INTEGRATED CIRCUITS

DATA SH EET

TDA1300T

Photodetector amplifiers and laser

supply

Product specification

Supersedes data of 1995 Sep 27

File under Integrated Circuits, IC01

1995 Nov 16

Philips Semiconductors Product specification

Photodetector amplifiers and laser

supply

FEATURES

• Six input buffer amplifiers with low-pass filtering with

virtually no offset

• HF data amplifier with a high or low gain mode

• Two built-in equalizers for single or double speed mode

ensuring high playability in both modes

• Full automatic laser control including stabilization and

an on/off switch and containing a separate supply V

for power reduction

• Applicable with N-sub laser with N-sub or P-sub monitor

diode

• Adjustable laser bandwidth and laser switch-on current

slope

• Protection circuit preventing laser damage due to supply

voltage dip

• Optimized interconnect between pick-up detector and

TDA1301

• Wide supply voltage range

• Wide temperature range

• Low-power consumption.

DDL

TDA1300T

GENERAL DESCRIPTION

The TDA1300 is an integrated data amplifier and laser

supply for three beam pick-up detectors applied in a wide

range of mechanisms for Compact Disc and Read Only

optical systems. It offers 6 amplifiers which amplify and

filter the focus and radial diode signals adequately and

provides an equalized RF signal for single or double speed

mode which can be switched by means of the speed

control pin.

The device can handle astigmatic, single foucault and

double foucault detectors and is applicable with all N-sub

laser, N-sub or P-sub monitor diode units.

After a single initial adjustment the circuit keeps control

over the laser diode current resulting in a constant light

output power independent of ageing. The chip is mounted

in a small SO24 package enabling mounting close to the

laser pick-up unit on the sledge.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DD

supply voltage 3 − 5.5 V

Diode current amplifiers 6 times

G

dn

I

os(d)

B 3 dB bandwidth I

amplification 1.43 1.55 1.67

offset current −−100 nA

= 1.67 µA50−−kHz

i(d)

RFE amplifier (built-in equalizer)

t

d(eq)

t

d(f)

equalization delay time fi= 0.3 MHz − 320 − ns

flatness delay time double-speed − 5 − ns

Laser supply

I

o(l)

output current V

=3V −−−100 mA

DDL

ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

TDA1300T SO24 plastic small outline package; 24 leads; body width 7.5 mm SOT137-1

