Philips SDI PDP Repair Manual

Colour Television Module

SDI PDP Repair Manual

S37SD-YD02 (37-inch SD v4)

S42SD-YD05, YD06, YD07 (42-inch SD v2, v3, v4)

S42AX-XD02, YD01 (42-inch HD v3, v4)

S50HW-XD03, XD04 (50-inch HD v3, v4)

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 15

3. Directions For Use 16

4. Mechanical Instructions 17

5. Service Modes, Error Codes, and Fault Finding 25

6. Block Diagrams, Test Point Overview, and

Waveforms 40

7. Circuit Diagrams and PWB Layouts 51

8. Alignments 52

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 71

10. Spare Parts List 72

11. Revision List 77

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by MW 0663 TV Service Printed in the Netherlands Subject to modification EN 3122 785 14993

EN 2 SDI PDP1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 PDP Overview

1.2 Serial Numbers

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different model executions.

• Specifications are indicative (subject to change).

1.1 PDP Overview

Table 1-1 PDP overview

PDP Type/Version Model Name H x V Pixel

1 37” SD v4 S37SD-YD02 852 x 480

2 42” SD v2 S42SD-YD06 852 x 480

3 42” SD v3 S42SD-YD05 852 x 480

4 42” SD v4 S42SD-YD07 852 x 480

5 42” HD v3 S42AX-XD02 1024 x 768

6 42” HD v4 S42AX-YD01 1024 x 768

7 50” HD v3 S50HW-XD03 1366 x 768

8 50” HD v4 S50HW-XD04 1366 x 768

Table 1-2 PDP vs Chassis overview

Display type Model # Chassis Chassis Manual #

37" SD v4 37PF9936/37 LC4.7U 3122 785 14742

37" SD v4 37PF9946/12 LC4.7E 3122 785 14722

37" SD v4 37PF9946/69 LC4.7A 3122 785 14761

42" SD v2 420P20/00 FM242 3122 785 14130

42" SD v2 42FD9925/01 FM242 3122 785 14130

42" SD v2 42FD9935/17 FM242 3122 785 14130

42" SD v2 42FD9935/93S FM242 3122 785 14130

42" SD v2 42FD9945/01 FM242 3122 785 14130

42" SD v2 42FD9953/17, /69, /93 FM242 3122 785 14130

42" SD v2 42HF9953/12Z FM24_AB 3122 785 13890

42" SD v2 42PF9936/37 FTP1.1U 3122 785 14381

42" SD v2 42PF9945/12 FTP1.1E 3122 785 14370

42" SD v2 42PF9945/69, /79, /98 FTP1.1U 3122 785 14381

42" SD v2 42PF9955/12 F21RE 3122 785 13890

42" SD v3 42PF9936D/37 LC4.7U 3122 785 14742

42" SD v3 42PF9946/12 LC4.7E 3122 785 14722

42" SD v3 42PF9946/79, /93, /98 LC4.7A 3122 785 14761

42" SD v3 42PF9956/12 FTP2.2E 3122 785 14651

42" SD v3 42PF9956/93 FTP2.2A 3122 785 14680

42" SD v4 42PF7320/10 LC4.9E 3122 785 15431

42" SD v4 42PF7320/79, /98 LC4.9A 3122 785 15450

42" HD v3 42PF9966/37 FTP2.2U 3122 785 14662

42" HD v3 42PF9966/79, /93, /98 FTP2.2A 3122 785 14680

42" HD v3 42PF9976/37 FTP2.2U 3122 785 14662

42" HD v4 42HF7543/37 BP2.3HU 3122 785 15900

42" HD v4 42PF7320A/37 BP2.3U 3122 785 15541

42" HD v4 42PF7520D/10 LC4.9E_AB 3122 785 15670

42" HD v4 42PF9630/78 FTP2.4L 3122 785 15470

42" HD v4 42PF9630A/37 BP2.2U 3122 785 15541

42" HD v4 42PF9630A/96 BP2.2U 3122 785 15541

42" HD v4 42PF9966/79, /98 FTP2.4A 3122 785 15470

50" HD v3 50PF9956/37 FTP2.2U 3122 785 14662

50" HD v3 50PF9966/12 FTP2.2E 3122 785 14651

50" HD v3 50PF9966/37 FTP2.2U 3122 785 14662

50" HD v3 50PF9966/69, /93 FTP2.2A 3122 785 14680

50" HD v4 50HF7543/37 BP2.3HU 3122 785 15900

50" HD v4 50PF7320/10 LC4.9E 3122 785 15431

50" HD v4 50PF7320/79, /93, /98 LC4.9A 3122 785 15450

50" HD v4 50PF9630/78 LC4.9L 3122 785 15450

50" HD v4 50PF9630A/96 BP2.2U 3122 785 15541

50" HD v4 50PF9830A/37 BP2.1U 3122 785 15541

50" HD v4 50PF9966/79 FTP2.4A 3122 785 15470

50" HD v4 50PF9967D/10 FTP2.4E_AB 3122 785 15740

In above table the link is given between the SDI Plasma Display

Panel and the Philips TV chassis (incl. chassis manual no.).

1.1.1 37” SD v4

Serial number label

Figure 1-1 External view (37” SD v4)

Figure 1-2 Points of screw mount (37” SD v4)

No Item Specification 37” SD v4

1 Pixel 852 (H) x 480 (V) pixels

2 Number of Cells 2556 (H) x 480 (V)

3 Pixel Pitch 0.960 mm (H) x 0.960 mm (V)

4 Cell Pitch R 0.320 (H) mm

5 Display size 817.92 (H) x 460.80 mm (V)

6 Screen size Diagonal 37" Colour Plasma

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50%

10 Dimensions 982 (W) x 582 (H) x 52.9 (D) mm

11 Weight Module 1 About 15.5 kg

12 Broadc. reception

Vertical frequency

Video/Logic Interface

Voltage label Panel module label

F_14991_049.eps

251005

(1 pixel = 1 R,G,B cells)

0.960 (V) mm

G 0.320 (H) mm

0.960 (V) mm

B 0.320 (H) mm

0.960 (V) mm

Display Module

and greater brightness

perpendicular to PDP module)

60/50 Hz, LVDS

Technical Specifications, Connections, and Chassis Overview

EN 3SDI PDP 1.

1.1.2 42" SD v2

Figure 1-3 External view (42” SD v2)

Serial number Model label Voltage label

1.1.3 42" SD v3

Serial number label Model label Voltage label

Figure 1-5 External view (42” SD v3)

This figure is not (yet) available

F_14991_035.eps

061005

Figure 1-4 Points of screw mount (42” SD v2)

No Item Specification 42” SD v2

1 Pixel 852 (H) x 480 (V) pixels

2 Number of Cells 2556 (H) x 480 (V)

3 Pixel Pitch 1.095 mm (H) x 1.110 mm (V)

4 Cell Pitch R 0.324 (H) mm

5 Display size 932.940 (H) x 532.800(V) mm

6 Screen size Diagonal 42" Colour Plasma

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50%

10 Dimensions 982 (W) x 582 (H) x 52.9 (D) mm

11 Weight Module 1 About 16.6 kg

12 Broadc. reception

Vertical frequency

Video/Logic Interface

(1 pixel = 1 R,G,B cells)

1.110 (V) mm

G 0.365 (H) mm

1.110 (V) mm

B 0.406 (H) mm

1.110 (V) mm

Display Module

and greater brightness

perpendicular to PDP module)

60/50 Hz, LVDS

Figure 1-6 Points of screw mount (42” SD v3)

No Item Specification 42” SD v3

1 Pixel 852 (H) x 480 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 2556 (H) x 480 (V)

3 Pixel Pitch 1.095 mm (H) x 1.110 mm (V)

4 Cell Pitch R 0.365 (H) mm

1.110 (V) mm

G 0.365 (H) mm

1.110 (V) mm

B 0.365 (H) mm

1.110 (V) mm

5 Display size 932.940 (H) x 532.800(V) mm

6 Screen size Diagonal 42" Colour Plasma

Display Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular

to PDP module)

10 Dimensions 982 (W) x 582 (H) x 52.9 (D) mm

11 Weight Module 1 About 16.6 kg

12 Broadc. reception

60/50 Hz, LVDS

Vertical frequency

Video/Logic Interface

EN 4 SDI PDP1.

Technical Specifications, Connections, and Chassis Overview

1.1.4 42" SD v4

Figure 1-7 External view (42” SD v4)

Serial no.

Voltage label

Panel module label

F_14991_003.eps

1.1.5 42" HD v3

Serial number label Panel model labelVoltage label

180705

Figure 1-9 External view (42” HD v3)

F_14991_005.eps

180705

Figure 1-8 Points of screw mount (42” SD v4)

No Item Specification 42” SD v4

1 Pixel 852 (H) x 480 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 2556 (H) x 480 (V)

3 Pixel Pitch 1.095 (H) mm x 1.110 (V) mm

4 Cell Pitch R 0.365 (H) mm x

1.110 (V) mm

G 0.365 (H) mm x

1.110 (V) mm

B 0.365 (H) mm x

1.110 (V) mm

5 Display size 932.940 (H) x 532.800(V) mm

6 Screen size Diagonal 42" Colour Plasma Dis-

play Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular

to PDP module)

10 Dimensions 982 (W) x 582 (H) x 54 (D) mm

11 Weight Module 1 About 15.4 kg

14 Broadc. reception

60 Hz/ 50 Hz, LVDS

Vertical frequency

Video/Logic Interface

Figure 1-10 Points of screw mount (42” HD v3)

No Item Specification 42” HD v3

1 Pixel 1.024 (H) x 768 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 3072 (H) x 768 (V)

3 Pixel Pitch 0.912mm (H) x 0.693mm (V)

4 Cell Pitch R Horizontal 0.304 mm

Vertical 0.693 mm

G Horizontal 0.304 mm

Vertical 0.693 mm

B Horizontal 0.304 mm

Vertical 0.693 mm

5 Display size 932.940 (H) x 532.800(V) mm

6 Screen size Diagonal 42" Colour Plasma

Display Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular

to PDP module)

10 Dimensions 982 (W) x 582 (H) x 52.9 (D) mm

11 Weight Module 1 About 18.0 kg

12 Broadc. reception

60/50 Hz, LVDS

Vertical frequency

Video/Logic Interface

Technical Specifications, Connections, and Chassis Overview

EN 5SDI PDP 1.

