PHILIPS SK5.0L CA Service Manual

Colour Television Chassis

SK5.0L

CA

H_17220_000.eps

210607

Contents Page

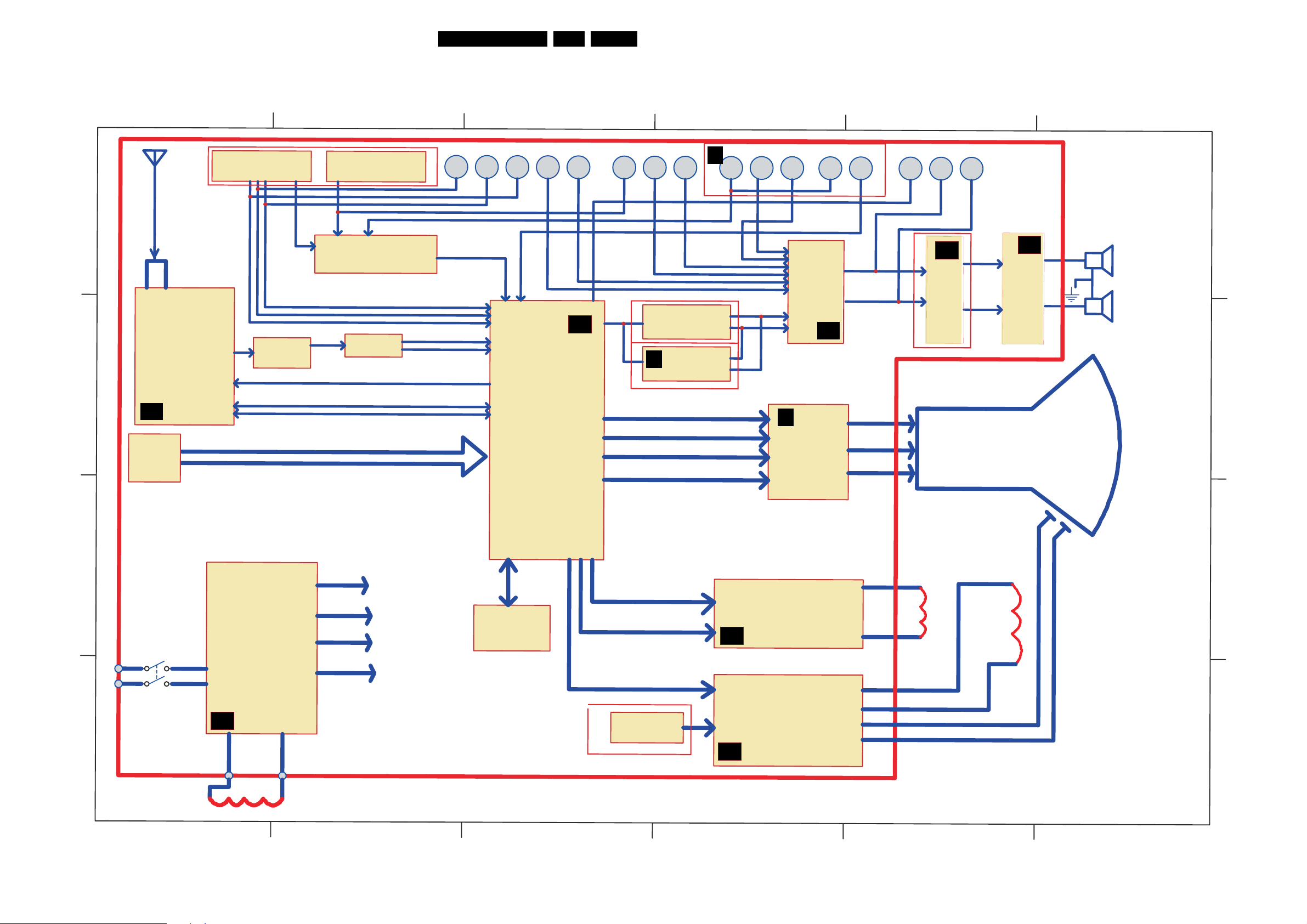

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 5

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 8

6. Block Diagrams, Test Point Overview, and

Waveforms

Block Diagram Chassis 9

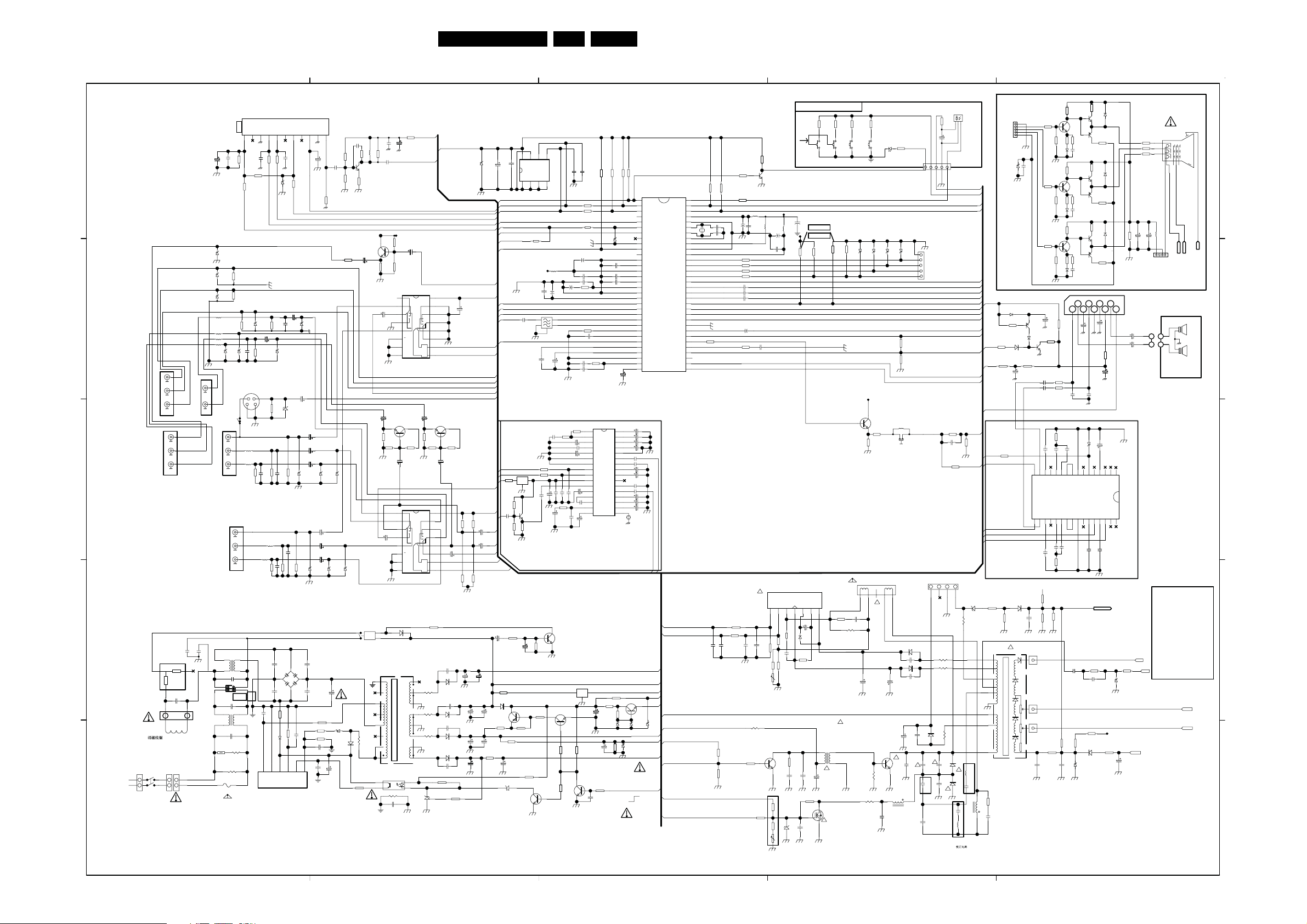

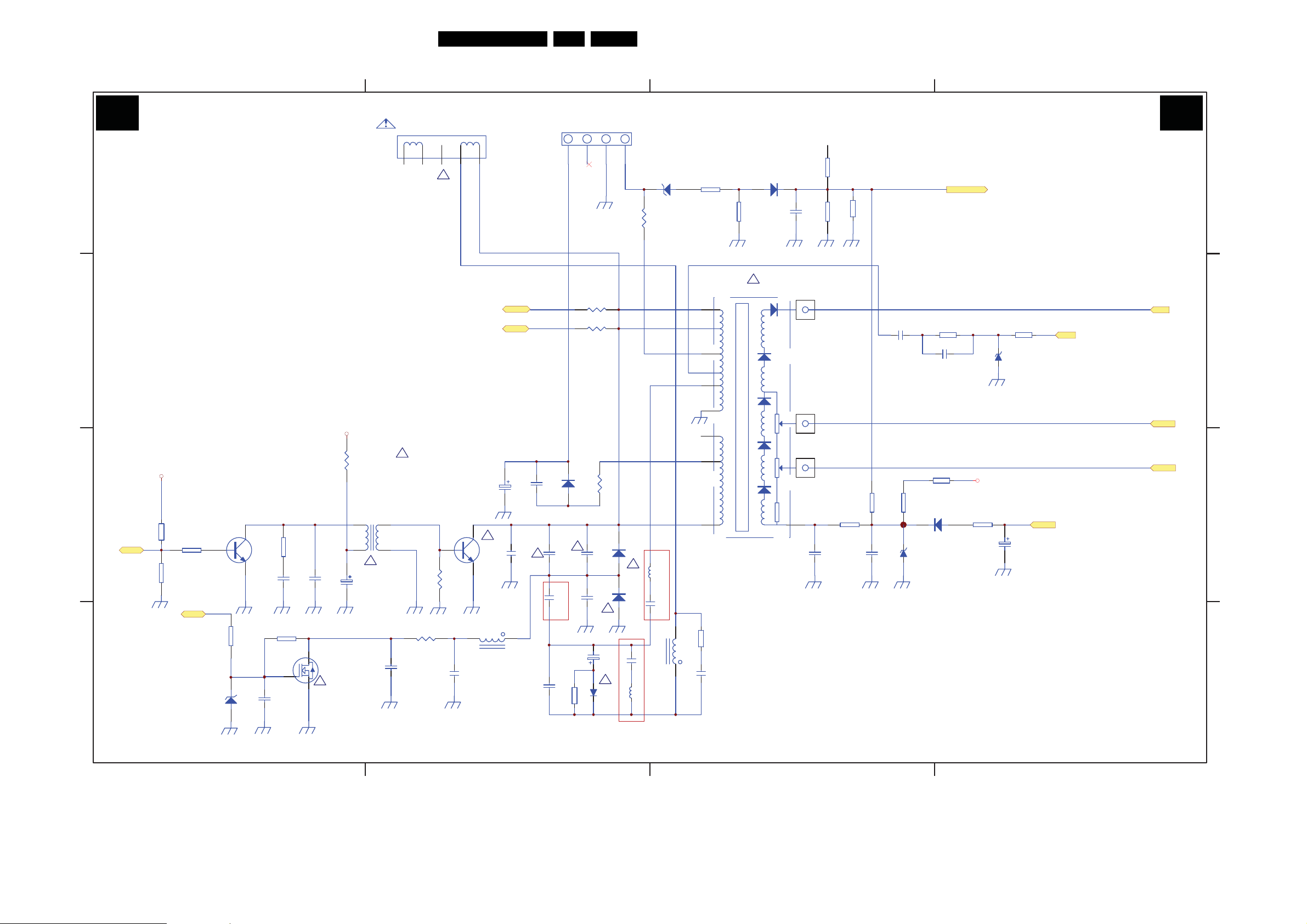

Schematic Overview Chassis 10

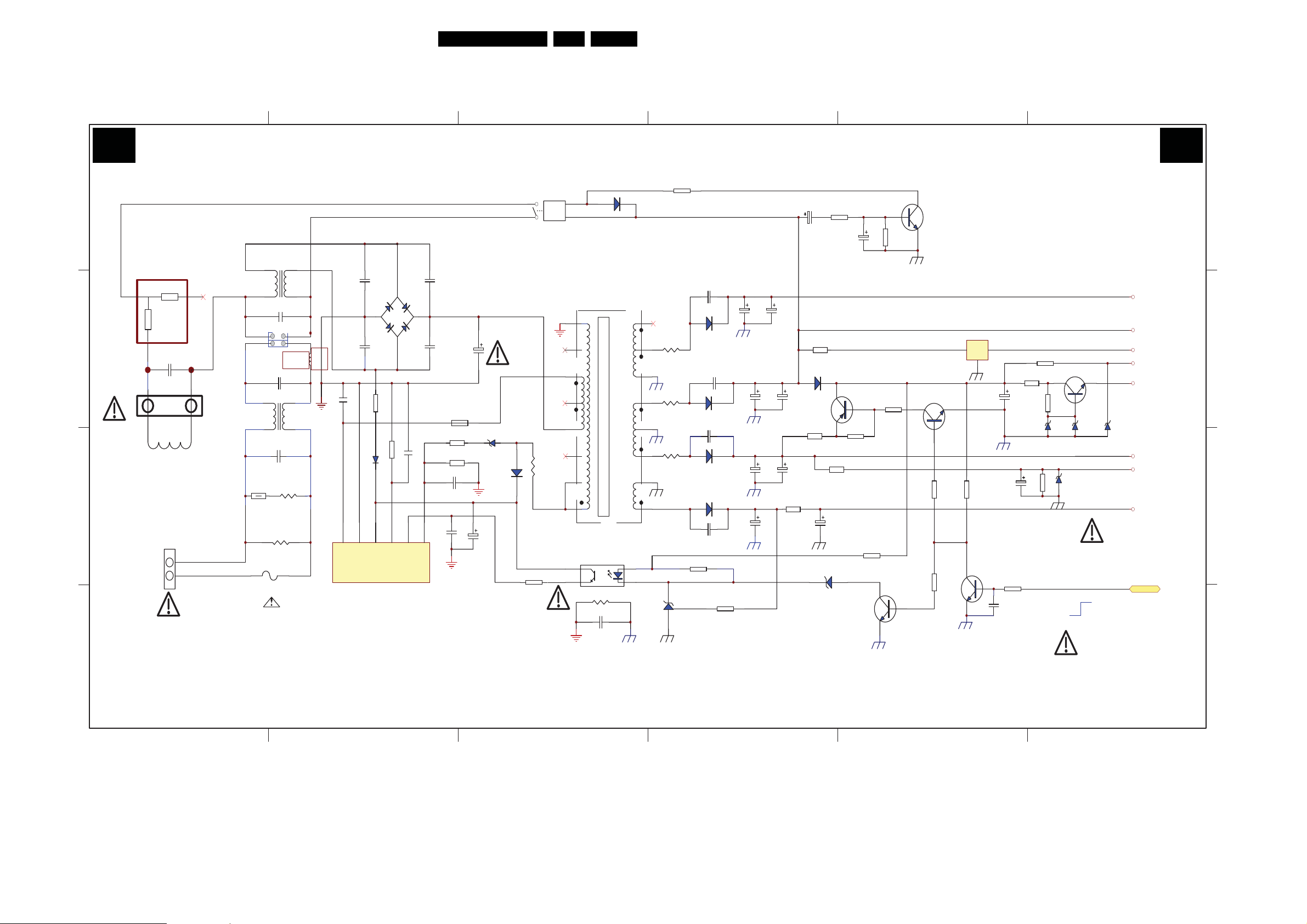

7. Circuit Diagrams and PWB Layouts

Mono Carrier: Power Supply (A1) 11 19-20

Mono Carrier: Line Deflection (A2) 12 19-20

Mono Carrier: Frame Deflection (A3) 13 19-20

Mono Carrier: Tuner IF (A4) 14 19-20

Mono Carrier: AV Switch (A5) 15 19-20

Mono Carrier: Tone Control (Optional) (A6) 16 19-20

Mono Carrier: Audio Amplifier (A7) 17 19-20

Mono Carrier: CPU & Decoder (A8) 18 19-20

CRT Board (B) 21 19-20

Keyboard Control Panel (D) 22 23

Mains Filter Panel (E) 24 24

Side A/V Panel (G) 25 25

8. Alignments 29

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 34

Abbreviation List 35

IC Data Sheets 36

10. Spare Parts List 51

11. Revision List 54

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JY 0768 BU CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17460

EN 2 SK5.0l CA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview (Mechanical chassis)

Note: Data below can deviate slightly from the actual situation,

due to the different set executions.

1.1 Technical Specifications

1.1.1 Vision

Display type : CRT

Screen size : 29” (72 cm), 4:3

Tuning system : PLL

TV Colour systems : NTSC, PAL M, N

Video playback : NTSC,

Presets/channels : 181 channels

Tuner bands : VHF

1.1.2 Sound

Sound systems : Stereo, SAP

Maximum power (W

):2 x 5

RMS

1.1.3 Miscellaneous

Power supply:

- Mains voltage (V

) : 100 - 240

AC

- Mains frequency (Hz) : 50 / 60

Ambient conditions:

- Temperature range (°C) : -5 to +45

- Maximum humidity : 90% R.H.