1995 Nov 16 2

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

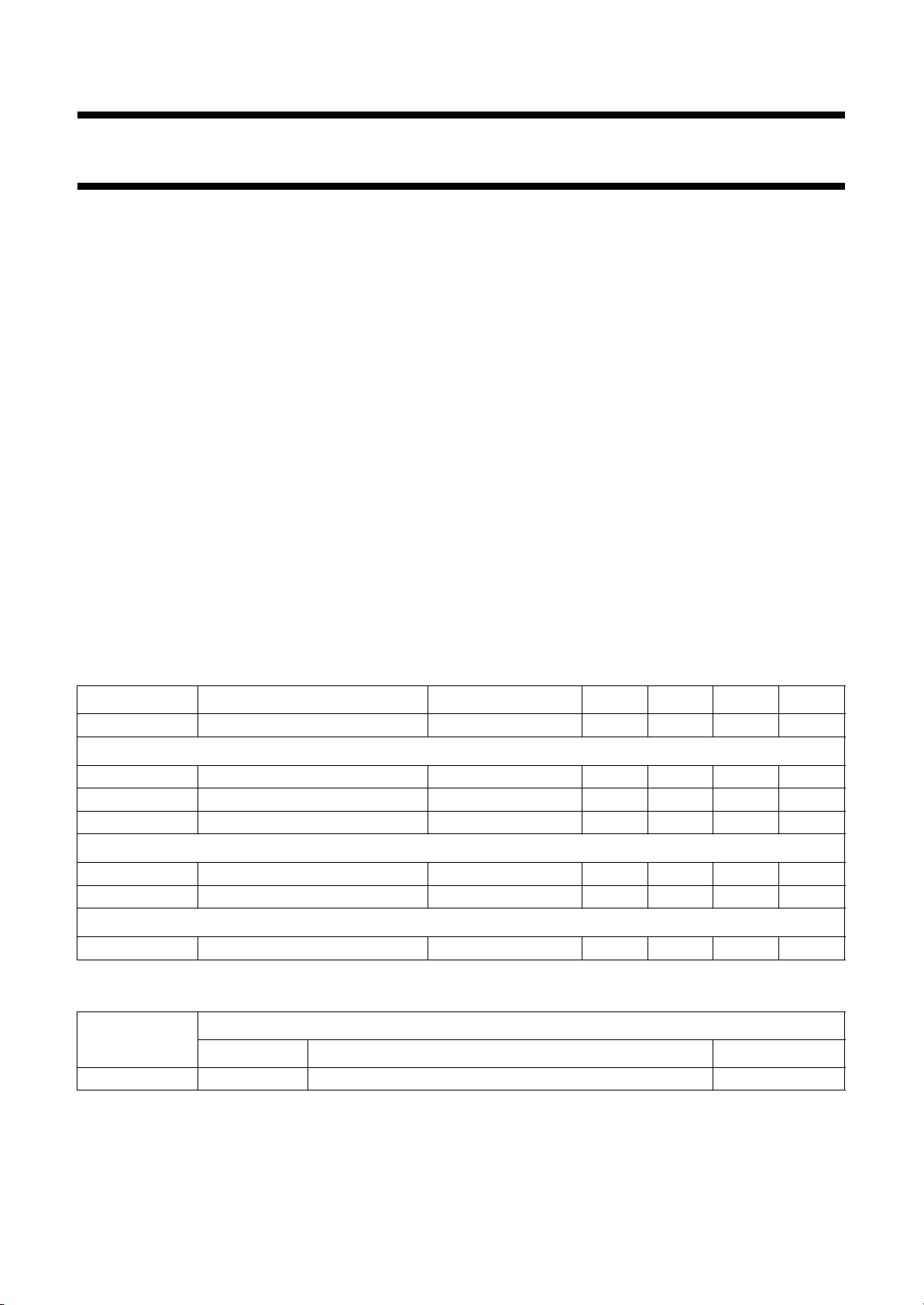

SCHEMATIC DIAGRAM

to

motor

spindle

left

right

clk

(SAA7345)

DECODER

PLL

AMP

POWER

SUBCODE

DECODER

MOTOR

CONTROL

KEYBORD

DISPLAY

PROCESSOR

DISPLAY

end_stop_switch

MBG473

DDD

V

DDA

V

NRST

DDD

V

DDA

V

DD

V

G SP RF(E)

OTD

CLO

D1

O1

I1

XTLI

D2

O2

DIODE

I2

XTLO

DIGITAL SERVO IC

D3

D4

O3

O4

AND

LASER

AMPLIFIER

I3

I4

XTLR

R1

O5

SUPPLY

I5

TS1

TDA1301

R2

V

O6

TDA1300

I6

RL

TS2

V

MI

RH

SICL

LDON

LDON

LO

SIDA

O ADJ GND

DDL

V

SILD

1 nF

clk

SSD

RA FO SL V

SSK

V

DD

V

2.5 to 5 V

DD

V

G SP RF(E)

O1

I1

focus

O2

I2

actuator

DIODE

O3

AMPLIFIER

I3

radial

actuator

sledge

(TDA7072/7073)

POWER AMPLIFIER

O4

O5

O6

AND

LASER

SUPPLY

TDA1300

I4

I5

I6

MI

LDON

LO

O ADJ GND

DDL

V

1 nF

ADJp

R

2.5 to 5 V

handbook, full pagewidth

Fig.1 Schematic diagram for CD player.