1.1.6 42" HD v4

Figure 1-11 External view (42” HD v4)

F_14991_010.eps

030805

1.1.7 50" HD v3

Serial Number

Figure 1-13 External view (50” HD v3)

Voltage

label

Panel module label

F_14991_011.eps

030805

Figure 1-12 Points of screw mount (42” HD v4)

No Item Specification 42” HD v4

1 Pixel 1.024 (H) x 768 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 3072 (H) x 768 (V)

3 Pixel Pitch 0.912mm (H) x 1.110mm (V)

4 Cell Pitch R Horizontal 0.304 mm

Vertical 0.693 mm

G Horizontal 0.304 mm

Vertical 0.693 mm

B Horizontal 0.304 mm

Vertical 0.693 mm

5 Display size 933.98 (H) x 532.220(V) mm

6 Screen size Diagonal 42" Colour Plasma

Display Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours (8-bit)

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular

to PDP module)

10 Dimensions 1000 (W) x 598 (H) x 64.4 (D) mm

11 Weight Module 1 About 20.0 kg

12 Broadc. reception

60/50 Hz, LVDS

Vertical frequency

Video/Logic Interface

Figure 1-14 Points of screw mount (50” HD v3)

No Item Specification 50” HD v3

1 Pixel 1366 (H) x 768 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 4,098 (H) x 768 (V) cells

3 Pixel Pitch 0.810mm (H) mm x 0.810 mm (V)

4 Cell Pitch R Horizontal 0.270mm

Vertical 0.810mm

G Horizontal 0.270mm

Vertical 0.810mm

B Horizontal 0.270mm

Vertical 0.810mm

5 Display size 1106.46 mm (H) x 622.08 mm (H)

6 Screen size Diagonal 50" Colour Plasma

Display Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular to

PDP module)

10 Dimensions 1184 (W) x 700 (H) x 60.1 (D) mm

11 Weight Module 1 About 18.0 kg

12 Broadc. reception

60/50 Hz, LVDS

Vertical frequency

Video/Logic Interface

EN 6 SDI PDP1.

Technical Specifications, Connections, and Chassis Overview

1.1.8 50" HD v4

Figure 1-15 External view (50” HD v4)

Serial No.

Volt age label

Panel module label

F_14991_012.eps

030805

1.2 Serial Numbers

ڞڞۇڼێێ ڌڏ ڿۄۂۄۏێ

ڤڟ گ۔ۋۀ

ڤڟ

ڨۀڼۉۄۉۂ

j

Area

ྙ ڜۍۀڼ ڃڞڕ ڞۃۀۊۉڼۉ ڇ ڮ ڕ ڮ ۃۀۉەۀۉڄ

ྚ ڨۊڿۀۇ ڕ ڎ ڿۄۂۄۏ

ྛ ڨۊڿېۇۀ ڧۄۉۀ ڕ ڜ ۙ ڵ

ྜ ڴۀڼۍ ڕ ڌ ڟۄۂۄۏ ژڙ ڭۊۏڼۏۀ ۀۑۀۍ۔ ڿۀھڼڿۀێ

ྜྷ ڨۊۉۏۃ ڃڣۀۓڕ ڌ ڟۄۂۄۏ ژڙ ڪھۏ ڈ ڜ ڇ کۊۑ ڈ ڝڇ ڟۀھ ڈ ڞڄ

ྞ ڟڼۏۀ ڕ ڌ ۙ ڎڌ

ྟ ڲۊۍۆۀۍ ڢۊېۍۋ ڕ ڜ ګڼۍۏڃڟڼ۔ڄڇ ڝ ګڼۍۏڃڜہۏۀۍۉۊۊۉڄڇ ڞ ګڼۍۏڃکۄۂۃۏڄ

2 6 1 4 0 8 07 0 8 6 5

h

WWX

Mod el

[ ` WZ WWWX

Mod ule

Ye ar

Month

Line

Da te

Figure 1-17 Module serial number

h

Worke r

S /N

Gro up

F_14991_004.eps

Serial No : 0001~9999

Date : 01~31

Month : 01~12

Year : 00(2000)

~99(2099)

Line No : 1 ~ 9

(0:Pilot Line)

Type : 02~48

(ex.50HDv3:26)

(Step of even)

180705

F_14991_013.eps

030805

Figure 1-16 Points of screw mount (50” HD v4)

No Item Specification 50” HD v4

1 Pixel 1366 (H) x 768 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 4,098 (H) x 768 (V) cells

3 Pixel Pitch 0.810mm (H) mm x 0.810 mm (V)

4 Cell Pitch R Horizontal 0.270mm

Vertical 0.810mm

G Horizontal 0.270mm

Vertical 0.810mm

B Horizontal 0.270mm

Vertical 0.810mm

5 Display size 1106.46 mm (H) x 622.08 mm (H)

6 Screen size Diagonal 50" Colour Plasma

Display Module

7 Screen aspect 16:9

8 Display colour 16.77 million colours

9 Viewing angle Over 160 deg (angle with 50% and

greater brightness perpendicular

to PDP module)

10 Dimensions 1175 (W) x 682 (H) x 65.5 (D) mm

11 Weight Module 1 About 25.4 kg

12 Broadc. reception

60/50 Hz, LVDS

Vertical frequency

Video/Logic Interface

Figure 1-18 Panel serial number

Technical Specifications, Connections, and Chassis Overview

1.3 Chassis Overview

1.3.1 37” SD v4

EN 7SDI PDP 1.

17

9

20

21

1

2

5

19

3

6 7 8

18

12, 13, 14 15, 1610 11

4

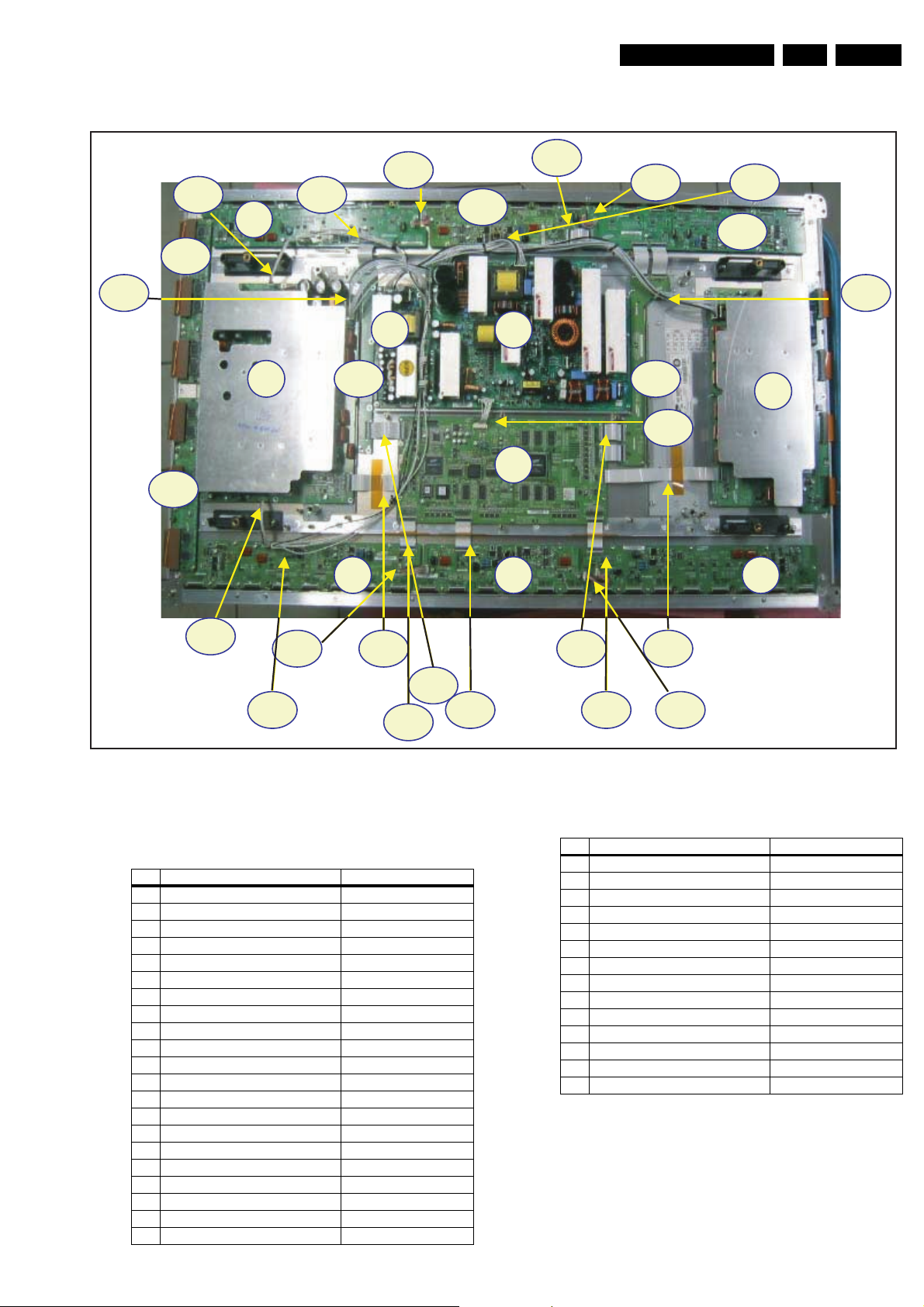

Figure 1-19 PWB location (37” SD v4)

