter Conditions Unit

t

W(burst)(min)

t

c(AGC)

t

su(demod)

t

h(demod)

minimum burst time of V

O(DC)

signal t

W(DI)(min)

AGC time constant 2514/f

demodulation set-up time 3200/f

demodulation hold time 3800/f

t

TX_OUT

V

O(DC)

DATA_IN

t

W(burst)

t

0

su

t

W(DI)

(1) (2) (3)

W(burst)(min)

t

h

t

W(DI)(min)

+ t

h

osc

(max.) s

osc

(≈max.) s

osc

002aaf04

s

s

(1) t

W(DI)>tW(DI)(min)

(2) t

W(DI)(min)=tsu

(3) t

W(DI)(min)<tsu

+1/f

cr

; wrong operation

Fig 8. Relationship between DATA_IN and TX_OUT (see Table 8)

T able 8. Relationship between DATA_IN

and TX_OUT

X = don’t care.

PD DATA_IN TX_OUT

1 X high-impedance

0 1 high-impedance (after t

)

h

0 0 active with DC offset

t

W(burst)

100 %

t

su

t

h

002aaf04

Fig 9. Pulse shape characteristics

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 12 of 29

Page 13

NXP Semiconductors

6

7

8

1 1.2 Timing diagrams

V

90 % V

DD

TDA5051A

Home automation modem

DD

CLK_OUT

DATA_IN

TX_OUT

(1)

not defined clock stable

HIGH

t

d(pu)(TX)

(1) DATA_IN is an edge-sensitive input and must be HIGH before starting a transmission.

Fig 10. Timing diagram during power-up in Transmission mode

90 % V

V

DD

CLK_OUT

RX_IN

DATA_OUT

DD

not defined

not defined

t

d(pu)(RX)

clock stable

HIGH

t

d(dem)(h)

002aaf04

002aaf04

Fig 11. Timing diagram during power-up in Reception mode

PD

DATA_IN

TX_OUT

t

d(pd)(TX)

normal operation wrong operation

TX_OUT

delayed by PD

002aaf04

Fig 12. Power-down sequence in Transmission mode

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 13 of 29

Page 14

NXP Semiconductors

9

0

TDA5051A

Home automation modem

PD

RX_IN

DATA_OUT

t

d(dem)(su)

DATA_OUT delayed by PD

t

d(pd)(RX)

Fig 13. Power-down sequence in Reception mode

PD

RX_IN

DATA_OUT

t

active(min)

I

DD(RX)

I

DD

I

DD(PD)

0

T

Fig 14. Power saving by dynamic control of power-down

t

d(pd)(RX)

002aaf04

002aaf05

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 14 of 29

Page 15

NXP Semiconductors

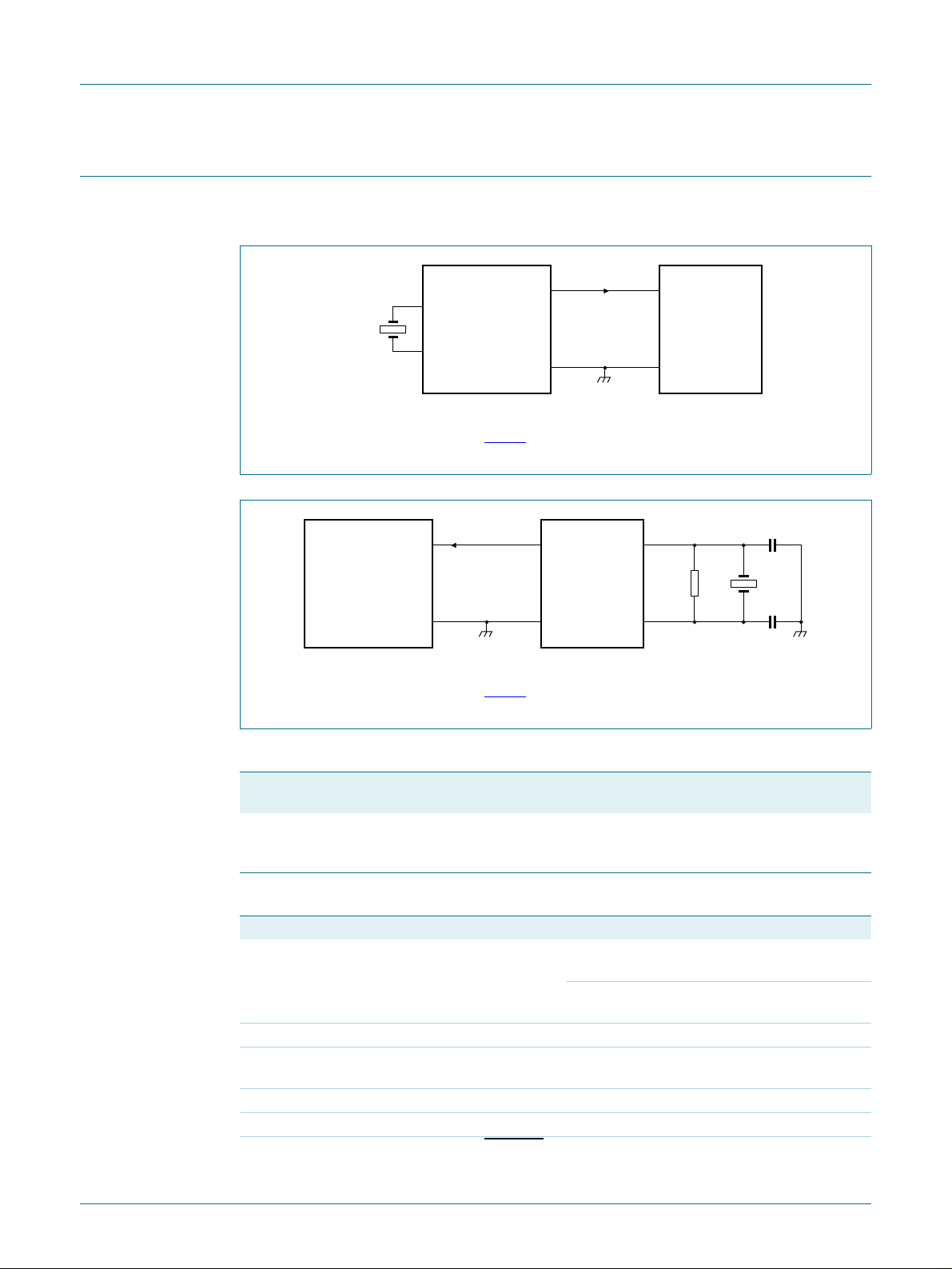

12. Application information

TDA5051A

Home automation modem

+5 V

250 V (AC)

MICRO-

CONTROLLER

max

+5 V

DATA_IN

DATA_OUT

CLK_OUT

47 nF

78L05

2

PD

T 630 mA

31

1

2

4

15

7

OSC1

7.3728 MHz

470 μF

(16 V)