photo-

configuration

N-sub monitor

1995 Nov 16 3

diodes

mon

ADJn

R

la

photo-

diodes

configuration

P-sub monitor

mon

la

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

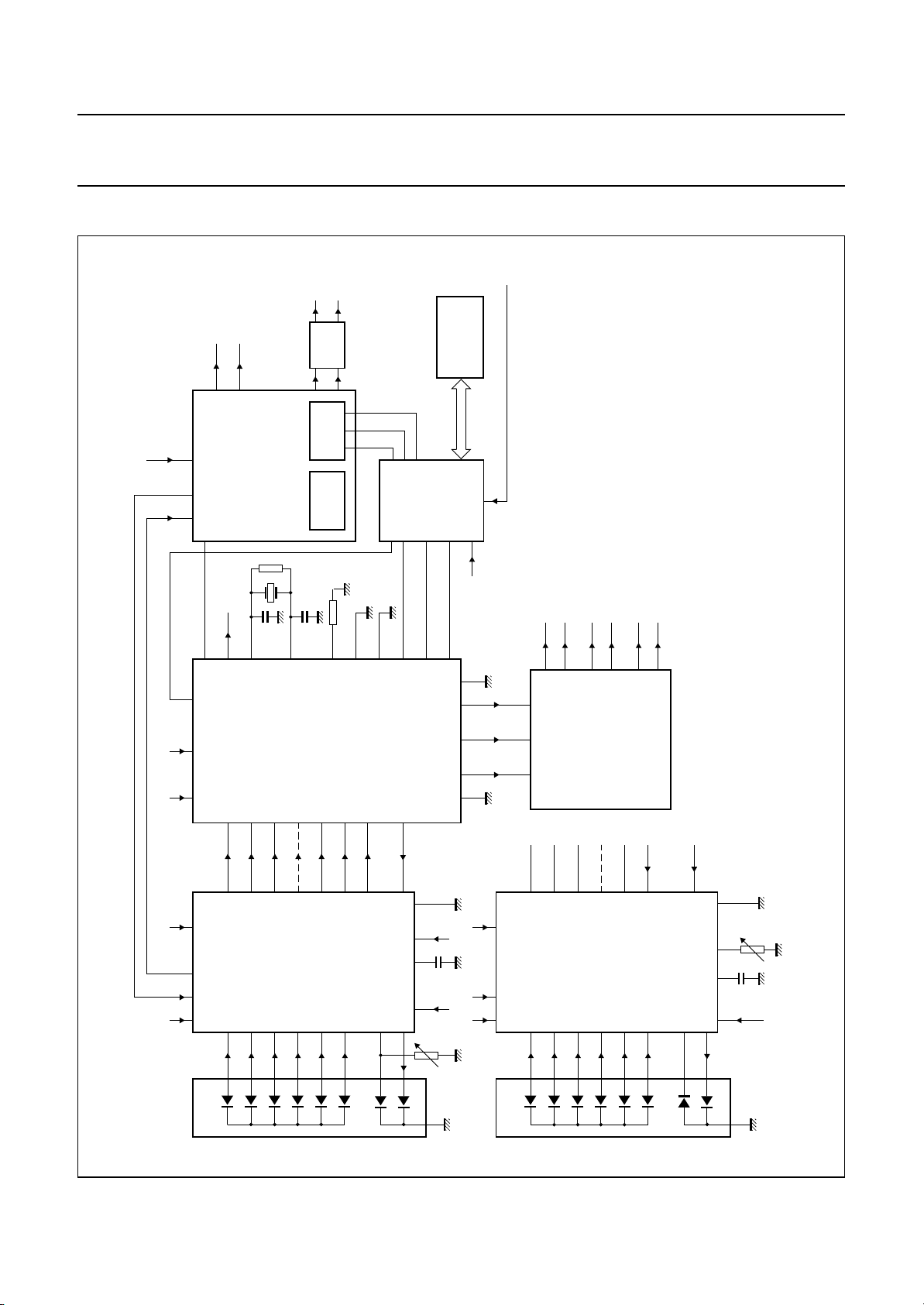

BLOCK DIAGRAM

handbook, full pagewidth

I6

23 2

in

I6

6

1.5x

Id6

out

O6

HG

LS

I5

20

in

I5

24

I4

22

I3

19

I2

21

I1

11

12

5

I4

in

4

I3

in

3

I2

in

2

I1

in

1

I

csin

1.5x

1.5x

1.5x

1.5x

1.5x

95, 120, 134 or

240 kΩ

I/V

−4

Id5

Id4

Id3

Id2

Id1

TDA1300T

out

out

out

out

out

5

O5

1

O4

3

O3

6

O2

4

O1

9

RFE

1995 Nov 16 4

ADJ

V

DD

GND

10

14

I

(P-sub)

ADJ

(N-sub) or

V

mon

17

MI

I

(P-sub)

mon

18

15

SUPPLY

V

gap

OTA

CL

ILO

ON/OFF

13

MBG474

(N-sub) or

V

DD

RF

8

V

DDL

16

LO

7

LDON

Fig.2 Block diagram.