Table 1-3 PWB overview (37” SD v4)

No. Location Name

1 Main PSU Assy PWB PSU

2 SUB-PSU Assy PWB SUB-PSU

3 LOGIC-MAIN Board Assy PWB LOGIC Main

4 X-MAIN Driving Board Assy PWB X Main

5 Y-MAIN Driving Board Assy PWBY Main

6 LOGIC E BUFFER Board Assy PWB Buffer

7 LOGIC F BUFFER Board Assy PWB Buffer

8 LOGIC G BUFFER Board Assy PWB Buffer

9 Y-BUFFER Board Assy PWB Buffer

10 LOGIC + Y-MAIN FFC Cable-flat

11 LOGIC + X-MAIN FFC Cable-flat

12 LOGIC + LOGIC BUF(E) FFC Cable-flat

13 LOGIC + LOGIC BUF(F) FFC Cable-flat

14 LOGIC + LOGIC BUF(G) FFC Cable-flat

15 LOGIC BUF(E) + LOG. BUF(F) Lead connector

16 LOGIC BUF(F) + LOG. BUF(G) Lead connector

17 PSU + SUB PSU Lead connector

18 PSU + LOGIC BUF(E) Lead connector

19 PSU + LOGIC MAIN Lead connector

20 PSU + Y-MAIN Lead connector

F_14991_027.eps

030805

EN 8 SDI PDP1.

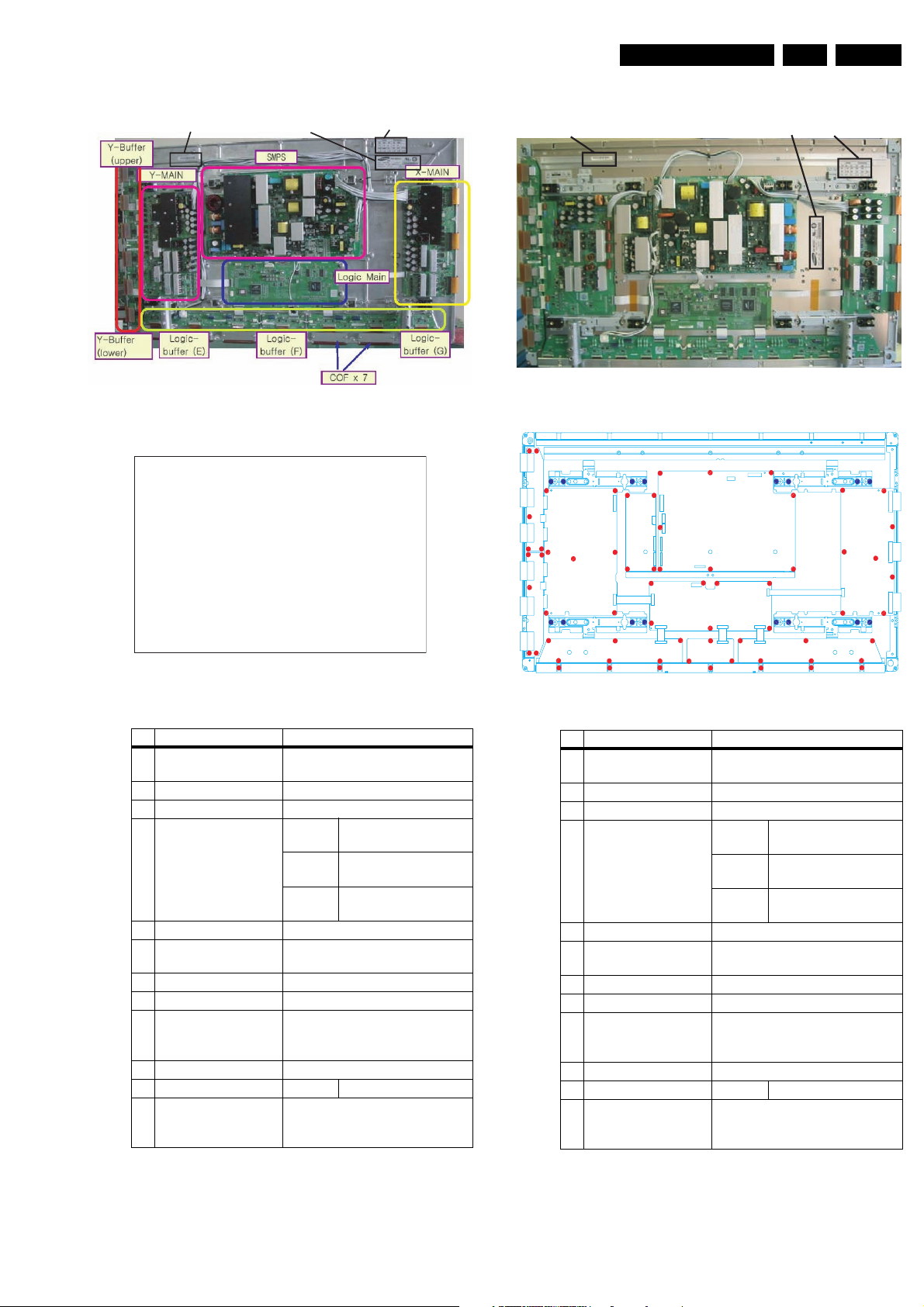

1.3.2 42” SD v2

Y- B uffer

(upper)

Y- MAIN

Technical Specifications, Connections, and Chassis Overview

ڮڨګڮ

X- MAIN

Logic Main

ogic -

Y- B uffer

(lower)

Table 1-4 PWB overview (42” SD v2)

No. Location Name

1 info not available

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

L

buffe r (E )

Logic-

buffe r (F)

Figure 1-20 PWB location (42” SD v2)

C O

F x

Logic

-

buffe r (G)

7

F_14991_033.eps

061005

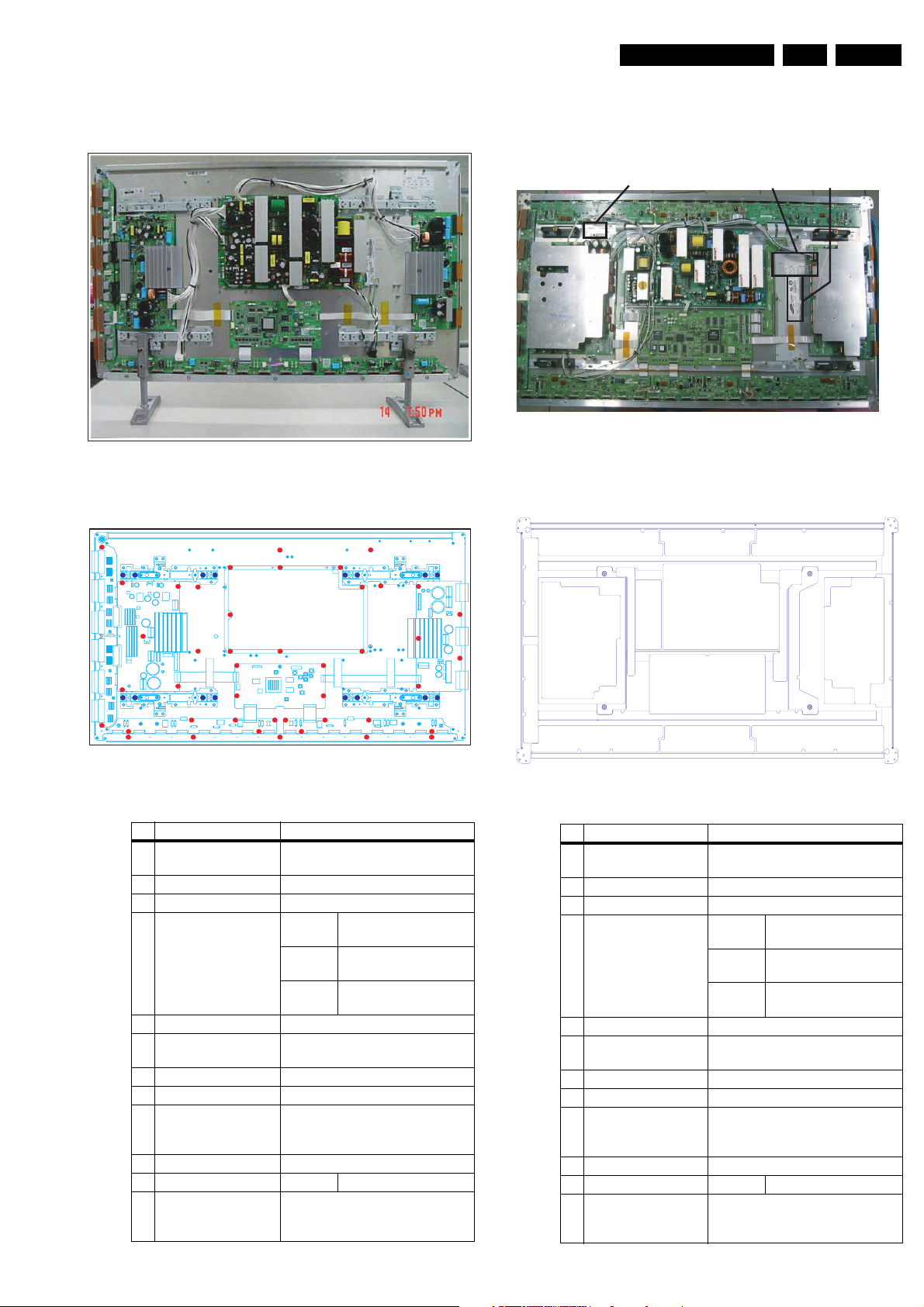

1.3.3 42” SD v3

Technical Specifications, Connections, and Chassis Overview

EN 9SDI PDP 1.