: UHF

1.2 Connection Overview

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Rear and Side Connections

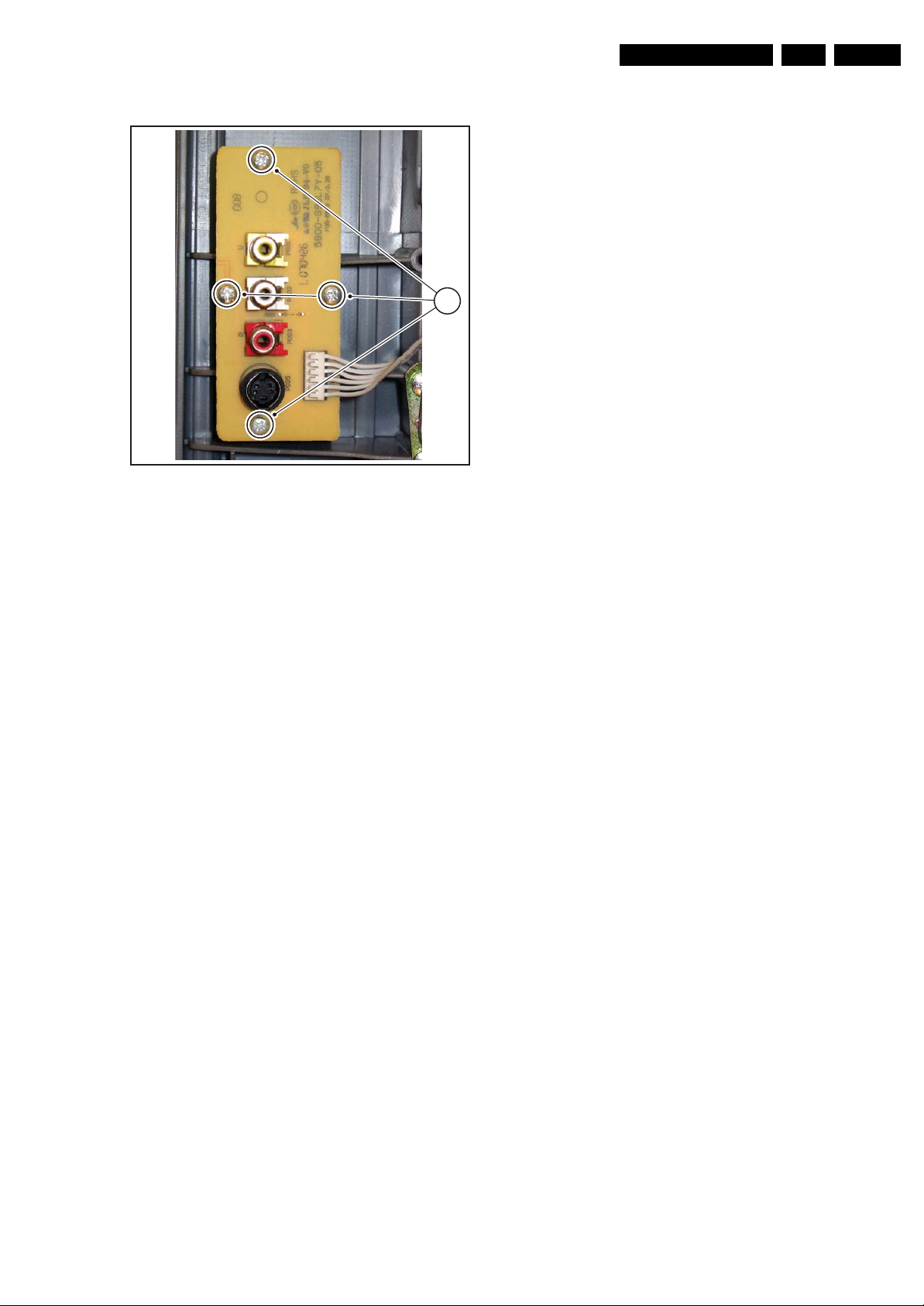

Figure 1-1 Rear and Side Connections

Aerial - In

- -F-connector Coax, 75 ohm D

Cinch: Video YPbPr - In

Gn -Video Y 1 V

Bu -Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh -Audio L 0.5 V

Rd - Audio R 0.5 V

Cinch: Video CVBS - In, Audio - In

Ye -Video CVBS 1 V

Wh -Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

H_17220_035.eps

280607

Power consumption

- Normal operation (W) : ≈ 105

- Stand-by (W) : < 3

Cinch: Video CVBS - Out, Audio - Out

Ye -Video CVBS 1 V

Wh -Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm kq

PP

/10 kohm kq

RMS

/ 10 kohm kq

RMS

Technical Specifications, Connections, and Chassis Overview

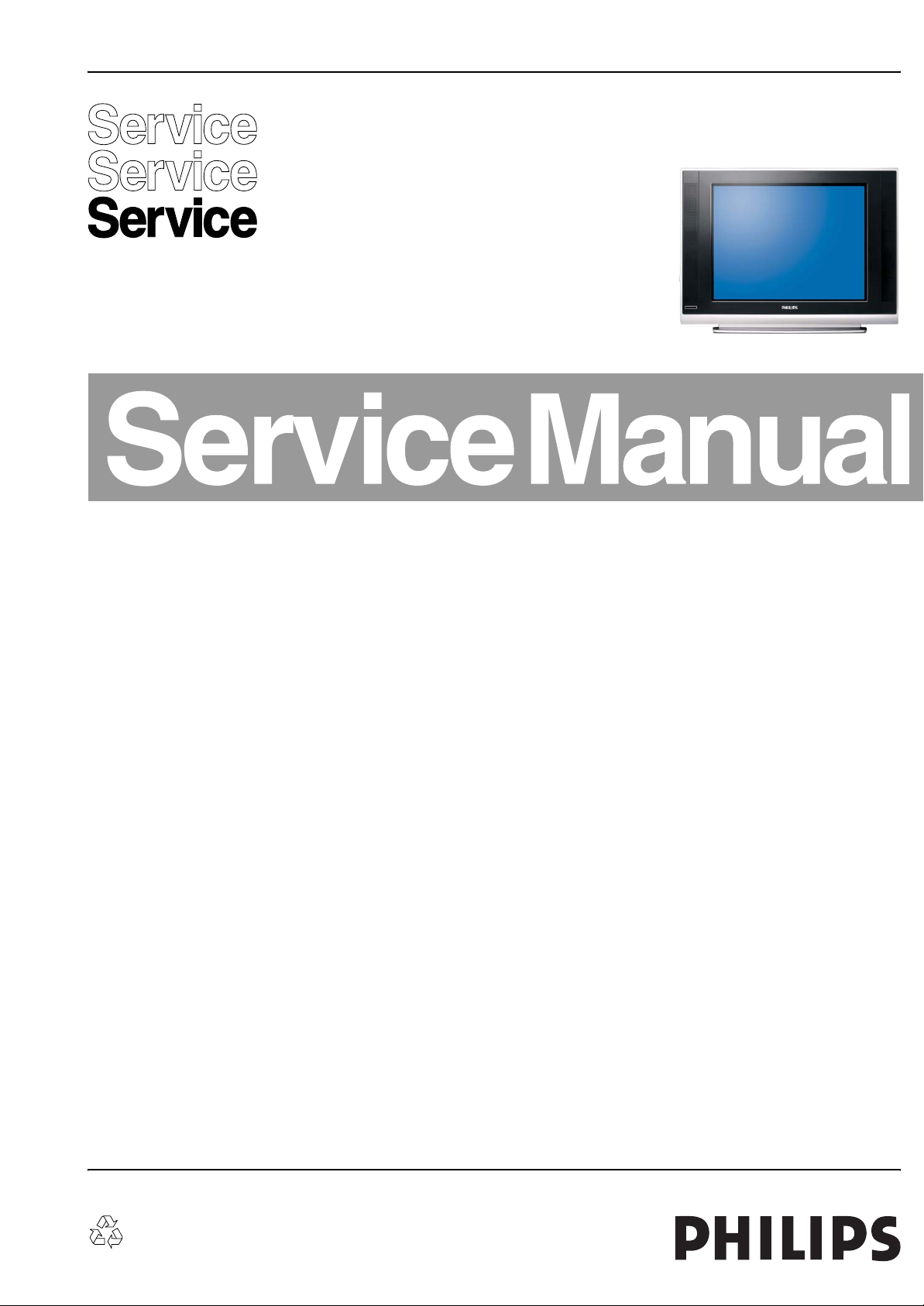

1.3 Chassis Overview (Mechanical chassis)

CRT BOARD

B

MAINS FILTER

E

CONTROL PANEL

D

EN 3SK5.0l CA 1.

Figure 1-2 PWB location

MONO CARRIER

BTSC PANEL

SIDE AV PANEL

A

M

G

POWER SUPPLY

A1

A2

LINE DEFLECTION

A3

FRAME DEFLECTION

A4

TUNER IF

A5

AV SWITCH

A6

TONE CONTROL

A7

AUDIO AMPLIFIER

A8

CPU & DECODER

H_17220_024.eps

280607

EN 4 SK5.0l CA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Maintenance Instructions

2.3 Warnings

2.4 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current flows. In particular this is valid

for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function, to prevent the cord from touching the CRT,

hot components, or heat sinks.

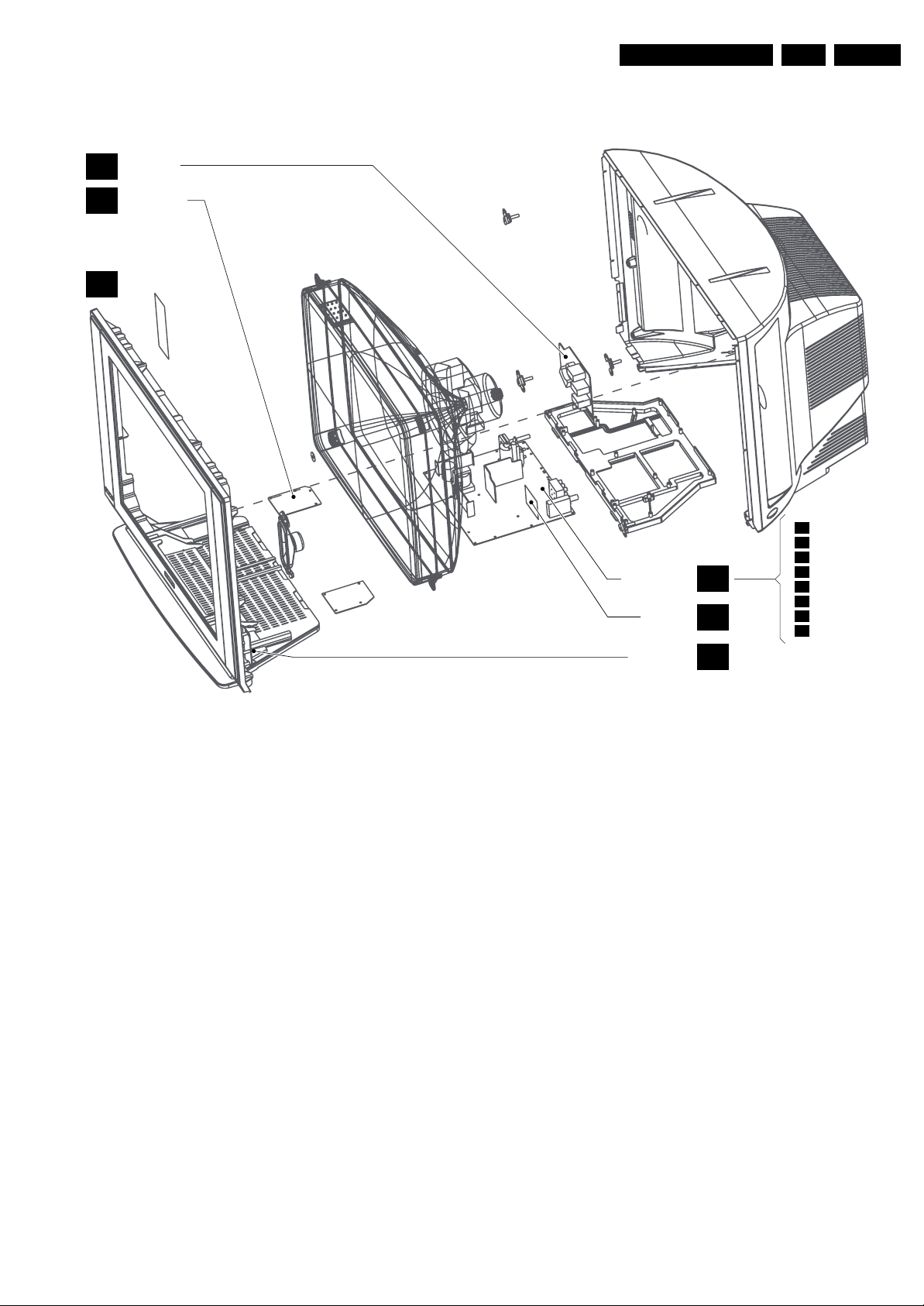

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the “general repair instruction” noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

picture tube, use the method shown in figure “Discharge

picture tube”, to discharge the picture tube. Use a high

voltage probe and a multi-meter (position V

until the meter reading is 0 V (after approx. 30 s).

V

E_06532_007.eps

250304

Figure 2-1 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and prevents circuits

from becoming unstable.

2.4 Notes

2.4.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I ), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D ) and without (E ) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G ) and in stand-by (F ). These values are

indicated by means of the appropriate symbols.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

). Discharge

DC

Directions for Use

EN 5SK5.0l CA 3.

2.4.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates

220 ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.4.3 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

-9

), or pico-farads (p= x10

-12

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.4.4 Alternative BOM identification

In September 2003, Philips CE introduced a change in the way

the serial number (or production number, see Figure 2-2) is

-6

),

).

composed. From this date on, the third digit in the serial

number (example: AG2B0335000001) indicates the number of

the alternative BOM (Bill of Materials used for producing the

specific model of TV set). It is possible that the same TV model

on the market is produced with e.g. two different types of

displays, coming from two different O.E.M.s.

By looking at the third digit of the serial number, the service

technician can see if there is more than one type of B.O.M.

used in the production of the TV set he is working with. He can

then consult the At Your Service Web site, where he can type

in the Commercial Type Version Number of the TV set (e.g.

28PW9515/12), after which a screen will appear that gives

information about the number of alternative B.O.M.s used.

If the third digit of the serial number contains the number 1

(example: AG1B033500001), then there is only one B.O.M.

version of the TV set on the market. If the third digit is a 2

(example: AG2B0335000001), then there are two different

B.O.M.s. Information about this is important for ordering the

correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26 = 35 different B.O.M.s can

be indicated by the third digit of the serial number.

2.4.5 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

EN 6 SK5.0l CA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Set Disassembly