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

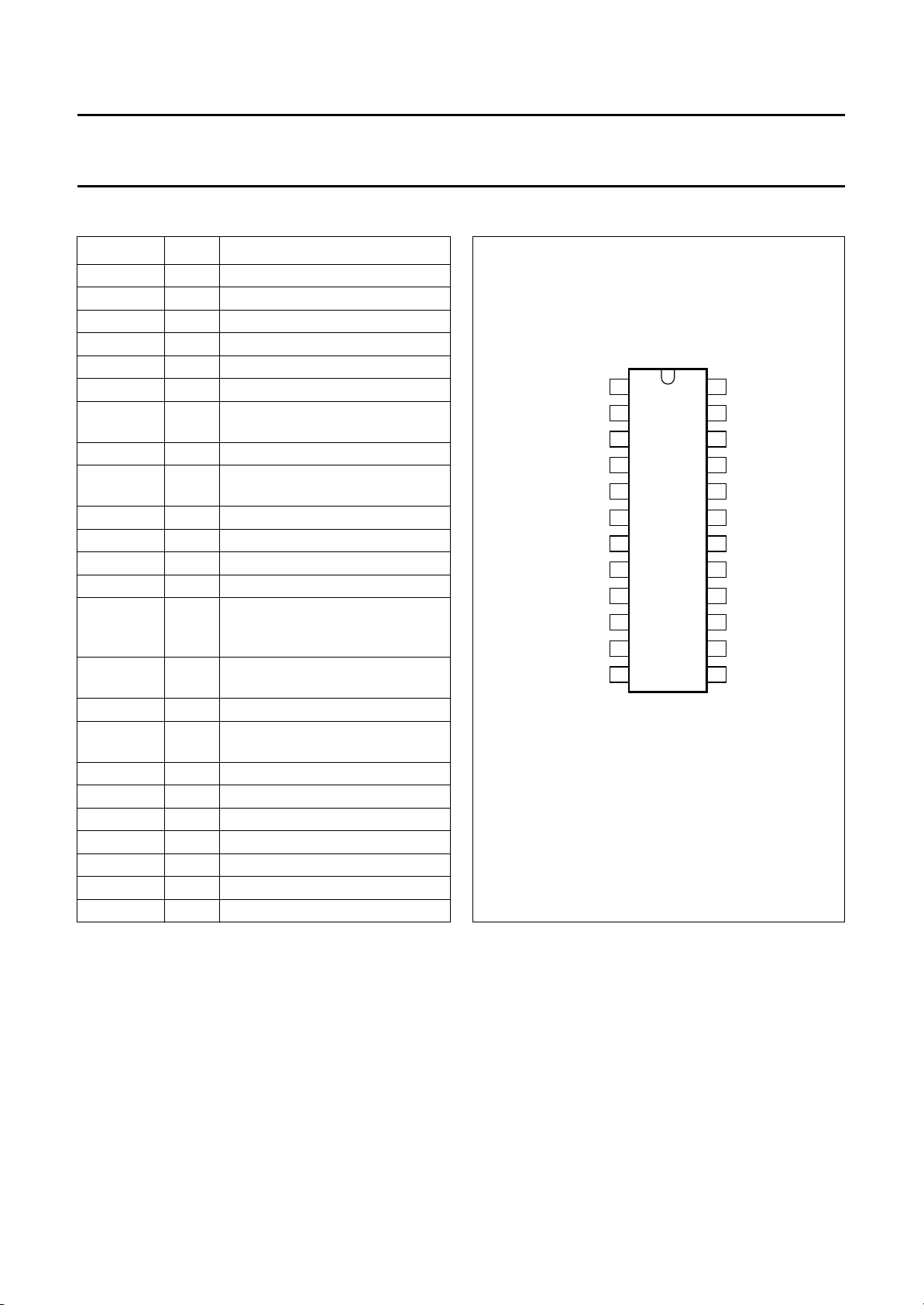

PINNING

SYMBOL PIN DESCRIPTION

O4 1 output of current amplifier 4

O6 2 output of current amplifier 6

O3 3 output of current amplifier 3

O1 4 output of current amplifier 1

O5 5 output of current amplifier 5

O2 6 output of current amplifier 2

LDON 7 control pin for switching the laser

on and off

V

DDL

8 laser supply voltage

RFE 9 equalized output voltage of sum

signal of amplifiers 1 to 4

RF 10 unequalized output

HG 11 control pin for gain switch

LS 12 control pin for speed switch

CL 13 external capacitor

ADJ 14 if connected via resistor to GND

P-sub monitor. If connected to

N-sub monitor

V

DD

GND 15 zero supply connection,

substrate connection

LO 16 output for the laser, current output

MI 17 input for the monitor diode of the

laser

V

DD

18 positive supply connection

I2 19 photo detector input 2 (central)

I5 20 photo detector input 5 (satellite)

I1 21 photo detector input 1 (central)

I3 22 photo detector input 3 (central)

I6 23 photo detector input 6 (satellite)

I4 24 photo detector input 4 (central)

handbook, halfpage

1

O4

2

O6

3

O3

4

O1

5

O5

6

O2

TDA1300T

7

LDON

8

V

DDL

9

RFE

10

RF

11

HG

12

LS

MBG472

Fig.3 Pin configuration.

24

I4

23

I6

22

I3

21

I1

20

I5

19

I2

18

V

DD

17

MI

16

LO

15

GND

14

ADJ

13

CL

1995 Nov 16 5

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

FUNCTIONAL DESCRIPTION

The TDA1302T can be divided into two main sections:

1. Laser control circuit

2. Photo diode signal filter and amplification section.

Laser control circuit

The main function of the laser control circuit is to control

the laser diode current in order to achieve a constant light

output power. This is done by monitoring the monitor

diode. There is a fixed relation between light output power

of the laser and the current of the monitor diode. The circuit

can handle P-sub or N-sub monitor diodes.