`G

XW

YXG YY

X_G

X

YG

\G

YW

Z

]G ^ _G

XX XY

X`G

GXZSGX[SGX\ X]SGX^

[G

Figure 1-21 PWB location (42” SD v3)

Table 1-5 PWB overview (42” SD v3)

No. Location Name

1 Main PSU Assy PWB PSU

2 SUB-PSU Assy PWB SUB-PSU

3 LOGIC-MAIN Board Assy PWB LOGIC Main

4 X-MAIN Driving Board Assy PWB X Main

5 Y-MAIN Driving Board Assy PWBY Main

6 LOGIC E BUFFER Board Assy PWB Buffer

7 LOGIC F BUFFER Board Assy PWB Buffer

8 LOGIC G BUFFER Board Assy PWB Buffer

9 Y-BUFFER (UPPER) Board Assy PWB Buffer

10 Y-BUFFER (DOWN) Board Assy PWB Buffer

11 LOGIC + Y-MAIN FFC Cable-flat

12 LOGIC + X-MAIN FFC Cable-flat

13 LOGIC + LOGIC BUF(E) FFC Cable-flat

14 LOGIC + LOGIC BUF(F) FFC Cable-flat

15 LOGIC + LOGIC BUF(G) FFC Cable-flat

16 LOGIC BUF(E) +LOG. BUF(F) Lead connector

17 LOGIC BUF(F) +LOG. BUF(G) Lead connector

18 PSU + SUB PSU Lead connector

19 PSU + LOGIC BUF(E) Lead connector

20 PSU + LOGIC MAIN Lead connector

21 PSU + Y-MAIN Lead connector

22 PSU + X-MAIN Lead connector

F_14991_034.eps

061005

EN 10 SDI PDP1.

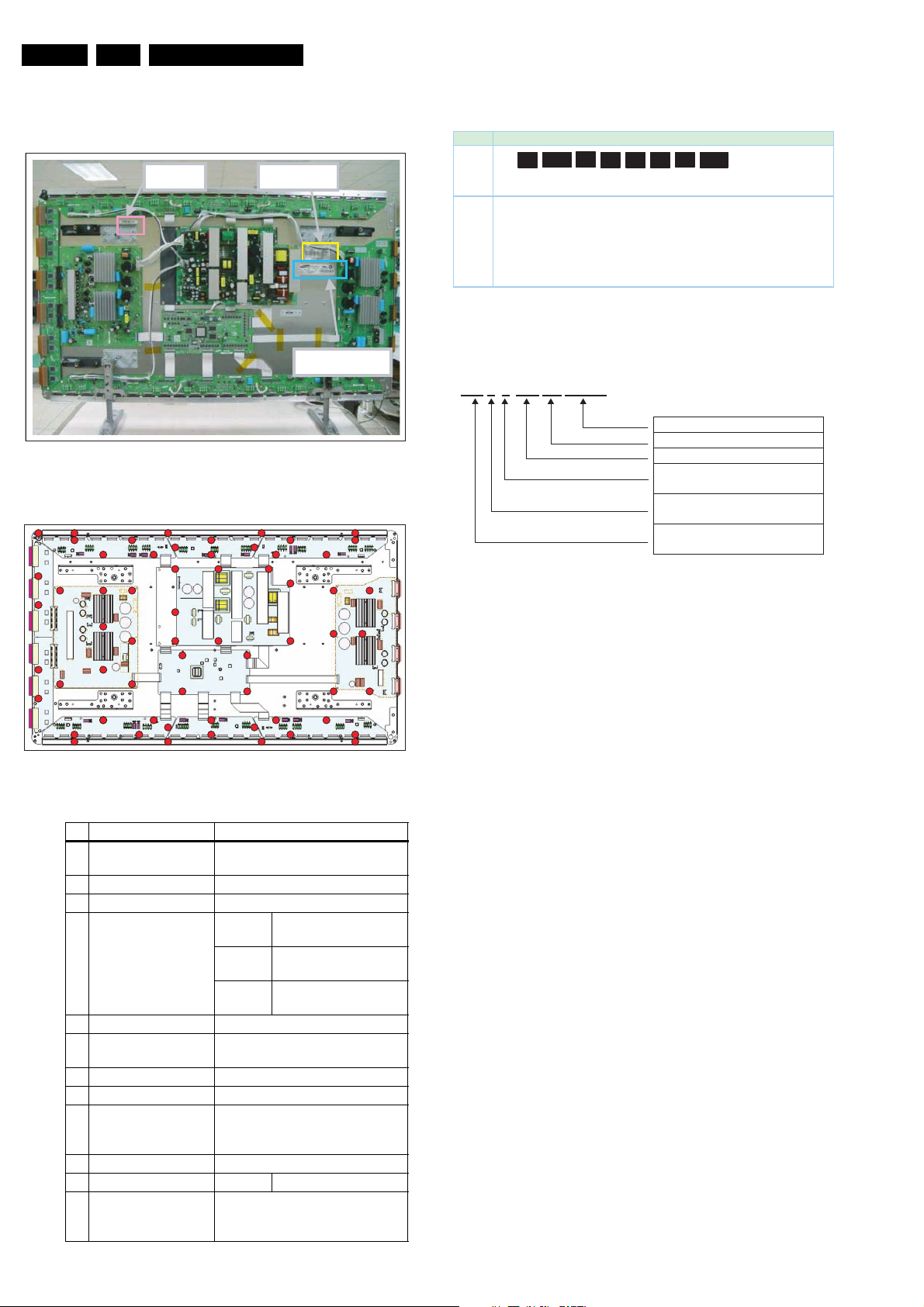

1.3.4 42” SD v4

7

Technical Specifications, Connections, and Chassis Overview

1

16

8

5 6

Figure 1-22 PWB location (42” SD v4)

Table 1-6 PWB overview (42” SD v4)

No. Location Name

1 SMPS SMPS

2 LOGIC-MAIN Board Assy PWB Logic Main

3 X-MAIN Driving Board Assy PWB X Main

4 Y-MAIN Driving Board Assy PWB Y Main

5 LOGIC E BUFFER Board Assy PWB buffer

6 LOGIC F BUFFER Board Assy PWB buffer

7 Y-BUFFER (UPPER) Board Assy PWB buffer

8 Y-BUFFER (DOWN) Board Assy PWB buffer

9 LOGIC + Y-MAIN FFC cable-flat

10 LOGIC + X-MAIN FFC cable-flat

11 LOGIC + LOGIC BUF (E) FFC cable-flat

12 LOGIC + LOGIC BUF (F) FFC cable-flat

13 LOGIC BUF (E) + (F) Lead connector

14 SMPS + LOGIC BUF (E) Lead connector

15 SMPS + LOGIC MAIN Lead connector

16 SMPS + Y-MAIN Lead connector

17 SMPS + X-MAIN Lead connector

3

174

2

15

10 9 11 121314

F_14991_001.eps

180705

1.3.5 42” HD v3

Technical Specifications, Connections, and Chassis Overview

EN 11SDI PDP 1.

8

9

5

18 21

14 15

1

2

4

20

17

3

20

11

22

6

7

10

19

13

Figure 1-23 PWB location (42” HD v3)

Table 1-7 PWB overview (42” HD v3)

No. Location Name

1 Main PSU Assy PWB PSU

2 SUB-PSU Assy PWB SUB-PSU

3 LOGIC-MAIN Board Assy PWB LOGIC Main

4 X-MAIN Driving Board Assy PWB X Main

5 Y-MAIN Driving Board Assy PWB Y Main

6 LOGIC E BUFFER Board Assy PWB Buffer

7 LOGIC F BUFFER Board Assy PWB Buffer

8 Y-BUFFER (UPPER) Board Assy PWB BuffeR

9 Y-BUFFER (DOWN) Board Assy PWB Buffer

10 LOGIC + Y-MAIN FFC Cable-flat

11 LOGIC + X-MAIN FFC Cable-flat

12 LOGIC + LOG. BUF(E) (Down) FFC Cable-flat

13 LOGIC + LOG. BUF(F) (Down) FFC Cable-flat

14 LOGIC + LOGIC BUF(E) (Up) FFC Cable-flat

15 LOGIC + LOGIC BUF(E) (Up) FFC Cable-flat

16 LOGIC BUF(E) + LOG. BUF(F) Lead connector

17 PSU + SUB PSU Lead connector

18 PSU + LOGIC BUF(E) (UP) Lead connector

19 PSU + LOGIC BUF(E) (Down) Lead connector

20 PSU + LOGIC MAIN Lead connector

21 PSU + Y-MAIN Lead connector

22 PSU + X-MAIN Lead connector

12

16

F_14991_014.eps

030805

EN 12 SDI PDP1.