4.2 Assembly / Board Removal

4.3 Set Re-assembly

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

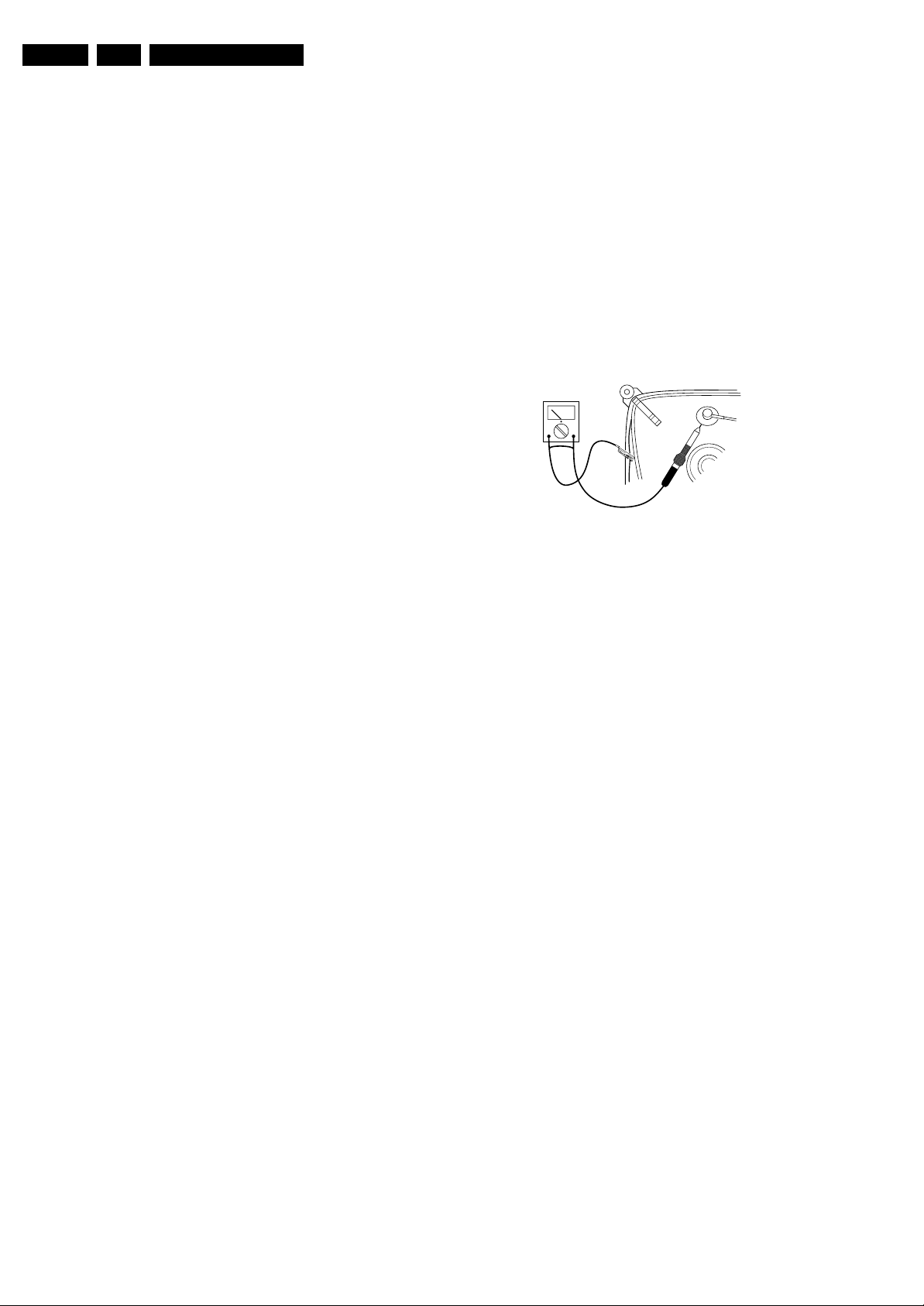

4.1 Set Disassembly

Follow the disassemble instructions in described order.

4.1.1 Rear Cover Removal

Warning: disconnect the mains power cord before you remove

the rear cover.

1. Remove all the fixation screws of the rear cover.

2. Now, pull the rear cover backwards and remove it.

4.2 Assembly / Board Removal

4.2.1 Power Switch and Control Panel removal

1. From the mono carrier disconnect the main power and the

keyboard circuit cables. Release the main power cord and

the keyboard circuit cable from it’s strain reliefs.

2. Then, remove the six fixation screws [1] of the power

switch and control panel and remove the board.

Figure 4-1 Rear Cover removal

H_17220_036.eps

280607

1

H_17230_027.eps

290607

Figure 4-2 Power Switch and Control Panel removal

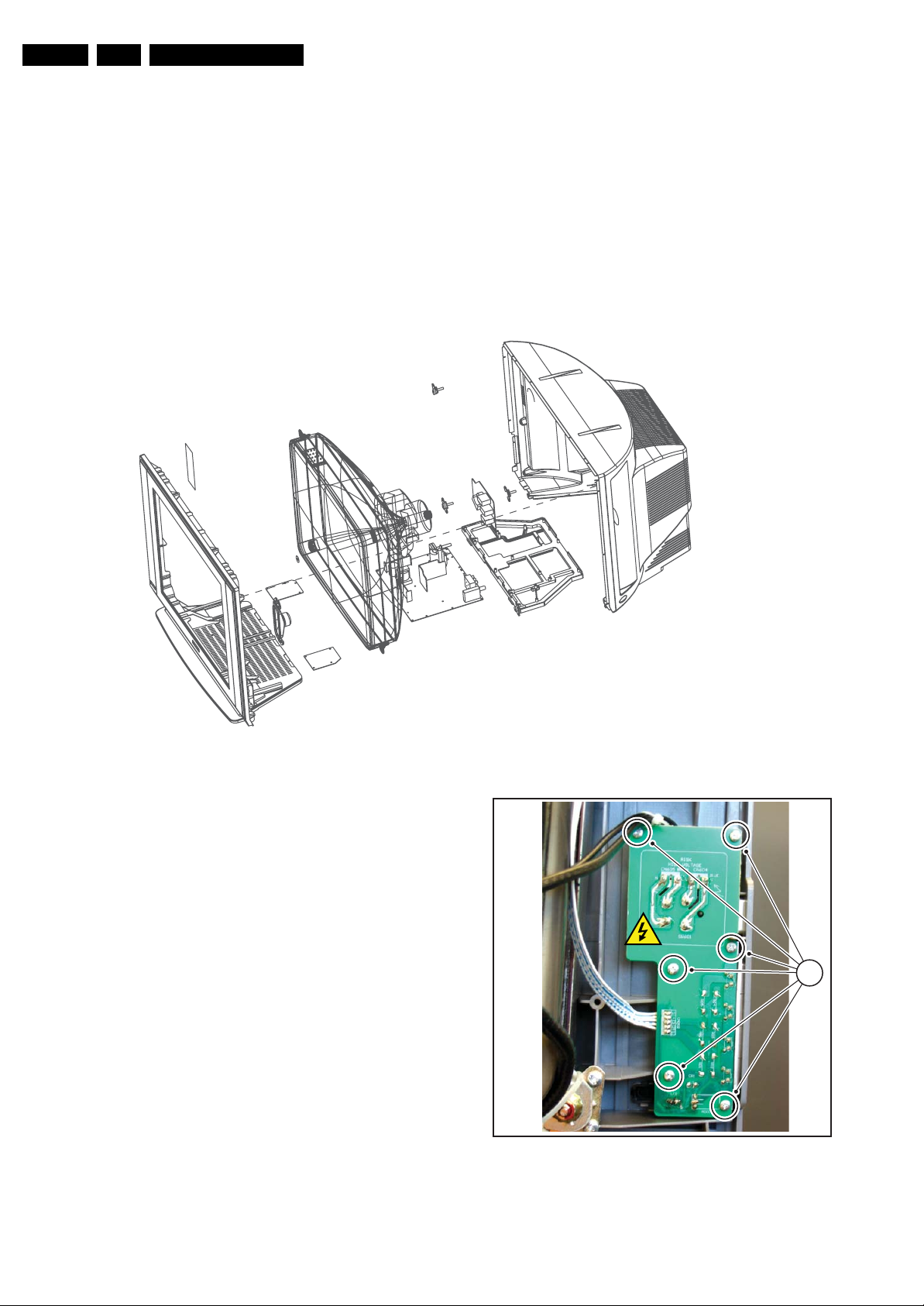

4.2.2 Side I/O Panel removal

Mechanical Instructions

1

H_17220_023.eps

210607

EN 7SK5.0l CA 4.

Figure 4-3 Side-I/O panel removal

1. Disconnect the side panel cable from the mono carrier and

remove the cable from it’s strain reliefs.

2. Then, remove the four fixation screws [1] and remove the

board.

4.3 Set Re-assembly

To re-assemble the whole set, do all processes in reverse

order.

Be sure that, before the rear cover is mounted:

• The mains cord is positioned correctly in its guiding

brackets (make sure that the strain reliefs are replaced in

its correct position and that it will function correctly!).

• All wires/cables are returned in their original positions.

EN 8 SK5.0l CA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Error Codes

5.4 Fault Finding

5.1 Test Points

See chapter 6 "Block Diagrams, Testpoint Overviews, and

Waveforms".

Perform measurements under the following conditions:

• Service Default Mode.

• Video: colour bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Ser vice Modes

This chassis does not contain a specific Service Mode. Service

and Alignment of the TV set can be done via the Factory Mode

by the service technician, see further down in this manual.

5.3 Error Codes

Not applicable.

5.4.6 Picture not or incorrect Coloured

• Check the circuit from IC201 to R.G.B. three gun circuit.

• Check the IC soldering and relevant circuitry on physical

damage or check for defective capacitors.

5.4.7 Picture with Horizontal Bright Line and Sound

Check both supply voltages of vertical IC301 and relevant

circuitry on correctness. Also check the vertical synchronizing

signal from IC201.

5.4.8 Remote Control Malfunction

Check the voltage on pin 64 of IC201. The normal value should

be 5.15 V. If this is correct check front control panels soldering

connections. If can't be solved, check the remote control,

crystal or transmitting diode of the remote control are in good

condition.

5.4.9 No Sound

Check power supply of sound IC (IC402) and relevant circuitry.

Check as well the BTSC board, check the power supply of

IC801 and relevant output signal pins 21 and 27 of this IC. Do

not exclude IC801 and/or IC402 to be defective. If needed

replace the speakers.

5.4 Fault Finding

5.4.1 Power on Failure

Check whether the power supply is working properly and

whether the values of voltages normal. If those are correct,

check line transistor and transformer are working properly or

check fore or back line for defects.

5.4.2 Horizontal Deflection Transistor Defective: No Picture, No Sound.

To find the fault for a defect horizontal deflection transistor

please check the following items:

• Over voltage to breakdown.

• Over current to burn.

• Horizontal frequency too low.

• Horizontal drive inefficient.

5.4.3 Picture Interference

• Check if the signal line contact is good.

• Change Tuner if is necessary.

5.4.4 Can't find any TV program

Checking method: Check the closed circuit from tuner to

picture decoder IC to detect whether there are defective

components. Or check whether the resistance of R117, R118,

R203 and R204 has increased which also could cause the

problem.

5.4.10 Poor Sound Quality

Check the sound system after searching the channel which

should set at NTSC or AUTO. If still has problem, check

accompany board circuit on chassis good or not.

5.4.5 No Good Picture or Double Image

Check the correctness of the signal from IF1/IF2 to Q101 and

relevant circuit. In this case the problem can be Q101 and/or

SAW101.

Block Diagrams, Test Point Overview, and Waveforms

A1

A2

A3

A4

A5

A6

A7

A8

B

M

G

6. Block Diagrams, Test Point Overview, and Waveforms

Block Diagram Chassis

EN 9SK5.0A CA 6.

<

75$&6

1(71$

$1

'

187

(

&

A4

4

H.

R&\

UWQ

OR

QL9

%*5

,5

),

30$)

/&6

$'6

75$&6

QL9

RHGL9

QX7

9HGLV

)(+:6

:$6

&*$UH

8

9

$

9

L

Q

&

),

$'7

7'$$3?0(

2,'8$

/

5

QL

&9%6 287

A8

&2863,/,+3

DLGQ,

$(5

5

9$

9

/

$'70$&,1

$'7670

5

*

%

9

$96: +()

$2%75&

5

'

A5

6+969$(',6

/

5

7829$

&<5/95

9

A6

5/

'

A7

/

5

/36

536

7'$

721( &21752/

7825

782*

782%

$037'$

75&

&

)5520,/6

%

$

99

9

)

2

%5

23

:

:6

$:

</33865(

9

)

52

G+

U

HYL

&

)9

2

5

1,$0

)9

2

30$5

+

XR

A1

RD9

X

W

$'730$9

RE9

WX

-$

A3

W

/6

,

0

3

75$

(9,5'+

9'<

+'<

A2

/,2&*('

H_17460_008.eps

%

$

280907

Block Diagrams, Test Point Overview, and Waveforms

EN 10SK5.0A CA 6.