MONITOR

N-sub

In this event pin 14 (ADJ) must be connected to the

positive supply voltage VDD to select the N-sub mode. With

an adjustable resistor (R

) across the diode the monitor

ADJn

current can be adjusted (and so the laser light output

power) if one knows that the control circuit keeps the

monitor voltage V

at a constant level of

mon

approximately 150 mV.

MONITOR

P-sub

R

ADJn

---------------C

L

KA

× 8709–×10×≅

ext

(Hz) in case of

f

BN

N-sub monitor

where A

amplifier, if applied, and K = ∆I

determined by the laser/monitor unit. I

represents the AC gain of an extra loop

ext

/∆I

laser

mon

which is

is the

mon

average current (pin 17) at typical light emission power

of the laser diode.

The third part is the power output stage, its input being the

integrator output signal. This stage has a separate supply

voltage (V

) thereby offering the possibility of reduced

DDL

power consumption by supplying this pin with the minimum

voltage necessary.

It also has a laser diode protection circuit which comes into

action just before the driving output transistor will get

saturated due to a large voltage dip on V

. Saturation

DDL

will result in a lower current of the laser diode, which

normally is followed immediately by an increment of the

voltage of the external capacitor CL. This could cause

damage to the laser diode at the end of the dip. The

protection circuit prevents an increment of the capacitor

voltage and thus offers full protection to the laser diode

under these circumstances.

In this event pin 14 (ADJ) is connected via resistor R

ADJp

to ground. The P-sub mode is selected and pin 14 (ADJ)

acts as reference bandgap voltage, providing together with

R

an adjustable current l

ADJp

keeps the monitor current at a level which is 10 × l

. Now the control circuit

ADJ

ADJ

.

The circuit is built-up in three parts:

The first part is the input stage which is able to switch

between both modes (N-sub or P-sub).

The second part is the integrator part which makes use of

an external capacitor CL. This capacitor has two different

functions:

1. During switch-on of the laser current, it provides a

current slope of typically:

≅

10

----------C

6–

(A/s)

L

∆I

LO

----------- t∆

2. After switch-on it ensures that the bandwidth is in

accordance with the typical formula:

KA

× 909–×10×

f

≅

BP

ext

-------------------------------------------------

×

C

LImon

(Hz) in case of

P-sub monitor.