1.3.6 42” HD v4

Technical Specifications, Connections, and Chassis Overview

Y

Figure 1-24 PWB location (42” HD v4)

Table 1-8 PWB overview (42” HD v4)

No. Location Name

1 SMPS SMPS

2 LOGIC-MAIN Board Assy PWBLOGIC Main

3 X-MAIN Driving Board Assy PWBX Main

4 Y-MAIN Driving Board Assy PCBY Main

5 LOGIC E BUFFER Board Assy PWB Buffer

6 LOGIC F BUFFER Board Assy PWB Buffer

7 Y-BUFFER (UPPER) Board Assy PWB Buffer

8 Y-BUFFER (DOWN) Board Assy PWB Buffer

9 LOGIC + Y-MAIN FFC Cable-flat

10 LOGIC + X-MAIN FFC Cable-flat

11 LOGIC + LOGIC BUF(E) FFC Cable-flat

12 LOGIC + LOGIC BUF(F) FFC Cable-flat

13 LOGIC BUF(E) + LOG. BUF(F) Lead connector

14 SMPS + LOGIC BUF(E) Lead connector

15 SMPS + LOGIC MAIN Lead connector

16 SMPS + Y-MAIN Lead connector

17 SMPS + X-MAIN Lead connector

F_14991_015.eps

030805

1.3.7 50” HD v3

Technical Specifications, Connections, and Chassis Overview

EN 13SDI PDP 1.

20

27

35

11

28 32

9

26

10

12

33 34

2 1

5 14 15

4

30

3

13

6 7 8

29

24

16

19

31 23 25

Table 1-9 PWB overview (50” HD v3)

No. Location Name

1 Main PUS Assy PWBPSU

2 SUB-PSU Assy PWBSUB-PSU

3 LOGIC-MAIN Board Assy PWBLOGIC Main

4 X-MAIN Driving Board Assy PWBX Main

5 Y-MAIN Driving Board Assy PCBY Main

6 LOGIC E BUFFER Board Assy PWB Buffer

7 LOGIC F BUFFER Board Assy PWB Buffer

8 LOGIC G BUFFER Board Assy PWB Buffer

9 LOGIC H BUFFER Board Assy PWB Buffer

10 LOGIC I BUFFER Board Assy PWB Buffer

11 LOGIC J BUFFER Board Assy PWB Buffer

12 Y-BUFFER (UPPER) Board Assy PWB Buffer

13 Y-BUFFER (DOWN) Board Assy PWB Buffer

14 SUB-R Assy PWB Buffer

15 SUB-L Assy PWB Buffer

16 LOGIC + Y-MAIN FFC Cable-flat

17 LOGIC + X-MAIN FFC Cable-flat

18 SUB R + LOGIC FFC Cable-flat

19 SUB L + LOGIC FFC Cable-flat

20 LOG.BUF(I) + LOG.BUF(J) (Up) FFC Cable-flat

21 LOGIC + LOG. BUF(E) (Down) FFC Cable-flat

21

Figure 1-25 PWB location (50” HD v3)

18 17

22

F_14991_016.eps

030805

No. Location Name

22 LOGIC + LOG. BUF(F) (Down) FFC Cable-flat

23 LOGIC + LOG. BUF(G) (Down) FFC Cable-flat

24 LOGIC BUF(E) + LOG. BUF(F) Lead connector

25 LOGIC BUF(F) + LOG. BUF(G) Lead connector

26 LOGIC BUF(H) + LOG. BUF(I) Lead connector

27 LOGIC BUF(I) + LOG. BUF(J) Lead connector

28 Y-MAIN + LOGIC BUF(H) Lead connector

29 Y-MAIN + LOGIC BUF(E) Lead connector

30 PSU + LOGIC MAIN Lead connector

31 PSU + LOGIC BUF(E) Lead connector

32 PSU + LOGIC BUF(H) Lead connector

33 PSU + Y-MAIN Lead connector

34 PSU + X-MAIN Lead connector

35 PSU + SUB PSU Lead connector

EN 14 SDI PDP1.