2.2 MΩ

XTAL

MOV

250 V (AC)

U

1N4006

7V5

(1.3 W)

100 μF

(16 V)

V

DDDVDDAP

3

TDA5051A

85 9 12

OSC2

27 pF27 pF

APGND

2 μF

250 V (AC)

68 Ω

(2 W)

1 mH

1N4006

V

DDA

1311

14

10

AGNDDGND

RX_IN

TX_OUT

47 nF

(63 V)

47 μH

10 nF

SA5.0A

47 nF/X2

250 V (AC)

47 μH

low R

1 μF

(16 V)

002aaf059

S

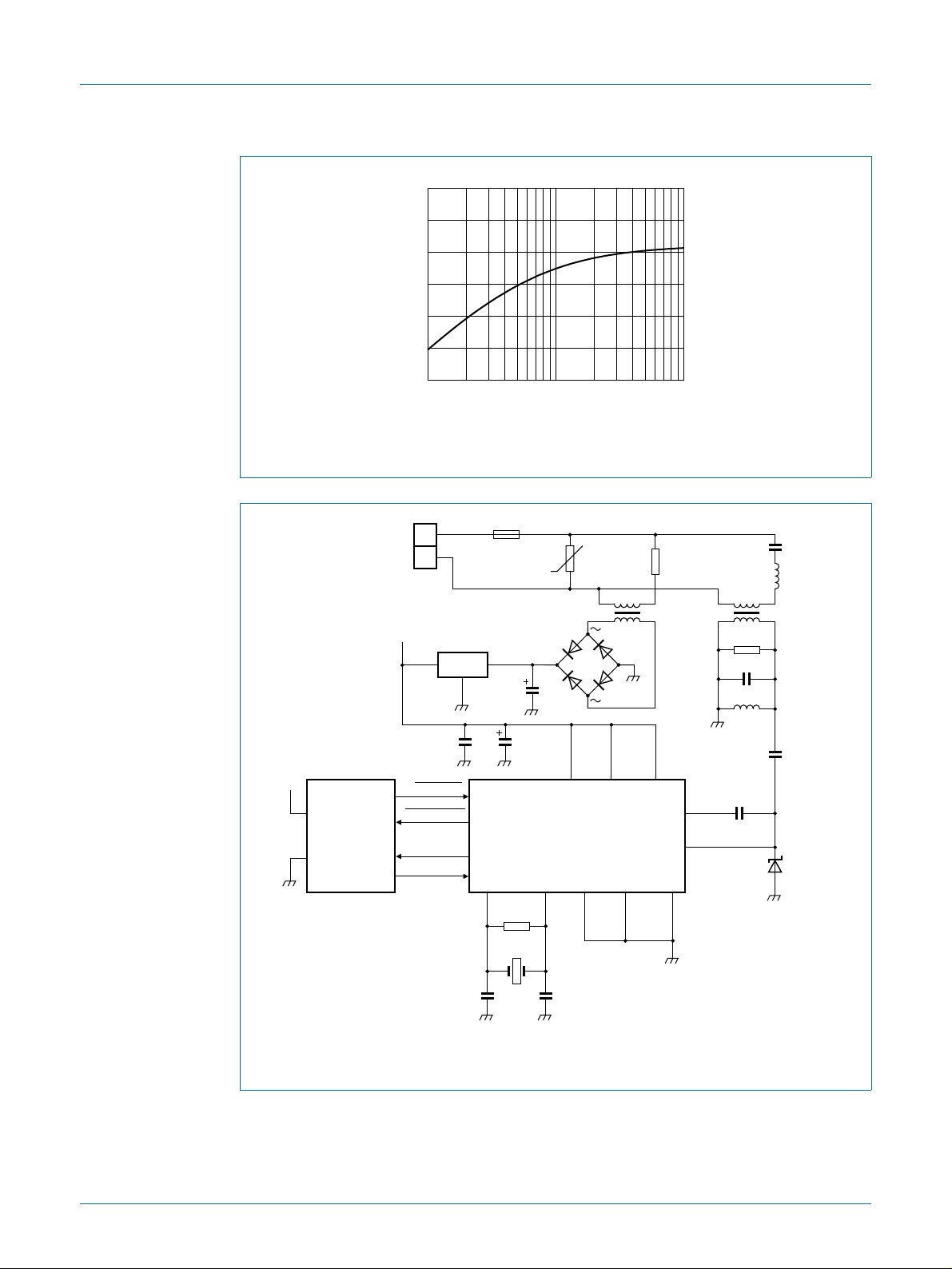

fcr = 115.2kHz for XTAL = 7.3728 MHz standard crystal.

Fig 15. Application diagram without power line insulation

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 15 of 29

Page 16

NXP Semiconductors

002aaf055

TDA5051A

Home automation modem

20

G

(dB)

−20

−60

−100

10 10

2

10

3

10

4

10

5

10

a. Gain

3

10

Z

i

(Ω)

2

10

10

10 10

2

10

3

10

4

10

5

10

b. Input impedance

fcr= 115.2 kHz; L = 47 μH; C = 47 nF.

Main features of the coupling network: 50 Hz rejection > 80 dB; anti-aliasing for the digital filter >

50 dB at the sampling frequency (

1

⁄

). Input impedance always higher than 10 Ω within the

2fosc

95 kHz to 148.5 kHz band.

Fig 16. Gain (a) and input impedance (b) of the coupling network

6

10

f (Hz)

002aaf431

6

10

f (Hz)

7

7

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 16 of 29

Page 17

NXP Semiconductors

002aaf056

130

V

o

(dBμV)

120

110

TDA5051A

Home automation modem

100

110

10

with coupling network; L = 47 μH; C = 47 nF.

Fig 17. Output voltag e as a function of line impedance

+5 V

250 V (AC)

MICRO-

CONTROLLER

max

+5 V

47 nF

DATA_IN

DATA_OUT

CLK_OUT

78L05

2

PD

1

2

4

15

T 630 mA

7

31

470 μF

(16 V)

100 μF

(16 V)

OSC1

2.2 MΩ

XTAL

7.3728 MHz

MOV

250 V (AC)

U

1 VA

+

FDB08

V

DDDVDDAP

3

TDA5051A

85 9 12

OSC2

1311

100 Ω

(0.5 W)

V

DDA

14

10

2

RX_IN

TX_OUT

AGNDDGND

1

2

Newport/

Murata

78250

100 Ω

100 nF

(63 V)

22 μH

10 nF

SA5.0A

470 nF/X2

250 V (AC)

47 μH

low R

6

5

1 μF

(16 V)