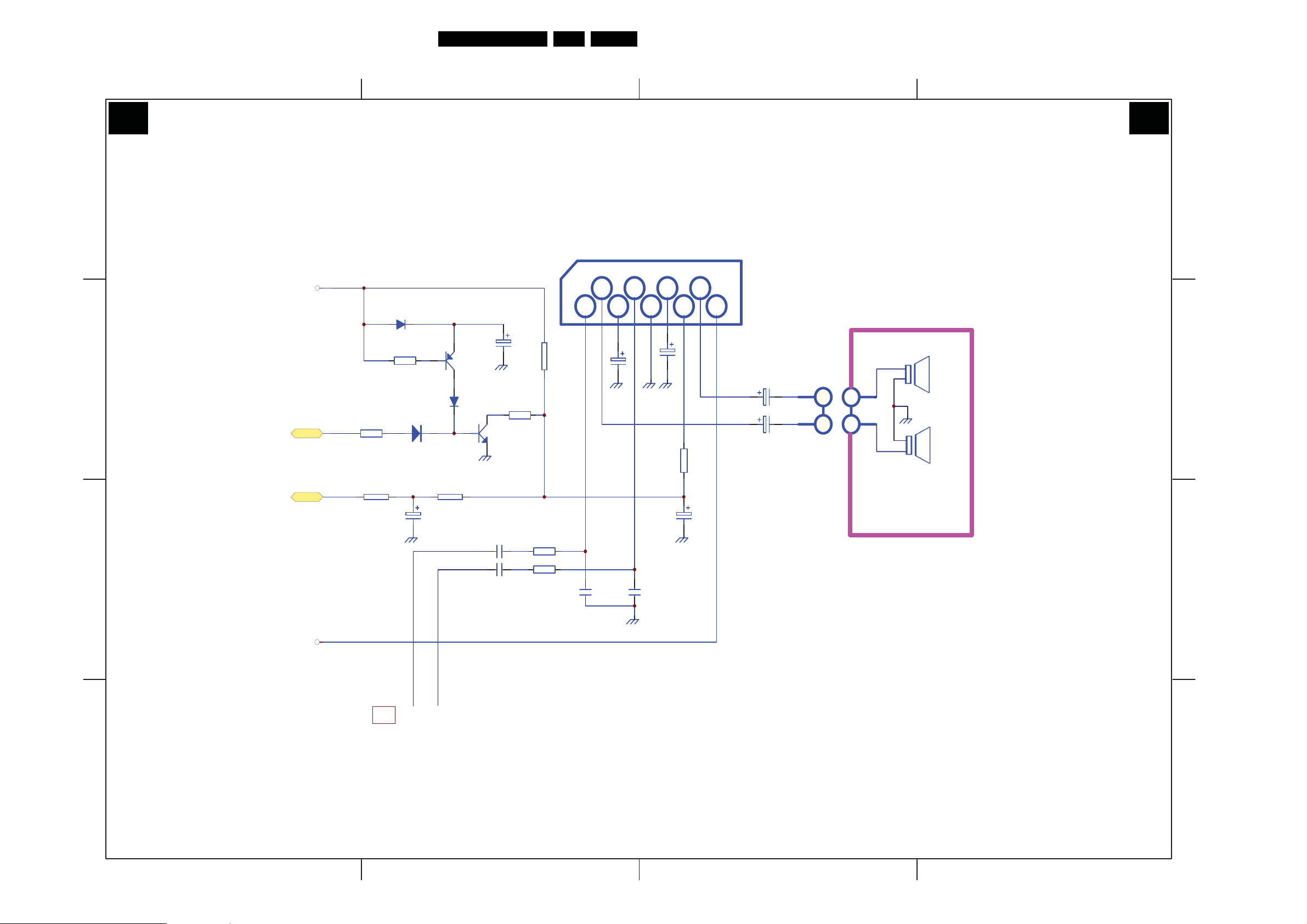

Schematic Overview Chassis

C110

E

VO

V

Y

U

D

LO

RO

Y

P701

U

YUV

V

V out

L out

P701

AV OUT

R out

C

B

AC220V 470PF

Rs

23

PTC601

Rp

9RM

1

C600

0.1uF/250V

CN603

DEGAUSSING

BLUE

CN601A

CN601B

SW601

1

1

AC90-270V

A

2

2

BROWN

C109

NC

10uF

8V2

ZD714

8V2

ZD705

8V2

L705

15uH

L702

33uH

L706

15uH

L701

33uH

ZD703

8V2

L

R

P701

SIDE AV IN

P701

REAR AV IN

C611

AC220V 470PF

C612

25mH

CN604

N

N

CN602

25mH

0.22uF/250V

VDR601

GAS DISCHAR GE

TUBE

CN601

N

2

1

L

1 2 3 4 5

R601

2.2M 1/2W

F601

T3.15A

AC250V

AGC1NC2SAS3SCL4SDA5NC6BM +5V7NC8BT +33V9IFGND10IF

C111

C112

R111

R113

47K

P702

V IN

L IN

R IN

PFC 15mH×2

0.22uF/250V

C601

R721

75

R722

100

Y

C603

0.22uF

AC250V

L

L

FOR EMC

C602

L601

R603

R112

100

100

100pF

100pF

R109

10K

ZD713

8V2

R701

47K

C003

1000p

C717

10uF

C

R780

47K

L704

15uH

L703

15uH

R776

47K

C604

1000pF

1

D

ZD101

5V1

R702

C702

47K

1000p

ZD701

8V2

ZD707

R779

8V2

75

R778

100

C002

1000p

R775

47K

C776

1000p

C603A

4700pF

AB

D603

C603D

4700pF

R602

2

200K

D604

0

3

4

5FB6

VCC

S/GND

IC601

STR-W6556A

C716

10uF

ZD706

C783

1000p

R604

39K

OLP/SS

R110

180

R723

75

C701

1000pF

S-VHS

L002

15uH

L003

15uH

R777

47K

V IN

L IN

R IN

L603

FOR CB

R600

L602

NTC

5RM

4321

KEYBOARD CIRCUIT

M001

234

5V

KEY

CN102

TV AUDIO OUT

CN401

CONNECT TO H502

4

R450

0.22

R451

0.22

D433

BA158

!

630V

123

RR1

100

CR1

10uF/16V

5

IR

GND

+5V_VCC

KEY

A2

A1

BCL

U / B in

Y / G in

V / R in

BLANK

TV L+R

C IN

CVBS/Y IN

TV CVBS IN

8V

X-RAY

AFC

H-out

R728

TV CVBS IN

1K

R729

C?

1K2

220PF/50V

R727

CVBS OUT

100

123

ZD402

18V

R423

6.2 2W

2W

R433

0.33

1W

D430

BY228

C431

3n9

!

L432

790uH

D431

RU4B

C433

C465

33nF

!

0.47uF

C464

0.18uF

L431

160uH

FOR SLIM

S

RD4

U101

45.75MHz

11

C103

0.82uH

NG

R106NGL101

R103

5.6K

C405

C101

47uF

0.01u

Q101

+5V

R108

1

33

VIDEO OUT

ZD702

8V2

C785

10uF

C777

10uF

C772

10uF

C774

10uF

8V2

ZD711

ZD709

8V2

8V2

C778

10uF

C770

10uF

C773

10uF

R719

ZD712

100

8V2

C603B

4700pF

CD

C607

C603C

4700pF

220uF

450V

L604

R606

C605

6K8

0.1uF

R605

100V

220

C606

470pF

7

C609

10nF

OCP/BD

C2717

R102

1K2

R105

22

R101

75

Q703

C1815

C710

R717

68

470uF

ZD710

ZD708

8V2

8V2

RL601

RELAY

ZD602

18V

R607

22

D605

BA158

C608

10uF

R608

2K2

L109

1

100uH

C163

C164

100nF

220uF

R107

820

C105

10nF

+12V

R713

22K

C720

10uF

R711

R712

75

22K

IC761

HEF4052

1

2

SIDE AV

REAR AV

0

C779

OUT

3

1

10uF

2

3

4

5

6

E

7

Vee

89

Vss

VIDEO SWITCH

AUDIO L out

C708

10uF

Q702

C1815

R706

1K8

R710

R708

20K

20K

R?

ELECTRO1

OUT L

IC762

HEF4052

L

1

SIDE L

2

0

3

1

2

C775

3

4

10uF

5

REAR L

6

E

7

Vee

89

Vss

AUDIO SWITCH

D627

1N4148

T603

16 1

15

14

13

12

11

10

TRANSFORMER

IC622

OPTOISO1

R610

C610 0.0022uF

2

3

4

5

6

<45V>

7

89

8.2M

<20V>

<12V>

<135V>

+8V_VCC

Vdd

0

1

2

3

AUDIO R out

R705

1K8

Vdd

0

1

2

3

R624

0.22 2W

R622

0.22 2W

R621

0.22 2W

+5V_VCC

IF

C118

ZD102

C117

5V1

100uF

100nF

STANDBY

SCL

+32V_BT

SDA

+8V_VCC

SDA

OPTION

SCL

KEY

AGC

VOL

+3.3V

MUTE

CVBS OUT

Q701

C1815

R707

20K

R

C771

10uF

680pF 500V

C462

560pF 2KV

D623

RU4YX

680pF 500V

D622

BYW36

C620

D621

BA158

D620

RU4B

R627

6.2K

+12V_VCC

R746

47K

R747

47K

C625

1000uF

16V

C622

470uF

C621

100uF

200V

CVBS/Y IN

C742

10uF

C741

10uF

50V

V in

Y in

U in

TV L

+12V_VCC

AUDIO L

AUDIO R

TV R

C628

1000uF

25v

C626

1000uF

C629

1500uF

50V

R609

0.18 / 5W

EW

VDRB

VDRA

IF

AGC

A1

A2

C IN

SDA

SCL

+12V

C879

QSS

1uF

A1

A2

C640

220uF

R632

1

D626

BA158

16V

R647

0.51 2W

3

250V

C780

100uF

R745

47K

R744

47K

C627

1000uF

25V

C623

50V

16

15

14

13

12

11

10

C707

10uF

R709

20K

R?

ELECTRO1

OUT R

16

15

SIDE R

14

REAR R

13

12

11

10

R640

0

C624

680pF 500V

R630

680

IC621

SE120

R854

10

R644

R633

5K1

C632

47uF

IC852

L7809

R857

47K

R858

47K

10K

ZD620

5V1

Vdd8PTC7SCL

WP1n.c.2A23Vss

only for scart

0.1U/63V

C105

10nF

In Out

Gnd

Q851

C1815

R860

1K

C639

47uF

Q624

A1013

R639

10K

R631

1K

6

5

SDA

IC102

24C08

4

R122

10K

L205

+8V

10uH

C120

C119

+

10uF/16V

4

1

5

2

SAW101

3

Q1976M

C136

C137

33PF

10UF

C863

47nF

R855

100

R856 100

C878

C877

0.1uF

C851

10uF

1uF

R851

2K2

C853

4.7uF

BTSC BOARD

Q625

C1815

R643

47K

+12V

R649

2K2

Q622

C1815

R635

22K

R634

10K

Q621

C1815

C108

100pF

R133 100

R134

R135

10uF/16V

C128

C133

+

1uF/50V R138

R151

39K

C138

4.7nF

R852

R853

8K2

150

C864

10uF

C865

0.1uF

C866

4.7uF

C876

C875

100pF

100pF

C854

0.22uF

FOR LATAM

IC104

In Out

L7808

R648

22K

C107

100pF

47

C129

+

10nF

4n7

18K

0.1U/63V

C139

330pF

1

2

3

4

5

6

7

8

9

10

11

C869

12

100uF

13

C852

14

0.47uF

15

16 17

C855

10uF

Gnd

16V

Q623

C1815

R145

22K

100

C135

R139

3.9K

TDA9850

VEO

VEI

Cnr

Cm

Cdec

AGND

DGND

SDA

SCL

Vcc

COMP

Vcap

Cp1

Cp2

Cph

Cadj CER

C641

2200uF

C114

47uF

C634

0.1uF

50V

R120

100uF

R460

100

R457

1K

R121

Q106

C1815

10K

R140

100

L105

C145

+

C727

0.1uF

0.1uF

C726

C725

0.1uF

C116

+

R147

390

100

C460

1nF/50V

50V

R404

100

10uH

C146

0.1uF

R144 100

R143

R142

R141

1uF

R406

1K/1W

R443

470

NTC

100

100

10K

C144

0.1U/63V

!