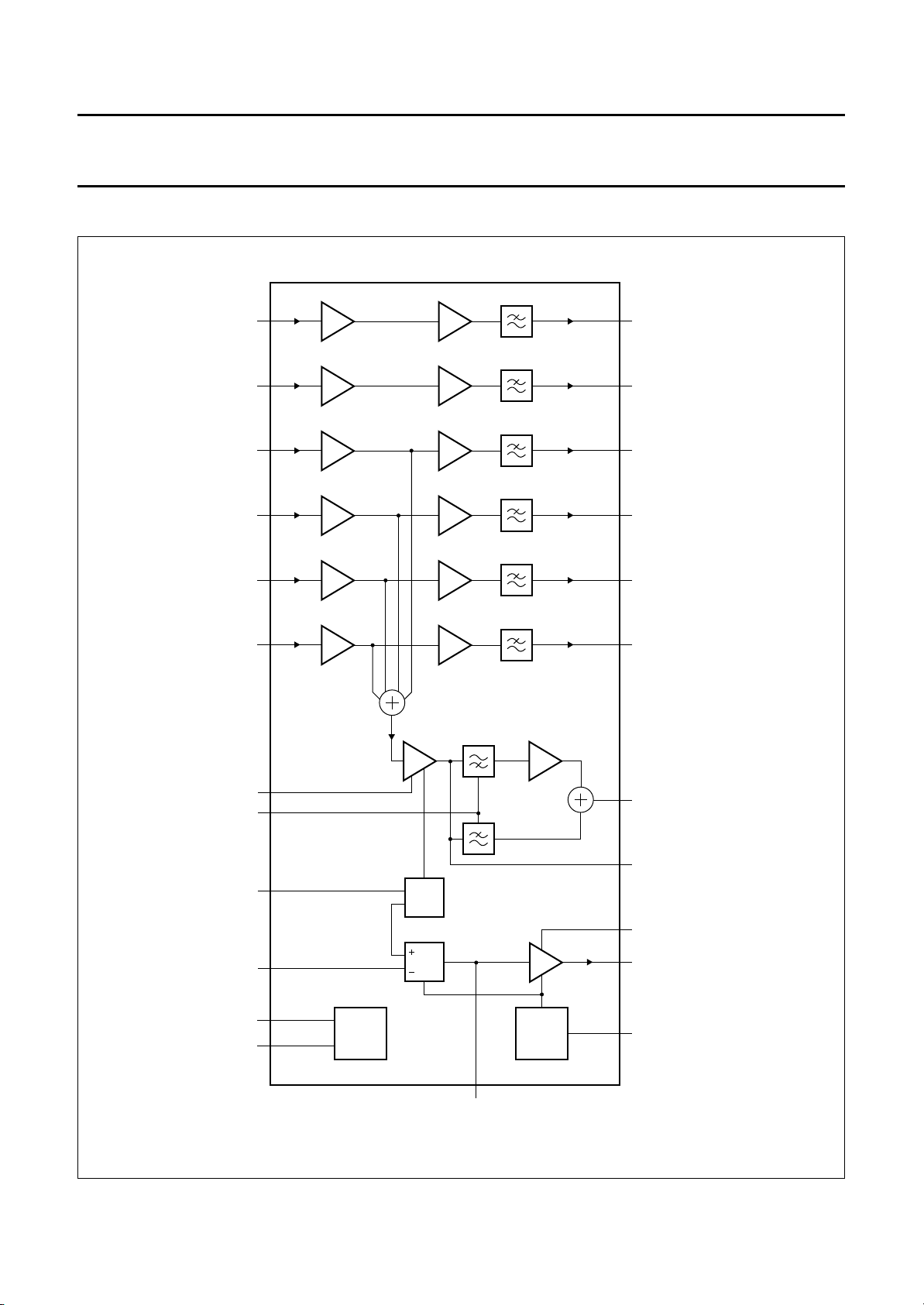

Photo diode signal filter and amplification section

This section has 6 identical current amplifiers.

Amplifiers 1 to 4 are designed to amplify the focus photo

diode signals. Each amplifier has two outputs, an

LF output and an internal RF output. Amplifiers 5 and 6

are used for the radial photo diode currents and only have

a LF output. All 6 output signals are low-pass filtered with

a corner frequency at 69 kHz. The internal RF output

signals are summed together and converted to a voltage

afterwards by means of a selectable transresistance.

This transresistance R

can be changed between 140 kΩ

RF

(3.3 V application) or 240 kΩ (5 V application) in

combination with the P-sub monitor. In the event of the

N-sub monitor selection, RRF can be changed between

70 kΩ (3.3 V application) and 120 kΩ (5 V application).

The RF signal is available directly at pin 10 but there is

also an unfiltered signal available at pin 9.

The used equalization filter has 2 different filter curves:

1. One for single-speed mode

2. One for double-speed mode.

1995 Nov 16 6

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

Table 1 Gain and monitor modes

PIN MODE

HG ADJ R

0R

to ground 140 kΩ P-sub

ADJp

0 1 70 kΩ N-sub

(1)

1

(1)

1

R

to ground 240 kΩ P-sub

ADJp

1 120 kΩ N-sub

Note

1. Logic 1 or not connected.

Table 2 Speed and laser modes; note 1

PIN DEFAULT

LS

LDON

(2)

11 0X

1X

Notes

1. 1 = HIGH voltage V

; 0 = LOW voltage GND; X = don’t care.

DD

2. If not connected.

3. X = don’t care.

RF

MONITOR

3.3 V

5V

MODE

SPEED LASER

SINGLE DOUBLE on off

INTENDED APPLICATION AREA

(3)

(3)

(3)

X

10

X

(3)

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

DD

P

max

T

stg

T

amb

(1)

V

es

supply voltage − 8V

maximum power dissipation − 300 mW

storage temperature −65 +150 °C

operating ambient temperature −40 +85 °C

electrostatic handling pin 16 note 2 −2+2kV

electrostatic handling (all other pins) −3+3kV

Notes

1. Classification A: human body model; C = 100 pF; R = 1500 Ω; V = ± 2000 V.

Charge device model: C = 200 pF; L = 2.5 µH; R = 0 Ω; V = 250 V.

2. Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ series resistor.

THERMAL RESISTANCE

SYMBOL PARAMETER VALUE UNIT

R

th j-a

from junction to ambient in free air 60 K/W

1995 Nov 16 7

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

QUALITY SPECIFICATION

In accordance with

Reference Handbook”

“SNW-FQ-611 part E”

. The numbers of the quality specification can be found in the

. The handbook can be ordered using the code 9397 750 00192.