S

Z

(Ω)

line

230 V

6 V

−

APGND

27 pF27 pF

002aaf060

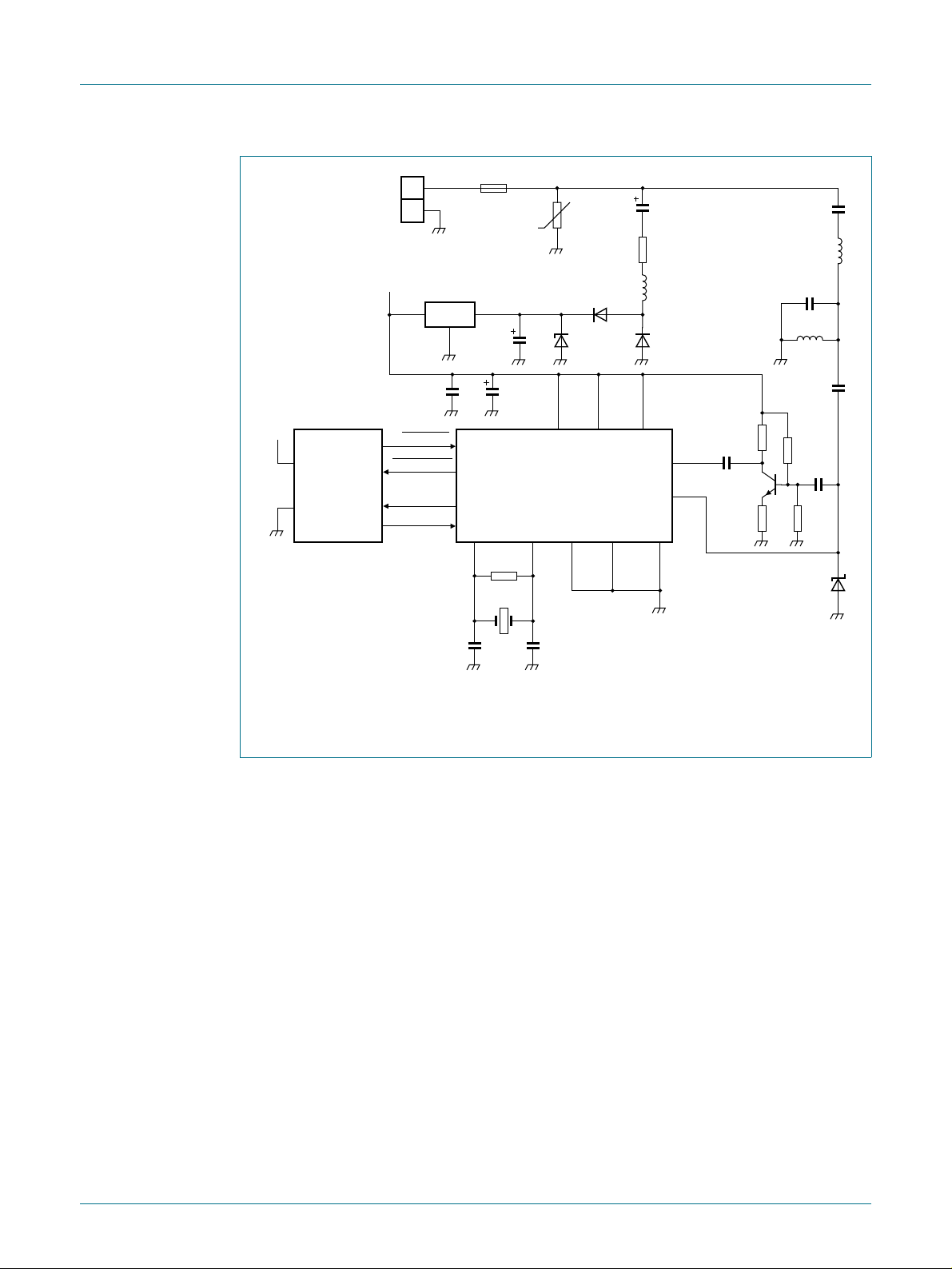

fcr= 115.2 kHz for XTAL = 7.3728 MHz standard crystal.