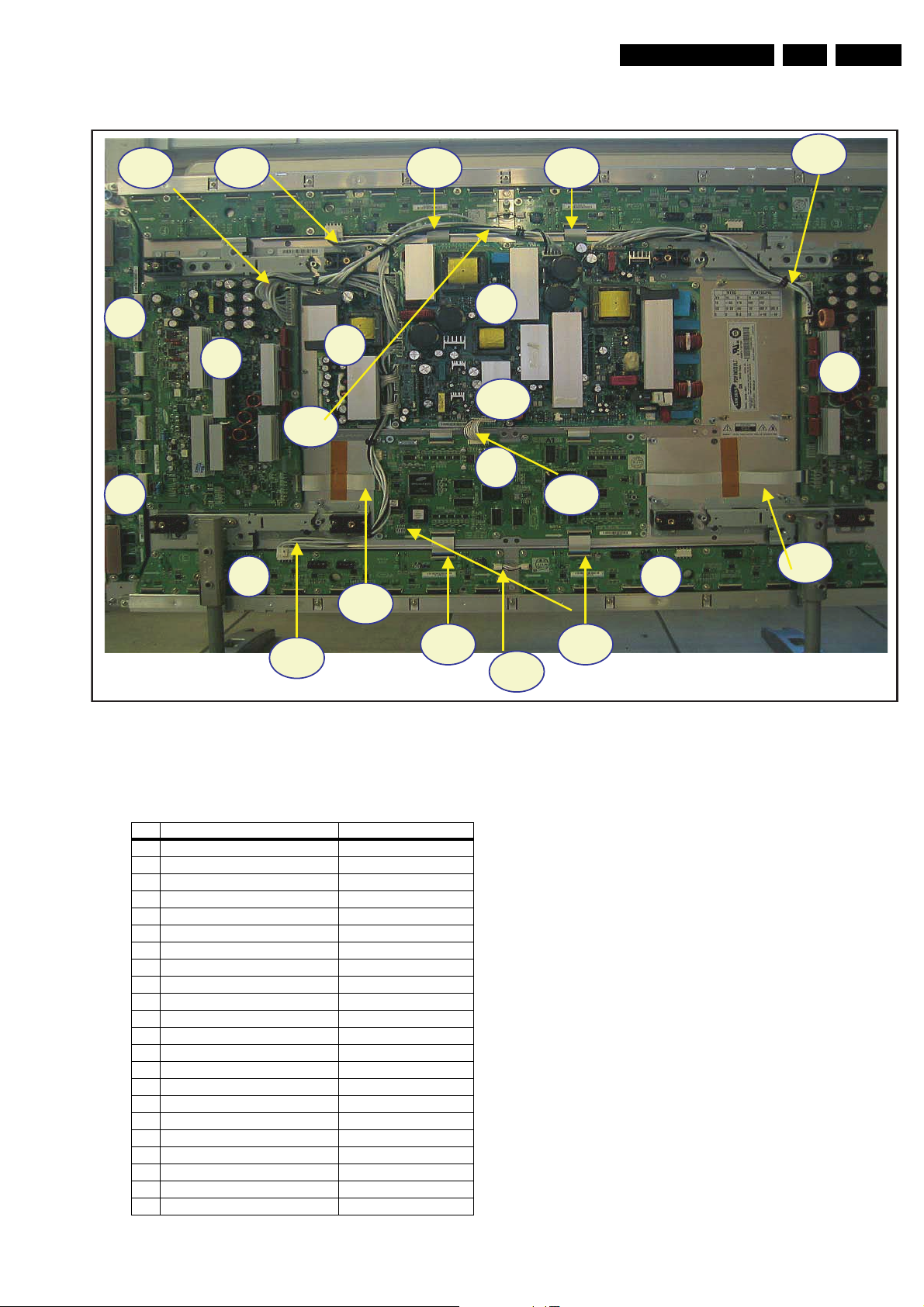

1.3.8 50” HD v4

Technical Specifications, Connections, and Chassis Overview

8

9

20

7

5

4

21

15 16

6

23

2

19

6

1918

17

7

1

24

3

22

18

5

10 12 14

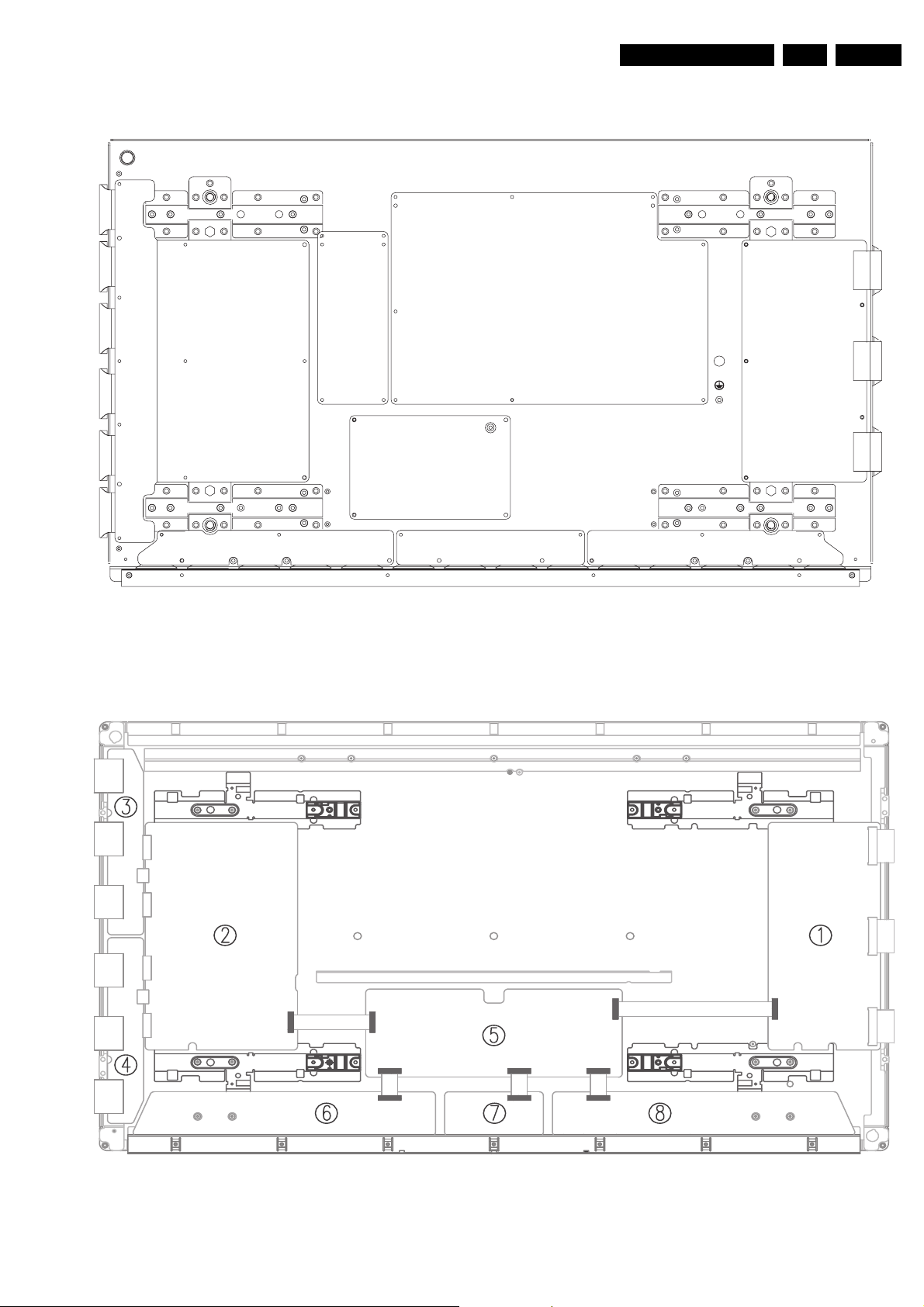

Figure 1-26 PWB location (50” HD v4)

Table 1-10 PWB overview (50” HD v4)

No. Location Name

1 SMPS SMPS

2 LOGIC-MAIN Board Assy PWBLOGIC Main

3 X-MAIN Driving Board Assy PWBX Main

4 Y-MAIN Driving Board Assy PCBY Main

5 LOGIC E BUFFER Board Assy PWB Buffer

6 LOGIC F BUFFER Board Assy PWB Buffer

7 LOGIC G BUFFER Board Assy PWB Buffer

8 Y-BUFFER (Upper) Board Assy PWB Buffer

9 Y-BUFFER (Down) Board Assy PWB Buffer

10 LOGIC + Y-MAIN FFC Cable-flat

11 LOGIC + X-MAIN FFC Cable-flat

12 LOGIC + LOG. BUF(G: Down) FFC Cable-flat

13 LOGIC + LOG. BUF(F: Down) FFC Cable-flat

14 LOGIC + LOG. BUF(E: Down) FFC Cable-flat

15 LOGIC + LOG. BUF(E: Upper) FFC Cable-flat

16 LOGIC + LOG. BUF(F: Upper) FFC Cable-flat

17 LOGIC + LOG. BUF(G: Upper) FFC Cable-flat

18 LOGIC BUF(E) + LOG. BUF(F) Lead connector

19 LOGIC BUF(F) + LOG. BUF(G) Lead connector

20 SMPS + LOGIC BUF(G: Down) Lead connector

21 SMPS + LOGIC BUF(E: Upper) Lead connector

22 SMPS + LOGIC MAIN Lead connector

23 SMPS + Y-MAIN Lead connector

24 SMPS + X-MAIN Lead connector

13

11

F_14991_017.eps

030805

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 15SDI PDP 2.

Index of this chapter:

2.1 Handling Precautions

2.2 Safety Precautions

2.3 Notes

Notes:

• Only authorised persons should perform servicing of this

module.

• When using/handling this unit, pay special attention to the

PDP Module: it should not be enforced into any other way

then next rules, warnings, and/or cautions.

• "Warning" indicates a hazard that may lead to death or

injury if the warning is ignored and the product is handled

incorrectly.

• "Caution" indicates a hazard that can lead to injury or

damage to property if the caution is ignored and the

product is handled incorrectly.

2.1 Handling Precautions

• The PDP module use high voltage that is dangerous to

humans. Before operating the PDP, always check for dust

to prevent short circuits. Be careful touching the circuit

device when power is “on”.

• The PDP module is sensitive to dust and humidity.

Therefore, assembling and disassembling must be done in

no dust place.

• The PDP module has a lot of electric devices. The service

engineer must wear equipment (for example, earth ring) to

prevent electric shock and working clothes to prevent

electrostatic.

• The PDP module use a fine pitch connector which is only

working by exactly connecting with flat cable. The operator

must pay attention to a complete connection when

connector is reconnected after repairing.

• The capacitor’s remaining voltage in the PDP module’s

circuit board temporarily remains after power is “off”.

Operator must wait for discharging of remaining voltage

during at least 1 minute.

2.2 Safety Precautions

2.2.1 Safety Precautions

parts and circuit board. Check the cord of AC power

preparing damage.

• Product Safety Mark: Some of electric or implement

material have special characteristics invisible that was

related on safety. In case of the parts are changed with new

one, even though the Voltage and Watt is higher than

before, the Safety and Protection function will be lost.

• The AC power always should be turned “off”, before next

repair.

• Check assembly condition of screw, parts and wire

arrangement after repairing. Check whether the material

around the parts get damaged.

2.2.2 ESD Precautions

There are parts, which are easily damaged by electrostatics

(for example Integrated Circuits, FETs, etc.) Electrostatic

damage rate of product will be reduced by the following

technics:

• Before handling semiconductor parts/assembly, must

remove positive electric by ground connection, or must

wear the antistatic wrist-belt and ring (it must be operated

after removing dust on it. It comes under precaution of

electric shock).

• After removing the assembly, lay it with the tracks on a

conductive surface to prevent charging.

• Do not use chemical stuff containing Freon. It generates

positive electric that can damage ESD sensitive devices.

• You must use a soldering device for ground-tip when

soldering or de-soldering these devices.

• You must use anti-static solder removal device. Most

removal devices do not have antistatic which can charge a

enough positive electric enough for damaging these

devices.

• Before removing the protective material from the lead of a

new device, bring the protective material into contact with

the chassis or assembly.

• When handing an unpacked device for replacement, do not

move around too much. Moving (legs on the carpet, for

example) generates enough electrostatic to damage the

device.

• Do not take a new device from the protective case until the

it is ready to be installed. Most devices have a lead, which

is easily short-circuited by conductive materials (such as

conductive foam and aluminium)

• Before replacing a board, discharge forcibly.

• The remaining electricity from board.

• When connecting FFC and TCPs to the module, recheck

that they are perfectly connected.

• To prevent electrical shock, be careful not to touch leads

during circuit operations.

• To prevent the Logic circuit from being damaged due to

wrong working, do not connect/disconnect signal cables

during circuit operations.

• Do thoroughly adjustment of a voltage label and voltageinsulation.

• Before reinstalling the chassis and the chassis assembly,

be sure to use all protective stuff including a nonmetal

controlling handle and the covering of partitioning type.

• Caution for design change: Do not install any additional

devices to the module, and do not change the electrical

circuit design.

• For example: Do not insert a subsidiary audio or video

connector. If you insert It, it cause danger on safety. And, if

you change the design or insert, manufacturer guarantee

will be not effect.

• If any parts of wire is overheats of damaged, replace it with

a new specified one immediately, and identify the cause of

the problem and remove the possible dangerous factors.

• Examine carefully the cable status if it is twisted or

damaged or displaced. Do not change the space between

2.3 Notes

A glass plate is positioned before the plasma display. This

glass plate can be cleaned with a slightly humid cloth. If due to

circumstances there is some dirt between the glass plate and

the plasma display panel, it is recommended to do some

maintenance by a qualified service employee only.

2.3.1 Safe PDP Handling

• The work procedures shown with the “Note” indication are

important for ensuring the safety of the product and the

servicing work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient working space.

• At all times, other than when adjusting and checking the

product, be sure to turn “off” the main POWER switch and

disconnect the power cable from the power source of the

display (jig or the display itself) during servicing.

• To prevent electric shock and breakage of PWBs, start the

servicing work at least 30 seconds after the main power

has been turned “off”. Especially when installing and

removing the Power Supply PWB and the SUS PWB in

which high voltages are applied, start servicing at least 2

minutes after the main power has been turned “off”.

EN 16 SDI PDP3.

Directions For Use

• While the main power is “on”, do not touch any parts or

circuits other than the ones specified. The high voltage

Power Supply block within the PDP module has a floating

ground. If any connection other than the one specified is

made between the measuring equipment and the high

voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

• When installing the PDP module in, and removing it from

the packing carton, be sure to have at least two persons

perform the work while being careful to ensure that the

flexible printed-circuit cable of the PDP module does not

get caught by the packing carton.