C461

1nF

R468

5.1

R469

5 OHM

NTC

R464

50K

+3.3V

L107

L106

10uH

10uH

+

C150

100uF

C149

10nF

TDA4865AJ

INP7INN6V out5 VP4 -17.5V4Vp3 pump3VP3-2VP1 +17.5V

35V

R452

5.6

J408

1K8

R459

1K8

0.1uF/100V

2W

R462

0.82

Q401

C2482

R467

33K

R466

39K

ZD440

8.2V

R132

R130

R131

3.3K

3.3K

3.3K

R149

R148

3.3K

IC201

1

STANDBY

2

SCL

3

SDA

4

AV3/TUNING

5

SCART ID

6

KEY

7

VOL

8

BAND

ZD103

8V2

9

Vss C/P

10

MUTE

11

PAL/NTSC

12

C127

C130

C131

IC851

Cs

Cw

Cts

Ctw

MAD

OUTL

Cnd

CL

Vref

SAP

Csde

OUTR

Cr

Css

Cmo

VssA

220nF

13

SECPLL

14

Vp2

220nF

15

DECDIG

2200pC132

16

PH2LF

17

PH1LF

18

GND3

19

DECBG

20

AVL/EWD

21

VDRB

22

VDRA

23

IF1

24

IF2

25

IREF

26

VSC

27

TUNER AGC

28

AUDEEM/S IF1

29

DECSDEM/SIF2

30

GND2

31

SNDPLL/SIFAGC

32

AVL/REFO

C140

4.7uF

C862

32

1uF

31

C861

1uF

30

C860

10uF

C809

29

10uF

28

27

C872

1uF

C867

26

0.1uF

25

C874

2.2uF

24

C868

100uF

23

C858

22

15nF

21

C871

1uF

20

C873

2.2uF

19

C877

4.7uF

C856

18

4.7uF

X851

503KHz

TDA9363 for AP

TDA9373 FOR Latam

AUDOUT/AMOUT

AUDEXT/QS SO

BTSC out R

BTSC out L

TV L

TV R

VDRA

VDRB

XTAL OUT

XTAL IN

TDA9384 for India

BLANKING

B / U IN

CVBS/Y IN

CVBSINT

IFVO/SVO

IRin

AV2

AV1

VddP

RESET

OscGnd

VddC

VpE

VddA

B OUT

G OUT

R OUT

BCL IN

G / Y IN

R / V IN

BLANK

C IN

GND1

Vp1

PLL IF

EHTO

FBISO

H. OUT

3.3K

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

X101

12MHz

R125

220

C160

470P

C147

33pF

C148

33pF

C161

470P

+21V_VCC

+12V_VCC

+8V_VCC

390

+5V_VCC

R645

R638

22

R114

J615

10K

+3.3V_VCC

Q626

+135V_VCC

C1815

R650

430

ZD621

ZD622

ZD105

5V1

+48V_VCC

+32V_BT

+135V_VCC

STANDBY

H:WORKING

L:STANDBY

+48V_VCC

+8V_VCC

H-out

+8V

R401

4K7

R403

NC

3V9

3V9

IC103

33V

39K

16V

EW

RD5

18K

10K

MENU

VOL-

VOL+

SW003

SW004

C151

+

100uF/16V

RCA :

R724 33K

R725 10K

SCART: R724 10 K

+8V

R725 75

R724

R725

33K

R414

10K

39K

TV CVBS OUT

IC301

1

R461

C455

100uF/50V

D452

BA158

C459

R463

220/2W

R405

5K6

C402

2200pF

500V

C441

0.01uF

50V

5.6 1/4W

100V

T401

5

1

4

3

!

C403

C404

220pF

4.7uF

50V

500V

R441

56K

Q440

F630

!

RD2

RD3

2K7

100

RD1

PRO+

SW002

R425

27K

C456

0.1uF/100V

R453

270 1W

LED

PROSW001

ZD104

8V2

R126

180

V - DEF

6

C453

2200uF/25V

100

LED

1

LED

ZD108

ZD107

ZD106

8V2

8V2

+8V

Q107

C1815

R127

XT155

100

XT-4.5

CN301

H-DEF

5

!

100V

+16.2V

-16.2V

C452

2200uF/25V

GND

8V2

1

B

2

G

3

R

4

BL

5

R413

100K

R412

27K

L103

12uH

GND

D450

BYW36

470pF

D451

BYW36

470pF

!

C437

C436

10uF

560pF

250V

2KV

N401

D2553

!

C432

C438

!

7n2

2n7 /2KV

R454

33

R440

2.2 2W

L440

C440

4.7uF

50V

2KV 2KV

C435

0.56uF

2.8mH

C463

0.39uF/ 400V

FOR SLIM

H501

GND

R

G

B

BL

ZD501

8V2

CRT AMPLIFY CIRCUIT

+8V_VCC

D763 IN4148

R766

47K

D761

R137

MUTE

1K

1N4148

PWM

15K

+20V_VCC

R748

+12V_VCC

150

SCL

SDA

AUDIO L

AUDIO R

TONE CONTROL

D404

R421

180

1N4148

R422

680

!

T402

4

+16.2V

5

-16.2V

8

HEATER

6

AFC

9

FBP

3

2

B+

10

180V

1

HY

FLYBACK

R432

270

L430

36uH

C442

2200PF

R OUT

C760

10uF/16V

C508

1000PF

R764

6.2KR763

L OUT

C407

NC

R515

2

15K

R510

Q504

22

C4544

R512

R511

R513

22

2K2

270

C502

D503

330PF

1N4148

R525

2

15K

R521

Q507

22

C4544

R522

R520

R523

22

2K2

270

C503

D505

330PF

1N4148

R506

2

15K

R501

Q501

22

C4544

R504

R502

R503

22

2K2

270

C501

D501

330PF

1N4148

123456789

C728

RO

RI

R768

100uF

Q760

91K

A1015

D762

R765

1N4148

1K

Q761

C1815

C750

R770 1K

1uF

R769 1K

C749

15

16

SCL

LOUT_R

SDA17LOUT_L18C_TL19N.C.20C_BL221C_BL122LIN_L23MOUT_L24MAD25SCOUT_L26C_PS227AIN_L28C_PS129AIN_R30P231SCIN_R

C748

5n6

C765

1uF

4700PF

R742

13K

C752

C753

C754

6n8

68nF

0.15uF/63V

9

10

12

13

14

N.C.

C_TR

LIN_R

C_BR111C_BR2

MOUT_R

C746

C745

0.15uF

68nF

R743

13K

8V

R413

100K

R412

R418

27K

NC

HV TO CRT

C445

2n2F/100V

FOCUS

SCREEN

7

ABL

C443

0.056uF

250V

R416

R419

1K

270K

R420

1K

C409

D403

0.1uF

5

R516

1

220

D504

Q506

BA158

BF420

Q505

BF421

R

R514

1

270

R526

1

220

D506

Q509

BA158

BF420

Q508

G

BF421

R524

1

270

R507

1

220

Q503

BF420

Q502

BF421

L in

C764

47uF

C761

50V

C766

4700PF

ZD715

8V2

5

6

7

8

V_P

GND

MIN_R

SCOUT_R

C744

15nF

X-ray

R407

22K

C444

39PF/50V

R417

3K3

D402

1N4148

8V2

R528

D502

2

BA158

220K

B

R505

1

270

IC760

TFA9843AJ---10W

TFA 9842AJ---6W

L out

C767

220uF

C769

470uF

C768

R771

470uF

10K

1uF

C740

100uF/16V

1P12

3

4

MIN_L

C_SMO

SCIN_L

IC740

TDA9859

32

C743

15nF

X-ray

R409

27K

ZD401

8V2

+8V_VCC

R424

ABL

2K

C410

10uF/16V

R517

2K7

R527

2K7

R508

2K7

C506

NC

H502

Lout

SW2

Rout

EHT

AFC

AFC

ABL

CRT

KR

KG

KB

C507

L501

10uH

NC

SCREEN

GND

+180V

HEATER

CN760

1

1

2

2

SW2

FOR RF Tube

R462 1 OHM ( 2W )

R417 4.7K ( 1/6W)

R419 390K (1/6W)

C463 0.36uF (400V)

C438 1500pF (2000V)

C431 6800pF (2000V)

C432 6800pF (2000V)

L440 790uH

L430 30uH

R423 5.6 (2W)

C433 18nF (630V)

R441 75K (1/6W)

R440 6.8 (2W)

C435 0 OHM

L431 not used

L432 not used

C464 not used

C465 not used

H_17460_002.eps

FOCUS

SCREEN

FOCUS

SPL

4RM 10W

8RM 6W

SPR

4RM 10W

8RM 6W

E

EHT

D

C

B

A

240907

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

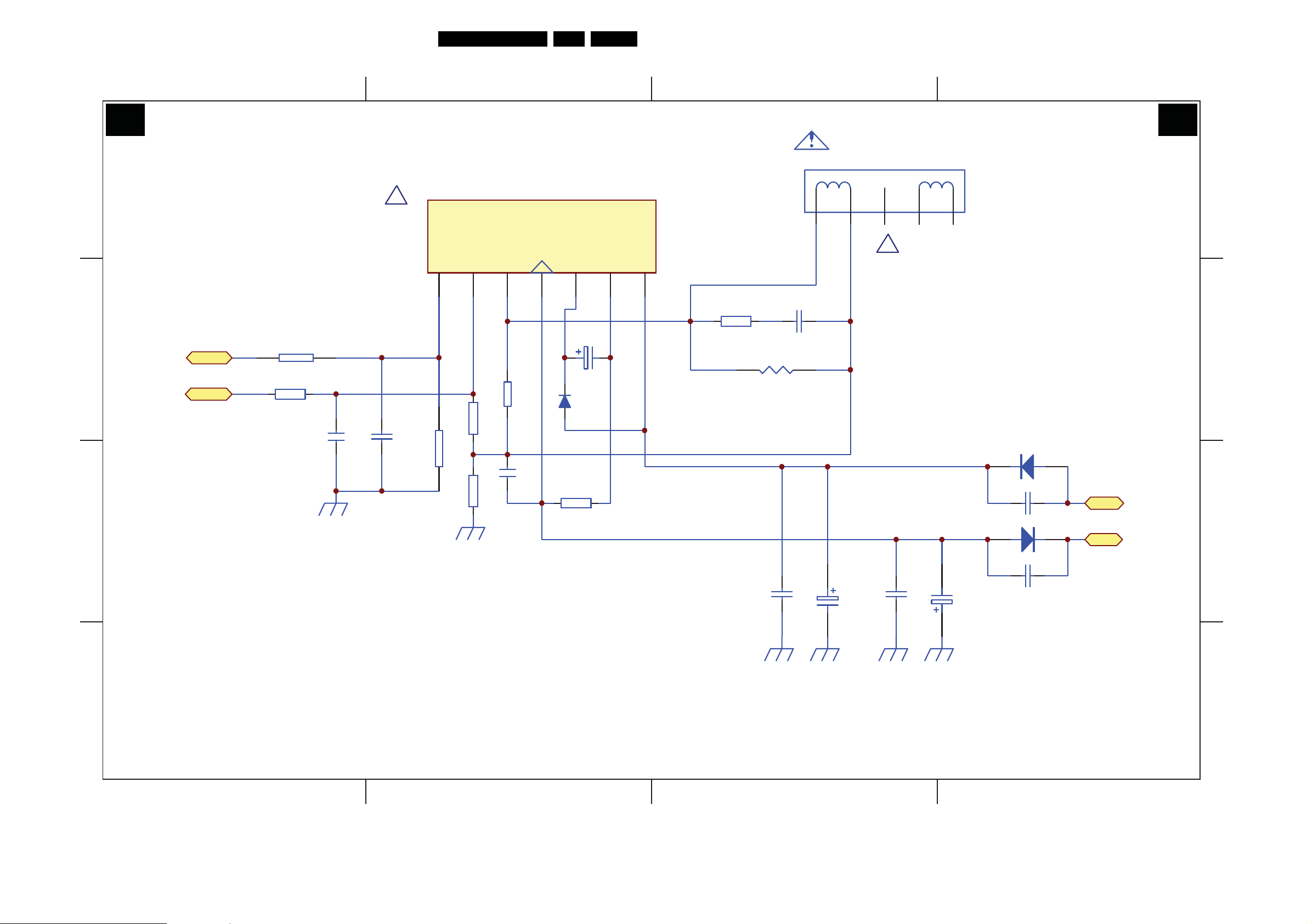

Mono Carrier: Power Supply

EN 11SK5.0A CA 7.