Fig 18. Application diagram with power line insulation

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 17 of 29

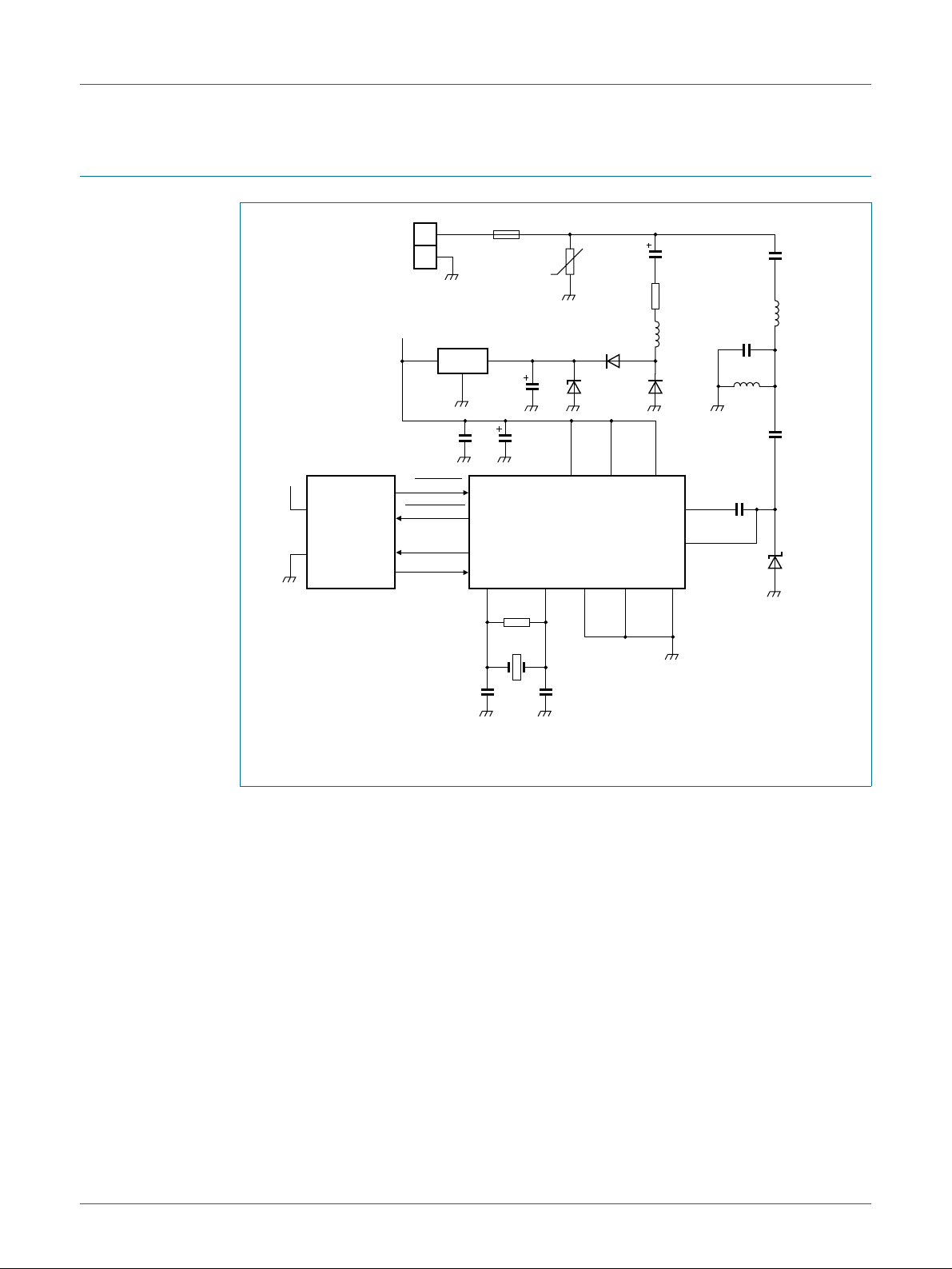

Page 18

NXP Semiconductors

61

TDA5051A

Home automation modem

+5 V

250 V (AC)

MICRO-

CONTROLLER

max

+5 V

DATA_IN

DATA_OUT

CLK_OUT

47 nF

78L05

2

PD

T 630 mA

31

1

2

4

15

7

OSC1

7.3728 MHz

470 μF

(16 V)

2.2 MΩ

XTAL

MOV

250 V (AC)

U

1N4006

7V5

(1.3 W)

100 μF

(16 V)

V

DDDVDDAP

3

TDA5051A

85 9 12

OSC2

27 pF27 pF

APGND

2 μF

250 V (AC)

68 Ω

(2 W)

1 mH

1N4006

V

DDA

1311

14

10

AGNDDGND

RX_IN

TX_OUT

10 nF

10 kΩ

BC547B

1 kΩ

47 nF/X2

250 V (AC)

47 μH

low R

47 nF

(63 V)

47 μH

1 μF

(16 V)

150 kΩ

10 nF

33 kΩ

SA5.0A

002aaf0

S

fcr= 115.2 kHz for XTAL = 7.3728 MHz standard crystal.

Fig 19. Application diagram without power line insulation, with impro ved sensit ivit y

(68 dBμV typ.)

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 18 of 29

Page 19

NXP Semiconductors

TDA5051A

Home automation modem

+5 V

250 V (AC)

MICRO-

CONTROLLER

max

+5 V

DATA_IN

DATA_OUT

CLK_OUT

47 nF

78L05

2

PD

1

2

4

15

T 630 mA

7

31

470 μF

(16 V)

100 μF

(16 V)

OSC1

2.2 MΩ

XTAL

7.3728 MHz

230 V

6 V

−

1311

100 Ω

(0.5 W)

V

DDA

14

10

RX_IN

TX_OUT

MOV

250 V (AC)

U

1 VA

+

FDB08

V

DDDVDDAP

3

TDA5051A

85 9 12

OSC2

27 pF27 pF

APGND

AGNDDGND

10 nF

10 kΩ

BC547B

1 kΩ

470 nF/X2

250 V (AC)

Newport/

Murata

78250

1

2

100 Ω

100 nF

(63 V)

22 μH

150 kΩ

SA5.0A

1 μF

(16 V)

10 nF

33 kΩ

002aaf062

47 μH

low R

6

5

S

fcr= 115.2 kHz for XTAL = 7.3728 MHz standard crystal.

Fig 20. Application diagram with power line insulation, with improved sensitivity

(68 dBμV typ.)

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 19 of 29

Page 20

NXP Semiconductors

2

2

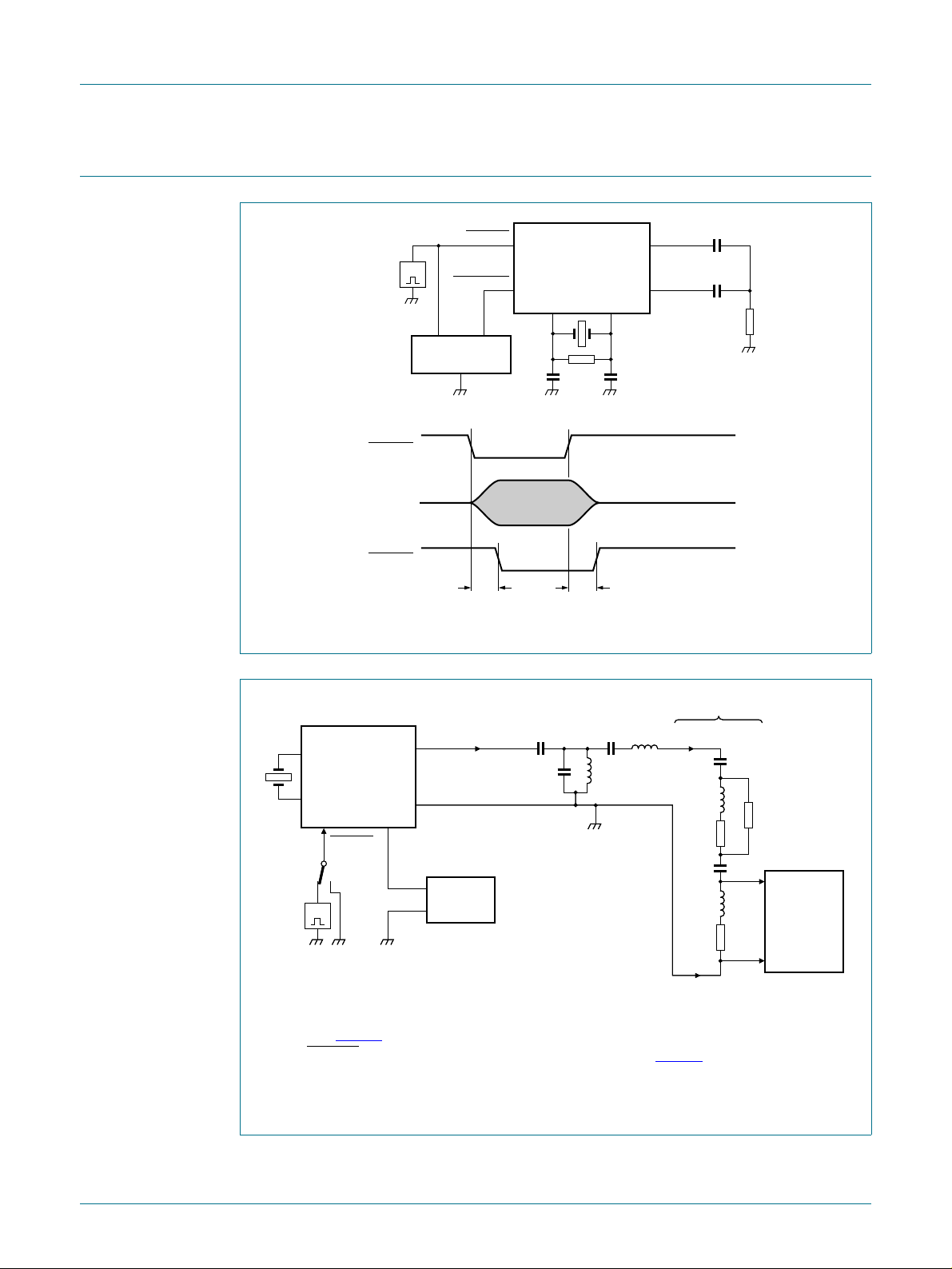

13. Test information

TDA5051A

Home automation modem

pulse

generator

300 Hz

50 %

DATA_IN

G

DATA_OUT

1

TDA5051A

(to be tested)