• When the surface of the panel comes into contact with the

cushioning materials, be sure to confirm that there is no

foreign matter on top of the cushioning materials before the

surface of the panel comes into contact with the cushioning

materials. Failure to observe this precaution may result in,

the surface of the panel being scratched by foreign matter.

• When handling the circuit PWB, be sure to remove static

electricity from your body before handling the circuit PWB.

• Be sure to handle the circuit PWB by holding the large parts

as the heat sink or transformer. Failure to observe this

3. Directions For Use

Not applicable.

precaution may result in the occurrence of an abnormality

in the soldered areas.

• Do not stack the circuit PWB. Failure to observe this

precaution may result in problems resulting from scratches

on the parts, the deformation of parts, and short-circuits

due to residual electric charge.

• Routing of the wires and fixing them in position must be

done in accordance with the original routing and fixing

configuration when servicing is completed. All the wires are

routed far away from the areas that become hot (such as

the heat sink). These wires are fixed in position with the

wire clamps so that the wires do not move, thereby

ensuring that they are not damaged and their materials do

not deteriorate over long periods of time. Therefore, route

the cables and fix the cables to the original position and

states using the wire clamps.

• Perform a safety check when servicing is completed. Verify

that the peripherals of the serviced points have not

undergone any deterioration during servicing. Also verify

that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in

accordance with the original

4. Mechanical Instructions

Index of this chapter:

4.1 Dis-assembling / Re-assembling

4.1.1 Flexible Printed Circuit of Y-Buffer (Upper and Lower)

4.1.2 Flat Cable Connector of X-main Board

4.1.3 FFC and TCP from Connector

4.1.4 Exchange of LBE, LBF, LBG board

4.1.5 Exchange YBU, YBL and YM board

4.1 Dis-assembling / Re-assembling

4.1.1 Flexible Printed Circuit of Y-Buffer (Upper and Lower)

• Dis-assembly: Pull out the FPC from the connector by

holding the lead of the FPC with both hands.

• Re-assembly: Push the lead of FPC with same force on

both sides into the connector.

Note: Be careful do not to damage the connector pin

during connecting.

Mechanical Instructions

EN 17SDI PDP 4.

Figure 4-1 Dis-assembly FPC of Y-buffer

Figure 4-2 Re-assembly FPC of Y-buffer

EN 18 SDI PDP4.

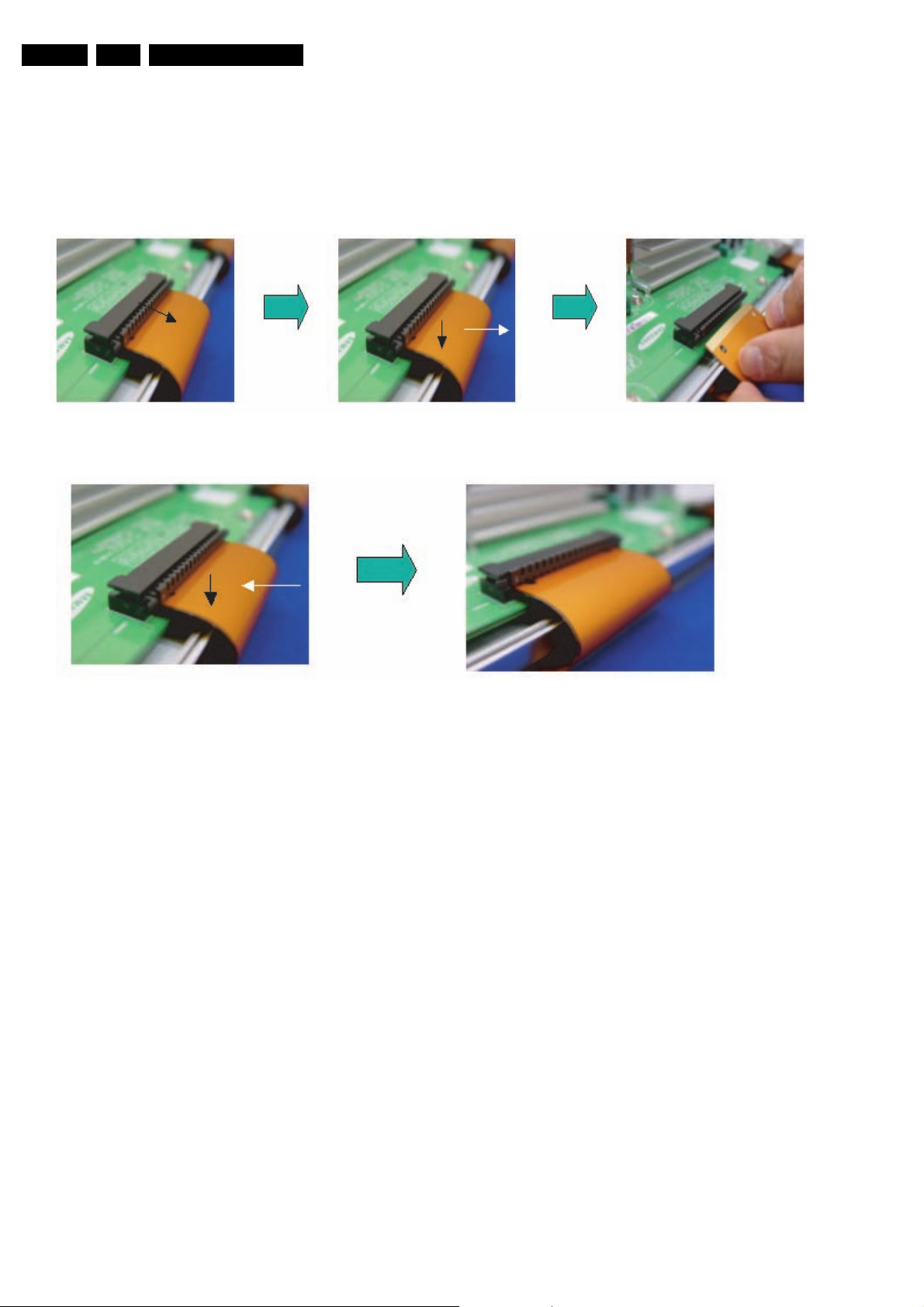

4.1.2 Flat Cable Connector of X-main Board

• Dis-assembly:

1. Pull out the clamp of connector.

2. Pull Flat cable out press down lightly.

3. Turn the Flat Cable reversely.

• Re-assembly: Put the Flat Cable into the connector press

down lightly until locking sound (“Click“) comes out.

Figure 4-3 Dis-assembly FCC of X-main board

Mechanical Instructions

Figure 4-4 Re-assembly FCC of X-main board

4.1.3 FFC and TCP from Connector

• Dis-assembling of TCP:

1. Open the clamp carefully.

2. Pull the TCP out from its connector.

• Re-assembling of TCP:

1. Put the TCP into the connector carefully

2. Close the clamp completely (until “Click” comes out.).

Mechanical Instructions

Notes:

• Checking whether the foreign material is on the connector

• Be careful, do not damage the board by ESD during

Figure 4-5 Dis-assembly of TCP

EN 19SDI PDP 4.

inside before assembling of TCP.

handling of TCP.

Figure 4-6 Re-assembly of TCP

Figure 4-7 Mis-assembly of TCP

The procedure of

assembling and disassembling of

FFC is same as TCP

Figure 4-8 Dis- and re-assembly of FFC

EN 20 SDI PDP4.