54321

6

A1 A1

D

C

B

POWER SUPPLY

Rs

23

PTC601

9RM

????

CN601

AC90-270V

Rp

1

C600

0.1uF/250V

CN603

DEGAUSSING

BLUE

BROWN

2

1

N

L

CN604

N

N

CN602

FOR EMC

L602

PFC 15mH×2

C602

0.22uF/250V

15mH

C601

0.22uF/250V

R603

VDR601

GAS DISCHARGE

TUBE

R601

2.2M 1/2W

F601

T3.15A

AC250V

T601

C603

0.22uF

AC250V

L

L

L601

FOR CB

R600

NTC

5RM

C604

1000pF

D604

0

3

1

D

S/GND

STR-W6556A

C603A

4700pF

AB

D603

CD

C603D

4700pF

R602

2

200K

R604

39K

C605

0.1uF

100V

4

5

6

VCC

FB

OLP/SS

IC601

C603B

4700pF

C603C

4700pF

7

OCP/BD

L604

R606

6K8

R605

220

C607

220uF

450V

C606

470pF

C609

10nF

C608

10uF

ZD602

18V

D605

BA158

R608

2K2

RL601

RELAY

R607

22

D627

1N4148

T603

16 1

15

14

13

12

11

10

TRANSFORMER

IC622

OPTOISO1

R610

8.2M

C610 0.0022uF

<20V>

2

3

<12V>

4

5

6

<45V>

7

<135V>

89

R640

0

R624

0.22 2W

R622

0.22 2W

R621

0.22 2W

IC621

SE120

680pF 500V

R630

680

C624

D623

RU4YX

C623

680pF 500V

D622

BYW36

C620

680pF 500V

D621

BA158

D620

RU4B

C462

560pF 2KV

R627

6.2K

50V

C627

1000uF

25V

C625

1000uF

16V

C622

470uF

50V

C621

100uF

200V

C628

1000uF

25v

0.18 / 5W

C626

1000uF

C629

1500uF

50V

R609

3

C640

220uF

16V

R647

0.51 2W

R632

1

D626

BA158

R633

5K1

C632

47uF

250V

R644

10K

ZD620

5V1

Q624

A101 3

R639

10K

C639

47uF

R631

1K

R643

47K

+12V

R649

2K2

Q621

C1815

Q622

C1815

Q625

C1815

R635

22K

R634

10K

IC104

L7808

In Out

Gnd

R648

22K

16V

Q623

C1815

C114

C634

0.1uF

50V

C641

2200uF

47uF

J615

10K

R638

22

R114

39K

390

R645

R650

430

ZD622

3V9

16V

+12V_VCC

Q626

C1815

ZD621

3V9

IC103

33V

+135V_VCC

+20V_VCC

+8V_VCC

+5V_VCC

+3.3V_VCC

ZD105

5V1

+48V_VCC

+32V_BT

STANDBY

H:WORKING

L:STANDBY

+20V_VCC

+12V_VCC

+8V_VCC

+5V_VCC

+3.3V_VCC

+48V_VCC

+32V_BT

+135V_VCC

STANDBY

D

C

B

A

5800-A5P190-00

1 2 3 4 65

H_17220_001.eps

180607

A

Circuit Diagrams and PWB Layouts

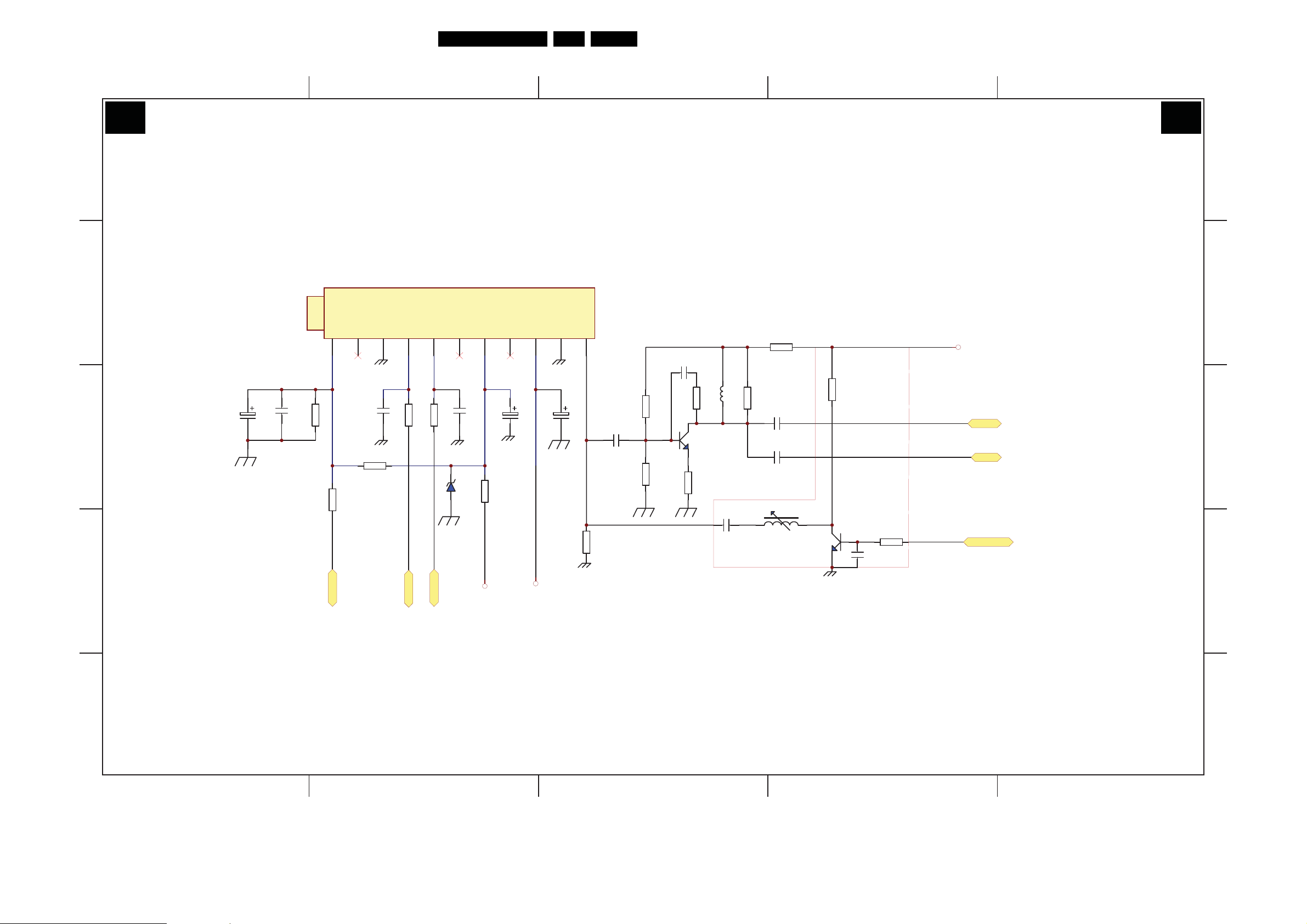

Mono Carrier: Line Deflection

EN 12SK5.0A CA 7.

321

4

A2 A2

LINE DEFLECTION

CN301

H-DEF

CN401

TO CRT

8V

5

D

6

!

4

R423

3.9 2W

ZD402

18V

R421

180

R422

680

D404

1N4148

C407

NC

R413

100K

R418

NC

R412

27K

X-ray

X-ray

1

2

3

!

T402

+V

-V

C

+48V_VCC

R450

0.22

R451

0.22

2W

+13V

-13V

HEATER

AFC

FBP

4

5

8

6

9

3

2

HV TO CRT

FOCUS

C445

2n2F/100V

R407

22K

C444

27PF/50V

ZD401

8V2

R409

27K

AFC

EHT

AFC

FOCUS

B+

R406

C403

220pF

500V

Q440

F630

!

1K/1W

T401

5

4

C404

4.7uF

50V

+8V_VCC

B

H-out

A

R401

4K7

R403

NC

R404

100

Por t

ZD440

8.2V

R443

470

Q401

C2482

C441

0.01uF

50V

R441

75K

R405

5K6

C402

2200pF

500V

!

D433

C437

C436

10uF

560pF

250V

2KV

1

3

!

0.01uF

100V

R440

6.8 2W

N401

D2553

R454

33

C440

4.7uF

50V

L440

!

790uH

C438

2n7 /2KV

!

C463

0.33uF

C432

8n2

2KV 2KV

C435

0.47uF

R430

15K

BA158

!

C406

1uF

250V

D432

BA158

C431

6n8

C433

33nF

630V

R433

0.33

1W

!

!

D430

BY228

!

D431

RU4B

160uH

C464

0.18uF

L431

L432

1.12mH

C465

0.47uF

10

180V

1 7

HY

R432

270

L430

20uH

C442

2200PF

FLYBACK

ABL

SCREEN

C443

0.056uF

250V

R420

1K

C409

0.1uF

R419

560K

R416

1K

D403

8V2

R417

5K6

D402

1N4148

R424

1K

+8V_VCC

ABL

C410

10uF/16V

SCREEN

ABL

D

C

B

A

5800-A5P190-00

FOR SLIM TUBE

????

S

1 2 3 4

H_17220_002.eps

180607

Circuit Diagrams and PWB Layouts

Mono Carrier: Frame Deflection

EN 13SK5.0A CA 7.

321

A3 A3

D

FRAME DEFLECTION

CN301

IC301

!

TDA4863AJ

6

5

4

!