“Quality

CHARACTERISTICS

V

(R

DD

ext

= 3.3 V; V

= 750 Ω, C

= 2.5 V; T

DDL

= 47 pF) at the RFE output pin.

ext

=25°C; R

amb

=48kΩ; HG = logic 1; LS = logic 1; with an external low pass filter

ADJ

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

I

V

V

P

DD

DD

DDL

diss

supply current laser off − 7 − mA

amplifier supply voltage 3 − 5.5 V

laser control supply voltage 2.5 − 5.5 V

power dissipation laser off; VDD=3V − 20 − mW

Diode current amplifiers (n = 1 to 6; m = 1 to 6)

I

i(d)

N

eq

V

i(d)

V

o(d)

G

dn

I

os(d)

Z

o(d)

B 3 dB bandwidth I

G

mm

diode input current note 1 −− 10 µA

equivalent noise input − 1 − pA/√Hz

diode input voltage I

= 1.67 µA − 0.9 − V

i(d)

diode output voltage −0.2 − VDD− 1V

amplification I

diode output offset current I

output impedance Idi= 1.67 µA; V

mismatch in amplification Idi= 1.67 µA;

= 1.67 µA;

i(d)

V

= 0 V; note 2

o(dn)

csin=Itsin

i(d)

= 0; note 3 −− 100 nA

=0V 500 −− kΩ

o(dn)

= 1.67 µA5068−kHz

1.43 1.55 1.67 times

−− 3%

V

o(dn)=Vo(dm)

Data amplifier; equalized single and double speed

V

RFO

R

RF nl

R

RF nh

R

RF pl

R

RF ph

V

RFMO

SR

RF

Z

oRF

t

d(eq)

t

d(f)

DC output voltage I

transresistance (gain) nl note 3 56 70 84 kΩ

transresistance (gain) nh note 3 96 120 144 kΩ

transresistance (gain) pl note 4 112 140 168 kΩ

transresistance (gain) ph note 4 200 240 285 kΩ

output voltage note 5 −− V

slew rate VSR= 1 V (peak-to-peak) − 6 − V/µs

output impedance fi= 1 MHz − 100 −Ω

equalization delay − 320 − ns

flatness delay (Φ/ω) LS = 1; note 6 − 10 − ns

=0 − 0.3 − V

csin

DD

− 1.2 V

LS = 0; note 6 − 5 − ns

G

R

B

RF

gain ratio note 6 4.5 6 − dB

unequalized output bandwidth I

= 1.67 µA35−MHz

i(d)

1995 Nov 16 8

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Control pins LDON, LS and HG (with 47 kΩ internal pull-up resistor)

V

IL

V

IH

I

IL

Laser output

V

o(l)

I

o(l)

/∆t slew rate output current C

∆

lo(l)

Monitor diode input

V

ref

I

L

) monitor input voltage P-sub mode − VDD− 0.7 − V

V

i(mon

I

i(mon)

∆T reference temperature drift N-sub mode − 40 − ppm

SR

ref

Reference source V

V

ref

∆T reference temperature drift − 40 − ppm

SR

ref

I

ADJ

Z

i

M multiplying factor (I

Notes to the characteristics

1. The maximum input current is defined as the current in which the amplification Adn reaches its minimum. Increasing

the supply voltage to VDD= 5 V increases the maximum input current (see also Figs 4 and 5).

2. The amplification increases if a larger supply voltage is used (see Fig.6).

3. Transresistance 70 kΩ and 120 kΩ is only available in N-sub monitor mode. (see Table 1).

4. Transresistance 140 kΩ and 240 kΩ is only available in P-sub monitor mode. (see Table 1).

5. Output voltage swing will be: V

6. For single speed the gain ratio is defined as gain difference between 1 MHz and 100 kHz, while the flatness delay is

defined up to 1 MHz (see Fig.7). For double speed the gain ratio is defined as gain difference between 2 MHz and

200 kHz, while the flatness delay is defined up to 2 MHz.

LOW level input voltage −0.2 − +0.5 V

HIGH level input voltage VDD− 1 − VDD+ 0.2 V

LOW level input current −− 100 µA

output voltage I

= 100 mA −0.2 − V

o(l)

DDL

− 0.7 V

output current −− −100 mA

=1nF − 3.4 − mA/µs

Lint

virtual reference voltage N-sub mode 130 150 170 mV

leakage current N-sub mode − 1 − nA

monitor input current P-sub mode −− 2mA

reference supply rejection N-sub mode −− 1%

and laser adjustment current I

ADJ

reference voltage R

ADJ

ADJ

=48kΩ 1.15 1.24 1.31 mV

reference supply rejection −− 1%

adjustment current R

input impedance R

mon/IADJ

) − 10 −−

RFS=VRFM

= 5.6 kΩ−−200 µA

ADJ

= 4.8 kΩ−1−kΩ

ADJ

− V

RFO(p-p)

.

1995 Nov 16 9

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

Transfer function

The equalized amplifier including C

and R

ext

has the following transfer functions, where ‘RFE’ refers to equalized

ext

output only and ‘RF’ refers to equalized and not equalized outputs.