2

78

Y1

Y2

OSCILLOSCOPE

DATA_IN

TX_OUT/RX_IN

DATA_OUT

t

d(dem)(su)

t

d(dem)(h)

Fig 21. Test set-up for measuring demodulation delay

XTAL

f

osc

10

14

TX_OUT

RX_IN

1 μF

10 nF

30 Ω

002aaf051

(3)

OSC1

OSC1

OSC2

OSC2

7

7

TDA5051A

TDA5051A

8

8

1 13, 3, 11

1 13, 3, 11

DATA_IN

DATA_IN

(2)(1)

(2)(1)

G

G

TX_OUT

TX_OUT

10

10

AGND, DGND, APGND

AGND, DGND, APGND

12, 5, 9

12, 5, 9

V

V

, V

, V

DDA

DDA

+5 V

+5 V

, V

, V

DDD

DDD

POWER

POWER

SUPPLY

SUPPLY

DDAP

DDAP

coupling network

coupling network

10 μF

10 μF

33 nF

33 nF

33 nF

33 nF

47 μH

47 μH

(3)

47 μH

47 μH

CISPR16 network

CISPR16 network

250 nF

250 nF

50 μH

50 μH

5 Ω

5 Ω

250 nF

250 nF

50 μH

50 μH

5 Ω

5 Ω

50 Ω

50 Ω

(1) Square wave TTL signal 300 Hz, duty factor = 50 % for measuring signal bandwidth

(see Figure 3

(2) DATA_IN

(3) Tuned for f

).

+ LOW for measuring total harmonic distortion (see Figure 3).

= 132.5 kHz.

cr

(4) The CISPR16 network provides a −6 dB attenuation.

Fig 22. Test set-up for measuring THD and bandwidth of the TX_OUT signal

(4)

(4)

SPECTRUM

SPECTRUM

ANALYZER

ANALYZER

50 Ω

50 Ω

002aaf05

002aaf05

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 20 of 29

Page 21

NXP Semiconductors

TDA5051A

Home automation modem

DATA_IN

TDA5051A

78

1

OSC1 OSC2

XTAL = 8.48 MHz

OSC1 OSC2

78

TDA5051A

(to be tested)

2

DATA_OUT

TX_OUT

10

AGND, DGND, APGND

12,

5,

9

RX_IN

14

12,

AGND, DGND, APGND

5,

9

out

DATA_IN

DATA_OUT

in

COUPLING

NETWORK

WHITE

NOISE

GENERATOR

COUPLING

NETWORK

V24/TTL

INTERFACE

(1) See Figure 22.

Fig 23. Test set-up for measuring Bit Error Rate (BER)

+

out

(1)

(1)

+

out

in

PSEUDO RANDOM SEQUENCE:

2

RXD

V24 SERIAL DATA

TXD

SPECTRUM

ANALYZER

PARAMETERS

600 BAUD

9

−1 BITS LONG

ANALYZER

50 Ω

002aaf053

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 21 of 29

Page 22

NXP Semiconductors

S

-1

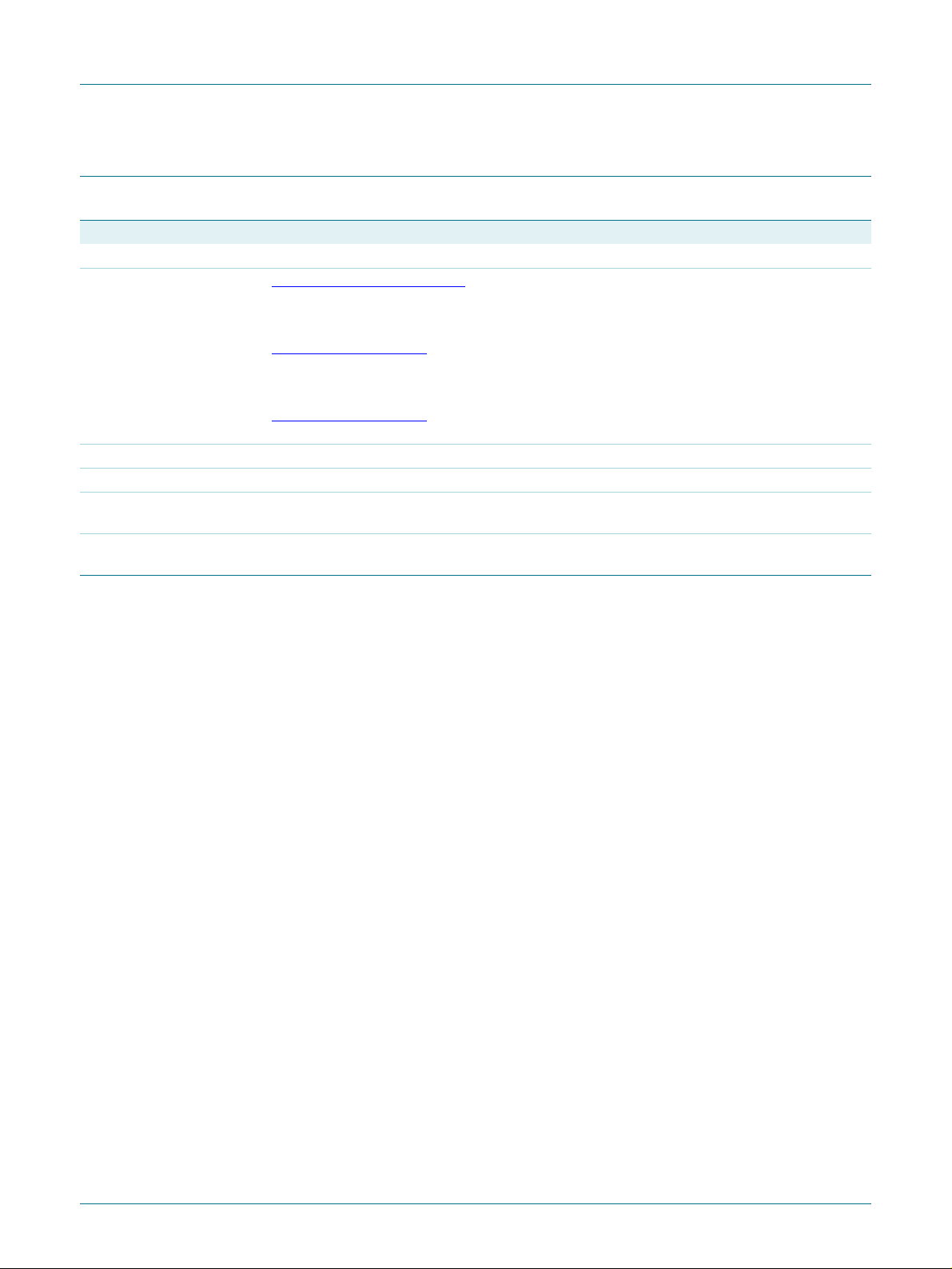

14. Package outline

TDA5051A

Home automation modem

O16: plastic small outline package; 16 leads; body width 7.5 mm

16

1

y

Z

pin 1 index

D

c

9

A

2

A

1

8

e

w M

b

p

E

H

E

detail X

A

X

v M

Q

(A )

L

p

L

A

3

θ

SOT162

A

0 5 10 mm

scale

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT162-1

A

A1A2A3b

max.

0.3

2.65

0.1

0.012

0.1

0.004

p

2.45

2.25

0.096

0.089

IEC JEDEC JEITA

075E03 MS-013

0.25

0.01

0.49

0.36

0.019

0.014

0.32

0.23

0.013

0.009

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm (0.006 inch) maximum per side are not included.

(1)E(1) (1)

cD

10.5

10.1

0.41

0.40

REFERENCES

eHELLpQ

7.6

7.4

0.30

0.29

1.27

0.05

10.65

10.00

0.419

0.394

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

0.25

0.25 0.1

0.01

0.01

EUROPEAN

PROJECTION

ywv θ

Z

0.9

0.4

0.035

0.004

0.016

ISSUE DATE

99-12-27

03-02-19

o

8

o

0

Fig 24. Package outline SOT162-1 (SO16)

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 22 of 29

Page 23

NXP Semiconductors

15. Handling information

All input and output pins are protected against ElectroS tatic Discharge (ESD) under

normal handling. When handling ensure that the appropriate precautions are taken as

described in JESD625-A or equivalent standards.

16. Soldering of SMD packages

This text provides a very brief insight into a complex technology. A more in-depth account

of soldering ICs can be found in Application Note AN10365 “Surface mount reflow

soldering description”.

16.1 Introduction to soldering

Soldering is one of the most common methods through which packages are attached to

Printed Circuit Boards (PCBs), to form electrical circuits. The soldered joint provides both

the mechanical and the electrical connection. There is no single soldering method that is

ideal for all IC packages. Wave soldering is often preferred when through-hole and

Surface Mount Devices (SMDs) are mixed on one printed wiring board; however, it is not

suitable for fine pitch SMDs. Reflow soldering is ideal for the small pitches and high

densities that come with increased miniaturization.

TDA5051A

Home automation modem

16.2 Wave and reflow soldering

Wave soldering is a joining technology in which the joints are made by so lder coming from

a standing wave of liquid solder. The wave soldering process is suitable for the following:

• Through-hole components

• Leaded or leadless SMDs, which are glued to the surface of the printed circuit board

Not all SMDs can be wave soldered. Packages with solder balls, and some leadless

packages which have solder lands underneath the body, cannot be wave soldered. Also,

leaded SMDs with leads having a pitch smaller than ~0.6 mm cannot be wave soldered,

due to an increased probability of bridging.

The reflow soldering process involves applying solder paste to a board, followed by

component placement and exposure to a temperature profile. Leaded packages,

packages with solder balls, and leadless packages are all reflow solderable.

Key characteristics in both wave and reflow soldering are:

• Board specifications, including the board finish, solder masks and vias

• Package footprints, including solder thieves and orientation

• The moisture sensitivity level of the packages

• Package placement

• Inspection and repair

• Lead-free soldering versus SnPb soldering

16.3 Wave soldering

Key characteristics in wave soldering are:

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 23 of 29

Page 24

NXP Semiconductors

• Process issues, such as application of adhesive and flux, clinching of leads, board

• Solder bath specifications, including temperature and impurities

16.4 Reflow soldering

Key characteristics in reflow soldering are:

• Lead-free versus SnPb soldering; note that a lead-free reflow process usually lea ds to

• Solder paste printing issues including smearing, release, and adjusting the process

• Reflow temperature profile; this profile includes preheat, reflow (in which the board is

Table 9. SnPb eutectic process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

< 2.5 235 220

≥ 2.5 220 220

TDA5051A

Home automation modem

transport, the solder wave parameters, and the time during which components are

exposed to the wave

higher minimum peak temperatures (see Figure 25

reducing the process window

window for a mix of large and small components on one board

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joint s (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 9

and 10

Volume (mm3)

< 350 ≥ 350

) than a SnPb process, thus

Table 10. Lead-free process (from J-STD-020C)

Package thickness (mm) Package reflow temperature (°C)

Volume (mm3)

< 350 350 to 2000 > 2000

< 1.6 260 260 260

1.6 to 2.5 260 250 245

> 2.5 250 245 245

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 25

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 24 of 29

.