INP

7

VDRA

C

VDRA

VDRB

VDRB

R460

100

R457

100

C460

1nF/50V

50V

C461

1nF

2W

B

INN

6

R459

1K8

R462

1

V out

5

35V

J408

1K8

0.1uF/100V

R452

5.6

C459

VP4 -13V

4

Vp3 pump

3

C455

100uF/50V

D452

BA158

R463

220/2W

2

VP3-

VP1 +13V

1

R461

5.6 1/4W

100V

C456

0.1uF/100V

R453

270 1W

100V

+14V

D450

BYW36

470pF

+V

-14V

D451

BYW36

+V

D

C

B

A

5800-A5P190-00

0.1uF

1 2 43

C453

0.1uF

1000uF/25V

C452

1000uF/25V

470pF

H_17220_003.eps

180607

A

Mono Carrier: Tuner IF

Circuit Diagrams and PWB Layouts

EN 14SK5.0A CA 7.

4321

A4 A4

TUNER IF

5

E

D

C109

10uF

C110

NC

R113

47K

AGC

NC2SAS

1

3

C112

100pF

SCL

4

R112

100

5

SDA

R111

100

NC

6

C111

100pF

BM +5V

7

NC

8

C113

220uF

BT +33V

IFGND

IF

9

10

11

C405

47uF

C

R109

10K

R110

180

AGC

B

AGC

SCL SDA

SCL

ZD101

5V1

SDA

+5V

R108

1

33

+8V_VCC

+8V_VCC

R101

75

+32V_BT

+32V_BT

U101

38.9MHz

R103

C101

0.01u

5.1K

R102

1K5

C103

10nF

R1061KL101

Q101

C2717

R105

22

1uH

C102

10nF

R107

470

R104

1

220

C105

10nF

C106

10nF

L102

31.9MHz

Q102

C1815

R116

10K

NTSC

C115

10nF

R117

10K

+5V

IF

SIF

SYSTEM

+5V

IF

SIF

SYSTEM

E

D

C

B

A

5800-A5P190-00

A

H_17220_004.eps

180607

1 2 3 45

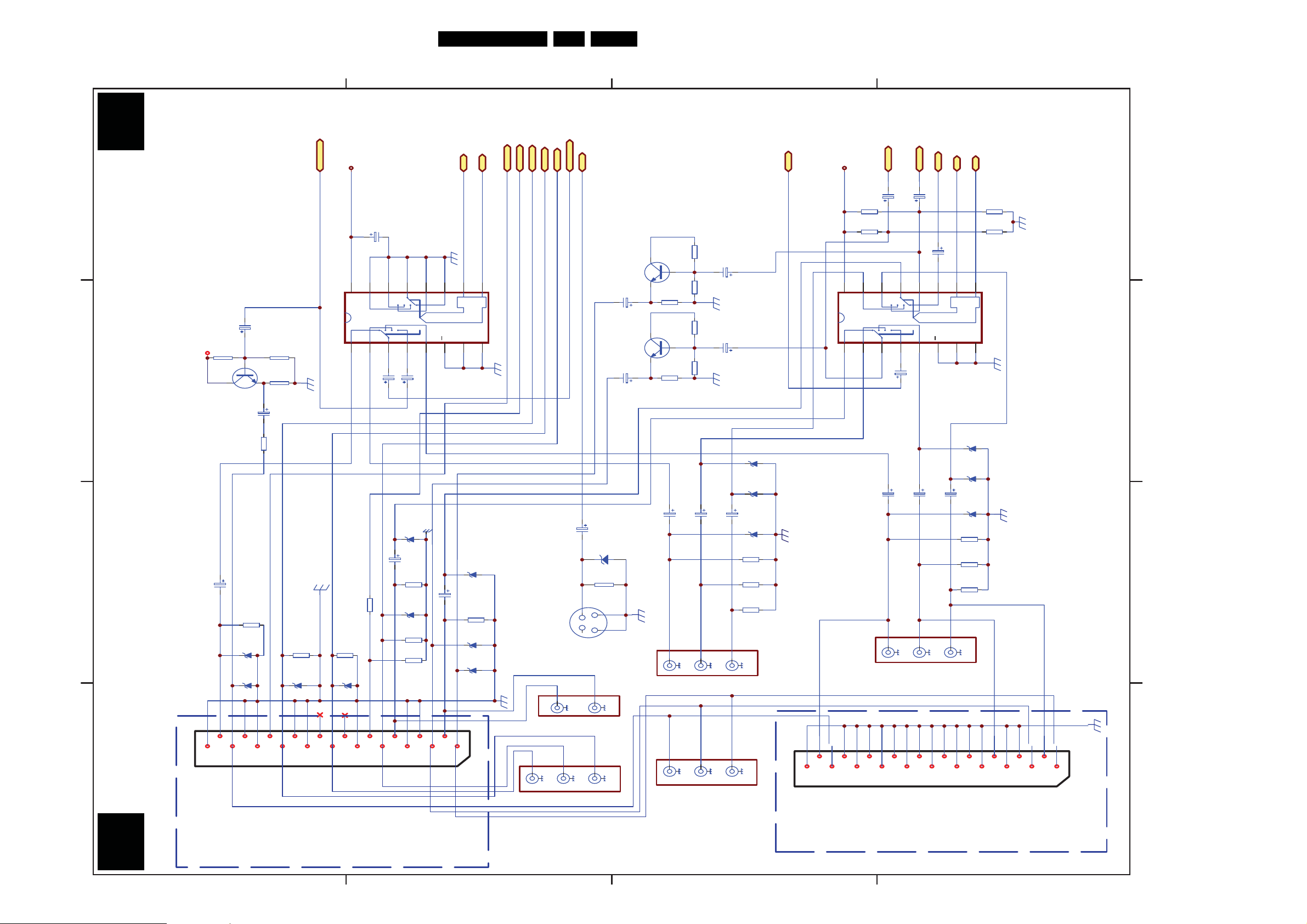

Mono Carrier: AV Switch

D

Circuit Diagrams and PWB Layouts

EN 15SK5.0A CA 7.

C

B

A

180607

H_17220_005.eps

IC762

HEF4052

+8V_VCC

16

1

L

+8V_VCC

Vdd

AUD IO L

AUD IO R

AUDIO L

AUDIO R

C741

C742

47K

47K

10uF

R

REAR R

12

13

14

012

3

3

2

0

1

3

4

5E6

C775

10uF

C778

10uF

C770

V IN

R746

R745

SIDE R

15

2

SIDE L

REAR L

L IN

10uF

C771

10uF

A1

TV R

TV R

11

C773

A2

A2

A1

R747

47K

R744

47K

10uF

10

Vee7Vss

R IN

AUDIO SWITCH

89

8V2

ZD710

8V2

ZD708

10uF

8V2

ZD712

75

R719

47K

R775

47K

R776

REAR AV IN

P701

R

L

+8V_VCC

CVBS OUT

4

+8V_VCC

C780

CVBS OUT

IC761

C720

10uF

+8V

R713

20K

321

Q703

C1815

C710

R717

R712

R711

470uF

68

75

HEF4052

100uF

12

13

14

15

16

Vdd

1

SCART1 AV

012

3

3

2

0

1

2

3

4

5E6

TV

OUT

10uF

C784

10uF

C779

SIDE AV

A1

A2

A2

A1

10

11

Vee7Vss

VIDEO SWITCH

89

V / R in

BLANK

OPTION

Y / G in

Y / G in

V / R in

BLANK

OPTION

only for scart

C IN

U / B in

CVBS/Y IN

C IN

U / B in

CVBS/Y IN

R707

1K8

1K8

R709

R708

R710

20K

20K

20K

20K

R?

ELECTRO1

OUT R

R?

ELECTRO1

OUT L

Q701

C1815

C707

10uF

AUDIO R out

C708

10uF

AUD IO L ou t

R705

Q702

C1815

R706

REAR AV

ZD711

VIDEO OUT

C774

R IN

10uF

ZD706

R778

ZD709

R780

R777

C719

10uF

75

R715

8V2

8V2

R721

ZD714

75

C777

10uF

C772

10uF

8V2

ZD702

10uF

C716

47K

R702

8V2

ZD701

C785

10uF

ZD707

8V2

R779

75

only for scart

C717

10K

J743

75

R722

8V2

8V2

ZD705

8V2

ZD713

75

R723

R731

820

10uF

47K

R701

8V2

ZD703

S-VHS

P702

V IN

L IN

P701

L

R

TV L

TV L

8V2

8V2

8V2

75

47K

47K

SIDE AV IN

AV SWITCH

A5 A5

21

GND

D

VI

17

19

VO

VIG

BL

VOG

15

V / R

BG

13

NC

RGND

Y / G

11

NC

9

OPT

GGND

5

7

L in

GND

U / B

BGND

NO USE

3

LO

1

R in

Y

U

RO

P701 21PIN

P701

V

YUV

V out

L out

P701

AV OUT

R out

21

GND

20

19

V inVOVIG

18

17

VOG

BL

16

14

BG

13

15

R

RG

NC

12

10

9

11

NC

G

GG

6

8

LI

5

7

OPT

B

BG

4

GND

LO

2

RI

1

3

P701 21PIN

RO

1 2 3 4

NO USE

2

4

6

8

10

12

14

16

18

20

5800-A5P190-00

C

B

A

Circuit Diagrams and PWB Layouts

Mono Carrier: Tone Control (Optional)

1 2345678910

EN 16SK5.0A CA 7.

SCL

+8V_VCC

+8V_VCC

A6 A6

TONE CONTROL

A

AUDIO R

AUDIO L

AUDIO R

AUDIO L

SDA

SCL

SDA

R748

0

A7

Audion Amplifier

B

R OUT

L OUT

IC740

C

D

E

F

13K

R743

5n6

15nF

15nF

C748

0.15uF

C746

C745

68nF

C744

C743

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

SDA

LOUT_L

C_TL

N.C.

C_BL2

C_BL1

LIN_L

MOUT_L

MAD

SCOUT_L

C_PS2

AIN_L

C_PS1

AIN_R

P2

SCIN_R

TDA9859

SCL

LOUT_R

C_TR

N.C.

C_BR2

C_BR1

LIN_R

MOUT_R

GND

SCOUT_R

V_P

MIN_R

C_SMO

MIN_L

P1

SCIN_L

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

6n8

0.15uF/63V

68nF

C753

C754

100uF/16V

C752

R742

13K

ZD715

8V2

C740

A

B

C

D

E

F

G

5800-A5P190-00

12345

678910

H_17220_006.eps

180607

G

Circuit Diagrams and PWB Layouts

Mono Carrier: Audio Amplifier

EN 17SK5.0A CA 7.

321

A7 A7

D

C

AUDIO AMPLIFIER

+8V_VCC

MUTE

PWM

+8V_VCC

MUTE

PWM

D763 IN4148

R137

1K

R763

15K

R766

47K

D761

1N4148

C760

10uF/16V

R OUT

R764

10K

Q760

A1015

D762

1N4148

Q761

C1815

C750

R765

1K

1uF

C728

100uF

R768

100K

R770 1K

RI

IC760

2

1

RO

3

C764

47uF

4

L in

6

5

C761

1uF

7

C767

220uF

8

R771

10K

L out

TFA9843AJ---10W

9

TFA 9842AJ---6W

C769

470uF

C768

470uF

Lout

SW2

Rout

CN760

1

2

1

2

SW2

SPL

4RM 10W

8RM 6W

SPR

4RM 10W

8RM 6W

50V

4

D

C

B

A

5800-A5P190-00

L OUT

+20V_VCC

1 2

+20V_VCC

Tone Control

A6

Pin 18

Pin 15

IC740 TDA9859

C749

1uF

R769 1K

C765

4700PF

C766

4700PF

B

A

H_17220_007.eps

180607

34

Loading...

Loading...