F

OR SINGLE SPEED (SP = LOGIC 1)

2

V

RFE

------------I

csin

F

OR DOUBLE SPEED (SP = LOGIC 0)

V

RFE

------------I

csin

1ks

–

R

RF

R

-----------------------------------------------------------------------11Q⁄ sω

1ks

------------------------------------------------------------------------ -

RF

11Q⁄ sω

2

ω

⁄

os

⁄ s2ω

–

⁄+×+

os

2

2

ω

⁄

⁄ s2ω

od

2

os

os

⁄+×+

2

od

1

----------------------1sω

××=

×××=

⁄+

1

----------------------------------------- 1sR

----------------------------------------- 1sR

1

×+

extCext

The denominator forms the denominator of a Bessel low-pass filter.

Table 3 Transresistance

SYMBOL DESCRIPTION TYP. UNIT

k internally defined 4

ω

os/ω1

= ωod/ω

2

internally defined 1.094

Q internally defined 0.691

ω

od

R

RF

R

ext

C

ext

=2×ω

os

internally defined 17.6 × 10

see Chapter “Characteristics” −

external resistor 750 Ω

external capacitor 47 pF

1

×+

extCext

−6

(1)

(2)

rad/s

1995 Nov 16 10

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

handbook, full pagewidth

24

I

i(max)

(µA)

20

16

12

8

3 3.5 4 4.5 5

↑ =test limit.

Fig.4 Maximum input current as a function of VDD.

VDD (V)

MBG471

5.5

40

handbook, full pagewidth

I

o

(µA)

30

20

10

0

010 30

→ =test limit. (1) Gdn= 1.43.

(2) VDD= 5.5V.

(3) VDD= 3.4V.

(1)

(2)

(3)

20

Fig.5 Output current as a function of input current.

Ii (µA)

MBG469

40

1995 Nov 16 11

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

1.75

handbook, full pagewidth

Io/I

i

(mA)

1.65

1.55

1.45

1.35

3 3.5 4 4.5 5

↓ = test limit.

Fig.6 Gain as a function of VDD.

VDD (V)

MBG470

5.5

9.0

handbook, full pagewidth

gain

(dB)

7.0

5.0

3.0

1.0

−1.0

10

(1) Single speed.

(2) Double speed.

(1)

(1)

2

10

Fig.7 Transfer of equalizer.

MBG468

450

t

d

(ns)

400

350

(2)

(2)

3

10

f (kHz)

300

250

200

4

10

1995 Nov 16 12

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

INTERNAL PIN CONFIGURATION

book, full pagewidth

V

DD

GND

V

I1

I2

I3

I4

I5

I6

DDL

LO

V

DD

47 kΩ

LDON

HG

LS

V

DD

O1

O2

O3

O4

O5

O6

ADJ

V

DD

V

DD

P-sub mode

CL

RF

RFE

MI

V

V

V

DD

DD

DD

V

from

LDON

circuitry

DD

1995 Nov 16 13

N-sub mode

MI

MBG475

Fig.8 Equivalent internal pin diagrams.

V

DD

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

PACKAGE OUTLINE

SO24: plastic small outline package; 24 leads; body width 7.5 mm

D

c

y

Z

24

pin 1 index

1

e

13

12

w M

b

p

SOT137-1

E

H

E

Q

A

2

A

1

L

p

L

detail X

(A )

A

X

v M

A

A

3

θ

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

mm

OUTLINE

VERSION

SOT137-1

A

max.

2.65

0.10

A1A2A

0.30

0.10

0.012

0.004

UNIT

inches

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1995 Nov 16 14

0 5 10 mm

b

3

p

2.45

2.25

0.096

0.089

IEC JEDEC EIAJ

075E05 MS-013AD

0.25

0.01

0.49

0.36

0.019

0.014

0.32

0.23

0.013

0.009

(1)E(1) (1)

cD

15.6

7.6

15.2

7.4

0.61

0.30

0.60

0.29

REFERENCES

scale

eHELLpQ

1.27

0.050

10.65

10.00

0.42

0.39

1.4

0.055

1.1

0.4

0.043

0.016

1.1

1.0

0.043

0.039

0.25

0.25 0.1

0.01

0.01

EUROPEAN

PROJECTION

ywv θ

Z

0.9

0.4

8

0.004

ISSUE DATE

0.035

0.016

92-11-17

95-01-24

0

o

o

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

Reflow soldering

Reflow soldering techniques are suitable for all SO

packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method. Typical reflow temperatures range from

215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

(order code 9398 652 90011).

Wave soldering

Wave soldering techniques can be used for all SO

packages if the following conditions are observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow.

• The package footprint must incorporate solder thieves at

the downstream end.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Repairing soldered joints

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

1995 Nov 16 15

Philips Semiconductors Product specification

Photodetector amplifiers and laser supply TDA1300T

DEFINITIONS

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

1995 Nov 16 16

Loading...

Loading...