Page 25

NXP Semiconductors

4

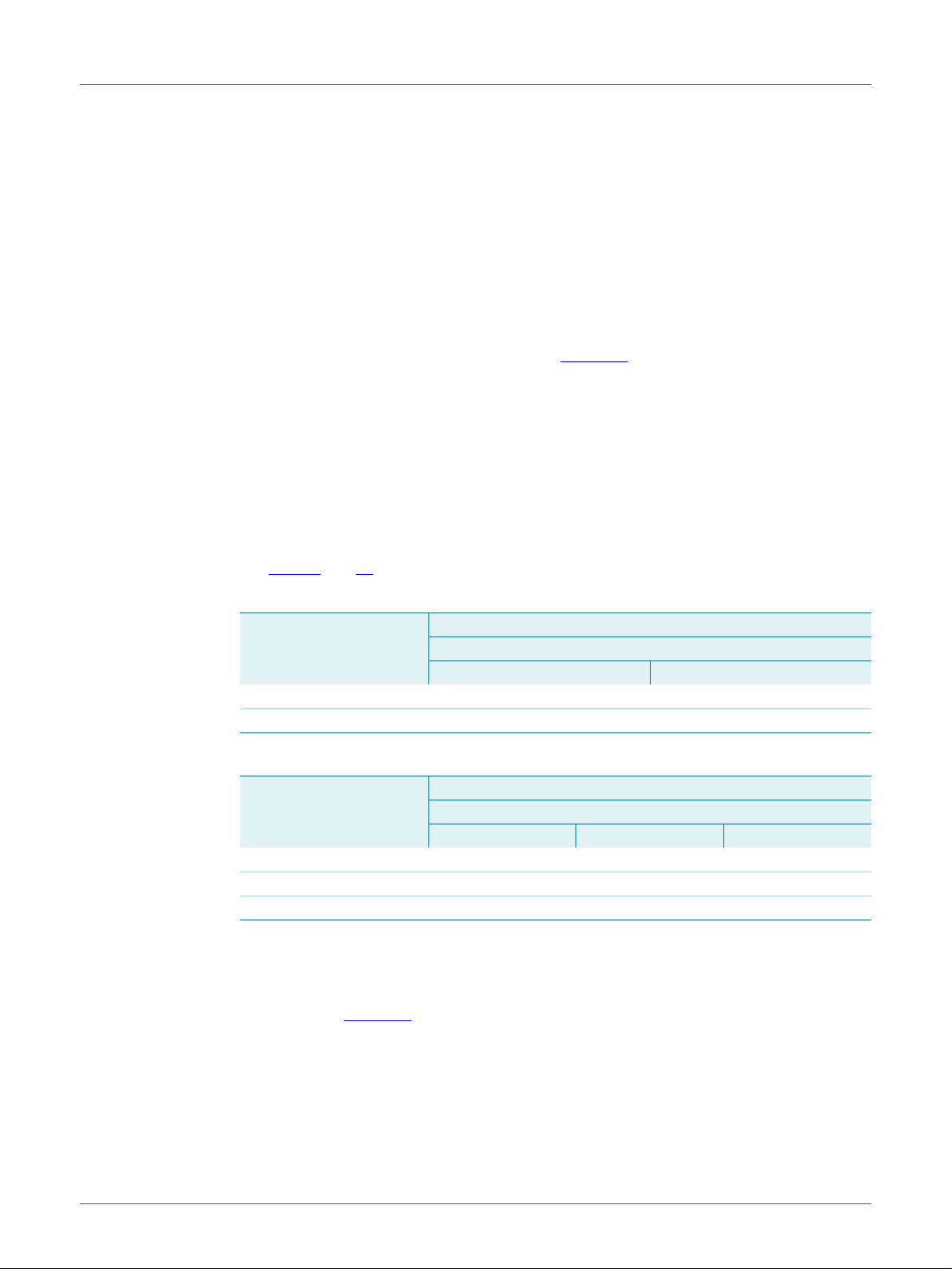

Fig 25. Temperature profiles for large and small components

maximum peak temperature

temperature

MSL: Moisture Sensitivity Level

= MSL limit, damage level

minimum peak temperature

= minimum soldering temperature

TDA5051A

Home automation modem

peak

temperature

time

001aac84

For further information on temperature profiles, refer to Application Note AN10365

“Surface mount reflow soldering description”.

17. Abbreviations

Table 11. Abbreviations

Acronym Description

ADC Analog-to-Digital Converter

AGC Automatic Gain Control

ASK Amplitude Shift Keying

CMOS Complementary Metal-Oxide Semiconductor

DAC Di gital-to-Analog Con v erter

HF High-Frequency

I/O Input/Output

IC Integrated Circuit

LC inductor-capacitor filter

NRZ Non-Return-to-Zero

RMS Root Mean Squared

ROM Read-Only Memory

THD Total Harmonic Distortion

TTL Transistor-Transistor Logic

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 25 of 29

Page 26

NXP Semiconductors

TDA5051A

Home automation modem

18. Revision history

Table 12. Revision history

Document ID Release date Data sheet status Change notice Supersedes

TDA5051A v.5 20110113 Product data sheet - TDA5051A v.4

Modifications:

• Table 1 “Quick reference data”, T

– Min value changed from −10 °C to −50 °C

– Max value changed from +80 °C to +100 °C

• Table 4 “Limiting values”, T

– Min value changed from −10 °C to −50 °C

– Max value changed from +80 °C to +100 °C

amb

• Table 5 “Characteristics”, descriptive line below title is changed from “T

to “T

TDA5051A v.4 20100701 Product data sheet - TDA5051A v.3

TDA5051A v.3 20100422 Preliminary data sheet - TDA5051A v.2

TDA5051A v.2

(9397 750 05035)

TDA5051A v.1

(9397 750 02571)

19990531 Product specification - TDA5051A v.1

19970919 Product specification - -

= −40 °C to +85 °C”

amb

, ambient temperature:

amb

, ambient temperature:

=0°C to 70 °C”

amb

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 26 of 29

Page 27

NXP Semiconductors

TDA5051A

Home automation modem

19. Legal information

19.1 Data sheet status

Document status

Objective [short] data sheet Development This document contains data from the objective specification for product development.

Preliminary [short] data sheet Qualification This document contains data from the preliminary specification.

Product [short] data sheet Production This document contains the product specification.

[1] Please consult the most recently issued document before initiating or completing a design.

[2] The term ‘short data sheet’ is explained in section “Definitions”.

[3] The product status of device(s) d escribed i n this docume nt may have changed since this docume nt was publis hed and ma y dif fer in case of multiple devices. The latest product status

information is available on the Internet at URL http://www.nxp.com.

[1][2]

Product status

[3]

Definition

19.2 Definitions

Draft — The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. NXP Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall have no liability for the consequences of

use of such information.

Short data sheet — A short data sheet is an extract from a full data sheet

with the same product type number(s) and title. A short data sheet is intended

for quick reference only and should not be relied u pon to co nt ain det ailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local NXP Semiconductors sales

office. In case of any inconsistency or conflict with the short data sheet, the

full data sheet shall prevail.

Product specification — The information and data provided in a Product

data sheet shall define the specification of the product as agreed between

NXP Semiconductors and its customer, unless NXP Semiconductors and

customer have explicitly agreed otherwise in writing. In no event however,

shall an agreement be valid in which the NXP Semiconductors product is

deemed to offer functions and qualities beyond those described in the

Product data sheet.

19.3 Disclaimers

Limited warranty and liability — Information in this document is believed to

be accurate and reliable. However, NXP Semiconductors does not give any

representations or warranties, expressed or implied, as to the accuracy or

completeness of such information and shall have no liability for the

consequences of use of such information.

In no event shall NXP Semiconductors be lia ble for any indirect, incidental,

punitive, special or consequential damages (including - without limitation - lost

profits, lost savings, business interruption, costs related to the removal or

replacement of any products or rework charges) whether or not such

damages are based on tort (including negligence), warranty, breach of

contract or any other legal theory.

Notwithstanding any damages that customer might incur for any reason

whatsoever, NXP Semi conductors’ aggregat e and cumulative liabil ity towards

customer for the products described herein shall be limited in accordance

with the Terms and conditions of commercial sale of NXP Semiconductors.