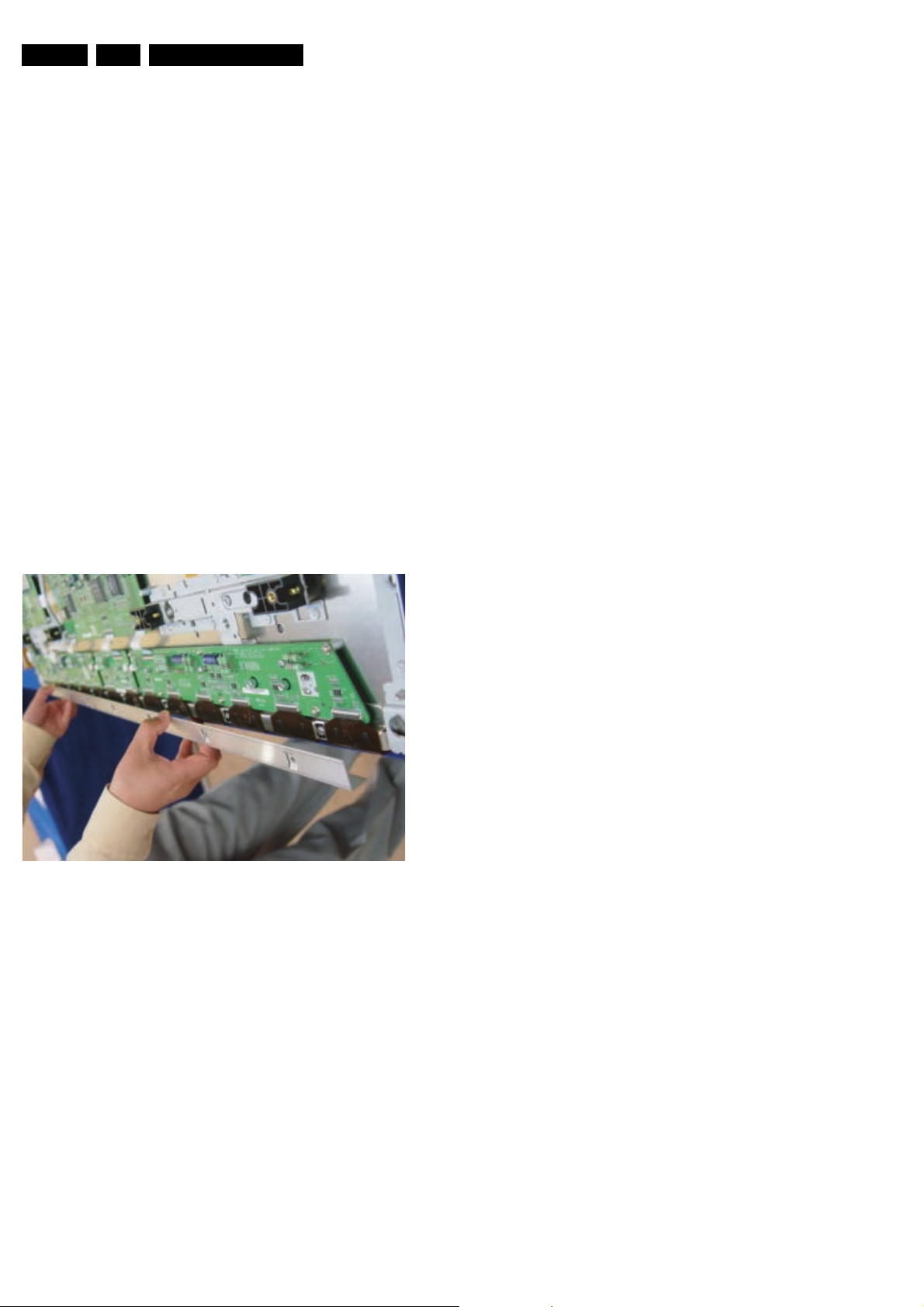

4.1.4 Exchange of LBE, LBF, LBG board

1. Depending on the model (see “Photo 2” per model.):

– 42" SD v3 - Remove the screws in order of 2-3-5-7-1-

4-6 (and 10-11-13-16-9-12-14 for HD) from heat sink

and then remove heat sink (Photo 1).

– 42" SD v4 - Remove the screws in order of 2-4-1-5-3

from heat sink and then remove heat sink (Photo 1).

– 42" HD v3, 37" SD v4, 50" HD v3 - Remove the

screws in order of “Centre - Left Side - Right Side” from

heat sink and then get rid of heat sink (Photo 1).

– 50" HD v4 - Remove the screws in order of 2-3-1-4

from heat sink and then remove heat sink (Photo 1).

2. Remove the TPC, FFC, and power cable from the

connectors.

3. Remove all the screws from the defective board.

4. Remove the defected board.

Note: When replacing the Logic board or Y-main board for

a lead-free (Pb-free) board, always replace them together.

(this is only valid for the 37” SD v4 displays!)

5. Replace the new board and then screw tightly.

6. Clean the connectors.

7. Re-connect the TCP, FFC, and power cable to the

connector.

8. Re-assemble the TCP heat sink. Use the same screw

mounting order as described above

Mechanical Instructions

Caution: If you screw too tight, it is possible to damage the

Driver IC of the TCP.

Figure 4-9 Photo 1 - Heatsink removal

Mechanical Instructions

EN 21SDI PDP 4.

Left

Centre Right

Figure 4-10 Photo 2 - 37” SD v4

4 6 17 532

Figure 4-11 Photo 2 - 42” SD v2 and v3

EN 22 SDI PDP4.

Mechanical Instructions

1

2

3

Figure 4-12 Photo 2 - 42” SD v4

XYG Z[G \G]G ^_

4

5

F_14991_028.eps

030805

YY

1

2

`XW XXXY X[G X\X] XZ

Figure 4-13 Photo 2 - 42” HD v3

3

Figure 4-14 Photo 2 - 42” HD v4

4

5

F_14991_028.eps

030805

Mechanical Instructions

F_14991_029.eps

030805

ཛGཛྷཝཞ

ཛ

G

ཛྷཝཞ

G

EN 23SDI PDP 4.

Left Centre Right

Figure 4-15 Photo 2 - 50” HD v3

Figure 4-16 Photo 2 - 50” HD v4

EN 24 SDI PDP4.

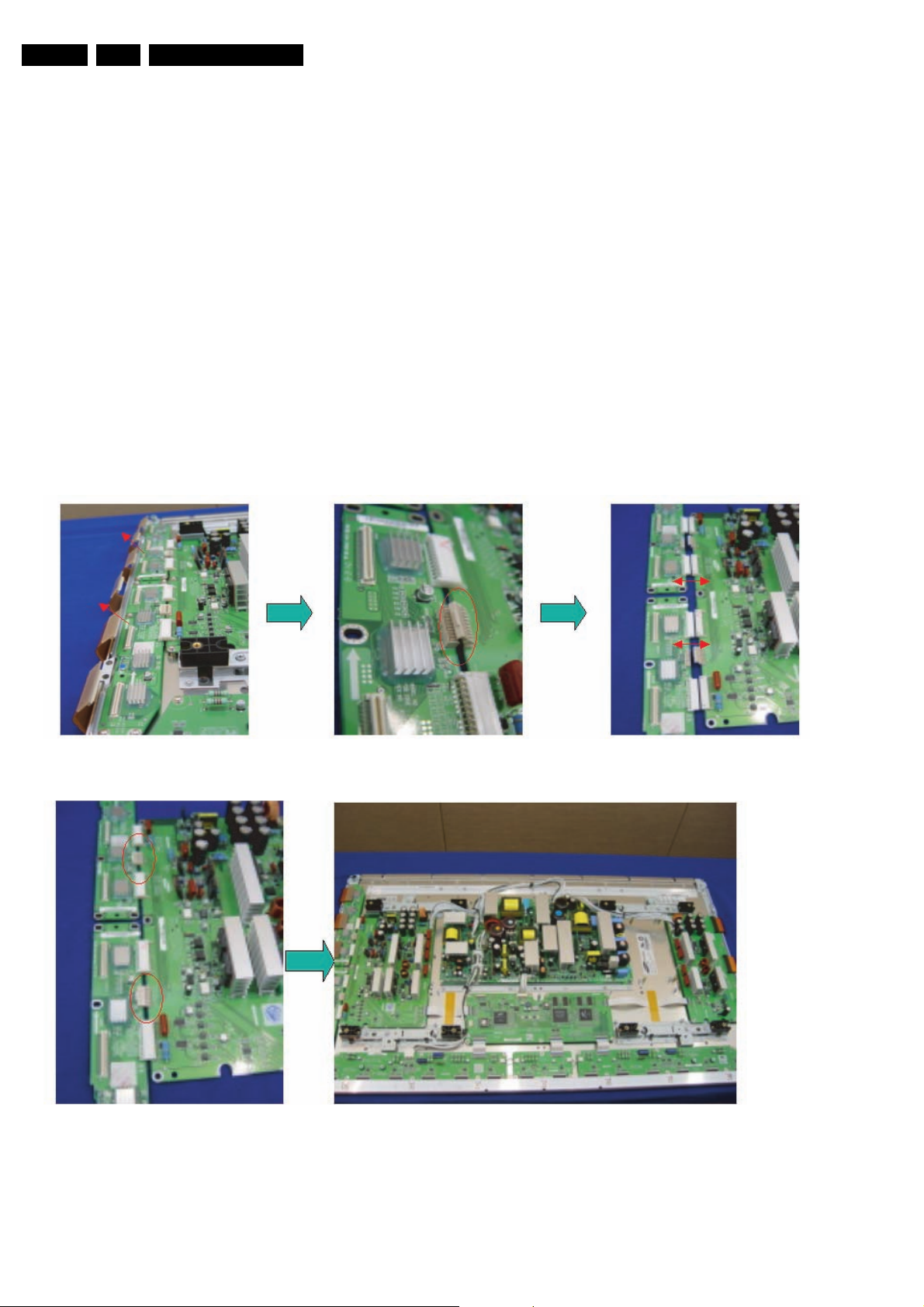

4.1.5 Exchange YBU, YBL and YM board

1. Separate all the FPC connector s of YBU (Y-Buffer upper)

and YBL (Y-Buffer lower). See “Photo 1”.

2. Separate all the connector of CN5001 and CN5008 from YMain. See “Photo 2”.

3. Loosen all the screws of YBU, YBL, and YM. See “Photo

3”.

4. Remove the board from chassis.

5. Remove the connector of CN5006 and CN5007 among

YBU, YBL and YM.

6. Remove the YBL and YBU from Y-main.

7. Remove the defected board.

Note: When replacing the Logic board or Y-main board for

a lead-free (Pb-free) board, always replace them together.

(this is only valid for the 37” SD v4 displays!)

8. Re-assemble the YBU and YBL to the Y-Main.

9. Connect the connector of CN5006 and CN5007 among

YBU, YBL and YM. See “Photo 4”.

10. Arrange the board on the chassis and then screw to fix.

11. Connect the FPC and YM of panel to the connector. See

“Photo 5”.

12. Supply the electric power to the module and then check the

waveform of the board.

13. Turn “off” the power after the waveform is adjusted.

Mechanical Instructions

Figure 4-17 Photo 1, 2, and 3: Dis-assembly of YBU, YBL, and YM

Figure 4-18 Photo 4 and 5: Re-assembly of YBU, YBL, and YM

Loading...

Loading...