Right to make changes — NXP Semiconductors reserves the right to make

changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use — NXP Semiconductors products are not designed,

authorized or warranted to be suitable for use in life support, life-critical or

safety-critical systems or equipment, nor in applications where failure or

malfunction of an NXP Semiconductors product can reasonabl y be expected

to result in personal injury, death or severe property or environmental

damage. NXP Semiconductors accepts no liability for inclusion and/or use of

NXP Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer’s own risk.

Applications — Applications that are described herein for any of these

products are for illustrative purposes only. NXP Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Customers are responsible for the design and operation of their applications

and products using NXP Semiconductors products, and NXP Semiconductors

accepts no liability for any assistance with applications or customer product

design. It is customer’s sole responsibility to determine whether the NXP

Semiconductors product is suitable and fit for the customer’s applications and

products planned, as well as for the planned application and use of

customer’s third party customer(s). Customers should provide appropriate

design and operating safeguards to minimize the risks associated with their

applications and products.

NXP Semiconductors does not accept any liability related to any default ,

damage, costs or problem which is based on any weakness or default in the

customer’s applications or products, or the application or use by customer’s

third party customer(s). Customer is responsible for doing all necessary

testing for the customer’s applications and products using NXP

Semiconductors products in order to avoid a default of the applications and

the products or of the application or use by customer’s third part y

customer(s). NXP does not accept any liability in this respect.

Limiting values — Stress above one or more limiting values (as defined in

the Absolute Maximum Ratings System of IEC 60134) will cause permanent

damage to the device. Limiting values are stress ratings only and (proper)

operation of the device at these or any other conditions above those given in

the Recommended operating conditions section (if present) or the

Characteristics sections of this document is not warranted. Constant or

repeated exposure to limiting values will permanently and irreversibly affect

the quality and reliability of the device.

Terms and conditions of commercial sale — NXP Semiconductors

products are sold subject to the general terms and conditions of commercial

sale, as published at http://www.nxp.com/profile/terms

agreed in a valid written individual agreement. In case an individual

agreement is concluded only the terms and conditions of the respective

agreement shall apply. NXP Semiconductors hereby expressly objects to

applying the customer’s general terms and conditions with regard to the

purchase of NXP Semiconductors products by customer.

No offer to sell or license — Nothing in this document may be interpreted or

construed as an offer to sell product s that is ope n for accept ance or the gr ant,

conveyance or implication of any license under any copyrights, patents or

other industrial or intellectual property rights.

Export control — This document as well as the item(s) described herein

may be subject to export control regulations. Export might require a prior

authorization from national authorities.

, unless otherwise

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 27 of 29

Page 28

NXP Semiconductors

TDA5051A

Home automation modem

Quick reference data — The Quick reference data is an extract of the

product data given in the Limiting values and Characteristics sections of this

document, and as such is not complete, exhaustive or legally binding.

Non-automotive qualified products — Unless this data sheet expressly

states that this specific NXP Semiconductors product is automotive qualified,

the product is not suitable for automotive use. It i s neither qua lif ied nor test ed

in accordance with automotive testing or application requirements. NXP

Semiconductors accepts no liability for inclusion and/or use of

non-automotive qualified products in automotive equ ipment or applications.

In the event that customer uses the product for design-in and use in

automotive applications to automotive specifications and standards, customer

(a) shall use the product without NXP Semiconductors’ warranty of the

product for such automotive applications, use and specifications, and (b)

whenever customer uses the product for automotive applications beyond

NXP Semiconductors’ specifications such use shall be solely at customer’s

own risk, and (c) customer fully indemnifies NXP Semiconductors for any

liability, da mages or failed produ ct cl aims resulting from custome r design and

use of the product for automotive applications beyond NXP Semiconductors’

standard warranty and NXP Semiconductors’ product specifications.

19.4 Trademarks

Notice: All referenced brands, prod uct names, service names and trad emarks

are the property of their respective owners.

20. Contact information

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

TDA5051A All information provided in this document is subject to legal disclaimers. © NXP B.V. 2011. All rights reserved.

Product data sheet Rev. 5 — 13 January 2011 28 of 29

Page 29

NXP Semiconductors

21. Contents

1 General description. . . . . . . . . . . . . . . . . . . . . . 1

2 Features and benefits . . . . . . . . . . . . . . . . . . . . 1

3 Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Quick reference data . . . . . . . . . . . . . . . . . . . . . 2

5 Ordering information. . . . . . . . . . . . . . . . . . . . . 2

6 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7 Pinning information. . . . . . . . . . . . . . . . . . . . . . 4

7.1 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 4

8 Functional description . . . . . . . . . . . . . . . . . . . 5

8.1 Transmission mode . . . . . . . . . . . . . . . . . . . . . 5

8.2 Reception mode . . . . . . . . . . . . . . . . . . . . . . . . 6

8.3 Data format. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8.3.1 Transmission mode . . . . . . . . . . . . . . . . . . . . . 6

8.3.2 Reception mode . . . . . . . . . . . . . . . . . . . . . . . . 6

8.4 Power-down mode . . . . . . . . . . . . . . . . . . . . . . 6

9 Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . . 7

10 Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . 7

11 Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

11.1 Configuration for clock . . . . . . . . . . . . . . . . . . 11

11.2 Timing diagrams. . . . . . . . . . . . . . . . . . . . . . . 13

12 Application information. . . . . . . . . . . . . . . . . . 15

13 Test information. . . . . . . . . . . . . . . . . . . . . . . . 20

14 Package outline . . . . . . . . . . . . . . . . . . . . . . . . 22

15 Handling information. . . . . . . . . . . . . . . . . . . . 23

16 Soldering of SMD packages . . . . . . . . . . . . . . 23

16.1 Introduction to soldering . . . . . . . . . . . . . . . . . 23

16.2 Wave and reflow soldering . . . . . . . . . . . . . . . 23

16.3 Wave soldering. . . . . . . . . . . . . . . . . . . . . . . . 23

16.4 Reflow soldering. . . . . . . . . . . . . . . . . . . . . . . 24

17 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . 25

18 Revision history . . . . . . . . . . . . . . . . . . . . . . . . 26

19 Legal information. . . . . . . . . . . . . . . . . . . . . . . 27

19.1 Data sheet status . . . . . . . . . . . . . . . . . . . . . . 27

19.2 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

19.3 Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

19.4 Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

20 Contact information. . . . . . . . . . . . . . . . . . . . . 28

21 Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TDA5051A

Home automation modem

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section ‘Legal information’.

© NXP B.V. 2011. All rights reserved.

For more information, please visit: http://www.nxp.com

For sales office addresses, please send an email to: salesaddresses@nxp.com

Date of release: 13 January 2011

Document identifier: TDA5051A

Loading...

Loading...